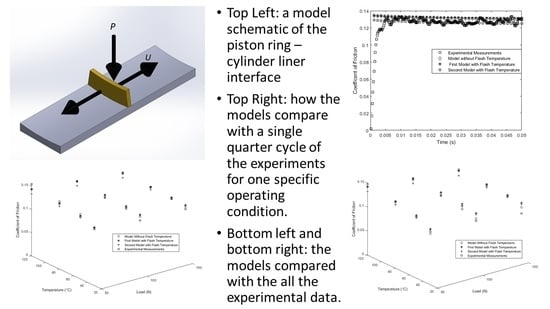

Figure 3 shows the overview of the iterative axisymmetric model of the piston ring–cylinder liner interface. While a full 3D model would be ideal, that was deemed to be too computationally expensive due to the number of iterations and finite element analyses required. The model is also pseudo-steady state, meaning it does not consider transient or dynamic effects, but it does consider different sliding speeds,

U (see

Figure 4). As shown in

Figure 3, the problem is solved iteratively by updating the forces, deformations, and surface separation with each iteration. On the inner radius of the ring, the applied load,

P, (50, 100, or 150 N) was converted to a pressure using the area on the inside. This mimics the loads applied in the experiment and those experienced in an actual engine (see

Figure 3). Combining the applied load on the inside with the contact and fluid pressures on the outside gives an equation that relates net radial force and surface separation. The location of the ring was numerically solved for a net zero radial force. The contact and hydrodynamic forces that solve the equilibrium equation are written in an Abaqus™ input file that creates the mesh shown later. The input file is then run in Abaqus™, and the toolbox abaqus2matlab is used to transfer the displacements back to MATLAB™. These displacements are then used to alter the piston ring profile, and the process is repeated until convergence is reached. The problem is considered converged when the difference in the forces between iterations is less than 0.5%. Additional details are provided in the following sections.

A profilometer was used to measure the surface height of a 1 mm

2 sample area from a cylinder liner and a piston ring. The diamond stylus employed has a tip radius of 2 μm and a resolution of 1 nm. Due to the profilometer’s sensitivity, it was operated on a self-leveling pneumatic vibration isolation table to ensure steadiness. The surface profiles are shown in

Figure 5,

Figure 6,

Figure 7 and

Figure 8. As shown in

Figure 5 and

Figure 6, the cylinder liner surface has a cross-hatched finishing. The ring surface (

Figure 7 and

Figure 8) also possesses some dimples by design. All surface parameters for the lubrication and the statistical rough surface contact modules were calculated from these measurements. Additional details about the parameter calculations are provided later.

2.1. Rough Surface Contact

This work uses the Greenwood–Williamson statistical model [

22] as a base for predicting the effects of rough surface contact. The equations to find the total contact load and area are

P is the total contact force,

An is the nominal area of contact (neglecting roughness),

h is the mean surface separation,

η is the areal asperity density, and

ϕ is the asperity height distribution. Asperities are assumed to be homogenous and evenly distributed; their RMS (root mean square) height is

σs. To calculate the statistical parameters, asperities were manually counted by scanning the surface profile and identifying points whose height was higher than any of the eight surrounding points. The radius of curvature of each asperity was calculated in two orthogonal directions, using

and

The two values were averaged to estimate asperity’s radius of curvature

r. This parameter was calculated for every asperity, and then it was averaged to find

R for all the asperities. The asperity density

η was found by dividing the number of asperities counted by the area scanned. The original G–W model assumes elastic Hertz contact and a constant value of

R. Different equations are used here because this work assumes the asperities are sinusoidal in nature and the loads are large enough for yielding to occur. The following relations were used to convert the asperity radius and density to frequency and amplitude:

For a single

(

λ = 1/

f) wavy asperity area to reach complete elastic contact, the pressure required is given by [

46]

where the effective elastic modulus to account for the deformations of both surfaces is given by

assuming plane strain. Assuming an average contact pressure of

, a required pressure

p* for complete contact, and letting

The following asymptotic solutions were found by Johnson, Greenwood, and Higginson [

46]:

for small values of

Pe and

when

Pe approached unity.

Jackson and Streator [

47] fitted a polynomial combining these equations using experimental data from Johnson et al. [

46]:

These equations neglect asperity yielding, so the elastic–plastic model developed by Krithivasan and Jackson is used instead. They derived an expression for the contact area above which elastic–plastic contact occurs. This was derived from spherical contact, so this work uses a model developed by Jackson et al. [

48] that computes the critical interference above which elastic–plastic relations are used. That expression from Ghaednia et al. [

49] is

Using this value of critical interference, the following equation was fitted to the FEM data of Krithivasan and Jackson [

24] that links the pressures required for complete contact under elastic and elastic–plastic loading:

The contact area for low loads is found using

where

and

is the critical contact area at which elastic–plastic contact begins.

The equation that links the contact area for low and high loads is

In this equation, is calculated by replacing Pe with Pep in Equations (12) and (16).

To apply sinusoidal asperities to the GW model, the surface separation needs to be calculated. Rostami and Jackson [

50] derived expressions by averaging the surface separation from a finite element model. Their fitted equations for the dimensionless surface separation

G are

for elastic contact and

for elastic–plastic contact. In these equations,

and

The integrals in Equations (2) and (3) were numerically evaluated for specified values of surface separation. To find the corresponding load, Equation (19) for elastic contact or Equation (20) for elastic–plastic contact was solved numerically.

2.2. Fluid Lubrication Model

The piston ring–cylinder wall interface is not exclusively boundary lubrication; fluid film lubrication plays an integral role in the overall system behavior. To calculate the hydrodynamic lift, the modified Reynolds equation that considers roughness effects via flow factors is employed. For rough surfaces in the mixed lubrication regime, the modified Reynolds equation is given as Equation (1).

Locker et al. [

45] used deterministic modeling of flow around the measured rough surfaces of a ring a cylinder to find the averaged flow factors over the entire surface and fitted empirical equations to the predicted flow factors:

For the surfaces being studied,

φx and

φz are related through the film thickness, roughness, and surface anisotropy index as

Because the model predicted mostly hydrodynamic lubrication at very low sliding speeds, a shear thinning model was introduced. A version of the Carreau model adapted from Jang, Khonsari, and Bair [

51] was introduced as follows:

μ2 was set to zero, and a fit was generated at a temperature of 60 °C using the data in

Table 1 below.

Figure 9 shows the fit to the shear thinning data, and

Table 2 shows the values of

G and

n. Although there is a limited amount of data available, the usage of a well-accepted phenomenological equation should limit the uncertainty.

It was presumed that the coefficients remained valid for different temperatures. A shear factor that reflects the surface roughness was added later in the model’s development when predicting the shear stress and friction from viscous shearing:

As an improved comparison to experimental data was sought, pressure and temperature viscosity effects were incorporated. This model uses the Barus equation to account for increased viscosity under loading.

Table 3 lists the values used for the pressure viscosity coefficient. There are concerns in the literature about properly accounting for pressure viscosity and shear rate to viscosity relations, but this is more important for contacts where higher pressures are likely, such as in rolling element bearings. The issues are most with Roelands Equation for piezo-viscosity [

52], which we are not using it for. The equations employed are well recognized in the literature and probably adequate for the limited ranges of temperature and pressure that are expected in this model.

With only two values provided, the coefficient was assumed to vary linearly. If the temperature was beyond the range of the provided values, the closer value was used without modification.

The Roelands equation was used to adjust the viscosity due to changes in temperature.

Figure 10 illustrates the viscosity fit as a function of temperature.

2.4. Temperature Adjustments Due to Frictional Heating

Due to the high friction coefficient in boundary lubrication, a large amount of heat can be generated, especially when the load is large. On the local scale, this is known as flash temperature. The following equation can be used to calculate the generated heat.

The heat depends on the total frictional force and the velocity–higher speeds and/or loads will result in a greater amount of heat generated. That manifests itself in a temperature increase in the surfaces as given by Equation (37) for a moving surface and 38 for a stationary surface [

57]. In the following equations,

k is the thermal conductivity,

rc is the applicable contact area, and

κ is the thermal diffusivity.

Based off an analogy with electrical current, Equations (37) and (38) can be combined for the case in which neither surface is adiabatic [

30]:

Equation (38) for heat conduction away from the surfaces assumes a low sliding speed for both of them but can be easily adapted if either surface is sliding rapidly. Solving it for the temperature change results in

There are several ways that the temperature will directly influence the model. First, the temperature will change the viscosity, as described by Equation (31). Second, the temperature could influence the strength of the material locally. The model incorporates the reduction in metals’ yield strength as the temperature increases modeled by Johnson and Cook [

58]. This would result in the surfaces becoming more liquid-like and less resistant to flow, meaning that the predicted dry friction coefficient would decrease. This assumes the adhesive friction model mentioned previously [

52,

53]. Following how shear strength is lowered by Johnson and Cook, then the friction can be approximately modified by the following: