Microalgae Oil-Based Metal Working Fluids for Sustainable Minimum Quantity Lubrication (MQL) Operations—A Perspective

Abstract

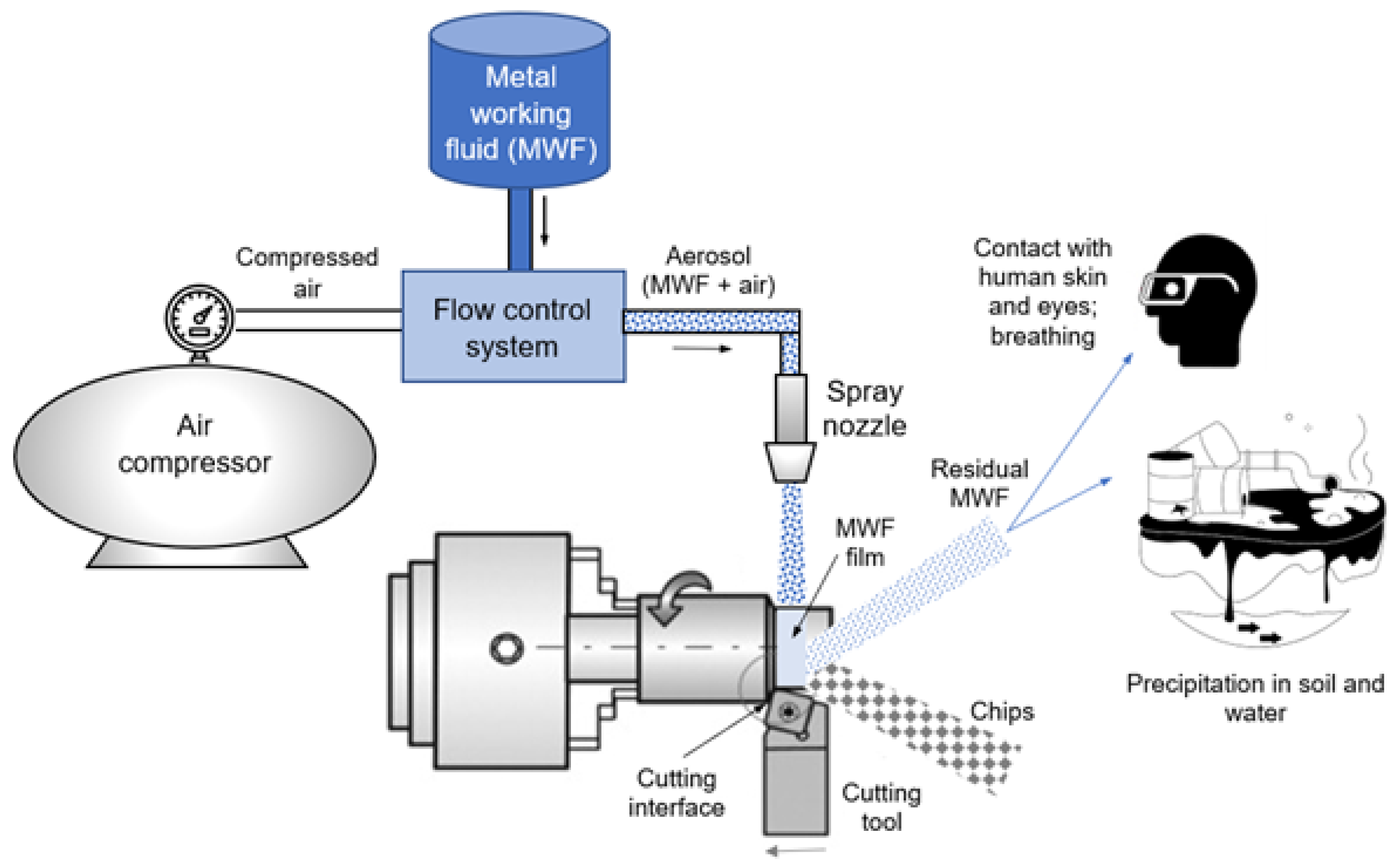

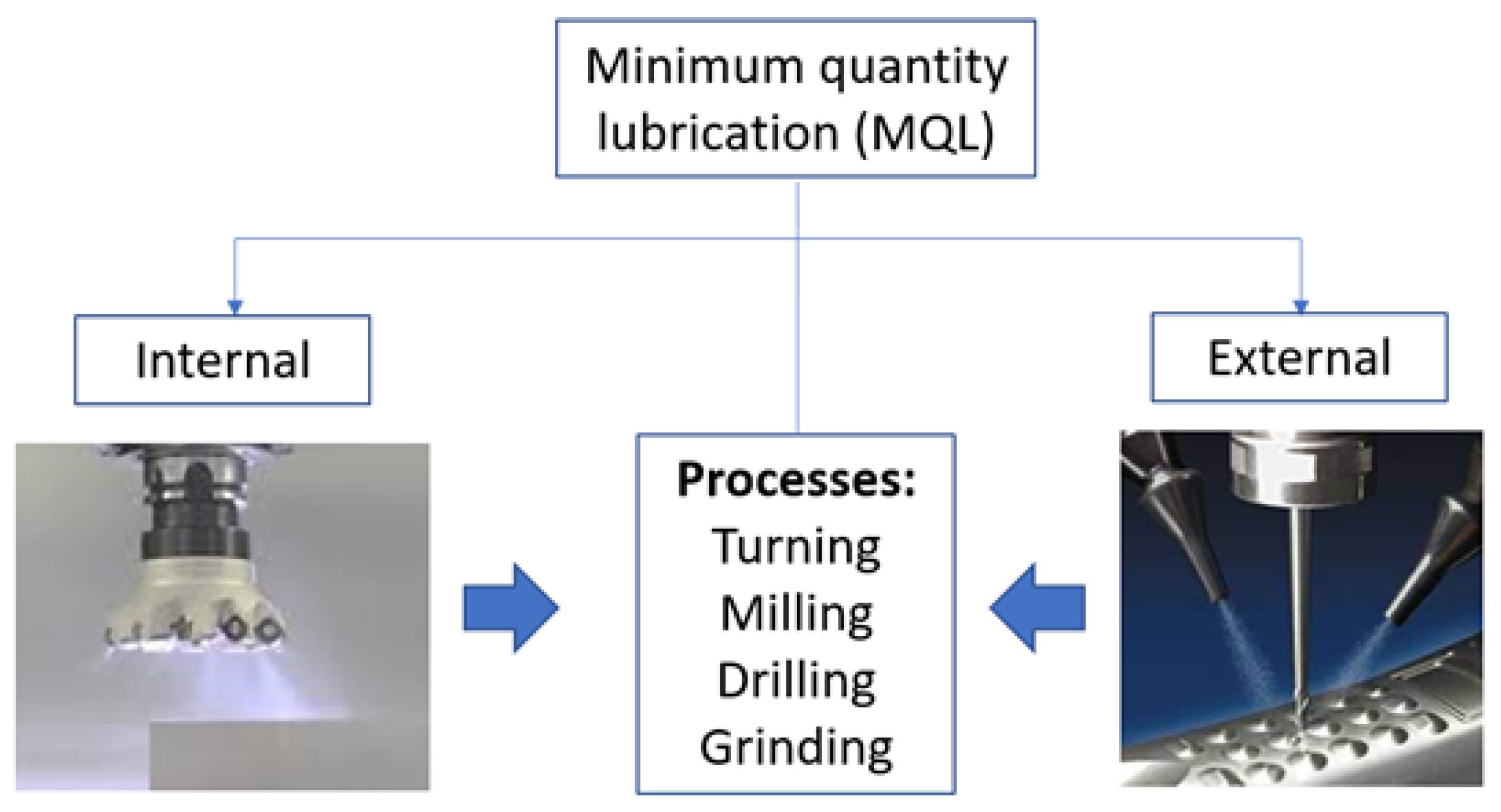

1. Introduction

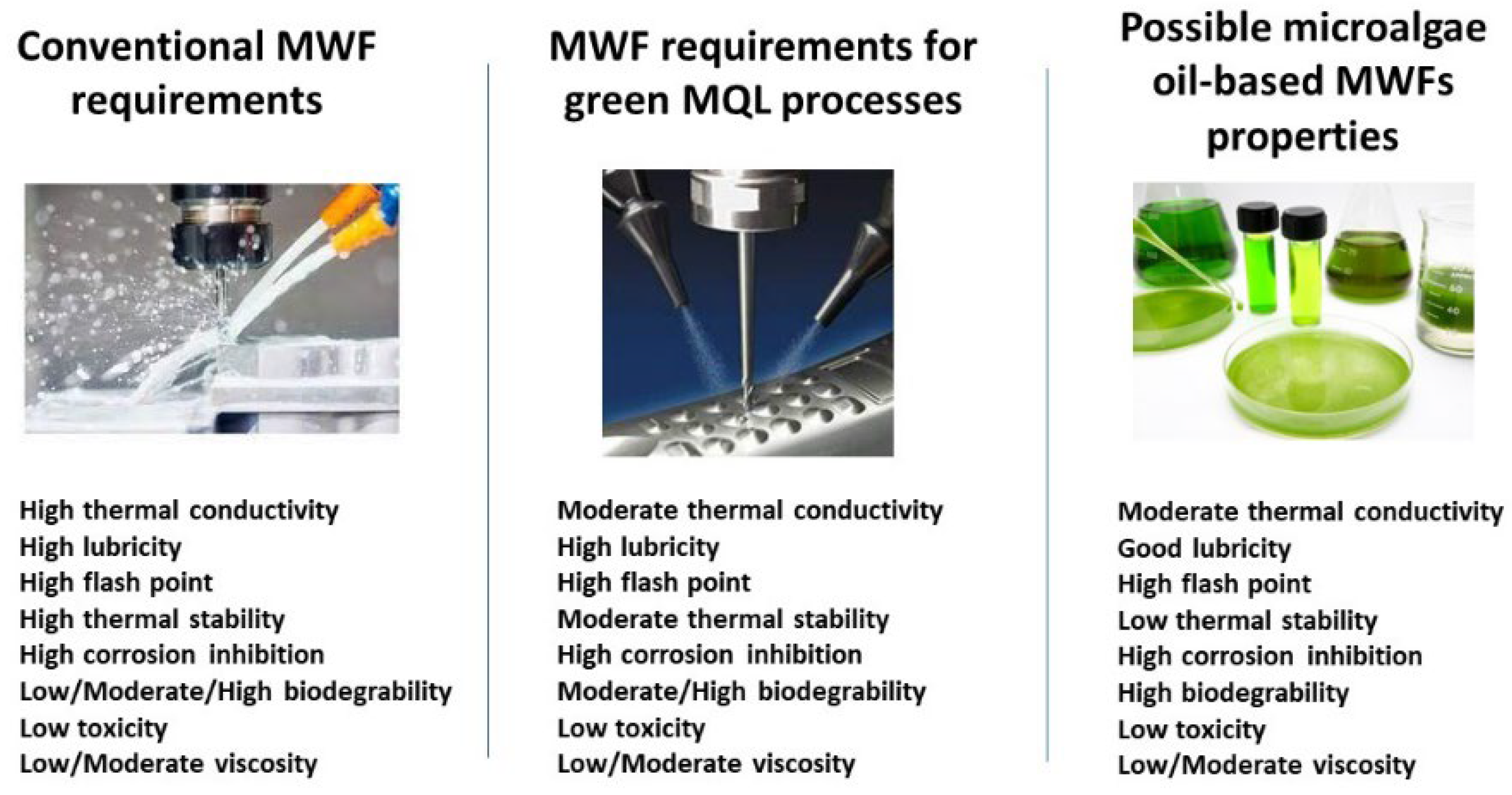

2. Considerations of MWFs for MQL Processes

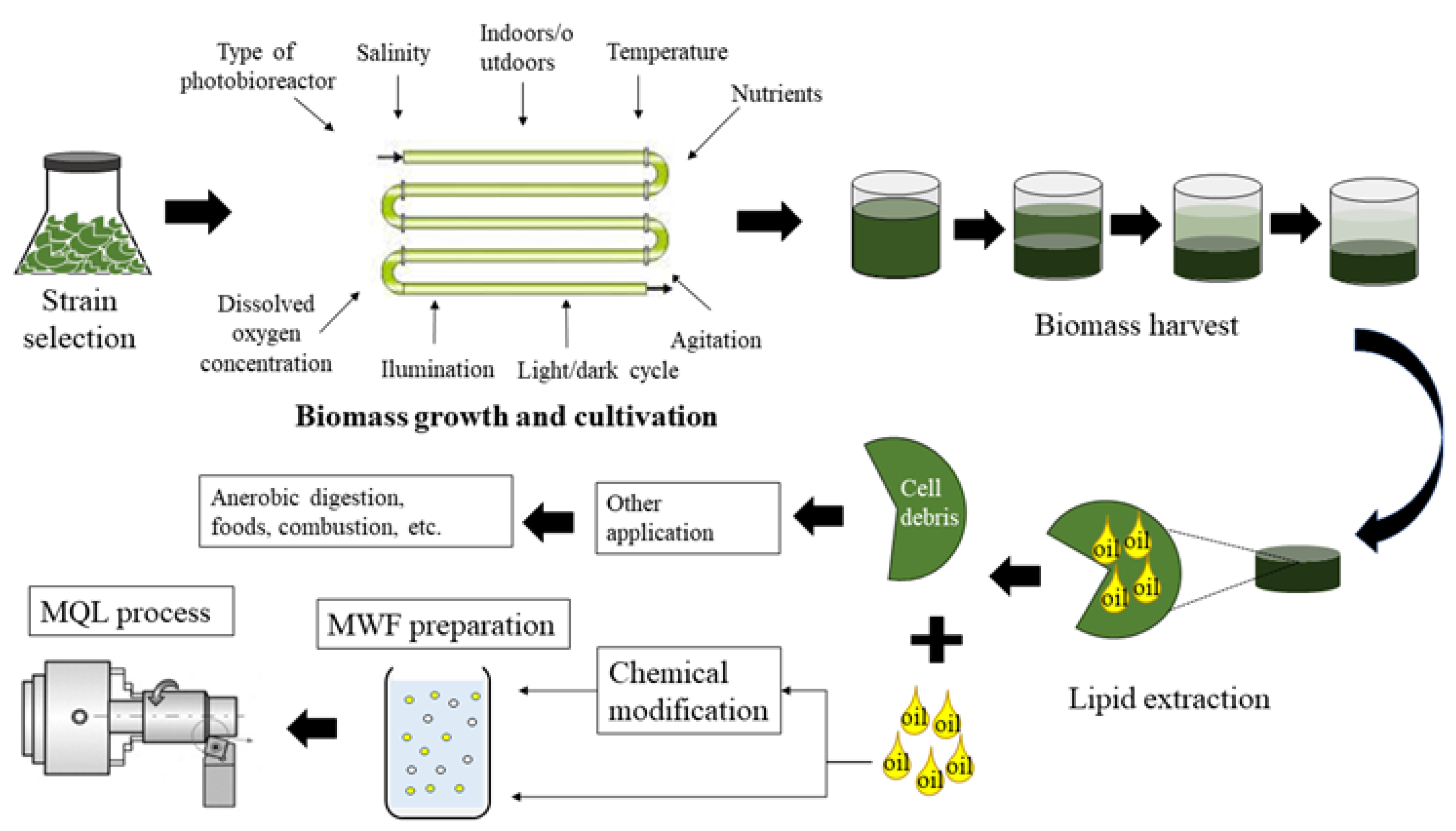

3. Typical Physicochemical Properties of Non-Edible Vegetable Oils and Microalgae Oil

4. Identification of Suitable Microalgae Oils for Use in MQL Operations

5. Current Challenges and Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sankaranarayanan, R.; Jesudoss, N.R.; Kumar, J.S.; Krolczyk, G.M. A Comprehensive Review on Research Developments of Vegetable-Oil Based Cutting Fluids for Sustainable Machining Challenges. J. Manuf. Process. 2021, 67, 286–313. [Google Scholar] [CrossRef]

- Campitelli, A.; Cristóbal, J.; Fischer, J.; Becker, B.; Schebek, L. Resource efficiency analysis of lubricating strategies for machining processes using Life Cycle Assessment Methodology. J. Clean. Prod. 2019, 222, 464–475. [Google Scholar] [CrossRef]

- Priarone, P.C.; Robiglio, M.; Settineri, L. On the concurrent optimization of environmental and economic targets for machining. J. Clean. Prod. 2018, 190, 630–644. [Google Scholar] [CrossRef]

- Nee, A.Y.C. Handbook of Manufacturing Engineering and Technology; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Álvarez, M.E.P.; Bárcena, M.M.; González, F.A. A review of Sustainable Machining Engineering: Optimization Process through Triple Bottom Line. J. Manuf. Sci. Eng. 2016, 138, 100801. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Mia, M.; Gupta, M.K.; Machado, Á.R.; Pintaude, G.; Unune, D.R.; Khanna, N.; Khan, A.M.; Tomaz, Í.; Wojciechowski, S.; et al. Resource saving by optimization and machining environments for Sustainable Manufacturing: A review and future prospects. Renew. Sustain. Energy Rev. 2022, 166, 112660. [Google Scholar] [CrossRef]

- Hassan, K. Comparative life cycle analysis of environmental and machining performance under Sustainable Lubrication Techniques. Hybrid Adv. 2022, 1, 100004. [Google Scholar] [CrossRef]

- Singh, G.; Aggarwal, V.; Singh, S. Critical review on ecological, economical and technological aspects of minimum quantity lubrication towards sustainable machining. J. Clean. Prod. 2020, 271, 122185. [Google Scholar] [CrossRef]

- Wickramasinghe, K.C.; Sasahara, H.; Rahim, E.A.; Perera, G.I.P. Green metalworking fluids for sustainable machining applications: A Review. J. Clean. Prod. 2020, 257, 120552. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A Review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Dilger, S.; Fluri, A.; Sonntag, H.-G. Bacterial contamination of preserved and non-preserved metal working fluids. Int. J. Hyg. Environ. Health 2005, 208, 467–476. [Google Scholar] [CrossRef]

- Li, K.; Aghazadeh, F.; Hatipkarasulu, S.; Ray, T.G. Health risks from exposure to metal-working fluids in machining and grinding operations. Int. J. Occup. Saf. Ergon. 2003, 9, 75–95. [Google Scholar] [CrossRef]

- Najiha, M.S.; Rahman, M.M.; Yusoff, A.R. Environmental impacts and hazards associated with metal working fluids and recent advances in the sustainable systems: A Review. Renew. Sustain. Energy Rev. 2016, 60, 1008–1031. [Google Scholar] [CrossRef]

- Wickramasinghe, K.C.; Sasahara, H.; Rahim, E.A.; Perera, G.I.P. Recent advances on high performance machining of aerospace materials and composites using vegetable oil-based metal working fluids. J. Clean. Prod. 2021, 310, 127459. [Google Scholar] [CrossRef]

- Khan, M.A.; Hussain, M.; Lodhi, S.K.; Zazoum, B.; Asad, M.; Afzal, A. Green metalworking fluids for sustainable machining operations and other sustainable systems: A Review. Metals 2022, 12, 1466. [Google Scholar] [CrossRef]

- Pranav, P.; Sneha, E.; Rani, S. Vegetable oil-based cutting fluids and its behavioral characteristics in Machining Processes: A Review. Ind. Lubr. Tribol. 2021, 73, 1159–1175. [Google Scholar] [CrossRef]

- Katna, R.; Suhaib, M.; Agrawal, N. Nonedible vegetable oil-based cutting fluids for machining processes—A Review. Mater. Manuf. Process. 2019, 35, 1–32. [Google Scholar] [CrossRef]

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Adediran, A.A.; Aliyu, S.J.; Akinlabi, S.A.; Jen, T.-C.; Akinlabi, E.T. Advances in the application of vegetable-oil-based cutting fluids to sustainable machining operations—A Review. Lubricants 2022, 10, 69. [Google Scholar] [CrossRef]

- Khan, S.; Das, P.; Quadir, M.A.; Thaher, M.; Annamalai, S.N.; Mahata, C.; Hawari, A.H.; Al Jabri, H. A comparative physicochemical property assessment and techno-economic analysis of biolubricants produced using chemical modification and additive-based routes. Sci. Total Environ. 2022, 847, 157648. [Google Scholar] [CrossRef]

- Atabani, A.E.; Silitonga, A.S.; Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Badruddin, I.A.; Fayaz, H. Non-edible vegetable oils: A critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renew. Sustain. Energy Rev. 2013, 18, 211–245. [Google Scholar] [CrossRef]

- Kenney, V.P.; Erichsen, R.L. Conflict between fuel and food: The ethical dimension. Energy Agric. 1983, 2, 285–306. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Franco-Morgado, M.; González-Sánchez, A.; Pérez-González, J.; Marín-Santibáñez, B.M. Microalgae biomass as a new potential source of sustainable green lubricants. Molecules 2022, 27, 1205. [Google Scholar] [CrossRef]

- Bouabidi, Z.B.; El-Naas, M.H.; Zhang, Z. Immobilization of microbial cells for the Biotreatment of wastewater: A Review. Environ. Chem. Lett. 2018, 17, 241–257. [Google Scholar] [CrossRef]

- Koyande, A.K.; Chew, K.W.; Rambabu, K.; Tao, Y.; Chu, D.-T.; Show, P.-L. Microalgae: A potential alternative to health supplementation for humans. Food Sci. Hum. Wellness 2019, 8, 16–24. [Google Scholar] [CrossRef]

- Matos, J.; Cardoso, C.; Bandarra, N.M.; Afonso, C. Microalgae as healthy ingredients for Functional Food: A Review. Food Funct. 2017, 8, 2672–2685. [Google Scholar] [CrossRef] [PubMed]

- Deniz, I.; García-Vaquero, M.; Imamoglu, E. Trends in red biotechnology: Microalgae for pharmaceutical applications. In Microalgae-Based Biofuels and Bioproducts; Muñoz, R., Gonzalez-Fernandez, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; ISBN 9780081010273. [Google Scholar]

- Ariede, M.B.; Candido, T.M.; Jacome, A.L.; Velasco, M.V.; de Carvalho, J.C.; Baby, A.R. Cosmetic attributes of algae—A review. Algal Res. 2017, 25, 483–487. [Google Scholar] [CrossRef]

- Suresh, P.; Balasubramanian, A.; Jayakumar, J. Biofuel production from microalgae: Current trends and future perspectives. In Microalgal Biotechnology; Apple Academic Press: Palm Bay, FL, USA, 2023; pp. 251–277. [Google Scholar] [CrossRef]

- Shuba, E.S.; Kifle, D. Microalgae to biofuels: ‘promising’ alternative and renewable energy, review. Renew. Sustain. Energy Rev. 2018, 81, 743–755. [Google Scholar] [CrossRef]

- Chandra, R.; Iqbal, H.M.N.; Vishal, G.; Lee, H.-S.; Nagra, S. Algal Biorefinery: A sustainable approach to valorize algal-based biomass towards multiple product recovery. Bioresour. Technol. 2019, 278, 346–359. [Google Scholar] [CrossRef]

- Chew, K.W.; Yap, J.Y.; Show, P.L.; Suan, N.H.; Juan, J.C.; Ling, T.C.; Lee, D.-J.; Chang, J.-S. Microalgae biorefinery: High value products perspectives. Bioresour. Technol. 2017, 229, 53–62. [Google Scholar] [CrossRef]

- Tang, D.Y.; Yew, G.Y.; Koyande, A.K.; Chew, K.W.; Vo, D.-V.N.; Show, P.L. Green technology for the industrial production of biofuels and bioproducts from microalgae: A Review. Environ. Chem. Lett. 2020, 18, 1967–1985. [Google Scholar] [CrossRef]

- Boubekri, N.; Shaikh, V. Minimum quantity lubrication (MQL) in machining: Benefits and drawbacks. J. Ind. Intell. Inf. 2015, 3, 205–209. [Google Scholar] [CrossRef]

- Liu, N.; Zou, X.; Yuan, J.; Jiang, H.; Zhang, Y.; Chen, Y. Optimization of MQL turning process considering the distribution and control of cutting fluid mist particles. Int. J. Adv. Manuf. Technol. 2021, 116, 1233–1246. [Google Scholar] [CrossRef]

- Zaman, P.B.; Dhar, N.R. Design and evaluation of an embedded double jet nozzle for MQL delivery intending machinability improvement in turning operation. J. Manuf. Process. 2019, 44, 179–196. [Google Scholar] [CrossRef]

- Jang, D.-Y.; Jung, J.; Seok, J. Modeling and parameter optimization for cutting energy reduction in MQL milling process. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 5–12. [Google Scholar] [CrossRef]

- Zhu, G.; Yuan, S.; Chen, B. Numerical and experimental optimizations of nozzle distance in minimum quantity lubrication (MQL) milling process. Int. J. Adv. Manuf. Technol. 2018, 101, 565–578. [Google Scholar] [CrossRef]

- Pal, A.; Chatha, S.S.; Sidhu, H.S. Experimental investigation on the performance of MQL drilling of Aisi 321 stainless steel using nano-graphene enhanced vegetable-oil-based cutting fluid. Tribol. Int. 2020, 151, 106508. [Google Scholar] [CrossRef]

- Awale, A.S.; Vashista, M.; Yusufzai, M.Z.K. Multi-objective optimization of MQL MIST parameters for eco-friendly grinding. J. Manuf. Process. 2020, 56, 75–86. [Google Scholar] [CrossRef]

- Sreejith, P.S.; Ngoi, B.K.A. Dry Machining: Machining of the Future. J. Mater. Process. Technol. 2000, 101, 287–291. [Google Scholar] [CrossRef]

- Madanchi, N.; Kurle, D.; Winter, M.; Thiede, S.; Herrmann, C. Energy Efficient Process Chain: The impact of cutting fluid strategies. Procedia CIRP 2015, 29, 360–365. [Google Scholar] [CrossRef]

- Weinert, K.; Inasaki, I.; Sutherland, J.W.; Wakabayashi, T. Dry Machining and minimum quantity lubrication. CIRP Ann. 2004, 53, 511–537. [Google Scholar] [CrossRef]

- Rudnick, L.R. Synthetics, Mineral Oils, and Bio-Based Lubricants: Chemistry and Technology; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2020. [Google Scholar]

- Farfan-Cabrera, L.I.; Gallardo-Hernández, E.A.; Pérez-González, J.; Marín-Santibáñez, B.M.; Lewis, R. Effects of jatropha lubricant thermo-oxidation on the tribological behaviour of engine cylinder liners as measured by a reciprocating friction test. Wear 2019, 426–427, 910–918. [Google Scholar] [CrossRef]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A review on the chemistry, production, and technological potential of bio-based lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

- Shell Techxplorer Digest: Evaluating the Storage Stability of GTL Oil Emulsions for Metalworking Fluids. Shell Global. (n.d.). Available online: https://www.shell.com/energy-and-innovation/shell-techxplorer-digest-pathways-to-decarbonisation/_jcr_content/root/main/section/simple_633466041_cop_89578642/list/list_item_copy_432158238.multi.stream/1670384886202/e0b7f0a069f1a312c894ffa91139bd135815ce45/evaluating-storage-stability-gtl-oil-emulsions-metalworking-fluids-shivaprasad.pdf (accessed on 23 March 2023).

- Shylesh, S.; Gokhale, A.A.; Ho, C.R.; Bell, A.T. Novel strategies for the production of fuels, lubricants, and chemicals from biomass. Acc. Chem. Res. 2017, 50, 2589–2597. [Google Scholar] [CrossRef] [PubMed]

- Pinheiro Pires, A.P.; Arauzo, J.; Fonts, I.; Domine, M.E.; Fernández Arroyo, A.; Garcia-Perez, M.E.; Montoya, J.; Chejne, F.; Pfromm, P.; Garcia-Perez, M. Challenges and opportunities for bio-oil refining: A Review. Energy Fuels 2019, 33, 4683–4720. [Google Scholar] [CrossRef]

- Cermak, S.C.; Isbell, T.A.; Bredsguard, J.W.; Thompson, T.D. Estolides: Synthesis and Applications. In Fatty Acids: Chemistry, Synthesis, and Application; Ahmad, M.U., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 431–475. ISBN 9780128095218. [Google Scholar]

- Romsdahl, T.; Shirani, A.; Minto, R.E.; Zhang, C.; Cahoon, E.B.; Chapman, K.D.; Berman, D. Nature-guided synthesis of advanced bio-lubricants. Sci. Rep. 2019, 9, 11711. [Google Scholar] [CrossRef]

- Encinar, J.M.; Nogales, S.; González, J.F. Biodiesel and biolubricant production from different vegetable oils through transesterification. Eng. Rep. 2020, 2, e12190. [Google Scholar] [CrossRef]

- Shomchoam, B.; Yoosuk, B. Eco-friendly lubricant by partial hydrogenation of palm oil over Pd/γ-al2o3 catalyst. Ind. Crops Prod. 2014, 62, 395–399. [Google Scholar] [CrossRef]

- Fernández, M.B.; Sánchez, M.J.F.; Tonetto, G.M.; Damiani, D.E. Hydrogenation of sunflower oil over different palladium supported catalysts: Activity and selectivity. Chem. Eng. J. 2009, 155, 941–949. [Google Scholar] [CrossRef]

- Chen, J.; de Liedekerke Beaufort, M.; Gyurik, L.; Dorresteijn, J.; Otte, M.; Gebbink, R.J.K. Highly efficient epoxidation of vegetable oils catalyzed by a manganese complex with hydrogen peroxide and acetic acid. Green Chem. 2019, 21, 2436–2447. [Google Scholar] [CrossRef]

- Danov, S.M.; Kazantsev, O.A.; Esipovich, A.L.; Belousov, A.S.; Rogozhin, A.E.; Kanakov, E.A. Recent advances in the field of selective epoxidation of vegetable oils and their derivatives: A review and perspective. Catal. Sci. Technol. 2017, 7, 3659–3675. [Google Scholar] [CrossRef]

- Huang, S.; Wu, H.; Jiang, Z.; Huang, H. Water-based nanosuspensions: Formulation, tribological property, lubrication mechanism, and applications. J. Manuf. Process. 2021, 71, 625–644. [Google Scholar] [CrossRef]

- Aguilar-Rosas, O.; Blanco, S.; Flores, M.; Shirai, K.; Farfan-Cabrera, L.I. Partially deacetylated and fibrillated shrimp waste-derived chitin as biopolymer emulsifier for green cutting fluids—Towards a cleaner production. Polymers 2022, 14, 525. [Google Scholar] [CrossRef]

- Khaled, U.; Beroual, A. AC dielectric strength of mineral oil-based Fe3O4 and al2o3 nanofluids. Energies 2018, 11, 3505. [Google Scholar] [CrossRef]

- Elmunafi, M.H.; Kurniawan, D.; Noordin, M.Y. Use of castor oil as cutting fluid in machining of hardened stainless steel with minimum quantity of lubricant. Procedia CIRP 2015, 26, 408–411. [Google Scholar] [CrossRef]

- Elmunafi, M.H.; Noordin, M.Y.; Kurniawan, D. Tool life of coated carbide cutting tool when turning hardened stainless steel under minimum quantity lubricant using castor oil. Procedia Manuf. 2015, 2, 563–567. [Google Scholar] [CrossRef]

- Talib, N.; Rahim, E.A. Performance evaluation of chemically modified crude jatropha oil as a bio-based metalworking fluids for machining process. Procedia CIRP 2015, 26, 346–350. [Google Scholar] [CrossRef]

- Sani, A.S.A.; Rahim, E.A.; Sharif, S.; Sasahara, H. Machining performance of vegetable oil with phosphonium- and ammonium-based ionic liquids via MQL technique. J. Clean. Prod. 2019, 209, 947–964. [Google Scholar] [CrossRef]

- Nashy, E.S.H.; Megahed, M.G.; El-Ghaffar, M.A.A. Preparation of fat-liquor based on jojoba oil under phase transfer catalysis. J. Am. Oil Chem. Soc. 2011, 88, 1239–1246. [Google Scholar] [CrossRef]

- Fattah, I.M.R.; Kalam, M.A.; Masjuki, H.H.; Wakil, M.A. Biodiesel production, characterization, engine performance, and emission characteristics of Malaysian alexandrian laurel oil. RSC Adv. 2014, 4, 17787–17796. [Google Scholar] [CrossRef]

- Sani, A.S.A.; Baharom, S.; Mamat, N.A.; Rozlan, A.S.M.; Talib, N. Comparative evaluation of Crude Tamanu oil performance as metalworking fluids. Mater. Today Proc. 2022, 48, 1783–1788. [Google Scholar] [CrossRef]

- Hossain, F.; Kosinkova, J.; Brown, R.; Ristovski, Z.; Hankamer, B.; Stephens, E.; Rainey, T. Experimental investigations of physical and chemical properties for microalgae HTL Bio-Crude using a large batch reactor. Energies 2017, 10, 467. [Google Scholar] [CrossRef]

- Melo, J.M.; Ribeiro, M.R.; Telles, T.S.; Amaral, H.F.; Andrade, D.S. Microalgae cultivation in wastewater from agricultural industries to benefit next generation of bioremediation: A bibliometric analysis. Environ. Sci. Pollut. Res. 2022, 29, 22708–22720. [Google Scholar] [CrossRef] [PubMed]

- Andreo-Martínez, P.; Ortiz-Martínez, V.M.; García-Martínez, N.; de los Ríos, A.P.; Hernández-Fernández, F.J.; Quesada-Medina, J. Production of biodiesel under supercritical conditions: State of the art and Bibliometric analysis. Appl. Energy 2020, 264, 114753. [Google Scholar] [CrossRef]

- Rumin, J.; Nicolau, E.; Gonçalves de Oliveira Junior, R.; Fuentes-Grünewald, C.; Flynn, K.J.; Picot, L. A bib-liometric analysis of microalgae research in the world, Europe, and the European Atlantic Area. Mar. Drugs 2020, 18, 79. [Google Scholar] [CrossRef] [PubMed]

- Miranda, A.M.; Hernandez-Tenorio, F.; Ocampo, D.; Vargas, G.J.; Sáez, A.A. Trends on CO2 capture with microalgae: A bibliometric analysis. Molecules 2022, 27, 4669. [Google Scholar] [CrossRef] [PubMed]

- Sales, M.B.; Borges, P.T.; Filho, M.N.R.; da Silva, L.R.M.; Castro, A.P.; Lopes, A.A.S.; de Lima, R.K.C.; de Sousa Rios, M.A.; Santos, J.C. Sustainable feedstocks and challenges in biodiesel production: An advanced bibliometric analysis. Bioengineering 2022, 9, 539. [Google Scholar] [CrossRef]

- ExxonMobil. Advanced Biofuels and Algae Research. 2022. Available online: https://corporate.exxonmobil.com/Climatesolutions/Advanced-biofuels/Advanced-biofuels-and-algae-research (accessed on 7 March 2023).

- Li-Beisson, N.Y.; Harwood, J. Lipids: From Chemical Structures, Biosynthesis, and Analyses to Industrial Applications. In Lipids in Plant and Algae Development; Nakamura, Y., Li-Beisson, N.Y., Eds.; Springer International Publishing: Cham, Switzerland, 2016; Volume 86, ISBN 978-3-319-25977-2. [Google Scholar]

- Abida, H.; Dolch, L.-J.; Meï, C.; Villanova, V.; Conte, M.; Block, M.A.; Finazzi, G.; Bastien, O.; Tirichine, L.; Bowler, C.; et al. Membrane glycerolipid remodeling triggered by nitrogen and phosphorus starvation inphaeodactylum tricornutum. Plant Physiol. 2014, 167, 118–136. [Google Scholar] [CrossRef]

- Khozin-Goldberg, I.; Cohen, Z. The effect of phosphate starvation on the lipid and fatty acid composition of the Fresh Water Eustigmatophyte Monodus subterraneus. Phytochemistry 2006, 67, 696–701. [Google Scholar] [CrossRef]

- Sun, X.-M.; Geng, L.-J.; Ren, L.-J.; Ji, X.-J.; Hao, N.; Chen, K.-Q.; Huang, H. Influence of oxygen on the bio-synthesis of polyunsaturated fatty acids in Microalgae. Bioresour. Technol. 2018, 250, 868–876. [Google Scholar] [CrossRef]

- Kitaya, Y.; Azuma, H.; Kiyota, M. Effects of temperature, CO2/O2 concentrations and light intensity on cellular multiplication of microalgae, Euglena gracilis. Adv. Space Res. 2005, 35, 1584–1588. [Google Scholar] [CrossRef]

- Liu, J.; Yuan, C.; Hu, G.; Li, F. Effects of light intensity on the growth and lipid accumulation of Microalga Scenedesmus sp. 11-1 under nitrogen limitation. Appl. Biochem. Biotechnol. 2012, 166, 2127–2137. [Google Scholar] [CrossRef]

- Che, C.A.; Kim, S.H.; Hong, H.J.; Kityo, M.K.; Sunwoo, I.Y.; Jeong, G.-T.; Kim, S.-K. Optimization of light intensity and photoperiod for Isochrysis galbana culture to improve the biomass and lipid production using 14-L pho-tobioreactors with mixed light emitting diodes (leds) wavelength under two-phase culture system. Bioresour. Technol. 2019, 285, 121323. [Google Scholar] [CrossRef]

- Chen, B.; Wan, C.; Mehmood, M.A.; Chang, J.-S.; Bai, F.; Zhao, X. Manipulating environmental stresses and stress tolerance of microalgae for enhanced production of lipids and value-added products—A Review. Bioresour. Technol. 2017, 244, 1198–1206. [Google Scholar] [CrossRef]

- Xia, L.; Rong, J.; Yang, H.; He, Q.; Zhang, D.; Hu, C. NaCl as an effective inducer for lipid accumulation in freshwater microalgae Desmodesmus Abundans. Bioresour. Technol. 2014, 161, 402–409. [Google Scholar] [CrossRef]

- Wang, T.; Ge, H.; Liu, T.; Tian, X.; Wang, Z.; Guo, M.; Chu, J.; Zhuang, Y. Salt stress induced lipid accumulation in heterotrophic culture cells of chlorella protothecoides: Mechanisms based on the multi-level analysis of oxidative response, key enzyme activity and biochemical alteration. J. Biotechnol. 2016, 228, 18–27. [Google Scholar] [CrossRef]

- Yuan, W.; Ma, Y.; Wei, W.; Liu, W.; Ding, Y.; Balamurugan, S. Sequential treatment with bicarbonate and low-temperature to potentiate both biomass and lipid productivity in nannochloropsis oceanica. J. Chem. Technol. Biotechnol. 2019, 94, 3413–3419. [Google Scholar] [CrossRef]

- Park, S.; Nguyen, T.H.; Jin, E.S. Improving lipid production by strain development in microalgae: Strategies, challenges and Perspectives. Bioresour. Technol. 2019, 292, 121953. [Google Scholar] [CrossRef]

- Ashour, M.; Omran, A.M. Recent advances in marine microalgae production: Highlighting human health products from microalgae in view of the coronavirus pandemic (COVID-19). Fermentation 2022, 8, 466. [Google Scholar] [CrossRef]

- Cabanelas, I.T.; Marques, S.S.; de Souza, C.O.; Druzian, J.I.; Nascimento, I.A. Botryococcus, what to do with it? effect of nutrient concentration on biorefinery potential. Algal Res. 2015, 11, 43–49. [Google Scholar] [CrossRef]

- Hempel, N.; Petrick, I.; Behrendt, F. Biomass productivity and productivity of fatty acids and amino acids of microalgae strains as key characteristics of suitability for biodiesel production. J. Appl. Phycol. 2012, 24, 1407–1418. [Google Scholar] [CrossRef]

- Guo, D.-S.; Ji, X.-J.; Ren, L.-J.; Li, G.-L.; Huang, H. Improving docosahexaenoic acid production by schizo-chytrium sp. using a newly designed high-oxygen-supply bioreactor. AIChE J. 2017, 63, 4278–4286. [Google Scholar] [CrossRef]

- Ren, L.-J.; Ji, X.-J.; Huang, H.; Qu, L.; Feng, Y.; Tong, Q.-Q.; Ouyang, P.-K. Development of a stepwise aeration control strategy for efficient docosahexaenoic acid production by schizochytrium SP. Appl. Microbiol. Bio-Technol. 2010, 87, 1649–1656. [Google Scholar] [CrossRef] [PubMed]

- Ren, L.-J.; Sun, L.-N.; Zhuang, X.-Y.; Qu, L.; Ji, X.-J.; Huang, H. Regulation of docosahexaenoic acid production by Schizochytrium sp.: Effect of nitrogen addition. Bioprocess Biosyst. Eng. 2013, 37, 865–872. [Google Scholar] [CrossRef] [PubMed]

- Meiser, A.; Schmid-Staiger, U.; Trösch, W. Optimization of eicosapentaenoic acid production by Phaeodacty-lum tricornutum in the flat panel airlift (FPA) reactor. J. Appl. Phycol. 2004, 16, 215–225. [Google Scholar] [CrossRef]

- Mirzaie, M.A.M.; Kalbasi, M.; Ghobadian, B.; Mousavi, S.M. Kinetic modeling of mixotrophic growth of Chlorella vulgaris as a new feedstock for biolubricant. J. Appl. Phycol. 2016, 28, 2707–2717. [Google Scholar] [CrossRef]

- Da Silva, A.P.; Bredda, E.H.; de Castro, H.F.; Da Rós, P.C.M. Enzymatic catalysis: An environmentally friendly method to enhance the transesterification of microalgal oil with fusel oil for production of fatty acid esters with potential application as biolubricants. Fuel 2020, 273, 117786. [Google Scholar] [CrossRef]

- Bredda, E.H.; Silva, M.B.; Castro, H.F.; Silva, A.P.; Rós, P.C. Microalgae as a source of functional pufas: A green low-cost pathway via enzymatic hydrolysis. J. Adv. Biol. Biotechnol. 2019, 20, 1–13. [Google Scholar] [CrossRef]

- Serejo, M.L.; Morgado, M.F.; García, D.; González-Sánchez, A.; Méndez-Acosta, H.O.; Toledo-Cervantes, A. Environmental resilience by Microalgae. In Microalgae Cultivation for Biofuels Production; Academic Press: Cambridge, MA, USA, 2020; pp. 293–315. [Google Scholar] [CrossRef]

- Markou, G.; Wang, L.; Ye, J.; Unc, A. Using agro-industrial wastes for the cultivation of microalgae and duckweeds: Contamination risks and biomass safety concerns. Biotechnol. Adv. 2018, 36, 1238–1254. [Google Scholar] [CrossRef]

- Udaiyappan, A.F.M.; Abu Hasan, H.; Takriff, M.S.; Abdullah, S.R.S. A review of the potentials, challenges and current status of microalgae biomass applications in industrial wastewater treatment. J. Water Process Eng. 2017, 20, 8–21. [Google Scholar] [CrossRef]

- Yin, Z.; Zhu, L.; Li, S.; Hu, T.; Chu, R.; Mo, F.; Hu, D.; Liu, C.; Li, B. A comprehensive review on cultivation and harvesting of microalgae for biodiesel production: Environmental Pollution Control and Future Directions. Bioresour. Technol. 2020, 301, 122804. [Google Scholar] [CrossRef]

| Oil | Main Physicochemical Properties | Advantages | Reference | ||||

|---|---|---|---|---|---|---|---|

| Density (g/mL) | Viscosity at 40 °C (mm2/s) | Viscosity Index | Pour Point (°C) | Flash Point (°C) | |||

| Mineral oil | 0.85 | 9 | 90–100 | −40 | 150 | - | [58] |

| Castor oil | 0.970 | 249.8 | 85 | −31 | 260 | In contrast to dry cutting, castor oil achieved better performance in MQL in terms of lubrication, tool life, cooling ability and surface roughness. | [1,59,60] |

| Jatropha oil | 0.917 | 36.97 | 186 | −3 | 273 | It exhibited excellent lubrication properties as cutting fluids. | [1,61,62] |

| Jojoba oil | 0.849 | 21.8 | 242 | 9 | 295 | Applying Jojoba oil as machining fluids helped to enhance surface finishing. | [1,63] |

| Neem oil | 0.910 | 48.32 | 40 | 7 | 250 | Neem oil was found to be an effective alternative as mineral oil-based coolant as it provides better results in terms of cutting force reduction, also ensures hazard-free environment at machining area. | [1,17] |

| Callophyllum Inophyllum oil | 0.896 | 53.136 | 159.2 | 8 | 218.5 | It was found to exhibit almost similar cutting forces and chips quality than synthetic ester, crude jatropha oil and refined bleached and deodorized palm olein. | [64,65] |

| Microalgae oil (Scenedesmus sp. Biocrude Oil) | 0.97 | 70.7–73.8 | - | - | - | - | [66] |

| Microalgae Strain | Fatty Acids | Main Lubricant Properties * | Reference | |||

|---|---|---|---|---|---|---|

| Lubricity | Viscosity | Pour Point | Oxidation Stability | |||

| B. braunii (UTEX LB 572) | MUFA (C:18) | ✓✓✓ | ✓✓ | ✓ | ✓✓✓ | [86] |

| B. braunii (IBL-C117) | MUFA (C:22) | ✓✓✓ | ✓✓✓ | ✓ | ✓✓✓ | [86] |

| B. terribilis (IBL-C115) | MUFA (C:18) | ✓✓✓ | ✓✓ | ✓ | ✓✓✓ | [86] |

| Chlorella sp. 800 | MUFA/PUFA (C:18) | ✓✓ | ✓✓ | ✓✓ | ✓✓ | [86] |

| Chlorella saccharophila 477 | PUFA (C:18) | ✓ | ✓ | ✓✓✓ | ✓ | [86] |

| Chlorella minutissima 494 | PUFA (C:18) | ✓ | ✓ | ✓✓✓ | ✓ | [86] |

| Chlorella sp. 313 | PUFA (C:18) | ✓ | ✓ | ✓✓✓ | ✓ | [86] |

| Chlorella minutissima 444 | PUFA (C:18) | ✓ | ✓ | ✓✓✓ | ✓ | [86] |

| Schizochytrium sp. | PUFA (C:22) | ✓ | ✓ | ✓✓✓ | ✓ | [87,88] |

| Schizochytrium sp. HX-308 | PUFA (C:22) | ✓ | ✓ | ✓✓✓ | ✓ | [89,90] |

| Phaeodactylum tricornutum | PUFA (C:20) | ✓ | ✓ | ✓✓✓ | ✓ | [91] |

| Chlorella vulgaris | MUFA (C:16) | ✓✓✓ | ✓✓ | ✓ | ✓✓✓ | [92] |

| Dunaliella salina | MUFA (C:18) | ✓✓✓ | ✓✓ | ✓ | ✓✓✓ | [93] |

| Nannochloropsis gaditana | SFA (C:18) | ✓✓✓ | ✓✓ | ✓ | ✓✓✓ | [94] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farfan-Cabrera, L.I.; Rojo-Valerio, A.; Calderon-Najera, J.d.D.; Coronado-Apodaca, K.G.; Iqbal, H.M.N.; Parra-Saldivar, R.; Franco-Morgado, M.; Elias-Zuñiga, A. Microalgae Oil-Based Metal Working Fluids for Sustainable Minimum Quantity Lubrication (MQL) Operations—A Perspective. Lubricants 2023, 11, 215. https://doi.org/10.3390/lubricants11050215

Farfan-Cabrera LI, Rojo-Valerio A, Calderon-Najera JdD, Coronado-Apodaca KG, Iqbal HMN, Parra-Saldivar R, Franco-Morgado M, Elias-Zuñiga A. Microalgae Oil-Based Metal Working Fluids for Sustainable Minimum Quantity Lubrication (MQL) Operations—A Perspective. Lubricants. 2023; 11(5):215. https://doi.org/10.3390/lubricants11050215

Chicago/Turabian StyleFarfan-Cabrera, Leonardo I., Alejandro Rojo-Valerio, Juan de Dios Calderon-Najera, Karina G. Coronado-Apodaca, Hafiz M. N. Iqbal, Roberto Parra-Saldivar, Mariana Franco-Morgado, and Alex Elias-Zuñiga. 2023. "Microalgae Oil-Based Metal Working Fluids for Sustainable Minimum Quantity Lubrication (MQL) Operations—A Perspective" Lubricants 11, no. 5: 215. https://doi.org/10.3390/lubricants11050215

APA StyleFarfan-Cabrera, L. I., Rojo-Valerio, A., Calderon-Najera, J. d. D., Coronado-Apodaca, K. G., Iqbal, H. M. N., Parra-Saldivar, R., Franco-Morgado, M., & Elias-Zuñiga, A. (2023). Microalgae Oil-Based Metal Working Fluids for Sustainable Minimum Quantity Lubrication (MQL) Operations—A Perspective. Lubricants, 11(5), 215. https://doi.org/10.3390/lubricants11050215