Halloysite Reinforced Natural Esters for Energy Applications

Abstract

1. Introduction

2. Materials and Methods

Nanolubricants Preparation

3. Experimental Details

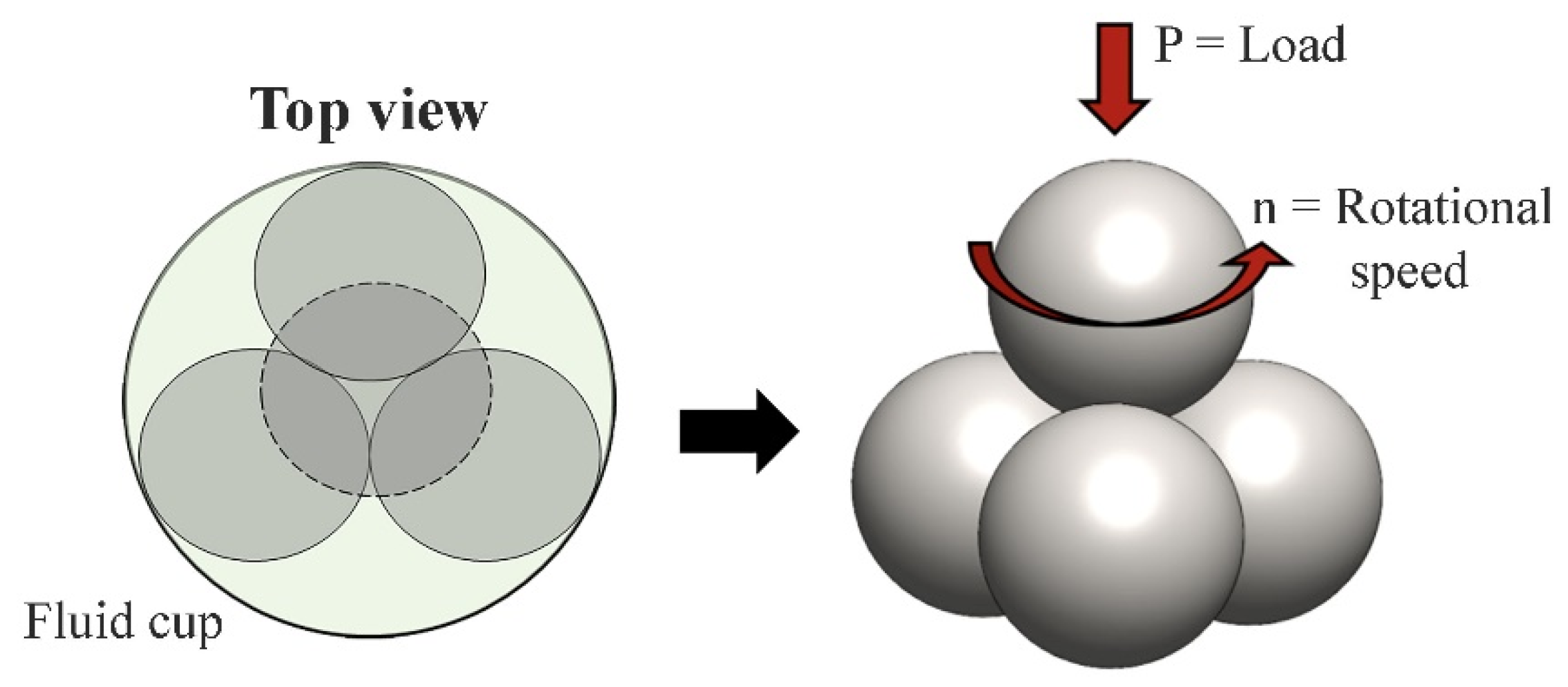

3.1. Tribological Evaluations

3.2. Thermal Conductivity Evaluations

4. Results and Discussion

4.1. Tribological Performance

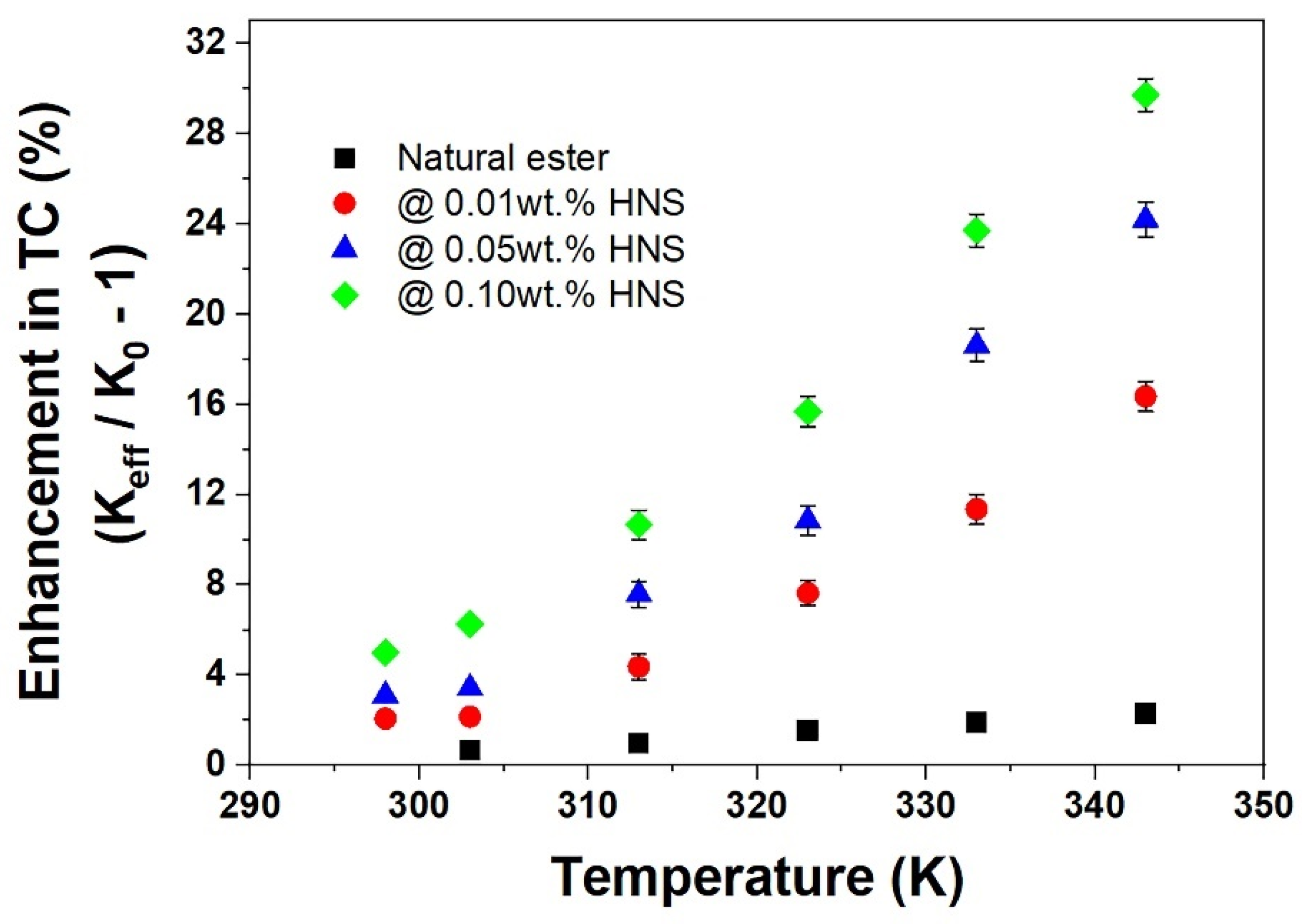

4.2. Thermal Performance

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wong, K.V.; De Leon, O. Applications of Nanofluids: Current and Future. Adv. Mech. Eng. 2010, 2, 519659. [Google Scholar] [CrossRef]

- Salehirad, M.; Nikje, M.M.A. Properties of Modified Hexagonal Boron Nitride as Stable Nanofluids for Thermal Management Applications. Russ. J. Appl. Chem. 2019, 92, 78–86. [Google Scholar] [CrossRef]

- Fofana, I. 50 years in the development of insulating liquids. IEEE Electr. Insul. Mag. 2013, 29, 13–25. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Narayanan, T.N.; Gao, G.; Rohde, M.; Tsentalovich, D.A.; Pasquali, M.; Ajayan, P.M. Electrically insulating thermal nano-oils using 2D fillers. ACS Nano 2012, 6, 1214–1220. [Google Scholar] [CrossRef]

- Contreras, J.E.; Rodriguez, E.A.; Taha-Tijerina, J. Chapter 39: Recent Trends of Nanomaterials for High-Voltage Applications. In Handbook of Nanomaterials for Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 724–738. [Google Scholar]

- Abas, N.; Kalair, A.; Khan, N. Review of fossil fuels and future energy technologies. Futures 2015, 69, 31–49. [Google Scholar] [CrossRef]

- Madanhire, I.; Mbohwa, C.; Madanhire, I.; Mbohwa, C. Development of Biodegradable Lubricants. In Mitigating Environmental Impact of Petroleum Lubricants; Springer: Berlin/Heidelberg, Germany, 2016; pp. 85–101. [Google Scholar]

- Nowak, P.; Kucharska, K.; Kamiński, M. Ecological and health effects of lubricant oils emitted into the environment. Int. J. Environ. Res. Public Health 2019, 16, 3002. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P. Ecological trends in machining as a key factor in sustainable production—A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Benedicto, E.; Carou, D.; Rubio, E.M. Technical, Economic and Environmental Review of the Lubrication/Cooling Systems used in Machining Processes. Procedia Eng. 2017, 184, 99–116. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Narayanan, T.N.; Avali, S.; Ajayan, P.M. 2D Structures-based Energy Management Nanofluids. In Proceedings of the ASME 2012 International Mechanical Engineering Congress & Exposition (IMECE 2012), Houston, TX, USA, 9–15 November 2012; p. 87890. [Google Scholar]

- Liu, R. The challenges and opportunities of nanofluids. In Proceedings of the 2019 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), Guangzhou, China, 7–10 April 2019; pp. 110–114. [Google Scholar]

- Sharma, P.; Said, Z.; Kumar, A.; Nizetic, S.; Pandey, A.; Hoang, A.T.; Huang, Z.; Afzal, A.; Li, C.; Le, A.T.; et al. Recent Advances in Machine Learning Research for Nanofluid-Based Heat Transfer in Renewable Energy System. Energy Fuels 2022, 36, 6626–6658. [Google Scholar] [CrossRef]

- Rafiq, M.; Lv, Y.Z.; Zhou, Y.; Ma, K.B.; Wang, W.; Li, C.R. Use of vegetable oils as transformer oils-A review. Renew. Sustain. Energy Rev. 2015, 52, 308–324. [Google Scholar] [CrossRef]

- Kumar, S.; Vo, D.-V.N.; Selvaraju, N.; Ramalingam, S.; Sikdar, S.; Rahman, H. Synergistic Study of Solid Lubricant Nano-Additives Incorporated in canola oil for Enhancing Energy Efficiency and Sustainability. Sustainability 2022, 14, 290. [Google Scholar]

- Fernández-Silva, S.D.; García-Morales, M.; Ruffel, C.; Delgado, M.A. Influence of the Nanoclay Concentration and Oil Viscosity on the Rheological and Tribological Properties of Nanoclay-Based Ecolubricants. Lubricants 2021, 9, 8. [Google Scholar] [CrossRef]

- Narayanan, G.A.A.; Babu, R.; Vasanthakumari, R. Studies on Halloysite Nanotubes (HNT) Natural Rubber Nanocomposites for Mechanical Thermal and Wear Properties. Int. J. Eng. Res. Technol. 2016, 5, 152–156. [Google Scholar]

- Ahmed Abdalglil Mustafa, W.; Dassenoy, F.; Sarno, M.; Senatore, A. A review on potentials and challenges of nanolubricants as promising lubricants for electric vehicles. Lubr. Sci. 2022, 34, 1–29. [Google Scholar] [CrossRef]

- Kadirgama, G.; Kamarulzaman, M.K.; Ramasamy, D.; Kadirgama, K.; Hisham, S. Classification of Lubricants Base Oils for Nanolubricants Applications—A Review. In ICMER 2021: Technological Advancement in Mechanical and Automotive Engineering; Ismail, M.Y., Mohd Sani, M.S., Kumarasamy, S., Hamidi, M.A., Shaari, M.S., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2023; pp. 205–213. [Google Scholar]

- Huang, Z.; Li, J.; Yao, W.; Wang, F.; Wan, F.; Tan, Y. Electrical and thermal properties of insulating oil-based nanofluids: A comprehensive overview. IET Nanodielectr. 2019, 2, 27–40. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.J. Thermal transport and Challenges on Nanofluids Performance. In Microfluidics and Nanofluidics, 1st ed.; Kandelousi, M.S., Ed.; IntechOpen: Rijeka, Croatia, 2018; pp. 215–256. [Google Scholar]

- Nagendramma, P.; Kaul, S. Development of ecofriendly/biodegradable lubricants: An overview. Renew. Sustain. Energy Rev. 2012, 16, 764–774. [Google Scholar] [CrossRef]

- Pawar, R.V.; Hulwan, D.B.; Mandale, M.B. Recent advancements in synthesis, rheological characterization, and tribological performance of vegetable oil-based lubricants enhanced with nanoparticles for sustainable lubrication. J. Clean. Prod. 2022, 378, 134454. [Google Scholar] [CrossRef]

- Ab Ghani, S.; Muhamad, N.A.; Noorden, Z.A.; Zainuddin, H.; Abu Bakar, N.; Talib, M.A. Methods for improving the workability of natural ester insulating oils in power transformer applications: A review. Electr. Power Syst. Res. 2018, 163, 655–667. [Google Scholar] [CrossRef]

- Thampi, A.D.; Prasanth, M.A.; Anandu, A.P.; Sneha, E.; Sasidharan, B.; Rani, S. The effect of nanoparticle additives on the tribological properties of various lubricating oils—Review. Mater. Today Proc. 2021, 47, 4919–4924. [Google Scholar] [CrossRef]

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Adediran, A.A.; Aliyu, S.J.; Akinlabi, S.A. Advances in the Application of Vegetable-Oil-Based Cutting Fluids to Sustainable Machining Operation: A Review. Lubricants 2022, 10, 69. [Google Scholar] [CrossRef]

- Dombek, G.; Nadolny, Z.; Marcinkowska, A. Thermal properties of natural ester and low viscosity natural ester in the aspect of the reliable operation of the transformer cooling system. Eksploat. Niezawodn. Maint. Reliab. 2019, 21, 384–391. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Ribeiro, H.; Aviña, K.; Martínez, J.M.; Godoy, A.P.; Cremonezzi, J.M. Thermal Conductivity Performance of 2D h-BN/MoS2/-Hybrid Nanostructures Used on Natural and Synthetic Esters. Nanomaterials 2020, 10, 1160. [Google Scholar] [CrossRef] [PubMed]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A review on the chemistry, production, and technological potential of bio-based lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, Z.; Lu, Z.; Wang, X.; Jia, L.; Wang, J.; Gao, Q.; Li, L.; Zhou, C.; Chen, G.; et al. Synthesis and tribological properties of bio-inspired green dopamine oil soluble additive. Tribol. Int. 2022, 174, 107697. [Google Scholar] [CrossRef]

- Durango-Giraldo, G.; Zapata-Hernandez, C.; Santa, J.F.; Buitrago-Sierra, R. Palm oil as a biolubricant: Literature review of processing parameters and tribological performance. J. Ind. Eng. Chem. 2022, 107, 31–44. [Google Scholar] [CrossRef]

- Abdalla, H.S.; Patel, S. The performance and oxidation stability of sustainable metalworking fluid derived from vegetable extracts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 2027–2040. [Google Scholar] [CrossRef]

- Petlyuk, A.M.; Adams, R.J. Oxidation stability and tribological behavior of vegetable oil hydraulic fluids. Tribol. Trans. 2004, 47, 182–187. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Aviña, K.; Diabb, J.M. Tribological and Thermal Transport Performance of SiO2-Based Natural Lubricants. Lubricants 2019, 7, 71. [Google Scholar] [CrossRef]

- Eberhardt, R.; Muhr, H.M.; Lick, W.; Baumann, F.; Pukel, G. Comparison of alternative insulating fluids. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 591–593. [Google Scholar]

- Fox, N.J.; Stachowiak, G.W. Vegetable oil-based lubricants—A review of oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- IEEE Power Engineering Society. C57.147-2018—IEEE Guide for Acceptance and Maintenance of Natural Ester Insulating Liquid in Transformers; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Choi, S.U.S.; Eastman, J.A. Enhancing thermal conductivity of fluids with nanoparticles. In Developments and Applications of Non-Newtonian Flows; ASME: New York, NY, USA, 1995; Volume 231, pp. 99–105. [Google Scholar]

- Li, H.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Extreme pressure and antiwear additives for lubricant: Academic insights and perspectives. Int. J. Adv. Manuf. Technol. 2022, 120, 1–27. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Progress of Nanofluid Application in Machining: A Review. Mater. Manuf. Process. 2015, 30, 813–828. [Google Scholar] [CrossRef]

- Ben Said, L.; Kolsi, L.; Ghachem, K.; Almeshaal, M.; Maatki, C. Application of nanofluids as cutting fluids in machining operations: A brief review. Appl. Nanosci. 2021, 1–32. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Deiab, I.; Eltaggaz, A. Sustainability assessment during machining Ti-6Al-4V with nano-additives-based minimum quantity lubrication. J. Manuf. Mater. Process. 2019, 3, 61. [Google Scholar] [CrossRef]

- Kadirgama, K. A comprehensive review on the application of nanofluids in the machining process. Int. J. Adv. Manuf. Technol. 2021, 115, 2669–2681. [Google Scholar] [CrossRef]

- Rapoport, L.; Leshchinsky, V.; Lapsker, I.; Volovik, Y.; Nepomnyashchy, O.; Lvovsky, M. tribological properties of WS2 nanoparticles under mixed lubrication. Wear 2003, 255, 785–793. [Google Scholar] [CrossRef]

- Sunil Kumar, D.; Garg, H.C.; Kumar, G. Tribological analysis of blended vegetable oils containing CuO nanoparticles as an additive. Mater. Today Proc. 2022, 51, 1259–1265. [Google Scholar] [CrossRef]

- Omrani, E.; Siddaiah, A.; Moghadam, A.D.; Garg, U.; Rohatgi, P.; Menezes, P.L. Ball Milled Graphene Nano Additives for Enhancing Sliding Contact in Vegetable Oil. Nanomaterials 2021, 11, 610. [Google Scholar] [CrossRef]

- Karthikeyan, K.M.B.; Vijayanand, J.; Arun, K.; Rao, V.S. Thermophysical and wear properties of eco-friendly nano lubricants. Mater. Today Proc. 2021, 39, 285–291. [Google Scholar] [CrossRef]

- Yadav, A.; Singh, Y.; Negi, P. A review on the characterization of bio based lubricants from vegetable oils and role of nanoparticles as additives. Mater. Today Proc. 2021, 46, 10513–10517. [Google Scholar] [CrossRef]

- Lim, S.K.; Azmi, W.H.; Jamaludin, A.S.; Yusoff, A.R.; Lim, S.K.; Azmi, W.H. Characteristics of Hybrid Nanolubricants for MQL Cooling Lubrication Machining Application. Lubricants 2022, 10, 350. [Google Scholar] [CrossRef]

- Gupta, H.S.; Sehgal, R.; Wani, M.F. Tribological characterization of eco-friendly bio-based mahua and flaxseed oil through nanoparticles. Biomass Convers. Biorefin. 2022, 1–13. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Shaji, S.; Sharma Kanakkillam, S.; Mendivil Palma, M.I.; Aviña, K. Tribological and Thermal Transport of Ag-Vegetable Nanofluids Prepared by Laser Ablation. Appl. Sci. 2020, 10, 1779. [Google Scholar] [CrossRef]

- Jacob, J.; Preetha, P.; Sindhu, T.K. Stability analysis and characterization of natural ester nanofluids for transformers. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1715–1723. [Google Scholar] [CrossRef]

- Farade, R.A.; Wahab, N.I.A.; Mansour, D.E.A.; Azis, N.B.; Jasni, J.B.; Soudagar, M.E.M. Development of Graphene Oxide-Based Nonedible Cottonseed Nanofluids for Power Transformers. Materials 2020, 13, 2569. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.A.; Tariq, M.; Khan, A.A.; Alamri, B.; Mihet-Popa, L. Assessment of Thermophysical Performance of Ester-Based Nanofluids for Enhanced Insulation Cooling in Transformers. Electronics 2022, 11, 376. [Google Scholar] [CrossRef]

- Lecouvet, B.; Horion, J.; D’Haese, C.; Bailly, C.; Nysten, B. Elastic modulus of halloysite nanotubes. Nanotechnology 2013, 24, 105704. [Google Scholar] [CrossRef] [PubMed]

- Yuan, P.; Tan, D.; Annabi-Bergaya, F. Properties and applications of halloysite nanotubes: Recent research advances and future prospects. Appl. Clay Sci. 2015, 112–113, 75–93. [Google Scholar] [CrossRef]

- Yang, S.; Li, S.; Yin, X.; Wang, L.; Chen, D.; Zhou, Y.; Wang, H. Preparation and characterization of non-solvent halloysite nanotubes nanofluids. Appl. Clay Sci. 2016, 126, 215–222. [Google Scholar] [CrossRef]

- Joussein, E.; Petit, S.; Churchman, J.; Theng, B.; Righi, D.; Delvaux, B. Halloysite clay minerals—A review. Clay Miner. 2005, 40, 383–426. [Google Scholar] [CrossRef]

- Lv, Y.; Sun, X.; Yan, S.; Xiong, S.; Wang, L.; Wang, H. Solvent-free halloysite nanotubes nanofluids based polyacrylonitrile fibrous membranes for protective and breathable textiles. Compos. Commun. 2022, 33, 101211. [Google Scholar] [CrossRef]

- Massaro, M.; Noto, R.; Riela, S. Past, Present and Future Perspectives on Halloysite Clay Minerals. Molecules 2020, 25, 4863. [Google Scholar] [CrossRef]

- Udoh, I.I.; Shi, H.; Daniel, E.F.; Li, J.; Gu, S.; Liu, F. Active anticorrosion and self-healing coatings: A review with focus on multi-action smart coating strategies. J. Mater. Sci. Technol. 2022, 116, 224–237. [Google Scholar] [CrossRef]

- Massaro, M.; Noto, R.; Riela, S. Halloysite Nanotubes: Smart Nanomaterials in Catalysis. J. Catal. 2022, 12, 149. [Google Scholar] [CrossRef]

- Paul, A.; Augustine, R.; Hasan, A.; Zahid, A.A.; Thomas, S.; Agatemor, C. Halloysite nanotube and chitosan polymer composites: Physicochemical and drug delivery properties. J. Drug Deliv. Sci. Technol. 2022, 72, 103380. [Google Scholar] [CrossRef]

- Same, S.; Nakhjavani, S.A.; Samee, G.; Navidi, G.; Jahanbani, Y.; Davaran, S. Halloysite clay nanotube in regenerative medicine for tissue and wound healing. Ceram. Int. 2022, 48, 31065–31079. [Google Scholar] [CrossRef]

- Liao, J.; Wang, H.; Liu, N.; Yang, H. Functionally modified halloysite nanotubes for personalized bioapplications. Adv. Colloid Interface Sci. 2023, 311, 102812. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.S.; Nair, K.P.; Tirth, V.; Elkhaleefa, A.; Rehan, M. Tribological evaluation of date seed oil and castor oil blends with halloysite nanotube additives as environment friendly bio-lubricants. Biomass Convers. Biorefin. 2021, 1–10. [Google Scholar] [CrossRef]

- Qin, Y.; Wu, M.; Yang, Y.; Yang, Y.; Yang, G. Enhanced ability of halloysite nanotubes to form multilayer nanocrystalline tribofilms by thermal activation. Tribol. Int. 2022, 174, 107718. [Google Scholar] [CrossRef]

- Yuan, Q.; Yang, Y.; Yang, Y.; Wu, M.; Yang, G. Formation mechanism of wear-resistant composite film by Span 80-decorated halloysite nanotubes. Ceram. Int. 2022, 48, 23897–23907. [Google Scholar]

- Suresha, B.; Hemanth, G.; Rakesh, A.; Adarsh, K.M. Tribological behaviour of pongamia oil as lubricant with and without halloysite nanotubes using four-ball tester. AIP Conf. Proc. 2019, 2128, 030011. [Google Scholar]

- Alberola, J.A.; Mondragón, R.; Juliá, J.E.; Hernández, L.; Cabedo, L. Characterization of halloysite-water nanofluid for heat transfer applications. Appl. Clay Sci. 2014, 99, 54–61. [Google Scholar] [CrossRef]

- Ba, T.; Alkurdi, A.Q.; Lukács, I.E.; Molnár, J.; Wongwises, S.; Gróf, G. A Novel Experimental Study on the Rheological Properties and Thermal Conductivity of Halloysite Nanofluids. Nanomaterials 2020, 10, 1834. [Google Scholar]

- Ba, T.; Baqer, A.; Saad Kamel, M.; Gróf, G.; Odhiambo, V.O.; Wongwises, S. Experimental Study of Halloysite Nanofluids in Pool Boiling Heat Transfer. Molecules 2022, 27, 729. [Google Scholar]

- Guimarey, M.J.G.; Liñeira del Río, J.M.; Fernández, J. Improvement of the lubrication performance of an ester base oil with coated ferrite nanoadditives for different material pairs. J. Mol. Liq. 2022, 350, 118550. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of Nanoparticles in Lubricating Oil: A Critical Review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Wu, P.R.; Liu, Z.; Cheng, Z.L. Growth of MoS2 Nanotubes Templated by Halloysite Nanotubes for the Reduction of Friction in Oil. ACS Omega 2018, 3, 15002–15008. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, G.; Geng, Z.; Tian, P.; Ren, K.; Wu, W.; Gong, Z. Ultra low friction of conductive carbon nanotube films and their structural evolution during sliding. Diam. Relat. Mater. 2021, 120, 108617. [Google Scholar] [CrossRef]

- Wang, B.; Qiu, F.; Barber, G.C.; Zou, Q.; Wang, J.; Guo, S. Role of nano-sized materials as lubricant additives in friction and wear reduction: A review. Wear 2022, 490–491, 204206. [Google Scholar] [CrossRef]

- Gara, L.; Zou, Q. Friction and Wear Characteristics of Water-Based ZnO and Al2O3 Nanofluids. Tribol. Trans. 2012, 55, 345–350. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Tsui, W.C.; Liu, T.C. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Azman, N.F.; Samion, S. Dispersion Stability and Lubrication Mechanism of Nanolubricants: A Review. Int. J. Precis. Eng. Manuf. Technol. 2019, 6, 393–414. [Google Scholar] [CrossRef]

- Shafi, W.K.; Charoo, M.S. An overall review on the tribological, thermal and rheological properties of nanolubricants. Tribol. Mater. Surf. Interfaces 2020, 15, 20–54. [Google Scholar] [CrossRef]

- Guo, W.; Li, G.; Zheng, Y.; Dong, C. Measurement of the thermal conductivity of SiO2 nanofluids with an optimized transient hot wire method. Thermochim. Acta 2018, 661, 84–97. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Aviña, K.; Martínez, J.M.; Arquieta-Guillén, P.Y.; González-Escobedo, M. Carbon Nanotori Structures for Thermal Transport Applications on Lubricants. Nanomaterials 2021, 11, 1158. [Google Scholar] [CrossRef] [PubMed]

- Taha-Tijerina, J.; Cadena-de la Peña, N.; Cue-Sampedro, R.; Rivera-Solorio, C. Thermo-physical evaluation of dielectric mineral oil-based nitride and oxide nanofluids for thermal transport applications. J. Therm. Sci. Technol. 2019, 14, JTST0007. [Google Scholar] [CrossRef]

| Materials | Properties and Characteristics | |

|---|---|---|

| Conventional Lubricant | Density (20 °C) | Kinetic Viscosity (mm2/s) |

| Natural ester | 0.92 g/cm3 | 190 @ 0 °C; 32–34 @ 40 °C; 7.7–8.3 @ 100 °C |

| Nanostructures | Properties | |

| Halloysite (HNS) | Chemical formula: H4Al2O9Si2. 2H2O Specific gravity: 2.57 g/cm3 Molecular weight: 294.19 g/mol Size–Length: 302 nm ± 83 nm; Diameter: 61 nm ± 18 nm | |

| Lubricant | WSD (μm) (Reduction %) |

|---|---|

| Natural ester | 205 |

| @ 0.01 wt.% HNS | 188 (8.29%) |

| @ 0.05 wt.% HNS | 128 (37.56%) |

| @ 0.10 wt.% HNS | 147 (28.29%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taha-Tijerina, J.J.; Aviña, K.; Padilla-Gainza, V.; Akundi, A. Halloysite Reinforced Natural Esters for Energy Applications. Lubricants 2023, 11, 65. https://doi.org/10.3390/lubricants11020065

Taha-Tijerina JJ, Aviña K, Padilla-Gainza V, Akundi A. Halloysite Reinforced Natural Esters for Energy Applications. Lubricants. 2023; 11(2):65. https://doi.org/10.3390/lubricants11020065

Chicago/Turabian StyleTaha-Tijerina, Jose Jaime, Karla Aviña, Victoria Padilla-Gainza, and Aditya Akundi. 2023. "Halloysite Reinforced Natural Esters for Energy Applications" Lubricants 11, no. 2: 65. https://doi.org/10.3390/lubricants11020065

APA StyleTaha-Tijerina, J. J., Aviña, K., Padilla-Gainza, V., & Akundi, A. (2023). Halloysite Reinforced Natural Esters for Energy Applications. Lubricants, 11(2), 65. https://doi.org/10.3390/lubricants11020065