Deformation Behavior of Crystalline Cr–Ni Multilayer Coatings by Using Molecular Dynamics Simulation

Abstract

:1. Introduction

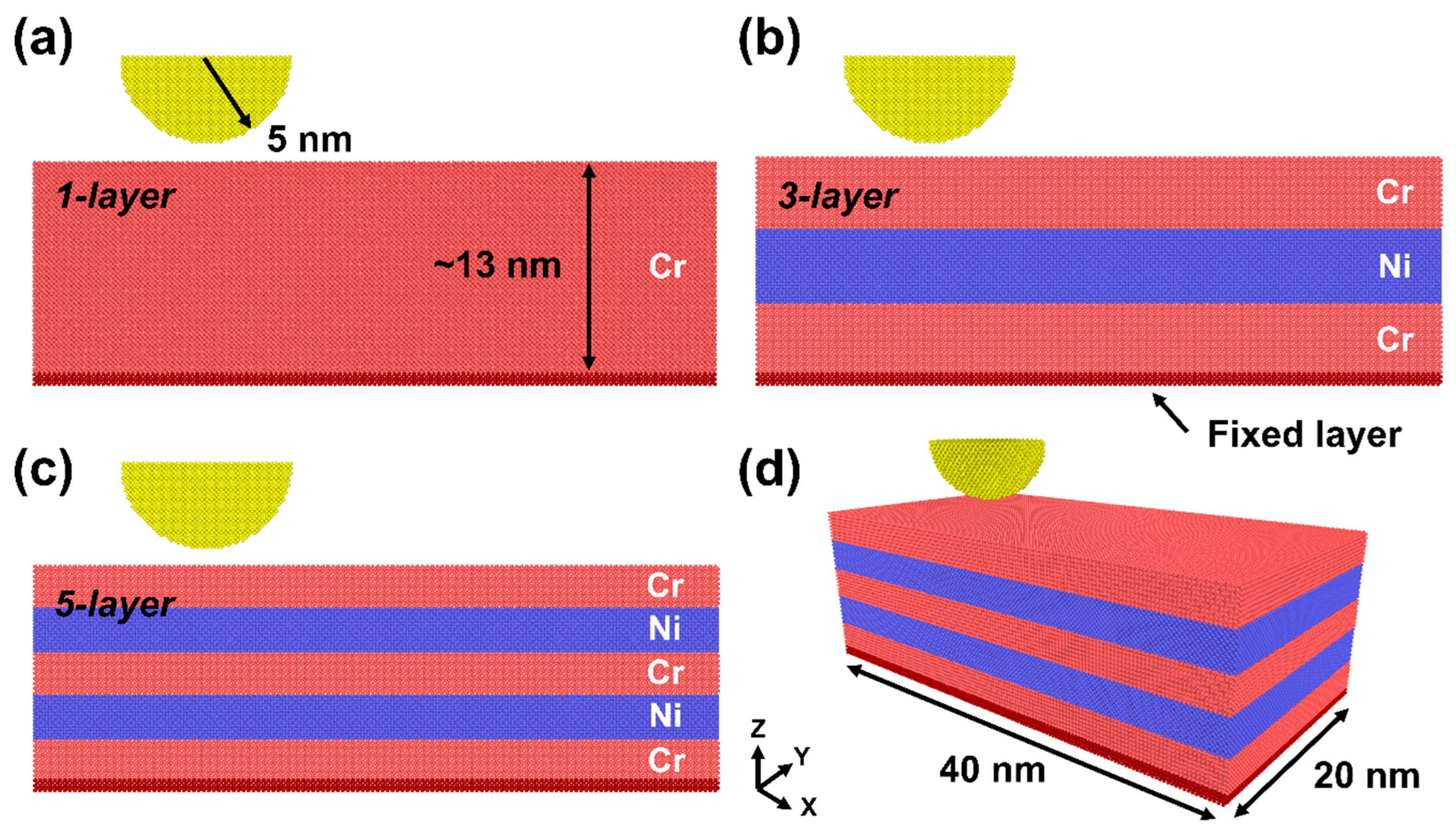

2. Simulation Details

2.1. Modeling and Computation

2.2. Simulation Procedure

3. Results and Discussion

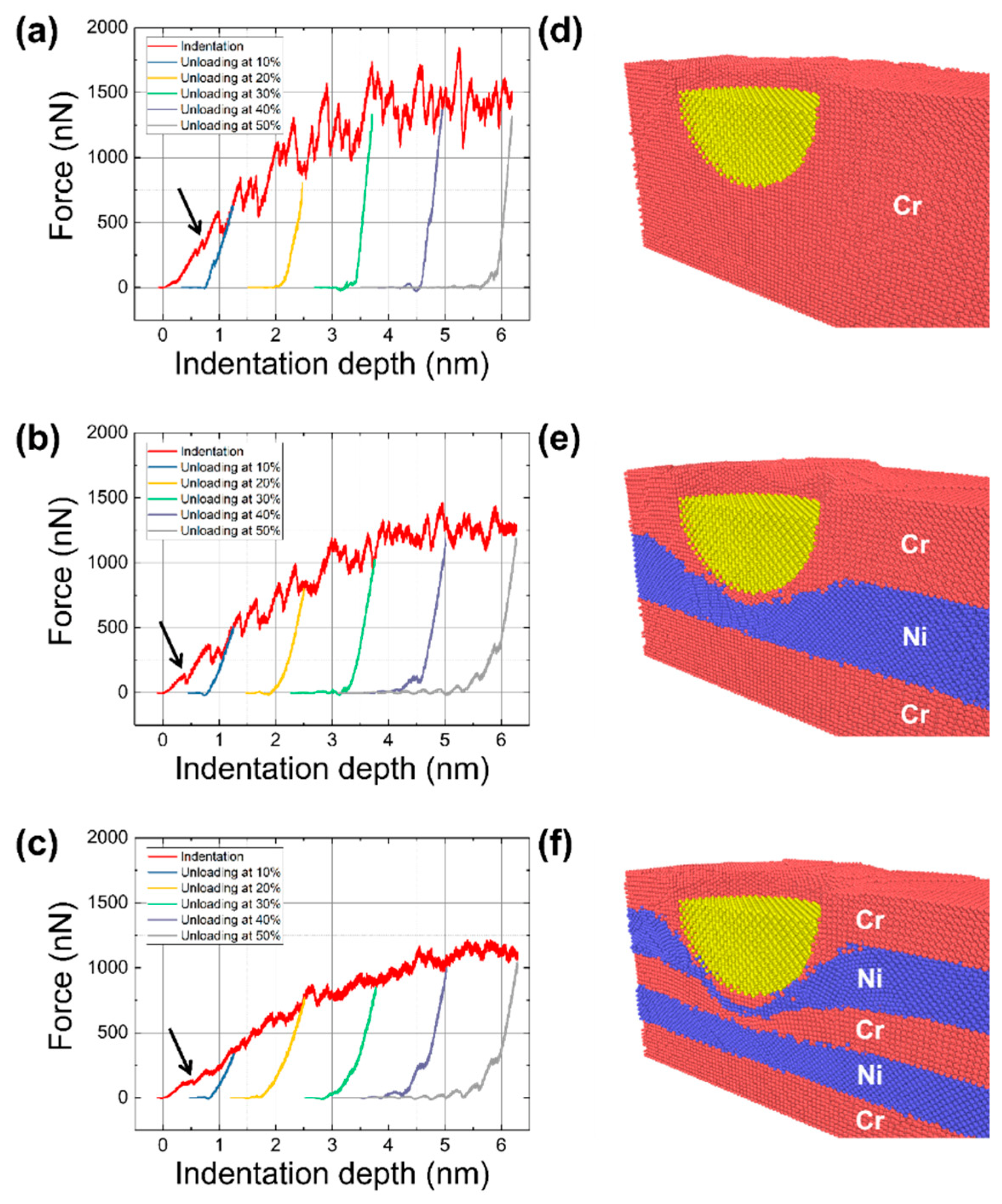

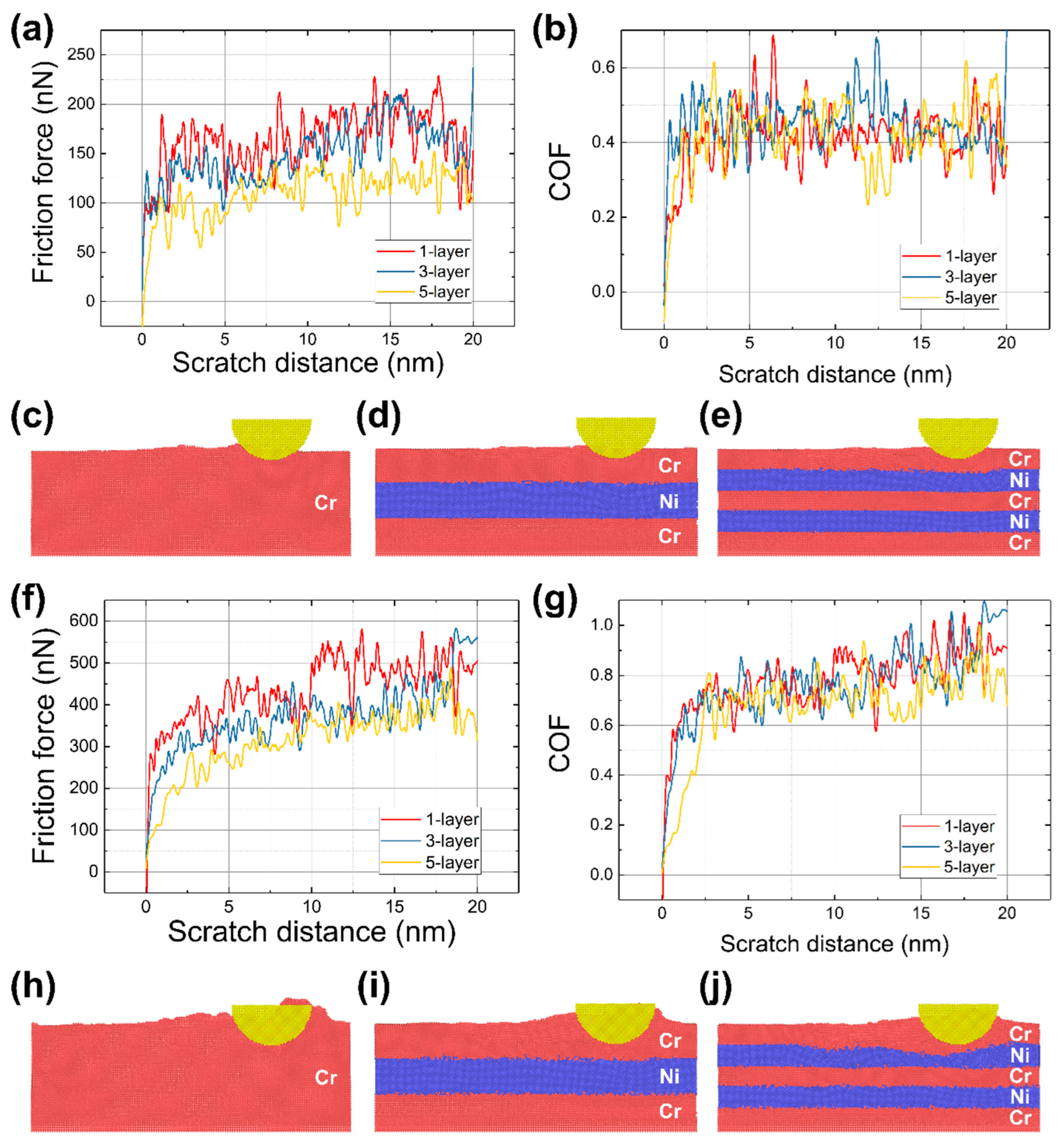

3.1. Deformation Behavior during Indentation and Scratch

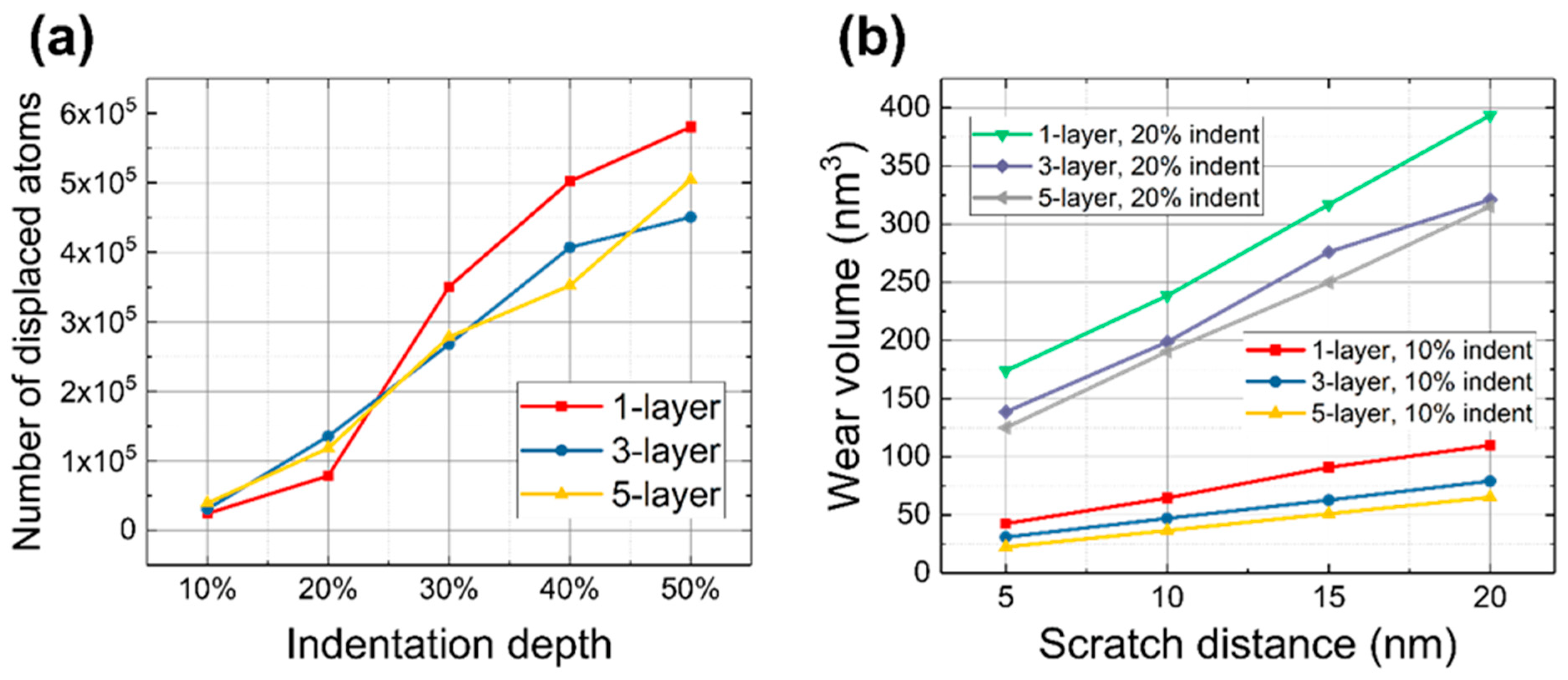

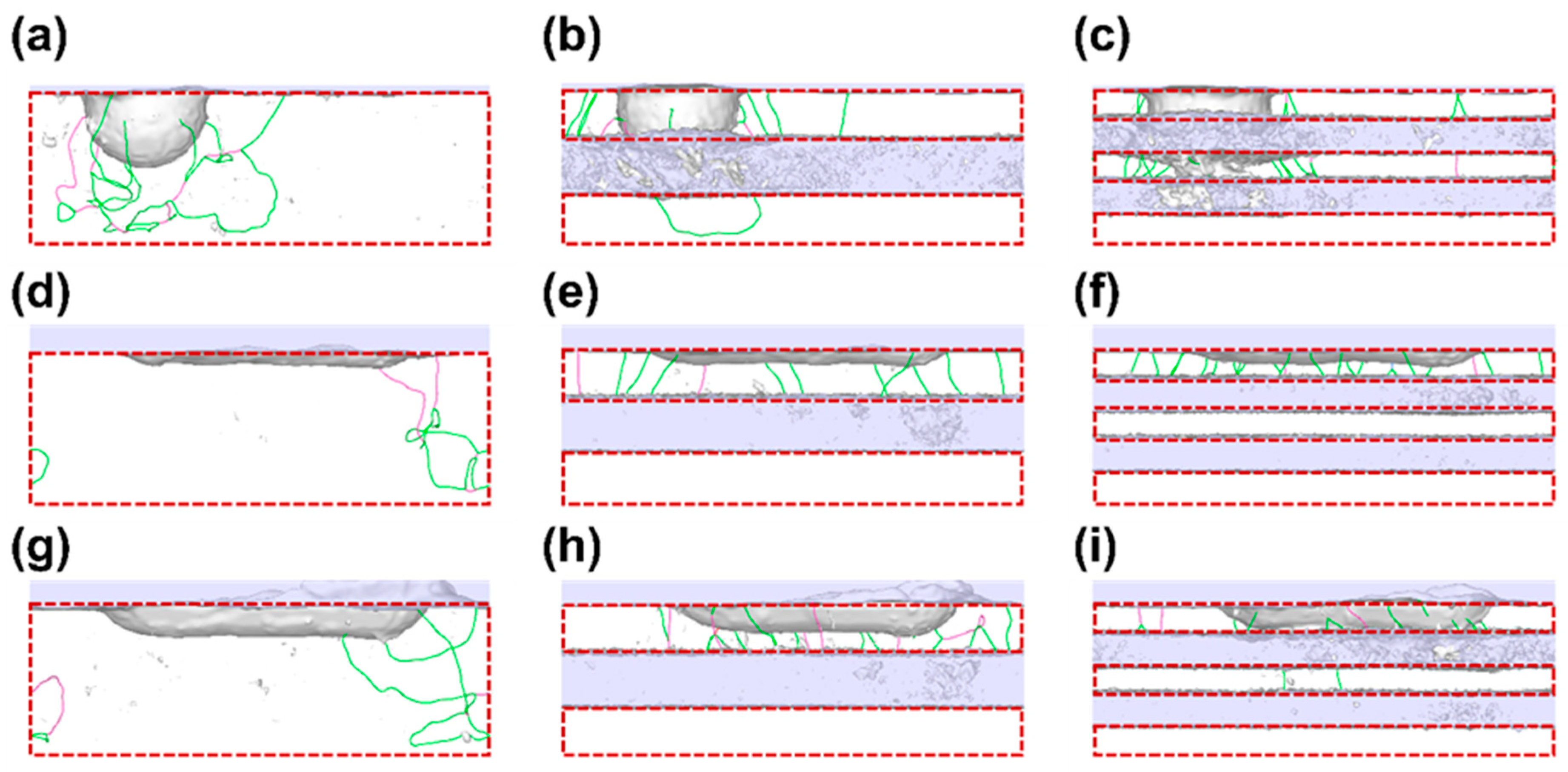

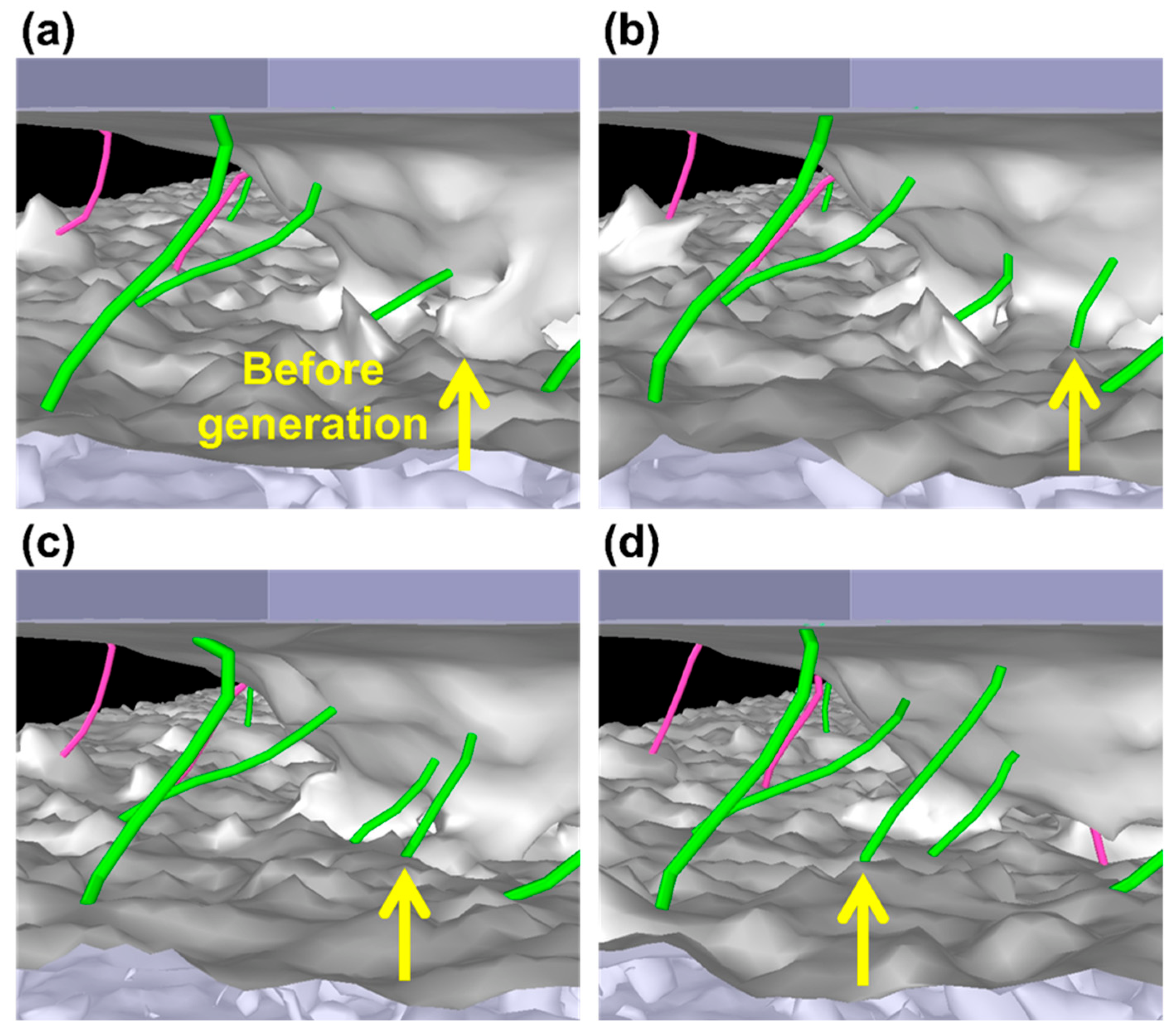

3.2. Dislocation Analysis during Indentation and Scratch

4. Conclusions

- Based on the F–D curves obtained in the indentation process, the five-layer model showed ~39% and ~12% smaller repulsion force than those of the one-layer and three-layer models, respectively. Unloading stiffnesses were calculated to be 5436, 3078, and 2342 nN/nm for one-, three-, and five-layer models, respectively. The results are attributed to the fact that Cr has been reported to have higher mechanical properties than Ni and that the one-layer model consisted of Cr atoms only.

- The friction force of the five-layer model during scratch simulations showed the lowest values among the models for both indentation depth of 10% and 20%. However, because the repulsion force of the five-layer model was also smaller than the other models, the COF of each model was not significantly different.

- At the indentation depth of 50% of the total thickness, the amount of plastic deformation of the one-layer model was 28.8% and 15.0% higher than those of the three-layer and five-layer models, respectively. The wear volume of the five-layer model when scratched was at most 68.4% lower than that of the one-layer model at the indentation depth of 10%.

- The number of dislocation lines in the five-layer model showed a consistently increasing trend when indented and scratched. The five-layer model showed 1.20~3.33-fold higher numbers of dislocation lines than those of the other models when scratched. Based on the increase in dislocation density, the mobility of dislocation lines was decreased, resulting in higher resistance to plastic deformation.

- This work is expected to provide a basic understanding of the excellent wear-resistance of multilayer coatings containing partially crystallized structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.J.; Yoo, S.S.; Kim, D.E. Nano-scale Wear: A Review. Int. J. Precis. Eng. Man. 2012, 13, 1709–1718. [Google Scholar] [CrossRef]

- Khadem, M.; Penkov, O.; Yang, H.-K.; Kim, D.-E. Tribology of multilayer coatings for wear reduction: A review. Friction 2017, 5, 248–262. [Google Scholar] [CrossRef] [Green Version]

- Al-Asadi, M.M.; Al-Tameemi, H.A. A review of tribological properties and deposition methods for selected hard protective coatings. Tribol. Int. 2022, 176, 107919. [Google Scholar] [CrossRef]

- Penkov, O.V.; Khadem, M.; Kim, D.-E. Hard, Flexible, and Transparent Nanolayered SiNx/BN Periodical Coatings. ACS Appl. Mater. Interfaces 2019, 11, 9685–9690. [Google Scholar] [CrossRef]

- Chen, Z.; Lou, M.; Geng, D.; Xu, Y.X.; Wang, Q.; Zheng, J.; Zhu, R.; Chen, Y.; Kim, K.H. Effect of the modulation geometry on mechanical and tribological properties of TiSiN/TiAlN nano-multilayer coatings. Surf. Coat. Technol. 2021, 423, 127586. [Google Scholar] [CrossRef]

- Liu, Z.R.; Xu, Y.X.; Peng, B.; Wei, W.; Chen, L.; Wang, Q. Structure and property optimization of Ni-containing AlCrSiN coatings by nano-multilayer construction. J. Alloys Compd. 2019, 808, 151630. [Google Scholar] [CrossRef]

- Nemati, N.; Bozorg, M.; Penkov, O.V.; Shin, D.G.; Sadighzadeh, A.; Kim, D.E. Functional Multi-Nanolayer Coatings of Amorphous Carbon/Tungsten Carbide with Exceptional Mechanical Durability and Corrosion Resistance. ACS Appl. Mater. Interfaces 2017, 9, 30149–30160. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Gershman, I.S.; Yamamoto, K.; Aguirre, M.H.; Covelli, D.; Arif, T.; Aramesh, M.; Shalaby, M.A.; Veldhuis, S. Surface/interface phenomena in nano-multilayer coating under severing tribological conditions. Surf. Interface Anal. 2017, 49, 584–593. [Google Scholar] [CrossRef]

- Khadem, M.; Penkov, O.V.; Jais, J.; Bae, S.M.; Dhandapani, V.S.; Kang, B.; Kim, D.E. Formation of discrete periodic nanolayered coatings through tailoring of nanointerfaces-Toward zero macroscale wear. Sci. Adv. 2021, 7, eabk1224. [Google Scholar] [CrossRef]

- Penkov, O.V.; Devizenko, A.Y.; Khadem, M.; Zubarev, E.N.; Kondratenko, V.V.; Kim, D.E. Toward Zero Micro/Macro-Scale Wear Using Periodic Nano-Layered Coatings. ACS Appl. Mater. Interfaces 2015, 7, 18136–18144. [Google Scholar] [CrossRef] [PubMed]

- Pogrebnjak, A.D.; Kravchenko, Y.O.; Bondar, O.V.; Zhollybekov, B.; Kupchishin, A.I. Structural Features and Tribological Properties of Multilayer Coatings Based on Refractory Metals. Prot. Met. Phys. Chem. Surf. 2018, 54, 240–258. [Google Scholar] [CrossRef]

- Thompson, C.V.; Carel, R. Stress and grain growth in thin films. J. Mech. Phys. Solids 1996, 44, 657–673. [Google Scholar] [CrossRef]

- Khachatryan, H.; Lee, S.-N.; Kim, K.-B.; Kim, M. Deposition of Al Thin Film on Steel Substrate: The Role of Thickness on Crystallization and Grain Growth. Metals 2018, 9, 12. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharyya, D.; Mara, N.A.; Dickerson, P.; Hoagland, R.G.; Misra, A. Transmission electron microscopy study of the deformation behavior of Cu/Nb and Cu/Ni nanoscale multilayers during nanoindentation. J. Mater. Res. 2009, 24, 1291–1302. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Mara, N.A.; Dickerson, P.; Hoagland, R.G.; Misra, A. A transmission electron microscopy study of the deformation behavior underneath nanoindents in nanoscale Al–TiN multilayered composites. Philos. Mag. 2010, 90, 1711–1724. [Google Scholar] [CrossRef]

- Mohamadnejad, S.; Basti, A.; Ansari, R. Analyses of Dislocation Effects on Plastic Deformation. Multiscale Sci. Eng. 2020, 2, 69–89. [Google Scholar] [CrossRef]

- Lubarda, V.A. Dislocation Burgers vector and the Peach–Koehler force: A review. J. Mater. Res. Technol. 2019, 8, 1550–1565. [Google Scholar] [CrossRef]

- Akasheh, F.; Zbib, H.M.; Hirth, J.P.; Hoagland, R.G.; Misra, A. Dislocation dynamics analysis of dislocation intersections in nanoscale metallic multilayered composites. J. Appl. Phys. 2007, 101, 084314. [Google Scholar] [CrossRef]

- Chang, H.-J.; Cordero, N.M.; Déprés, C.; Fivel, M.; Forest, S. Micromorphic crystal plasticity versus discrete dislocation dynamics analysis of multilayer pile-up hardening in a narrow channel. Arch. Appl. Mech. 2016, 86, 21–38. [Google Scholar] [CrossRef]

- Ghoniem, N.M.; Han, X. Dislocation motion in anisotropic multilayer materials. Philos. Mag. 2005, 85, 2809–2830. [Google Scholar] [CrossRef]

- Kaneko, Y.; Hirota, S.; Hashimoto, S. Discrete Dislocation Dynamics Simulation on Strengths of Dislocation Network Stacks in Multilayered Structures. Key Eng. Mater. 2007, 353–358, 1086–1089. [Google Scholar] [CrossRef]

- Chakraborty, A.; Hunter, A.; Capolungo, L. Effect of microstructure, layer thickness, and interface behavior on the plasticity of accumulative roll bonded nanometallic laminates using dislocation dynamics simulations. J. Mater. Res. 2021, 36, 2715–2728. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, J.; Sagar, S.; Dube, T.; Kim, B.-G.; Jung, Y.-G.; Koo, D.D.; Jones, A.; Zhang, J. Molecular dynamics modeling of mechanical and tribological properties of additively manufactured AlCoCrFe high entropy alloy coating on aluminum substrate. Mater. Chem. Phys. 2021, 263, 124341. [Google Scholar] [CrossRef]

- Wu, W.-P.; Şopu, D.; Eckert, J. Molecular Dynamics Study of the Nanoindentation Behavior of Cu64Zr36/Cu Amorphous/Crystalline Nanolaminate Composites. Materials 2021, 14, 2756. [Google Scholar] [CrossRef]

- Fang, T.-H.; Wu, J.-H. Molecular dynamics simulations on nanoindentation mechanisms of multilayered films. Comp. Mater. Sci. 2008, 43, 785–790. [Google Scholar] [CrossRef]

- Wang, J.; Hoagland, R.G.; Liu, X.Y.; Misra, A. The influence of interface shear strength on the glide dislocation–interface interactions. Acta Mater. 2011, 59, 3164–3173. [Google Scholar] [CrossRef]

- Wang, J.; Misra, A. An overview of interface-dominated deformation mechanisms in metallic multilayers. Curr. Opin. Solid State Mater. Sci. 2011, 15, 20–28. [Google Scholar] [CrossRef]

- Shao, S.; Medyanik, S.N. Dislocation–interface interaction in nanoscale fcc metallic bilayers. Mech. Res. Commun. 2010, 37, 315–319. [Google Scholar] [CrossRef]

- Fu, T.; Peng, X.; Weng, S.; Zhao, Y.; Gao, F.; Deng, L.; Wang, Z. Molecular dynamics simulation of effects of twin interfaces on Cu/Ni multilayers. Mater. Sci. Eng. A 2016, 658, 1–7. [Google Scholar] [CrossRef]

- Fu, T.; Peng, X.; Chen, X.; Weng, S.; Hu, N.; Li, Q.; Wang, Z. Molecular dynamics simulation of nanoindentation on Cu/Ni nanotwinned multilayer films using a spherical indenter. Sci. Rep. 2016, 6, 35665. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Peng, X.; Fu, T.; Sun, R.; Feng, C.; Wang, Z. MD simulation of nanoindentation on (001) and (111) surfaces of Ag–Ni multilayers. Phys. E Low-Dimens. Syst. Nanostruct. 2015, 74, 481–488. [Google Scholar] [CrossRef]

- Etminanfar, M.R.; Sohi, M.H. Corrosion resistance of multilayer coatings of nanolayered Cr/Ni electrodeposited from Cr(III)–Ni(II) bath. Thin Solid Film. 2012, 520, 5322–5327. [Google Scholar] [CrossRef]

- Mansoor, N.S.; Fattah-Alhosseini, A.; Shishehian, A.; Elmkahah, H. Tribological properties of different types of coating materials deposited by cathodic arc-evaporation method on Ni-Cr dental alloy. Mater. Res. Express 2019, 6, 056421. [Google Scholar] [CrossRef]

- Stott, F.H.; Lin, D.S.; Wood, G.C.; Stevenson, C.W. The tribological behaviour of nickel and nickel-chromium alloys at temperatures from 20° to 800 °C. Wear 1976, 36, 147–174. [Google Scholar] [CrossRef]

- Flores, M.; Muhl, S.; Andrade, E. The relation between the plasma characteristic and the corrosion properties of TiN/Ti multilayers deposited by unbalanced magnetron sputtering. Thin Solid Film. 2003, 433, 217–223. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Lewis, D.B.; Münz, W.D. Recent progress in large scale manufacturing of multilayer/superlattice hard coatings. Surf. Coat. Technol. 2000, 133–134, 166–175. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; in’t Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS—A flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Howells, C.A.; Mishin, Y. Angular-dependent interatomic potential for the binary Ni-Cr system. Model. Simul. Mater. Sci. Eng. 2018, 26, 085008. [Google Scholar] [CrossRef] [Green Version]

- Jones, J.E. On the determination of molecular fields—II. From the equation of state of a gas; Series A, Containing Papers of a Mathematical and Physical Character. Proc. R. Soc. Lond. 1924, 106, 463–477. [Google Scholar]

- Lorentz, H. Ueber die Anwendung des Satzes vom Virial in der kinetischen Theorie der Gase. Ann. Der Phys. 1881, 248, 127–136. [Google Scholar] [CrossRef]

- Berthelot, D. Sur le mélange des gaz. Compt. Rendus 1898, 126, 1703–1706. [Google Scholar]

- Maghfiroh, C.; Arkundato, A.; Maulina, W. Parameters (σ, ε) of Lennard-Jones for Fe, Ni, Pb for Potential and Cr based on Melting Point Values Using the Molecular Dynamics Method of the Lammps Program. J. Phys. Conf. Ser. 2020, 1491, 012022. [Google Scholar] [CrossRef]

- Meng, S.; Liu, Z.; Zhao, X.; Fan, B.; Liu, H.; Guo, M.; Hao, H. Efficient corrosion inhibition by sugarcane purple rind extract for carbon steel in HCl solution: Mechanism analyses by experimental and in silico insights. RSC Adv. 2021, 11, 31693–31711. [Google Scholar] [CrossRef]

- Ma, Y.; Fan, B.; Wang, M.; Yang, B.; Hao, H.; Sun, H.; Zhang, H. Two-step preparation of trazodone and its corrosion inhibition mechanism for carbon steel. Chem. J. Chin. Univ. 2019, 40, 1706–1716. [Google Scholar]

- Nosé, S. A molecular dynamics method for simulations in the canonical ensemble. Mol. Phys. 1984, 52, 255–268. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Stukowski, A.; Albe, K. Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Model. Simul. Mater. Sci. Eng. 2010, 18, 085001. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Abadi, P.P.; Maschmann, M.R.; Baur, J.W.; Graham, S.; Cola, B.A. Deformation response of conformally coated carbon nanotube forest. Nanotechnology 2013, 24, 475707. [Google Scholar] [CrossRef]

- Giallonardo, J.D.; Erb, U.; Aust, K.T.; Palumbo, G. The influence of grain size and texture on the Young’s modulus of nanocrystalline nickel and nickel–iron alloys. Philos. Mag. 2011, 91, 4594–4605. [Google Scholar] [CrossRef]

- Petersen, K.E.; Guarnieri, C. Young’s modulus measurements of thin films using micromechanics. J. Appl. Phys. 1979, 50, 6761–6766. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seo, K.-J.; Kim, D.-E. Deformation Behavior of Crystalline Cr–Ni Multilayer Coatings by Using Molecular Dynamics Simulation. Lubricants 2022, 10, 357. https://doi.org/10.3390/lubricants10120357

Seo K-J, Kim D-E. Deformation Behavior of Crystalline Cr–Ni Multilayer Coatings by Using Molecular Dynamics Simulation. Lubricants. 2022; 10(12):357. https://doi.org/10.3390/lubricants10120357

Chicago/Turabian StyleSeo, Kuk-Jin, and Dae-Eun Kim. 2022. "Deformation Behavior of Crystalline Cr–Ni Multilayer Coatings by Using Molecular Dynamics Simulation" Lubricants 10, no. 12: 357. https://doi.org/10.3390/lubricants10120357

APA StyleSeo, K.-J., & Kim, D.-E. (2022). Deformation Behavior of Crystalline Cr–Ni Multilayer Coatings by Using Molecular Dynamics Simulation. Lubricants, 10(12), 357. https://doi.org/10.3390/lubricants10120357