Research Progress on Current-Carrying Friction with High Stability and Excellent Tribological Behavior

Abstract

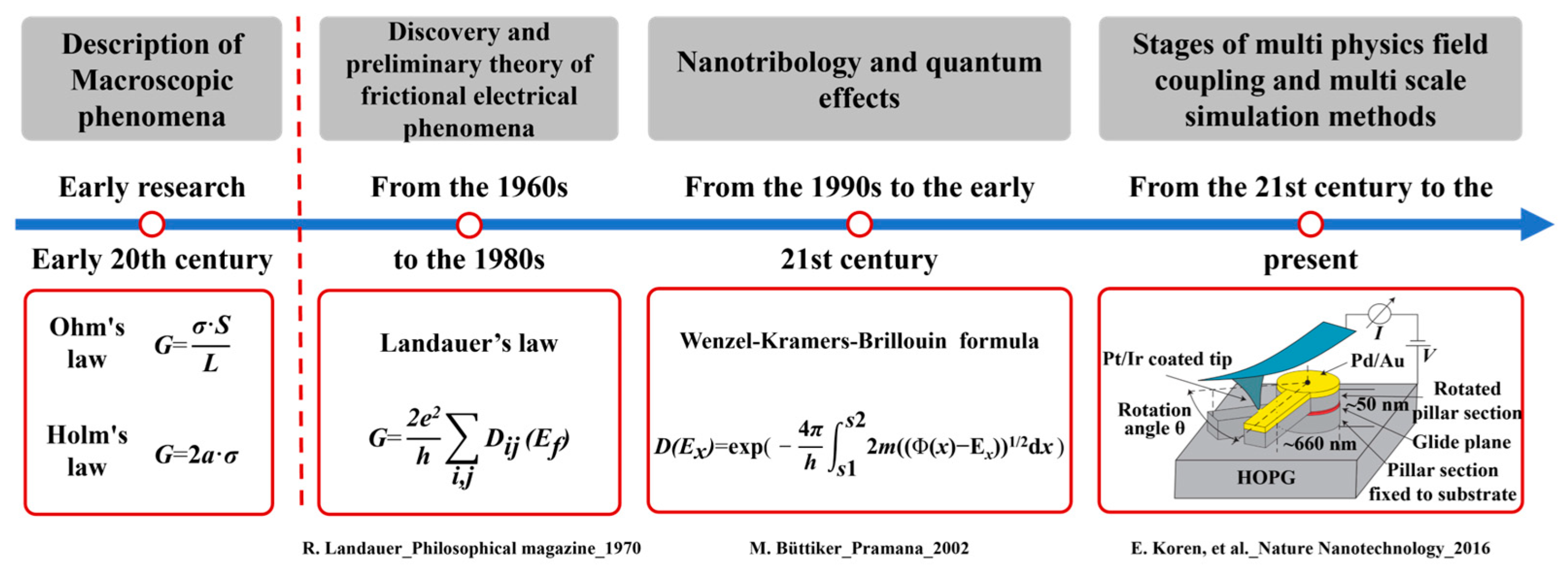

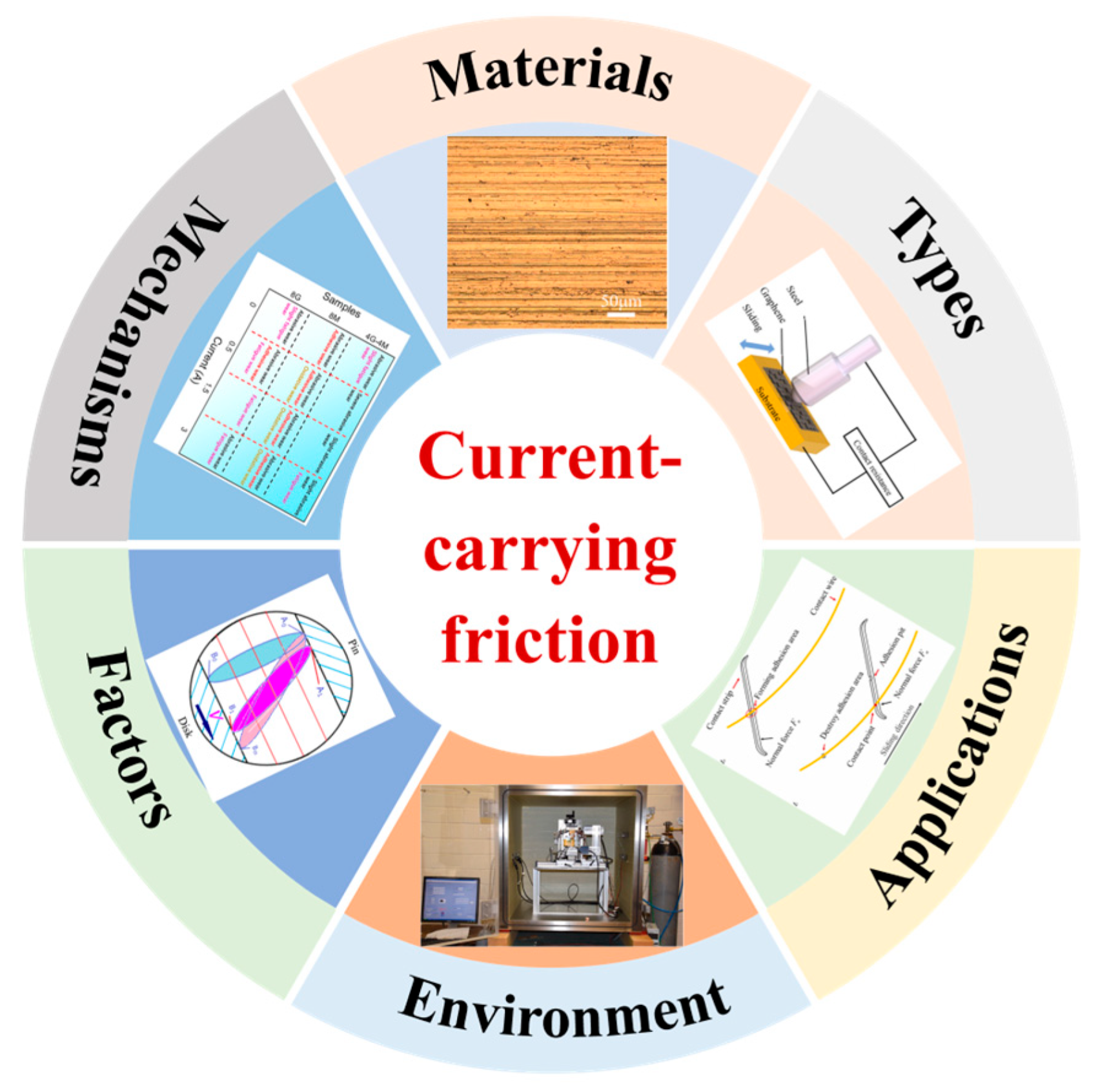

1. Introduction

2. Progress on Current-Carrying Friction

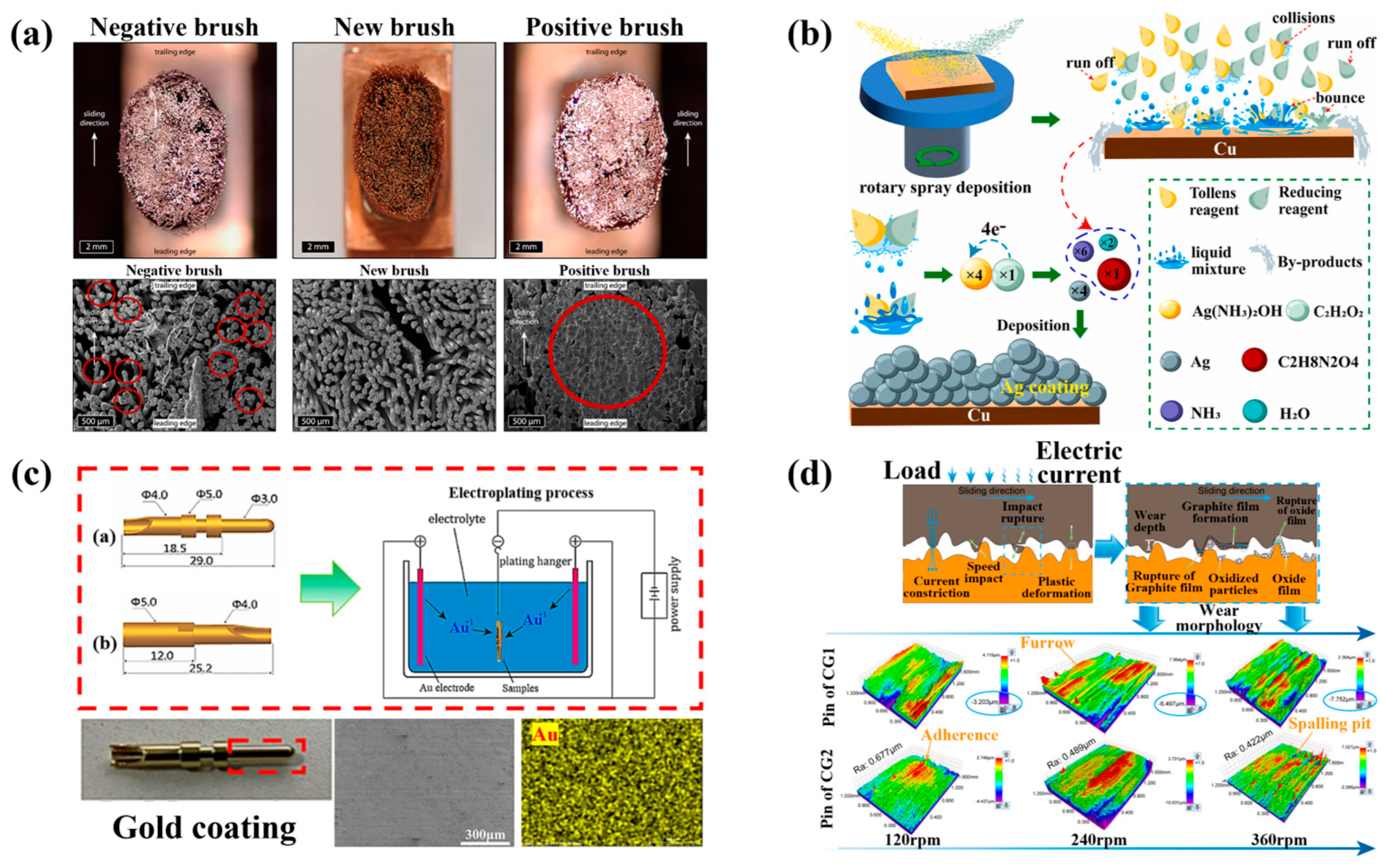

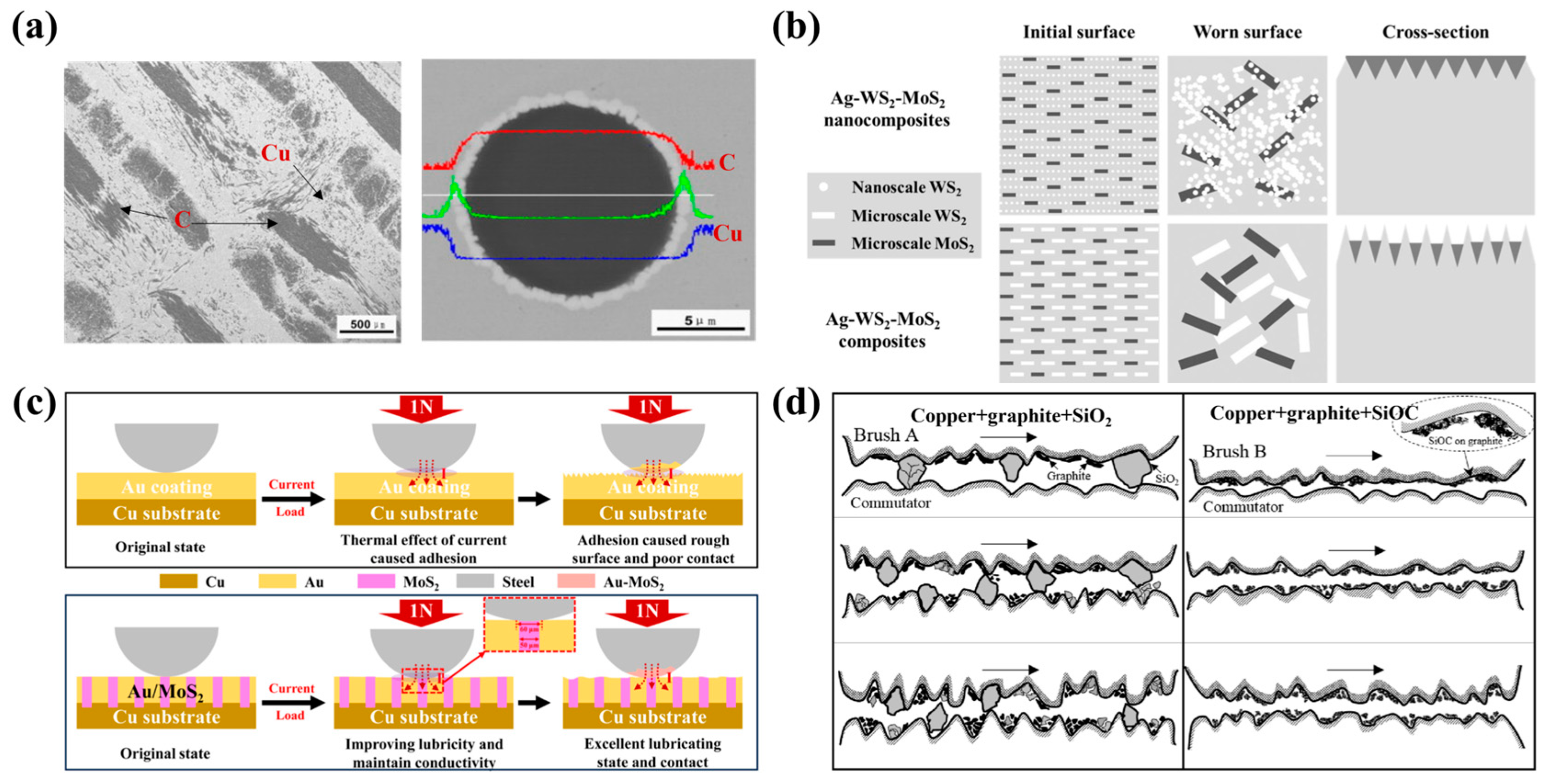

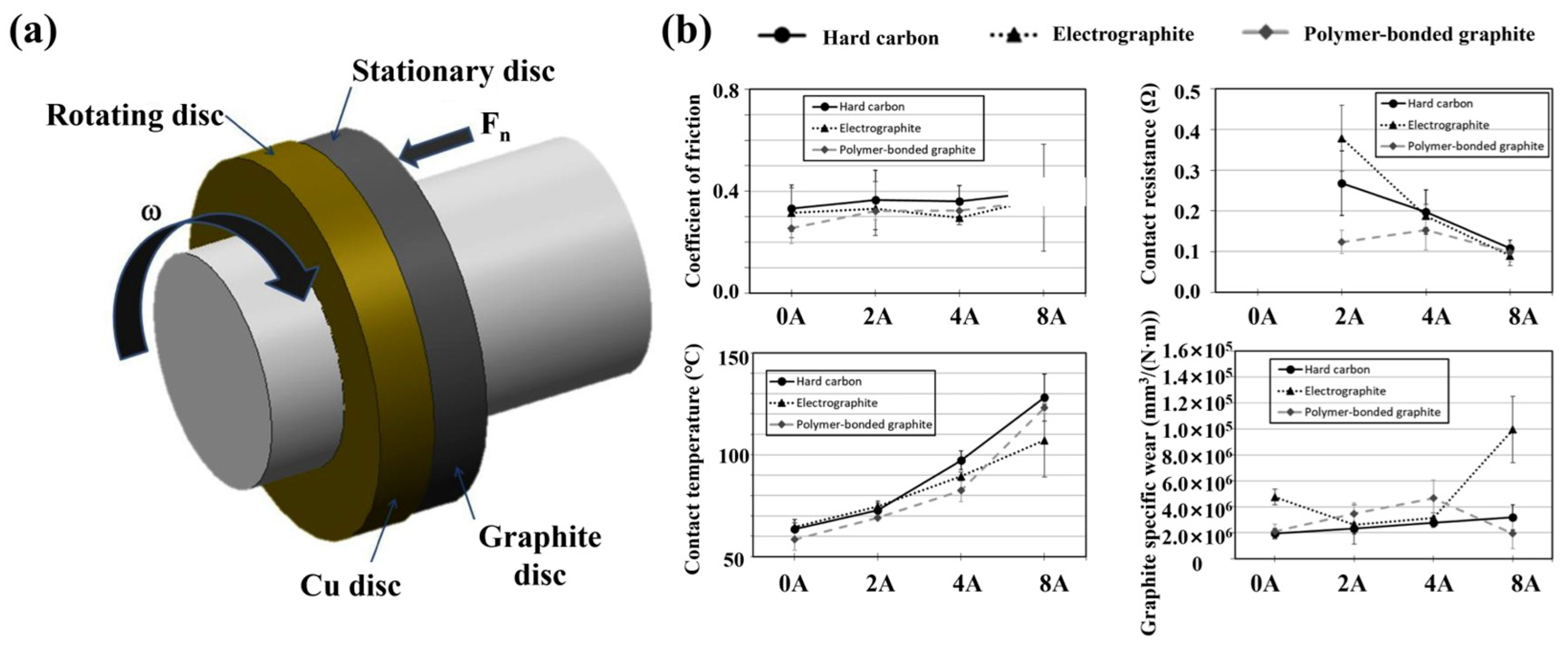

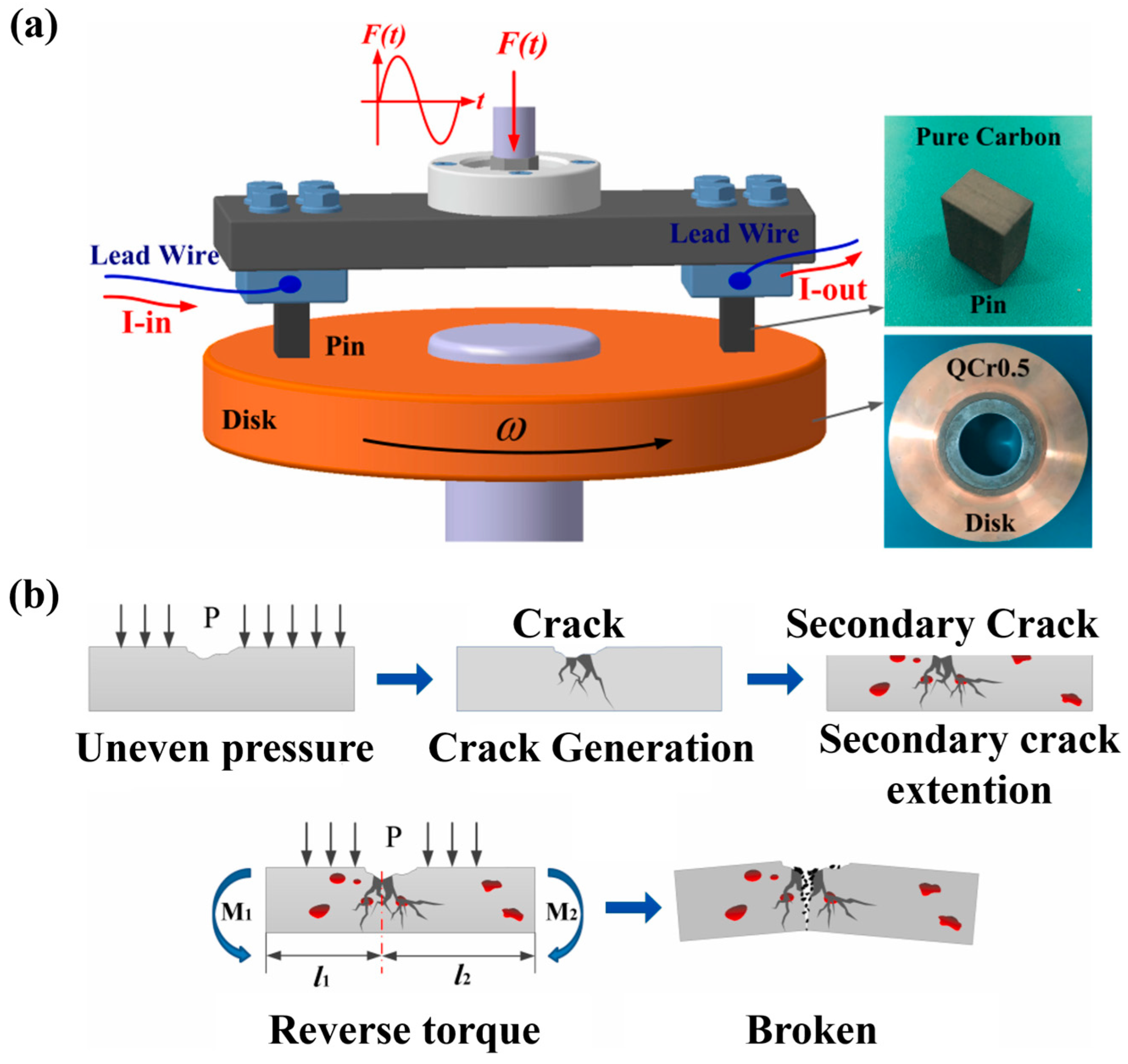

2.1. Materials of Current-Carrying Friction

2.2. Contact Types of Current-Carrying Friction

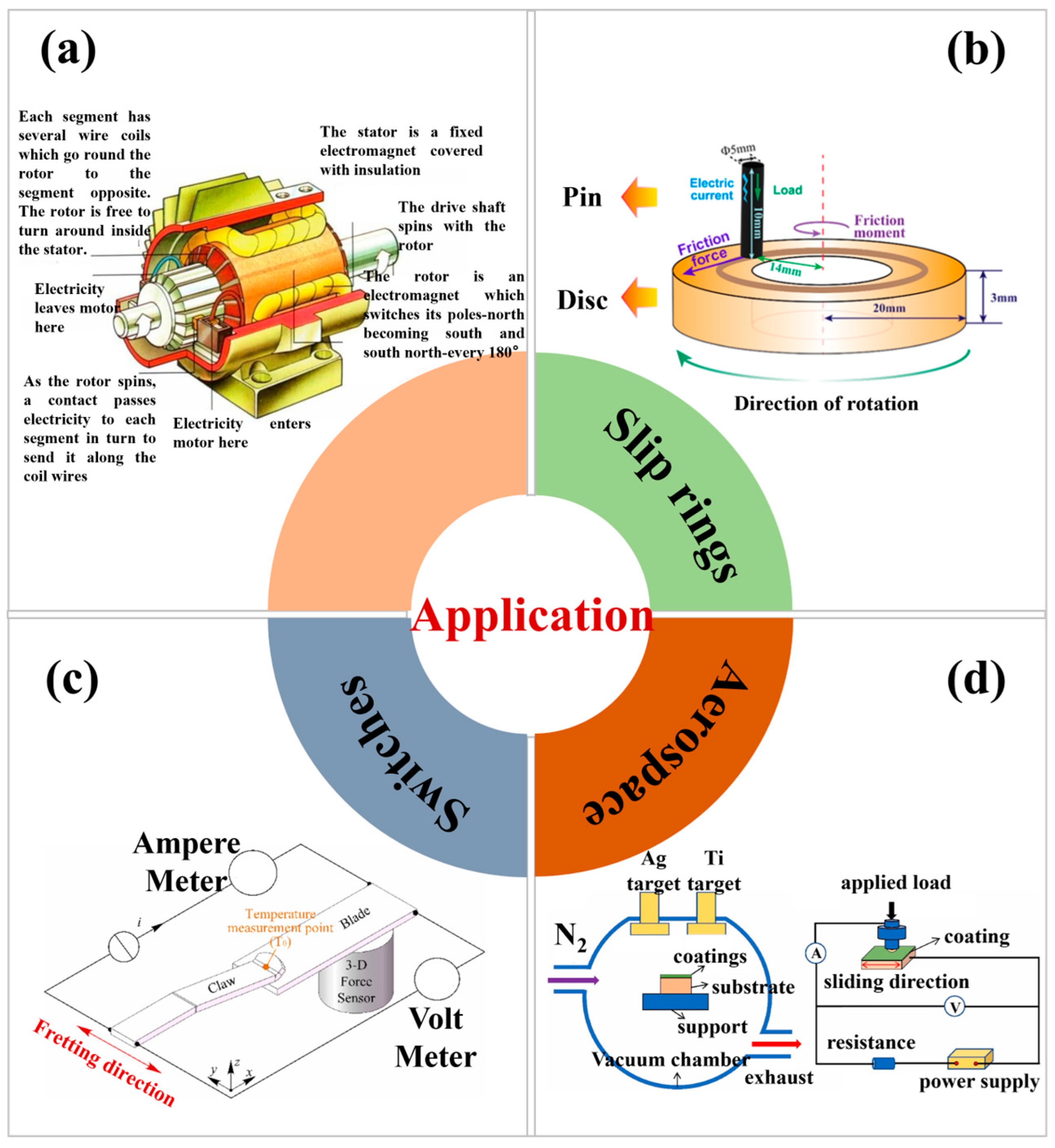

2.3. Applications of Current-Carrying Friction

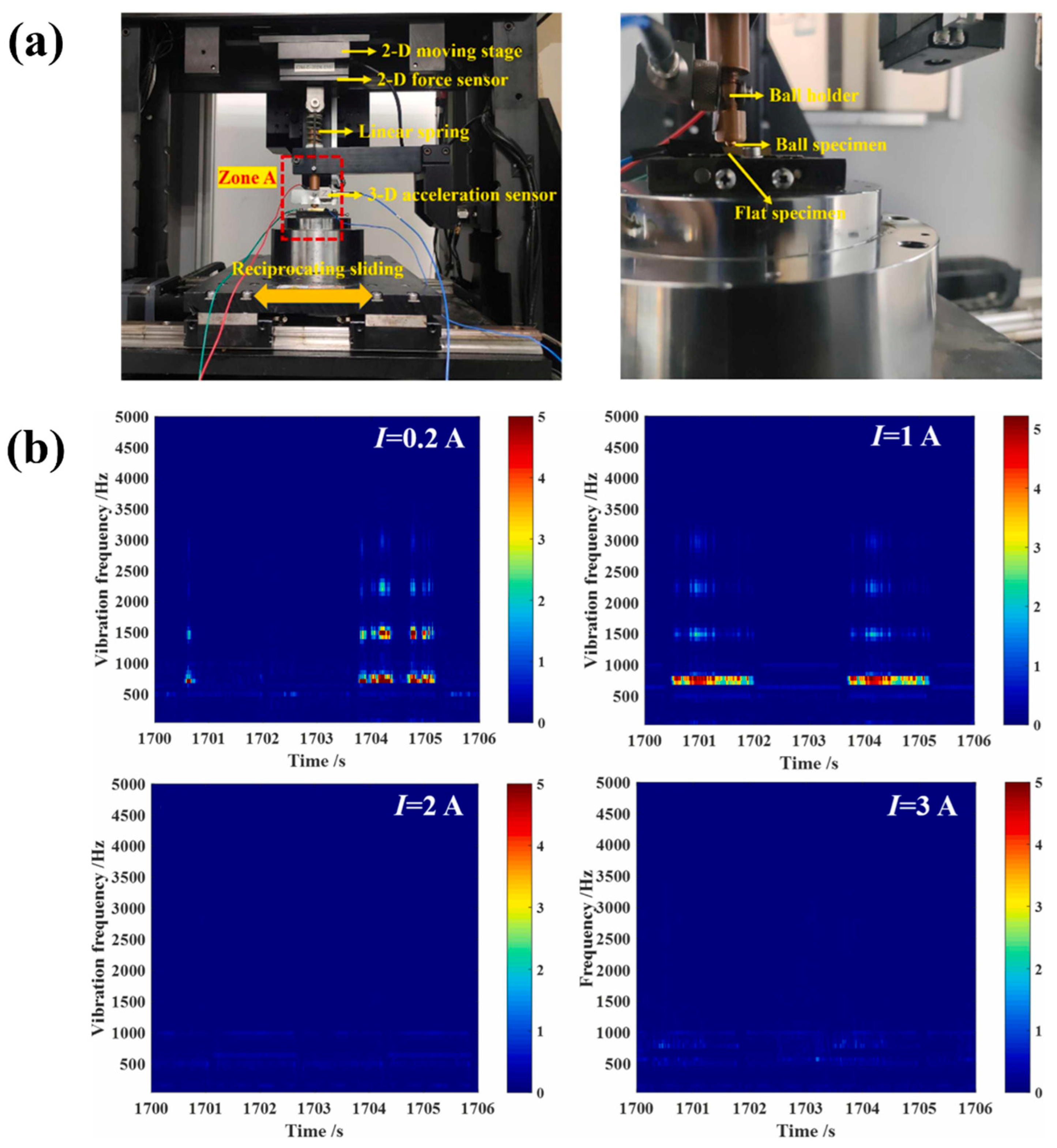

2.4. Environment in Current-Carrying Friction

2.5. Influence Factors of Current-Carrying Friction

2.6. Mechanism of Current-Carrying Friction

3. Future Prospects

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Sumant, A.V. Macroscale superlubricity enabled by graphene nanoscroll formation. Science 2015, 348, 1118–1122. [Google Scholar] [CrossRef] [PubMed]

- Hod, O.; Meyer, E.; Zheng, Q.; Urbakh, M. Structural superlubricity and ultralow friction across the length scales. Nature 2018, 563, 485–492. [Google Scholar] [CrossRef]

- Fu, Y.; Qin, H.; Xu, X.; Zhang, X.; Guo, Z. What are the progresses and challenges, from the electrical properties of current-carrying friction system to tribological performance, for a stable current-carrying interface? J. Bio Tribo-Corros. 2021, 8, 4. [Google Scholar] [CrossRef]

- Huang, Q.; Song, C.; Liu, Z.; Hou, X.; Pang, X.; Sun, C.; Lu, H.; Wang, S.; Zhang, Y. Research progress on the characteristics of current-carrying tribology in electrical transmission. Space Sol. Power Wirel. Transm. 2024, 1, 37–47. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, W.; Xu, X.; Zhong, H.; Wei, D.; Liu, X. Understanding electric current effects on tribological behaviors of instantaneous current-carrying pair with recurrence plot. J. Tribol. 2024, 1–26. [Google Scholar] [CrossRef]

- He, F.; Xie, G.; Luo, J. Electrical bearing failures in electric vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Li, S.; Yang, X.; Kang, Y.; Li, Z.; Li, H. Progress on current-carry friction and wear: An overview from measurements to mechanism. Coatings 2022, 12, 1345. [Google Scholar] [CrossRef]

- Cao, Z.; Xia, Y.; Ge, X. Conductive capacity and tribological properties of several carbon materials in conductive greases. Ind. Lubr. Tribol. 2016, 68, 577–585. [Google Scholar] [CrossRef]

- Huang, Z.; Zhai, H.; Li, M.; Liu, X.; Zhou, Y. Friction behaviors and effects on current-carrying wear characteristics of bulk Ti3AlC2. Tribol. Trans. 2014, 57, 300–307. [Google Scholar] [CrossRef]

- Yang, Z.; Ge, Y.; Zhang, X.; Shangguan, B.; Zhang, Y.; Zhang, J. Effect of carbon content on friction and wear properties of copper matrix composites at high speed current-carrying. Materials 2019, 12, 2881. [Google Scholar] [CrossRef]

- Argibay, N.; Bares, J.A.; Sawyer, W.G. Asymmetric wear behavior of self-mated copper fiber brush and slip-ring sliding electrical contacts in a humid carbon dioxide environment. Wear 2010, 268, 455–463. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene as a protective coating and superior lubricant for electrical contacts. Appl. Phys. Lett. 2014, 105, 231907. [Google Scholar] [CrossRef]

- Poljanec, D.; Kalin, M.; Kumar, L. Influence of contact parameters on the tribological behaviour of various graphite/graphite sliding electrical contacts. Wear 2018, 406–407, 75–83. [Google Scholar] [CrossRef]

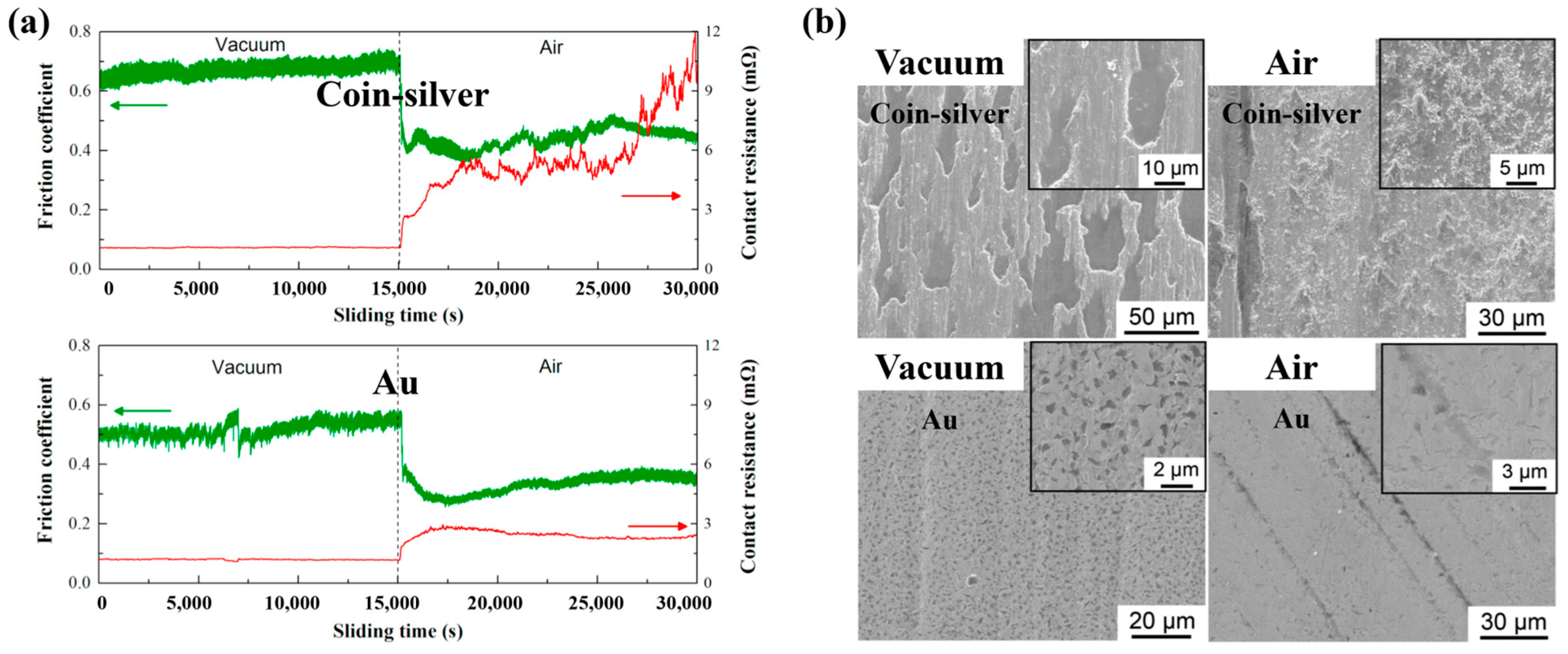

- Xiao, J.-K.; Liu, L.-M.; Zhang, C.; Zhang, L.; Zhou, K.-C. Sliding electrical contact behavior of brass fiber brush against coin-silver and Au plating. Wear 2016, 368–369, 461–469. [Google Scholar] [CrossRef]

- Xie, X.-L.; Zhang, L.; Xiao, J.-K.; Qian, Z.-Y.; Zhang, T.; Zhou, K.-C. Sliding electrical contact behavior of AuAgCu brush on Au plating. Trans. Nonferrous Met. Soc. China 2015, 25, 3029–3036. [Google Scholar] [CrossRef]

- Lin, J.-W.; Chang, H.-C. Measurement of friction surface and wear rate between a carbon graphite brush and a copper ring. Tribol. Trans. 2011, 54, 887–894. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Li, X.; Li, A.; Lu, Z.; Zhang, G.; Wu, Z. The friction and wear properties of metal-doped DLC films under current-carrying condition. Tribol. Trans. 2019, 62, 1119–1128. [Google Scholar] [CrossRef]

- Lin, Y.; Li, J.Z.; Pan, J.; Zhang, C.; Ni, D.R.; Chen, Q.; Song, W.L.; Lu, J.Y.; Li, B.; Liu, L. Current-carrying wear behavior and the interface evolution of the Cu/Al tribological pair. Eng. Fail. Anal. 2023, 153, 107549. [Google Scholar] [CrossRef]

- Jiang, J.; Dai, J.; Yang, H.; Wang, Q. Wear behavior of Cu matrix composites reinforced with mixture of carbon and carbon nanotubes. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2009, 24, 254–257. [Google Scholar] [CrossRef]

- Cao, Z.; Xia, Y. Study on the preparation and tribological properties of fly ash as lubricant additive for steel/steel pair. Tribol. Lett. 2017, 65, 104. [Google Scholar] [CrossRef]

- Wang, L.; Tang, Q.; Liang, T.; Liu, C.; Sun, D.; Wang, S.; Li, J.; Zhang, S.; Meng, Y.; Huang, Y. Lubrication performance of graphene in the sliding electrical contact interface. Friction 2024, 12, 2760–2773. [Google Scholar] [CrossRef]

- Bouchoucha, A.; Chekroud, S.; Paulmier, D. Influence of the electrical sliding speed on friction and wear processes in an electrical contact copper–stainless steel. Appl. Surf. Sci. 2004, 223, 330–342. [Google Scholar] [CrossRef]

- Zhou, N.; Zhi, X.; Cheng, Y.; Sun, Y.; Wang, J.; Gu, Z.; Li, Z.; Zhang, W. Contact strip of pantograph heuristic wear model and its application. Tribol. Int. 2024, 194, 109546. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Z.; Song, K.; Pang, X.; Bao, S. Triboelectric behaviors of materials under high speeds and large currents. Friction 2013, 1, 259–270. [Google Scholar] [CrossRef]

- Ding, T.; Chen, G.X.; Bu, J.; Zhang, W.H. Effect of temperature and arc discharge on friction and wear behaviours of carbon strip/copper contact wire in pantograph–catenary systems. Wear 2011, 271, 1629–1636. [Google Scholar] [CrossRef]

- Plesca, A. Thermal analysis of sliding electrical contacts with mechanical friction in steady state conditions. Int. J. Therm. Sci. 2014, 84, 125–133. [Google Scholar] [CrossRef]

- Ji, D.-H.; Xiao, L.; Hu, Q.; Chen, S.; Li, Q.; Shen, M. The effect of temperature on the current-carrying tribological behaviour of C/Cu Contact pairs in high humidity environments. Tribol. Lett. 2024, 72, 63. [Google Scholar] [CrossRef]

- Song, C.; Sun, Y.; Zhang, Y.; Pang, X.; Chen, T.; Sun, C.; Zhang, Y. Current-carrying property and damage mechanism of rolling contact pairs in different water conditions: From vapor to liquid. Wear 2021, 477, 203857. [Google Scholar] [CrossRef]

- Wu, R.; Song, C.; Wu, H.; Lv, B.; Zhang, Y.; Zhang, Y. Effect of relative humidity on the current-carrying tribological properties of Cu–C sliding contact pairs. Wear 2022, 492–493, 204219. [Google Scholar] [CrossRef]

- Wang, Y.A.; Li, J.X.; Yan, Y.; Qiao, L.J. Effect of surface film on sliding friction and wear of copper-impregnated metallized carbon against a Cu–Cr–Zr alloy. Appl. Surf. Sci. 2012, 258, 2362–2367. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Y.; Zhao, F.; Bao, S. Dynamic variation of arc discharge during current-carrying sliding and its effect on directional erosion. Tribol. Int. 2016, 94, 71–76. [Google Scholar] [CrossRef]

- Liu, X.-L.; Gao, M.-S.; Hu, M.-J.; Cao, Y.; Guan, X.; Zhang, W.-L.; Zhang, S.; Xiao, Q.; Zheng, Y.-T.; Chen, D.-Y.; et al. Study the influence of power-current impact with different conditions on the current-carrying wear property of carbon brush/friction disc contact. Tribol. Int. 2023, 189, 108985. [Google Scholar] [CrossRef]

- Sun, Y.; Song, C.; Liu, Z.; Li, J.; Wang, L.; Sun, C.; Zhang, Y. Tribological and conductive behavior of Cu/Cu rolling current-carrying pairs in a water environment. Tribol. Int. 2020, 143, 106055. [Google Scholar] [CrossRef]

- Yang, H.J.; Hu, Y.; Chen, G.X.; Zhang, W.H.; Wu, G.N. Correlation between the wear and vibration of the contact strip in a contact wire rubbing against a contact strip with electrical current. Tribol. Trans. 2014, 57, 86–93. [Google Scholar] [CrossRef]

- Sun, K.; Diao, D. Current density effect on current-carrying friction of amorphous carbon film. Carbon 2020, 157, 113–119. [Google Scholar] [CrossRef]

- Song, J.; Yuan, H.; Schinow, V. Fretting corrosion behavior of electrical contacts with tin coating in atmosphere and vacuum. Wear 2019, 426–427, 1439–1445. [Google Scholar] [CrossRef]

- Zhou, T.; Wang, X.; Qin, L.-X.; Qiu, W.-T.; Li, S.-F.; Jiang, Y.-B.; Jia, Y.-L.; Li, Z. Electrical sliding friction wear behaviors and mechanisms of Cu–Sn matrix composites containing MoS2/graphite. Wear 2024, 548–549, 205388. [Google Scholar] [CrossRef]

- Holm, R. Electric Contacts: Theory and Application; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Greenwood, J.A.; Williamson, J.B.P.; Bowden, F.P. Contact of nominally flat surfaces. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Landauer, R. Electrical resistance of disordered one-dimensional lattices. Philos. Mag. 1970, 21, 863–867. [Google Scholar] [CrossRef]

- Brandbyge, M.; Mozos, J.-L.; Ordejón, P.; Taylor, J.; Stokbro, K. Density-functional method for nonequilibrium electron transport. Phys. Rev. B 2002, 65, 165401. [Google Scholar] [CrossRef]

- Büttiker, M. Charge densities and charge noise in mesoscopic conductors. Pramana 2002, 58, 241–257. [Google Scholar] [CrossRef]

- Pourfath, M. The Non-Equilibrium Green’s Function Method for Nanoscale Device Simulation; Springer: Berlin/Heidelberg, Germany, 2014; Volume 3. [Google Scholar]

- Ustunel, H.; Toffoli, D. Tribology at the atomic scale with density functional theory. Electron. Struct. 2022, 4, 023002. [Google Scholar] [CrossRef]

- Koren, E.; Leven, I.; Lörtscher, E.; Knoll, A.; Hod, O.; Duerig, U. Coherent commensurate electronic states at the interface between misoriented graphene layers. Nat. Nanotechnol. 2016, 11, 752–757. [Google Scholar] [CrossRef] [PubMed]

- Wolloch, M.; Levita, G.; Restuccia, P.; Righi, M.C. Interfacial charge density and its connection to adhesion and frictional forces. Phys. Rev. Lett. 2018, 121, 026804. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Liu, W.; Sarkar, D.; Jena, D.; Banerjee, K. Computational study of metal contacts to monolayer transition-metal dichalcogenide semiconductors. Phys. Rev. X 2014, 4, 031005. [Google Scholar] [CrossRef]

- Qian, G.; Feng, Y.; Zhang, J.-C.; Wang, Y.; Zhang, T.-C.; Xiao, K.-S. High-speed electrical sliding wear behaviors of Cu-WS2-graphite-WS2 nanotubes composite. Sci. Eng. Compos. Mater. 2018, 25, 343–351. [Google Scholar] [CrossRef]

- Grandin, M.; Wiklund, U. Wear and electrical performance of a slip-ring system with silver–graphite in continuous sliding against PVD coated wires. Wear 2016, 348–349, 138–147. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, X.; Xu, J.; Luo, H. Characterization and tribological properties of graphene/copper composites fabricated by electroless plating and powder metallurgy. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 903–912. [Google Scholar] [CrossRef]

- Wang, Y.A.; Li, J.X.; Yan, Y.; Qiao, L.J. Effect of electrical current on tribological behavior of copper-impregnated metallized carbon against a Cu–Cr–Zr alloy. Tribol. Int. 2012, 50, 26–34. [Google Scholar] [CrossRef]

- Liu, X.-L.; Cai, Z.-B.; Xiao, Q.; Shen, M.-X.; Yang, W.-B.; Chen, D.-Y. Fretting wear behavior of brass/copper-graphite composites as a contactor material under electrical contact. Int. J. Mech. Sci. 2020, 184, 105703. [Google Scholar] [CrossRef]

- Ding, T.; Chen, G.X.; Wang, X.; Zhu, M.H.; Zhang, W.H.; Zhou, W.X. Friction and wear behavior of pure carbon strip sliding against copper contact wire under AC passage at high speeds. Tribol. Int. 2011, 44, 437–444. [Google Scholar] [CrossRef]

- Zhou, W.; Peng, K.; Ran, L.; Ge, Y.; Yi, M. Effect of electrical current on tribological property of the Mo2C modified C/C-Cu composite. Tribology 2016, 36, 503–509. [Google Scholar] [CrossRef]

- Sun, Y.; Song, C.; Zhang, Y.; Li, M.; Zhang, Y. Oxidation on the current-carrying rolling surface and its subsequent impact on the damage of Cu contact pairs in O2/N2 mixture. Mater. Lett. 2021, 288, 129349. [Google Scholar] [CrossRef]

- Yu, H.-L.; Xu, Y.; Shi, P.-J.; Xu, B.-S.; Wang, X.-L.; Liu, Q. Tribological properties and lubricating mechanisms of Cu nanoparticles in lubricant. Trans. Nonferrous Met. Soc. China 2008, 18, 636–641. [Google Scholar] [CrossRef]

- Du, J.; Lu, M.; Fang, J.; Li, W.; Chen, D. Current-carrying friction behavior and wear mechanism of Ag coatings by rotary spray deposition. Wear 2024, 546–547, 205367. [Google Scholar] [CrossRef]

- Ren, W.; Du, Y.; Cui, L.; Wang, P.; Song, J. Research on fretting regimes of gold-plated copper alloy electrical contact material under different vibration amplitude and frequency combinations. Wear 2014, 321, 70–78. [Google Scholar] [CrossRef]

- Cao, Z.; Li, R.; Shou, M.; Luo, R.; Wei, B.; Wang, T. Mechanical properties and tribological behaviors of Ag/graphene composite coating under sliding friction and current-carrying fretting. Tribol. Int. 2024, 197, 109811. [Google Scholar] [CrossRef]

- Li, X.; Ji, L.; Ju, P.; Li, H.; Zhou, H.; Chen, J.; Gou, X.; Duan, W. Preparation and vacuum current-carrying tribological behavior of Au film by magnetron sputtering. Tribology 2022, 42, 283–293. [Google Scholar] [CrossRef]

- Ren, W.; Wang, P.; Song, J.; Zhai, G. Effects of current load on wear and fretting corrosion of gold-plated electrical contacts. Tribol. Int. 2014, 70, 75–82. [Google Scholar] [CrossRef]

- Liu, X.-L.; Zhang, S.; Zhang, T.-M.; Xiao, Q.; Guan, X.; Zhang, W.-L.; Zheng, Y.-T.; Gao, M.-S.; Chen, D.-Y.; Yang, W.-B. Study on the wear properties of conductive terminals with different coatings at low temperatures. Mater. Lett. 2023, 349, 134897. [Google Scholar] [CrossRef]

- Kalin, M.; Poljanec, D. Influence of the contact parameters and several graphite materials on the tribological behaviour of graphite/copper two-discelectrical contacts. Tribol. Int. 2018, 126, 192–205. [Google Scholar] [CrossRef]

- Hu, M.-J.; Liu, X.-L.; Zhou, C.-W.; Wang, D.-Y.; Xiao, Q.; Guan, X.; Zhang, S.; Xu, Z.-B. Comparative study of the current-carrying tribological properties of carbon graphite composites with different hardnesses. Int. J. Mech. Sci. 2023, 245, 108133. [Google Scholar] [CrossRef]

- Yang, Z.; Song, Y.; Jiao, J.; Li, W.; Bao, S.; Zhang, Y. Optimization of current-carrying friction and wear properties of copper-carbon composite materials based on damage. Tribol. Int. 2024, 191, 109074. [Google Scholar] [CrossRef]

- Chen, W.; Wang, Y.; Zhang, L.; Feng, C.; Zhou, K. The effect of hot extrusion on mechanical and tribological behavior of Ag-Cu/MoS2 composites. Tribol. Trans. 2016, 59, 375–384. [Google Scholar] [CrossRef]

- Yin, J.; Zhang, H.B.; Xiong, X.; Tan, C.; Yang, S.L. Effect of carbon matrix content on bending properties of C/C–Cu composites. Mater. Res. Innov. 2014, 18, S4-495–S4-498. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, C.; Qiao, S.; Yang, Z. Fabrication and microstructure of C/Cu composites. Adv. Eng. Mater. 2010, 12, 493–496. [Google Scholar] [CrossRef]

- Zhou, W.; Yi, M.; Peng, K.; Ran, L.; Ge, Y. Preparation of a C/C–Cu composite with Mo2C coatings as a modification interlayer. Mater. Lett. 2015, 145, 264–268. [Google Scholar] [CrossRef]

- Wu, J.-S.; Li, J.-F.; Zhang, L.; Qian, Z.-Y. Effects of environment on dry sliding wear behavior of silver–copper based composites containing tungsten disulfide. Trans. Nonferrous Met. Soc. China 2017, 27, 2202–2213. [Google Scholar] [CrossRef]

- Kang, X.; Zhang, L. Enhanced sliding electrical contact properties of silver matrix self-lubricating nanocomposite using molecular level mixing process and spark plasma sintering. Powder Technol. 2020, 372, 94–106. [Google Scholar] [CrossRef]

- Pei, L.; Ji, L.; Li, H.; Cai, H.; Xue, Y. Current-carrying tribological behavior of textured Au/MoS2 coatings in vacuum. Surf. Topogr. Metrol. Prop. 2024, 12, 025006. [Google Scholar] [CrossRef]

- Grandin, M.; Wiklund, U. Friction, wear and tribofilm formation on electrical contact materials in reciprocating sliding against silver-graphite. Wear 2013, 302, 1481–1491. [Google Scholar] [CrossRef]

- Hu, Z.L.; Chen, Z.H.; Xia, J.T. Study on surface film in the wear of electrographite brushes against copper commutators for variable current and humidity. Wear 2008, 264, 11–17. [Google Scholar] [CrossRef]

- Song, Y.; Yang, Z.; Jiao, J.; Li, W.; Zhao, M.; Bao, S.; Zhang, Y. Research on damage optimization of copper-carbon gradient composite materials for current-carrying friction. Tribol. Int. 2024, 195, 109635. [Google Scholar] [CrossRef]

- Lin, X.; Liu, R.; Chen, J.; Xiong, X.; Liao, N. Study on current-carrying friction and wear properties of copper-graphite brush material reinforced by organosilicon. J. Mater. Res. Technol. 2021, 12, 365–375. [Google Scholar] [CrossRef]

- Liu, X.; Tu, C.; Wu, G.; Gao, M.; Liu, Y.; Chen, Y.; Cai, W.-H.; Li, R. Investigation of the enhancement in current-carrying friction performance with internal “copper network structure” constructed by pre-oxidized carbon fibers of the carbon skateboard. Tribol. Int. 2024, 198, 109820. [Google Scholar] [CrossRef]

- He, F.; Yang, X.; Bian, Z.; Xie, G.; Guo, D.; Luo, J. In-Plane Potential Gradient Induces Low Frictional Energy Dissipation during the Stick-Slip Sliding on the Surfaces of 2D Materials. Small 2019, 15, e1904613. [Google Scholar] [CrossRef]

- Elkady, O.A.M.; Abu-Oqail, A.; Ewais, E.M.M.; El-Sheikh, M. Physico-mechanical and tribological properties of Cu/h-BN nanocomposites synthesized by PM route. J. Alloys Compd. 2015, 625, 309–317. [Google Scholar] [CrossRef]

- Cao, Z.; Xia, Y.; Xi, X. Nano-montmorillonite-doped lubricating grease exhibiting excellent insulating and tribological properties. Friction 2017, 5, 219–230. [Google Scholar] [CrossRef]

- Li, P.; Ju, P.; Ji, L.; Li, H.; Liu, X.; Chen, L.; Zhou, H.; Chen, J. Toward robust macroscale superlubricity on engineering steel substrate. Adv. Mater. 2020, 32, 2002039. [Google Scholar] [CrossRef]

- Wang, D.; Chen, X.; Li, F.; Chen, W.; Li, H.; Yao, C. Influence of normal load, electric current and sliding speed on tribological performance of electrical contact interface. Microelectron. Reliab. 2023, 142, 114929. [Google Scholar] [CrossRef]

- Song, H.; Ji, L.; Li, H.; Wang, J.; Liu, X.; Zhou, H.; Chen, J. Self-forming oriented layer slip and macroscale super-low friction of graphene. Appl. Phys. Lett. 2017, 110, 073101. [Google Scholar] [CrossRef]

- Toth, G.; Mäklin, J.; Halonen, N.; Palosaari, J.; Juuti, J.; Jantunen, H.; Kordas, K.; Sawyer, W.G.; Vajtai, R.; Ajayan, P.M. Carbon-nanotube-based electrical brush contacts. Adv. Mater. 2009, 21, 2054–2058. [Google Scholar] [CrossRef]

- Groth, K.; Heidenfelder, F.; Holinski, R. Advancements of tribological performance of carbon brushes in electrical motors. Ind. Lubr. Tribol. 2001, 53, 5–10. [Google Scholar] [CrossRef]

- Yang, H.J.; Chen, G.X.; Gao, G.Q.; Wu, G.N.; Zhang, W.H. Experimental research on the friction and wear properties of a contact strip of a pantograph–catenary system at the sliding speed of 350 km/h with electric current. Wear 2015, 332–333, 949–955. [Google Scholar] [CrossRef]

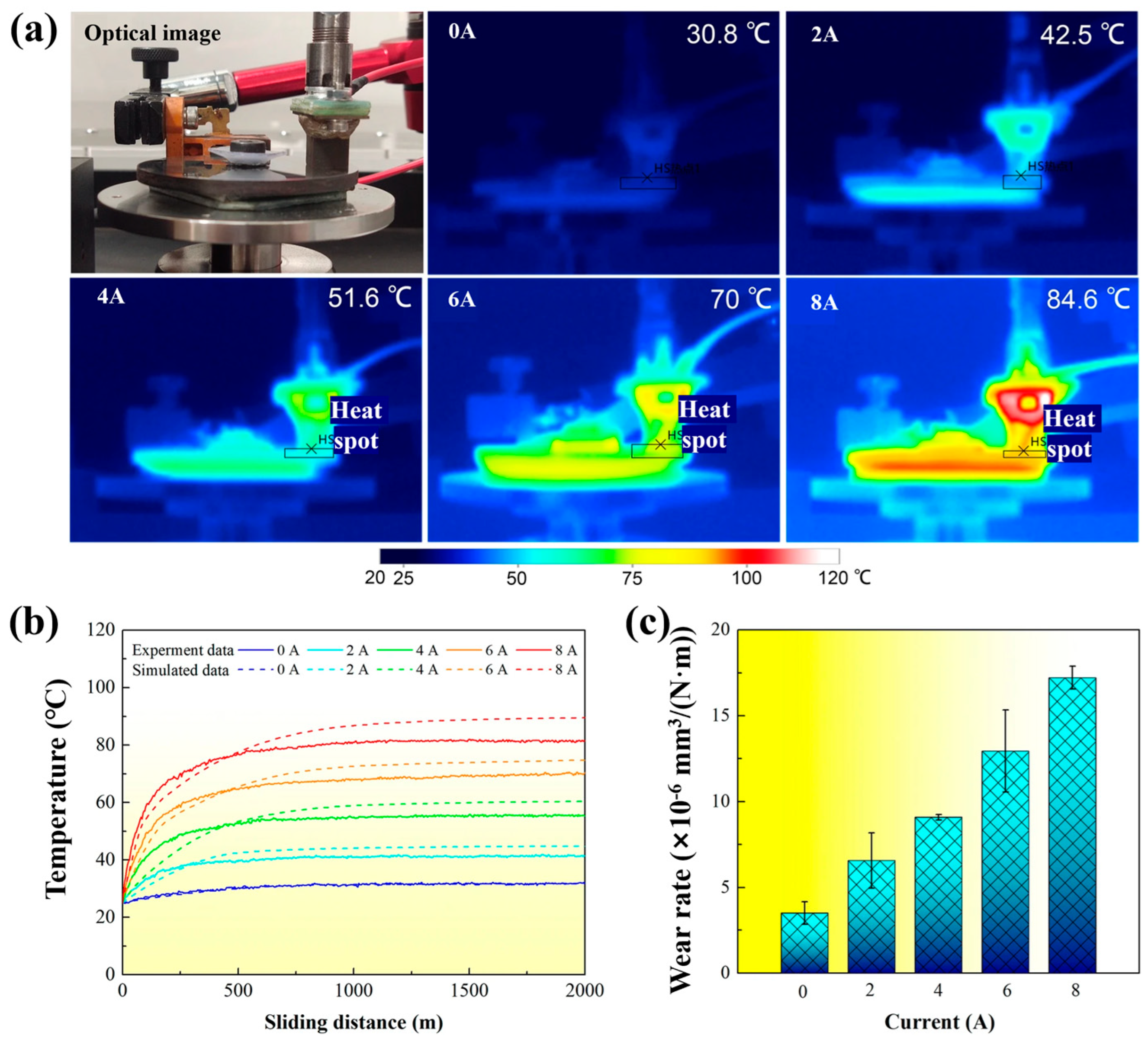

- Zhou, Y.; Du, M.; Zuo, X. Influence of electric current on the temperature rise and wear mechanism of copper–graphite current-carrying friction pair. J. Tribol. 2022, 144, 101701. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Pang, X.; Song, C.; Ni, F.; Zhang, Y. Evolution processes of the tribological properties in pantograph/catenary system affected by dynamic contact force during current-carrying sliding. Wear 2021, 477, 203809. [Google Scholar] [CrossRef]

- Xue, P.; Chen, C.; Fan, X.; Diao, D. Current-carrying friction in carbon coated ball bearing. Friction 2023, 11, 2008–2020. [Google Scholar] [CrossRef]

- Meng, Y.; Ren, W.; Han, Y.; Zhang, C. Effects of current load on wear and melt erosion of electrical contacts under fretting condition. Tribol. Int. 2024, 194, 109511. [Google Scholar] [CrossRef]

- Wang, D.W.; Li, F.Q.; Chen, X.; Xiang, Z.Y.; Zhao, F. Probing the effect of the electric current on the tribological performances of the electrical contact surfaces with graphene coating. Tribol. Int. 2023, 178, 108121. [Google Scholar] [CrossRef]

- Chen, T.; Song, C.; Liu, Z.; Wang, L.; Sun, C.; Pang, X.; Zhang, Y. Effect of elastic contact force on tribological characteristics of current-carrying roll rings in rotating conductive joints. Tribol. Trans. 2023, 66, 175–184. [Google Scholar] [CrossRef]

- Holle, M.J.; Misak, H.E.; Malik, R.A.; Alarifi, I.M.; Asmatulu, R. Structural analysis and wear behavior of different graphite-based brushes for aircraft starter generator application. Adv. Compos. Hybrid Mater. 2021, 4, 162–172. [Google Scholar] [CrossRef]

- Cho, K.H.; Hong, U.S.; Lee, K.S.; Jang, H. Tribological properties and electrical signal transmission of copper–graphite composites. Tribol. Lett. 2007, 27, 301–306. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, C.; Li, R.; Shou, M.; Zheng, K.; Luo, R.; Wei, B.; Wang, T.; Wu, L. Mechanical properties and current-carrying tribological behaviors of sliver-titanium nitride composite ceramic coating. Ceram. Int. 2024, 50, 23419–23428. [Google Scholar] [CrossRef]

- Liu, X.-L.; Guan, X.; Zhong, Y.; Xiao, Q.; Cao, Y.; Zhang, W.-L.; Zhang, S.; Zheng, Y.-T.; Gao, M.-S.; Chen, D.-Y.; et al. Effect of different gaps in the conductor rail joints on the current-carrying wear performance of carbon skateboards/conductive rail contact. Wear 2024, 536–537, 205172. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Zhang, Y.Z.; Du, S.M.; Song, C.F.; Yang, Z.H.; Shangguan, B. Tribological properties of pure carbon strip affected by dynamic contact force during current-carrying sliding. Tribol. Int. 2018, 123, 256–265. [Google Scholar] [CrossRef]

- Yang, Y.; Pei, L.; Zhang, H.; Feng, K.; Ju, P.; Duan, W.; Ji, L.; Li, H.; Liu, X.; Zhou, H.; et al. Magnetron sputtering NbSe2 film as lubricant for space current-carrying sliding contact. Friction 2023, 11, 383–394. [Google Scholar] [CrossRef]

- Ouyang, H.; Wang, P.; Li, C.; Gao, R.; Shen, T.; Li, Y. Effect of humidity on the friction and wear behavior of C/C-CuNi composites. Diam. Relat. Mater. 2024, 146, 111144. [Google Scholar] [CrossRef]

- Gao, G.; Wang, Q.; Wang, H.; Qian, P.; Peng, W.; Ma, Y.; Dong, D.; Wang, X.; He, S.; Yang, Z.; et al. Study on current-carrying tribological characteristics of C-Cu sliding electric contacts under water accumulation from rainfall condition. Phys. Scr. 2024, 99, 055970. [Google Scholar] [CrossRef]

- Huang, W.; Kong, L.; Wang, X. Electrical sliding friction lubricated with ionic liquids. Tribol. Lett. 2016, 65, 17. [Google Scholar] [CrossRef]

- Wu, H.; Liu, C.; Niu, G.; Zhang, L.; Liu, H.; Kang, X. Effect of the contact load and rotation speed on the formation of rolling current-carrying arc and the corresponding material damage. J. Mater. Res. Technol. 2024, 32, 1696–1703. [Google Scholar] [CrossRef]

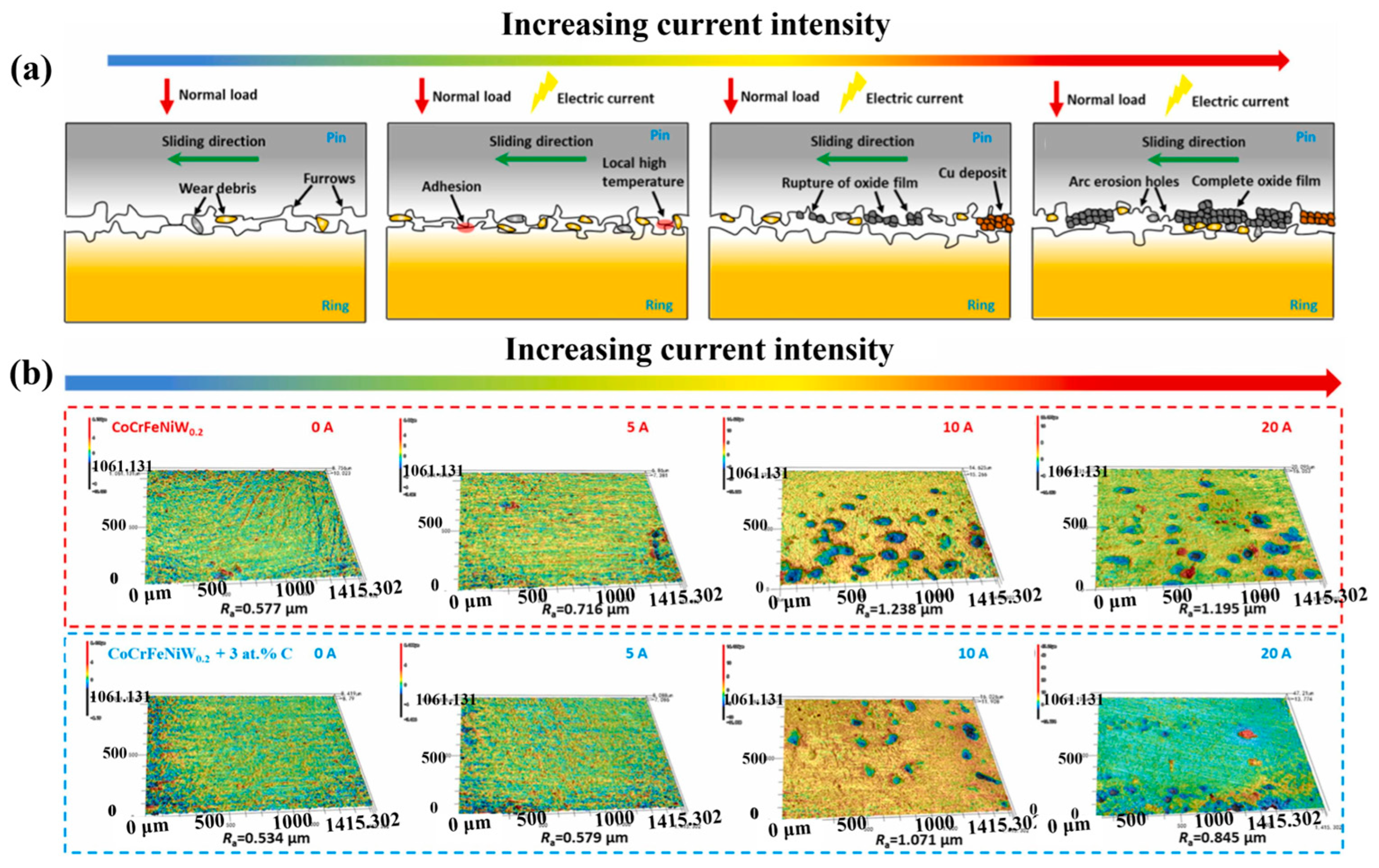

- Wang, P.; Wu, K.; Wu, W.; Pan, A.; Guo, Z.; Chen, S. Current-carrying wear behavior of CoCrFeNiW0.2 and CoCrFeNiW0.2+3at%C high entropy alloys. Tribol. Int. 2024, 197, 109749. [Google Scholar] [CrossRef]

- Li, S.; Jia, C.; Guo, X.; Song, K.; Wang, X.; Guo, H.; Su, J. Enhancement mechanism of carbon fiber on the current-carrying tribological properties of Cf-Al2O3/Cu composites. Wear 2023, 530–531, 205033. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, J.-K.; Xiao, S.-X.; Xu, G.-M.; Chen, J.; Zhang, C. Effect of electrical current on the tribological property of Cu-graphite brush. Tribol. Lett. 2024, 72, 29. [Google Scholar] [CrossRef]

- Ding, C.; Wang, X.; Chen, G.X.; Shu, M.H. Effect of temperature on friction and wear behaviors of carbon/copper with and without electric current. China Mech. Eng. 2010, 21, 843–847. [Google Scholar]

- Zhao, H.; Feng, Y.; Wu, K.; Wu, S.; Wang, W. Chaotic dynamic analysis of electrical contact resistance measured in sliding current-carrying friction. Tribol. Int. 2024, 200, 110178. [Google Scholar] [CrossRef]

- Li, C.; Wang, G.; Han, Q.; Feng, G.; Wang, L.; Wang, S. Effects of current-carrying conditions on lubrication and tribological performance of ionic liquid. J. Mol. Liq. 2022, 367, 120471. [Google Scholar] [CrossRef]

- Zhang, J.; Jia, L.; Xing, Z.; Lu, Z. Surface failure and repair technology of current-carrying sliding friction components. Tribology 2024, 44, 696–714. [Google Scholar] [CrossRef]

- Hao, W.; Xia, Y.; Yi, Z. Current carrying tribological properties of multi arc ion plated titanium nitride doped silver coating. Mater. Res. Express 2024, 11, 056401. [Google Scholar] [CrossRef]

- Cheng, G.; Li, X.; Zhang, D.; Lv, B.; Zhuang, G.; Liu, Z.; Li, Q.; Mo, Y.; Luo, C.; Zhou, M. Mechanism of multilayer graphene/ionic liquid synergistic regulation of interface state under current-carrying friction. Adv. Eng. Mater. 2024, 26, 2301629. [Google Scholar] [CrossRef]

- Zhou, Y.; Wen, D.; Wang, Y.; Zuo, X.; Zhu, R.; Mia, M.F. Tribo-electrical properties of copper matrix composites in salt-fog environment. Tribol. Int. 2024, 192, 109299. [Google Scholar] [CrossRef]

- Liu, X.; Wang, L.; Xue, Q. A novel carbon-based solid–liquid duplex lubricating coating with super-high tribological performance for space applications. Surf. Coat. Technol. 2011, 205, 2738–2746. [Google Scholar] [CrossRef]

- Zhang, Y.; Xin, W.; Wang, C.; Song, C.; Zhang, Y. Failure analysis of the pure carbon strip affected by dynamic contact force during current-carrying sliding. Eng. Fail. Anal. 2023, 152, 107437. [Google Scholar] [CrossRef]

- Song, A.; Shi, R.; Lu, H.; Wang, X.; Hu, Y.; Gao, H.-J.; Luo, J.; Ma, T. Fluctuation of interfacial electronic properties induces friction tuning under an electric field. Nano Lett. 2022, 22, 1889–1896. [Google Scholar] [CrossRef] [PubMed]

- Song, A.; Shi, R.; Lu, H.; Gao, L.; Li, Q.; Guo, H.; Liu, Y.; Zhang, J.; Ma, Y.; Tang, X.; et al. Modeling atomic-scale electrical contact quality across two-dimensional interfaces. Nano Lett. 2019, 19, 3654–3662. [Google Scholar] [CrossRef]

- Song, A.; Gao, L.; Zhang, J.; Liu, X.; Hu, Y.-Z.; Ma, T.-B.; Zheng, Q.; Luo, J. Achieving a superlubricating ohmic sliding electrical contact via a 2D heterointerface: A computational investigation. Nanoscale 2020, 12, 7857–7863. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, P.; Wang, X.; Jing, G.; Li, F.; Bai, P.; Tian, Y. Research Progress on Current-Carrying Friction with High Stability and Excellent Tribological Behavior. Lubricants 2024, 12, 349. https://doi.org/10.3390/lubricants12100349

Wei P, Wang X, Jing G, Li F, Bai P, Tian Y. Research Progress on Current-Carrying Friction with High Stability and Excellent Tribological Behavior. Lubricants. 2024; 12(10):349. https://doi.org/10.3390/lubricants12100349

Chicago/Turabian StyleWei, Peng, Xueqiang Wang, Guiru Jing, Fei Li, Pengpeng Bai, and Yu Tian. 2024. "Research Progress on Current-Carrying Friction with High Stability and Excellent Tribological Behavior" Lubricants 12, no. 10: 349. https://doi.org/10.3390/lubricants12100349

APA StyleWei, P., Wang, X., Jing, G., Li, F., Bai, P., & Tian, Y. (2024). Research Progress on Current-Carrying Friction with High Stability and Excellent Tribological Behavior. Lubricants, 12(10), 349. https://doi.org/10.3390/lubricants12100349