Research on the Milling Performance of Micro-Groove Ball End Mills for Titanium Alloys

Abstract

:1. Introduction

2. Micro-Groove Distribution Locations and Micro-Groove Sources

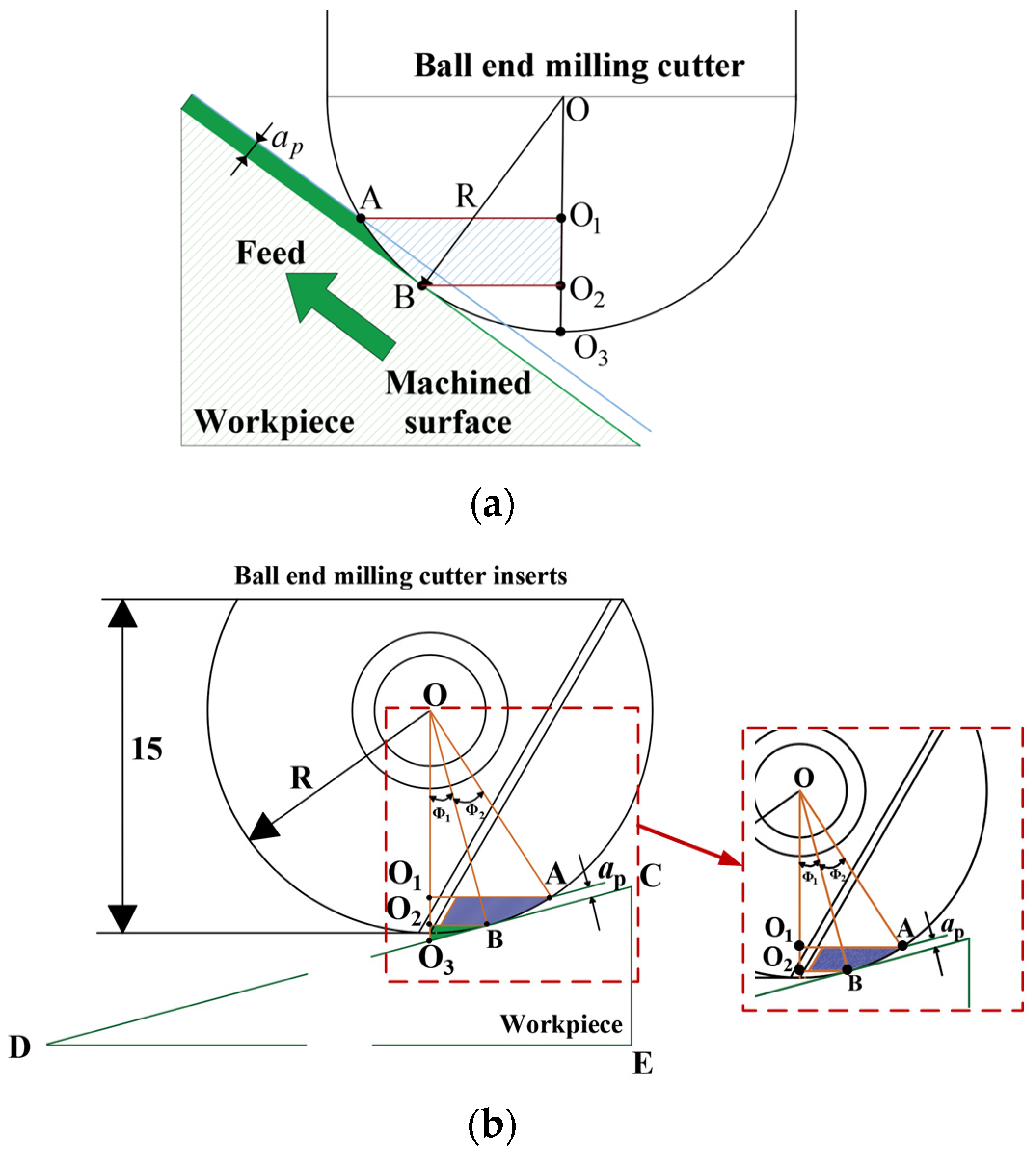

2.1. Carbide Ball End Milling Cutter Micro-Groove Distribution Location

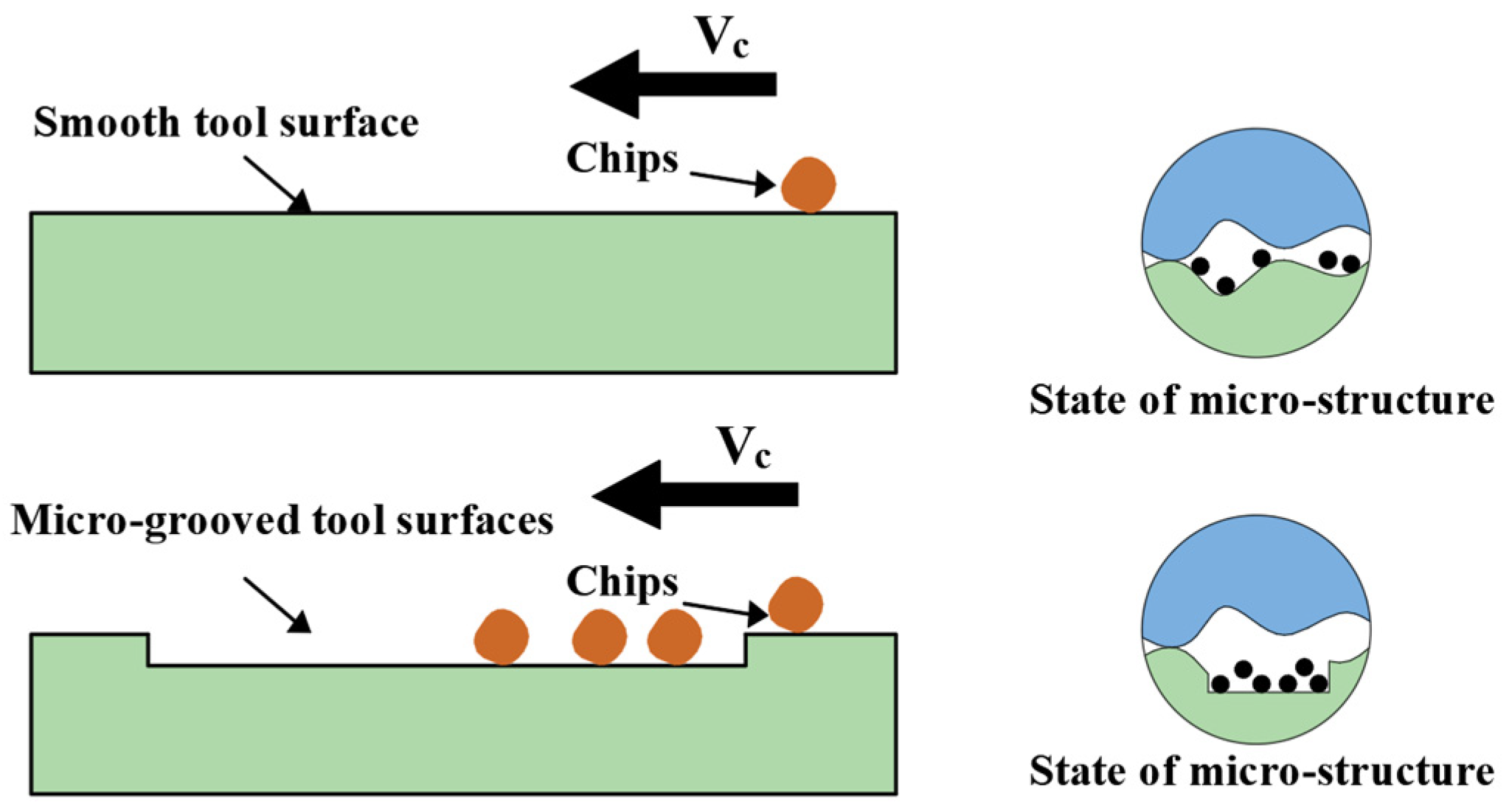

2.2. Sources of Micro-Grooves

3. Micro-Groove Milling Cutter Finite Element Simulation Test

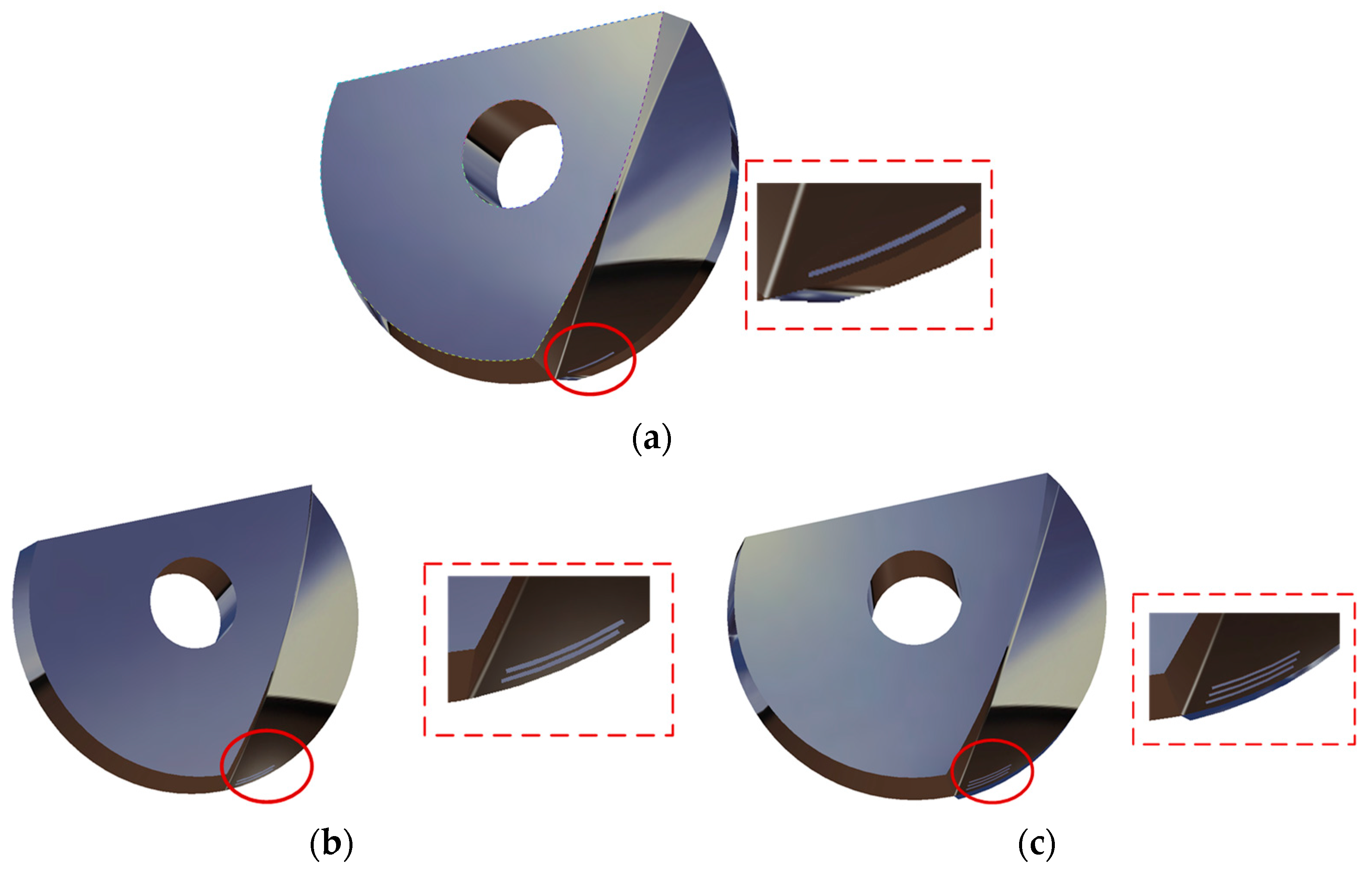

3.1. Establishment of 3D Model of Micro-Grooved Milling Cutter

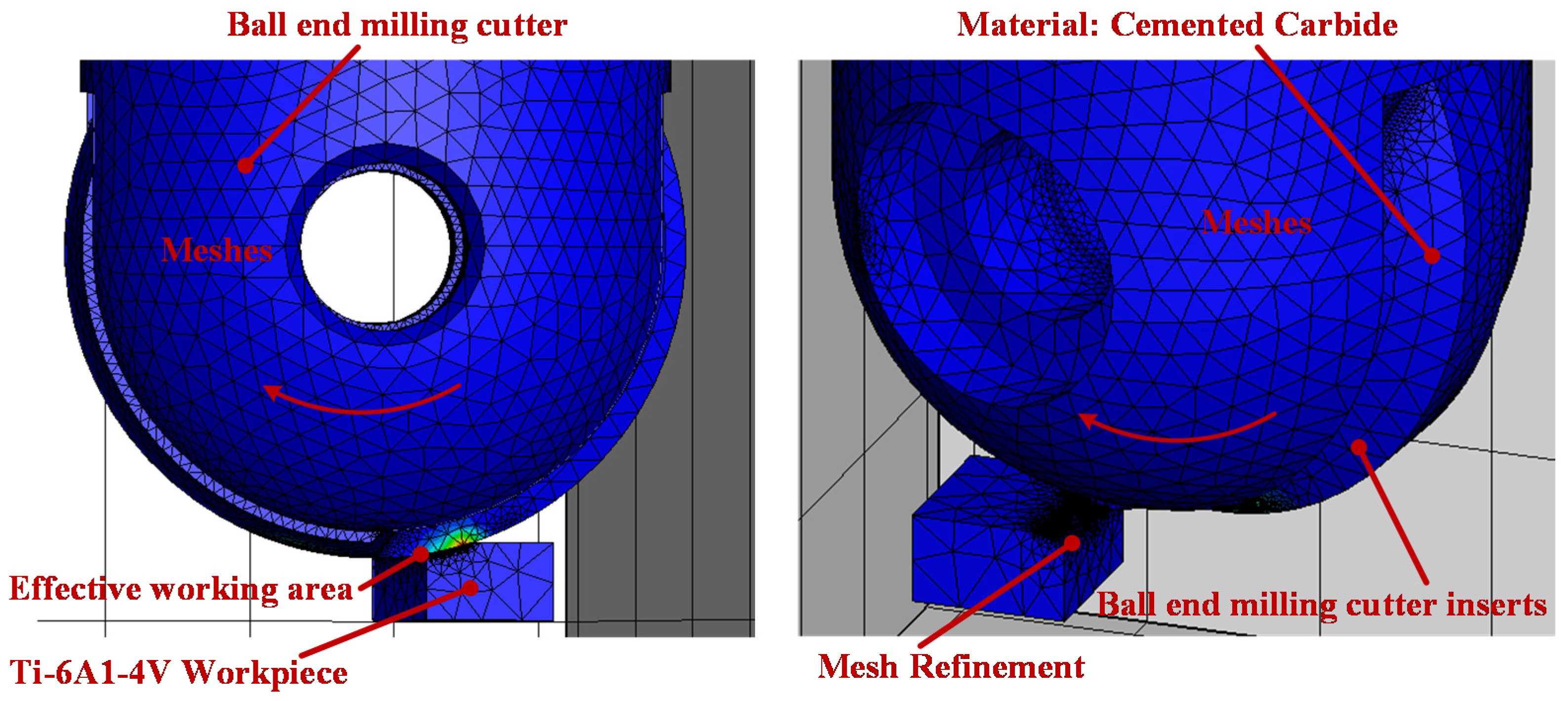

3.2. Finite Element Simulation Test of Milling by Micro-Grooved Milling Cutter

3.3. Experimental Results and Analysis

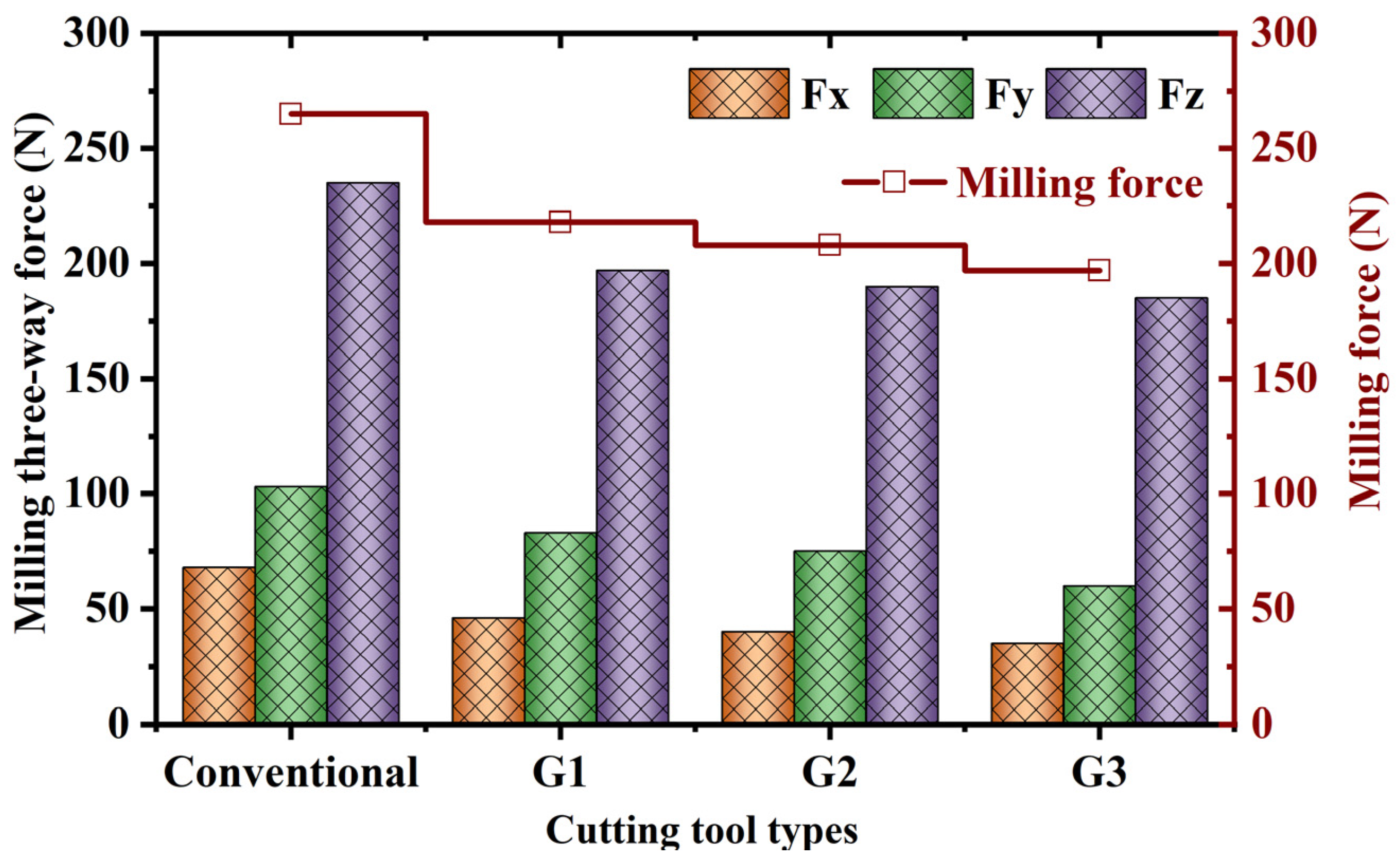

3.3.1. The Influence of Micro-Groove Count on Milling Force

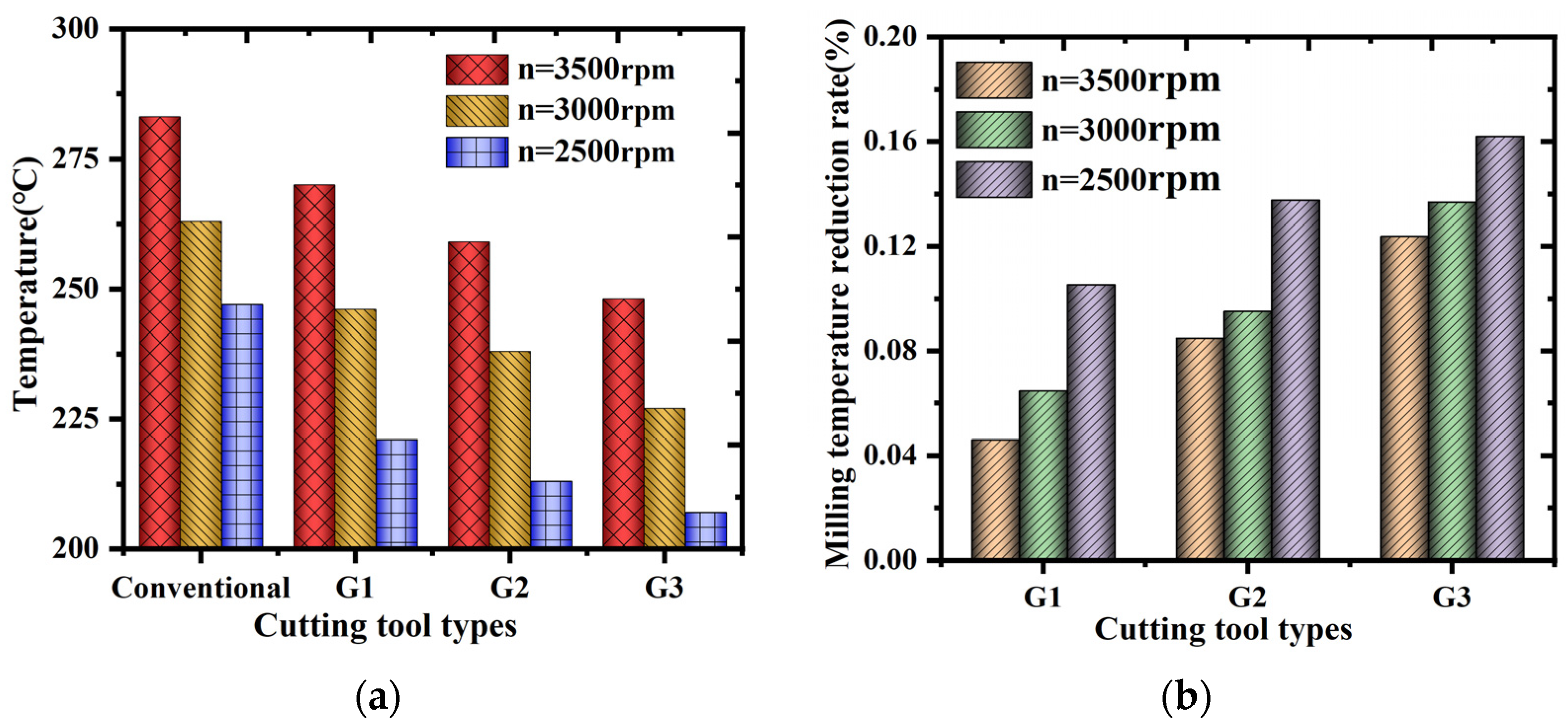

3.3.2. Effect of Micro-Grooved Area on Temperature

3.3.3. The Influence of Micro-Groove Area on Chip Formation

4. Micro-Groove Milling Cutter Test

4.1. Laser Fabrication of Micro-Groove Milling Cutters

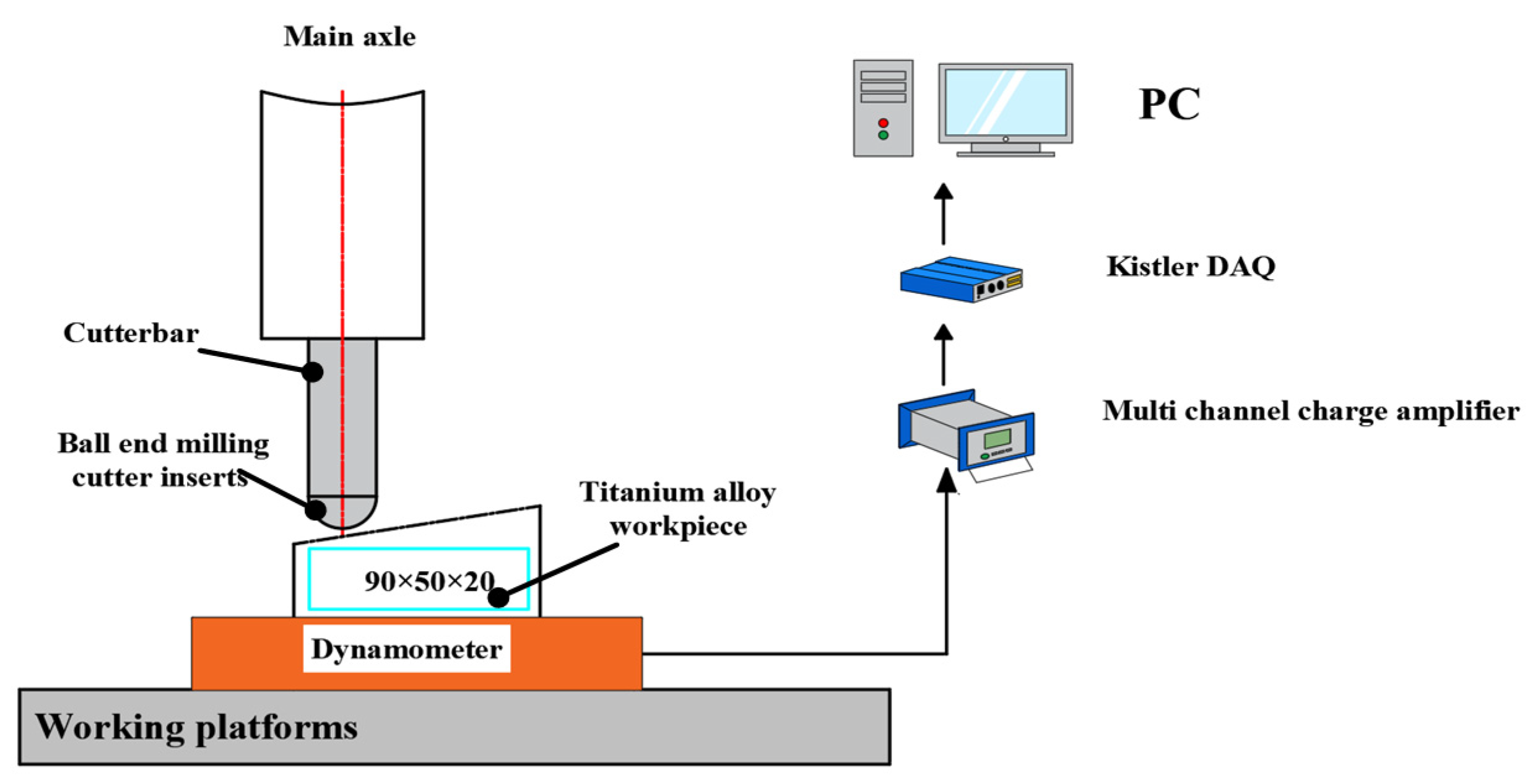

4.2. Micro-Groove Milling Cutter Test

4.3. Milling Results and Analysis of Micro-Groove Milling Cutter

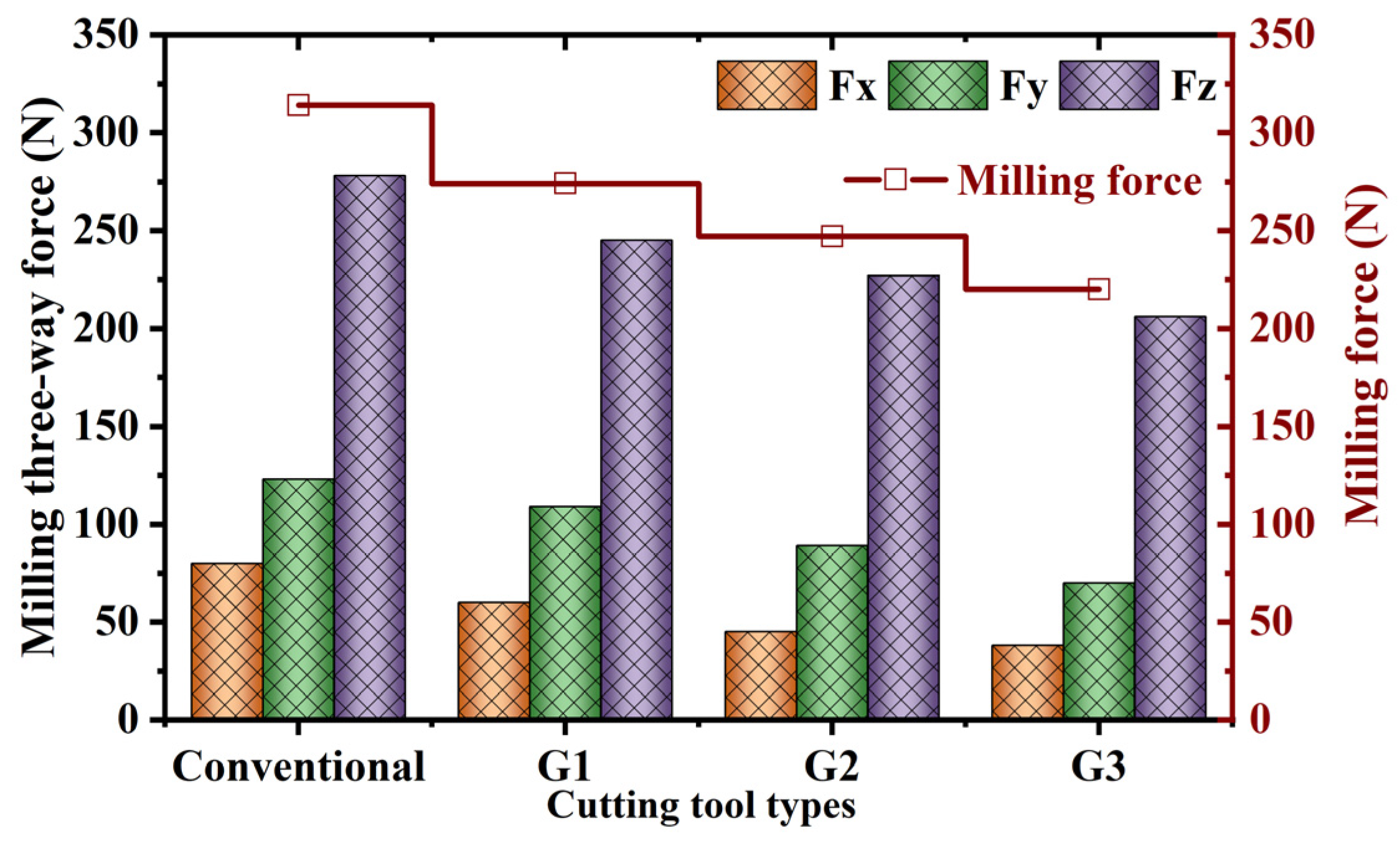

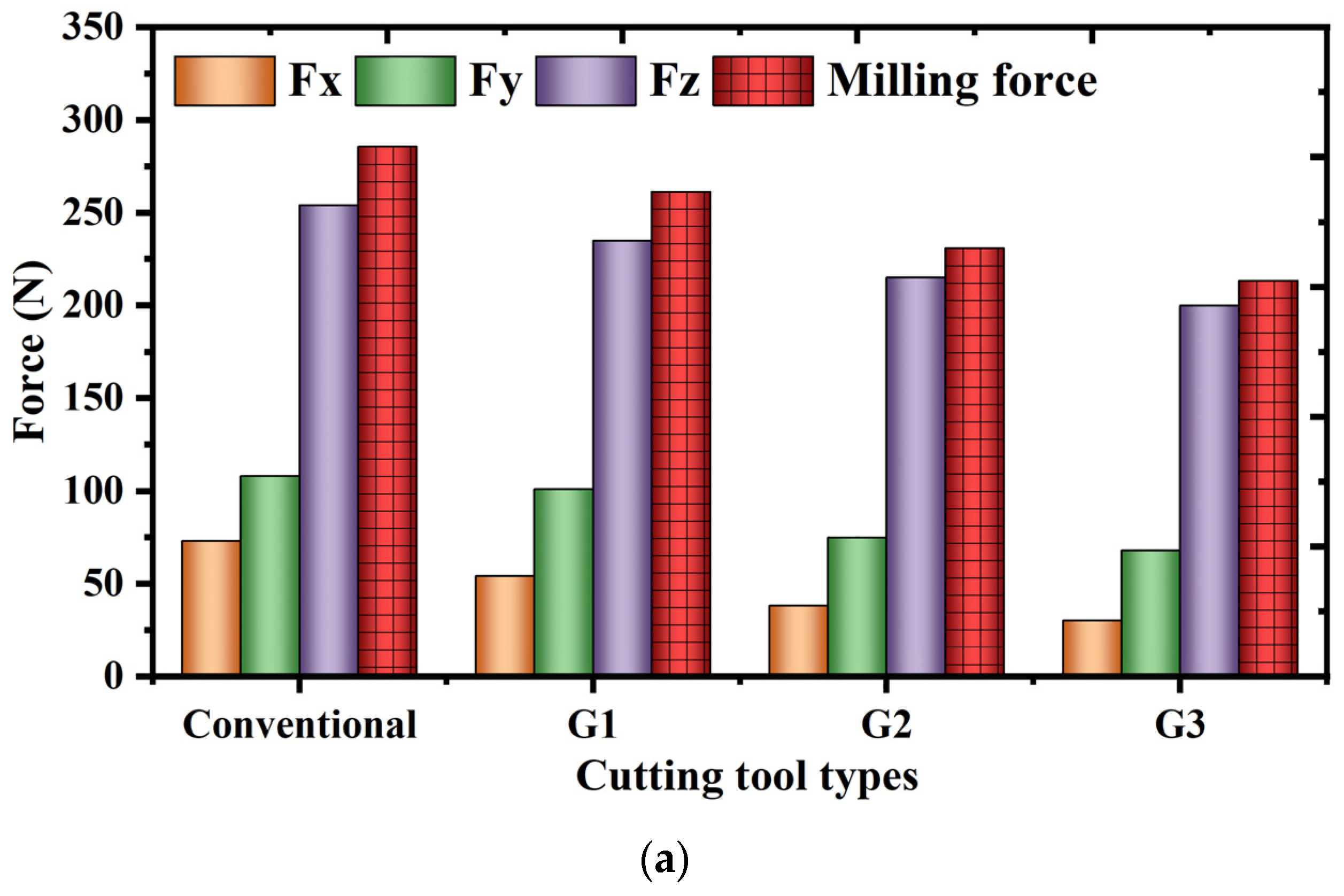

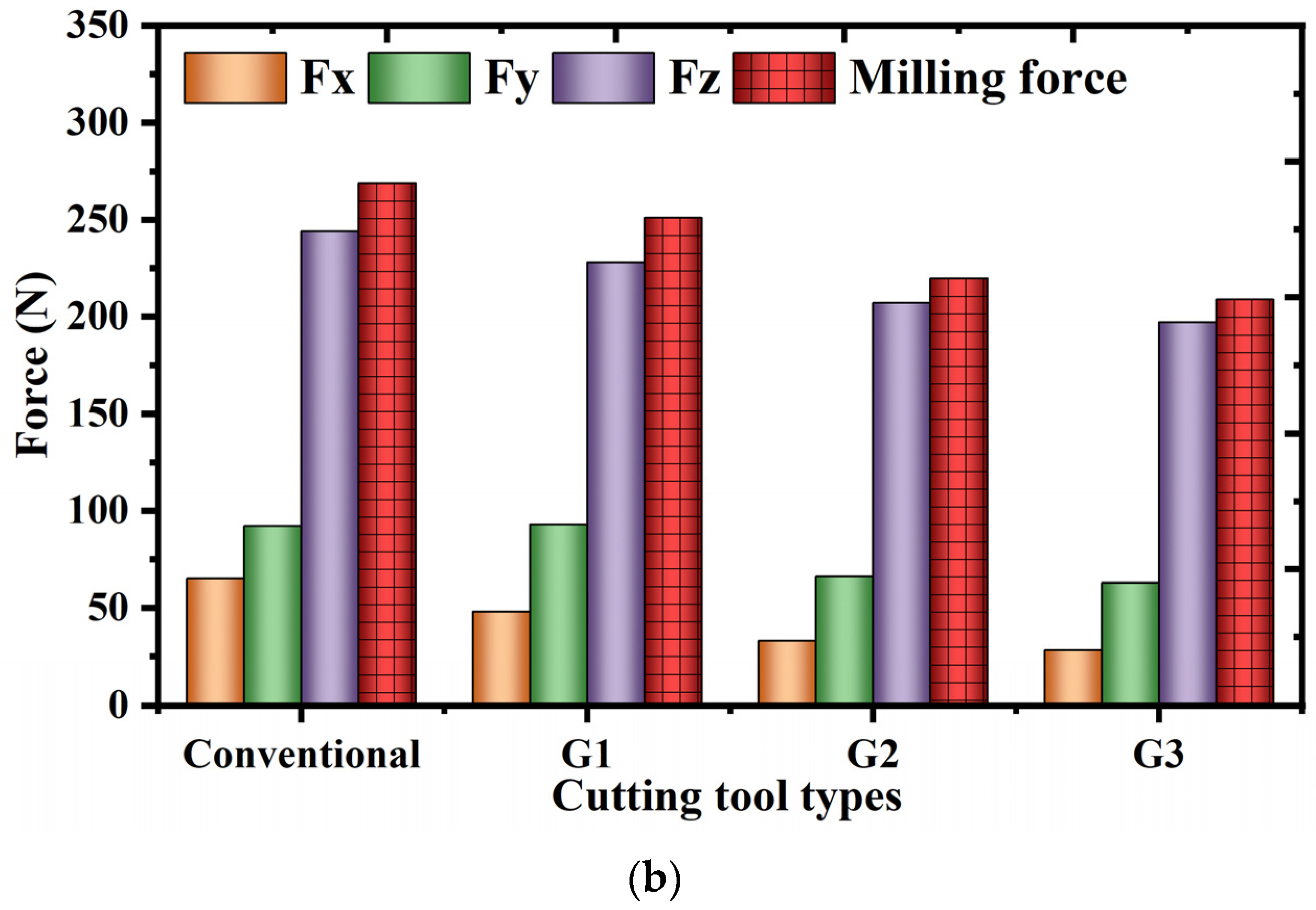

4.3.1. Impact of Micro-Groove Surface Area on Milling Forces

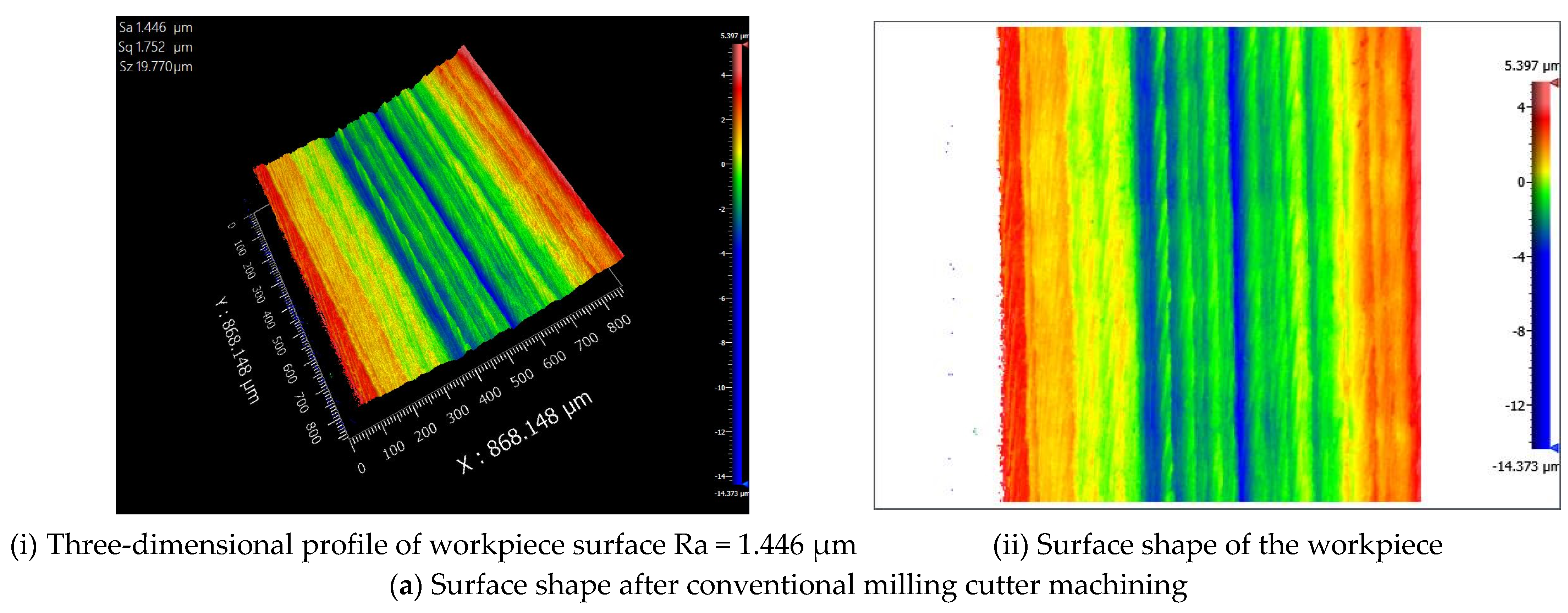

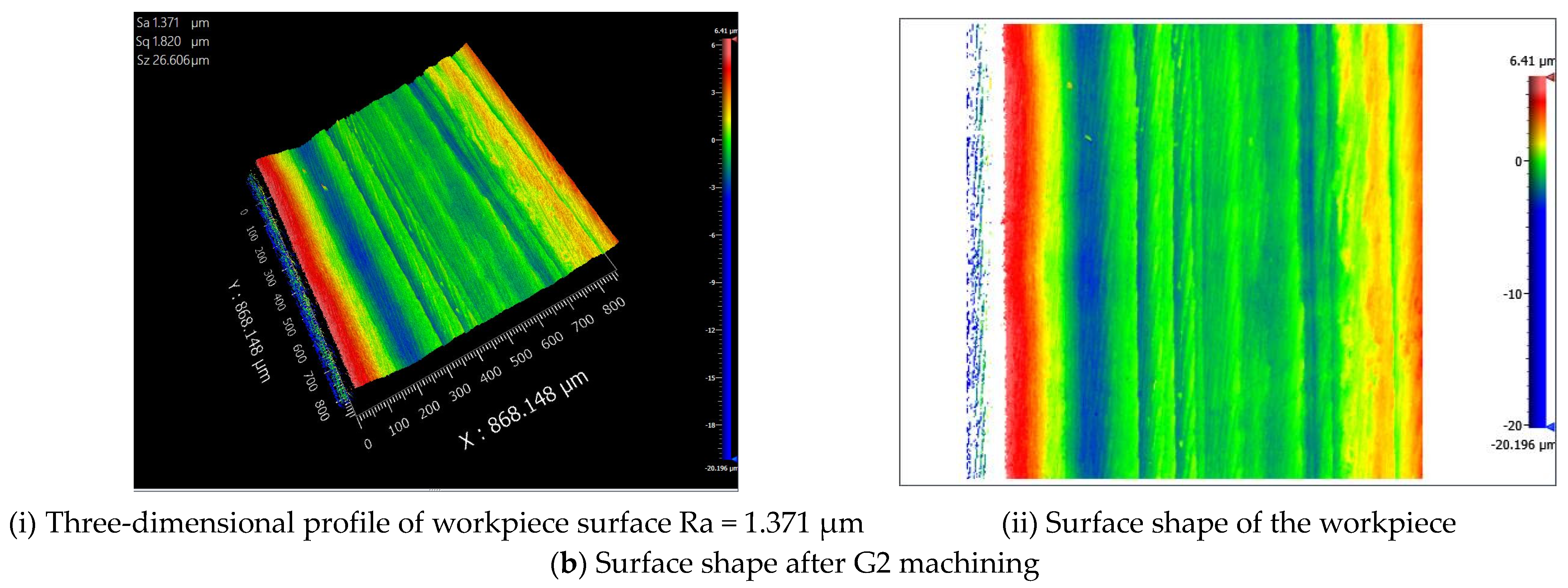

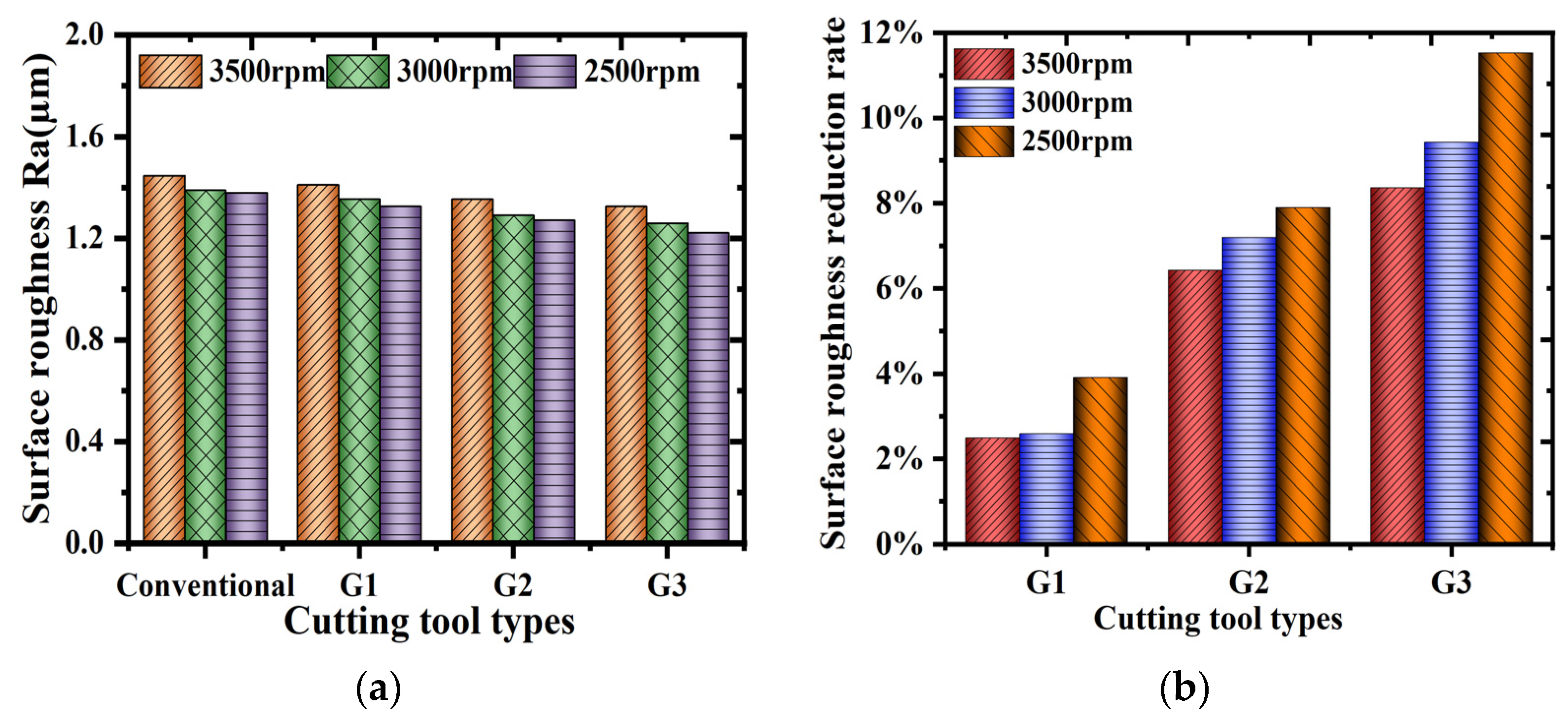

4.3.2. Effect of Micro-Groove Area on Surface Roughness of Machined Workpiece

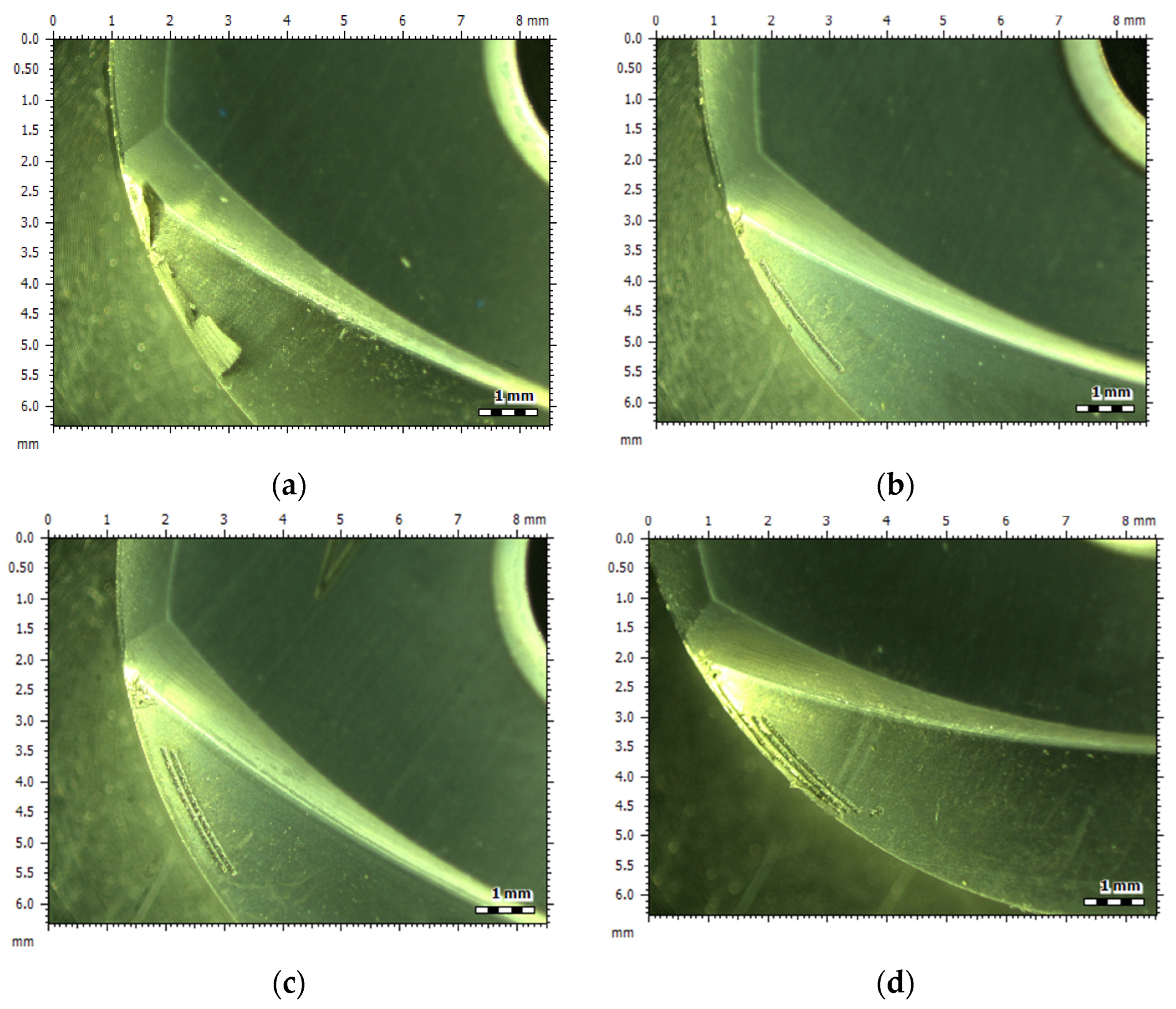

4.3.3. Effect of Micro-Groove Area on Chip Adhesion Resistance

5. Conclusions

- Through finite element simulation experiments on milling titanium alloys, it was found that compared to conventional milling cutters, micro-groove milling cutters promote a reduction in milling force and temperature, enhance chip resistance to adhesion, and change the concentration location of high stress areas on the surface of the milling cutter. Meanwhile, it was found that milling force, milling cutter surface stress, and milling temperature decreased significantly as the area occupied by micro-grooves on the milling cutter surface increased.

- Milling experiments showed that micro-grooved ball end mills help reduce milling forces, achieving good simulation consistency. When using a cutter with three micro-grooves, the milling force decreased by 10% to 30%, and the surface roughness decreased by 8% to 12%. It was also found that as the spindle speed increases, the curling radius of the chip decreases.

- The test results prove that preparing micro-grooves in the working area of the milling cutter surface changes the friction state between the milling cutter and chips, increases the heat dissipation area of the milling cutter surface, and allows the micro-grooves to be used as a storage container for chips, improving the resistance of the milling cutter surface to chip adhesion.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, P.; Tong, X.; Yang, S.; Wang, X. Uniform-Density Micro-Textured Ball-End Milling Cutter Model Based on Fractal and Uniform Distribution Theory. Coatings 2023, 13, 1446. [Google Scholar] [CrossRef]

- Patil, S.; Jadhav, S.; Kekade, S.; Supare, A.; Powar, A.; Singh, R.K.P. The influence of cutting heat on the surface integrity during machining of titanium alloy Ti6Al4V. Procedia Manuf. 2016, 5, 857–869. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, H. Wear optimization of titanium alloy cutter milled with microtextured ball-end milling cutter. Adv. Mech. Eng. 2020, 12, 1687814019892102. [Google Scholar] [CrossRef]

- Cotterell, M.; Byrne, G. Dynamics of chip formation during orthogonal cutting of titanium alloy Ti–6Al–4V. CIRP Ann. 2008, 57, 93–96. [Google Scholar] [CrossRef]

- Taylor, C.M.; Hernandez, S.G.A.; Marshall, M.; Broderick, M. Cutting fluid application for titanium alloys Ti-6Al-4V and Ti-10V-2Fe-3Al in a finish turning process. Procedia CIRP 2018, 77, 441–444. [Google Scholar] [CrossRef]

- Khanna, N.; Davim, J.P. Design-of-experiments application in machining titanium alloys for aerospace structural components. Measurement 2015, 61, 280–290. [Google Scholar] [CrossRef]

- Arulkirubakaran, D.; Senthilkumar, V.; Kumawat, V. Effect of micro-textured tools on machining of Ti–6Al–4V alloy: An experimental and numerical approach. Int. J. Refract. Met. Hard Mater. 2016, 54, 165–177. [Google Scholar] [CrossRef]

- Özel, T.; Biermann, D.; Enomoto, T.; Mativenga, P. Structured and textured cutting tool surfaces for machining applications. CIRP Ann. 2021, 70, 495–518. [Google Scholar] [CrossRef]

- Dogra, M.; Sharma, V.S.; Sachdeva, A.; Suri, N.M.; Dureja, J.S. Tool wear, chip formation and workpiece surface issues in CBN hard turning: A review. Int. J. Precis. Eng. Manuf. 2010, 11, 341–358. [Google Scholar] [CrossRef]

- Varga, J.; Ižol, P.; Vrabeľ, M.; Kaščák, Ľ.; Drbúl, M.; Brindza, J. Surface Quality Evaluation in the Milling Process Using a Ball Nose End Mill. Appl. Sci. 2023, 13, 10328. [Google Scholar] [CrossRef]

- Karpat, Y. Investigating elastic recovery of monocrystalline silicon during plunging experiments with chamfered diamond tools. Precis. Eng. 2023, 84, 119–135. [Google Scholar] [CrossRef]

- Khani, S.; Razfar, M.R.; Haghighi, S.S.; Farahnakian, M. Optimization of microtextured tools parameters in thread turning process of aluminum 7075 aerospace alloy. Mater. Manuf. Process. 2020, 35, 1330–1338. [Google Scholar] [CrossRef]

- Kümmel, J.; Braun, D.; Gibmeier, J.; Schneider, J.; Greiner, C.; Schulze, V.; Wanner, A. Study on micro texturing of uncoated cemented carbide cutting tools for wear improvement and built-up edge stabilisation. J. Mater. Process. Technol. 2015, 215, 62–70. [Google Scholar] [CrossRef]

- Ribeiro, F.S.F.; Lopes, J.C.; Bianchi, E.C.; de Angelo Sanchez, L.E. Applications of texturization techniques on cutting tools surfaces—A survey. Int. J. Adv. Manuf. Technol. 2020, 109, 1117–1135. [Google Scholar] [CrossRef]

- Yang, S.; Su, S.; Liu, X.; Han, P. Study on Milling Temperature of Titanium Alloy with Micro-Textured Ball End Milling Cutter under Radius of Blunt Edge. Appl. Sci. 2020, 10, 587. [Google Scholar] [CrossRef]

- Tong, X.; Liu, X.; Yang, S.; Wang, L.; He, C. Optimising milled titanium alloy concave surface quality with micro-textured ball-end milling cutters. Int. J. Manuf. Res. 2021, 16, 122–134. [Google Scholar] [CrossRef]

- Patel, K.; Liu, G.; Shah, S.R.; Özel, T. Effect of micro-textured tool parameters on forces, stresses, wear rate, and variable friction in titanium alloy machining. J. Manuf. Sci. Eng. 2020, 142, 021007. [Google Scholar] [CrossRef]

- Zheng, K.; Yang, F.; Zhang, N.; Liu, Q.; Jiang, F. Study on the cutting performance of micro textured tools on cutting Ti-6Al-4V titanium alloy. Micromachines 2020, 11, 137. [Google Scholar] [CrossRef]

- Li, Q.; Yang, S.; Zhang, Y.; Zhou, Y.; Cui, J. Evaluation of the machinability of titanium alloy using a micro-textured ball end milling cutter. Int. J. Adv. Manuf. Technol. 2018, 98, 2083–2092. [Google Scholar] [CrossRef]

- Alagan, N.T.; Zeman, P.; Hoier, P.; Beno, T.; Klement, U. Investigation of micro-textured cutting tools used for face turning of alloy 718 with high-pressure cooling. J. Manuf. Process. 2019, 37, 606–616. [Google Scholar] [CrossRef]

- Yang, F.; Pan, C.; Shi, Y. Fabricating Micro-texture on Surface of Cutting Tool Based on NC WEDM Technology. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 440, p. 022084. [Google Scholar]

- Kumar, V.U.; Raj, D.S. Performance analysis of tools with rake face textures produced using wire-EDM in turning AISI4340. Mater. Manuf. Process. 2021, 36, 1146–1160. [Google Scholar] [CrossRef]

- Sharma, R.; Pradhan, S.; Bathe, R.N. Design and fabrication of honeycomb micro-texture using femtosecond laser machine. Mater. Manuf. Process. 2021, 36, 1314–1322. [Google Scholar] [CrossRef]

- Puoza, J.C.; Hua, X.; Liu, Q.; Kang, Z.; Zhang, P. Manufacturing of micro-textures on metals by nanosecond laser micromachining. Adv. Mater. Process. Technol. 2018, 4, 86–99. [Google Scholar] [CrossRef]

- Sun, X.; Wang, X.; Hu, Y.; Duan, J.A. The effect of micro-texture on wear resistance of WC/Co-based tools during cutting Ti-6Al-4V. Appl. Phys. A 2021, 127, 453. [Google Scholar] [CrossRef]

- Phokobye, S.N.; Daniyan, I.A.; Tlhabadira, I.; Masu, L.; VanStaden, L.R. Model design and optimization of carbide milling cutter for milling operation of M200 tool steel. Procedia CIRP 2019, 84, 954–959. [Google Scholar] [CrossRef]

- Pan, J.; Ni, J.; He, L.; Cui, Z.; Feng, K. Influence of micro-structured milling cutter on the milling load and surface roughness of 6061 aluminum alloy. Int. J. Adv. Manuf. Technol. 2020, 110, 3201–3208. [Google Scholar] [CrossRef]

- Li, Q. Design Guidelines and Experimental Study of Micro-Texture of YG8 Ball End Milling Cutter for Cutting Titanium Alloy. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar]

- Yang, S.; Han, P.; Tong, X.; Liu, X.; Zhang, X. Study on forming technology of mesoscopic geometric features of tools and its role. J. Mech. Eng. 2024, 60, 317–351. [Google Scholar]

- Yang, S.; Yu, S.; He, C. The surface integrity of titanium alloy when using micro-textured ball-end milling cutters. Micromachines 2018, 10, 21. [Google Scholar] [CrossRef]

- Yang, S.; Han, P.; Su, S.; Zhang, N.; Ren, W. Study on surface work hardening of titanium alloy milled by micro-textured ball milling cutter. Int. J. Adv. Manuf. Technol. 2021, 112, 2497–2508. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Salem, A.; Hegab, H.; Hosseini, A.; Balazinski, M. Micro-textured cutting tools: Phenomenological analysis and design recommendations. CIRP Ann. 2021, 70, 65–68. [Google Scholar] [CrossRef]

- Yang, S. Research on the Design and Cutting Performance of PCBN Bionic Tool Based on the Tooth Profile Conformation of Cap Shell Teeth. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2023. [Google Scholar]

- Wang, B.; Zhu, J.; Xie, T.; Fu, L.; Yang, W.; Li, D.; Zhou, L. A new Cu-W bionic shell pearl multilayer structure. Surf. Coat. Technol. 2023, 461, 129433. [Google Scholar] [CrossRef]

- Jia, H. Strong Woven Research on Three-Dimensional Graphene Oxide-Based Biomimetic Shell Pearl Layer Block Material. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2020. [Google Scholar]

- Li, R.; Zhao, X. Analysis of the effect of shape factor on stress field and temperature field. Mach. Tools Hydraul. 2020, 48, 134–137. [Google Scholar]

- Zhao, X.; Zou, Z.; Shi, H.; He, L.; Hu, X. Simulation analysis of the influence of micro milling cutter geometry parameters on TC4 alloy machining. Comb. Mach. Tools Autom. Mach. Technol. 2020, 9–13. [Google Scholar] [CrossRef]

- Tong, X.; Yang, S.; He, C.; Zheng, M. Multiobjective optimization of cutting performance of ball end milling cutter with variable density micro-weave configuration. J. Mech. Eng. 2019, 55, 221–232. [Google Scholar]

| Dimensional Parameters | Spacing (μm) | Length (μm) | Width (μm) | Depth (μm) |

|---|---|---|---|---|

| Numerical Value | 150 | 1200 | 60 | 60 |

| Group | Spindle Speed n (rpm) | Feed per Tooth f (mm/z) | Depth of Cut ap (mm) |

|---|---|---|---|

| 1 | 2500 | 0.1 | 0.5 |

| 2 | 3000 | 0.1 | 0.5 |

| 3 | 3500 | 0.1 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Shi, H.; Wang, B.; Ma, C.; Li, Q. Research on the Milling Performance of Micro-Groove Ball End Mills for Titanium Alloys. Lubricants 2024, 12, 204. https://doi.org/10.3390/lubricants12060204

Zhang S, Shi H, Wang B, Ma C, Li Q. Research on the Milling Performance of Micro-Groove Ball End Mills for Titanium Alloys. Lubricants. 2024; 12(6):204. https://doi.org/10.3390/lubricants12060204

Chicago/Turabian StyleZhang, Shihong, Hu Shi, Baizhong Wang, Chunlu Ma, and Qinghua Li. 2024. "Research on the Milling Performance of Micro-Groove Ball End Mills for Titanium Alloys" Lubricants 12, no. 6: 204. https://doi.org/10.3390/lubricants12060204

APA StyleZhang, S., Shi, H., Wang, B., Ma, C., & Li, Q. (2024). Research on the Milling Performance of Micro-Groove Ball End Mills for Titanium Alloys. Lubricants, 12(6), 204. https://doi.org/10.3390/lubricants12060204