The Use of Non-Edible Green Oils to Lubricate DC04 Steel Sheets in Sheet Metal Forming Process

Abstract

1. Introduction

2. Material and Methods

2.1. Test Materials

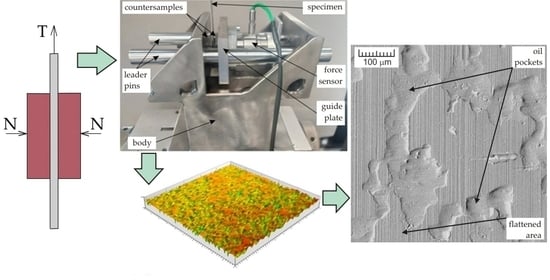

2.2. Friction Test

3. Results and Discussion

4. Conclusions

- The value of the COF decreased with increasing nominal pressure in the range of pressures considered between 3 and 12 MPa.

- In general, the moringa and karanja oil-based bio-lubricants achieved the lowest COF values. The results obtained showed no breakage of the lubricating film during the friction process within the nominal pressures analyzed.

- Under the most favorable lubrication conditions, karanja oil reduced the COF by approximately 33% (sample pre-strain 21%, nominal pressure of 6 MPa). Both non-edible lubricants provided the best lubrication during testing: (i) samples pre-strained at 7% in the whole range of nominal pressures, and (ii) samples pre-strained at 21% within the nominal pressures between 6 and 12 MPa. In the case of the smallest pre-straining of the specimens, karanja oil was the most effective within the nominal pressures of 3–6 MPa, while at higher pressures, the moringa oil lowered the COF value to a greater extent.

- The lubrication efficiency of the sunflower and rape-seed oils ranged between approximately 6 and 23.4%, 3.5 and 14.9%, and 10.5 and 24.9%, for the specimens pre-strained at 7%, 14%, and 21%, respectively.

- The lubrication efficiency of oils was different in the case of the highest degree of pre-straining of specimens (21%) when compared to the pre-strained sheets at 7 and 14%. After an initial increase in the value of the CLE, its value declined for the highest value of nominal pressure.

- The value of the Sa parameter showed a tendency to decrease in relation to the sample not subjected to the friction process. In addition to flattening, a ploughing mechanism was revealed at the highest pressure, which consisted in the formation of scratches as a result of the impact of the highest asperities of the roughness of a hard tool.

- It was found that with an increase in the amount of pre-straining, the sheet metal put more resistance to flattening the summits of the asperities, especially when the nominal pressure was greater than 6 MPa. Pre-strained specimens at 7% of deformation showed a kurtosis of more than 3 in most of the tested conditions.

- The negative values of skewness confirmed that as the nominal pressure increased, the sheet was more resistant to the production of low peaks and low valleys caused by friction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Trzepieciński, T.; Kubit, A.; Fejkiel, R.; Chodoła, Ł.; Ficek, D.; Szczęsny, I. Modelling of Friction Phenomena Existed in Drawbead in Sheet Metal Forming. Materials 2021, 14, 5887. [Google Scholar] [CrossRef] [PubMed]

- Bay, N.; Olsson, D.D.; Andreasen, J.L. Lubricant test methods for sheet metal forming. Tribol. Int. 2008, 41, 844–853. [Google Scholar] [CrossRef]

- Krawiec, S. Kompozycje Smarów Plastycznych i Stałych w Procesie Tarcia Stalowych Węzłów Maszyn; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2011. [Google Scholar]

- Żaba, K.; Trzepieciński, T.; Rusz, S.; Puchlerska, S.; Balcerzak, M. Full-Field Temperature Measurement of Stainless Steel Specimens Subjected to Uniaxial Tensile Loading at Various Strain Rates. Materials 2021, 14, 5259. [Google Scholar] [CrossRef] [PubMed]

- Hol, J.; Wiebenga, J.H.; Varleer, B. Friction and lubrication modelling in sheet metal forming: Influence of lubrication amount, tool roughness and sheet coating on product quality. Mater. Sci. Eng. 2017, 896, 012026. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Oleksik, V.; Pepelnjak, T.; Najm, S.M.; Paniti, I.; Maji, K. Emerging trends in single point incremental sheet forming of lightweight metals. Metals 2021, 11, 1188. [Google Scholar] [CrossRef]

- Żaba, K.; Głodzik, M.; Puchlerska, S.; Pociecha, D.; Nowosielski, M.; Kwiatkowski, M. Analysis of the aluminium formability in the incremental sheet forming process. In Proceedings of the METAL 2015 Conference, Brno, Czech, 3–5 June 2015; pp. 1–6. [Google Scholar]

- Slota, J.; Šiser, M.; Gajdoš, I. Failure prediction of axisymmetric cup in deep drawing and expansion processes. Open Eng. 2018, 8, 354–362. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Fejkiel, R.; Kubit, A.; Bochnowski, W. Evaluation of friction coefficient of an auto-body steel sheet. Zesz. Nauk. Politech. Rzesz. Mech. 2016, 88, 247–258. [Google Scholar] [CrossRef]

- Evin, E.; Ábel, M.; Viňáš, J.; Tkáčová, J.; Antoszewski, B. Tribological characteristics of stamping dies with coatings. Zesz. Nauk. Politech. Rzesz. Mech. 2013, 85, 129–137. [Google Scholar] [CrossRef]

- Jivan, R.B.; Eskandarzade, M.; Bewsher, S.R.; Leighton, M.; Mohammadpour, M.; Saremi-Yarahmadi, S. Application of solid lubricant for enhanced frictional efficiency of deep drawing process. J. Mech. Eng. Sci. 2021, 236, 624–634. [Google Scholar] [CrossRef]

- Mousavi, A.; Sperk, T.; Gietzelt, T.; Kunze, T.; Lasagni, A.F.; Brosius, A. Effect of contact area on friction force in sheet metal forming operations. Key Eng. Mater. 2018, 767, 77–84. [Google Scholar] [CrossRef]

- Wilson, W.R.D. Friction and lubrication in sheet metal forming. In Mechanics of Sheet Metal Forming; Koistinen, D.P., Wang, N.M., Eds.; Springer: Boston, MA, USA, 1978; pp. 157–177. [Google Scholar]

- Behrens, B.A.; Maier, H.J.; Hübner, S.; Bonk, C.; Almohallami, A.; Lummer, C.; Schein, P.; Scheland, H.; Moritz, M.C. Wear behavior of MoS2 lubricant layers during sheet metal forming. Procedia Eng. 2017, 183, 357–362. [Google Scholar] [CrossRef][Green Version]

- Lee, K.; Moon, C.; Lee, M.G. A Review on friction and lubrication in automotive metal forming: Experiment and modeling. Int. J. Automot. Technol. 2021, 22, 1743–1761. [Google Scholar] [CrossRef]

- Bucur, A.; Lazarecu, L.; Pop, G.M.; Achimas, G.; Gebhardt, A. A tribological performance of biodegradable lubricants under different surface roughness of tools. Acdemic J. Manuf. Eng. 2019, 17, 1–7. [Google Scholar]

- Nowak, P.; Kucharska, K.; Kamiński, M. Ecological and health effects of lubricant oils emitted into the environment. Int. J. Environ. Res. Public Health 2019, 16, 3002. [Google Scholar] [CrossRef] [PubMed]

- Aluyor, E.O.; Obahiagbon, K.O.; Ori-jesu, M. Biodegradation of vegetable oils: A review. Sci. Res. Essay 2009, 4, 543–548. [Google Scholar]

- Drabik, J. Charakterystyki tribologiczne smarów plastycznych wytworzonych na modyfikowanych olejach roślinnych. Tribologia 2015, 2, 31–40. [Google Scholar]

- Woma, T.Y.; Lawal, S.A.; Abdulrahman, A.S.; Olutoye, M.A.; Ojapah, M.M. Vegetable oil based lubricants: Challenges and prospects. Tribol. Online 2019, 14, 60–70. [Google Scholar] [CrossRef]

- Dunford, N.T. Edible Oil Quality. Available online: https://extension.okstate.edu/fact-sheets/edible-oil-quality.html (accessed on 20 July 2022).

- Trzepieciński, T. Tribological performance of environmentally friendly bio-degradable lubricants based on a combination of boric acid and bio-based oils. Materials 2020, 13, 3892. [Google Scholar] [CrossRef]

- Trzepieciński, T. Polynomial multiple regression analysis of the lubrication effectiveness of deep drawing quality steel sheets by eco-friendly vegetable oils. Materials 2022, 15, 1151. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Szpunar, M. Assessment of the effectiveness of lubrication of Ti-6Al-4V titanium alloy sheets using radial basis function neural networks. Acta Polytech. 2021, 61, 489–496. [Google Scholar] [CrossRef]

- Karthik, A.V. Vegetable oil as a forming lubricant for deep drawing of AA6061. Int. J. Eng. Sci. Comput. 2016, 6, 1580–1582. [Google Scholar]

- Carcel, A.C.; Palomares, D.; Rodilla, E.; Pérez Puig, M.A. Evaluation of vegetable oils as pre-lube oils for stamping. Mater. Des. 2005, 26, 587–593. [Google Scholar] [CrossRef]

- Syahrullail, S.; Afifah, Z.N. Bio-lubricant for metal forming. Mytribos Symp. 2017, 2, 54–56. [Google Scholar]

- Shashidhara, Y.M.; Jayaram, S.R. Deep drawing of 304 L steel sheet using vegetable oils as forming lubricants. Int. J. Adv. Res. Technol. 2012, 1, 1–5. [Google Scholar]

- Więckowski, W.; Dyja, K. The effect of the use of technological lubricants based on vegetable oils on the process of titanium sheet metal forming. Arch. Metall. Mater. 2017, 62, 489–494. [Google Scholar] [CrossRef][Green Version]

- Keshtiban, P.M.; Ghaleh, S.S.G.; Alimirzaloo, V. Lubrication efficiency of vegetable oil nano-lubricants and solid powder lubricants. J. Mater. Des. Appl. 2018, 233, 1384–1392. [Google Scholar] [CrossRef]

- EN 10130: 2006; Cold Rolled Low Carbon Steel Flat Products for Cold Forming—Technical Delivery Conditions. European Committee for Standardization: Brussels, Belgium, 2006.

- EN ISO 6892-1:2020; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 6507-1:2018; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 25178:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 3105:1994; Glass Capillary Kinematic Viscometers—Specifications and Operating Instructions. International Organization for Standardization: Geneva, Switzerland, 1994.

- Trzepieciński, T.; Fejkiel, R. On the influence of deformation of deep drawing quality steel sheet on surface topography and friction. Tribol. Int. 2017, 115, 78–88. [Google Scholar] [CrossRef]

- Vollertsen, F.; Hu, Z. Tribological size effects in sheet metal forming measured by a strip drawing test. CIRP Ann. 2006, 55, 291–294. [Google Scholar] [CrossRef]

- Kirkhorn, L.; Frogner, K.; Andersson, M.; Stahl, J.E. Improved tribotesting for sheet metal forming. Procedia CIRP 2012, 3, 507–512. [Google Scholar] [CrossRef]

- Ten Thije, R.H.W.; Akkerman, R.; van der Meer, L.; Ubbink, M.P. Tool-ply friction in thermoplastic composite forming. Int. J. Mater. Form. 2008, 1, 953–956. [Google Scholar] [CrossRef]

- Dou, S.; Xia, J. Analysis of Sheet Metal Forming (Stamping Process): A Study of the Variable Friction Coefficient on 5052 Aluminum Alloy. Metals 2019, 9, 853. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, L.; Politis, D.J.; Zhang, J.; Gharbi, M.M.; Leyvraz, D.; Wang, L. Experimental and modelling studies of the transient tribological behaviour of a two-phase lubricant under complex loading conditions. Friction 2022, 10, 911–926. [Google Scholar] [CrossRef]

- van der Heide, E. Lubricant Failure in Sheet Metal Forming Processes. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 12 April 2002. [Google Scholar]

- Wang, C.; Guo, B.; Shan, D. Friction related size-effect in microforming—A review. Manuf. Rev. 2014, 1, 23. [Google Scholar] [CrossRef]

- Dubar, L.; Hubert, C.; Christiansen, P.; Bay, N.; Dubois, A. Analysis of fluid lubrication mechanisms in metal forming at mesoscopic scale. CIRP Ann. 2012, 61, 271–274. [Google Scholar] [CrossRef]

- Shao, Z.; Li, N.; Lin, J.; Dean, T. Formability evaluation for sheet metals under hot stamping conditions by a novel biaxial testing system and a new materials model. Int. J. Mech. Sci. 2017, 120, 149–158. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Z. The effects of through-thickness shear stress on the formability of sheet metal–A review. J. Manuf. Processes 2021, 71, 269–289. [Google Scholar] [CrossRef]

- Banabic, D. Sheet Metal Forming Processes; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Dariani, B.M.; Liaghat, G.H.; Gerdooei, M. Experimental investigation of sheet metal formability under various strain rates. J. Eng. Manuf. 2009, 223, 703–712. [Google Scholar] [CrossRef]

- Reddy, A.C.S.; Rajesham, S.; Reddy, P.R.; Umamaheswar, A.C. Formability: A review on different sheet metal tests for formability. AIP Conf. Proc. 2020, 2269, 030026. [Google Scholar]

- Bhatt, M.R.; Buch, S. Prediction of formability for sheet metal component using artificial intelligent technique. In Proceedings of the 2nd International Conference on Signal Processing and Integrated Networks (SPIN), Noida, India, 19–20 February 2015; pp. 388–393. [Google Scholar]

- Xie, Y.; Wu, Y.; Jalali, A.; Zhou, H.; Khadimallah, M.A. Effects of thickness reduction in cold rolling process on the formability of sheet metals using ANFIS. Sci. Rep. 2022, 12, 10434. [Google Scholar] [CrossRef]

- Kumar, J.P.; Kumar, R.U.; Ramakrishna, B.; Ramu, B.; Saheb, K.B. Formability of sheet metals—A review. Mater. Sci. Eng. 2018, 455, 012081. [Google Scholar]

- Tisza, M.; Kovács, Z.P. New methods for predicting the formability of sheet metals. Prod. Processes Syst. 2012, 5, 45–54. [Google Scholar]

- Magrinho, J.P.; Silva, M.B.; Reis, L.; Martins, P.A.F. Formability limits, fractography and fracture toughness in sheet metal forming. Materials 2019, 12, 1493. [Google Scholar] [CrossRef] [PubMed]

- Chhikara, S.; Khatta, R.; Verma, S.P.; Shamrao, D.M. Review on sheet metal formability. Int. J. Adv. Res. Innov. 2020, 8, 82–85. [Google Scholar]

- Jaremenko, C.; Ravikumar, N.; Affronti, E.; Merklein, M.; Maier, A. Determination of forming limits in sheet metal forming using deep learning. Materials 2019, 12, 1051. [Google Scholar] [CrossRef]

- Wankhede, P.; Suresh, K. A review on the evaluation of formability in sheet metal forming. Adv. Mater. Processing Technol. 2020, 6, 458–485. [Google Scholar] [CrossRef]

- Emments, W.C. Formability, A Review of Parameters and Processes That Control, Limit or Enhance the Formability of Sheet Metal; Springer: Heidelberg, Germany, 2011. [Google Scholar]

- Erichsen, A.M. Process and Apparatus for Testing Metal Sheets and Plater. GB Patent no. 91228571 (A), 6 January 1913. [Google Scholar]

- ISO 20482:2013; Sheet and Strip—Erichsen Cupping Test. International Organization for Standardization: Geneva, Switzerland, 2013.

- Sedlaček, M.; Vilhena, L.M.S.; Podgornik, B.; Vižintin, J. Surface topography modelling for reduced friction. Stroj. Vestn. J. Mech. Eng. 2011, 57, 674–680. [Google Scholar] [CrossRef]

- Wang, W.Z.; Che, H.; Hu, Y.Z.; Wang, H. Effect of surface roughness parameters on mixed lubrication characteristics. Tribol. Int. 2006, 39, 522–527. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Influence of surface preparation on roughness parameters, friction and wear. Wear 2009, 266, 482–487. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

| Oil | Kinematic Viscosity, mm2/s | Density, g/cm3 | Flash Point, °C |

|---|---|---|---|

| Sunflower | 58 | 0.920 | 319.1 |

| Rape-seed | 51 | 0.914 | 314.0 |

| Moringa | 73 | 0.897 | 268.5 |

| Karanja | 75 | 0.936 | 212.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trzepieciński, T.; Szewczyk, M.; Szwajka, K. The Use of Non-Edible Green Oils to Lubricate DC04 Steel Sheets in Sheet Metal Forming Process. Lubricants 2022, 10, 210. https://doi.org/10.3390/lubricants10090210

Trzepieciński T, Szewczyk M, Szwajka K. The Use of Non-Edible Green Oils to Lubricate DC04 Steel Sheets in Sheet Metal Forming Process. Lubricants. 2022; 10(9):210. https://doi.org/10.3390/lubricants10090210

Chicago/Turabian StyleTrzepieciński, Tomasz, Marek Szewczyk, and Krzysztof Szwajka. 2022. "The Use of Non-Edible Green Oils to Lubricate DC04 Steel Sheets in Sheet Metal Forming Process" Lubricants 10, no. 9: 210. https://doi.org/10.3390/lubricants10090210

APA StyleTrzepieciński, T., Szewczyk, M., & Szwajka, K. (2022). The Use of Non-Edible Green Oils to Lubricate DC04 Steel Sheets in Sheet Metal Forming Process. Lubricants, 10(9), 210. https://doi.org/10.3390/lubricants10090210