Analysis of Grooves Used for Bearing Lubrication Efficiency Enhancement under Multiple Parameter Coupling

Abstract

:1. Introduction

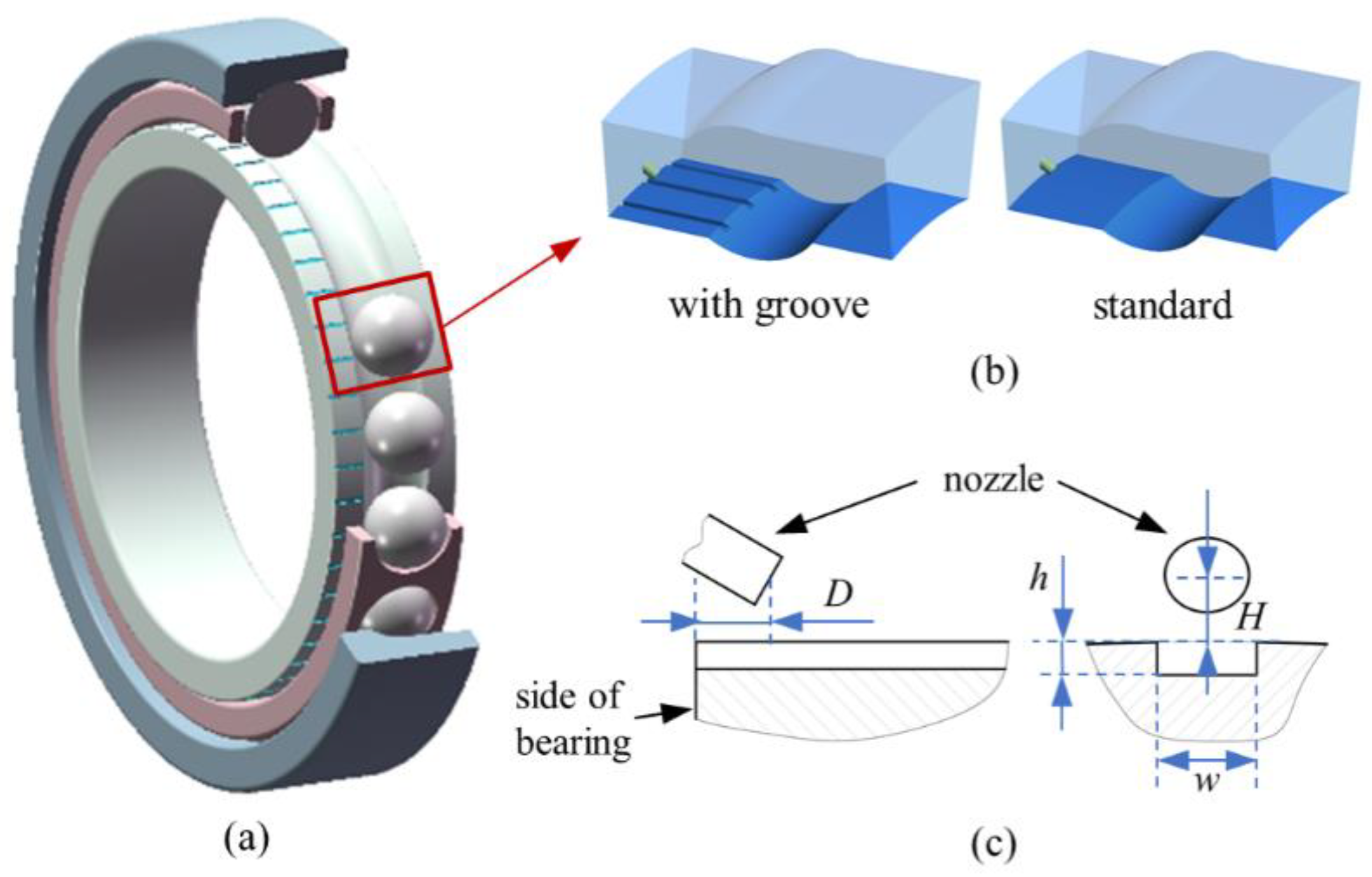

2. Analysis of Lubrication Efficiency Enhancing Mechanism of Groove

2.1. Bearing Simulation Model

2.2. Boundary Conditions

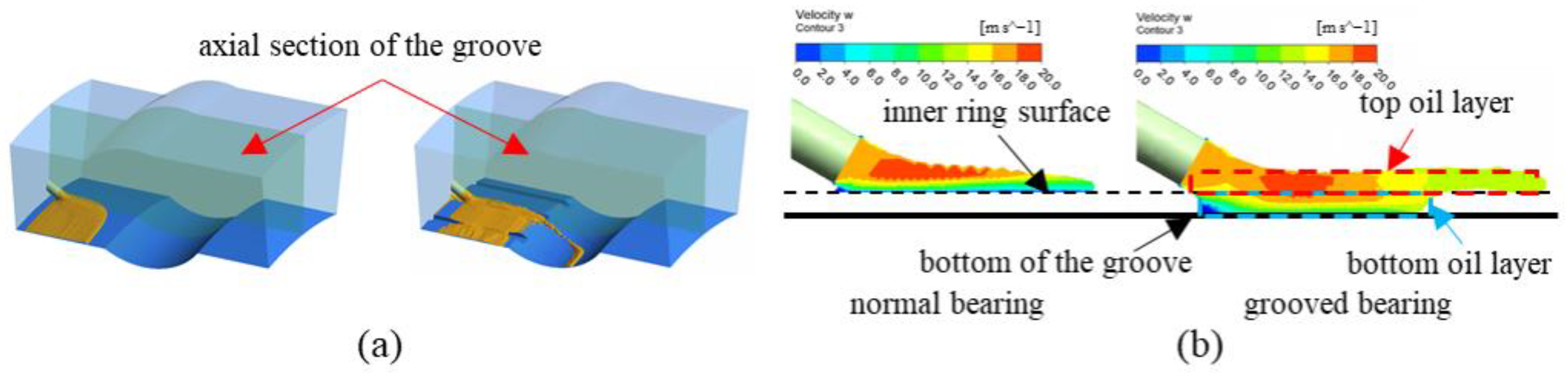

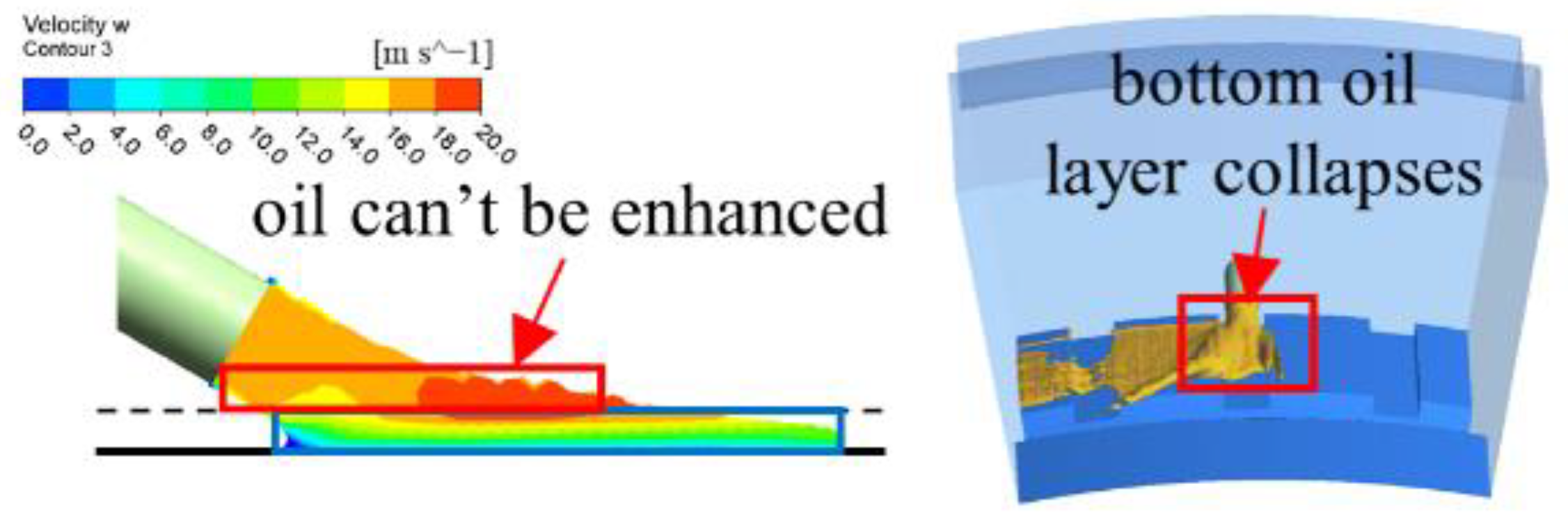

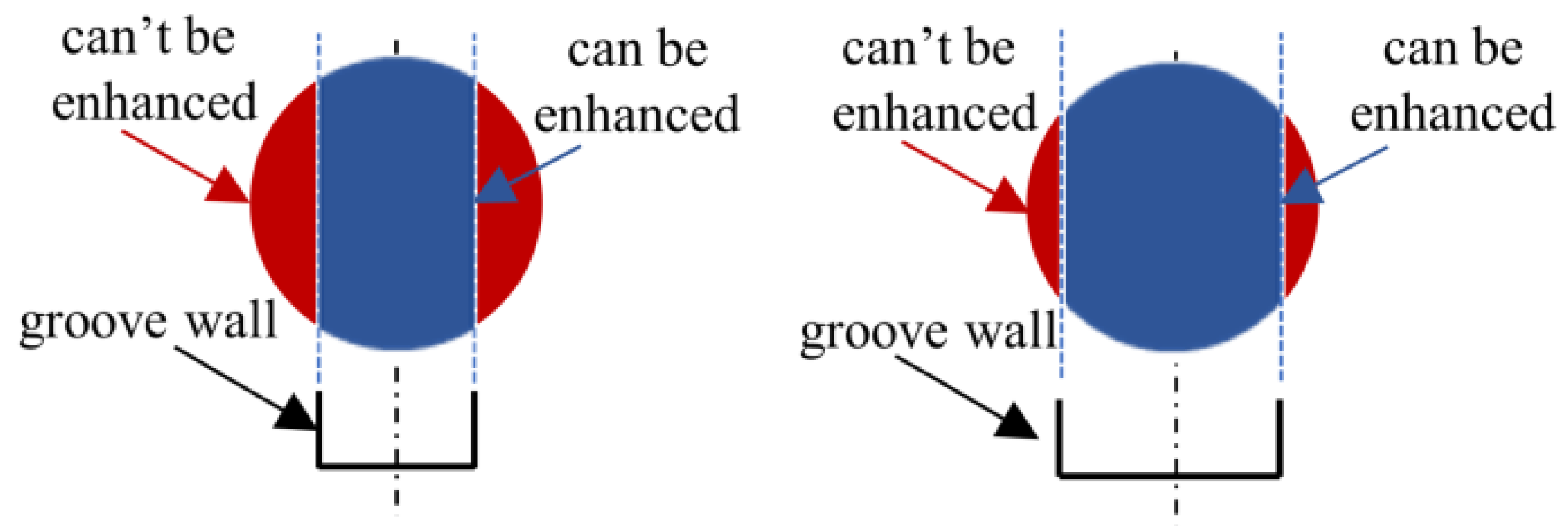

2.3. Oil-Flow-Enhancing Mechanism of Grooves

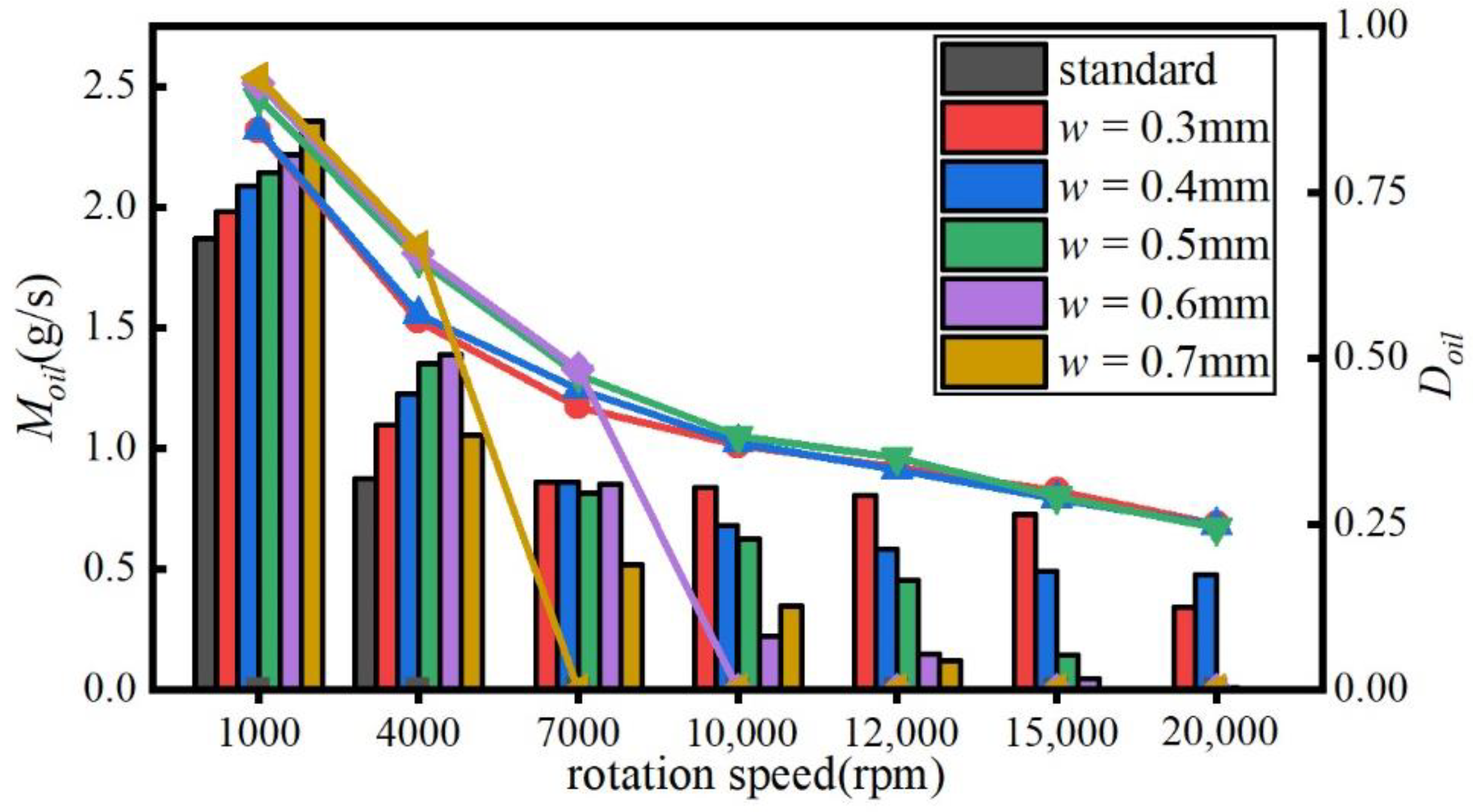

3. Effect of Rotation Speed on the Enhancing Capacity of Grooves

3.1. Simulation Results and Discussion

3.2. Experimental Verification

3.2.1. Experimental System

3.2.2. Results and Discussion

4. Influence of Oil Supply Situation on the Enhancing Capacity of the Grooves

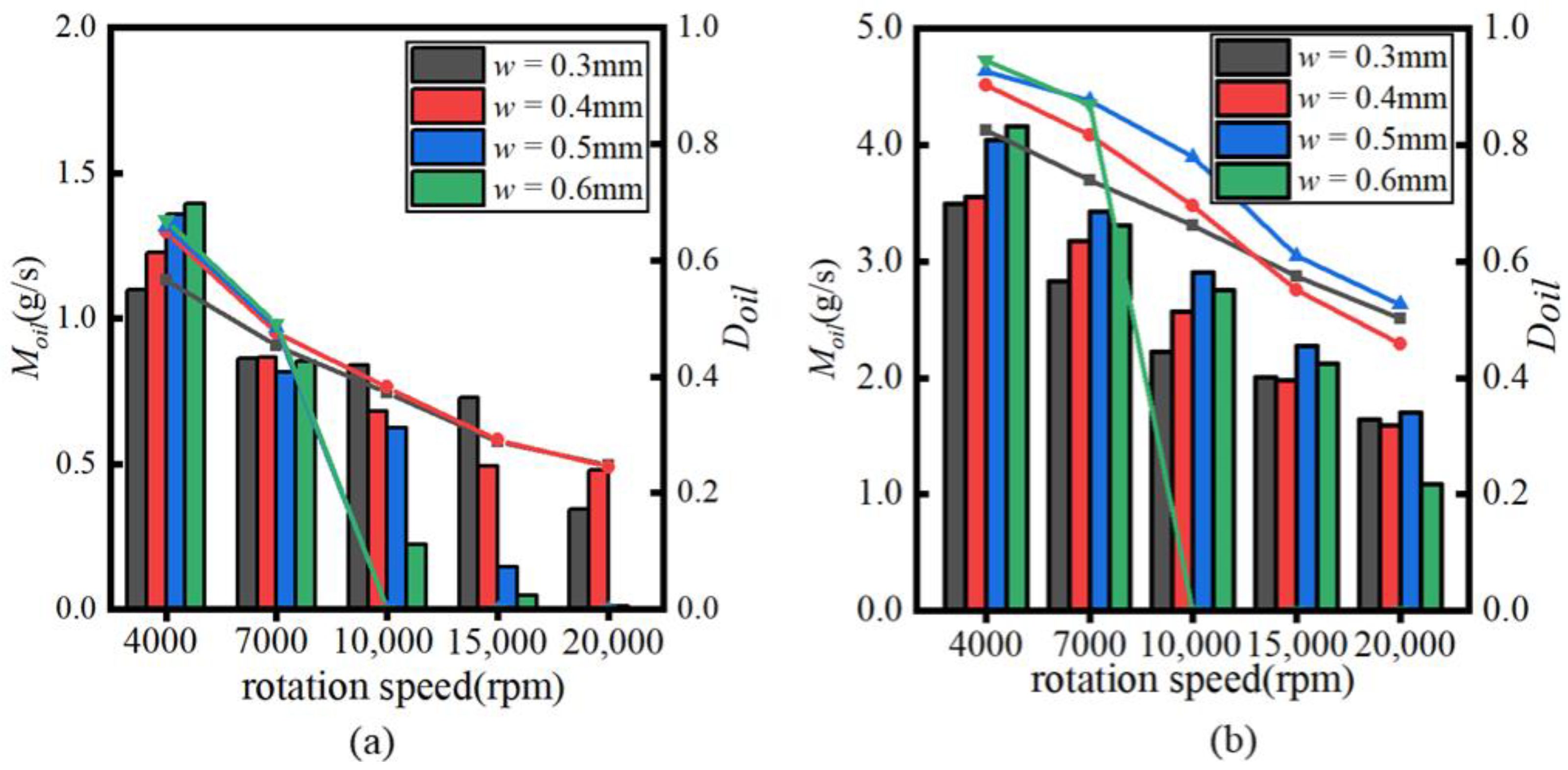

4.1. Influence of Oil Supply Amount on the Groove Width under Different Rotation Speed

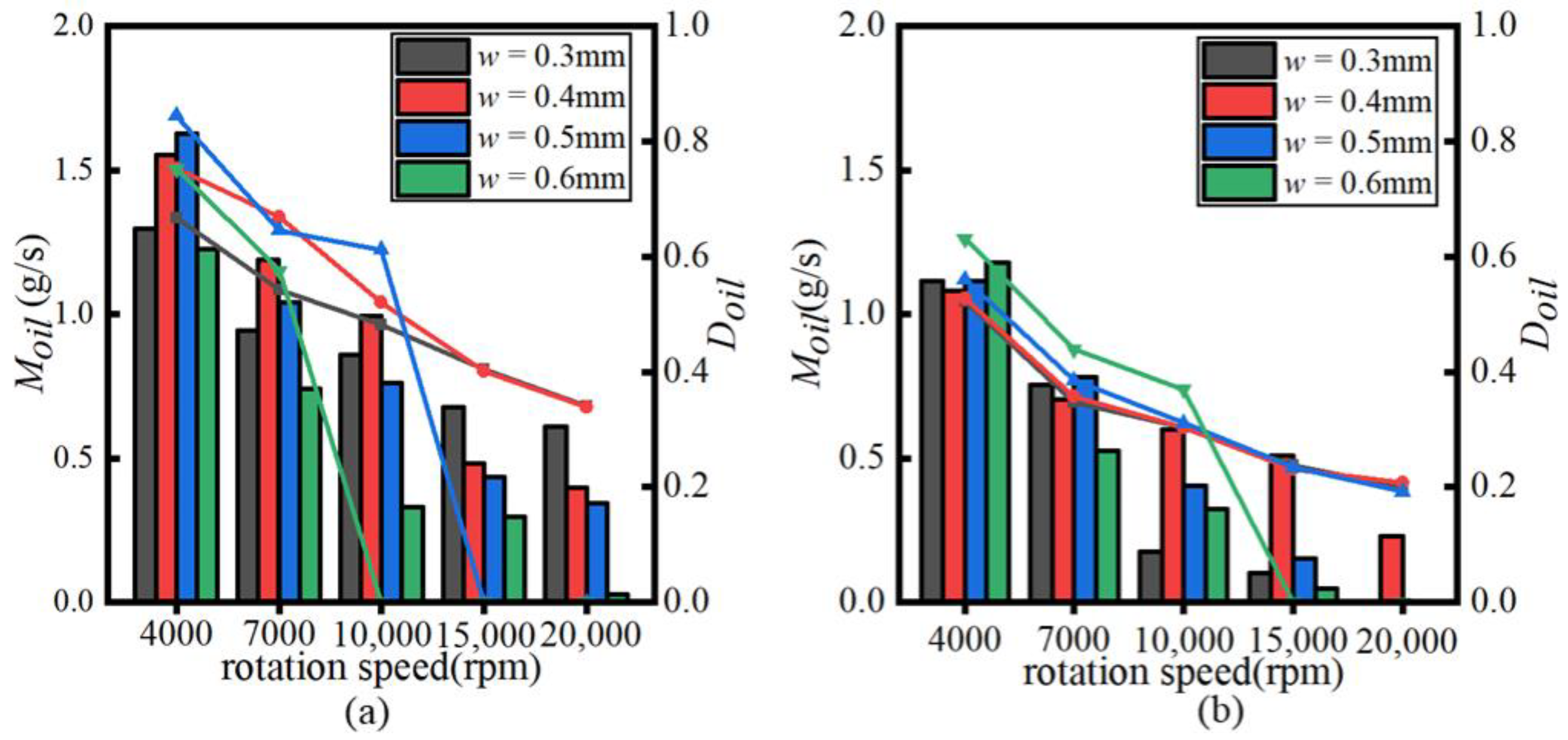

4.2. Influence of Nozzle Diameter d on the Groove Width under Different Rotation Speed

5. Conclusions

- The oil distribution in the groove can be divided into the top oil layer and the bottom oil layer. The bottom oil layer is the key for groove to achieve oil flow enhancement.

- The trend of the experimental results is in good agreement with the trend of the simulation results. Compared with that of the groove of width 0.5 mm, the enhancing capacity of groove of width 0.3 mm seems more adaptive to the increase of rotation speed from 1000 to 5000 rpm.

- The most adaptive width increases with the increase of oil supply amount and nozzle diameter. To achieve better enhancing capacity, the groove width should be no bigger than the nozzle diameter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ma, S.; Zhang, X.; Yan, K.; Zhu, Y.; Hong, J. A Study on Bearing Dynamic Features under the Condition of Multiball–Cage Collision. Lubricants 2022, 10, 9. [Google Scholar] [CrossRef]

- Li, H.; Shin, Y.C. Analysis of bearing configuration effects on high speed spindles using an integrated dynamic thermo-mechanical spindle model. Int. J. Mach. Tools Manuf. 2004, 44, 347–364. [Google Scholar] [CrossRef]

- Pinel, S.I.; Signer, H.R.; Zaretsky, E.V. Comparison between oil-mist and oil-jet lubrication of high-speed, small-bore, angular-contact ball bearings. Tribol. Trans. 2001, 44, 327–338. [Google Scholar] [CrossRef] [Green Version]

- Yan, K.; Wang, Y.; Zhu, Y.; Hong, J.; Zhai, Q. Investigation on heat dissipation characteristic of ball bearing cage and inside cavity at ultra high rotation speed. Tribol. Int. 2016, 93, 470–481. [Google Scholar] [CrossRef]

- Yan, K.; Dong, L.; Zheng, J.; Li, B.; Wang, D.; Sun, Y. Flow performance analysis of different air supply methods for high speed and low friction ball bearing. Tribol. Int. 2018, 121, 94–107. [Google Scholar] [CrossRef]

- Zhang, R. Investigation on the Two-Phase Flow and Heat Transfer Inside High-speed Ball Bearings for in Vehicular Transmission. Master’s Thesis, Beijing Institute of Technology, Beijing, China, 2016; pp. 36–54. [Google Scholar]

- Li, Z.H. Effect of Operation Parameters on the Performance of Rolling Bear under Oil-air Lubrication. Master’s Thesis, Qingdao Technological University, Qingdao, China, 2016; pp. 24–28. [Google Scholar]

- Zheng, D.Z.; Gu, L.; Wang, L.Q.; Wei, Y.Q. Effect of lubrication oil supply parameters on the performance of high-speed rolling bearing. J. Harbin Inst. Technol. 2006, 38, 11–14. [Google Scholar]

- Liu, M.Y.; Guo, F.; Jiao, Y.H.; Peng, S.L.; Wang, X. A novel guide-type nozzle for oil-air lubrications. China Mech. Eng. 2018, 29, 1284–1288. [Google Scholar]

- Jiao, Y.H.; Peng, S.L.; Liu, M.Y.; Peng, S.L.; Wang, X. FLUENT Simulation of a Novel Guide-Type Nozzle for Oil-Air Lubrication. Mach. Des. Manuf. 2019, 29, 238–241. [Google Scholar]

- NSK. Super Precision Bearings. [EB/OL]. Available online: https://www.nsk-literature.com/en/super-precision-bearings (accessed on 14 January 2022).

- NTN. Precision Rolling Bearings. [EB/OL]. Available online: https://www.ntn.com.cn/feedl/pdf/CAT.NO.2260C.pdf (accessed on 14 January 2022).

- Wang, B.M.; Bai, C.; Nan, Y.; Wu, Y. Influences of Nozzle Structure on Air Curtain Effect in Oil-air Lubrication of Angular Contact Ball Bearings. China Mech. Eng. 2021, 32, 2197–2202. [Google Scholar]

- Liu, H.B.; Liu, G.P.; Hao, J.H.; Yang, M.K. Oil penetration mechanism induced by different bearing wall grooves. J. Aerosp. Power 2019, 34, 1127–1136. [Google Scholar]

- Ge, L.F.; Yan, K.; Wang, C.; Zhu, Y.; Hong, J. A novel method for bearing lubrication enhancement via the inner ring groove structure. J. Phys. Conf. Ser. 2021, 1820, 012092. [Google Scholar] [CrossRef]

- Ge, L.; Wang, C.; Yan, K.; Zhu, Y.; Hong, J. Design of groove structures for bearing lubrication enhancement based on the flow mechanism analysis. Tribol. Int. 2021, 158, 106950. [Google Scholar] [CrossRef]

- Ge, L.F.; Chen, F.; Yan, K.; Hong, J.; Zhu, Y.S. Research on Lubrication Efficiency Enhancement of High-speed Bearing under Oil-starvation Conditions. J. Mech. Eng. 2021, 1–8. Available online: http://kns.cnki.net/kcms/detail/11.2187.TH.20211116.1650.030.html (accessed on 18 February 2022).

- Wang, C.; Yan, K.; Zhu, Y.S.; Hong, J. Design of Groove Structure on Bearing Ring Surface for Lubrication Enhancement. J. Xi’an Jiaotong Univ. 2022, 1–8. Available online: http://kns.cnki.net/kcms/detail/61.1069.T.20210830.1027.002.html (accessed on 18 February 2022).

| Physical Properties | Value | Physical Properties | Value |

|---|---|---|---|

| Density ρ (kg/m3) | 876 | Surface tension γ (n/m) | 0.04 |

| Viscosity μ (kg/m∙s) | 0.058 | Contact angle θCA (°) | 52.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Wang, M.; Zhu, L. Analysis of Grooves Used for Bearing Lubrication Efficiency Enhancement under Multiple Parameter Coupling. Lubricants 2022, 10, 39. https://doi.org/10.3390/lubricants10030039

Wang C, Wang M, Zhu L. Analysis of Grooves Used for Bearing Lubrication Efficiency Enhancement under Multiple Parameter Coupling. Lubricants. 2022; 10(3):39. https://doi.org/10.3390/lubricants10030039

Chicago/Turabian StyleWang, Chao, Mingkai Wang, and Linbo Zhu. 2022. "Analysis of Grooves Used for Bearing Lubrication Efficiency Enhancement under Multiple Parameter Coupling" Lubricants 10, no. 3: 39. https://doi.org/10.3390/lubricants10030039

APA StyleWang, C., Wang, M., & Zhu, L. (2022). Analysis of Grooves Used for Bearing Lubrication Efficiency Enhancement under Multiple Parameter Coupling. Lubricants, 10(3), 39. https://doi.org/10.3390/lubricants10030039