Influence of Additive Chemistry on the Tribological Behavior of Steel/Copper Friction Pairs

Abstract

:1. Introduction

2. Experiment Section

2.1. Materials

2.2. Tribological Testing

2.3. Surface Characterizations

3. Results and Discussion

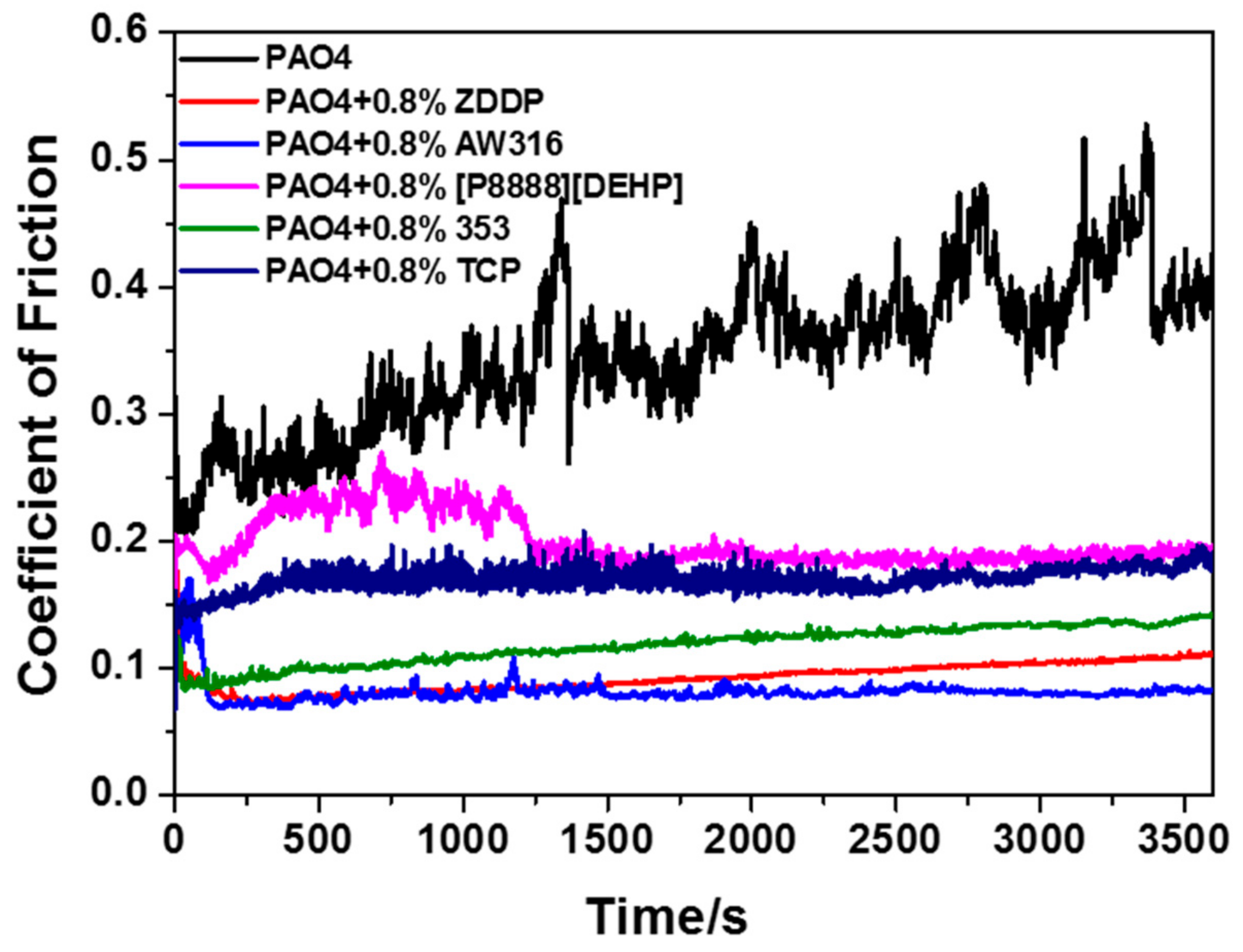

3.1. Friction-Reducing Behaviors

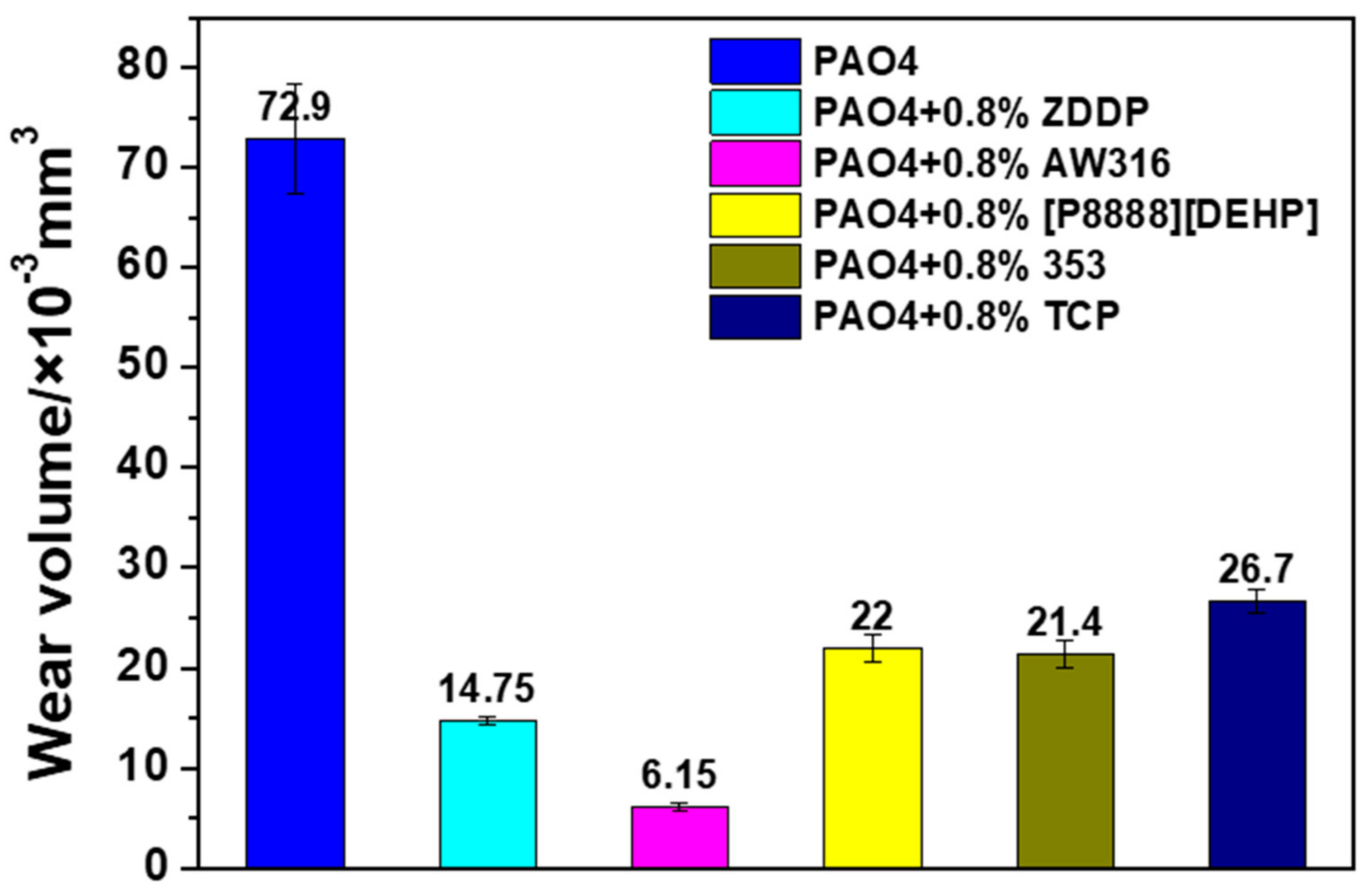

3.2. Anti-Wear Performances

3.3. Worn Surfaces Analysis

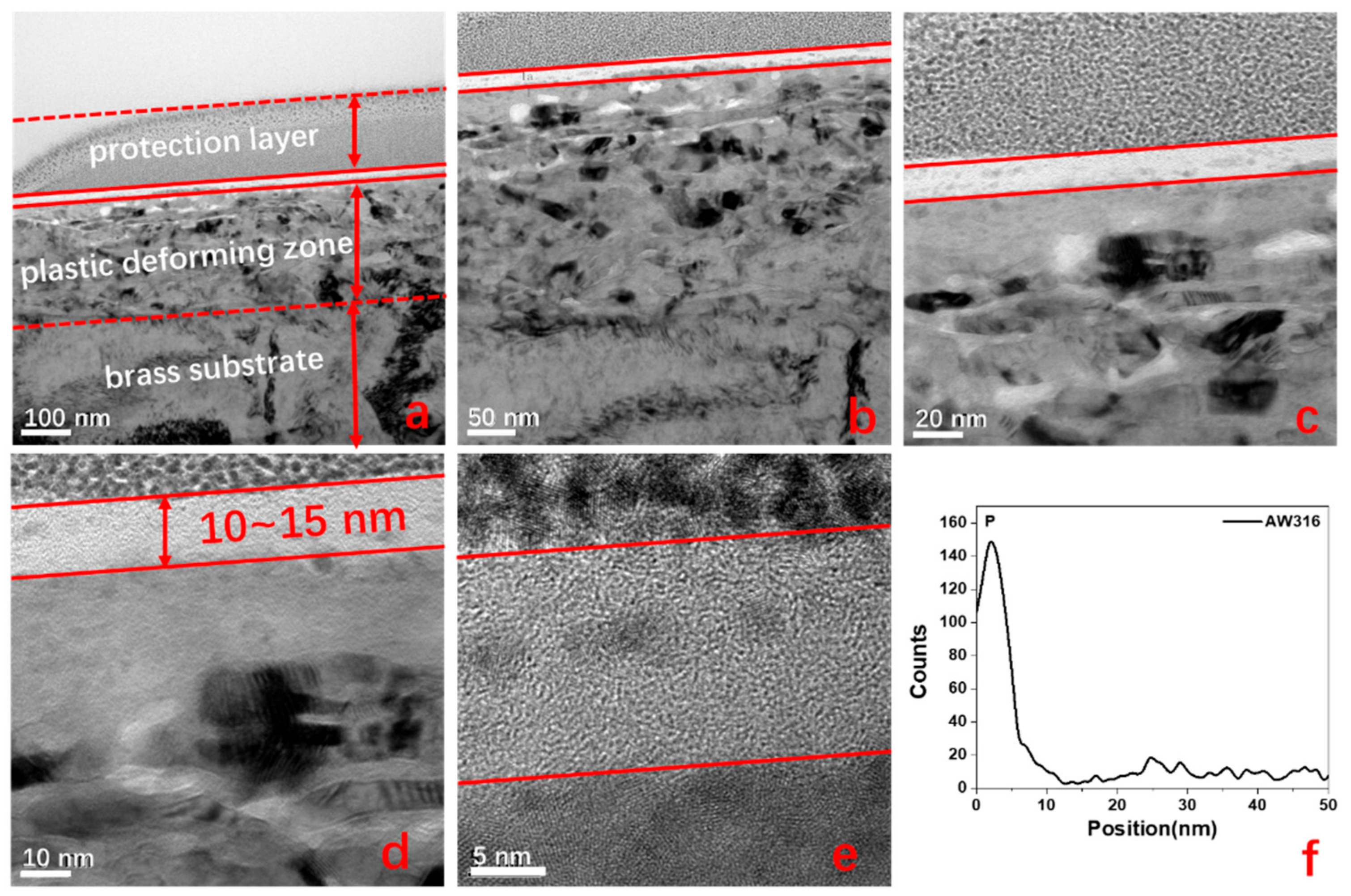

3.4. FIB-TEM Analysis

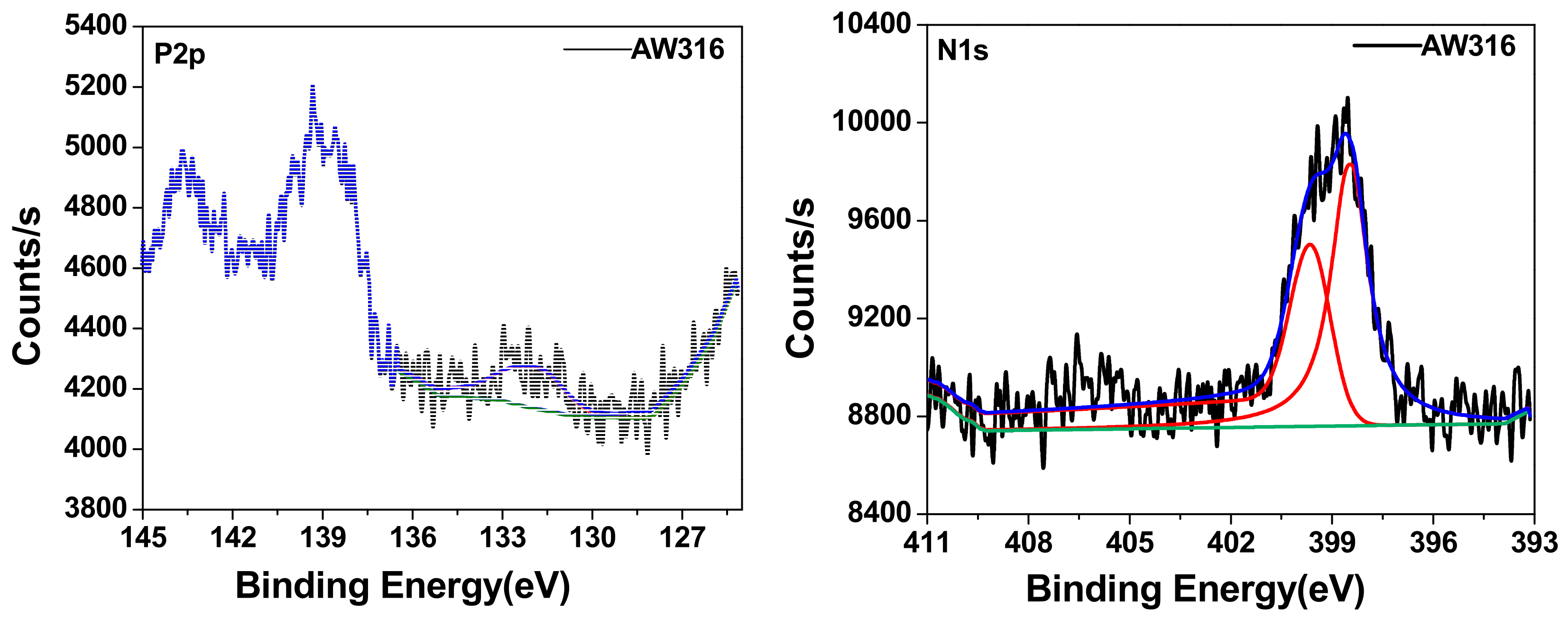

3.5. XPS Analysis

4. Conclusions

- (1)

- Tribological behavior was highly determined by the chemical structure of anti-wear additives. Higher chemical activity (high polarity and high acid value) is a favorite to achieve better tribological performance.

- (2)

- A protic ionic liquid (amine phosphate, AW316) was found to possess the best anti-wear additive for steel–copper sliding, which achieves the lowest mean friction coefficient (0.083) and smallest wear volume (6.15 × 10−3 mm3).

- (3)

- The superior tribological performance of AW316 can be attributed to the rapid formation of an even boundary lubrication film with a thickness of 10–15 nm and is composed of oxides, phosphates, and cuprous oxide.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jisa, R.; Ristic, A.; Brenner, J.; Lebersorger, T.; Ilo, S.; Neumayer, H.; Franek, F. Effectiveness of lubricant additives for copper-alloy-steel sliding contacts. Lubri. Sci. 2010, 22, 183–193. [Google Scholar] [CrossRef]

- Unlu, B.S.; Atik, E. Investigation of tribological properties of boronised pure Cu journal bearings. Surf. Eng. 2010, 26, 173–177. [Google Scholar] [CrossRef]

- Padgurskas, J.; Snitka, V.; Jankauskas, V.; Andriusis, A. Selective transfer phenomenon in lubricated sliding surfaces with copper and its alloy coatings made by electro-pulse spraying. Wear 2006, 260, 652–661. [Google Scholar] [CrossRef]

- Zhai, W.; Lu, W.; Liu, X.; Zhou, L. Nanodiamond as an effective additive in oil to dramatically reduce friction and wear for fretting steel/copper interfaces. Tribol. Int. 2019, 129, 75–81. [Google Scholar] [CrossRef]

- Huynh, K.K.; Tieu, K.A.; Pham, S.T. Synergistic and Competitive Effects between Zinc Dialkyldithiophosphates and Modern Generation of Additives in Engine Oil. Lubricants 2021, 9, 35. [Google Scholar] [CrossRef]

- Zavos, A. Effect of Coating and Low Viscosity Oils on Piston Ring Friction under Mixed Regime of Lubrication through Analytical Modelling. Lubricants 2021, 9, 124. [Google Scholar] [CrossRef]

- Vrček, A.; Hultqvist, T.; Baubet, Y.; Björling, M.; Marklund, P.; Larsson, R. Micro-Pitting and Wear Assessment of PAO vs Mineral-Based Engine Oil Operating under Mixed Lubrication Conditions: Effects of Lambda, Roughness Lay and Sliding Direction. Lubricants 2019, 7, 42. [Google Scholar] [CrossRef] [Green Version]

- Moshkovich, A.; Perfilyev, V.; Meshi, L.; Samuha, S.; Cohen, S.; Cohen, H.; Laikhtman, A.; Rapoport, L. Friction, wear and structure of Cu samples in the lubricated steady friction state. Tribol. Int. 2012, 46, 154–160. [Google Scholar] [CrossRef]

- Pichugin, S.; Malyshev, V. Infrared Spectral Studies of Copper-Containing Film on the Steel Sample. Int. J. Org. Chem. 2015, 5, 11–14. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.B.; Chen, H.; Shi, X.N.; Liu, X.; Duan, G.J. Tribological properties of ionic liquids for steel/aluminum, steel/copper and steel/Si3N4 ceramic contacts under boundary lubrication. Ind. Lubr. Tribol. 2018, 70, 1158–1168. [Google Scholar] [CrossRef]

- Han, Y.Y.; Qiao, D.; Zhang, S.W.; Feng, D.P. Influence of phosphate and phosphonate ionic liquid structures on lubrication for different alloys (Mg, Al, Cu). Tribol. Int. 2017, 114, 469–477. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, L.; Dong, R.; Zhang, C.Y.; Sun, W.J.; Fan, M.J.; Yang, D.S.; Zhou, F.; Liu, W.M. Study on the synthesis and tribological properties of anti-corrosion benzotriazole ionic liquid. Rsc Adv. 2017, 7, 11030–11040. [Google Scholar] [CrossRef] [Green Version]

- Cai, M.R.; Liang, Y.M.; Zhou, F.; Liu, W.M. Anticorrosion imidazolium ionic liquids as the additive in poly(ethylene glycol) for steel/Cu-Sn alloy contacts. Faraday Discuss. 2012, 156, 147–157. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.W.; Ding, Q.; Feng, D.P.; Qin, B.F.; Hu, L.T. The corrosion and lubrication properties of 2-Mercaptobenzothiazole functionalized ionic liquids for bronze. Tribol. Int. 2017, 114, 121–131. [Google Scholar] [CrossRef]

- Li, W.; Kumara, C.; Meyer, H.M.; Luo, H.; Qu, J. Compatibility between Various Ionic Liquids and an Organic Friction Modifier as Lubricant Additives. Langmuir 2018, 34, 10711–10720. [Google Scholar] [CrossRef]

- Mao, J.; Chen, G.; Zhao, J.; He, Y.; Luo, J. An investigation on the tribological behaviors of steel/copper and steel/steel friction pairs via lubrication with a graphene additive. Friction 2021, 9, 228–238. [Google Scholar] [CrossRef] [Green Version]

- Barnhill, W.C.; Qu, J.; Luo, H.; Meyer, H.M., III; Ma, C.; Chi, M.; Papke, B.L. Phosphonium-Organophosphate Ionic Liquids as Lubricant Additives: Effects of Cation Structure on Physicochemical and Tribological Characteristics. ACS Appl. Mater. Interfaces 2014, 6, 22585–22593. [Google Scholar] [CrossRef]

- Li, W.; Kumara, C.; Luo, H.; Meyer, H.M., III; He, X.; Ngo, D.; Kim, S.H.; Qu, J. Ultralow Boundary Lubrication Friction by Three-Way Synergistic Interactions among Ionic Liquid, Friction Modifier, and Dispersant. ACS Appl. Mater. Interfaces 2020, 12, 17077–17090. [Google Scholar] [CrossRef]

- Cao, M.; Wang, H.; Ji, S. Hollow core-shell structured Cu2O@ Cu1.8S spheres as novel electrode for enzyme free glucose sensing. Mater. Sci. Eng. C 2019, 95, 174–182. [Google Scholar] [CrossRef]

- Zhang, X.; Li, K.; Yan, P.; Liu, Z.; Pu, L. N-type Cu2O doped activated carbon as catalyst for improving power generation of air cathode microbial fuel cells. Bioresour. Technol. 2015, 187, 299–304. [Google Scholar] [CrossRef]

- Li, W.; Wu, Y.; Wang, X.; Liu, W. A study of P-N compound as multifunctional lubricant additive. Lubri. Sci. 2011, 23, 363–373. [Google Scholar] [CrossRef]

- Zhao, G.; Wu, X.; Li, W.; Wang, X. Hydroquinone bis(diphenyl phosphate) as an Antiwear/Extreme Pressure Additive in Polyalkylene Glycol for Steel/Steel Contacts at Elevated Temperature. Ind. Eng. Chem. Res. 2013, 52, 7419–7424. [Google Scholar] [CrossRef]

- Ma, R.; Li, W.M.; Zhao, Q.; Zheng, D.D.; Wang, X.B. In Situ Synthesized Phosphate-based Ionic Liquids as High-Performance Lubricant Additives. Tribol. Lett. 2019, 67, 9. [Google Scholar] [CrossRef]

- Charlier, J.; Detalle, V.; Valin, F. Study of ultrathin polyamide-6, 6 films on clean copper and platinum. J. Vac. Sci. Technol. A 1997, 15, 353–364. [Google Scholar] [CrossRef]

- Uvdal, K.; Bodö, P.; Ihs, A. X-ray photoelectron and infrared spectroscopy of glycine adsorbed upon copper. J. Colloid Interface Sci. 1990, 140, 207–216. [Google Scholar] [CrossRef]

| Materials | Composition |

|---|---|

| AISI 52100 | C, 1.04%; Mn, 0.11%; Si, 0.25%; Cr, 1.58%; Fe-balance |

| H62 Brass | Cu, 60.5–63.5%; Fe, 0.15%; Pb, 0.8%; Sb, 0.005%, Bi, 0.002%, P, 0.01%, Zn-balance |

| Item Number | Composition | Mean Coefficient of Friction |

|---|---|---|

| a | PAO4 base oil | 0.349 |

| b | PAO4 + 0.8% ZDDP | 0.093 |

| c | PAO4 + 0.8% AW316 | 0.082 |

| d | PAO4 + 0.8% [P8888][DEHP] | 0.199 |

| e | PAO4 + 0.8% 353 | 0.118 |

| f | PAO4 + 0.8% TCP | 0.170 |

| Elements (wt.%) | PAO4 | PAO4 + 0.8%ZDDP | PAO4 + 0.8%AW316 | PAO4 + 0.8%[P8888][DEHP] | PAO4 + 0.8%353 | PAO4 + 0.8%TCP |

|---|---|---|---|---|---|---|

| O | 4.23 | 3.69 | 4.51 | 5.04 | 5.69 | 3.67 |

| Fe | 1.00 | 1.63 | 1.40 | 1.97 | 1.86 | 0.78 |

| Cu | 54.80 | 54.68 | 63.76 | 60.78 | 53.77 | 67.71 |

| P | - | 0.76 | 0.75 | 0.99 | 0.56 | 0.22 |

| S | - | 1.63 | - | - | 2.12 | - |

| N | - | - | 2.52 | - | - | - |

| Zn | 38.86 | 35.76 | 25.56 | 28.59 | 34.60 | 24.61 |

| Pb | 1.11 | 1.85 | 1.50 | 2.63 | 1.40 | 3.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, H.; Chen, Y.; Ma, R.; Li, W.; Zhao, G.; Qi, Y.; Lou, W. Influence of Additive Chemistry on the Tribological Behavior of Steel/Copper Friction Pairs. Lubricants 2022, 10, 91. https://doi.org/10.3390/lubricants10050091

Su H, Chen Y, Ma R, Li W, Zhao G, Qi Y, Lou W. Influence of Additive Chemistry on the Tribological Behavior of Steel/Copper Friction Pairs. Lubricants. 2022; 10(5):91. https://doi.org/10.3390/lubricants10050091

Chicago/Turabian StyleSu, Huaigang, Yunlong Chen, Rui Ma, Weimin Li, Gaiqing Zhao, Yanxing Qi, and Wenjing Lou. 2022. "Influence of Additive Chemistry on the Tribological Behavior of Steel/Copper Friction Pairs" Lubricants 10, no. 5: 91. https://doi.org/10.3390/lubricants10050091

APA StyleSu, H., Chen, Y., Ma, R., Li, W., Zhao, G., Qi, Y., & Lou, W. (2022). Influence of Additive Chemistry on the Tribological Behavior of Steel/Copper Friction Pairs. Lubricants, 10(5), 91. https://doi.org/10.3390/lubricants10050091