Research Progress Regarding the Use of Metal and Metal Oxide Nanoparticles as Lubricant Additives

Abstract

:1. Introduction

2. Lubrication Mechanism of Nanolubricant Additives

2.1. Micro-Bearing Effect

2.2. Protective Film Effect

2.3. Polishing Effect

2.4. Repair Effect

3. Metal Nanoparticles and Metal Oxide Nanoparticle Lubricating Additives

4. Lubricating Additive for Composite Nanomaterials Containing Silver and Copper

4.1. Silver-Containing Composite Nanolubricating Additive

4.2. Copper-Containing Composite Nanolubricating Additive

5. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kato, K. Wear in relation to friction—A review. Wear 2000, 241, 151–157. [Google Scholar] [CrossRef]

- Bhaumik, S.; Paleu, V.; Pathak, R.; Maggirwar, R.; Katiyar, J.K.; Sharma, A.K. Tribological investigation of r-GO additived biodegradable cashew nut shells liquid as an alternative industry lubricant. Tribol. Int. 2019, 135, 500–509. [Google Scholar] [CrossRef]

- Gong, H.J.; Yu, C.C.; Zhang, L.; Xie, G.X.; Guo, D.; Luo, J.B. Intelligent lubricating materials: A review. Compos. Part. B-Eng. 2020, 202, 108450. [Google Scholar] [CrossRef]

- Tang, X.J.; Li, J.N. Tribological characteristics of nano-lubricated high-speed rolling bearings considering interaction between nanoparticles and rough surface. Lubricants 2022, 6, 117. [Google Scholar] [CrossRef]

- Toth, A.D.; Szabo, A.I.; Lesko, M.Z.; Rohde-Brandenburger, J.; Kuti, R. Tribological properties of the nanoscale spherical Y2O3 particles as lubricant additives in automotive application. Lubricants 2022, 2, 28. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, Z.X.; Xing, C.F.; Li, Q.; Fan, J.J. Tribo-surface variation caused by Ti2AlC and Ti3AlC2 particles-containing lubricant under cyclic impact loading. Lubricants 2022, 3, 33. [Google Scholar] [CrossRef]

- Uflyand, I.E.; Zhinzhilo, V.A.; Burlakova, V.E. Metal-containing nanomaterials as lubricant additives: State-of-the-art and future development. Friction 2019, 7, 93–116. [Google Scholar] [CrossRef] [Green Version]

- Luo, J.B.; Zhou, X. Superlubricitive engineering-future industry nearly getting rid of wear and frictional energy consumption. Friction 2020, 8, 643–665. [Google Scholar] [CrossRef]

- Fei, J.; Zhao, B.; Li, C.Y.; Liu, T.; Zhou, M. Carbon spheres wrapped with 2D covalent organic polymer as lubricant additives for enhancing tribological properties. Colloids Surf. A 2022, 633, 127862. [Google Scholar] [CrossRef]

- Alazemi, A.A. Experimental study of the lubrication mechanism of micro-spherical solid particles between flat surfaces. Lubricants 2021, 9, 81. [Google Scholar] [CrossRef]

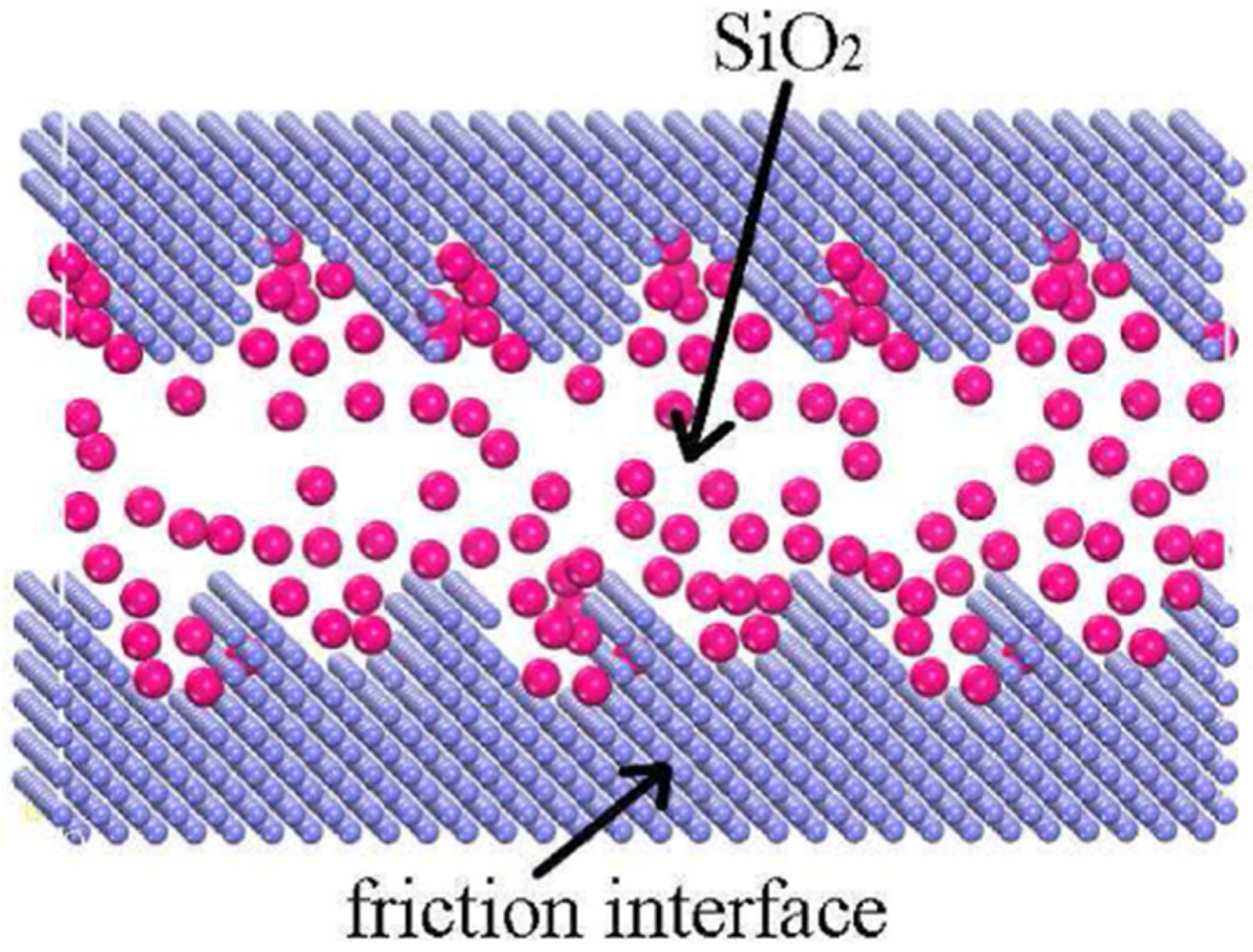

- Shen, Y.D.; Lei, W.W.; Tang, W.T.; Ouyang, T.C.; Liang, L.Z.; Tian, Z.Q.; Shen, P.K. Synergistic friction-reduction and wear-resistance mechanism of 3D graphene and SiO2 nanoblend at harsh friction interface. Wear 2022, 488–489, 204175. [Google Scholar] [CrossRef]

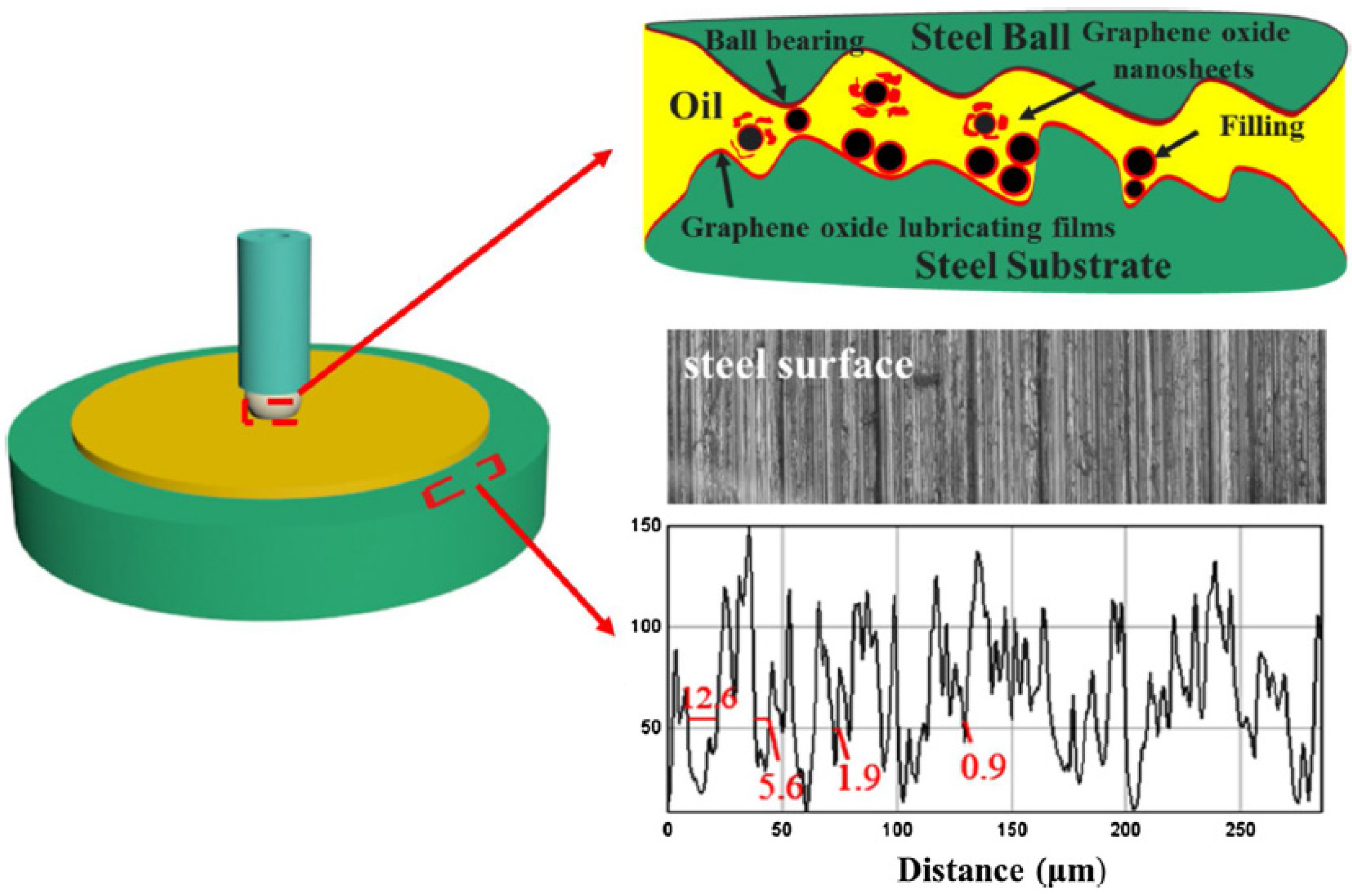

- Gu, Y.F.; Fei, J.; Huang, J.F.; Zhang, L.J.; Qu, M.; Zheng, X.H. Carbon microspheres coated with graphene oxide nanosheets as oil-based additives for tribological applications. Mater. Today. Commun. 2022, 25, 101271. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, L.L.; Cheng, G.G.; Yuan, N.Y.; Ding, J.N.; Pesika, N.S. Water-based lubrication of hard carbon microspheres as lubricating additives. Tribol. Lett. 2018, 66, 148. [Google Scholar] [CrossRef]

- Guan, Z.P.; Zhang, P.; Florian, V.; Wu, Z.C.; Zeng, D.H.; Liu, J.; Wang, B.B.; Tu, X.H.; Li, S.J.; Li, W. Preparation and tribological behaviors of magnesium silicate hydroxide-MoS2 nanoparticles as lubricant additive. Wear 2022, 492, 204237. [Google Scholar] [CrossRef]

- Kharissova, O.V.; Irkha, V.A.; Drogan, E.G.; Zagrebelnaya, A.I.; Burlakova, V.E.; Scherbakow, I.N.; Popov, L.D.; Uflyand, I.E. Copper-containing nanomaterials derived from copper(II) laurate as antifriction additives for oil lubricants. J. Inorg. Organomet. Polym. Mater. 2021, 31, 934–944. [Google Scholar] [CrossRef]

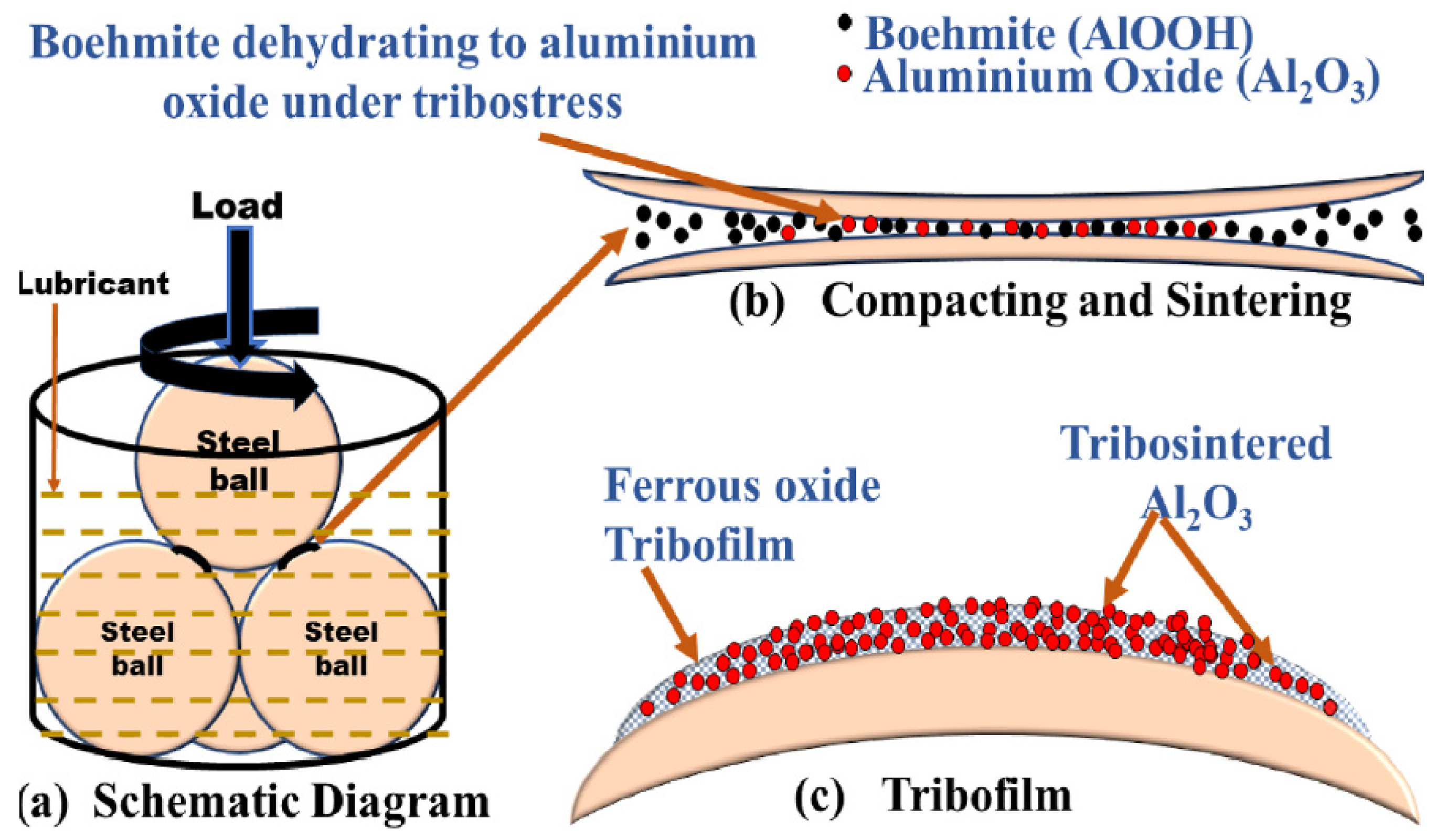

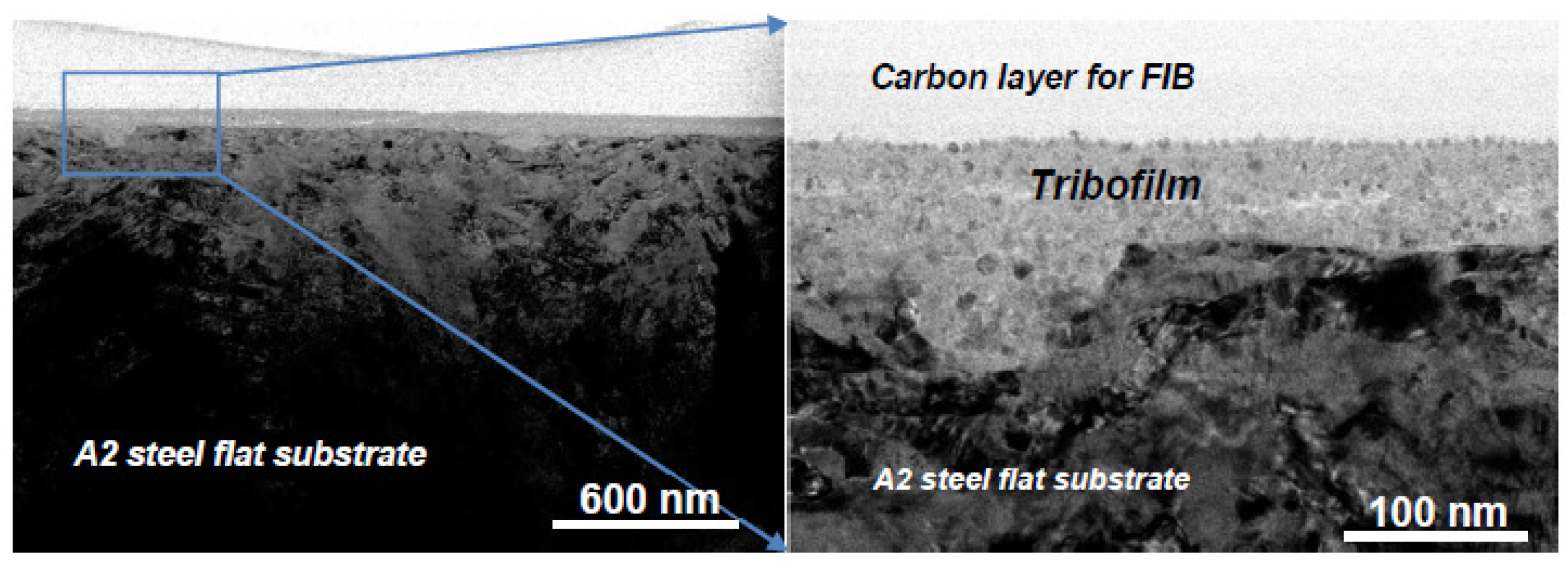

- Maurya, U.; Vasu, V. Boehmite nanoparticles for potential enhancement of tribological performance of lubricants. Wear 2022, 498, 204311. [Google Scholar] [CrossRef]

- Guo, J.D.; Zhao, Y.X.; Sun, B.; Wang, P.C.; Wang, Z.J.; Dong, H. Research progress of nano copper lubricant additives on engineering tribology. Metals 2021, 11, 2006. [Google Scholar] [CrossRef]

- Wang, B.X.; Qiu, F.; Barber, G.C.; Zou, Q.; Wang, J.; Guo, S.Y.; Yuan, Y.F.; Jiang, Q.C. Role of nano-sized materials as lubricant additives in friction and wear reduction: A review. Wear 2022, 490–491, 204206. [Google Scholar] [CrossRef]

- Waqas, M.; Zahid, R.; Bhutta, M.U.; Khan, Z.A.; Saeed, A. A Review of friction performance of lubricants with nano additives. Materials 2021, 14, 6310. [Google Scholar] [CrossRef]

- He, T.X.; Chen, N.C.; Fang, J.H.; Cai, G.X.; Wang, J.; Chen, B.S.; Liang, Q.L. Micro/nano carbon spheres as liquid lubricant additive: Achievements and prospects. J. Mol. Liq. 2022, 357, 119090. [Google Scholar] [CrossRef]

- Yu, H.L.; Xu, Y.; Shi, P.J.; Wang, H.M.; Wei, M.; Zhao, K.K.; Xu, B.S. Microstructure, mechanical properties and tribological behavior of tribofilm generated from natural serpentine mineral powders as lubricant additive. Wear 2013, 297, 802–810. [Google Scholar] [CrossRef]

- Barnhill, W.C.; Gao, H.; Kheireddin, B.; Papke, B.L.; Luo, H.M.; West, B.H.; Qu, J. Tribological bench and engine dynamometer tests of a low viscosity SAE 0W-16 engine oil using a combination of ionic liquid and ZDDP as anti-wear additives. Front. Mech. Eng. 2015, 1, 12. [Google Scholar] [CrossRef] [Green Version]

- Mordukhovich, G.; Qu, J.; Howe, J.Y.; Bair, S.; Yu, B.; Luo, H.M.; Smolenski, D.J.; Blau, P.J.; Bunting, B.C.; Dai, S. A low-viscosity ionic liquid demonstrating superior lubricating performance from mixed to boundary lubrication. Wear 2013, 301, 740–746. [Google Scholar] [CrossRef]

- Le, V.N.A.; Lin, J.W. Tribological properties of aluminum nanoparticles as additives in an aqueous glycerol solution. Appl. Sci. 2017, 7, 80. [Google Scholar] [CrossRef] [Green Version]

- Le, V.N.A.; Lin, J.W. Influence of aluminum nanoparticles additives on tribological properties of base oil. Key Eng. Mater. 2017, 737, 184–191. [Google Scholar] [CrossRef]

- Kumara, C.; Luo, H.M.; Leonard, D.N.; Meyer, H.M.; Qu, J. Organic-modified silver nanoparticles as lubricant additives. ACS Appl. Mater. Inter. 2017, 9, 37227–37237. [Google Scholar] [CrossRef]

- Battez, A.H.; Gonzalez, R.; Viesca, J.L.; Fernandez, J.E.; Fernandez, J.M.D.; Machado, A.; Chou, R.; Riba, J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 2008, 265, 422–428. [Google Scholar] [CrossRef]

- Sanchez-Lopez, J.C.; Abad, M.D.; Kolodziejczyk, L.; Guerrero, E.; Fernandez, A. Surface-modified Pd and Au nanoparticles for anti-wear applications. Tribol. Int. 2011, 44, 720–726. [Google Scholar] [CrossRef]

- Viesca, J.L.; Battez, A.H.; Gonzalez, R.; Chou, R.; Cabello, J.J. Antiwear properties of carbon-coated copper nanoparticles used as an additive to a polyalphaolefin. Tribol. Int. 2011, 44, 829–833. [Google Scholar] [CrossRef]

- Kolodziejczyk, L.; Martinez- Martinez, D.; Rojas, T.C.; Fernandez, A.; Sanchez-Lopez, J.C. Surface-modified Pd nanoparticles as a superior additive for lubrication. J. Nanopart. Res. 2007, 9, 639–645. [Google Scholar] [CrossRef]

- Ghaednia, H.; Jackson, R.L.; Khoddadadi, J.M. Experimental analysis of stable CuO nanoparticle enhanced lubricants. J. Exp. Nanosci. 2015, 10, 1–18. [Google Scholar] [CrossRef]

- Padgurskas, J.; Rukuiza, R.; Prosycevaas, I.; Kreivaitis, R. Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles. Tribol. Int. 2013, 60, 224–232. [Google Scholar] [CrossRef]

- Li, Y.H.; Liu, T.T.; Zhang, Y.J.; Zhang, P.Y.; Zhang, S.M. Study on the tribological behaviors of copper nanoparticles in three kinds of commercially available lubricants. Ind. Lubr. Tribol. 2018, 70, 519–526. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, L.; Zhao, S.L.; Meng, Z. Experimental study on the suspension stability and tribological properties of nano-copper in LCKD-320 (#) lubricating oil. Appl. Nanosci. 2021, 11, 45–54. [Google Scholar] [CrossRef]

- Borda, F.L.G.; Oliveira, S.J.R.; Lazaro, L.M.S.M.; Leiroz, A.J.K. Experimental investigation of the tribological behavior of lubricants with additive containing copper nanoparticles. Tribol. Int. 2018, 117, 52–58. [Google Scholar] [CrossRef]

- Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E. Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol. Int. 2013, 65, 28–36. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, N.K.; Sharma, A.; Lila, M.K.; Singla, A.; Chinnasamy, V. Brucea Javanica: A novel nonedible feedstock for bio-based lubricant application with the effect of ZrO2 nanoparticles. Environ. Prog. Sustain. 2021, 40, e13602. [Google Scholar] [CrossRef]

- Nagabhooshanam, N.; Baskar, S.; Prabhu, T.R.; Arumugam, S. Evaluation of tribological characteristics of nano zirconia dispersed biodegradable canola oil methyl ester metalworking fluid. Tribol. Int. 2020, 151, 106510. [Google Scholar] [CrossRef]

- Elinski, M.B.; Lamascus, P.; Zheng, L.; Jackson, A.; Wiacek, R.J.; Carpick, R.W. Cooperativity between zirconium dioxide nanoparticles and extreme pressure additives in forming protective tribofilms: Toward enabling low viscosity lubricants. Tribol. Lett. 2020, 68, 107. [Google Scholar] [CrossRef]

- Casado, J.E.; Gonzalez, A.F.; Huerga, A.J.D.; Rodriguez- Solla, H.; Diaz-Garcia, M.E.; Badia-Laino, R. Unctuous ZrO2 nanoparticles with improved functional attributes as lubricant additives. Nanotechnology 2017, 28, 495704. [Google Scholar] [CrossRef]

- Li, J.N.; Cao, L.; Su, H.J.; Wan, Y.; Wang, Y.S. SnS2 nanosheets as an excellent lubricant additive in polyalphaolefin oil. Lubr. Sci. 2020, 33, 123–132. [Google Scholar] [CrossRef]

- Tao, C.L.; Wang, B.X.; Barber, G.C.; Schall, J.D.; Lan, H.Q. Tribological behaviour of SnO2 nanoparticles as an oil additive on brass. Lubr. Sci. 2018, 30, 247–255. [Google Scholar] [CrossRef]

- Singh, Y.; Badhotiya, G.K.; Gwalwanshi, M.; Negi, P.; Bist, A. Magnesium oxide (MgO) as an additive to the neem oil for efficient lubrication. Mater. Today Proc. 2021, 46, 10478–10481. [Google Scholar] [CrossRef]

- Arumugam, S.; Baskar, S.; Sankaranarayanan, S.; Athreya, S.H.; Narayanna, N.L.; Prasad, S.S.D. Influence of morphology of anti-wear nano additives on tribological behavior of chemically modified rapeseed oil. IOP Conf. Ser. Mater. Sci. Eng. 2018, 390, 012017. [Google Scholar] [CrossRef]

- Marino, F.; Lopez, E.R.; Arnosa, A.; Gomez, M.A.G.; Pineiro, Y.; Rivas, J.; Alvarez-Lorenzo, C.; Fernandez, J. ZnO nanoparticles coated with oleic acid as additives for a polyalphaolefin lubricant. J. Mol. Liq. 2022, 348, 118401. [Google Scholar] [CrossRef]

- Pena-Paras, L.; Gutierrez, J.; Irigoyen, M.; Lozano, M.; Velarde, M.; Maldonado-Cortes, D.; Taha-Tijerina, J. Study on the anti-wear properties of metal-forming lubricants with TiO2 and CuO nanoparticle additives. IOP Conf. Ser. Mater. Sci. Eng. 2018, 400, 062022. [Google Scholar] [CrossRef]

- Yilmaz, A.C. Tribological enhancement features of various nanoparticles as engine lubricant additives: An experimental study. Arab. J. Sci. Eng. 2020, 45, 1125–1134. [Google Scholar] [CrossRef]

- Akl, S.Y.; Abdel-Rehim, A.A.; Elsoudy, S. An Experimental Investigation of Tribological Performance of a Lubricant Using Different Nano Additives; SAE Technical Paper Series, 2018-01-0833; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Wang, L.; Gong, P.W.; Li, W.; Luo, T.; Cao, B.Q. Mono-dispersed Ag/graphene nanocomposite as lubricant additive to reduce friction and wear. Tribol. Int. 2020, 146, 106228. [Google Scholar] [CrossRef]

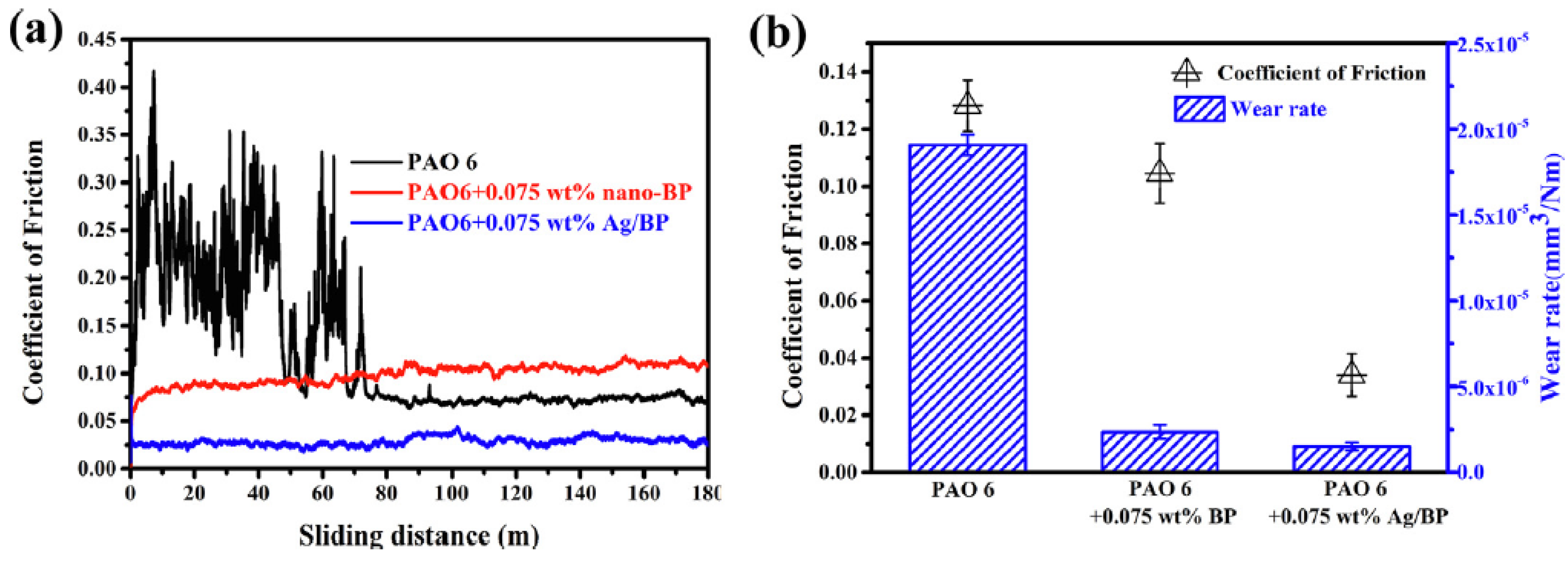

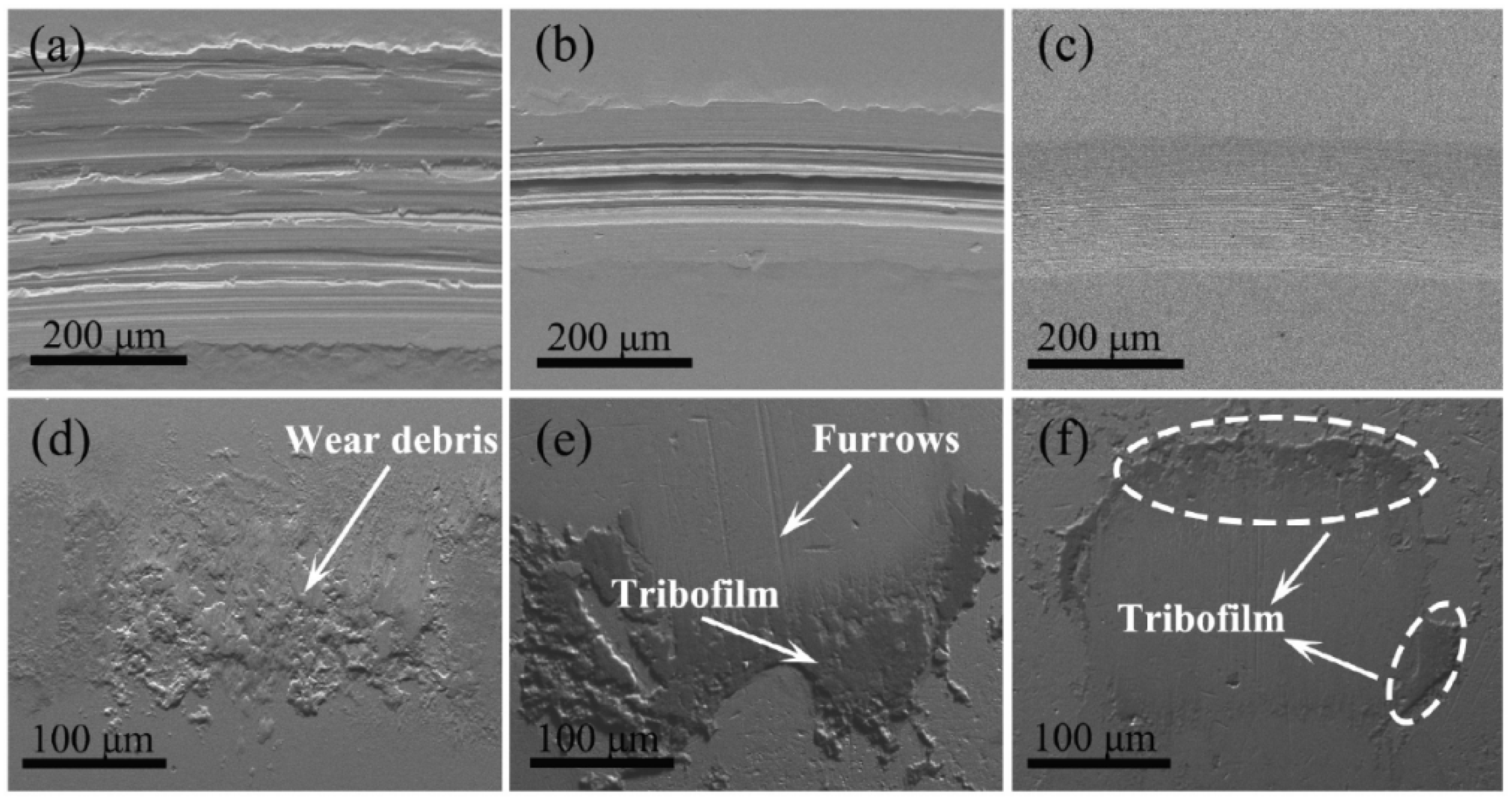

- Tang, G.B.; Su, F.H.; Xu, X.; Chu, P.K. 2D black phosphorus dotted with silver nanoparticles: An excellent lubricant additive for tribological applications. Chem. Eng. J. 2020, 392, 123631. [Google Scholar] [CrossRef]

- Wang, W.; Xie, G.X.; Luo, J.B. Black phosphorus as a new lubricant. Friction 2018, 6, 116–142. [Google Scholar] [CrossRef] [Green Version]

- Meng, Y.; Su, F.H.; Chen, Y.Z. Supercritical fluid synthesis and tribological applications of silver nanoparticle-decorated graphene in engine oil nanofluid. Sci. Rep. 2016, 6, 31246. [Google Scholar] [CrossRef] [PubMed] [Green Version]

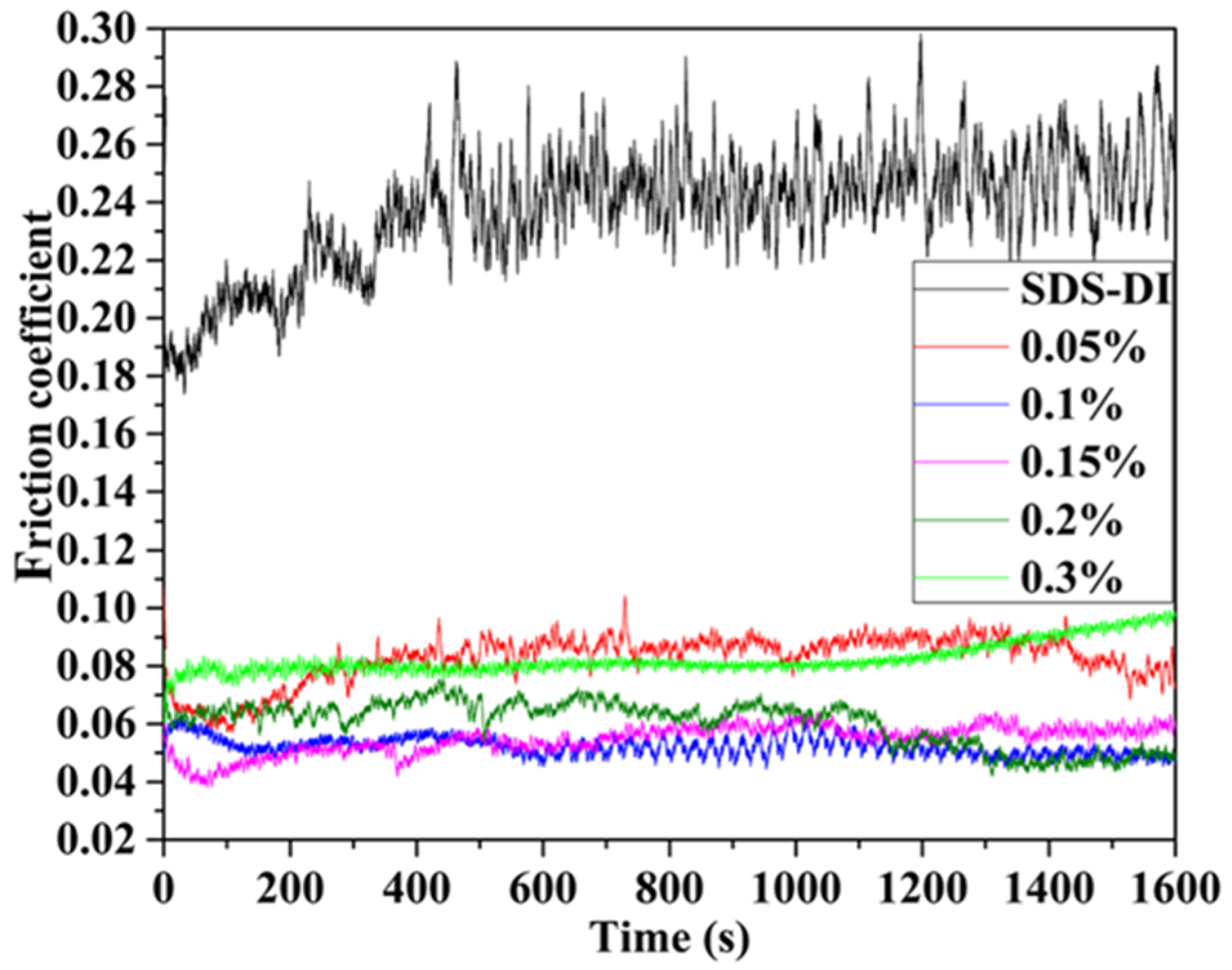

- Liu, T.T.; Zhou, C.H.; Gao, C.P.; Zhang, Y.J.; Yang, G.B.; Zhang, P.Y.; Zhang, S.M. Preparation of Cu@SiO2 composite nanoparticle and its tribological properties as water-based lubricant additive. Lubr. Sci. 2020, 32, 69–79. [Google Scholar] [CrossRef]

- Zang, C.; Yang, M.; Liu, E.B.; Qian, Q.H.; Zhao, J.H.; Zhen, J.M.; Zhang, R.; Jia, Z.F.; Han, W.F. Synthesis, characterization and tribological behaviors of hexagonal boron nitride/copper nanocomposites as lubricant additives. Tribol. Int. 2021, 165, 107312. [Google Scholar] [CrossRef]

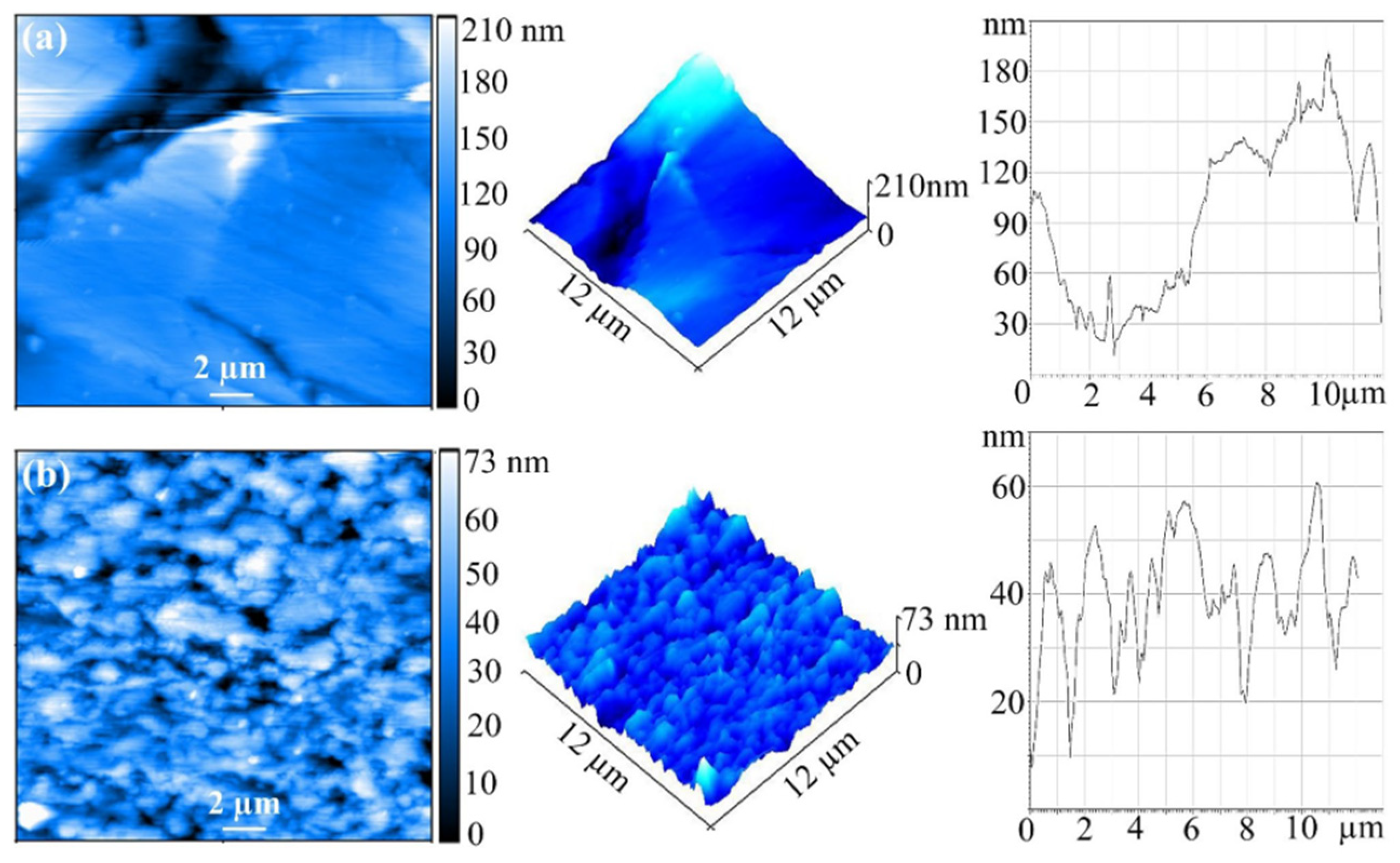

- Ma, X.L.; Gan, C.L.; Li, X.P.; Li, Y.T.; Feng, P.; Fan, X.Q.; Ye, X.Y.; Zhu, M.H. Tribological properties of SiO2@Cu and SiO2@MoS2 core-shell microspheres as lubricant additives. Tribol. Lett. 2021, 69, 108. [Google Scholar] [CrossRef]

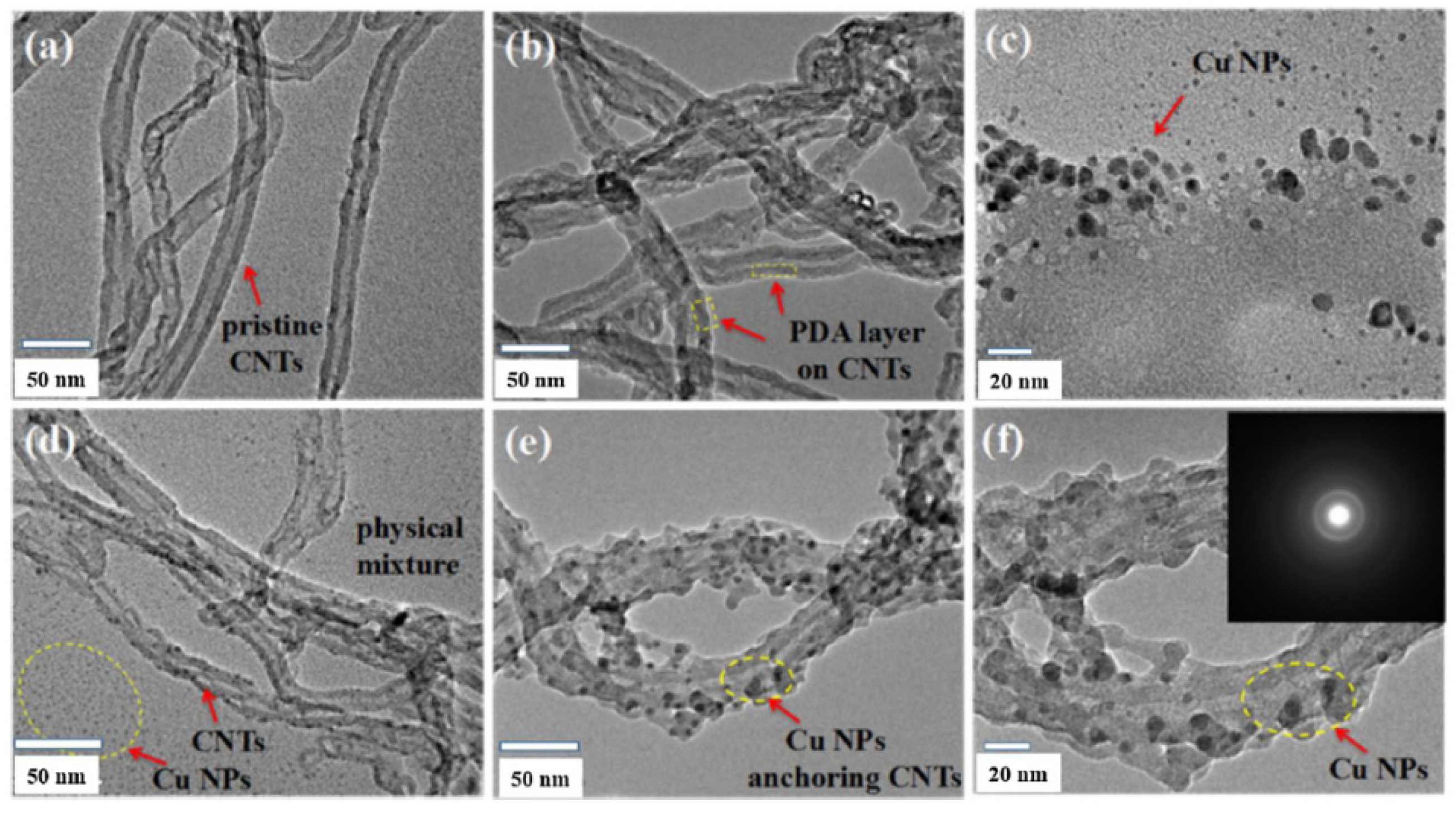

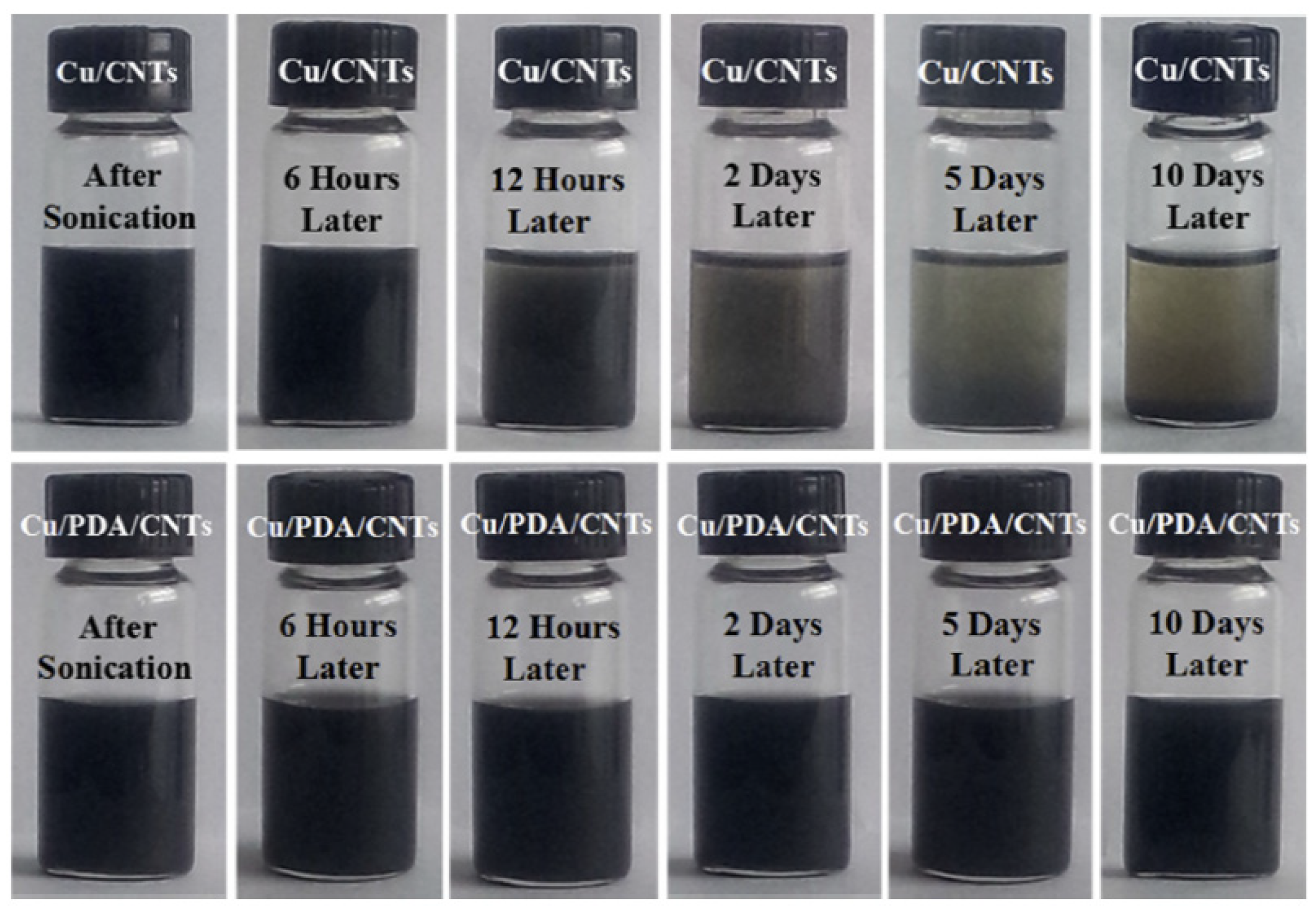

- Wang, Z.Q.; Ren, R.R.; Song, H.J.; Jia, X.H. Improved tribological properties of the synthesized copper/carbon nanotube nanocomposites for rapeseed oil-based additives. Appl. Surf. Sci. 2018, 428, 630–639. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, F.; Li, C.; Li, D.; Sa, X.; Yu, Y.; Li, C.; Yang, Y.; Wang, J. Research Progress Regarding the Use of Metal and Metal Oxide Nanoparticles as Lubricant Additives. Lubricants 2022, 10, 196. https://doi.org/10.3390/lubricants10080196

Du F, Li C, Li D, Sa X, Yu Y, Li C, Yang Y, Wang J. Research Progress Regarding the Use of Metal and Metal Oxide Nanoparticles as Lubricant Additives. Lubricants. 2022; 10(8):196. https://doi.org/10.3390/lubricants10080196

Chicago/Turabian StyleDu, Fengming, Cong Li, Dawei Li, Xiaoxia Sa, Yang Yu, Chengdi Li, Yuxing Yang, and Jinlong Wang. 2022. "Research Progress Regarding the Use of Metal and Metal Oxide Nanoparticles as Lubricant Additives" Lubricants 10, no. 8: 196. https://doi.org/10.3390/lubricants10080196

APA StyleDu, F., Li, C., Li, D., Sa, X., Yu, Y., Li, C., Yang, Y., & Wang, J. (2022). Research Progress Regarding the Use of Metal and Metal Oxide Nanoparticles as Lubricant Additives. Lubricants, 10(8), 196. https://doi.org/10.3390/lubricants10080196