A Multi-Scale Investigation to Predict the Dynamic Instabilities Induced by Frictional Contact

Abstract

1. Introduction

2. Governing Equation

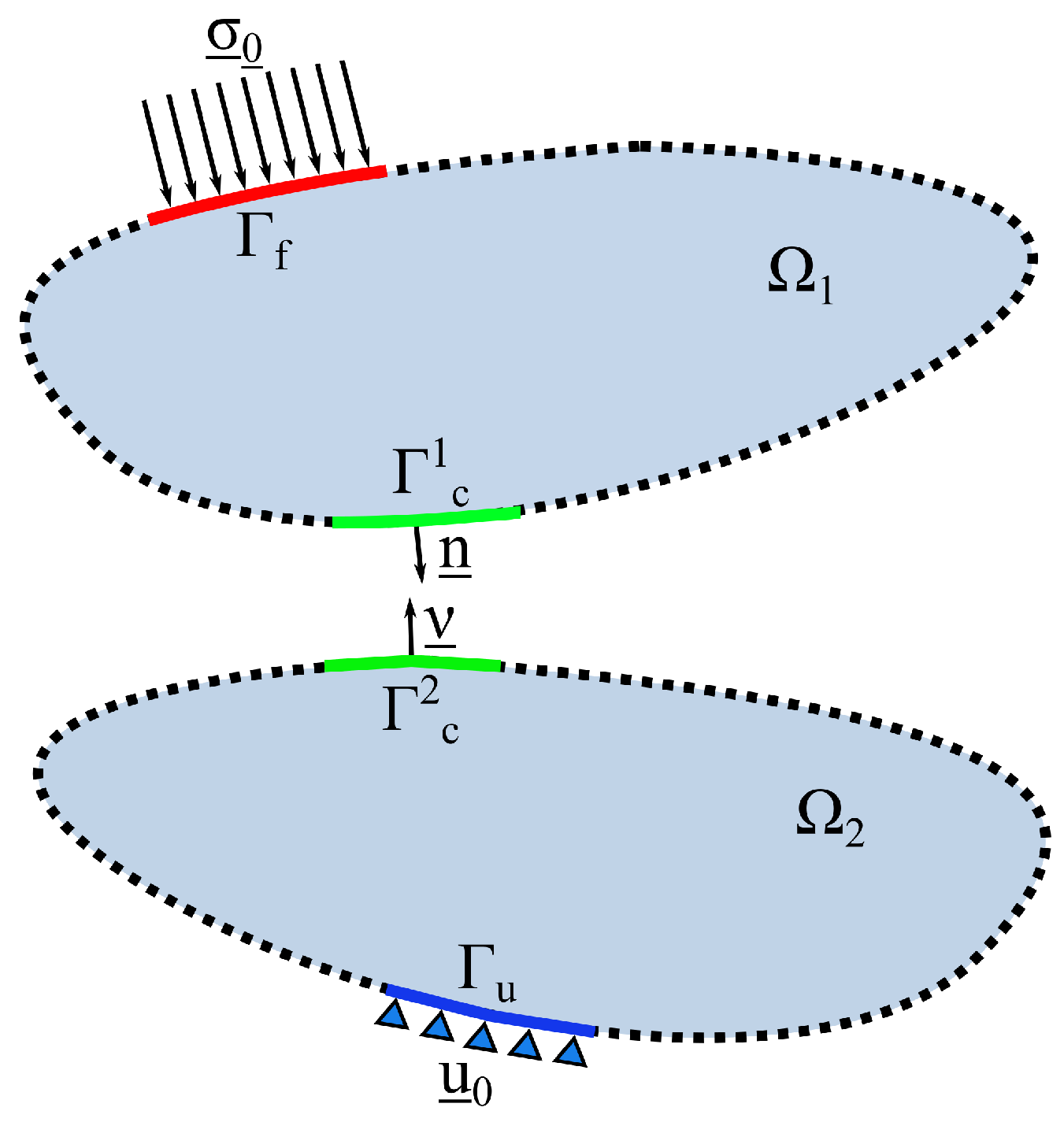

2.1. General Framework

- static balance of momentum equation,

- compatibility equations,

- constitutive relation,where is the Cauchy stress tensor and is the so-called small strain tensor, which is related to the displacement field . and are the stress and the displacement field imposed on the boundaries and , respectively. is the Hook fourth-order tensor for the considered domain.

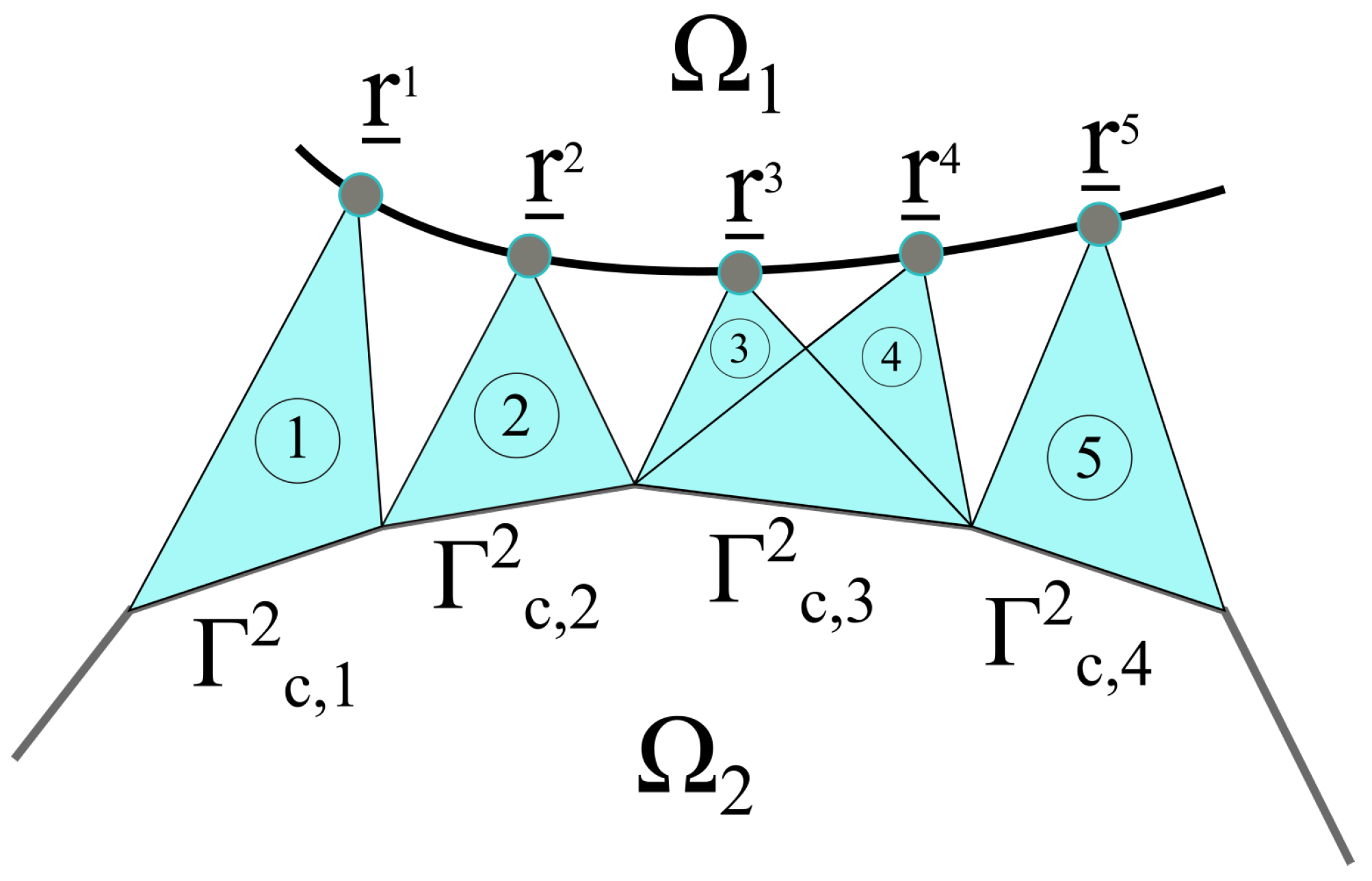

2.2. Variation Formulation of the Frictionless Contact Problem

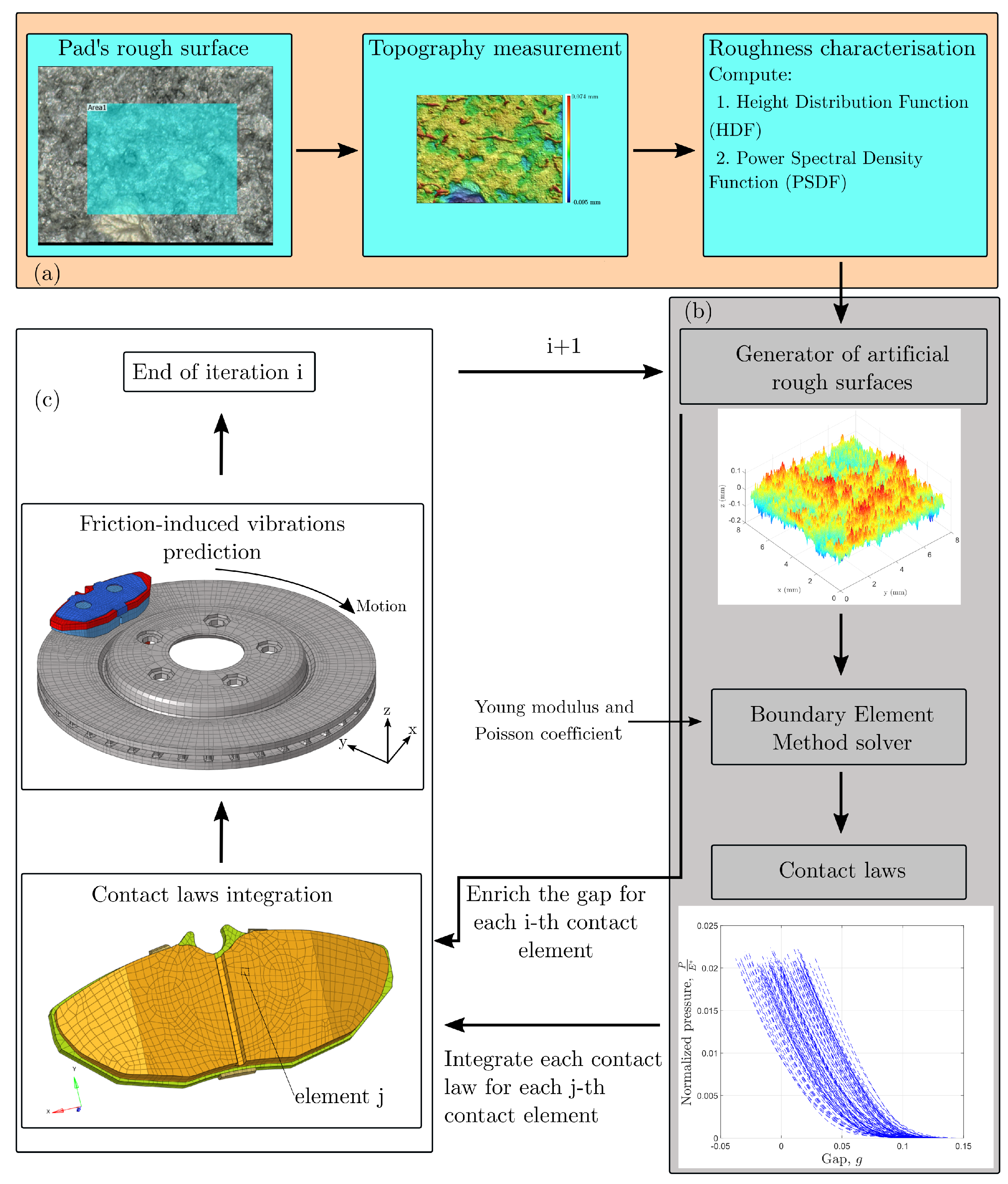

2.3. Overview of the Embedded Computational Strategy to Include the Roughness on Macro-Scale Model

3. Application to a Disc Brake System

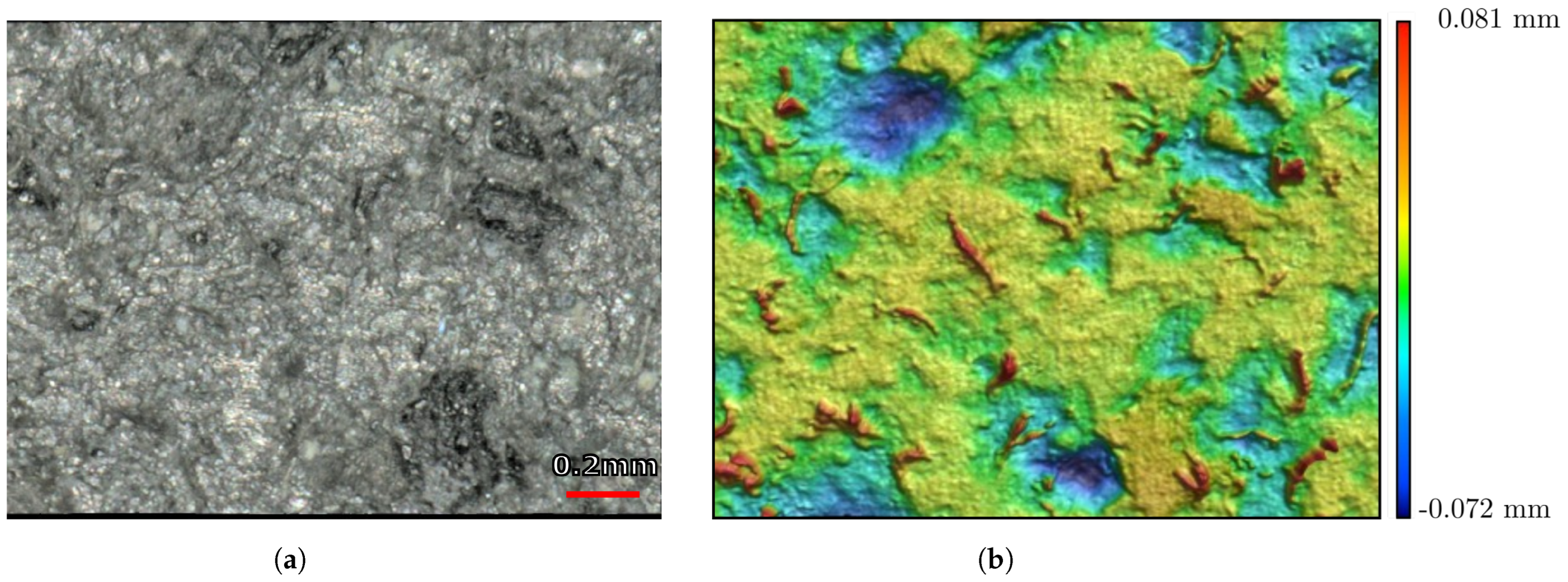

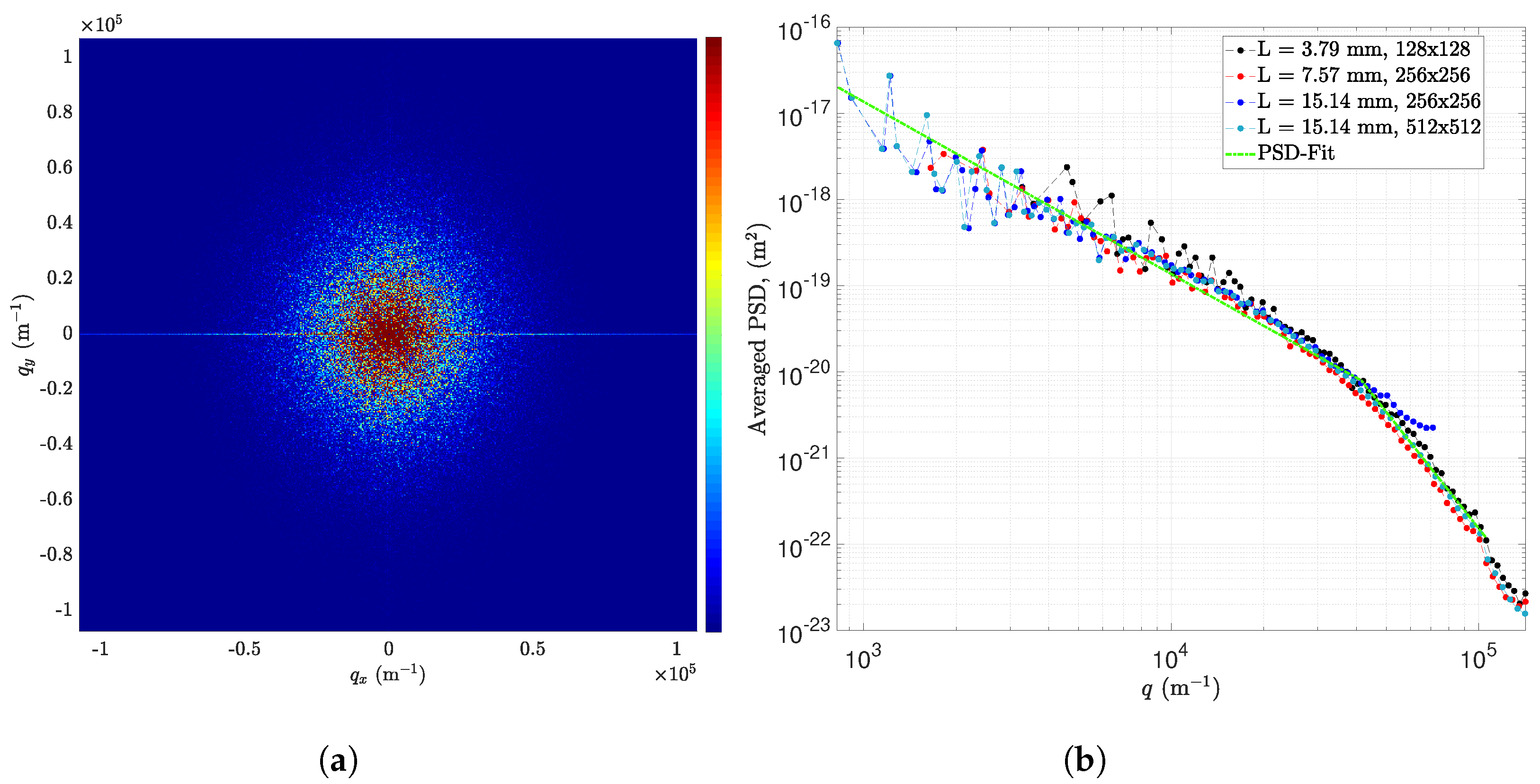

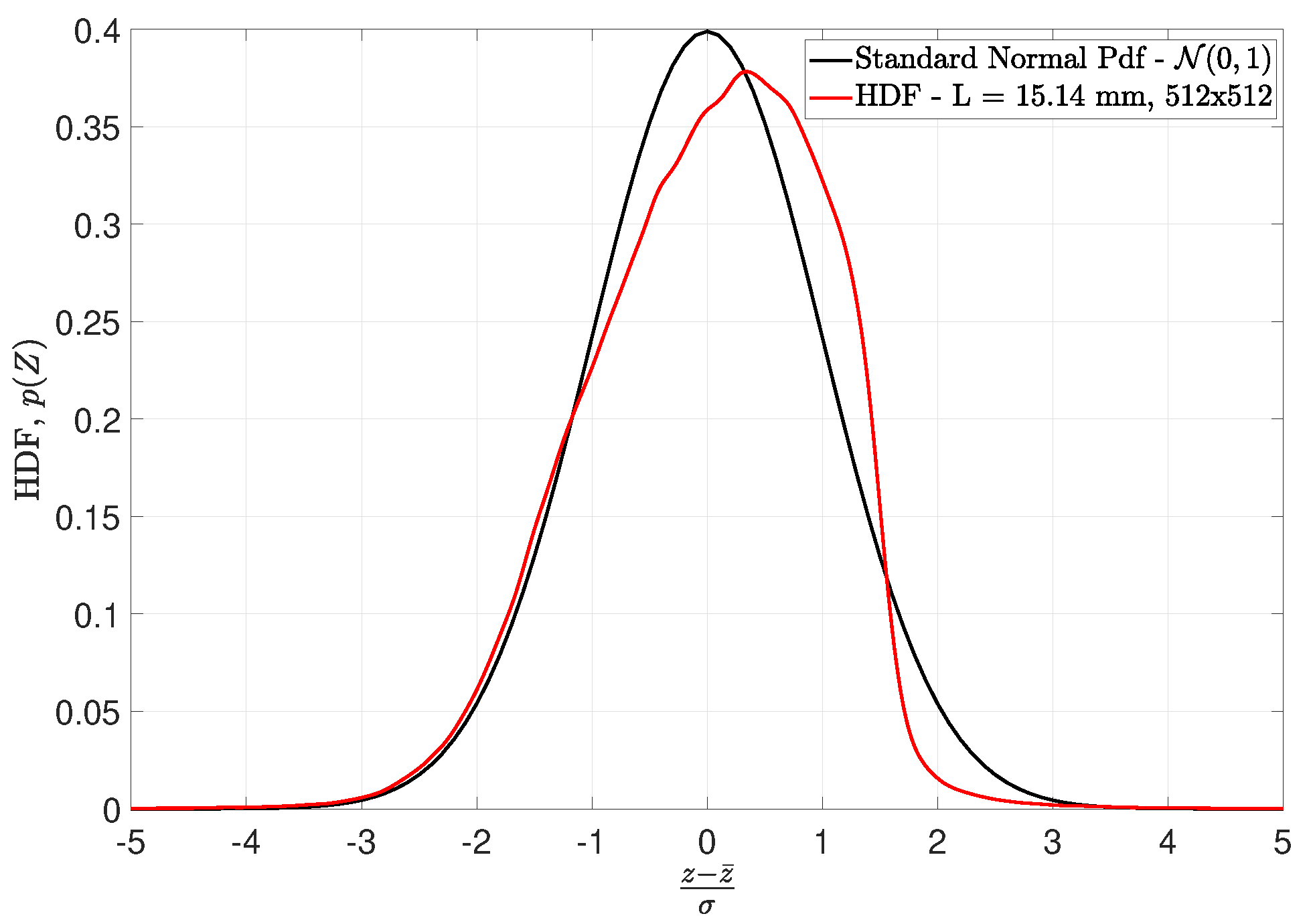

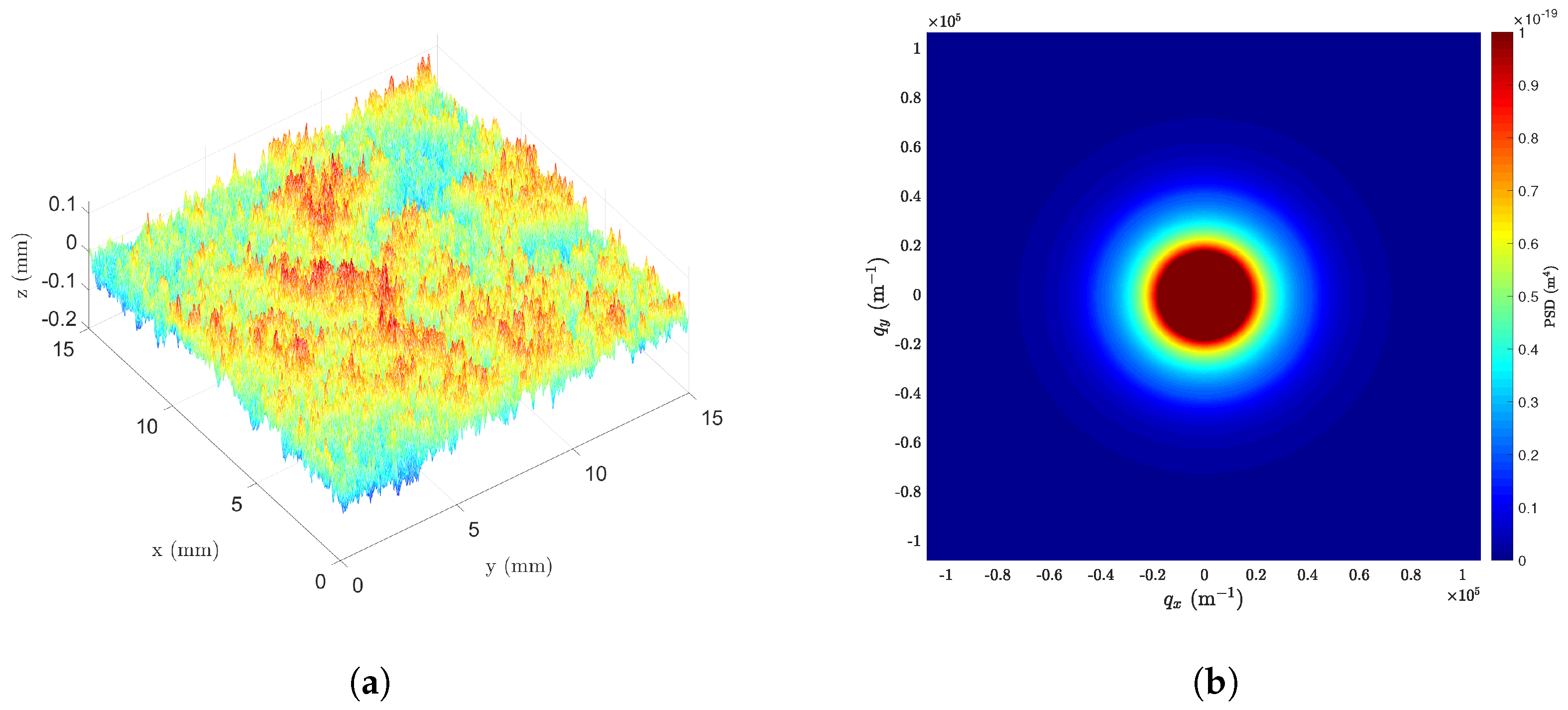

3.1. Pad Surface Characterization

3.2. Contact Law of Pad/Disc Interfaces

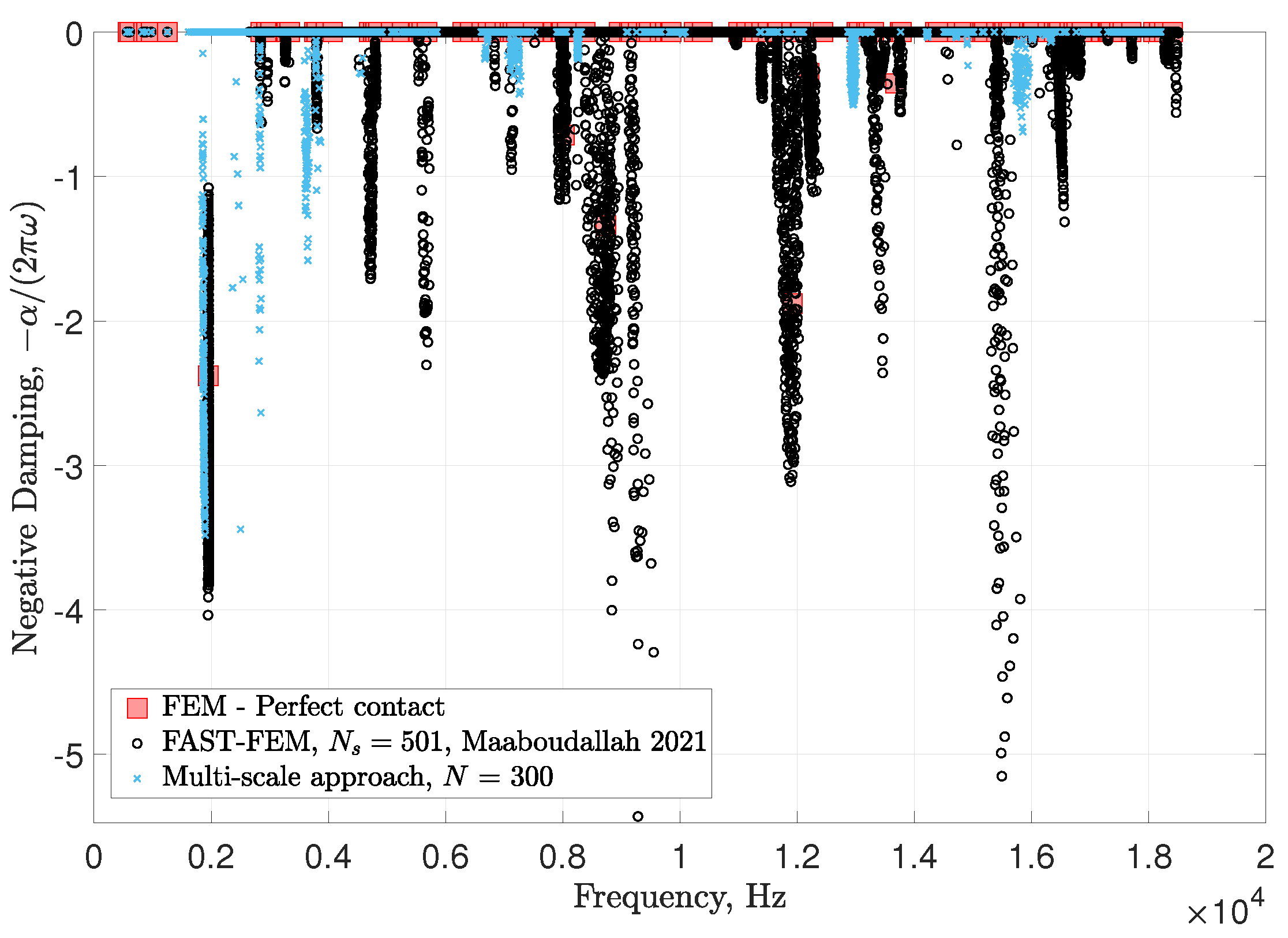

3.3. Application to Dynamic Instabilities Prediction

- 1.

- Artificial rough surface generation: The purpose of this step is to use the characterized HDF and PSD to generate a batch of artificial rough surfaces similar to the measured topography.

- 2.

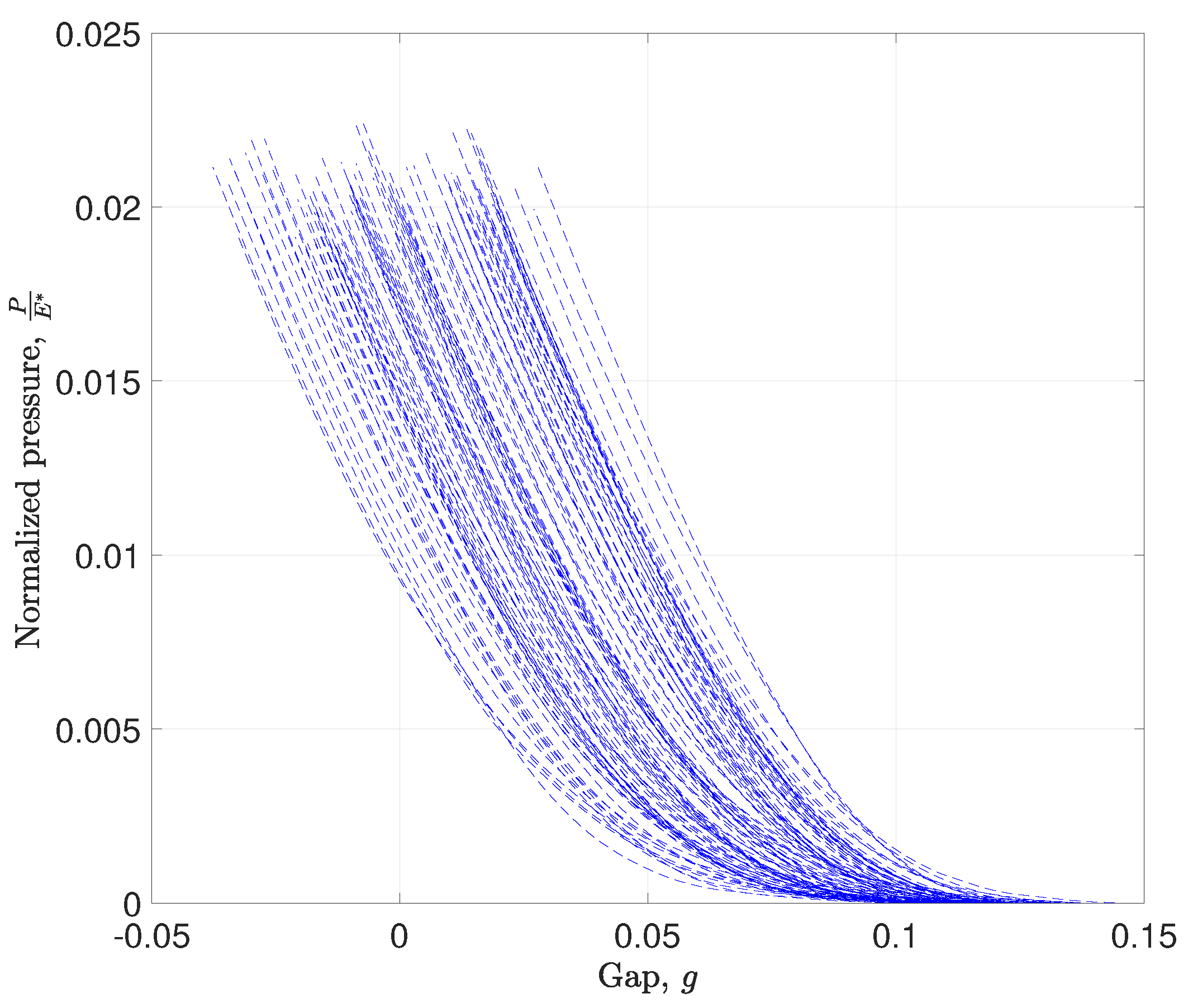

- Micro-scale contact simulations: Here, BEM solver introduced in [38,50] is used to solve the elastic contact problem considering artificial surface asperities and a rigid half-plane. The resolution is performed on the whole batch of the generated rough surfaces. Solving the micro-scale contact problem minimizes the convex quadratic program (QP) (see Equation (50) in [38]). The obtained results are the contact load (or the contact pressure) and the separation between the two contacting bodies.

- 3.

- Enrichment of the contact element: The objective of the third step is to assign each micro-scale contact law (obtained in the second step) to each flat patch (i.e., contact element). Moreover, the gap between slave and master nodes of the macro-scale FE model (disc brake system FE model) is modified by adding a threshold to each gap in order to activate the contact elements in a non-uniform manner. As mentioned above, the added threshold depends closely on the measured HDF.

- 4.

- Complex eigenvalues analysis: At this stage, the traditional CEA is performed. The beginning of the last step starts with a quasi-static analysis. Its goal is to solve, progressively as the load increases, the frictional contact using the enriched contact elements. At the end of this step, the well-known complex modal analysis is performed to compute both complex eigenvalues and eigenvectors and identify the unstable modes (those with negative damping). For more details, see Section 2.1 in [4].

4. Conclusions

- 1.

- Roughness characterization using the power spectral density function and the height distribution function;

- 2.

- Micro-scale contact simulations on the characterization roughness using the boundary element method;

- 3.

- Enrichment of the contact finite element using (i) the micro-scale contact laws (obtained from BEM) and (ii) the modified gap functions (obtained from HDF);

- 4.

- Performing the complex eigenvalue analysis on the updated stiffness matrix.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| HDF | height distribution function |

| ACF | autocorrelation function |

| PSD | power spectral density |

| FEM | finite element method |

| BEM | boundary element method |

| GFMD | Green’s function molecular dynamics |

| RVE | representative volume element |

| CEA | complex eigenvalues analysis |

| N2S | Node-to-Surface |

| CLSM | confocal laser scanning microscopy |

| RV | random variable |

| RMS | root mean square |

| FAST | Fourier sensitivity amplitude test |

References

- Sun, S.; Li, L.; Yue, Z.; Yang, W.; Zhao, Z.; Cao, R.; Li, S. Experimental and numerical investigation on fretting fatigue behavior of Nickel-based single crystal superalloy at high temperature. Mech. Mater. 2020, 150, 103595. [Google Scholar] [CrossRef]

- Yastrebov, V.A.; Durand, J.; Proudhon, H.; Cailletaud, G. Rough surface contact analysis by means of the Finite Element Method and of a new reduced model. Comptes Rendus Mécanique 2011, 339, 473–490. [Google Scholar] [CrossRef]

- Tison, T.; Heussaff, A.; Massa, F.; Turpin, I.; Nunes, R.F. Improvement in the predictivity of squeal simulations: Uncertainty and robustness. J. Sound Vib. 2014, 333, 3394–3412. [Google Scholar] [CrossRef]

- Maaboudallah, F.; Atalla, N. An efficient numerical strategy to predict the dynamic instabilities of a rubbing system: Application to an automobile disc brake system. Comput. Mech. 2021, 67, 1465–1483. [Google Scholar] [CrossRef]

- Maaboudallah, F.; Atalla, N. A “data-driven uncertainty” computational method to model and predict instabilities of a frictional system. Adv. Model. Simul. Eng. Sci. 2023, 10, 3. [Google Scholar] [CrossRef]

- Zhou, Q.; Luo, D.; Hua, D.; Ye, W.; Li, S.; Zou, Q.; Chen, Z.; Wang, H. Design and characterization of metallic glass/graphene multilayer with excellent nanowear properties. Friction 2022, 10, 1913–1926. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, Z.; Wang, Y.; Zhou, Q.; Yang, T.; Li, Q.; Jia, Q.; Wang, H. Friction-induced rapid amorphization in a wear-resistant (CoCrNi)88Mo12 dual-phase medium-entropy alloy at cryogenic temperature. Compos. Part B Eng. 2023, 263, 110833. [Google Scholar] [CrossRef]

- Hetzler, H.; Willner, K. On the influence of contact tribology on brake squeal. Tribol. Int. 2012, 46, 237–246. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.B.P.; Bowden, F.P. Contact of nominally flat surfaces. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Nayak, P.R. Random Process Model of Rough Surfaces. J. Lubr. Technol. 1971, 93, 398–407. [Google Scholar] [CrossRef]

- Abbott, E.J.; Firestone, F.A. Specifying Surface Quality—A Method Based on Accurate Measurement and Comparison. J. Mech. Eng. 1933, 55, 569–572. [Google Scholar]

- Bhushan, B. Solid Surface Characterization. In Introduction to Tribology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; Chapter 2; pp. 9–89. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Albohr, O.; Tartaglino, U.; Volokitin, A.I.; Tosatti, E. On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter 2004, 17, R1–R62. [Google Scholar] [CrossRef]

- Persson, B.N.J. Contact mechanics for randomly rough surfaces. Surf. Sci. Rep. 2006, 61, 201–227. [Google Scholar] [CrossRef]

- Majumdar, A.; Bhushan, B. Fractal Model of Elastic-Plastic Contact Between Rough Surfaces. J. Tribol. 1991, 113, 1–11. [Google Scholar] [CrossRef]

- Dodds, C.J.; Robson, J.D. The description of road surface roughness. J. Sound Vib. 1973, 31, 175–183. [Google Scholar] [CrossRef]

- Majumdar, A.; Tien, C.L. Fractal characterization and simulation of rough surfaces. Wear 1990, 136, 313–327. [Google Scholar] [CrossRef]

- Najah, M.; Maaboudallah, F.; Boucherit, M.; Ferguson, M.; Fréchette, L.; Charlebois, S.; Boone, F.; Ecoffey, S. Spectral analysis of the topography parameters for isotropic Gaussian rough surfaces applied to gold coating. Tribol. Int. 2022, 165, 107339. [Google Scholar] [CrossRef]

- Hertz, H. Ueber die Berührung fester elastischer Körper. J. Für Die Reine Und Angew. Math. 1882, 1882, 156–171. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar] [CrossRef]

- Archard, J.F.; Allibone, T.E. Elastic deformation and the laws of friction. Proc. R. Soc. London. Ser. A. Math. Phys. Sci. 1957, 243, 190–205. [Google Scholar] [CrossRef]

- Longuet-Higgins, M.S.; Deacon, G.E.R. Statistical properties of an isotropic random surface. Philos. Trans. R. Soc. London. Ser. Math. Phys. Sci. 1957, 250, 157–174. [Google Scholar] [CrossRef]

- Yastrebov, V.A.; Anciaux, G.; Molinari, J.F. The role of the roughness spectral breadth in elastic contact of rough surfaces. J. Mech. Phys. Solids 2017, 107, 469–493. [Google Scholar] [CrossRef]

- Ciavarella, M.; Delfine, V.; Demelio, G. A “re-vitalized” Greenwood and Williamson model of elastic contact between fractal surfaces. J. Mech. Phys. Solids 2006, 54, 2569–2591. [Google Scholar] [CrossRef]

- Ciavarella, M.; Greenwood, J.A.; Paggi, M. Inclusion of “interaction” in the Greenwood and Williamson contact theory. Wear 2008, 265, 729–734. [Google Scholar] [CrossRef]

- Paggi, M.; Ciavarella, M. The coefficient of proportionality κ between real contact area and load, with new asperity models. Wear 2010, 268, 1020–1029. [Google Scholar] [CrossRef]

- Zhang, S.; Song, H.; Sandfeld, S.; Liu, X.; Wei, Y.G. Discrete GreenwoodWilliamson Modeling of Rough Surface Contact Accounting for Three-Dimensional Sinusoidal Asperities and Asperity Interaction. J. Tribol. 2019, 141, 121401. [Google Scholar] [CrossRef]

- Afferrante, L.; Carbone, G.; Demelio, G. Interacting and coalescing Hertzian asperities: A new multiasperity contact model. Wear 2012, 278–279, 28–33. [Google Scholar] [CrossRef]

- Persson, B.N.J. Theory of rubber friction and contact mechanics. J. Chem. Phys. 2001, 115, 3840–3861. [Google Scholar] [CrossRef]

- Hyun, S.; Pei, L.; Molinari, J.F.; Robbins, M.O. Finite-element analysis of contact between elastic self-affine surfaces. Phys. Rev. E 2004, 70, 026117. [Google Scholar] [CrossRef]

- Yang, C.; Persson, B.N.J. Contact mechanics: Contact area and interfacial separation from small contact to full contact. J. Phys. Condens. Matter 2008, 20, 215214. [Google Scholar] [CrossRef]

- Yastrebov, V.A.; Anciaux, G.; Molinari, J.F. From infinitesimal to full contact between rough surfaces: Evolution of the contact area. Int. J. Solids Struct. 2015, 52, 83–102. [Google Scholar] [CrossRef]

- Polonsky, I.A.; Keer, L.M. A numerical method for solving rough contact problems based on the multi-level multi-summation and conjugate gradient techniques. Wear 1999, 231, 206–219. [Google Scholar] [CrossRef]

- Campañá, C.; Müser, M.H. Practical Green’s function approach to the simulation of elastic semi-infinite solids. Phys. Rev. B 2006, 74, 075420. [Google Scholar] [CrossRef]

- Campañá, C.; Müser, M.H. Contact mechanics of real vs. randomly rough surfaces: A Green’s function molecular dynamics study. Europhys. Lett. Assoc. 2007, 77, 38005. [Google Scholar] [CrossRef]

- Wriggers, P. Finite element algorithms for contact problems. Arch. Comput. Methods Eng. 1995, 2, 1–49. [Google Scholar] [CrossRef]

- Yastrebov, V.A. Numerical Methods in Contact Mechanics, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Maaboudallah, F.; Najah, M.; Atalla, N. A Review on the Contact Mechanics Modeling of Rough Surfaces in the Elastic Regime: Fundamentals, Theories, and Numerical Implementations; IntechOpen: Rijeka, Croatia, 2022; Chapter 5. [Google Scholar] [CrossRef]

- Wriggers, P.; Reinelt, J. Multi-scale approach for frictional contact of elastomers on rough rigid surfaces. Comput. Methods Appl. Mech. Eng. 2009, 198, 1996–2008. [Google Scholar] [CrossRef]

- Wriggers, P.; Nettingsmeier, J. Homogenization and Multi-Scale Approaches for Contact Problems. In Computational Contact Mechanics; Wriggers, P., Laursen, T.A., Eds.; CISM International Centre for Mechanical Sciences; Springer: Berlin/Heidelberg, Germany, 2007; pp. 129–161. [Google Scholar] [CrossRef]

- Waddad, Y.; Magnier, V.; Dufrénoy, P.; De Saxcé, G. A multiscale method for frictionless contact mechanics of rough surfaces. Tribol. Int. 2016, 96, 109–121. [Google Scholar] [CrossRef]

- Bonari, J.; Marulli, M.R.; Hagmeyer, N.; Mayr, M.; Popp, A.; Paggi, M. A multi-scale FEM-BEM formulation for contact mechanics between rough surfaces. Comput. Mech. 2020, 65, 731–749. [Google Scholar] [CrossRef]

- Paggi, M.; Reinoso, J. A variational approach with embedded roughness for adhesive contact problems. Mech. Adv. Mater. Struct. 2020, 27, 1731–1747. [Google Scholar] [CrossRef]

- Renault, A.; Massa, F.; Lallemand, B.; Tison, T. Experimental investigations for uncertainty quantification in brake squeal analysis. J. Sound Vib. 2016, 367, 37–55. [Google Scholar] [CrossRef]

- Fenton, G.A.; Griffiths, D. Random Field Generation and the Local Average Subdivision Method. In Probabilistic Methods in Geotechnical Engineering; Griffiths, D.V., Fenton, G.A., Eds.; CISM Courses and Lectures; Springer: Vienna, Austria, 2007; pp. 201–223. [Google Scholar]

- Li, C.C.; Der Kiureghian, A. Optimal Discretization of Random Fields. J. Eng. Mech. 1993, 119, 1136–1154. [Google Scholar] [CrossRef]

- Zhang, Z.; Oberst, S.; Lai, J.C.S. On the potential of uncertainty analysis for prediction of brake squeal propensity. J. Sound Vib. 2016, 377, 123–132. [Google Scholar] [CrossRef]

- Magnier, V.; Brunel, J.F.; Dufrénoy, P. Impact of contact stiffness heterogeneities on friction-induced vibration. Int. J. Solids Struct. 2014, 51, 1662–1669. [Google Scholar] [CrossRef]

- Maaboudallah, F.; Atalla, N. Beyond the main order sensitivity analysis for a frictional system: Is the eXtended FAST algorithm applicable? Nonlinear Dyn. 2022, 111, 5593–5614. [Google Scholar] [CrossRef]

- Bemporad, A.; Paggi, M. Optimization algorithms for the solution of the frictionless normal contact between rough surfaces. Int. J. Solids Struct. 2015, 69–70, 94–105. [Google Scholar] [CrossRef]

- Borri, C.; Paggi, M. Topology simulation and contact mechanics of bifractal rough surfaces. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 1345–1358. [Google Scholar] [CrossRef]

- Wu, J.J. Simulation of rough surfaces with FFT. Tribol. Int. 2000, 33, 47–58. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maaboudallah, F.; Atalla, N. A Multi-Scale Investigation to Predict the Dynamic Instabilities Induced by Frictional Contact. Lubricants 2023, 11, 344. https://doi.org/10.3390/lubricants11080344

Maaboudallah F, Atalla N. A Multi-Scale Investigation to Predict the Dynamic Instabilities Induced by Frictional Contact. Lubricants. 2023; 11(8):344. https://doi.org/10.3390/lubricants11080344

Chicago/Turabian StyleMaaboudallah, Farouk, and Noureddine Atalla. 2023. "A Multi-Scale Investigation to Predict the Dynamic Instabilities Induced by Frictional Contact" Lubricants 11, no. 8: 344. https://doi.org/10.3390/lubricants11080344

APA StyleMaaboudallah, F., & Atalla, N. (2023). A Multi-Scale Investigation to Predict the Dynamic Instabilities Induced by Frictional Contact. Lubricants, 11(8), 344. https://doi.org/10.3390/lubricants11080344