Improvement of Mechanical Properties and Adhesion of Ti-Al-Si-N Coatings by Alloying with Ta

Abstract

:1. Introduction

2. Materials and Methods

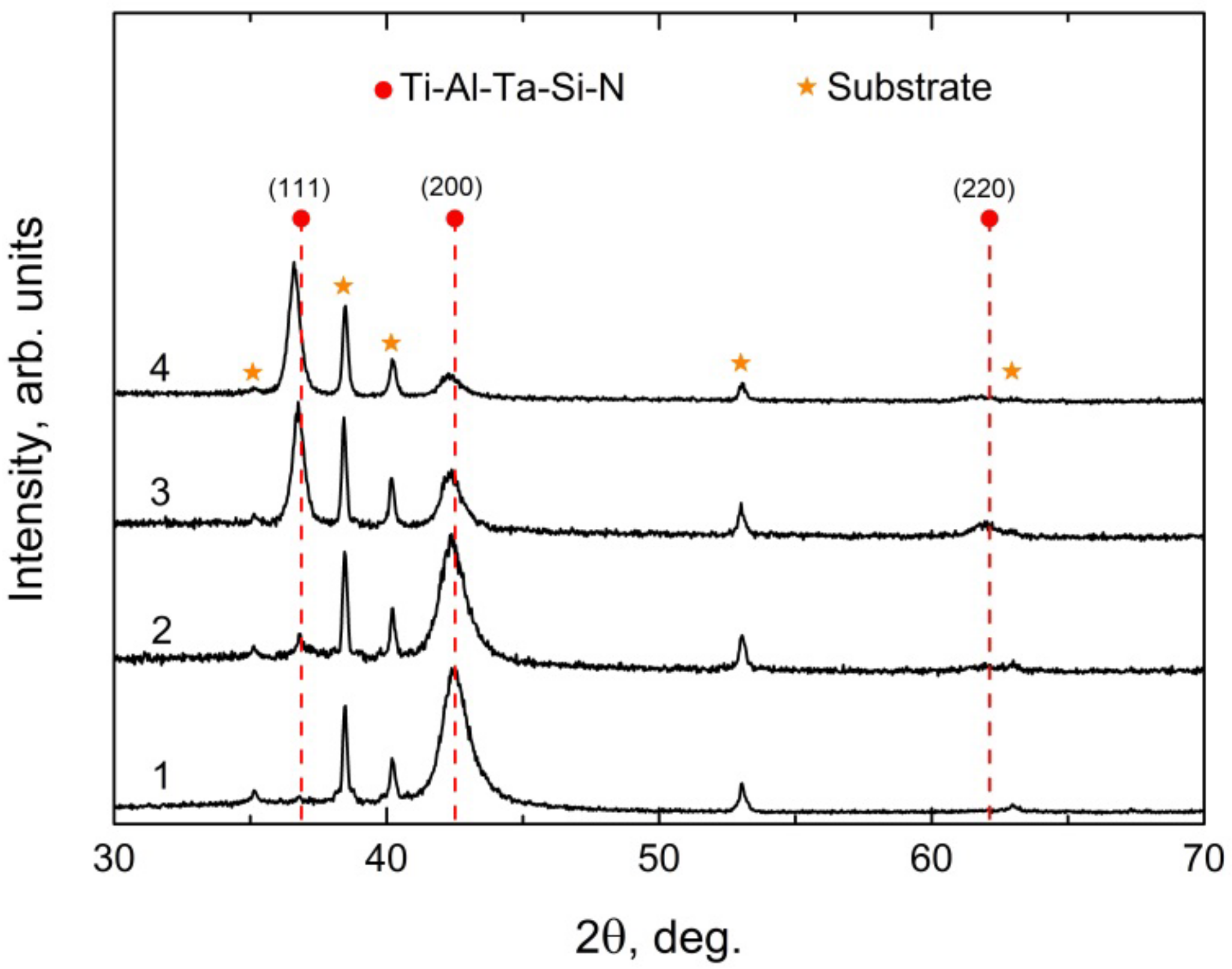

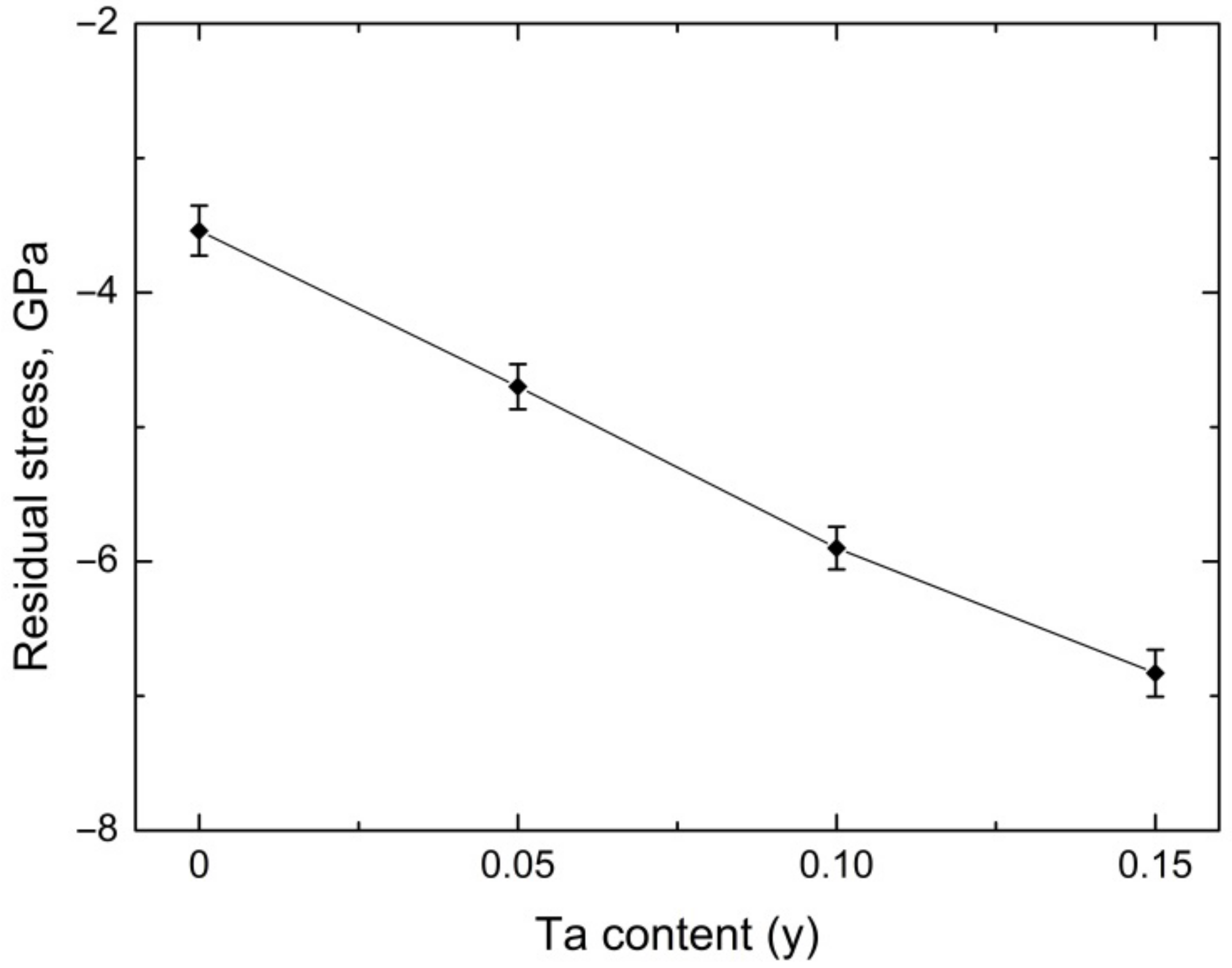

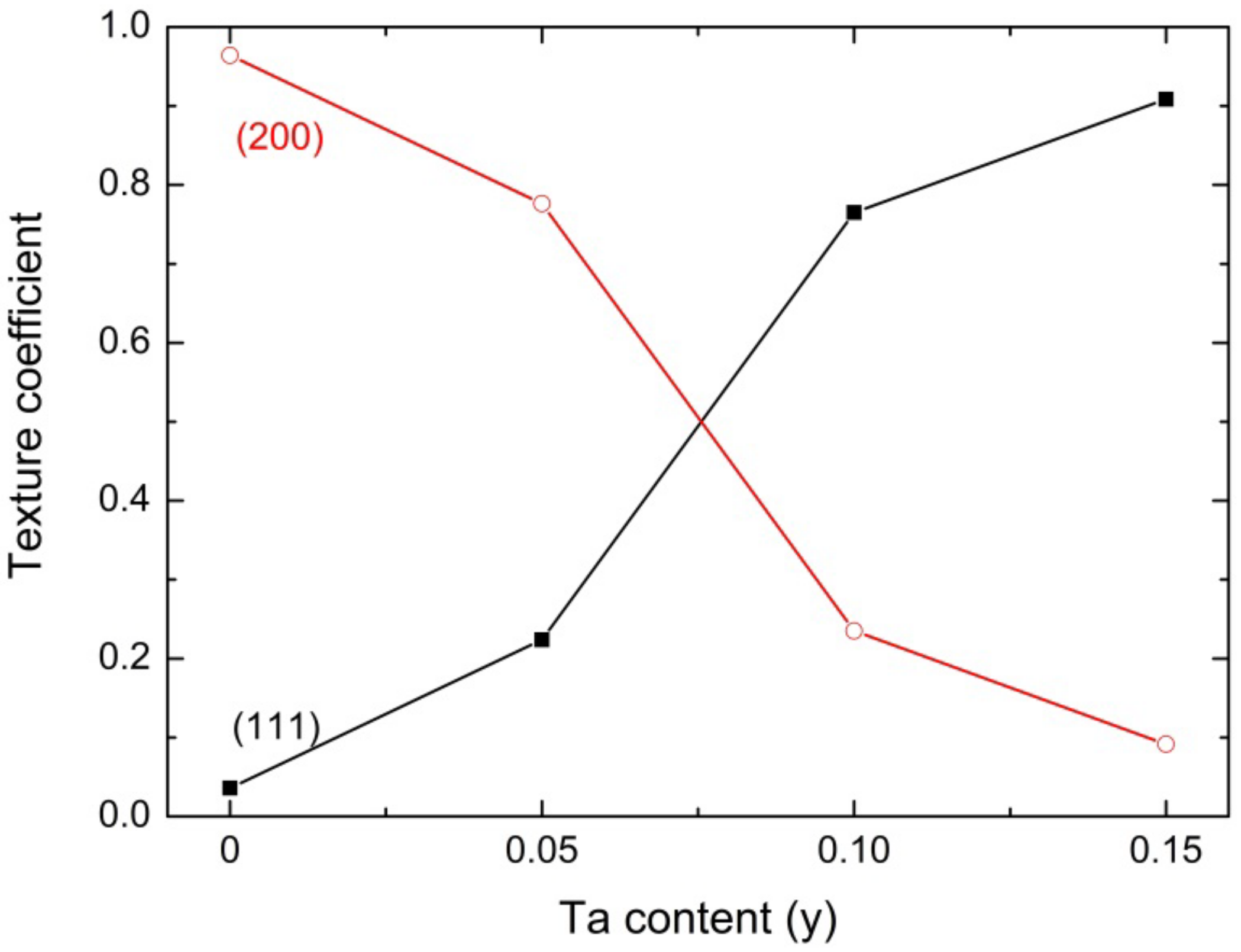

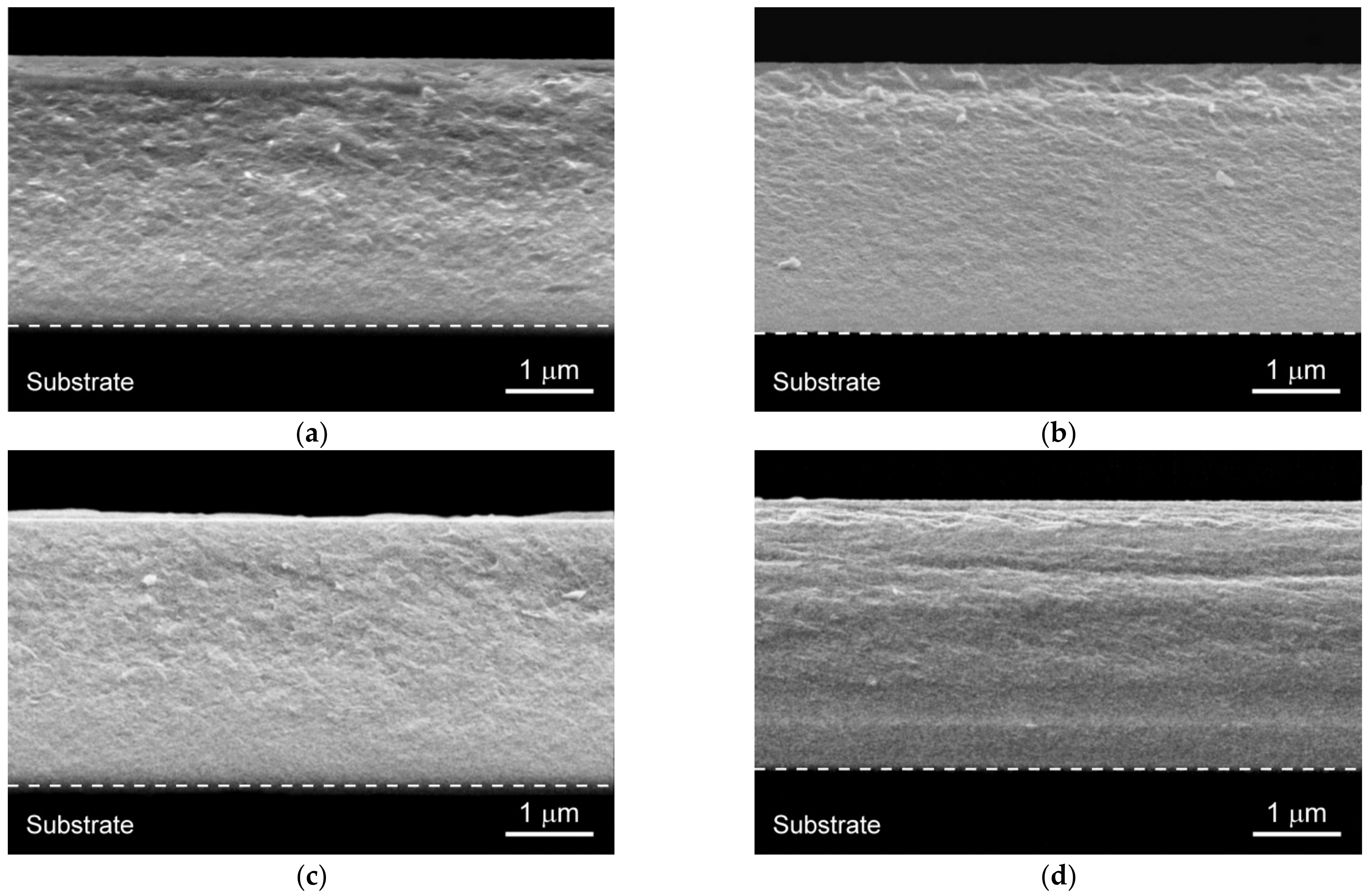

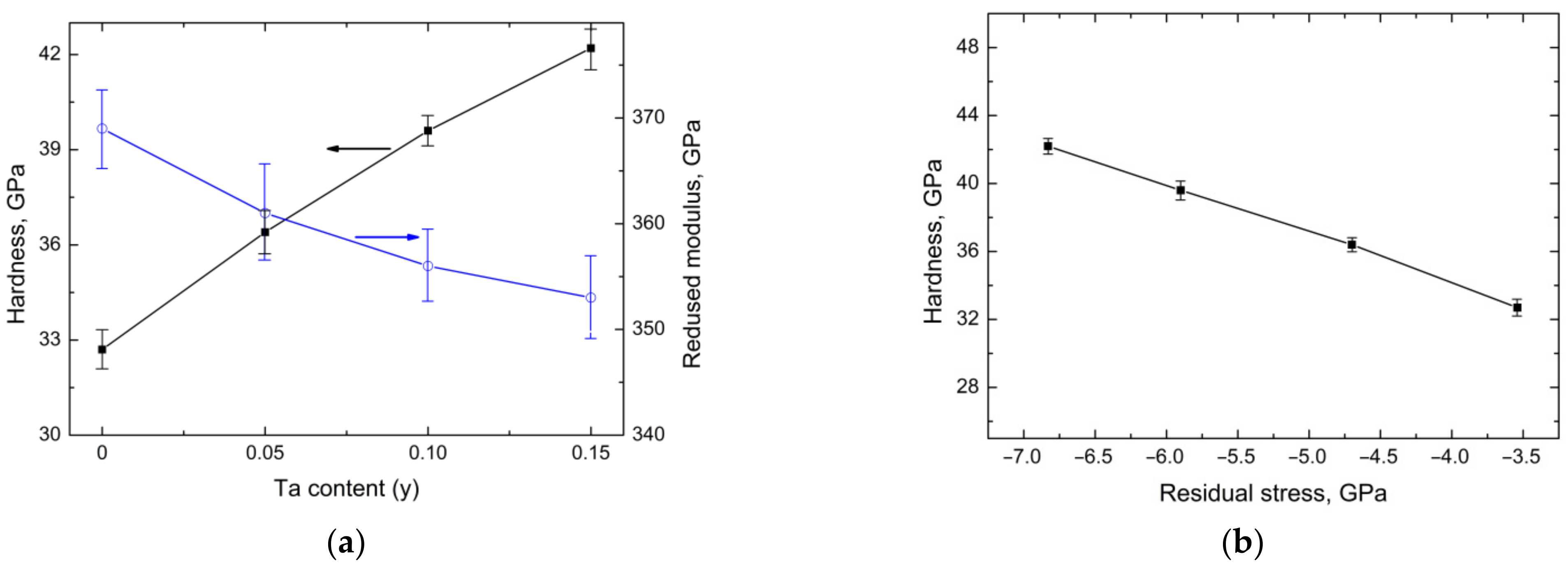

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- PalDey, S.; Deevi, S.C. Single Layer and Multilayer Wear Resistant Coatings of (Ti,Al)N: A Review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Wang, B.; Song, Q.; Ren, X.; Wan, Y. Effects of Al content in TiAlN coatings on tool wear and cutting temperature during dry machining IN718. Tribol. Intern. 2022, 171, 107540. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; da Silva, F.J.G.; Pinto, G.F.; Baptista, A.; Alexandre, R. Characteristics and Wear Mechanisms of TiAlN-based Coatings for Machining Applications: A Comprehensive Review. Metals 2021, 11, 260. [Google Scholar] [CrossRef]

- Liu, Z.-J.; Shum, P.W.; Shen, Y.G. Hardening Mechanisms of Nanocrystalline Ti–Al–N Solid Solution Films. Thin Solid Films 2004, 468, 161–166. [Google Scholar] [CrossRef]

- Çalişkan, H.; Panjan, P.; Paskvale, S. Monitoring of Wear Characteristics of TiN and TiAlN Coatings at Long Sliding Distances. Tribol. Trans. 2014, 57, 496–502. [Google Scholar] [CrossRef]

- Shulepov, I.A.; Kashkarov, E.B.; Stepanov, I.B.; Syrtanov, M.S.; Sutygina, A.N.; Shanenkov, I.; Obrosov, A.; Weiß, S. The Formation of Composite Ti-Al-N Coatings Using Filtered Vacuum Arc Deposition with Separate Cathodes. Metals 2017, 7, 497. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Paulitsch, J.; Du, Y.; Mayrhofer, P.H. Thermal Stability and Oxidation Resistance of Ti-Al-N Coatings. Surf. Coat. Technol. 2012, 206, 2954–2960. [Google Scholar] [CrossRef] [Green Version]

- Rogström, L.; Ullbrand, J.; Almer, J.; Hultman, L.; Jansson, B.; Odén, M. Strain Evolution during Spinodal Decomposition of TiAlN Thin Films. Thin Solid Films 2012, 520, 5542–5549. [Google Scholar] [CrossRef] [Green Version]

- Shugurov, A.R.; Panin, A.V.; Dmitriev, A.I.; Nikonov, A.Y. Multiscale Fracture of Ti-Al-N Coatings under Uniaxial Tension. Phys. Mesomech. 2021, 24, 185–195. [Google Scholar] [CrossRef]

- Zhou, M.; Makino, Y.; Nose, M.; Nogi, K. Phase Transition and Properties of Ti–Al–N Thin Films Prepared by r.f.-plasma Assisted Magnetron Sputtering. Thin Solid Films 1999, 339, 203–208. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Hultman, L.; Schneider, J.M.; Staron, P.; Clemens, H. Spinodal Decomposition of Cubic Ti1−xAlxN: Comparison between Experiments and Modeling. Int. J. Mater. Res. 2007, 98, 1054–1059. [Google Scholar] [CrossRef]

- Rachbauer, R.; Massl, S.; Stergar, E.; Holec, D.; Kiener, D.; Keckes, J.; Patscheider, J.; Stiefel, M.; Leitner, H.; Mayrhofer, P.H. Decomposition Pathways in Age Hardening of Ti-Al-N Films. J. Appl. Phys. 2011, 110, 023515. [Google Scholar] [CrossRef] [Green Version]

- McIntyre, D.; Greene, J.E.; Håkansson, G.; Sundgren, J.-E.; Münz, W.-D. Oxidation of Metastable Single-phase Polycrystalline Ti0.5Al0.5N Films: Kinetics and Mechanisms. J. Appl. Phys. 1990, 67, 1542–1553. [Google Scholar] [CrossRef]

- Chavee, L.; Serag, E.; da Silva Pires, M.; Lucas, S.; Haye, E. A mechanistic approach of oxidation resistance, structural and mechanical behaviour of TiAlN coatings. Appl. Surf. Sci. 2022, 586, 152851. [Google Scholar] [CrossRef]

- Carvalho, S.; Rebouta, L.; Cavaleiro, A.; Rocha, L.A.; Gomes, J.; Alves, E. Microstructure and Mechanical Properties of Nanocomposite (Ti,Si,Al)N Coatings. Thin Solid Films 2001, 398, 391–396. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, L.; Wang, X. Microstructure and properties of TiAlSiN ultra-hard coatings prepared by plasma immersion ion implantation and deposition with TiAlSi alloy cathodes. Vacuum 2020, 174, 109194. [Google Scholar] [CrossRef]

- Zhang, K.; Xin, L.; Ma, T.; Chang, H.; Lu, Y.; Feng, C.; Zhu, S.; Wange, F. Investigation of the role of silicon in TiAlSiN coating deposited on TiAl alloys during long-term oxidation. Corros. Sci. 2022, 204, 110394. [Google Scholar] [CrossRef]

- Tillmann, W.; Dildrop, M. Influence of Si Content on Mechanical and Tribological Properties of TiAlSiN PVD Coatings at Elevated Temperatures. Surf. Coat. Technol. 2017, 321, 448–454. [Google Scholar] [CrossRef]

- Pei, F.; Liu, H.J.; Chen, L.; Xu, Y.X.; Du, Y. Improved Properties of TiAlN Coating by Combined Si-Addition and Multilayer Architecture. J. Alloys Compd. 2019, 790, 909–916. [Google Scholar] [CrossRef]

- Zhu, L.; Hu, M.; Ni, W.; Liu, Y. High Temperature Oxidation Behavior of Ti0.5Al0.5N Coating and Ti0.5Al0.4Si0.1N Coating. Vacuum 2012, 86, 1795–1799. [Google Scholar] [CrossRef]

- Chen, L.; Yang, B.; Xu, Y.; Pei, F.; Zhou, L.; Du, Y. Improved Thermal Stability and Oxidation Resistance of Al–Ti–N Coating by Si Addition. Thin Solid Films 2014, 556, 369–375. [Google Scholar] [CrossRef]

- Liew, W.Y.H.; Lim, H.P.; Melvin, G.J.H.; Dayou, J.; Jiang, Z.-T. Thermal Stability, Mechanical Properties, and Tribological Performance of TiAlXN Coatings: Understanding the Effects of Alloying Additions. J. Mater. Res. Technol. 2022, 17, 961–1012. [Google Scholar] [CrossRef]

- Veprek, S.; Männling, H.-D.; Jilek, M.; Holubar, P. Avoiding the High-Temperature Decomposition and Softening of (Al1−xTix)N Coatings by the Formation of Stable Superhard nc-(Al1−xTix)N/a-Si3N4 Nanocomposite. Mater. Sci. Eng. A 2004, 366, 202–205. [Google Scholar] [CrossRef]

- Veprek, S.; Zhang, R.F.; Veprek-Heijman, M.G.J.; Sheng, S.H.; Argon, A.S. Superhard Nanocomposites: Origin of Hardness Enhancement, Properties and Applications. Surf. Coat. Technol. 2010, 204, 1898–1906. [Google Scholar] [CrossRef]

- Dmitriev, A.I.; Nikonov, A.Y.; Österle, W. MD Sliding Simulations of Amorphous Tribofilms Consisting of either SiO2 or Carbon. Lubricants 2016, 4, 24. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Zhou, F. Progress in Tribological Properties of Nano-Composite Hard Coatings under Water Lubrication. Lubricants 2017, 5, 5. [Google Scholar] [CrossRef] [Green Version]

- Pfeiler, M.; Zechner, J.; Penoy, M.; Michotte, C.; Mitterer, C.; Kathrein, M. Improved Oxidation Resistance of TiAlN Coatings by Doping with Si or B. Surf. Coat. Technol. 2009, 203, 3104–3110. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Yang, S.-M. High Temperature Oxidation Behavior of Multicomponent TiAlSiN Coatings. Thin Solid Films 2010, 518, S34–S37. [Google Scholar] [CrossRef]

- Liu, Z.R.; Pei, F.; Chen, L.; Mayrhofer, P.H. Effect of Si-Addition on Structure and Thermal Stability of Ti-Al-N Coatings. J. Alloys Compd. 2022, 917, 165483. [Google Scholar] [CrossRef]

- Sui, X.; Li, G.; Qin, X.; Yu, H.; Zhou, X.; Wang, K.; Wang, Q. Relationship of Microstructure, Mechanical Properties and Titanium Cutting Performance of TiAlN/TiAlSiN Composite Coated Tool. Ceram. Int. 2016, 42, 7524–7532. [Google Scholar] [CrossRef]

- Li, G.; Li, L.; Han, M.; Luo, S.; Jin, J.; Wang, L.; Gu, J.; Miao, H. The Performance of TiAlSiN Coated Cemented Carbide Tools Enhanced by Inserting Ti Interlayers. Metals 2019, 9, 918. [Google Scholar] [CrossRef] [Green Version]

- Gu, J.; Li, L.; Ai, M.; Xu, Y.; Xu, Y.; Li, G.; Deng, D.; Peng, H.; Luo, S.; Zhang, P. Improvement of Solid Particle Erosion and Corrosion Resistance Using TiAlSiN/Cr Multilayer Coatings. Surf. Coat. Technol. 2020, 402, 126270. [Google Scholar] [CrossRef]

- Derflinger, V.H.; Schütze, A.; Ante, M. Mechanical and Structural Properties of Various Alloyed TiAlN-based Hard Coatings. Surf. Coat. Technol. 2006, 200, 4693–4700. [Google Scholar] [CrossRef]

- Chen, L.; Wang, S.Q.; Du, Y.; Zhou, S.Z.; Gang, T.; Fen, J.C.; Chang, K.K.; Li, Y.W.; Xiong, X. Machining Performance of Ti–Al–Si–N Coated Inserts. Surf. Coat. Technol. 2010, 205, 582–586. [Google Scholar] [CrossRef]

- Lü, W.; Li, G.; Zhou, Y.; Liu, S.; Wang, K.; Wang, Q. Effect of High Hardness and Adhesion of Gradient TiAlSiN Coating on Cutting Performance of Titanium Alloy. J. Alloys Compd. 2020, 820, 153137. [Google Scholar] [CrossRef]

- Kot, M.; Rakowski, W.; Major, Ł.; Lackner, J. Load-Bearing Capacity of Coating–Substrate Systems Obtained from Spherical Indentation Tests. Mater. Des. 2013, 46, 751–757. [Google Scholar] [CrossRef]

- Estupiñan, F.A.; Moreno, C.M.; Olaya, J.J.; Ardila, L.C. Wear Resistance of TiAlCrSiN Coatings Deposited by Means of the Co-Sputtering Technique. Lubricants 2021, 9, 64. [Google Scholar] [CrossRef]

- Mikula, M.; Truchlý, M.; Sangiovanni, D.G.; Plašienka, D.; Roch, T.; Gregor, M.; Ďurina, P.; Janík, M.; Kúš, P. Experimental and Computational Studies on Toughness Enhancement in Ti-Al-Ta-N Quaternaries. J. Vac. Sci. Technol. A 2017, 35, 060602. [Google Scholar] [CrossRef]

- Seidl, W.M.; Bartosik, M.; Kolozsvári, S.; Bolvardi, H.; Mayrhofer, P.H. Influence of Ta on the Fracture Toughness of Arc Evaporated Ti-Al-N. Vacuum 2018, 150, 24–28. [Google Scholar] [CrossRef]

- Shugurov, A.R.; Kuzminov, E.D.; Kasterov, A.M.; Panin, A.V.; Dmitriev, A.I. Tuning of Mechanical Properties of Ti1−xAlxN Coatings through Ta Alloying. Surf. Coat. Technol. 2020, 382, 125219. [Google Scholar] [CrossRef]

- Eremeev, S.V.; Shugurov, A.R. Chemical Bonding Analysis in Ti1–x–yAlxTayN Solid Solutions. Surf. Coat. Technol. 2020, 395, 125802. [Google Scholar] [CrossRef]

- Rachbauer, R.; Holec, D.; Mayrhofer, P.H. Increased thermal stability of Ti–Al–N thin films by Ta alloying. Surf. Coat. Technol. 2012, 211, 98–103. [Google Scholar] [CrossRef]

- Hollerweger, R.; Riedl, H.; Paulitsch, J.; Arndt, M.; Rachbauer, R.; Polcik, P.; Primig, S.; Mayrhofer, P.H. Origin of high temperature oxidation resistance of Ti–Al–Ta–N coatings. Surf. Coat. Technol. 2014, 257, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Shugurov, A.R.; Panin, A.V.; Kasterov, A.M. Effect of Ta alloying on isothermal oxidation behavior of DC magnetron sputtered Ti1-xAlxN coatings on titanium substrate. Surf. Coat. Technol. 2021, 421, 127488. [Google Scholar] [CrossRef]

- Shugurov, A.; Kuzminov, E. Effect of Ta Content on Scratching Behavior of Ti-Al-Ta-N Coatings on Titanium Substrate. Metals 2022, 12, 1017. [Google Scholar] [CrossRef]

- Xian, G.; Zhao, H.-B.; Fan, H.-Y.; Du, H. Structure and Mechanical Properties of Zr/TiAlN Films Prepared by Plasma-Enhanced Magnetron Sputtering. Rare Met. 2015, 34, 717–724. [Google Scholar] [CrossRef]

- Stoney, G.G.; Parsons, C.A. The Tension of Metallic Films Deposited by Electrolysis. Proc. R. Soc. Lond. A 1909, 82, 172–175. [Google Scholar] [CrossRef] [Green Version]

- Oliver, W.C.; Pharr, G.M. An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Tanaka, Y.; Ichimiya, N.; Onishi, Y.; Yamada, Y. Structure and Properties of Al–Ti–Si–N Coatings Prepared by the Cathodic Arc Ion Plating Method for High Speed Cutting Applications. Surf. Coat. Technol. 2001, 146, 215–221. [Google Scholar] [CrossRef]

- Hsu, T.-W.; Greczynski, G.; Boyd, R.; Kolozsvári, S.; Polcik, P.; Bolz, S.; Bakhit, B.; Odén, M. Influence of Si Content on Phase Stability and Mechanical Properties of TiAlSiN Films Grown by AlSi-HiPIMS/Ti-DCMS Co-Sputtering. Surf. Coat. Technol. 2021, 427, 127661. [Google Scholar] [CrossRef]

- Scherrer, P. Bestimmung Der Inneren Struktur Und Der Größe von Kolloidteilchen Mittels Röntgenstrahlen. Kolloidchemie Ein Lehrbuch; Zsigmondy, R., Ed.; Springer: Berlin/Heidelberg, Germany, 1912; pp. 387–409. ISBN 978-3-662-33915-2. [Google Scholar]

- Pelleg, J.; Zevin, L.Z.; Lungo, S.; Croitoru, N. Reactive-Sputter-Deposited TiN Films on Glass Substrates. Thin Solid Films 1991, 197, 117–128. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, Z.; Bartosik, M.; Zhang, Y.; Mayrhofer, P.H.; He, Y. Insight into the Structural Evolution during TiN Film Growth via Atomic Resolution TEM. J. Alloys Compd. 2018, 754, 257–267. [Google Scholar] [CrossRef]

- Karlsson, L.; Hultman, L.; Sundgren, J.-E. Influence of Residual Stresses on the Mechanical Properties of TiCxN1–x (x = 0, 0.15, 0.45) Thin Films Deposited by Arc Evaporation. Thin Solid Films 2000, 371, 167–177. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Kunc, F.; Musil, J.; Mitterer, C. A Comparative Study on Reactive and Non-Reactive Unbalanced Magnetron Sputter Deposition of TiN Coatings. Thin Solid Films 2002, 415, 151–159. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Anders, A.; Brown, I.G. Nanoindentation and Nanoscratching of Hard Carbon Coatings for Magnetic Disks. Mater. Res. Soc. Symp. Proc. 1995, 383, 447–452. [Google Scholar] [CrossRef] [Green Version]

- Musil, J. Hard Nanocomposite Coatings: Thermal Stability, Oxidation Resistance and Toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Bull, S.J. Failure Modes in Scratch Adhesion Testing. Surf. Coat. Technol. 1991, 50, 25–32. [Google Scholar] [CrossRef]

- Favache, A.; Sacré, C.-H.; Coulombier, M.; Libralesso, L.; Guaino, P.; Raskin, J.-P.; Bailly, C.; Nysten, B.; Pardoen, T. Fracture Mechanics Based Analysis of the Scratch Resistance of Thin Brittle Coatings on a Soft Interlayer. Wear 2015, 330, 461–468. [Google Scholar] [CrossRef]

- Hutchinson, J.W.; Suo, Z. Mixed Mode Cracking in Layered Materials. Adv. Appl. Mech. 1991, 29, 63–191. [Google Scholar] [CrossRef]

- Evans, A.G.; He, M.Y.; Hutchinson, J.W. Effect of Interface Undulations on the Thermal Fatigue of Thin Films and Scales on Metal Substrates. Acta Mater. 1997, 45, 3543–3554. [Google Scholar] [CrossRef]

- Strawbridge, A.; Evans, H.E.; Ponton, C.B. Spallation of Oxide Scales from NiCrAlY Overlay Coatings. Mater. Sci. Forum 1997, 251, 365–372. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shugurov, A.R.; Kuzminov, E.D.; Garanin, Y.A.; Panin, A.V.; Dmitriev, A.I. Improvement of Mechanical Properties and Adhesion of Ti-Al-Si-N Coatings by Alloying with Ta. Lubricants 2022, 10, 178. https://doi.org/10.3390/lubricants10080178

Shugurov AR, Kuzminov ED, Garanin YA, Panin AV, Dmitriev AI. Improvement of Mechanical Properties and Adhesion of Ti-Al-Si-N Coatings by Alloying with Ta. Lubricants. 2022; 10(8):178. https://doi.org/10.3390/lubricants10080178

Chicago/Turabian StyleShugurov, Artur R., Evgenii D. Kuzminov, Yuriy A. Garanin, Alexey V. Panin, and Andrey I. Dmitriev. 2022. "Improvement of Mechanical Properties and Adhesion of Ti-Al-Si-N Coatings by Alloying with Ta" Lubricants 10, no. 8: 178. https://doi.org/10.3390/lubricants10080178

APA StyleShugurov, A. R., Kuzminov, E. D., Garanin, Y. A., Panin, A. V., & Dmitriev, A. I. (2022). Improvement of Mechanical Properties and Adhesion of Ti-Al-Si-N Coatings by Alloying with Ta. Lubricants, 10(8), 178. https://doi.org/10.3390/lubricants10080178