Influence of Cross-Shear and Contact Pressure on Wear Mechanisms of PEEK and CFR-PEEK in Total Hip Joint Replacements

Abstract

:1. Introduction

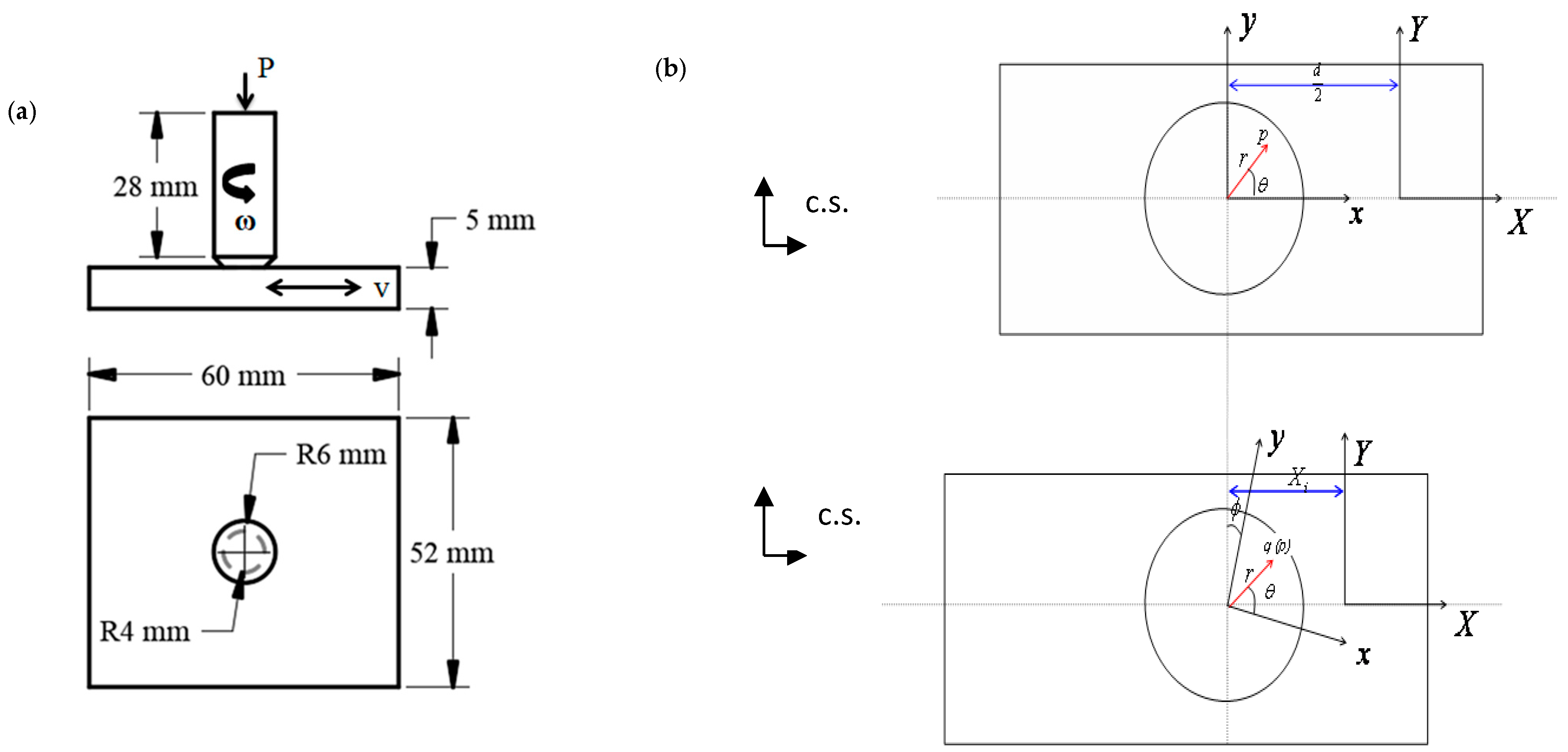

2. Materials and Methods

3. Results and Discussion

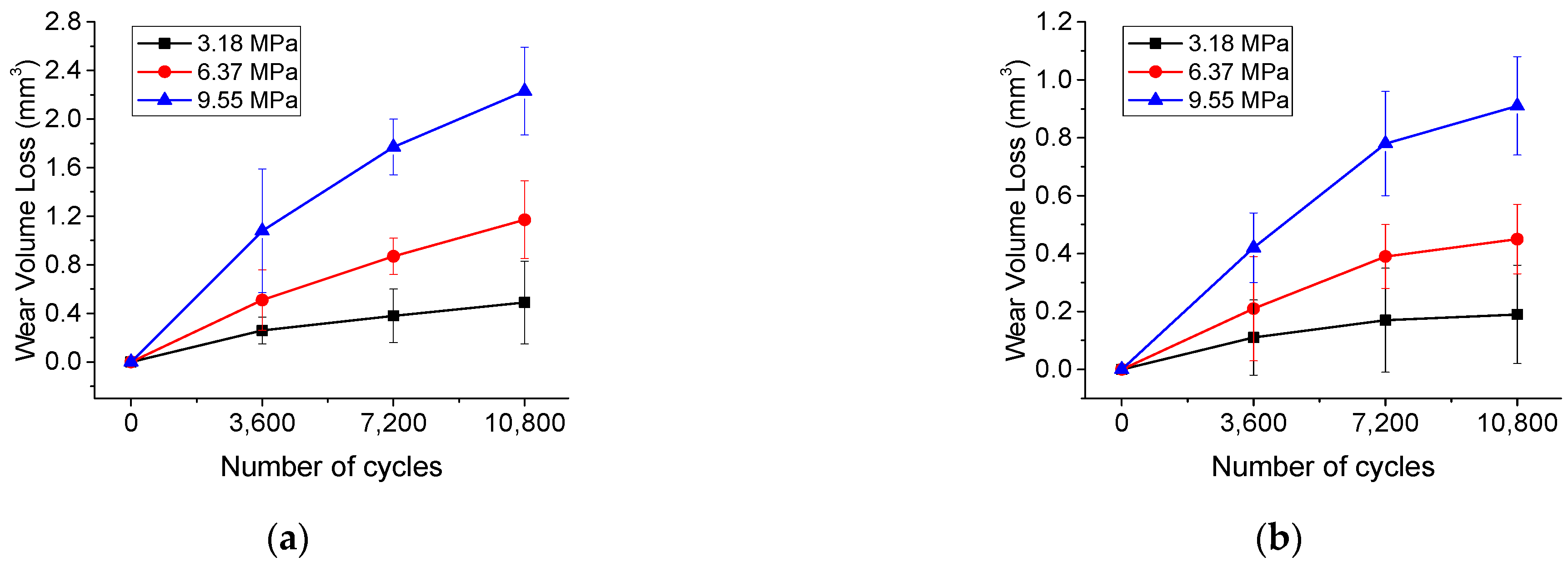

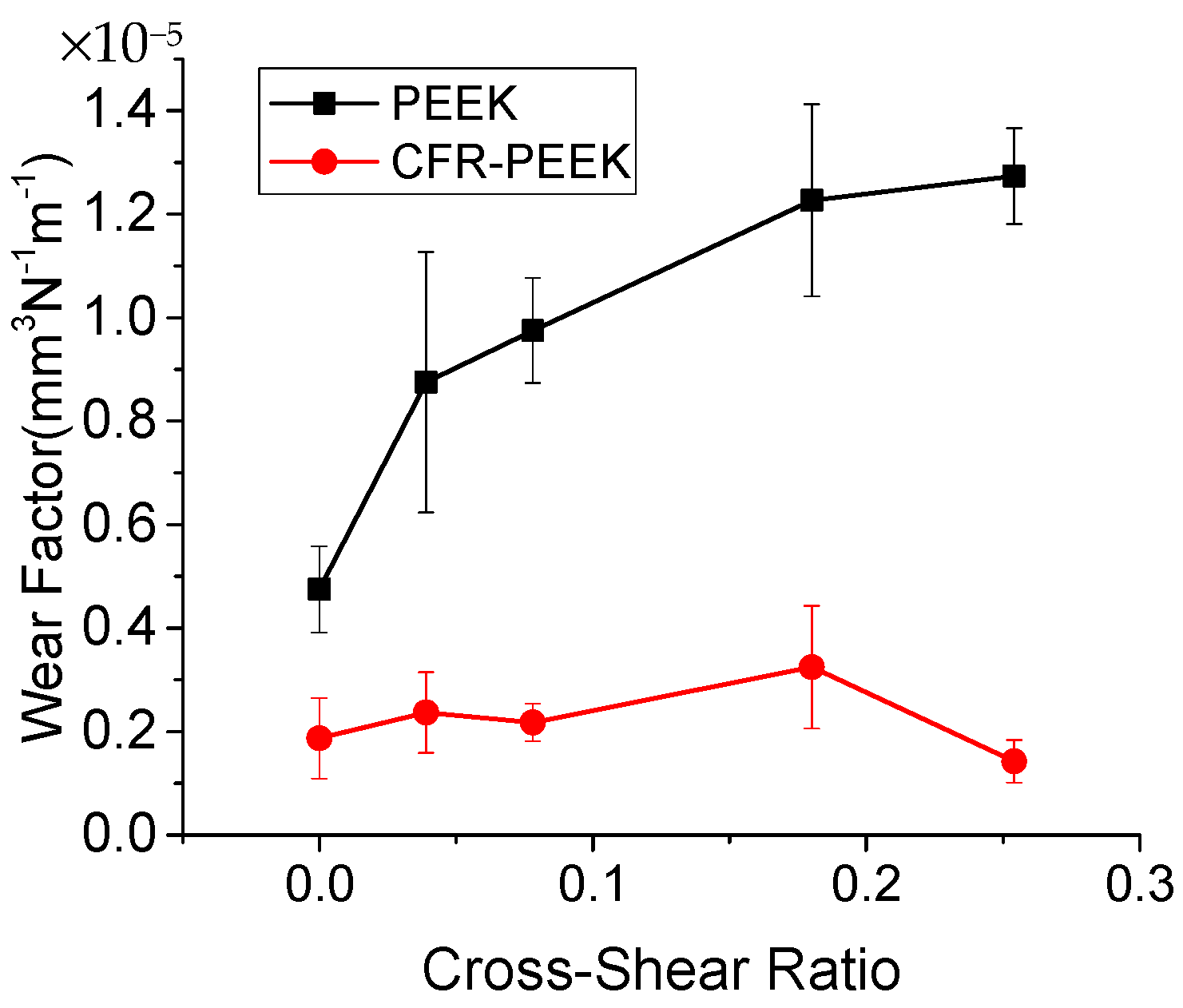

3.1. Wear Analysis

3.2. Surface Topography Analysis

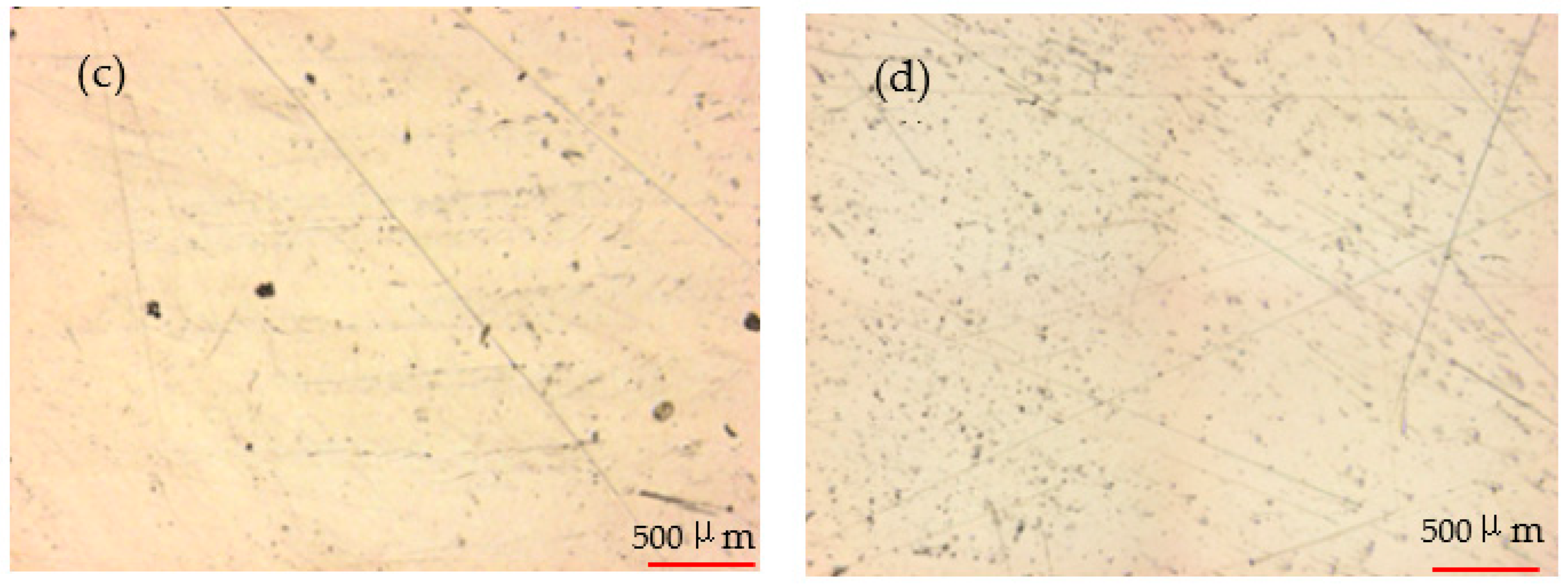

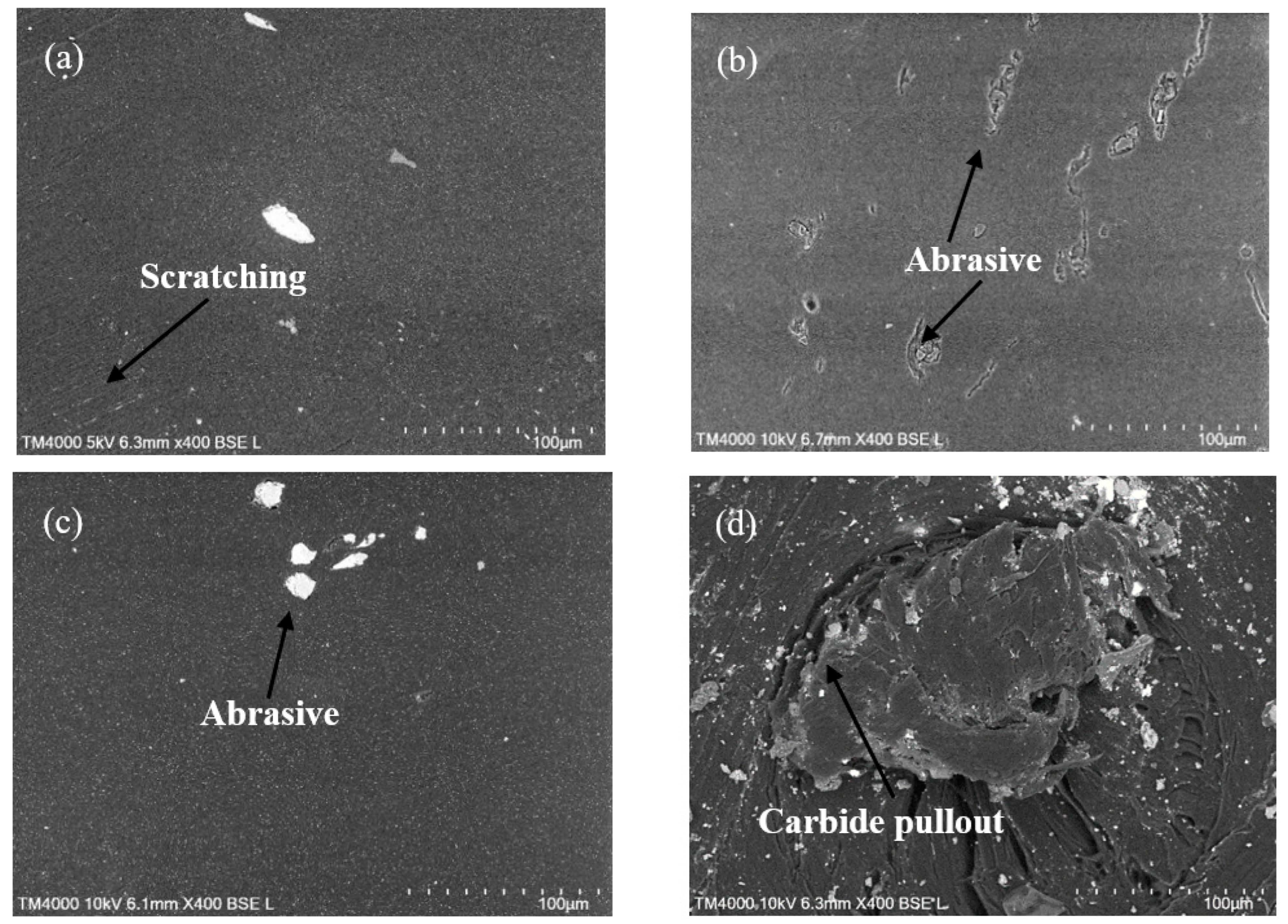

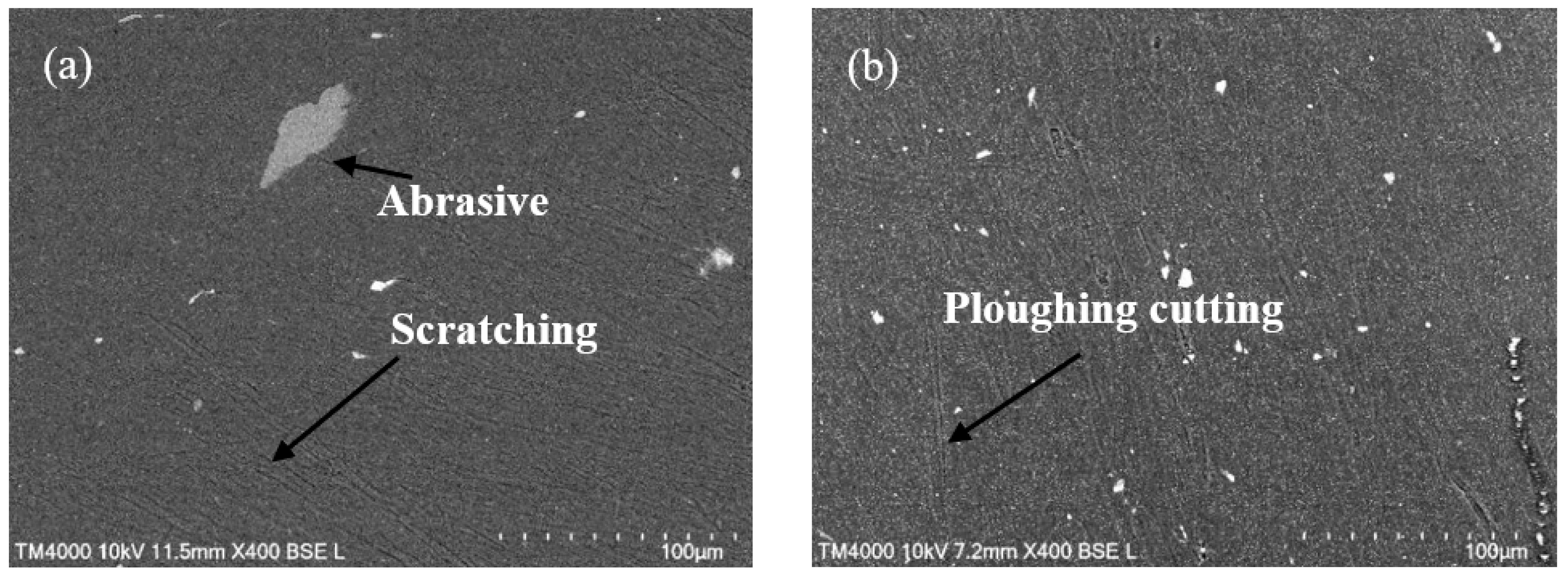

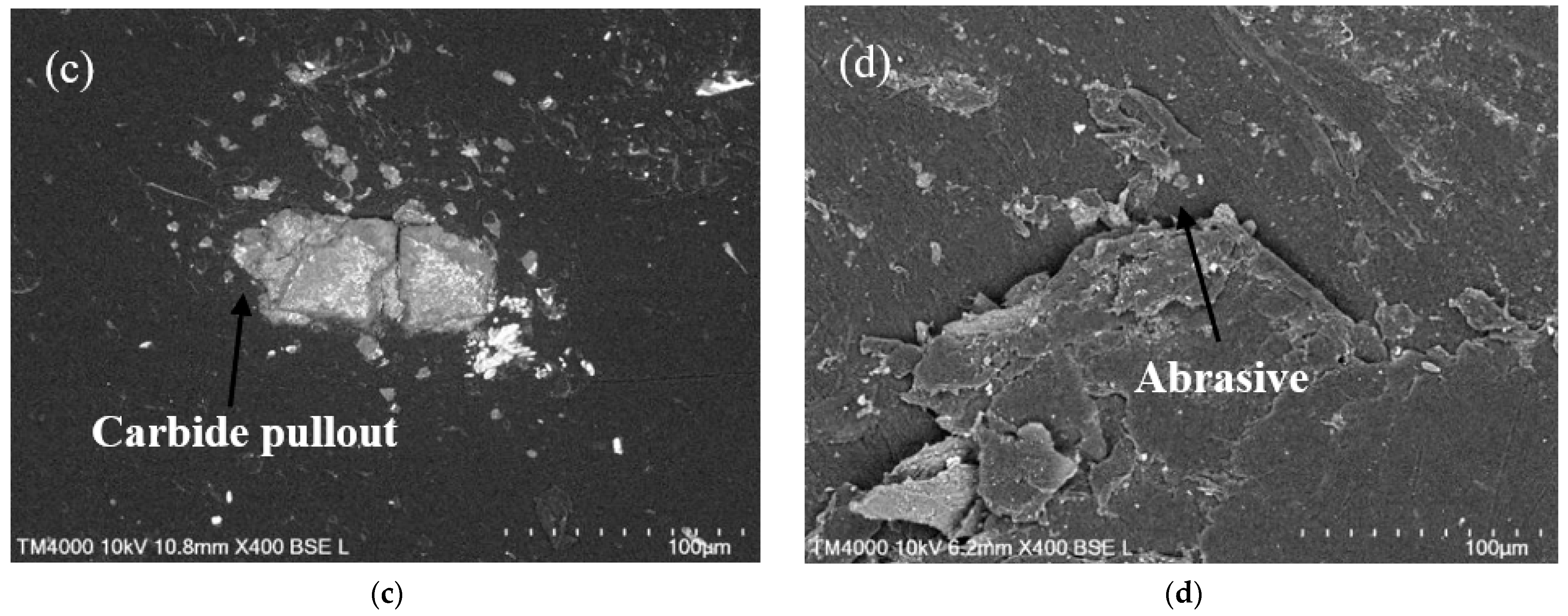

3.3. Worn Surface Microstructures

4. Conclusions

- (1)

- As the cross-shear ratio increased from 0 to 0.254, the wear factor of PEEK increased from (4.75 ± 0.83) × 10−6 to (1.27 ± 0.09) ×10−5, while the wear factor of CFR-PEEK did not show obvious and regular changes with the change in the cross-shear ratio, which basically remained below 2.0 × 10−6. It could be found that PEEK exhibited a higher wear level than that of CFR-PEEK. Therefore, PEEK is not an ideal replacement for UHMWPE in current artificial hip joint replacement. However, CFR-PEEK exhibited excellent wear performance in the experiment and the wear of CFR-PEEK was not affected by the cross-shear ratio significantly. This showed that CFR-PEEK had great potential in artificial hip joint applications.

- (2)

- From the single-direction motion condition to the multi-directional motion condition, with the development of the cross-shear ratio and contact pressure, the worn surface of PEEK became rougher, the arithmetic average of the height amplitude of the surface Sa also increased from 0.49 to 3.97, and a number of pits gradually appeared on the worn surface. The CFR-PEEK had a lighter degree of wear and its worn surface was smoother than that of PEEK. The Sa of the CFR-PEEK surface was only about a half of that of PEEK under a cross-shear ratio of 0.254 at a pressure of 3.18 MPa, which indicated that CFR-PEEK was a material with excellent wear resistance in these circumstances.

- (3)

- The wear mechanism of PEEK was scratching, plough cutting and abrasion. Wear mechanism of the CFR-PEEK was abrasion and carbide pullout, which was due to its material properties. In conclusion, CFR-PEEK is suitable as a hip joint material under low load conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Learmonth, L.D.; Young, C.; Rorabeck, C. The operation of the century: Total hip replacement. Lancet 2007, 370, 1508–1519. [Google Scholar] [CrossRef]

- Abdelgaied, A.; Fisher, J.; Jennings, L.M. A comprehensive combined experimental and computational framework for pre-clinical wear simulation of total knee replacements. J. Mech. Behav. Biomed. Mater. 2018, 78, 282–291. [Google Scholar] [CrossRef] [PubMed]

- Cowie, R.M.; Briscoe, A.; Fisher, J.; Jennings, L.M. Wear and Friction of UHMWPE-on-PEEK OPTIMA. J. Mech. Behav. Biomed. Mater. 2019, 89, 65–71. [Google Scholar] [CrossRef] [PubMed]

- Galvin, A.; Kang, L.; Tipper, J.; Stone, M.; Ingham, E.; Jin, Z.M.; Fisher, J. Wear of crosslinked polyethylene under different tribological conditions. J. Mater. Sci. Mater. Med. 2006, 17, 235–243. [Google Scholar] [CrossRef] [PubMed]

- O’Brien, S.T.; Luo, Y.H.; Brandt, J.M. In-vitro and in-silico investigations on the influence of contact pressure on cross-linked polyethylene wear in total knee replacements. Wear 2015, 332–333, 687–693. [Google Scholar] [CrossRef]

- Sargeant, A.; Goswami, T. Hip implants: Paper V. Physiol. Effects. Mater. Des. 2004, 27, 287–307. [Google Scholar]

- He, M.M.; Huang, Y.; Xu, H.; Feng, G.J.; Liu, L.M.; Li, Y.B.; Sun, D.; Zhang, L. Modification of polyetheretherketone implants: From enhancing bone integration to enabling multi-modal therapeutics. Acta Biomater. 2021, 22, 47. [Google Scholar]

- Utzschneider, S.; Becker, F.; Grupp, T.M.; Sievers, B.; Paulus, A.; Gottschalk, O.; Jansson, V. Inflammatory response against different carbon fiber-reinforced PEEK wear particles compared with UHMWPE in vivo. Acta. Biomater. 2010, 6, 4296–4304. [Google Scholar] [CrossRef]

- Dworak, M.; Rudawski, A.; Markowski, J.; Blazewicz, S. Dynamic mechanical properties of carbon fibre-reinforced PEEK composites in simulated body-fluid. Compos. Struct. 2017, 161, 428–434. [Google Scholar] [CrossRef]

- Elliott, D.M.; Fisher, J.; Clark, D.T. Effect of counterface surface roughness and its evolution on the wear and friction of PEEK and PEEK-bonded carbon fiber composites on the stainless steel. Wear 1998, 217, 288–296. [Google Scholar] [CrossRef]

- Davim, J.P.; Nuno, M.; Baptista, A.M. Effect of Carbon fiber reinforcement in the frictional behavior of PEEK in a water lubricated environment. Wear 2001, 251, 1100–1104. [Google Scholar] [CrossRef]

- Brockett, C.L.; Carbone, S.; Fisher, J.; Jennings, M. PEEK and CFR-PEEK as alternative bearing materials to UHMWPE in a fixed bearing total knee replacement: An experimental wear study. Wear 2016, 374–375, 86–91. [Google Scholar] [CrossRef] [PubMed]

- Wang, A. A unified theory of wear for ultra-high molecular weight polyethylene in multi-directional sliding. Wear 2001, 248, 38–47. [Google Scholar] [CrossRef]

- Goreham-Voss, C.M.; Hyde, P.J.; Hall, R.M.; Fisher, J.; Brown, T.D. Cross-shear implementation in sliding-distance-coupled finite element analysis of wear in metal-on-polyethylene total joint arthroplasty: Intervertebral total disc replacement as an illustrative application. J. Biomech. 2010, 43, 1674–1681. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, R.K.; Korduba, L.A.; Wang, A. An improved theoretical model of orientation softening and cross-shear wear of ultra high molecular weight polyethylene. Wear 2011, 271, 2230–2233. [Google Scholar] [CrossRef]

- Schwenke, T.; Wimmer, M.A. Cross-shear in metal-on-polyethylene articulation of orthopaedic implants and its relationship to wear. Wear 2013, 301, 168–174. [Google Scholar] [CrossRef] [Green Version]

- Patten, E.W.; Citters, D.V.; Ries, M.D.; Pruitt, L.A. Quantifying cross-shear under translation, rolling, and rotation, and its effect on UHMWPE wear. Wear 2014, 313, 125–134. [Google Scholar] [CrossRef]

- Scholes, S.C.; Unsworth, A. Wear studies on the likely performance of PEEK/CoCrMo for use as artificial joint bearing materials. J. Mater. Sci. Mater. Med. 2009, 20, 163–170. [Google Scholar] [CrossRef]

- Borjali, A.; Monson, K.; Raeymaekers, B. Predicting the polyethylene wear rate in pin-on-disc experiments in the context of prosthetic hip implants: Deriving a data-driven model using machine learning methods. Tribol. Int. 2019, 133, 101–110. [Google Scholar] [CrossRef]

- East, R.H.; Briscoe, A.; Unsworth, A. Wear of PEEK-OPTIMA® and PEEK-OPTIMA®-Wear Performance articulating against highly cross-linked polyethylene. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2015, 229, 187–193. [Google Scholar] [CrossRef]

- Langhornb, J.; Borjalia, A.; Hippensteelb, E.; Nelsonb, W.; Raeymaekersa, B. Microtextured CoCrMo alloy for use in metal-on-polyethylene prostheticjoint bearings: Multi-directional wear and corrosion measurements. Tribol. Int. 2018, 124, 178–183. [Google Scholar] [CrossRef] [PubMed]

- Kang, L.; Galvin, A.L.; Brown, T.D.; Jin, Z.M.; Fisher, J. Quantification of the effect of cross-shear on the wear of conventional and highly cross-linked UHMWPE. J. Biomech. 2008, 41, 340–346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdelgaied, A.; Brockett, C.L.; Liu, F.; Jennings, L.M.; Fisher, J.; Jin, Z.M. Quantification of the effect of crossshear and applied nominal contact pressure on the wear of moderately cross-linked polyethylene. Proc. Inst. Mech. Eng. Part H 2013, 227, 18–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brockett, C.L.; Carbone, S.; Fisher, J.; Jennings, L.M. Influence of conformity on the wear of total knee replacement: An experimental study. Proc. Inst. Mech. Eng. Part H 2018, 232, 127–134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chamberlain, K.A.; Rankin, K.S.; Briscoe, A.; Deehan, D.; Hyde, P.J. Wear properties of poly-ether-ether-ketone bearing combinations under zero and cross shear kinematics in total knee arthroplasty. J. Biomed. Mater. Res. Part B 2019, 107, 445–453. [Google Scholar] [CrossRef] [Green Version]

- Brockettn, C.L.; Carbone, S.; Abdelgaied, A.; Fisher, J.; Jennings, L.M. Influence of contact pressure, cross-shear and counterface material on the wear of PEEK and CFR-PEEK for orthopaedic applications. J. Mech. Behav. Biomed. Mater. 2016, 63, 10–16. [Google Scholar] [CrossRef] [Green Version]

- Galvin, A.L.; Kang, L.; Udofia, I.; Jennings, L.M.; McEwen, H.M.J.; Jin, Z.M.; Fisher, J. Effect of conformity and contact stress on wear in fixed-bearing total knee prostheses. J. Biomech. 2009, 42, 1898–1902. [Google Scholar] [CrossRef]

- Saikko, V. In vitro wear simulation on the RandomPOD wear testing system as a screening method for bearing materials intended for total knee arthroplasty. J. Biomech. 2014, 47, 2774–2778. [Google Scholar] [CrossRef] [Green Version]

- Schwiesau, J.; Schilling, C.; Kaddick, C.; Utzschneider, S.; Jansson, V.; Fritz, B.; Blömer, W.; Grupp, T.M. A Definition and evaluation of testing scenarios for knee wear simulation under conditions of highly demanding daily activities. Med. Eng. Phys. 2013, 35, 591–600. [Google Scholar] [CrossRef]

- Evans, A.; Horton, H.; Unsworth, A.; Briscoe, A. The influence of nominal stress on wear factors of carbon fibre–reinforced polyetheretherketone (PEEK-OPTIMA® Wear Performance) against zirconia toughened alumina (Biolox® delta ceramic). Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2014, 228, 587. [Google Scholar] [CrossRef]

| Material | Co | Cr | Mo | Ni | Fe | Mn | C | Tensile Strength (MPa) | Section Shrinkage (%) | Breaking Elongation (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| CoCrMo | Balanced | 28.08 | 6.13 | 0.1 | 0.1 | 0.24 | 0.099 | 1160 | 29.5 | 31 |

| Contact Pressure/MPa | 3.18 | 6.37 | 9.55 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Rotating angle of the pin around Z-axis/° | ±20 | ±30 | ±55 | ±20 | ±30 | ±55 | ±20 | ±30 | ±55 |

| Reciprocating amplitude of the plate in Y-direction/mm | 20 | 28 | 38 | 20 | 28 | 38 | 20 | 28 | 38 |

| CSR | 0.039 | 0.087 | 0.254 | 0.039 | 0.087 | 0.254 | 0.039 | 0.087 | 0.254 |

| Cross-Shear Ratio | 0 | 0.039 | 0.078 | 0.18 | 0.254 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Contact pressure (MPa) | 3.18 | 6.37 | 9.55 | 3.18 | 6.37 | 9.55 | 3.18 | 6.37 | 9.55 | 3.18 | 6.37 | 9.55 | 3.18 | 6.37 | 9.55 |

| Sa of PEEK surface (μm) | 0.49 | 0.52 | 0.77 | 0.81 | 0.98 | 1.21 | 1.52 | 1.74 | 1.98 | 1.82 | 2.14 | 2.35 | 3.17 | 3.55 | 3.97 |

| Sa of CFR-PEEK surface (μm) | 0.28 | 0.49 | 0.66 | 0.51 | 0.79 | 1.09 | 0.88 | 1.05 | 1.29 | 1.13 | 1.36 | 1.38 | 1.19 | 1.44 | 1.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, R.; Wang, B.; Liu, J.; Yan, Z.; Dong, L. Influence of Cross-Shear and Contact Pressure on Wear Mechanisms of PEEK and CFR-PEEK in Total Hip Joint Replacements. Lubricants 2022, 10, 78. https://doi.org/10.3390/lubricants10050078

Shi R, Wang B, Liu J, Yan Z, Dong L. Influence of Cross-Shear and Contact Pressure on Wear Mechanisms of PEEK and CFR-PEEK in Total Hip Joint Replacements. Lubricants. 2022; 10(5):78. https://doi.org/10.3390/lubricants10050078

Chicago/Turabian StyleShi, Ruimin, Bukang Wang, Jiquan Liu, Zhiwei Yan, and Lei Dong. 2022. "Influence of Cross-Shear and Contact Pressure on Wear Mechanisms of PEEK and CFR-PEEK in Total Hip Joint Replacements" Lubricants 10, no. 5: 78. https://doi.org/10.3390/lubricants10050078

APA StyleShi, R., Wang, B., Liu, J., Yan, Z., & Dong, L. (2022). Influence of Cross-Shear and Contact Pressure on Wear Mechanisms of PEEK and CFR-PEEK in Total Hip Joint Replacements. Lubricants, 10(5), 78. https://doi.org/10.3390/lubricants10050078