Abstract

The liner is a wear-prone component in ball mills, subject to continuous impacts, squeezing, and abrasion from the grinding media during operation. Its service performance directly affects the working efficiency of the ball mill. The service life of mining ball mill liners is about 8 months, and frequent downtimes occur due to liner wear and loss of effectiveness, with liner replacement accounting for about 6% of the total cost, resulting in huge economic losses. This paper focuses on a Φ305 mm × 150 mm experimental ball mill, using the discrete element software Rocky Discrete Element Method (DEM) (software version number Rocky 2022 R2) for simulation modeling analysis. With Φ10 mm and Φ20 mm mono-size particle simulations serving as reference groups, this study investigates the motion states and liner abrasion patterns under different liner heights for both sizes of grinding media in Equilibrium Quality Manufacturer (EQM) and Original Equipment Manufacturer (OEM) gradations. The results indicate that the impact of liner height on the wear of the ball mill liners is related to the size and gradation of the grinding media. The degree of liner wear from highest to lowest is as follows: EQM > Φ20 mm > OEM > Φ10 mm. Due to the effect of the cylinder end cap, the wear at the axial center of the ball mill liner is more severe than at both ends, and the wear on the facing side of the liner is more severe than on the backside. A thorough study of the influence of ball mill grinding media gradation on the wear pattern of liners is of great theoretical significance for optimizing liner structures, improving grinding efficiency, and promoting energy saving and cost reduction in ball mills. This study provides theoretical guidance for understanding the mechanisms behind liner wear in ball mills and predicting the liner lifespan.

1. Introduction

The liner is a wear-resistant part that protect the cylinder of the ball mill and lifts the grinding media. It has high energy consumption and its service performance directly affects the working efficiency of the ball mill [1]. As a large-scale grinding device, the ball mill has outstanding issues such as high energy consumption and significant loss of steel balls and liners. The movement state of the grinding medium is an important factor leading to the wear of the liners. Statistically, China processes billions of tons of ore every year, and approximately 5% of the country’s annual electricity generation and millions of tons of steel are consumed in ore grinding processes [2,3,4]. At the same time, wear and tear of the liners leads to frequent shutdowns of ball mills, causing significant economic losses. Therefore, research on the grading of the ball mill’s grinding medium concerning the wear patterns of the liner holds significant theoretical importance for optimizing the structure of the liner, improving grinding efficiency, and enhancing the energy-saving and consumption-reduction performance of the ball mills.

Due to the extremely harsh milling environment of the ball mill liner and the complex and variable working conditions, the wear process of liners is very complex, involving many factors. The liner installed on the inner surface of the cylinder has to withstand the impact and grinding of the grinding medium, as well as the wear caused by slurry corrosion. Therefore, under the condition of ensuring the normal operation of the ball mill, determining how to reduce the wear of the liner, increase the service time of the liner, and improve the quality and efficiency for enterprises have become an important research directions.

Currently, the service life of the mining ball mill liner is about 8 months, and the consumption of the liner for crushing ores is about 0.2 kg/t, with the replacement of the liner accounting for about 6% of the total cost of the ball mill [3]. To reduce the wear of the liner during the grinding process and improve the liner’s working efficiency, scholars both domestically and internationally often employ a combination of DEM simulation and experimental methods to explore the wear mechanism of ball mill liners. The research achievements include the following. In 2015, Dominik Boemer [5] used the DEM to numerically simulate the liner of a ball mill and calibrate it with experimental data. In 2018, Cleary [6,7,8] and others used DEM simulation to process data from 22 sets of ball mill operations, identifying fitting models for operational parameters and material movement characteristics to create wear management strategies. Additionally, in terms of wear, in 2018, Ni [9] used a custom-made liner friction wear testing device to analyze the laws of the rolling friction coefficient, wear morphology, and friction temperature rise under single and multiple contact conditions between steel balls and liners, finding that the wear of liners can be mitigated in the slurry environment. In 2019, Xu [10] and others combined DEM with the Shear Impact Energy Model (SEMI) to study the impact of the grinding medium shape on liner wear, showing that non-spherical wear was greater than spherical wear. In 2020, Xu [11] and others analyzed the impact of single and multiple grinding medium particles on liner wear. In 2021, Egidijus and others used the discrete element method and the Archard wear model to verify its reliability in dry sand rubber wheel tests. In 2022, Xie [12] used DEMSLab 2020 software to study the wet ball milling process of spherical particle systems from perspectives such as particle movement, power consumption and energy utilization, and wear of liners and grinding medium. In 2023, Zhang [13] and others, based on the EDEM 2018 software, studied the operating conditions of ball mills under different liner wear scenarios.

In summary, the grading of the grinding medium in terms of the wear mechanism of ball mill liners is one of the key issues in studying liner wear. The material, size, grading, and distribution state of the grinding medium can directly or indirectly affect the wear of liners. However, the impact of different grinding medium gradings requires further detailed analysis and summary. Although there have been some research achievements regarding the wear of ball mill liners, there are significant differences in research levels, methods, and experimental conditions, and there is a lack of systematic and comprehensive studies. Therefore, in the future, it will be necessary to delve deeper into the wear mechanisms of liners, establish more comprehensive and reasonable models, and integrate data from various aspects to optimize liner materials and ball mill design schemes.

This research employs the Rocky DEM 2022 R2 software and the Archard wear model to simulate the wear issue of liners in a Φ305 mm × 150 mm experimental ball mill. Considering different liner heights, it explores the impact of two types of grinding media, with diameters of 10 mm and 20 mm, on the wear of the liners under two conditions of grading: equal quantity mixing and equal mass mixing.

2. Discrete Element Method

The discrete element method is a numerical simulation method commonly used in geomechanics, powder processing, grinding technology, mixing and stirring, and other industrial processes. As a numerical simulation method, DEM is utilized to analyze the motion laws and mechanical properties of granular particles by employing contact models and Newton’s second law to determine force and position information. One commonly utilized contact model is the Hertz–Mindlin (no slip) contact model, which is known for its effectiveness in simulating particle collisions and interactions. In this research, the soft particle contact method is employed along with the Hertz–Mindlin (no slip) contact model to ensure an accurate representation of particle behavior and interactions within the system.

According to Newton’s second law, the equation of motion for any particle i in a DEM simulation can be expressed as [14]:

where Ii, wi, mi, vi, and Ri are the moment of inertia, angular velocity, mass, and radius. Fn,ij and Ft,ij are the normal and tangential forces between particles i and j, respectively. ur,ij is the rolling friction coefficient between particle i and j. g is the gravitational acceleration. t is time. ∑M and ∑F are the resultant torque and resultant force of particle i, respectively.

Additionally, the normal force Fn,ij and tangential force Ft,ij between particle i and j are, respectively:

where δn and δt are the normal and tangential amounts of overlap between particles i and j, respectively. vn,ij and vt,ij are the normal relative velocity and tangential relative velocity between particles i and j, respectively. us,ij is the static friction coefficient between particle i and j. Ω is the conversion coefficient. E*, m*, R*, and G* are the equivalent elastic modulus, equivalent mass, equivalent contact radius, and equivalent shear modulus between particles i and j, respectively, whose expression is as follows:

where ei and ej are Poisson’s ratio of particles i and j, respectively.

This paper uses the discrete element software Rocky DEM to simulate the wear behavior of ball mill liners. The wear model adopted is based on Archard’s wear law, which correlates the volumetric loss of material with the work done by the frictional forces on the material surface [11]. The wear calculation formula is:

where V represents the total volume of material worn from the contact surface; Fτ is the tangential force applied on the contact surface; sτ is the sliding distance on the contact surface; H is the hardness of the material subjected to wear; and k is a dimensionless empirical constant.

In the Rocky DEM software, the Archard wear law is considered in an incremental form:

where ∆V is the volume of material worn during the analog time step; ∆Wτ is the tangential work or shear work done by the particles when colliding with the surface within the same time step; and C is a coefficient, where C = k/H.

3. Discrete Element Simulation Geometric Model and Parameter Settings

3.1. Discrete Element Simulation Geometric Model

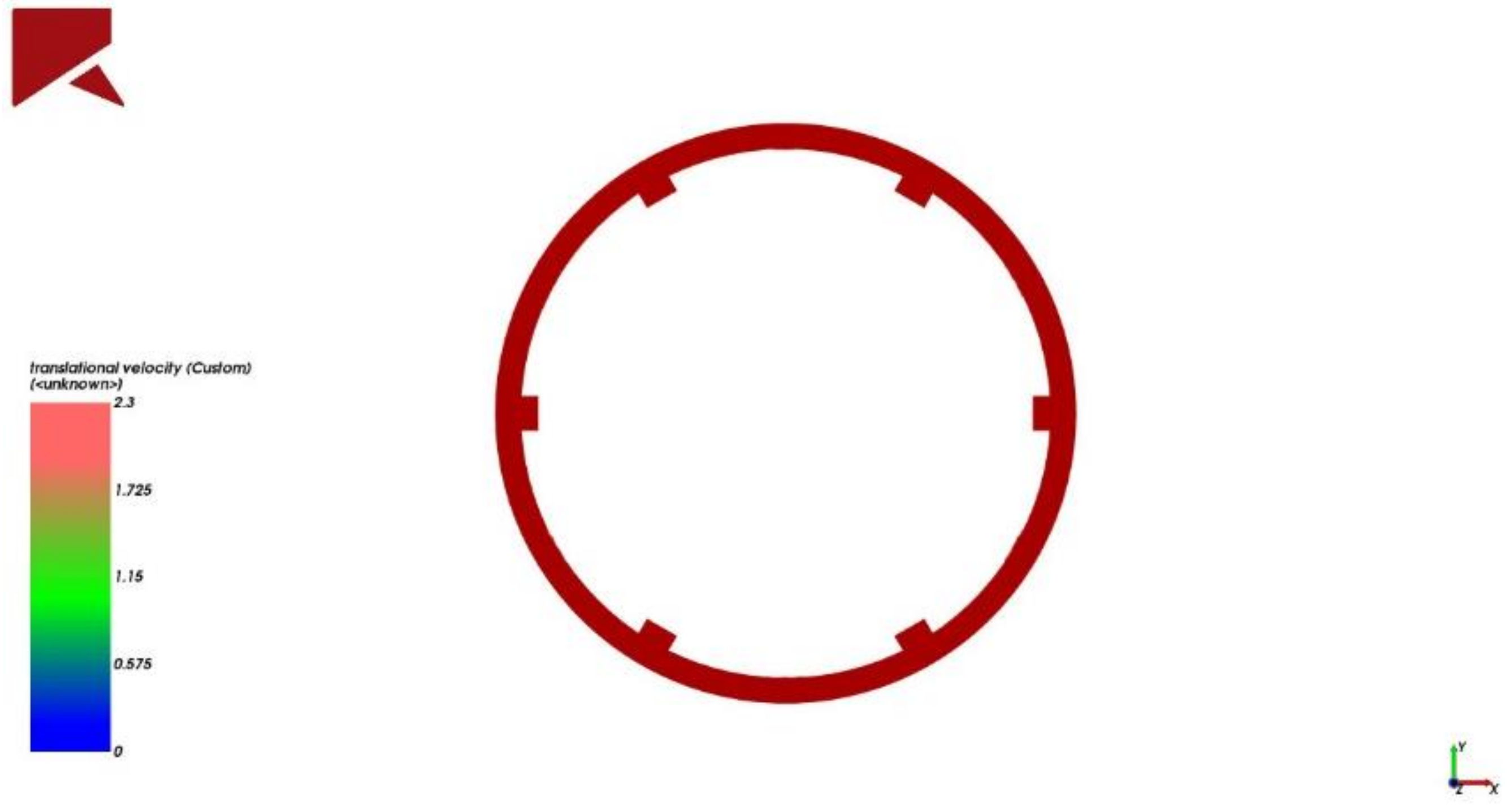

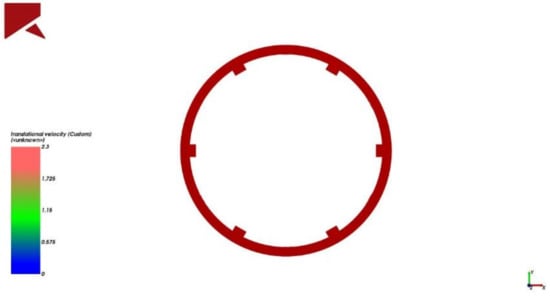

This research uses a Φ305 mm × 150 mm experimental ball mill as the prototype. It uses Solidworks 2020 software to establish the geometric model of the ball mill, as shown in Figure 1. The cylinder inside the experimental ball mill is equipped with six rectangular liners (cross-sectional dimensions: 10 mm base width × height 20 mm, 25 mm, 30 mm), with a critical speed of 76.77 r/min.

Figure 1.

Geometric model of the ball mill.

3.2. Parameter Settings

The main physical parameters set by this discrete element simulation are those of the steel balls and the cylinder. The contact parameters mainly include the static friction coefficient, dynamic friction coefficient, and restitution coefficient between steel balls and between steel balls and the cylinder. The specific parameter values are shown in Table 1 and Table 2.

Table 1.

Material physical parameters [15].

Table 2.

Contact parameters.

4. Simulation Scheme Design

In Katubilwa’s paper [16], the grinding media mixing was divided into two situations: one consisting of an equal number of grinding media, termed EQM, and the other known as OEM. This research explores the motion states of grinding media and the wear condition of liners under different liner heights, using Φ10 mm and Φ20 mm steel balls as grinding media in a Φ305 mm × 150 mm experimental ball mill, based on the two ways mentioned above of grinding media mixing.

The ball filling used in this research is 35%, and the mill speed is 56% of the critical speed. The discrete element numerical simulation time step is 2.4213 × 10−5 s, with a total simulation time of 100 s. The calculation for wear starts at 10 s, with a wear shear ratio value of 3 × 10−6 m3/J. To compare the mixing behavior of grinding media under equal number (EQM) and equal mass (OEM) mixing in a ball mill, Φ10 mm and Φ20 mm steel balls were selected as the control group. The specific experimental scheme is shown in Table 3, and the grading of the grinding media is shown in Table 4.

Table 3.

Experimental scheme.

Table 4.

The grading of grinding media.

5. Simulation Results and Analysis

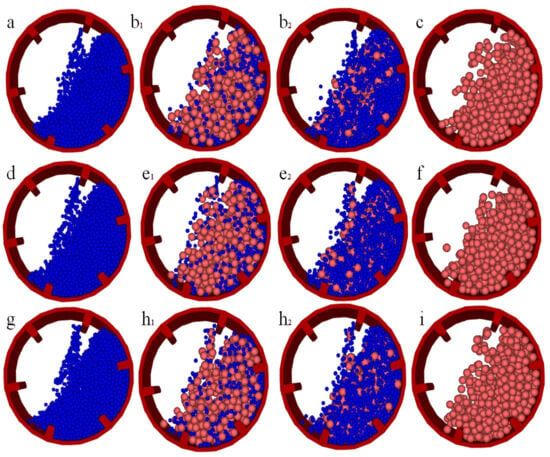

5.1. Analysis of the Distribution of Grinding Media Movement State in Ball Mills

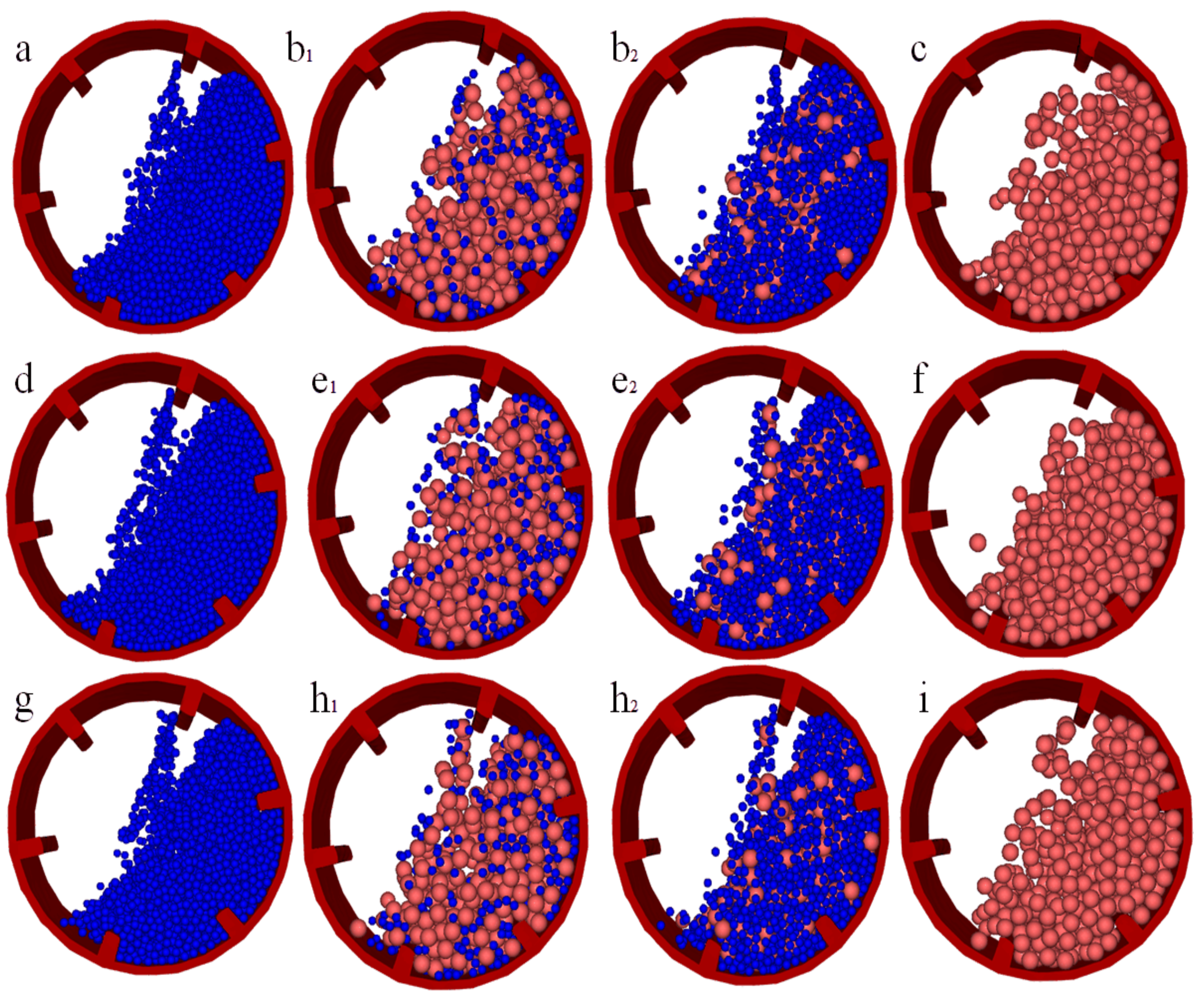

As shown in Figure 2, the distribution diagram of the radial movement state of the grinding media at t = 100 s in various groups of discrete element simulations is presented. In the diagram, the blue particles represent small steel balls with a diameter of Φ10 mm, and the red particles represent large steel balls with a diameter of Φ20 mm. From Figure 2, it can be observed that the large and small steel balls are mixed, with the large balls mainly concentrated in the inner layer and the small balls primarily gathering around the outer layer of the large balls, resulting in stratification. This phenomenon is consistent with the findings in the papers by Zhang and others [14,16]. The main reasons for this phenomenon are as follows: on the one hand, it is because the length-to-diameter ratio of the cylinder is relatively small, and the end cover effect has a lesser impact on particle stratification; on the other hand, it is due to the high rotational speed causing the particles to undertake a dropping motion. At this time, the small particles are lifted to a greater height under the influence of the liner, making it easier for them to fall into areas without particles. When other particles fall into this area, the small particles have already occupied the outermost layer of the cylinder. The liner height has an influence on the charge loading behavior of the ball mill. As the liner height increases, the shoulder angle of the charge gradually increases and the toe angle of the charge gradually increases. This indicates that changes in the liner height can affect the motion trajectory and behavioral characteristics of the charge inside the ball mill. The changes in the shoulder angle and toe angle of the charge reflect that the motion state of the charge inside the ball mill has changed, which may affect the grinding efficiency and product quality of the ball mill. Therefore, in the design and operation optimization of the ball mill, the influence of the liner height on the charge loading behavior needs to be fully considered in order to achieve the optimal grinding performance.

Figure 2.

Distribution of the radial motion states of the grinding media in a ball mill at different conditions.

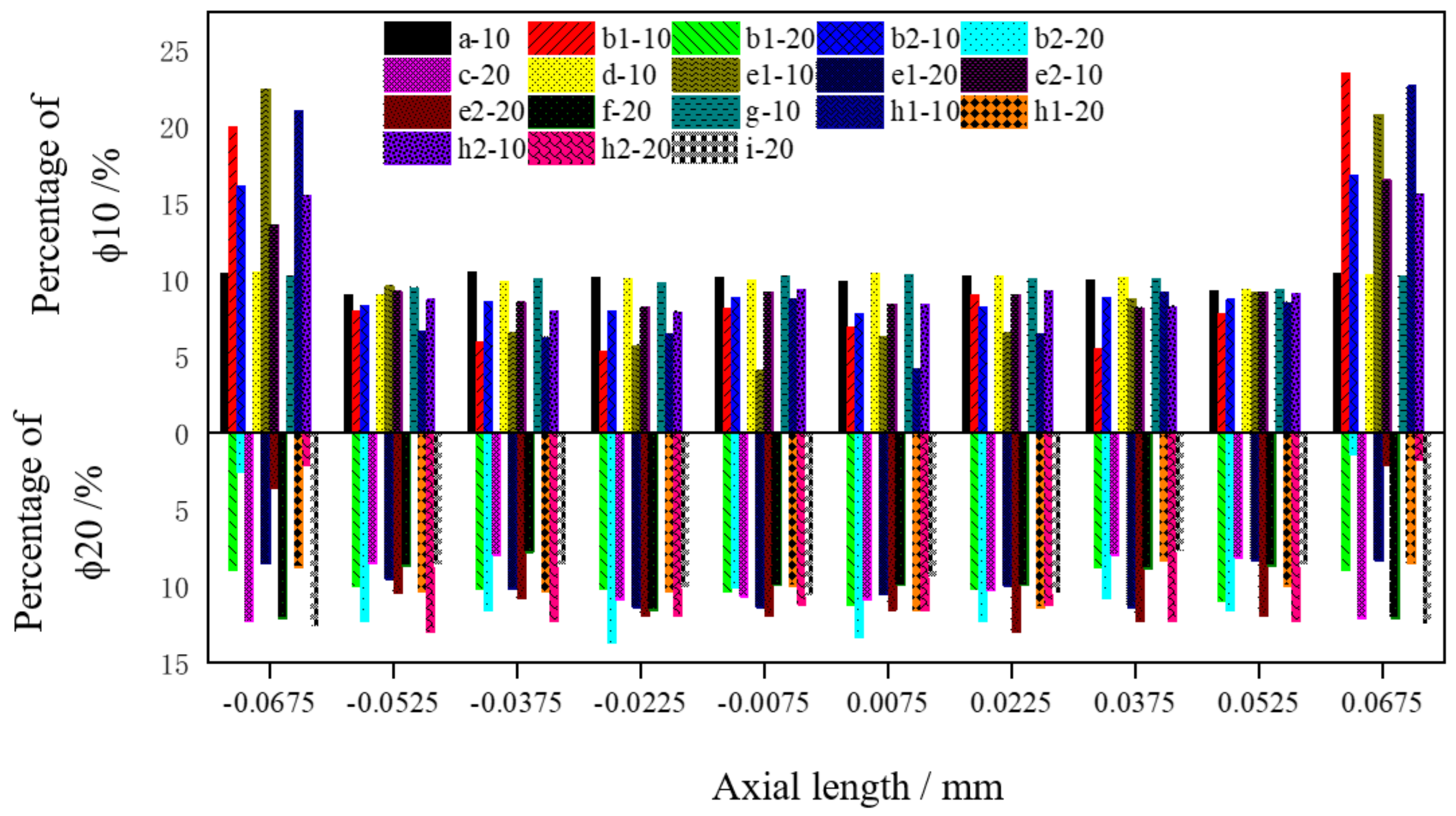

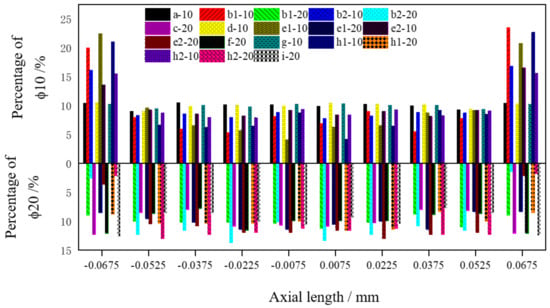

Research on the grinding media motion state in ball mills primarily focuses on the radial motion of the cylinder end face, while studies on the axial motion of the grinding media and the impact of the cylinder end face on the grinding media motion state are less common. For this reason, this research, based on the post-processing function of the discrete element software Rocky DEM, exports the axial position data of the grinding media in the cylinder. Using the column statistics function integrated into the Origin 2022 software, the axial length of the ball mill cylinder is divided into 15 intervals, and the number of steel balls in each interval is counted. This results in a chart depicting the percentage distribution of the grinding media quantity under different working conditions, as shown in Figure 3. The upper half of the chart shows the distribution of the percentage of small steel balls with a diameter of 10 mm, while the lower half shows the distribution for larger steel balls with a diameter of 20 mm. According to Figure 3, particles in a single grinding medium group are distributed relatively evenly in the middle of the cylinder; the highest percentage of particles is at the end caps. In the mixed grinding media group, the smaller particles have the highest percentage at the two end faces of the cylinder and are distributed relatively evenly in the middle, while the larger particles have the smallest percentage in the areas closest to the end caps and are distributed relatively evenly in the middle. The main reasons for this are: (1) the particles are influenced by the end cap effect, which enhances the lifting of particles at the end caps more than other areas, making it easier for particles to be lifted there; also, vacancies are filled by particles from other areas, resulting in a higher quantity of particles at the end caps compared to the center; (2) the smaller particles have a stronger ability to move towards the end caps compared to the larger particles, resulting in the displacement of larger particles by smaller ones; thus, in the mixed grinding media group, the quantity of larger particles is the least at the end caps, while smaller particles are the most numerous. The research results indicate that the effect of the ball mill cylinder end face on the motion state of the grinding media cannot be ignored.

Figure 3.

Axial distribution diagram of the percentage of grinding media in a ball mill.

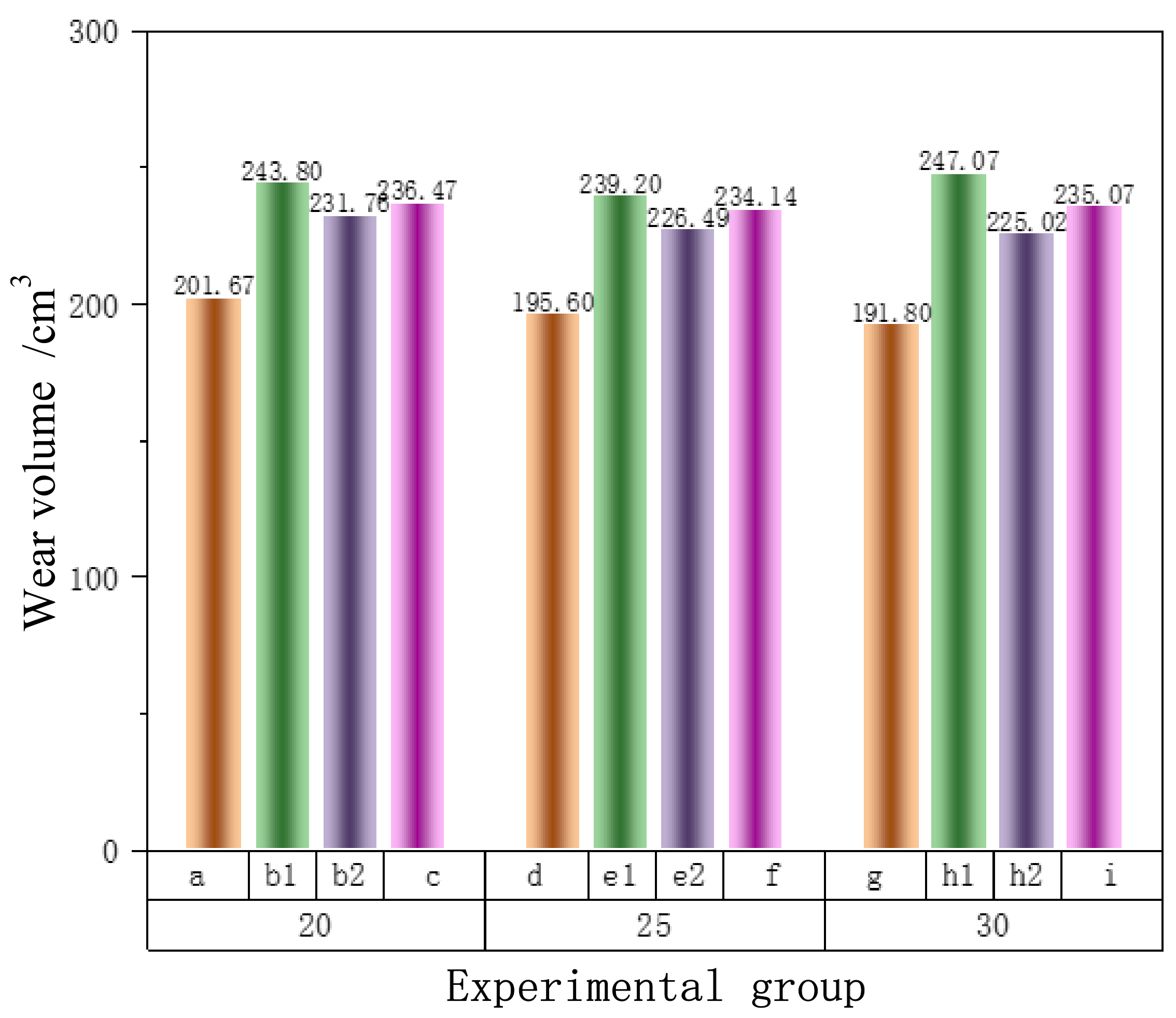

5.2. Analysis of the Wear Volume of the Ball Mill Liner

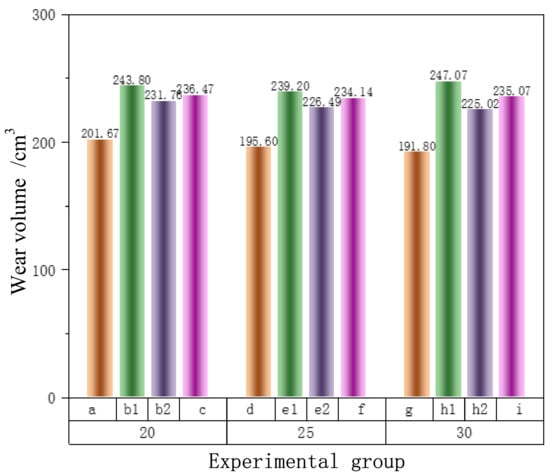

Based on the Rocky DEM simulation analysis, the geometric model of the ball mill barrel can be imported into SpaceClaim 2022 software to calculate the volume of the cylinder geometric model. The cylinder volume before and after the simulation is subtracted, which is the wear volume of the liner. As shown in Figure 4, it represents the wear volume of liner under each group of simulations. In the figure, the wear volume of the liner is represented by the Y-axis, the group sequence number by the X-axis, and the different columnar strip colors represent different grinding media gradation schemes. The orange columnar bars represent the ball matching scheme with only Φ10 mm small steel balls; green represents the EQM ball matching scheme; purple represents the OEM ball matching scheme; and pink represents the ball matching scheme with only Φ20 mm large steel balls.

Figure 4.

Wear volume of the liner.

According to the literature [17], the grinding medium in the ball mill will cause abrasive wear on the surface of the liner during the movement process, and larger particles will produce greater impact force and stress when hitting the liner, thereby leading to increased wear of the liner. In addition, the larger particles will also enhance the interaction force between the grinding media, affecting the stability of the entire milling system, and thereby further intensifying the wear of the liner. Therefore, there is a significant correlation between the size of particles in the ball mill and liner wear. However, it can be seen from Figure 2 that under three different liner heights, the wear volume of the green EQM condition is slightly higher than the wear volume of the pink Φ20 mm condition. Under the same liner height, the liner wear amount under the purple OEM condition ranks third, and the liner wear volume under the orange Φ10 mm condition is the smallest. In the case of a single grinding medium, the larger the diameter of the grinding medium, the more severe the liner wear. However, when mixing two types of grinding media, theoretically, the liner wear under the EQM condition should be less than the wear under the fully Φ20 mm condition. However, the simulation calculation results are inconsistent with the theory, possibly because adding an appropriate amount of Φ10 mm small steel balls increases the contact area with the liner, thereby leading to increased liner wear. At the same time, the smaller number of Φ20 mm large steel balls will limit the particle crushing ability, so the liner wearability under the OEM condition is lower than the liner wearability under the Φ20 mm condition.

With the increase in liner height, under the condition of a Φ10 mm grinding media ratio, the wear volume of the liner continues to decrease; under the condition of a Φ20 mm grinding media ratio, the wear volume of the liner first decreases and then increases. The OEM grinding media ratio follows the wear pattern of the Φ10 mm grinding media ratio, and the EQM grinding media ratio follows the wear pattern of the Φ20 mm grinding media ratio. The research results show that the effect of liner height on the wear of the ball mill liner is related to the size and ratio of the grinding media. The selection of the correct ball size is driven by the desire to achieve adequate liberation in the grinding process, and not to minimize the wear of the internals of the mill. Wear is usually solved by using more appropriate construction materials for the mill liner and the grinding media.

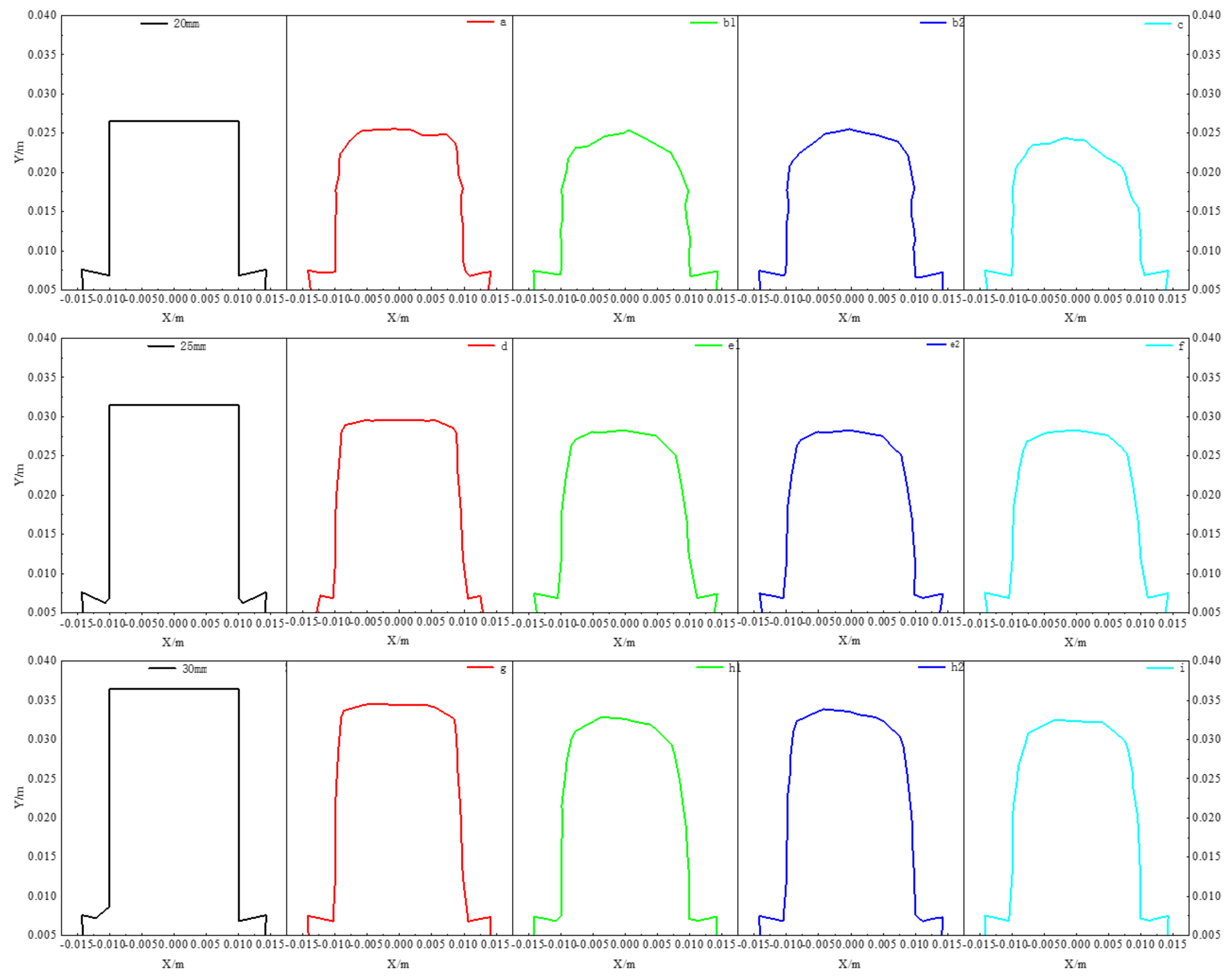

5.3. Analysis of Radial Wear of the Ball Mill Liner

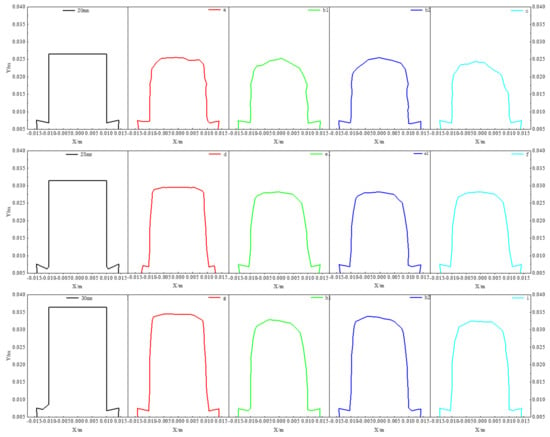

Figure 5 shows the wear profile of the cross-section in the middle position of the liner. The range of the X-axis is from −0.0175 m to 0.0175 m, and the Y-axis range is from 0.005 m to 0.04 m. The shape on the far left represents the initial contour of the backing plate, and the other shapes represent the radial wear profiles of the backing plate at different heights in sequence.

Figure 5.

The profile of radial wear of the liner.

From Figure 5, it is known that the degree of radial wear of the liners is in the order of EQM > Φ20 mm > OEM > Φ10 mm. It can be observed from the graph that the wear on the front of the liner is more severe than on the back, and this phenomenon becomes more pronounced with larger particles. This is because, during the grinding process, the front of the liner is subjected to greater impact and friction, resulting in more severe wear. In contrast, the back of the liner experiences relatively minor wear due to its smaller contact area and exposure to less impact and friction forces.

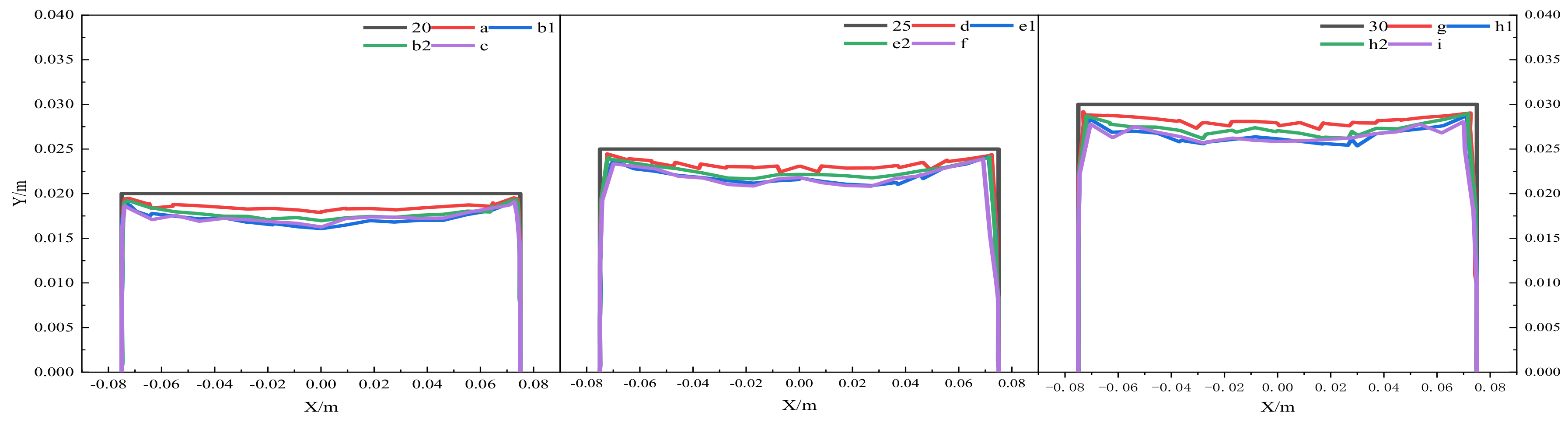

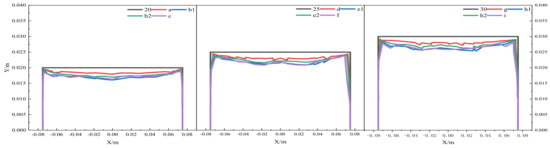

5.4. Analysis of Axial Wear of the Ball Mill Liner

Figure 6 shows the axial wear profiles of the simulated liners for different groups. In the figure, the black line represents the initial profile shape of the ball mill liner. The wear profile of the liner after wear confirms that the wear degree of the liner is EQM > Φ20 mm > OEM > Φ10 mm. In addition, the wear degree of the liner at the end cover is lighter than that at the center, indicating that although a large number of particles are accumulated at the end cover, most of the pressure exerted by the particles on the liner is offset by the friction force of the end cover, with only a small portion being borne by the liner at the end cover. Therefore, special attention should be paid to the wear of the liner at the center position of the ball mill cylinder when studying liner wear. Wear is an inevitable consequence of grinding ore in tumbling mills, and operations monitor the liner health routinely to ensure that they are replaced at the optimum time as the consequences of not replacing the lifter/liner are catastrophic.

Figure 6.

Profile of axial wear of the liner.

6. Conclusions

This research takes the Φ305 mm × 150 mm experimental ball mill as the research object, based on the discrete element software Rocky DEM for simulation modeling analysis, with Φ10 mm and Φ20 mm as two mono-size particle simulations as the reference group, to explore the movement state and liner wear behavior of two kinds of grinding media under different liner heights in the EQM and OEM gradations. The ball mill model is based on a small-scale experimental ball mill, which has structural differences from the actual industrial ball mills. The structure of the experimental ball mill has been simplified to some extent. Furthermore, the amount of charge that needs to be processed in industrial ball mills is enormous, making it difficult to simulate one-to-one using discrete element software. The main research conclusions are as follows:

- (1)

- During the movement process of the ball mill grinding media, the grinding media of different sizes will show a stratification phenomenon, with larger particles inside and smaller particles outside, and the number of particles at the axial end cover is greater than that at the axial center.

- (2)

- The impact of the liner height on the wear of the ball mill liner is related to the size of the grinding media and the gradation of the grinding media, and the ranking of the degree of liner wear in descending order is EQM > Φ20 mm > OEM > Φ10 mm.

- (3)

- Due to the effect of the cylinder end cover, the wear at the axial center of the ball mill liner is more severe than at both ends, and the wear on the face of the liner is more severe than on the back.

Author Contributions

Conceptualization, Z.Y. and D.M.; methodology, Z.Y. and D.M.; software, Z.Y. and D.M.; validation, Z.Y., D.M. and T.L.; formal analysis, Z.Y. and D.M.; investigation, Z.Y. and D.M.; resources, Z.Y. and D.M.; data curation, Z.Y. and D.M.; writing—original draft preparation, Z.Y.; writing—review and editing, Z.Y.; visualization, Z.Y.; supervision, Z.Y. and D.M.; project administration, Z.Y.; funding acquisition, Z.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Doctoral Scientific Research Foundation of Suzhou University [grant number 2023BSK016], the Excellent Scientific Research and Innovation Teams in Anhui Province’s Universities [grant number 2023AH010055] and the Key Project of Natural Science Research in Universities of Anhui Province [grant number 2022AH051380; 2024AH051812], the Key Research and Development Program Projects in Anhui Province [grant number 2023t070200], Anhui Province Higher Education Quality Project [grant number 2023sdxx088], and Excellent Academic Technology Backbone Project of Suzhou University [grant number 2024XJGG08].

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

We wish to thank Yin, who conceived and designed the schemes; and Li and Ma, who performed the experiments and analyzed the data.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

References

- Zhang, Z.Y.; Liu, Y.F.; Fu, X.W. Research on influence of liner wear on material grinding effect for ball mill. Min. Process. Equip. 2023, 51, 35–39. [Google Scholar]

- Duan, X.X.; Xiao, Q.F. Crushing and Grinding, 3rd ed.; Metallurgical Industry Press: Beijing, China, 2012. [Google Scholar]

- Zhang, Q.; Xiao, Q.F.; Zhao, F.G.; Ma, S.; Yang, S. Failure analysis of ball mill liner and optimization countermeasure. Nonferrous Met. Miner. Process. Sect. 2021, 6, 131–139. [Google Scholar]

- Xiao, Q.F.; Shao, Y.F.; Zhou, Q.; Liu, X.Y.; Zhang, Q.; Wang, Q.K. Research and application on the modification of the liner of semi-autogenous mill based on discrete element method. Nonferrous Met. Miner. Process. Sect. 2023, 11, 65–70. [Google Scholar]

- Boemer, D. Discrete Element Method Modeling of Ball Mills—Liner Wear Evolution. Master’s Thesis, University of Liège, Liège, Belgium, 2015. [Google Scholar]

- Cleary, P.W.; Owen, P. Development of models relating charge shape and power draw to SAG mill operating parameters and their use in devising mill operating strategies to account for liner wear. Miner. Eng. 2018, 117, 42–62. [Google Scholar] [CrossRef]

- Cleary, P.W.; Owen, P. Effect of particle shape on structure of the charge and nature of energy utilization in a SAG mill. Miner. Eng. 2019, 132, 48–68. [Google Scholar] [CrossRef]

- Cleary, P.W. Effect of rock shape representation in DEM on flow and energy utilisation in a pilot SAG mill. Comput. Part. Mech. 2019, 6, 461–477. [Google Scholar] [CrossRef]

- Ni, X. Study on Impact Friction and Wear Behavior of Ball Bill under Dry and Wet Conditions. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2018. [Google Scholar]

- Xu, L.; Luo, K.; Zhao, Y.Z.; Fan, J.; Cen, K. Influence of particle shape on liner wear in tumbling mills: A DEM study. Powder Technol. 2019, 350, 26–35. [Google Scholar] [CrossRef]

- Xu, L.; Bao, S.; Zhao, Y.Z. Multi-level DEM study on liner wear in tumbling mills for an engineering level approach. Powder Technol. 2020, 364, 332–342. [Google Scholar] [CrossRef]

- Katinas, E.; Chotěborský, R.; Linda, M.; Kuře, J. Sensitivity analysis of the influence of particle dynamic friction, rolling resistance and volume/shear work ratio on wear loss and friction force using DEM model of dry sand rubber wheel test. Tribol. Int. 2021, 1, 1–14. [Google Scholar] [CrossRef]

- Xie, C.H. Combined Non-Spherical Dem Model and Numerical Simulation Study of Ball Milling Process. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2022. [Google Scholar]

- Yin, Z.X. Study on Breakage and Size Distribution Behaviour of Iron Ore Particle in Ball Mills. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar]

- Zhang, Y.C. Study on Media Stratification Behavior of Ball Mill Based on Discrete Element Method. Master’s Thesis, Jiangsu Ocean University, Lianyungang, China, 2022. [Google Scholar]

- Katubilwa, F.M. Effect of Ball Size Distribution on Milling Parameters. Ph.D. Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2008. [Google Scholar]

- Xu, L.; Luo, K.; Zhao, Y.Z.; Fang, J.; Cen, K. Effect of particle size on liner wear in semi-autogenous mill. J. Zhejiang Univ. Eng. Sci. 2019, 53, 2255–2263. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).