Tribological Properties of Ti6Al4V Titanium Textured Surfaces Created by Laser: Effect of Dimple Density

Abstract

:1. Introduction

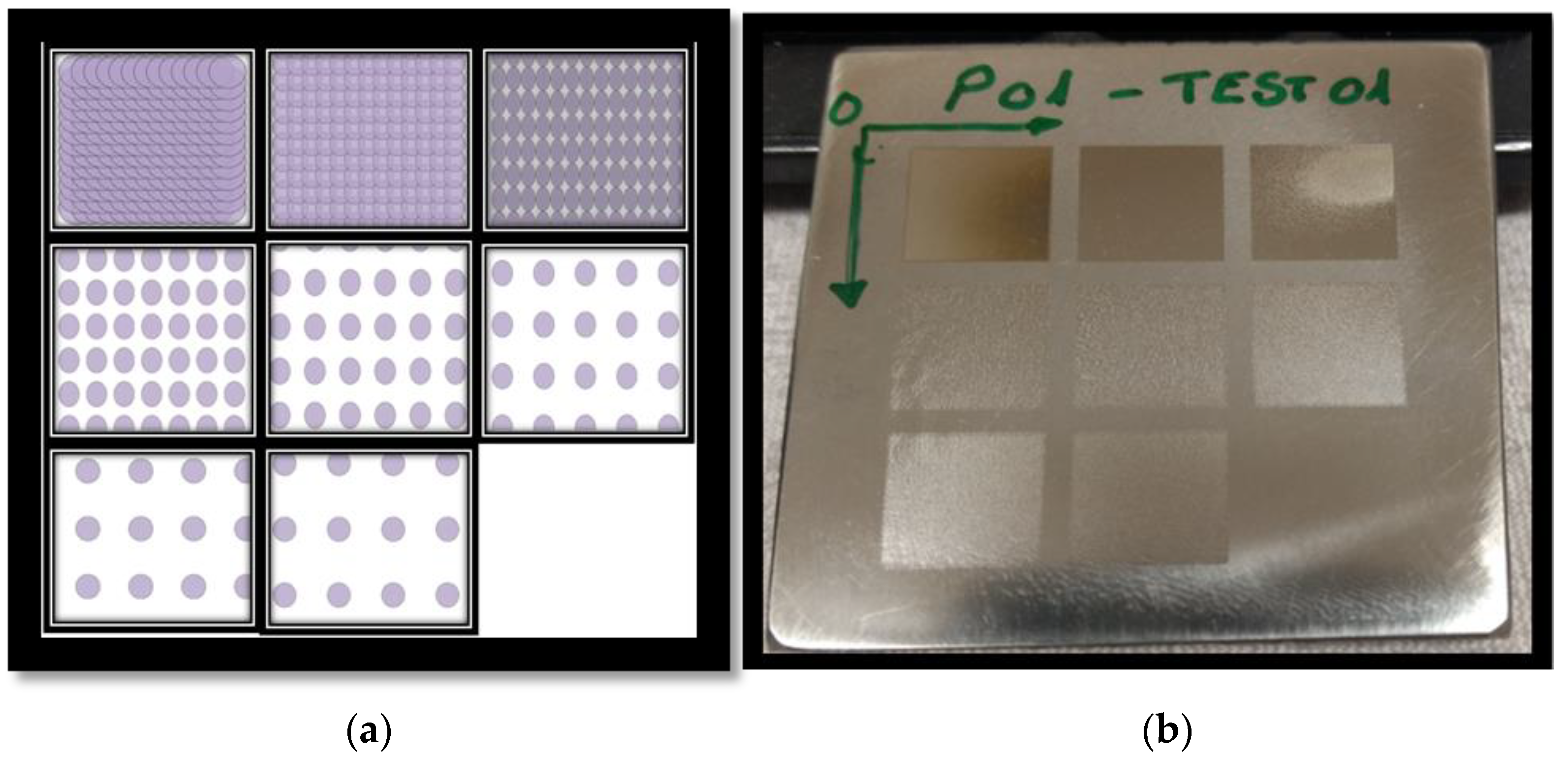

2. Materials and Methods

2.1. Samples

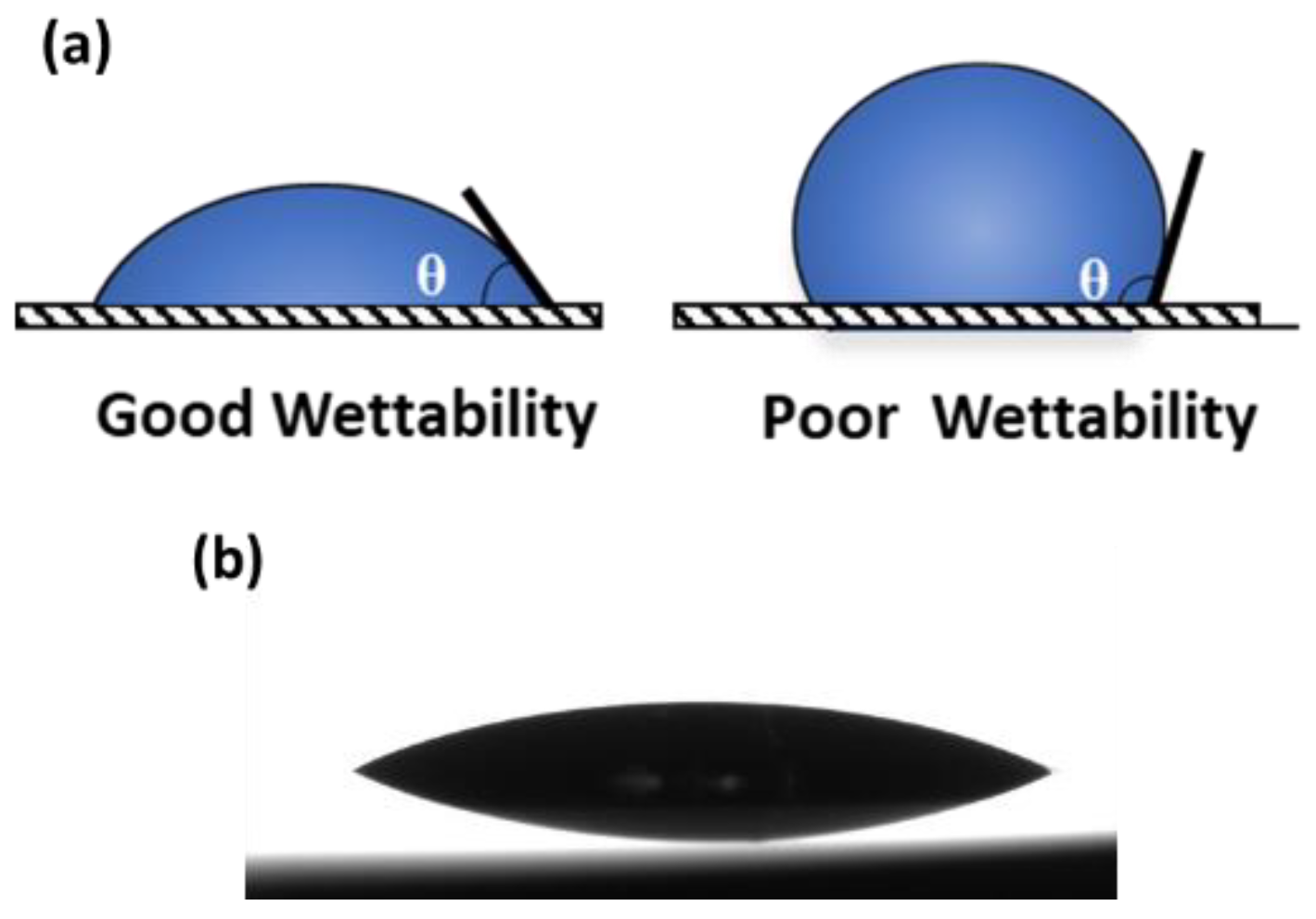

2.2. Contact Angle Tests

2.3. The Roughness of Textured Surfaces

2.4. Surface Hardness Test

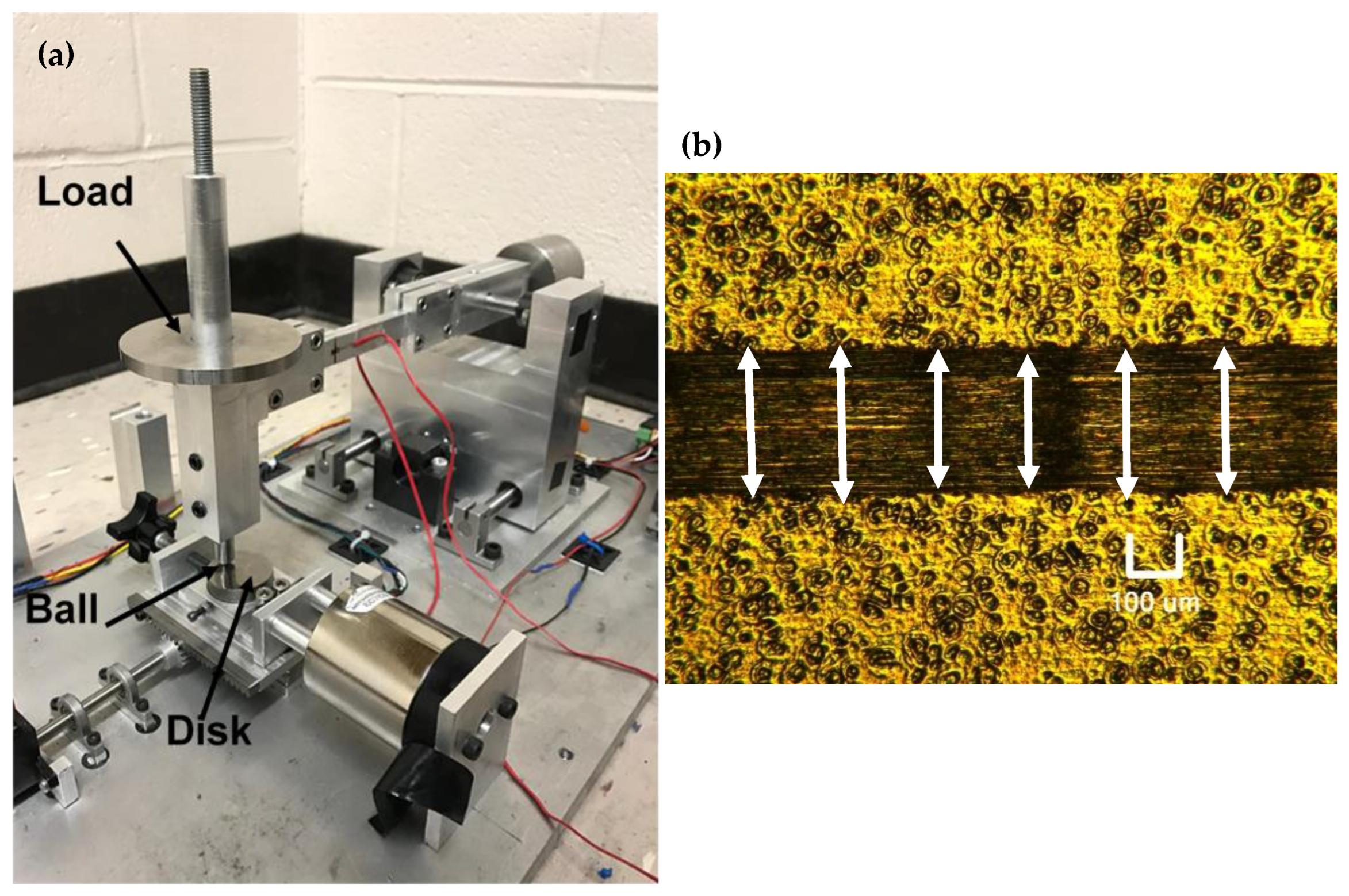

2.5. Tribological Tests

3. Results

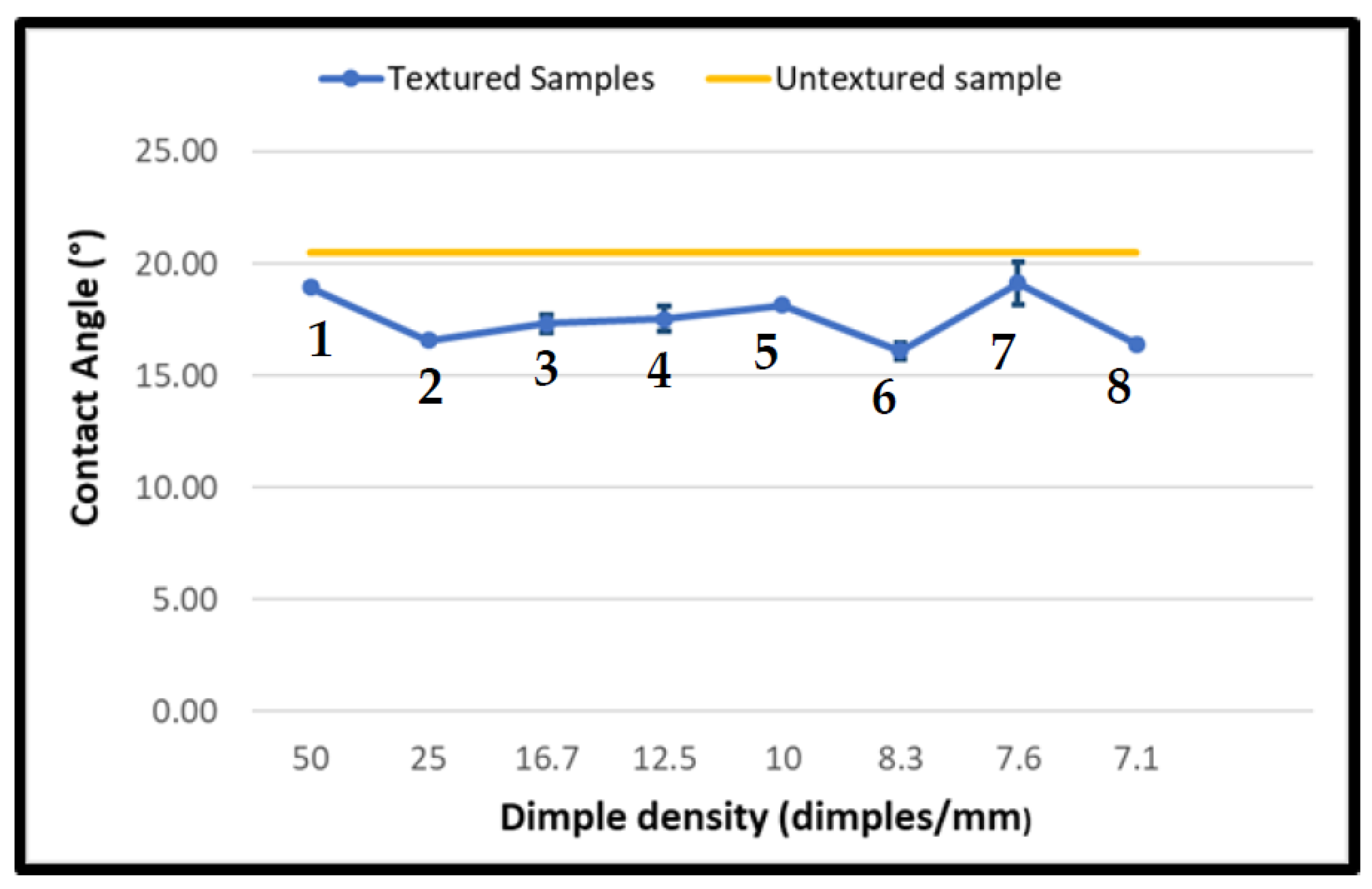

3.1. Wettability

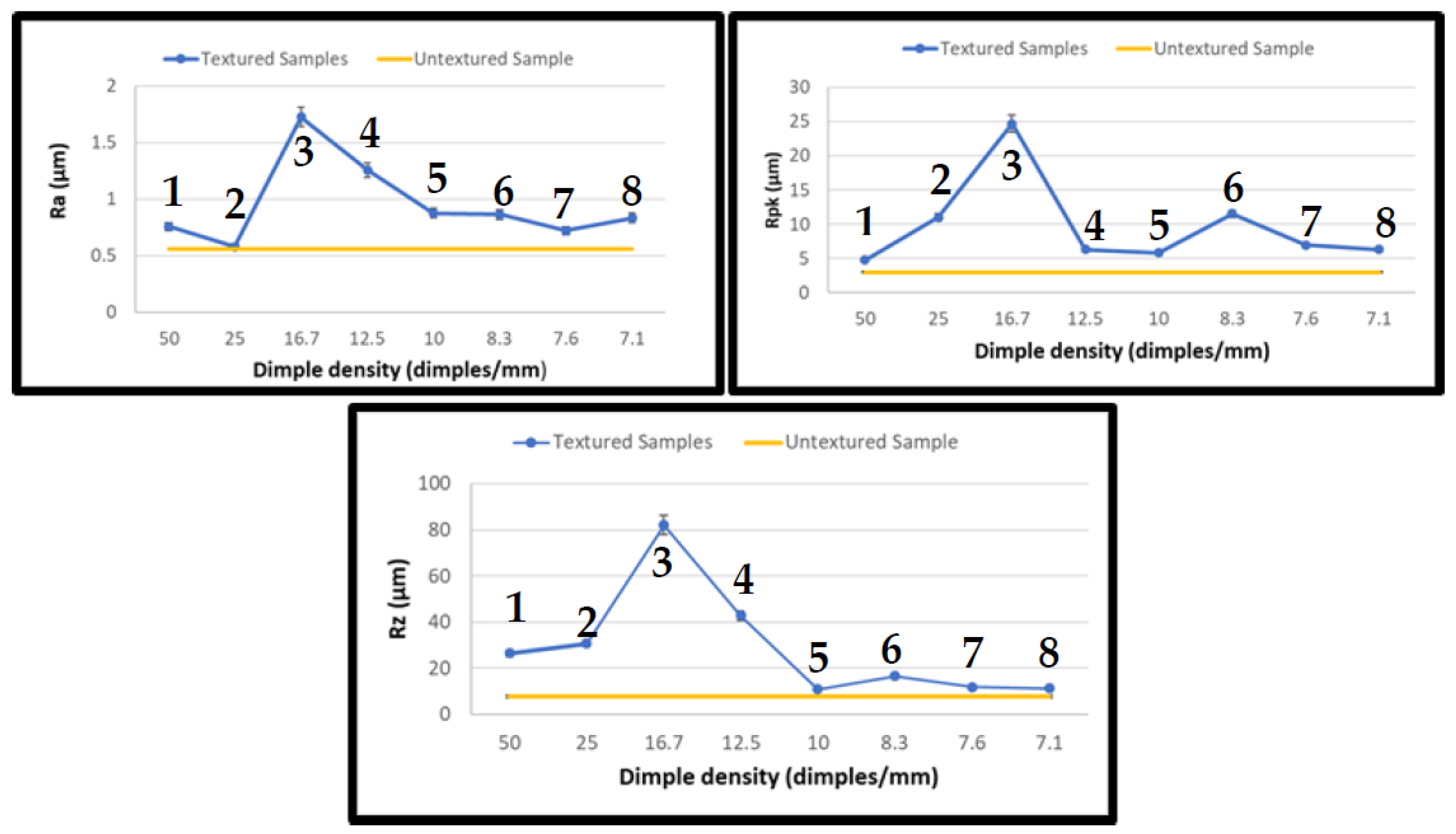

3.2. Surface Roughness

3.3. Surface Hardness

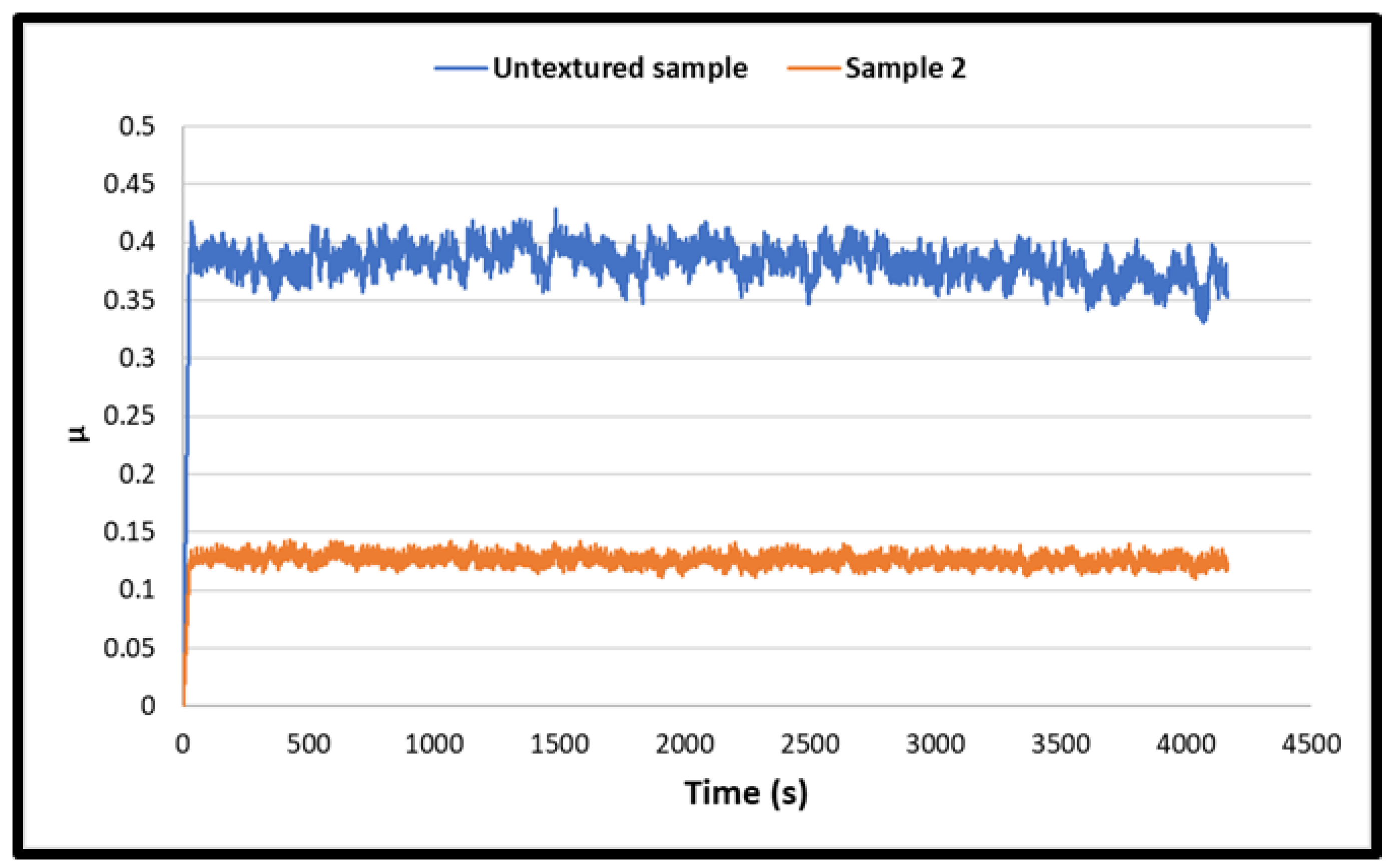

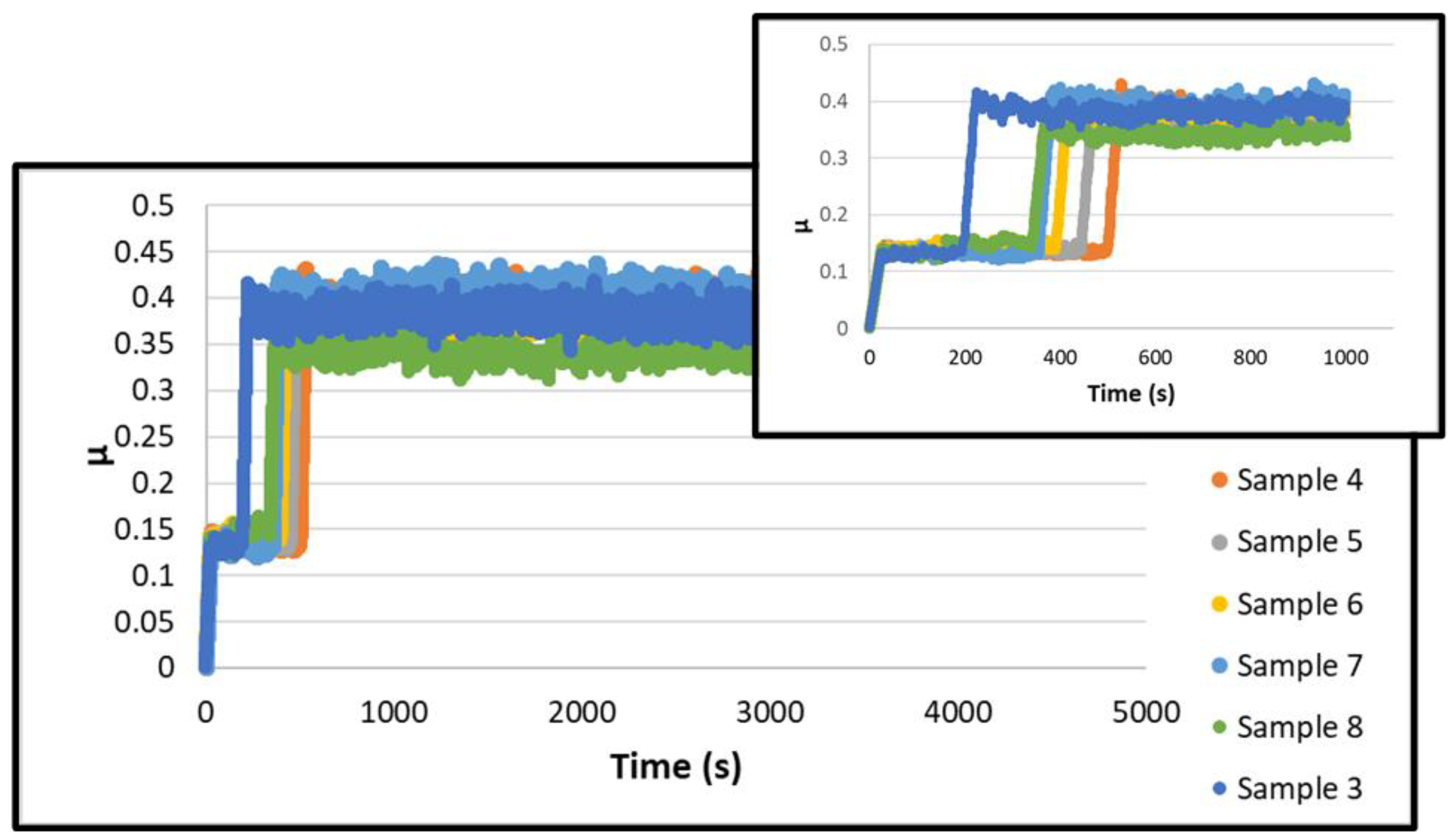

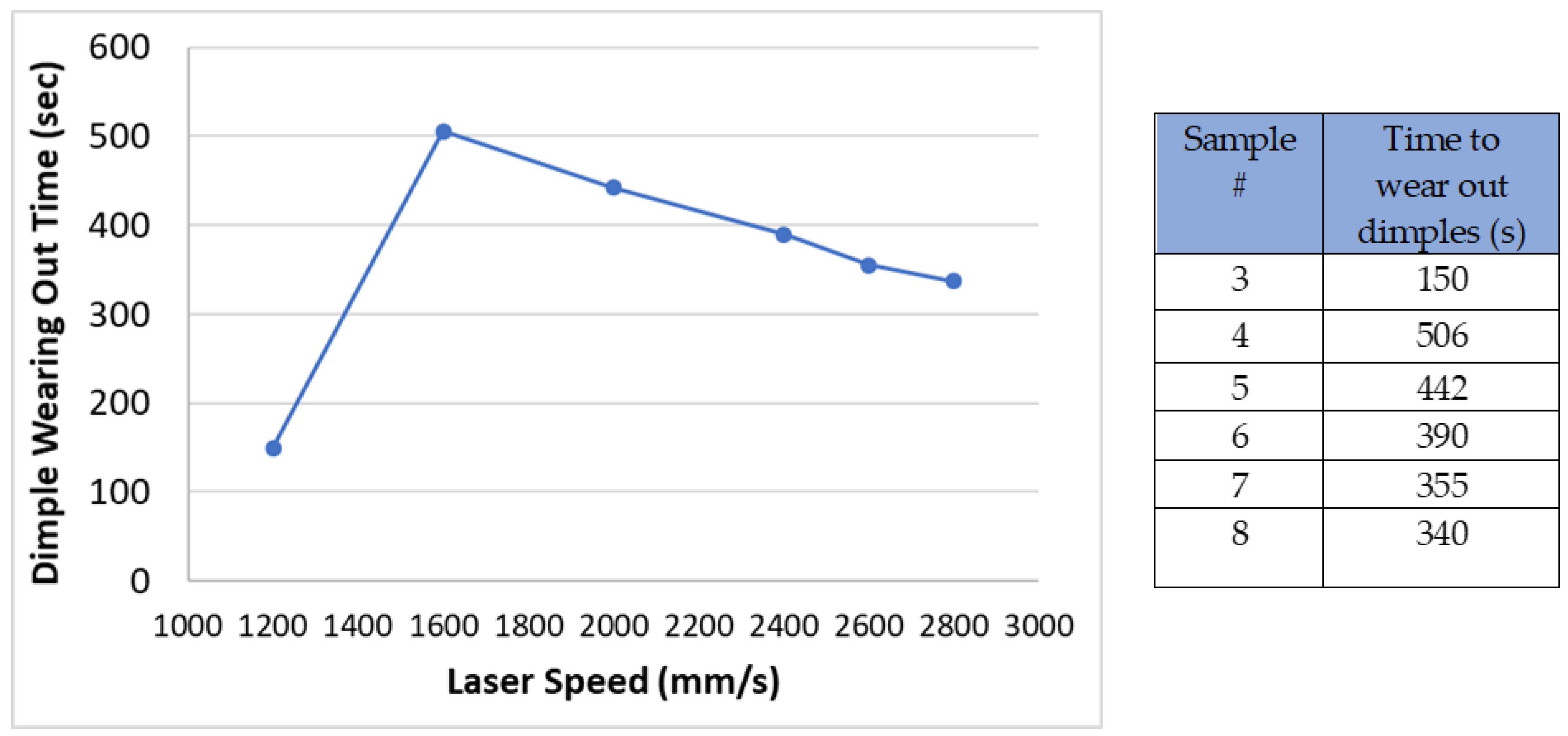

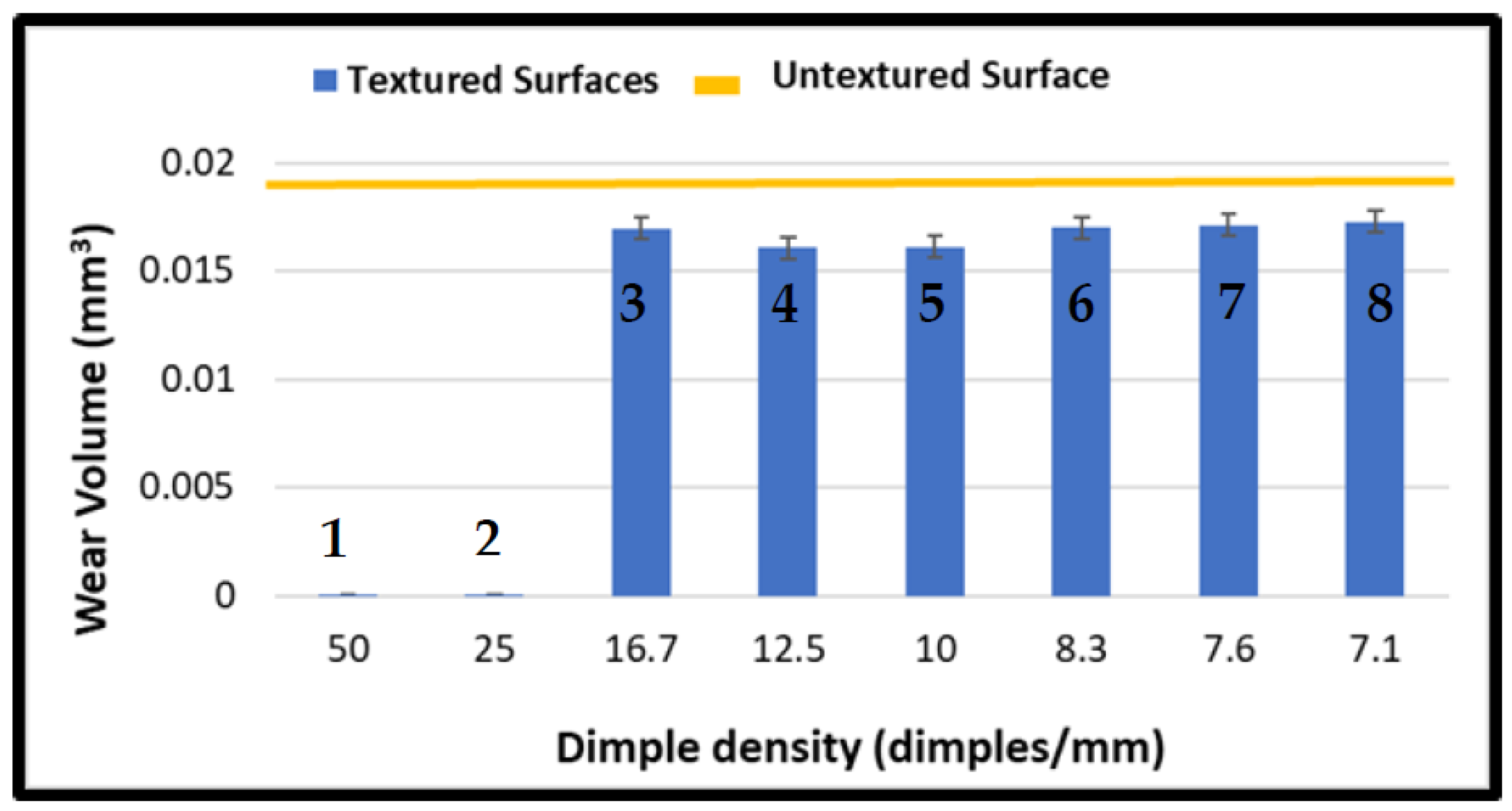

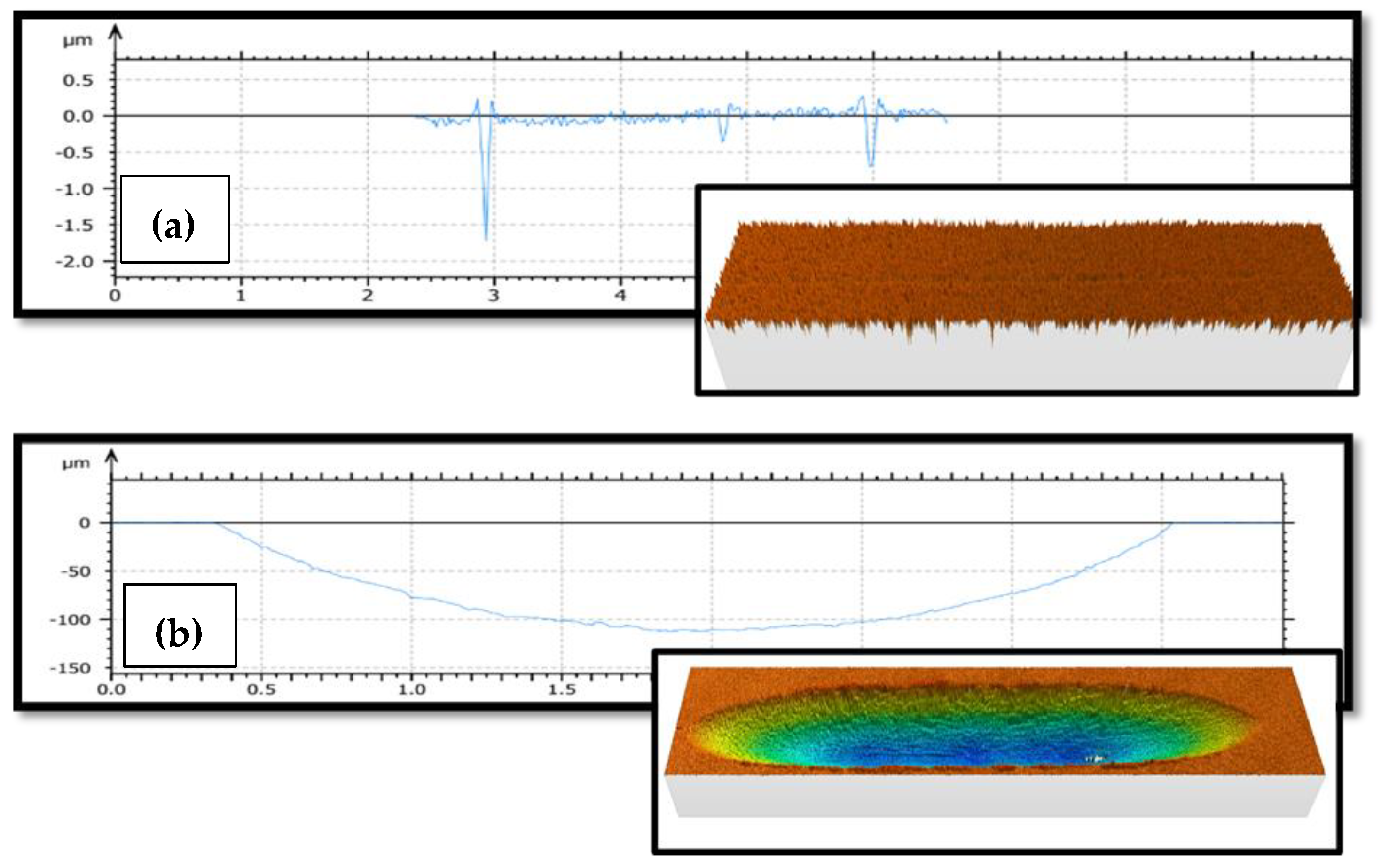

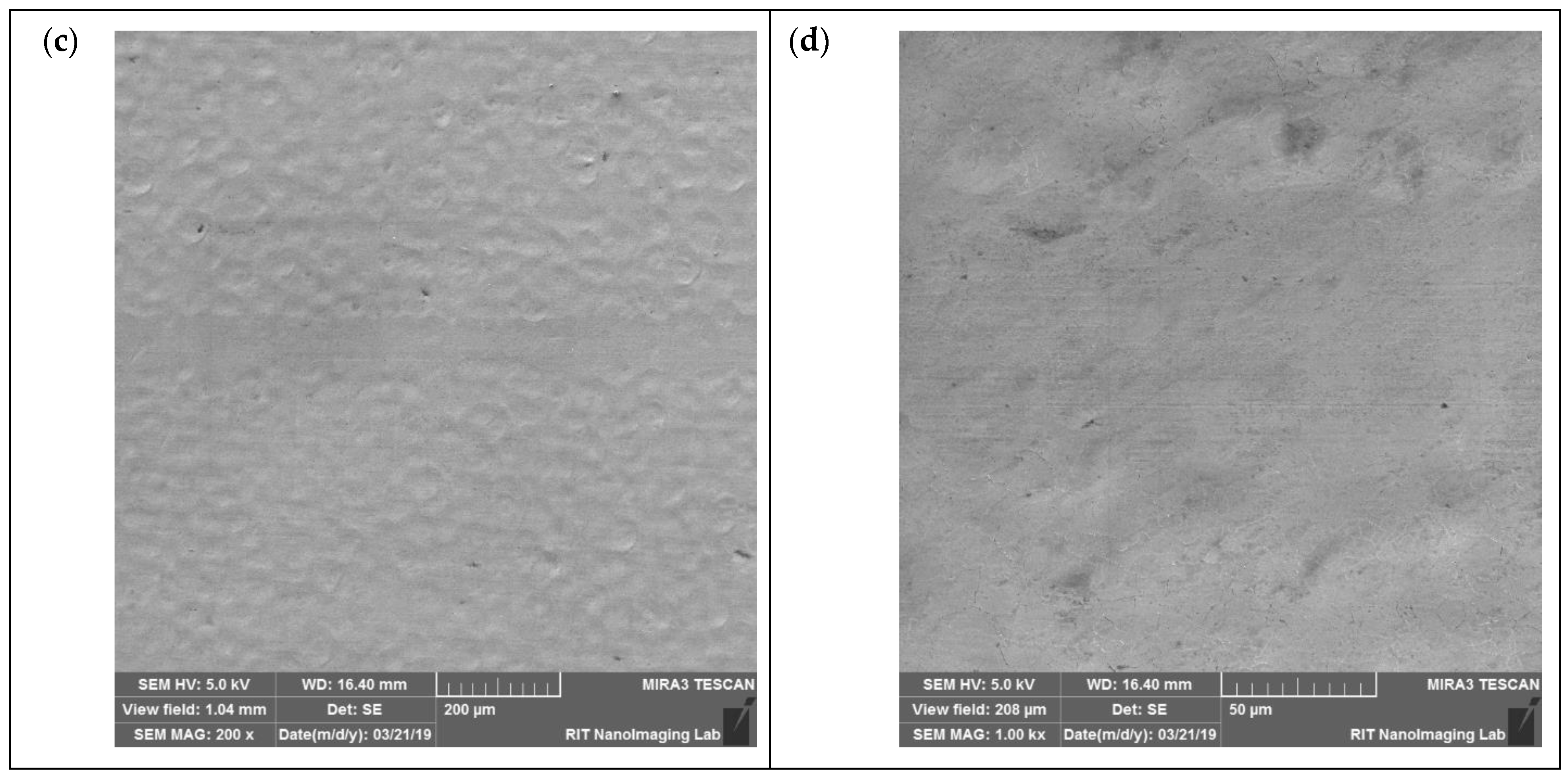

3.4. Tribological Results

4. Conclusions

- Samples with the highest dimple densities (sample 1 and sample 2), showed a friction reduction of around 67% and wear reduction of almost 99% with respect to the untextured surface.

- For the sample with the highest dimple density (50 dimples/mm), created with the lowest laser speed, an important increase in the surface hardness was observed due to longer exposure to laser treatment. This increased surface hardness may have influenced the tribological properties of the sample.

- Sample 2 with a dimple density of 25 dimples/mm showed a very low increase in surface hardness, with better tribological performance that could be attributed to the surface texturing effect.

- Samples with dimple densities ranging from 16.7 to 7.1 dimples/mm (sample 3 to sample 8) showed highly similar friction coefficients, which were slightly lower than that of the untextured sample, with an average reduction in friction of 6%. These samples presented low friction coefficients at the beginning of the test, when there were fresh dimples on their surfaces. However, as the test progressed, these dimples were worn out, and the effect of the textured surface was canceled. As a result, high friction values were observed through the rest of the test.

- The dimple wear-out time observed in samples 3 to 8 was greatly influenced by the dimple density.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; He, B.; Lyu, T.; Zou, Y. A Review on Additive Manufacturing of Titanium Alloys for Aerospace Applications: Directed Energy Deposition and Beyond Ti-6Al-4V. Jom 2021, 73, 1804–1818. [Google Scholar] [CrossRef]

- Zhao, Q.; Sun, Q.; Xin, S.; Chen, Y.; Wu, C.; Wang, H.; Xu, J.; Wan, M.; Zeng, W.; Zhao, Y. High-strength titanium alloys for aerospace engineering applications: A review on melting-forging process. Mater. Sci. Eng. A 2022, 845, 143260. [Google Scholar] [CrossRef]

- Cecchel, S.; Montesano, L.; Cornacchia, G. Wear and Corrosion Characterization of a Ti–6Al–4V Component for Automotive Applications: Forging versus Selective Laser Melting Technologies. Adv. Eng. Mater. 2022, 2200082, 1–10. [Google Scholar] [CrossRef]

- You, S.H.; Lee, J.H.; Oh, S.H. A Study on Cutting Characteristics in Turning Operations of Titanium Alloy used in Automobile. Int. J. Precis. Eng. Manuf. 2019, 20, 209–216. [Google Scholar] [CrossRef] [Green Version]

- Aufa, A.N.; Hassan, M.Z.; Ismail, Z. Recent advances in Ti-6Al-4V additively manufactured by selective laser melting for biomedical implants: Prospect development. J. Alloys Compd. 2022, 896, 163072. [Google Scholar] [CrossRef]

- Chirico, C.; Vaz Romero, A.; Gordo, E.; Tsipas, S.A. Improvement of wear resistance of low-cost powder metallurgy β-titanium alloys for biomedical applications. Surf. Coat. Technol. 2022, 434, 128207. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Tribology International The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars. Tribol. Int. 2019, 135, 389–396. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Solomon, S.; Plattner, G.-K.; Knutti, R.; Friedlingstein, P. Irreversible climate change due to carbon dioxide emissions. Proc. Natl. Acad. Sci. USA 2009, 106, 1704–1709. [Google Scholar] [CrossRef] [Green Version]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Bruzzone, A.A.G.; Costa, H.L.; Lonardo, P.M.; Lucca, D.A. Advances in engineered surfaces for functional performance. CIRP Ann.-Manuf. Technol. 2008, 57, 750–769. [Google Scholar] [CrossRef]

- Iglesias, P.; Bermúdez, M.D.; Carrión, F.J.; Martínez-Nicolás, G.; Martínez-Nicolás, G. Friction and wear of aluminium-steel contacts lubricated with ordered fluids-neutral and ionic liquid crystals as oil additives. Wear 2004, 256, 386–392. [Google Scholar] [CrossRef]

- Guo, H.; Smith, T.W.T.W.; Iglesias, P. The study of hexanoate-based protic ionic liquids used as lubricants in steel-steel contact. J. Mol. Liq. 2020, 299, 112208. [Google Scholar] [CrossRef]

- Iglesias, P.; Bermúdez, M.D.; Moscoso, W.; Rao, B.C.; Shankar, M.R.; Chandrasekar, S. Friction and wear of nanostructured metals created by large strain extrusion machining. Wear 2007, 263, 636–642. [Google Scholar] [CrossRef]

- Tock, A.; Saldana, C.; Iglesias, P. Tribological Performance of Textured Surfaces Created by Modulation-Assisted Machining. J. Tribol. 2018, 140, 061704. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Sasaki, S. Environmentally friendly tribology (Eco-tribology). J. Mech. Sci. Technol. 2010, 24, 67–71. [Google Scholar] [CrossRef]

- Cao, W.; Hu, T.; Fan, H.; Hu, L. Laser surface texturing and tribological behaviour under solid lubrication on titanium and titanium alloy surfaces. Int. J. Surf. Sci. Eng. 2021, 15, 50–66. [Google Scholar] [CrossRef]

- Daskalova, A.; Lasgorceix, M.; Bliznakova, I.; Angelova, L.; Hoquet, S.; Leriche, A.; Trifonov, A.; Buchvarov, I. Ultra-fast laser surface texturing of β-tricalcium phosphate (β-TCP) ceramics for bone-tissue engineering applications. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2020; Volume 1492. [Google Scholar] [CrossRef]

- De La Guerra Ochoa, E.; Otero, J.E.; Tanarro, E.C.; Morgado, P.L.; Lantada, A.D.; Munoz-Guijosa, J.M.; Sanz, J.M. Optimising lubricated friction coefficient by surface texturing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2013, 227, 2610–2619. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, Y.; Zhu, H.; Yang, H. The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Yuan, S.; Huang, W.; Wang, X. Orientation effects of micro-grooves on sliding surfaces. Tribol. Int. 2011, 44, 1047–1054. [Google Scholar] [CrossRef]

- Gualtieri, E.; Borghi, A.; Calabri, L.; Pugno, N.; Valeri, S. Increasing nanohardness and reducing friction of nitride steel by laser surface texturing $. Tribol. Int. 2009, 42, 699–705. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, M.; Dong, G.N.; Zhang, D.Y.; Chin, K.S. A mixed lubrication model for studying tribological behaviors of surface texturing. Tribol. Int. 2016, 93, 583–592. [Google Scholar] [CrossRef]

- Ronen, A.; Etsion, I.; Kligerman, Y. Friction-reducing surface-texturing in reciprocating automotive components. Tribol. Trans. 2001, 44, 359–366. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Khaskhoussi, A.; Risitano, G.; Calabrese, L.; D’andrea, D. Investigation of the Wettability Properties of Different Textured Lead/Lead-Free Bronze Coatings. Lubricants 2022, 10, 82. [Google Scholar] [CrossRef]

- Volpe, A.; Covella, S.; Gaudiuso, C.; Ancona, A. Improving the laser texture strategy to get superhydrophobic aluminum alloy surfaces. Coatings 2021, 11, 369. [Google Scholar] [CrossRef]

- Pang, M.; Liu, X.; Liu, K. Effect of wettability on the friction of a laser-textured cemented carbide surface in dilute cutting fluid. Adv. Mech. Eng. 2017, 9, 1687814017738154. [Google Scholar] [CrossRef] [Green Version]

- Akbarzadeh, S.; Khonsari, M.M. Effect of surface pattern on stribeck curve. Tribol. Lett. 2010, 37, 477–486. [Google Scholar] [CrossRef]

- Wang, X.; Liu, W.; Zhou, F.; Zhu, D. Preliminary investigation of the effect of dimple size on friction in line contacts. Tribol. Int. 2009, 42, 1118–1123. [Google Scholar] [CrossRef]

- Salguero, J.; Del Sol, I.; Vazquez-Martinez, J.M.; Schertzer, M.J.; Iglesias, P. Effect of laser parameters on the tribological behavior of Ti6Al4V titanium microtextures under lubricated conditions. Wear 2019, 426–427, 1272–1279. [Google Scholar] [CrossRef]

- Senatore, A.; Risitano, G.; Scappaticci, L.; D’andrea, D. Investigation of the tribological properties of different textured lead bronze coatings under severe load conditions. Lubricants 2021, 9, 34. [Google Scholar] [CrossRef]

- Abril, S.O.; Del Socorro Fonseca-Vigoya, M.; Pabón-León, J. CFD Analysis of the Effect of Dimples and Cylinder Liner Honing Groove on the Tribological Characteristics of a Low Displacement Engine. Lubricants 2022, 10, 61. [Google Scholar] [CrossRef]

- Niu, Y.; Pang, X.; Yue, S.; Shangguan, B.; Zhang, Y. The friction and wear behavior of laser textured surfaces in non-conformal contact under starved lubrication. Wear 2021, 476, 203723. [Google Scholar] [CrossRef]

- Ullah, M.Z.; Rizwan, M.; Raza, A.; Ahmed, A.; Abid, M. Effect of dimple shape and depth on tribological performance of textured surface. In Proceedings of the 2021 18th International Bhurban Conference on Applied Sciences and Technologies, Islamabad, Pakistan, 12–16 January 2021; pp. 719–725. [Google Scholar] [CrossRef]

- Kligerman, Y.; Etsion, I.; Shinkarenko, A. Improving Tribological Performance of Piston Rings by Partial Surface Texturing. J. Tribol. 2005, 127, 632. [Google Scholar] [CrossRef]

- Mehta, P.; Liu, R.; Mann, J.B.; Saldana, C.; Iglesias, P. Effect of textured surfaces created by modulation-assisted machining on the Stribeck curve and wear properties of steel-aluminum contact. Int. J. Adv. Manuf. Technol. 2018, 99, 399–409. [Google Scholar] [CrossRef]

- Byun, J.W.; Shin, H.S.; Kwon, M.H.; Kim, B.H.; Chu, C.N. Surface texturing by micro ECM for friction reduction. Int. J. Precis. Eng. Manuf. 2010, 11, 747–753. [Google Scholar] [CrossRef]

- Costa, H.; Hutchings, I. Some innovative surface texturing techniques for tribological purposes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 429–448. [Google Scholar] [CrossRef] [Green Version]

- Scaraggi, M.; Mezzapesa, F.P.; Carbone, G.; Ancona, A.; Sorgente, D.; Lugarà, P.M. Minimize friction of lubricated laser-microtextured-surfaces by tuning microholes depth. Tribol. Int. 2014, 75, 123–127. [Google Scholar] [CrossRef]

- Qu, J.; Truhan, J.J. An efficient method for accurately determining wear volumes of sliders with non-flat wear scars and compound curvatures. Wear 2006, 261, 848–855. [Google Scholar] [CrossRef]

- Schertzer, M.J.; Iglesias, P. Meta-Analysis Comparing Wettability Parameters and the Effect of Wettability on Friction Coefficient in Lubrication. Lubricants 2018, 6, 70. [Google Scholar] [CrossRef] [Green Version]

- Bombard, A.J.F.; Gonçalves, F.R.; Shahrivar, K.; Ortiz, A.L.; de Vicente, J. Tribological behavior of ionic liquid-based magnetorheological fluids in steel and polymeric point contacts. Tribol. Int. 2015, 81, 309–320. [Google Scholar] [CrossRef]

- Matczak, L.; Johanning, C.; Gil, E.; Smith, T.W.T.W.; Schertzer, M.J.M.; Iglesias Victoria, P.; Guo, H.; Smith, T.W.T.W.; Schertzer, M.J.M.; Iglesias, P. Effect of cation nature on the lubricating and physicochemical properties of three ionic liquids. Tribol. Int. 2018, 124, 23–33. [Google Scholar] [CrossRef]

- Qu, J.; Truhan, J.J.; Dai, S.; Luo, H.; Blau, P.J. Ionic liquids with ammonium cations as lubricants or additives. Tribol. Lett. 2006, 22, 207–214. [Google Scholar] [CrossRef]

- Vidyasagar, K.E.C.; Pandey, R.K.; Kalyanasundaram, D. An exploration of frictional and vibrational behaviors of textured deep groove ball bearing in the vicinity of requisite minimum load. Friction 2021, 9, 1749–1765. [Google Scholar] [CrossRef]

- Syed, I.; Sarangi, M. Hydrodynamic lubrication with deterministic micro textures considering fluid inertia effect. Tribol. Int. 2014, 69, 30–38. [Google Scholar] [CrossRef]

- Liu, W.; Ni, H.; Chen, H.; Wang, P. Numerical simulation and experimental investigation on tribological performance of micro-dimples textured surface under hydrodynamic lubrication. Int. J. Mech. Sci. 2019, 163, 105095. [Google Scholar] [CrossRef]

- Xue, X.; Lu, L.; Wang, Z.; Li, Y.; Guan, Y. Improving tribological behavior of laser textured Ti-20Zr-10Nb-4Ta alloy with dimple surface. Mater. Lett. 2021, 305, 130876. [Google Scholar] [CrossRef]

- Wang, Y.-Q.; Wu, G.-F.; Han, Q.-G.; Fang, L.; Ge, S.R. Tribological properties of surface dimple-textured by pellet-pressing. Procedia Earth Planet. Sci. 2009, 1, 1513–1518. [Google Scholar] [CrossRef] [Green Version]

| Element | % |

|---|---|

| Ti | balanced |

| Al | 6% |

| V | 4% |

| Fe | <0.25% |

| O | <0.2% |

| Sample No. | Laser Spot Size (μm) | Laser Speed (mm/s) | Laser Frequency (Hz) | Spacing between Two Laser Passes (μm) | Dimple Density (dimples/mm) | Dimple Depth (μm) |

|---|---|---|---|---|---|---|

| Sample 1 | 60 | 400 | 20,000 | 20 | 50 | 6 |

| Sample 2 | 60 | 800 | 20,000 | 40 | 25 | 6 |

| Sample 3 | 60 | 1200 | 20,000 | 60 | 16.7 | 8 |

| Sample 4 | 60 | 1600 | 20,000 | 80 | 12.5 | 7 |

| Sample 5 | 60 | 2000 | 20,000 | 100 | 10 | 7 |

| Sample 6 | 60 | 2400 | 20,000 | 120 | 8.3 | 7 |

| Sample 7 | 60 | 2600 | 20,000 | 140 | 7.6 | 8 |

| Sample 8 | 60 | 2800 | 20,000 | 160 | 7.1 | 7 |

| Sample 9 | Untextured | - | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaikwad, A.; Vázquez-Martínez, J.M.; Salguero, J.; Iglesias, P. Tribological Properties of Ti6Al4V Titanium Textured Surfaces Created by Laser: Effect of Dimple Density. Lubricants 2022, 10, 138. https://doi.org/10.3390/lubricants10070138

Gaikwad A, Vázquez-Martínez JM, Salguero J, Iglesias P. Tribological Properties of Ti6Al4V Titanium Textured Surfaces Created by Laser: Effect of Dimple Density. Lubricants. 2022; 10(7):138. https://doi.org/10.3390/lubricants10070138

Chicago/Turabian StyleGaikwad, Akshay, Juan Manuel Vázquez-Martínez, Jorge Salguero, and Patricia Iglesias. 2022. "Tribological Properties of Ti6Al4V Titanium Textured Surfaces Created by Laser: Effect of Dimple Density" Lubricants 10, no. 7: 138. https://doi.org/10.3390/lubricants10070138

APA StyleGaikwad, A., Vázquez-Martínez, J. M., Salguero, J., & Iglesias, P. (2022). Tribological Properties of Ti6Al4V Titanium Textured Surfaces Created by Laser: Effect of Dimple Density. Lubricants, 10(7), 138. https://doi.org/10.3390/lubricants10070138