Parameter Effects on the Static Characteristics of the Multi-Foil Aerodynamic Journal Bearing with Bump-Backing Foils

Abstract

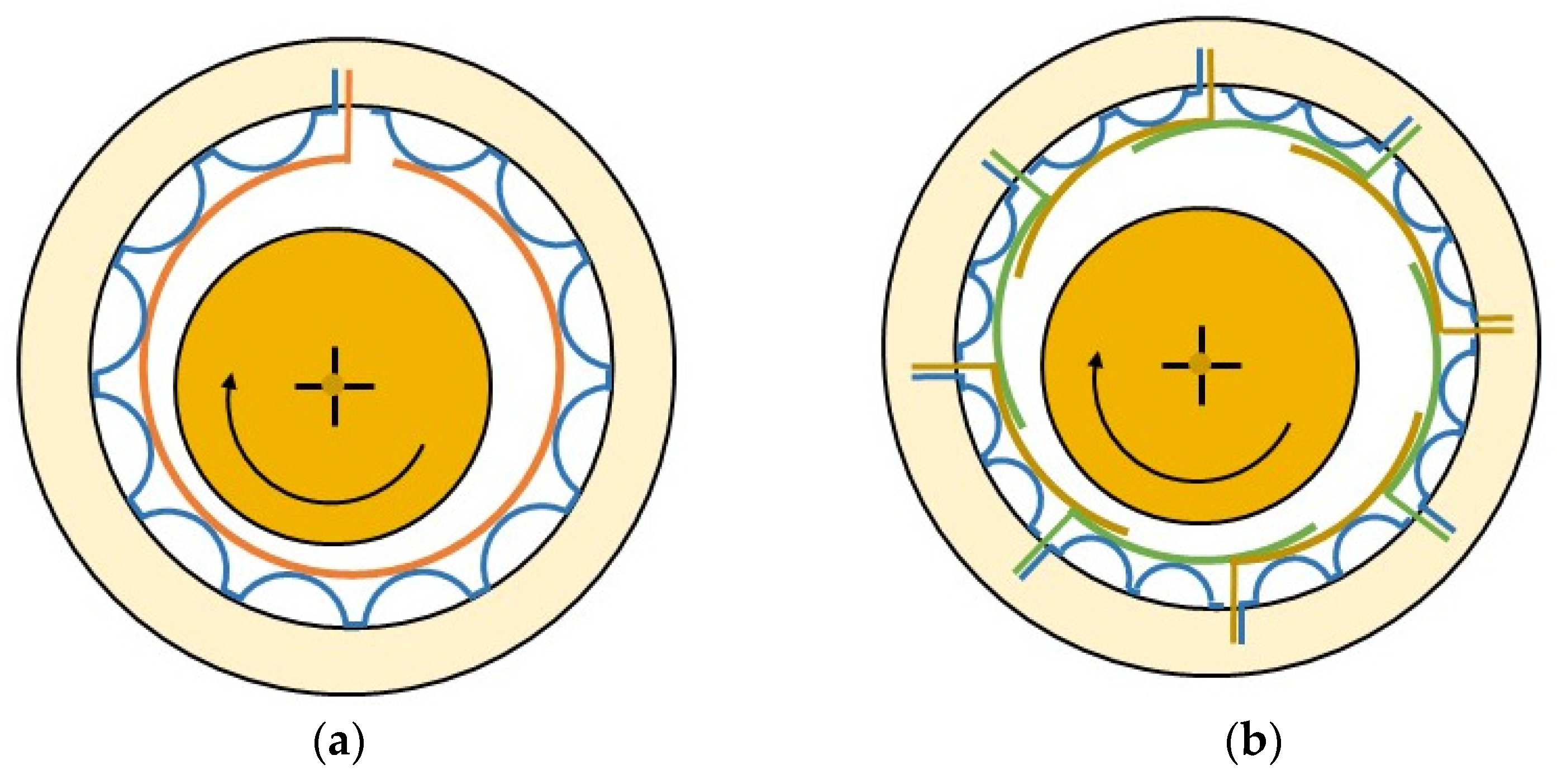

:1. Introduction

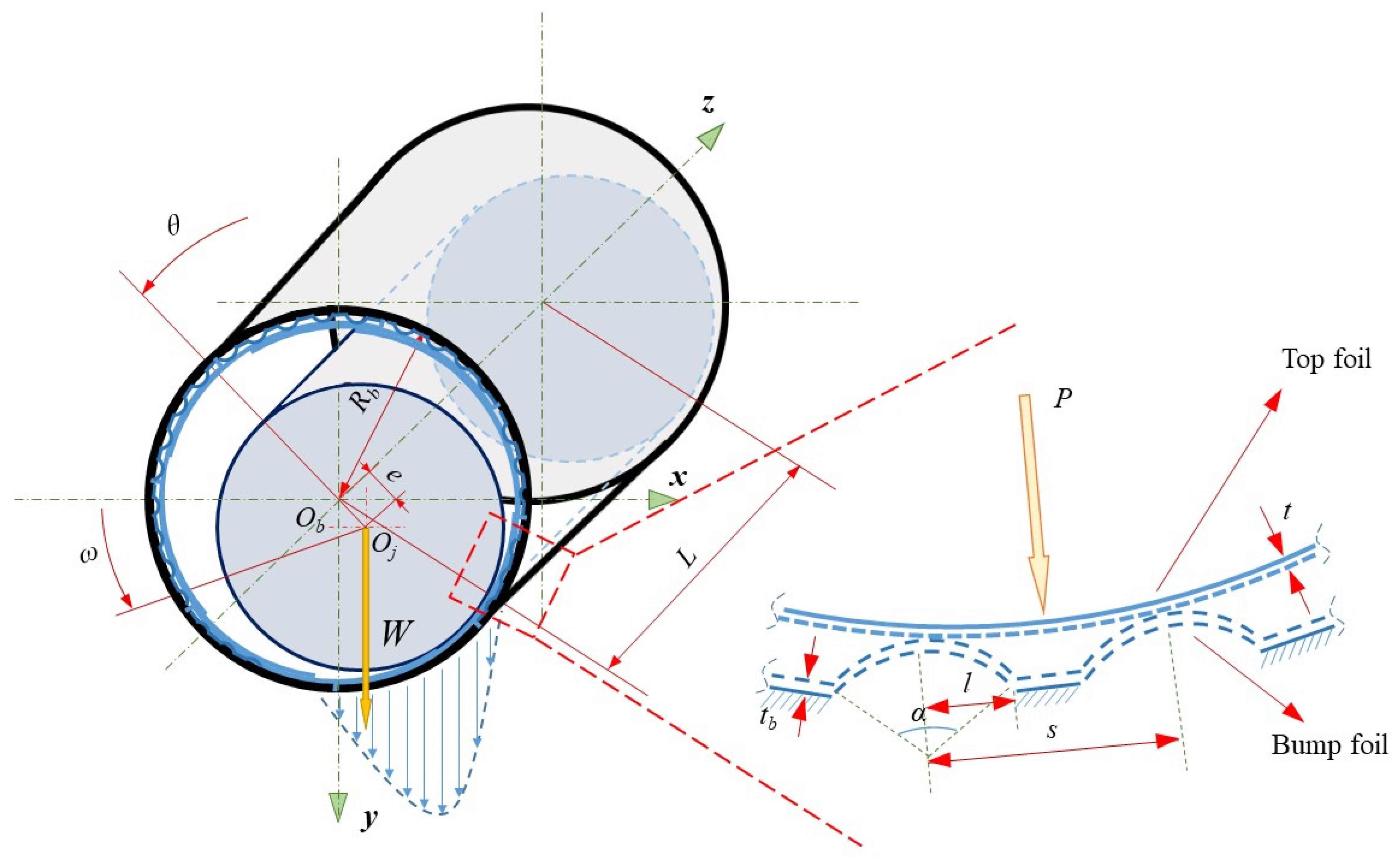

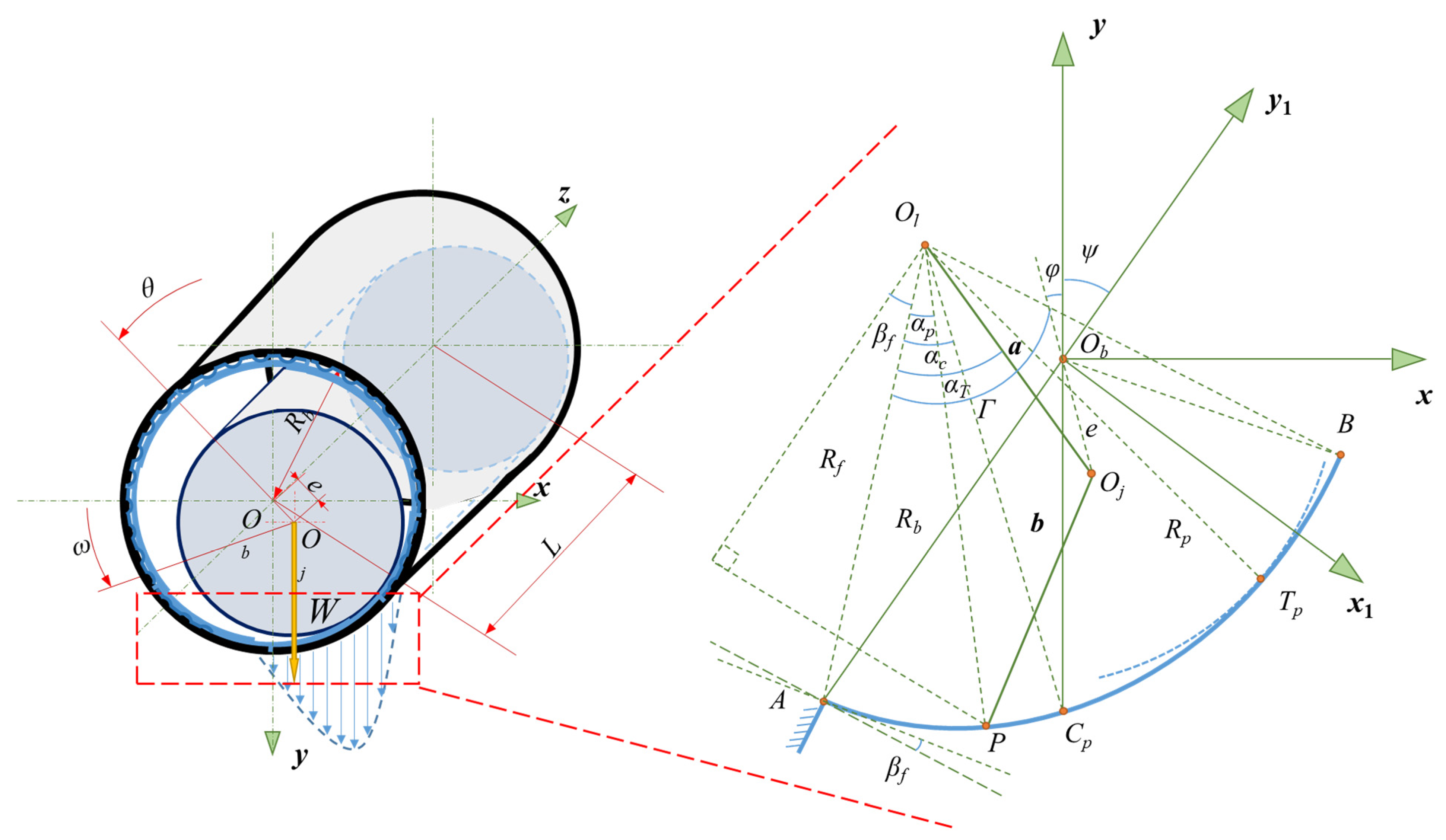

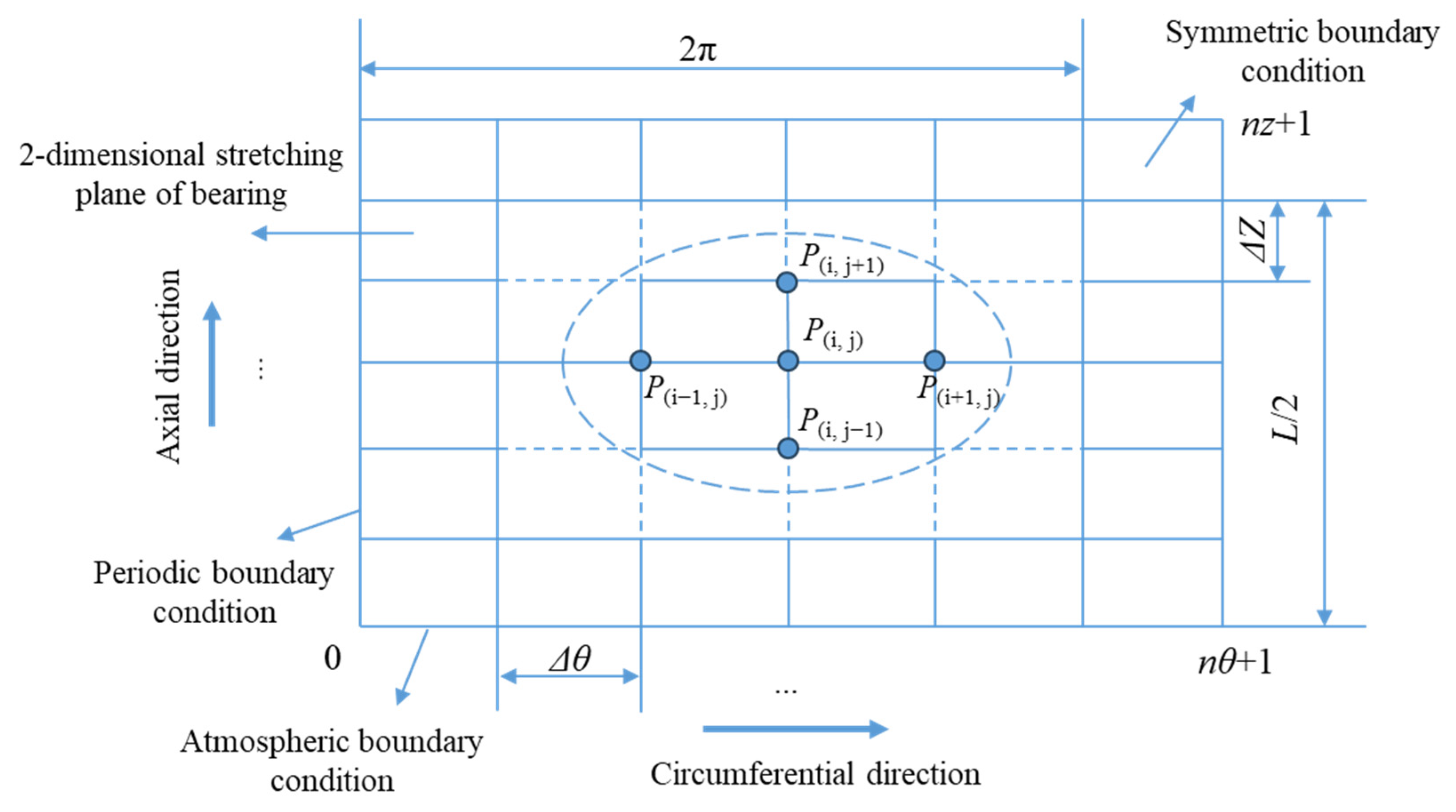

2. Numerical Models

2.1. Reynolds Equation

2.2. Gas Film Thickness Equation

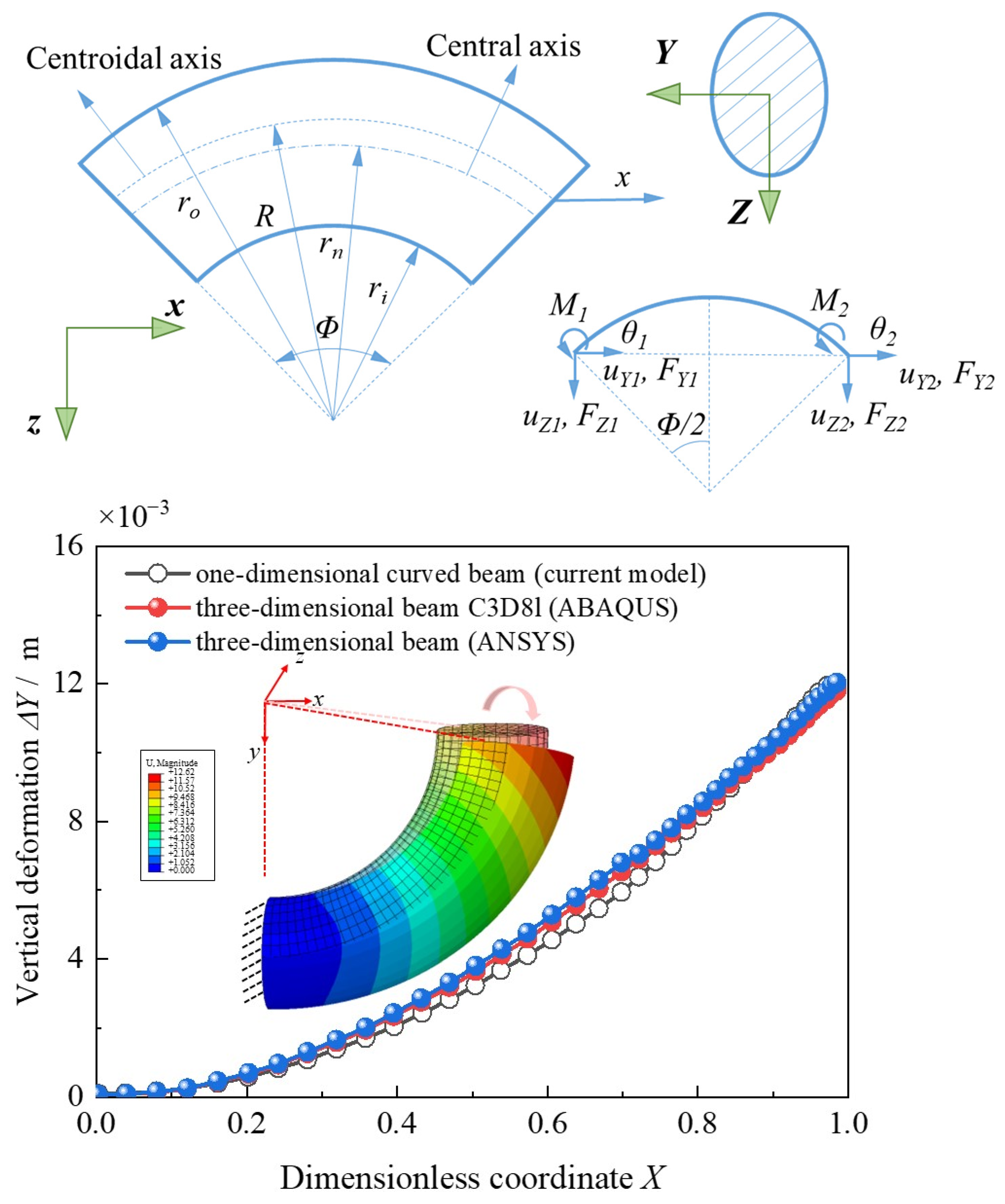

2.3. The Amount of Foil Deformation

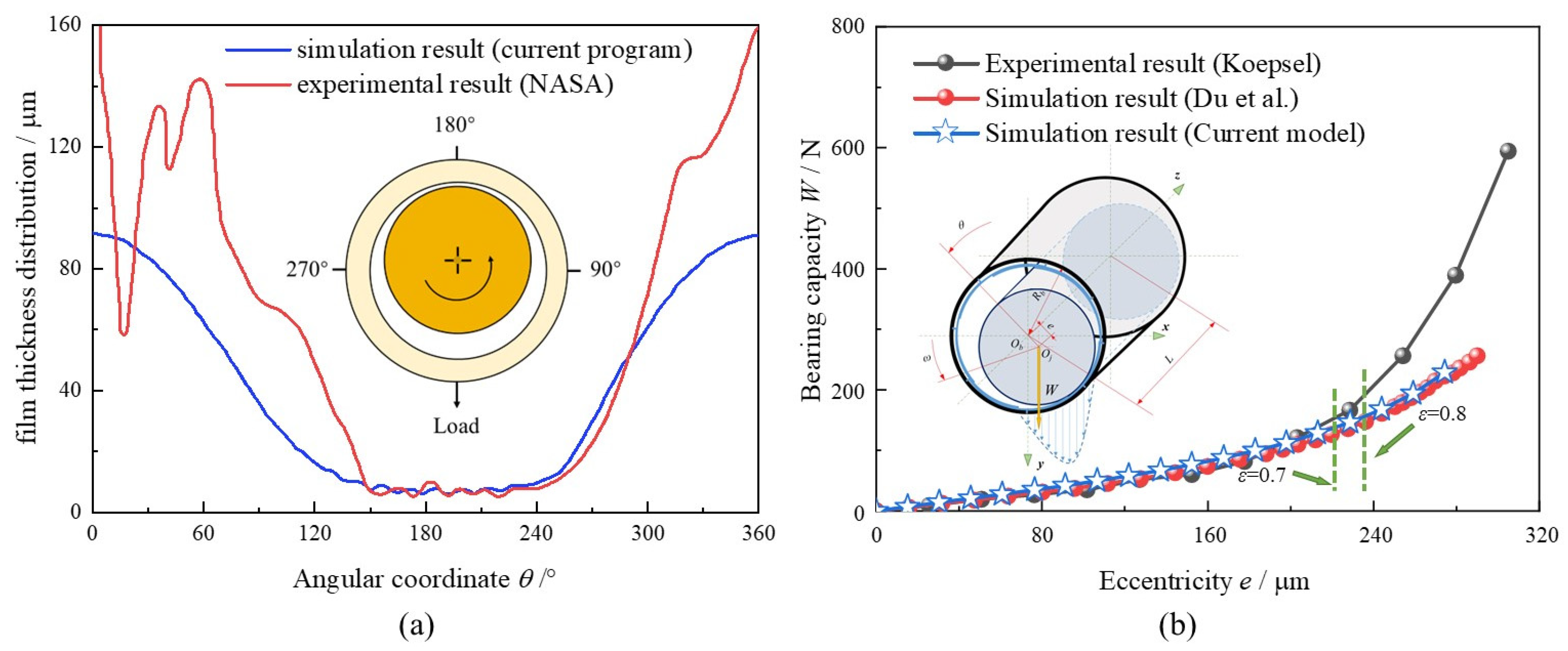

2.4. Validation of Model

3. Results and Discussion

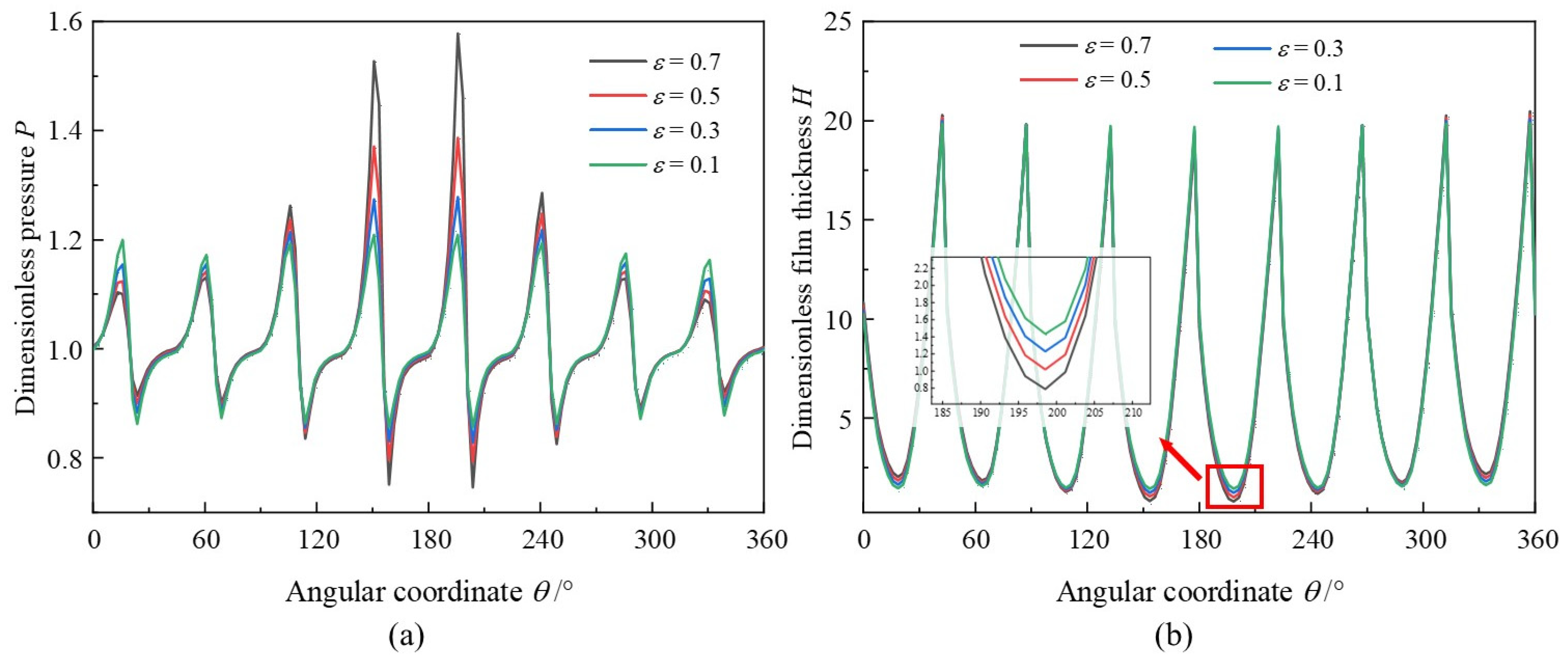

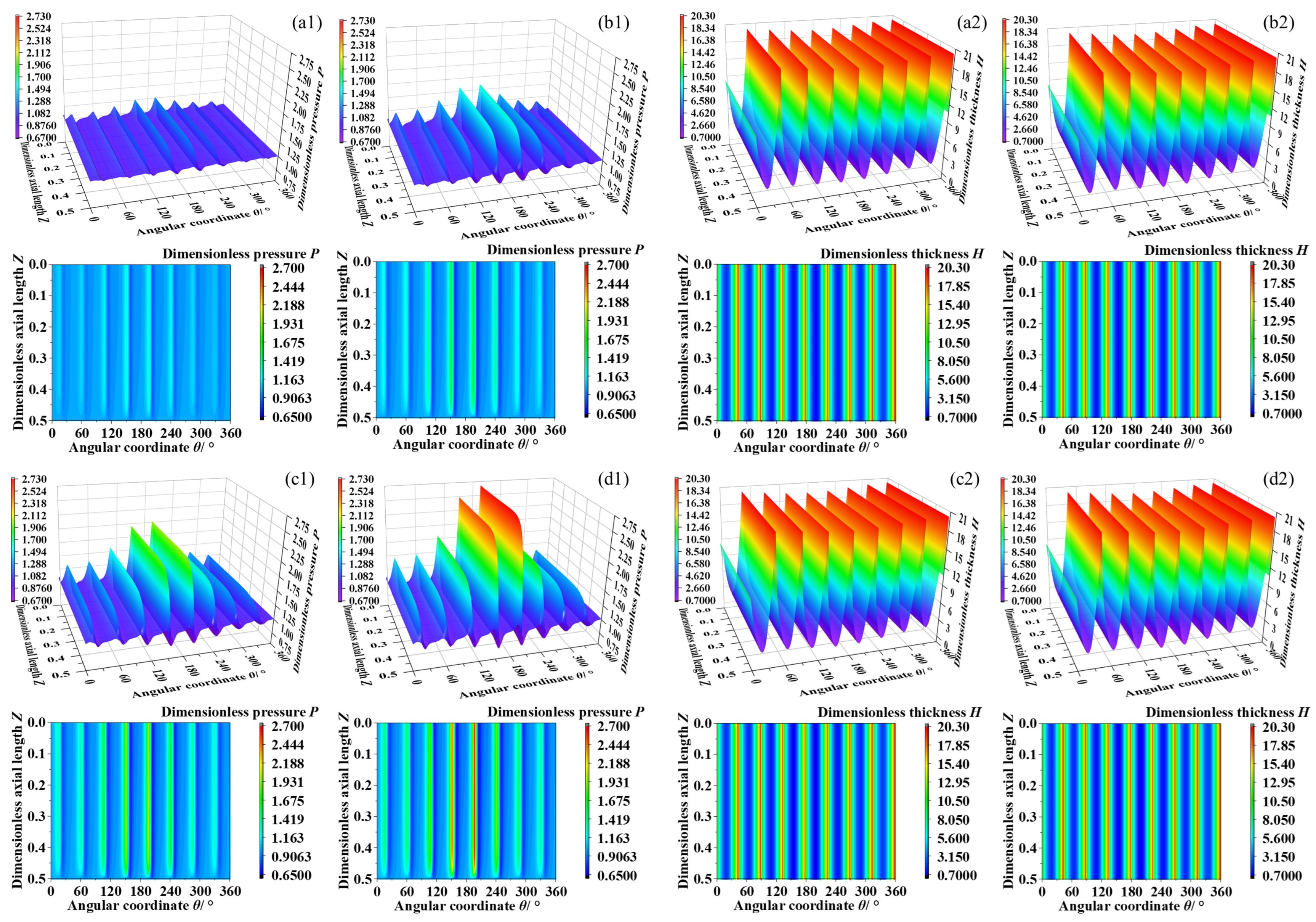

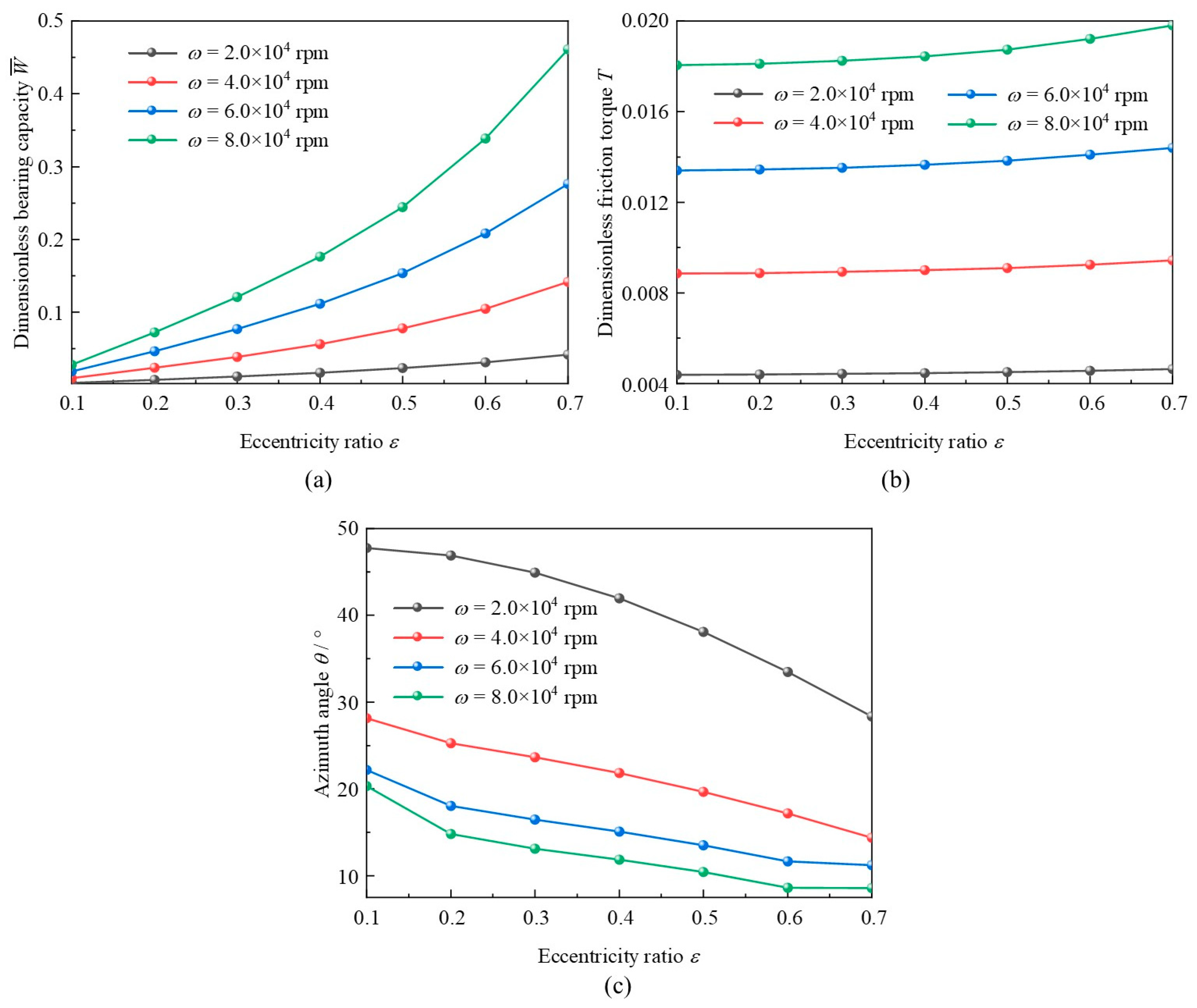

3.1. Eccentricity Ratio

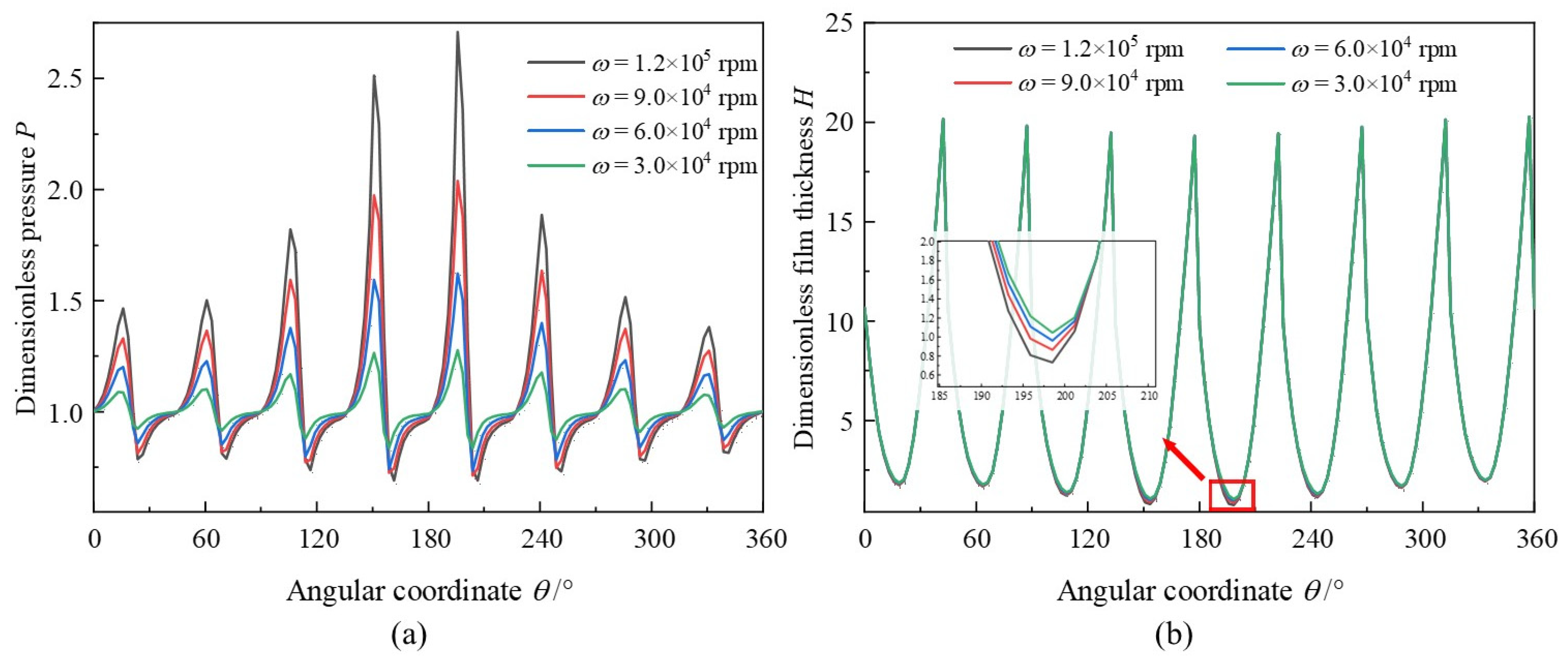

3.2. Bearing Speed

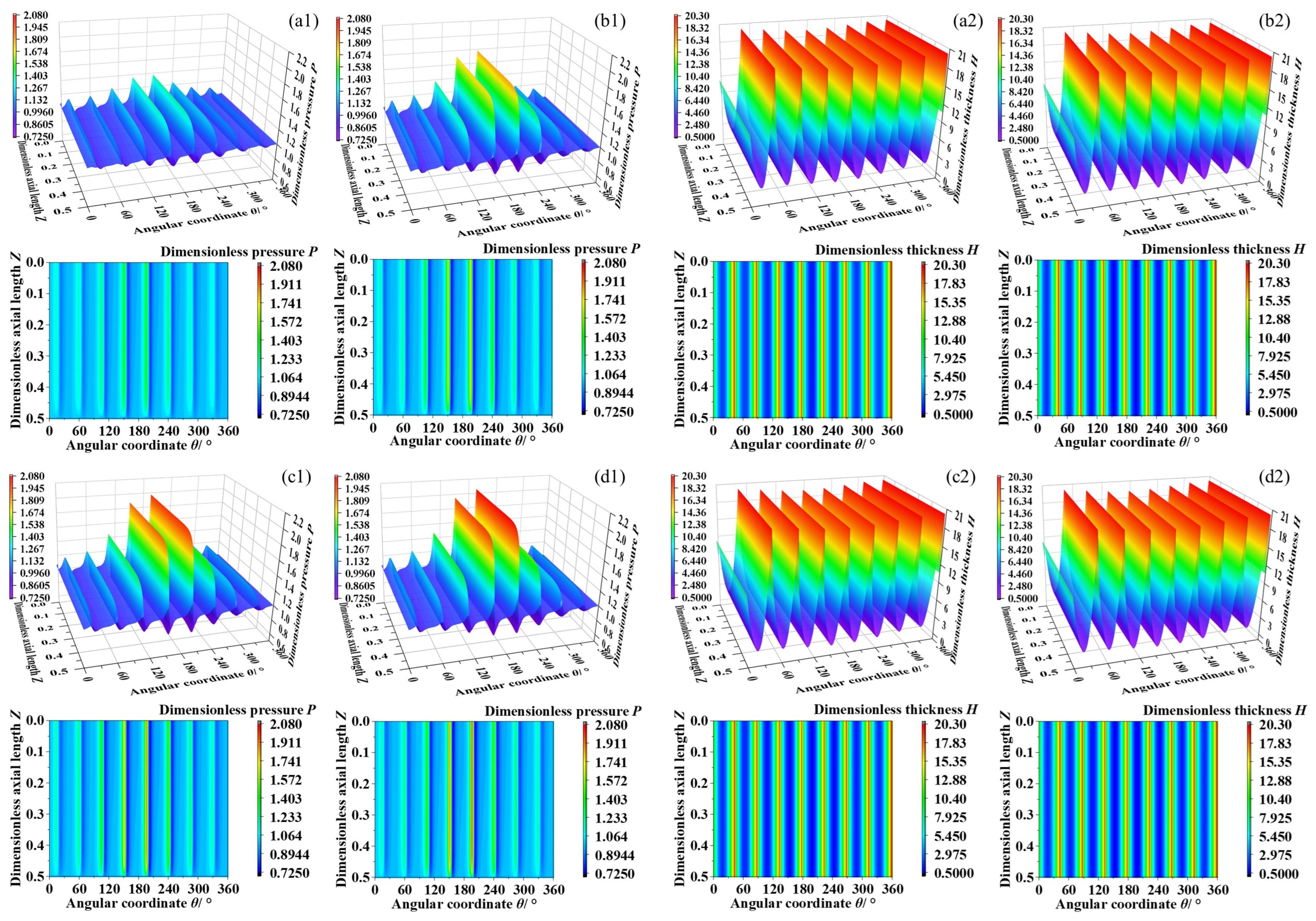

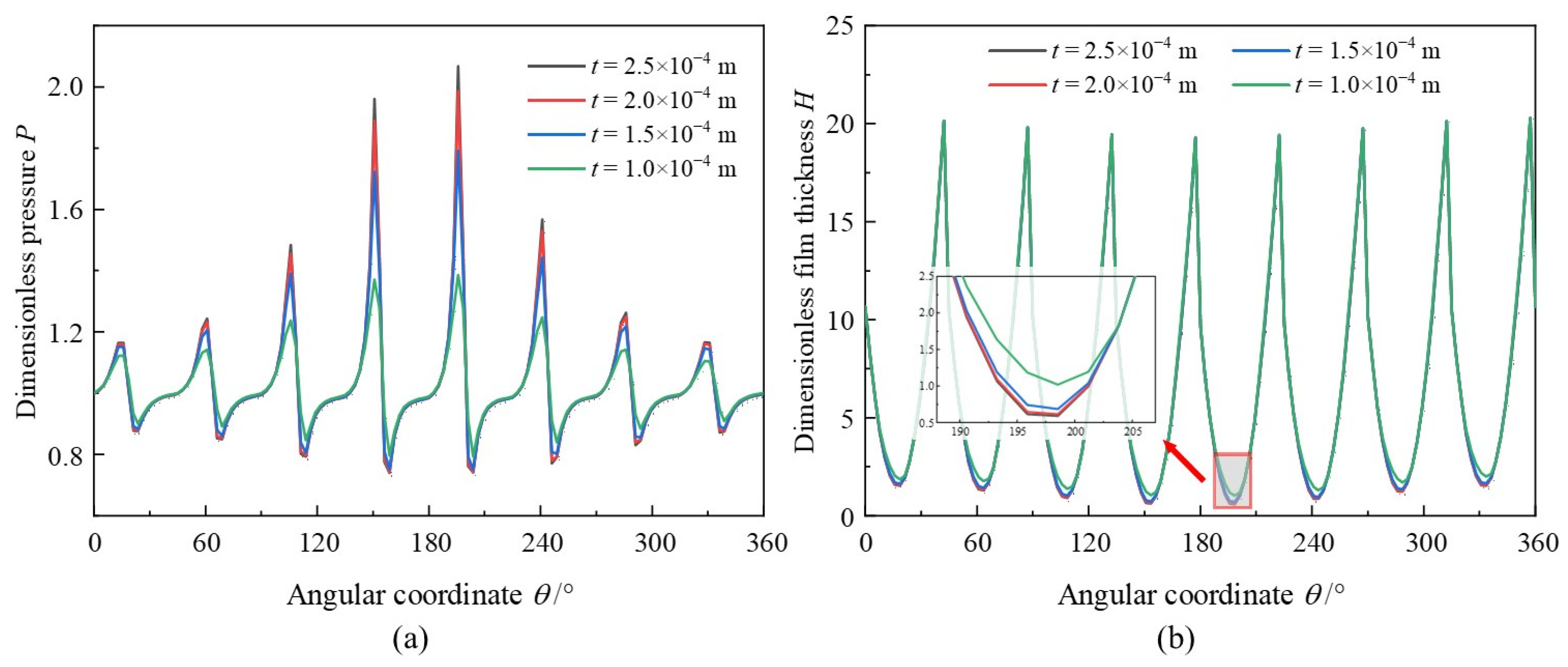

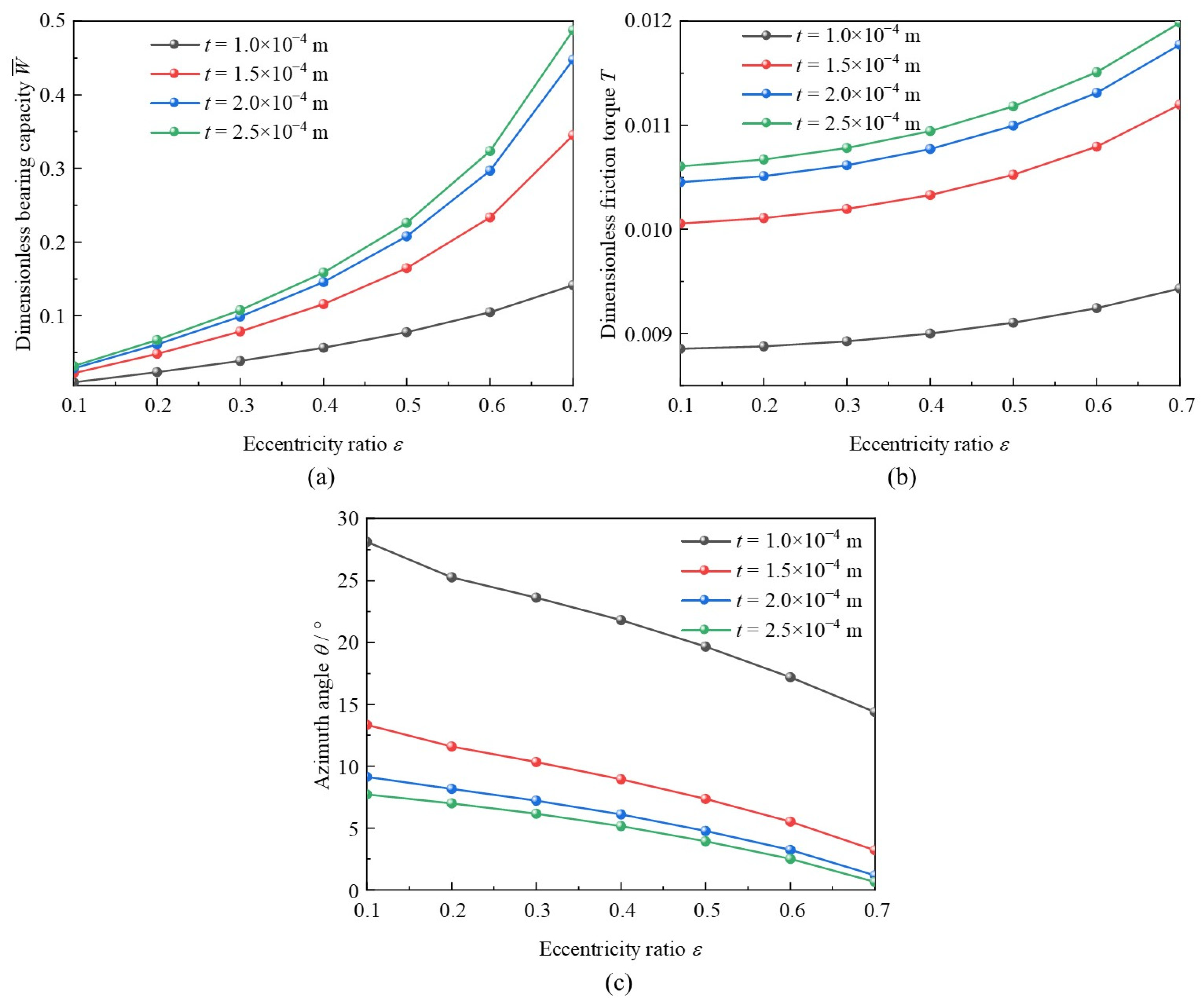

3.3. Foil Thickness

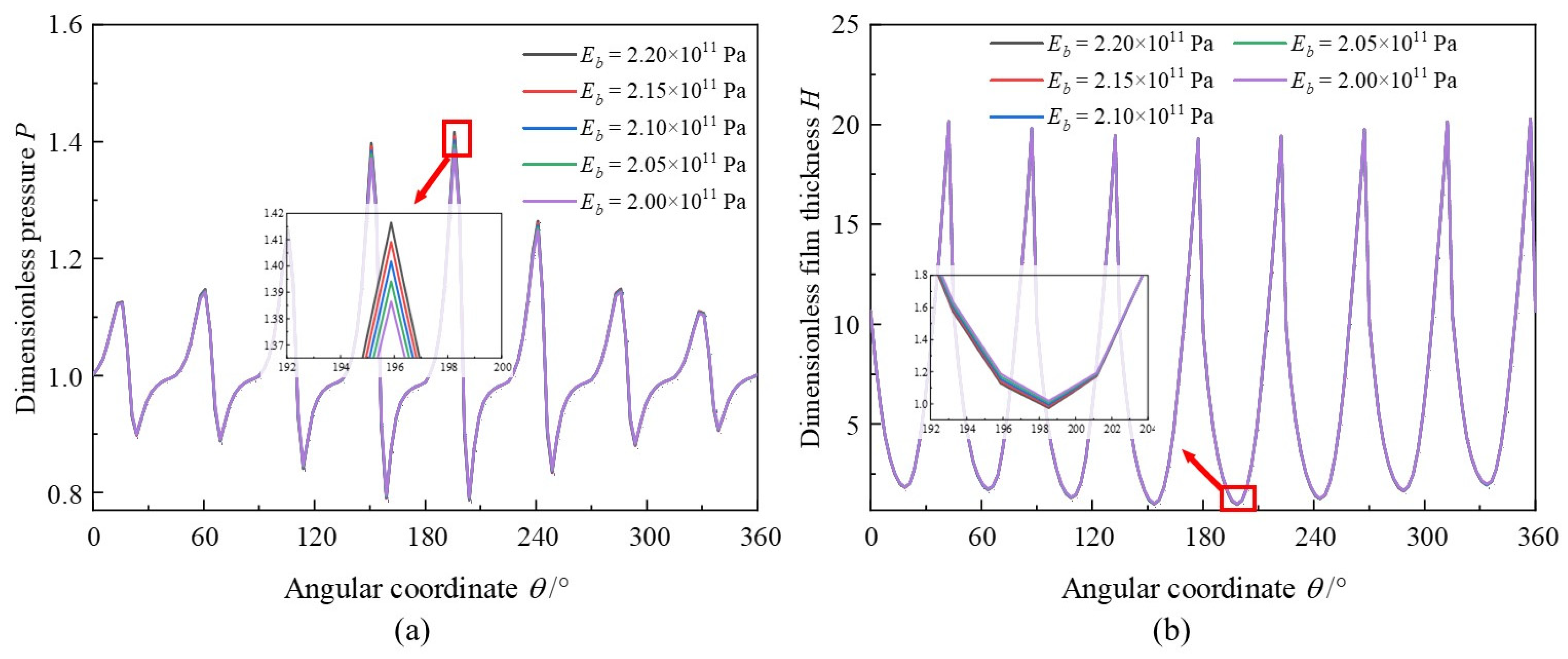

3.4. Foil Elastic Modulus

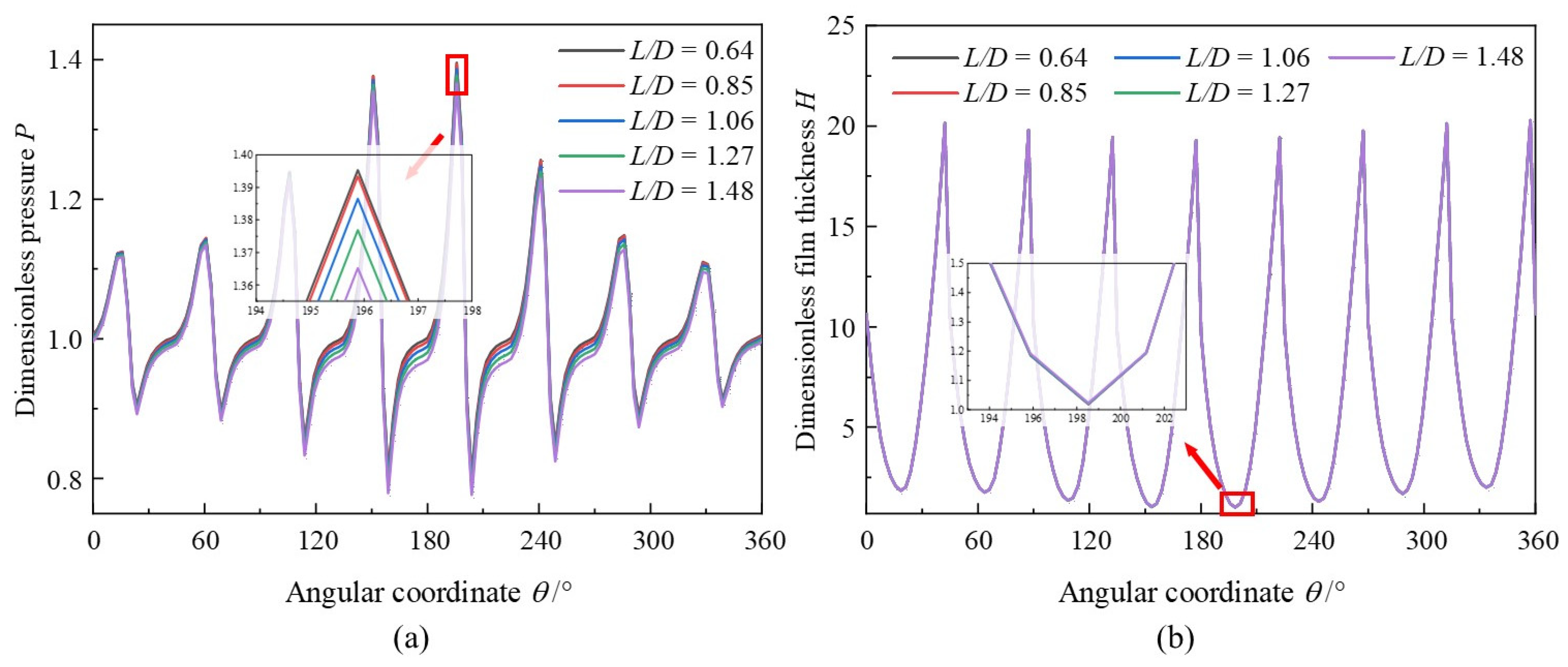

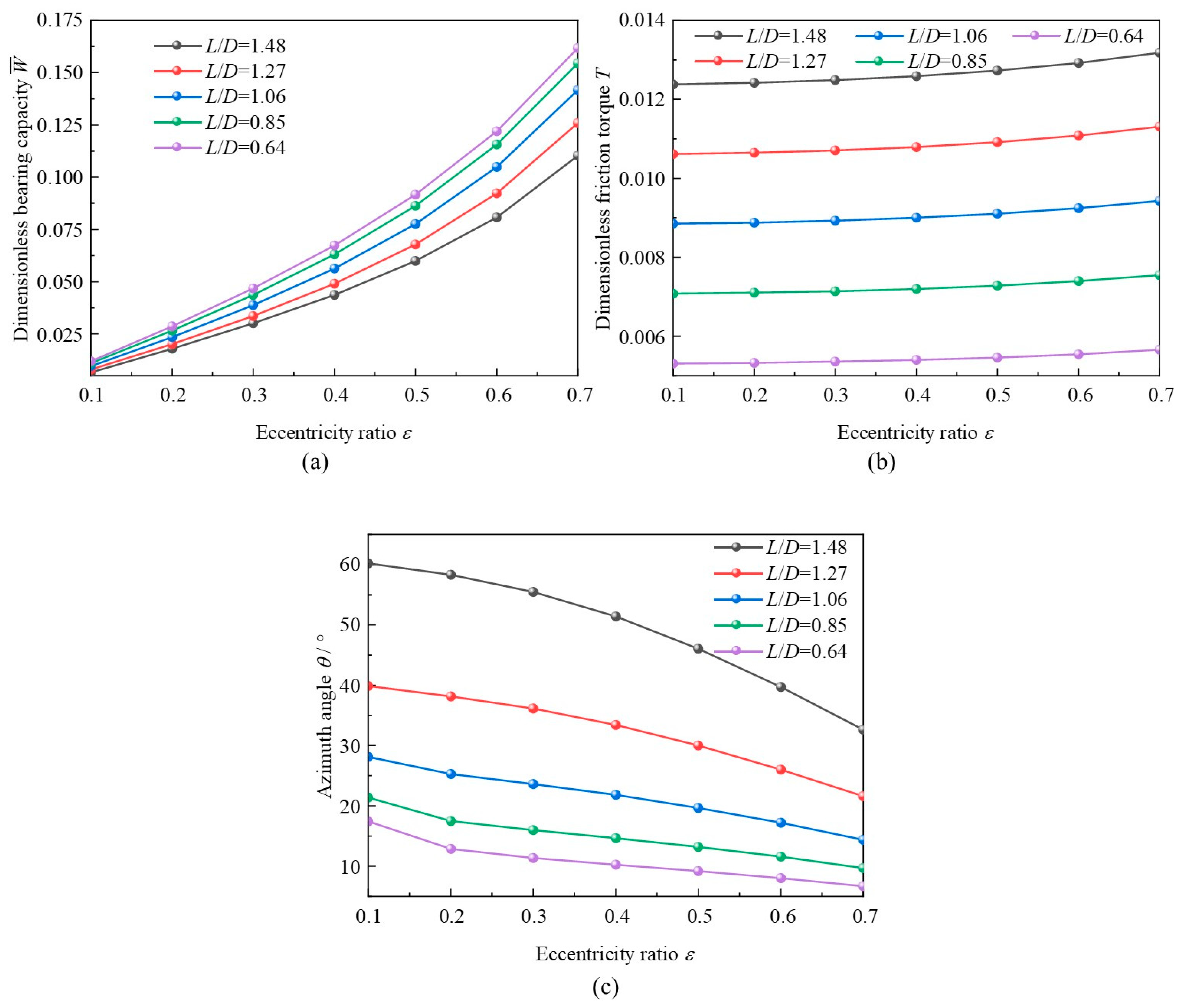

3.5. Length-to-Diameter Ratio

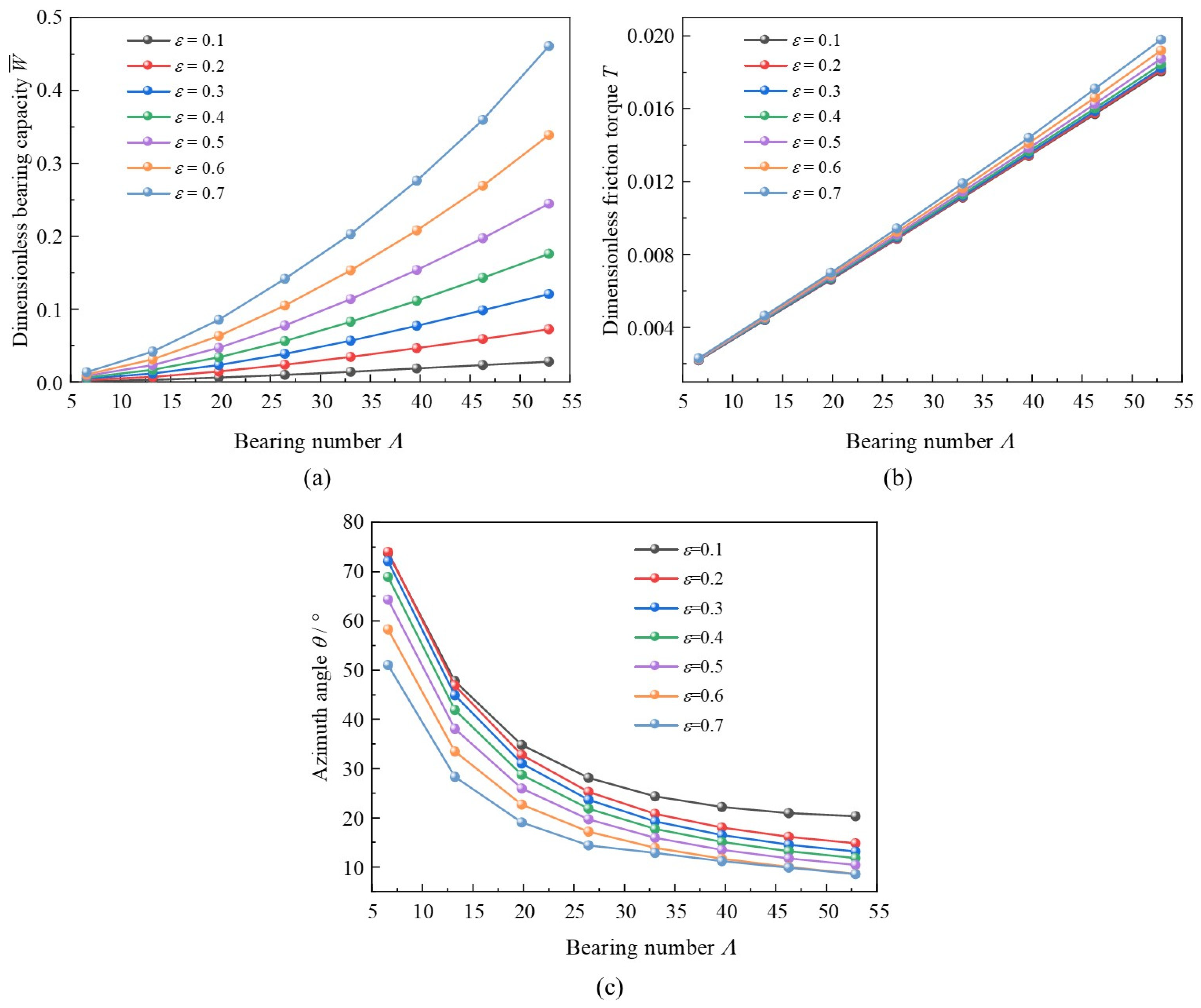

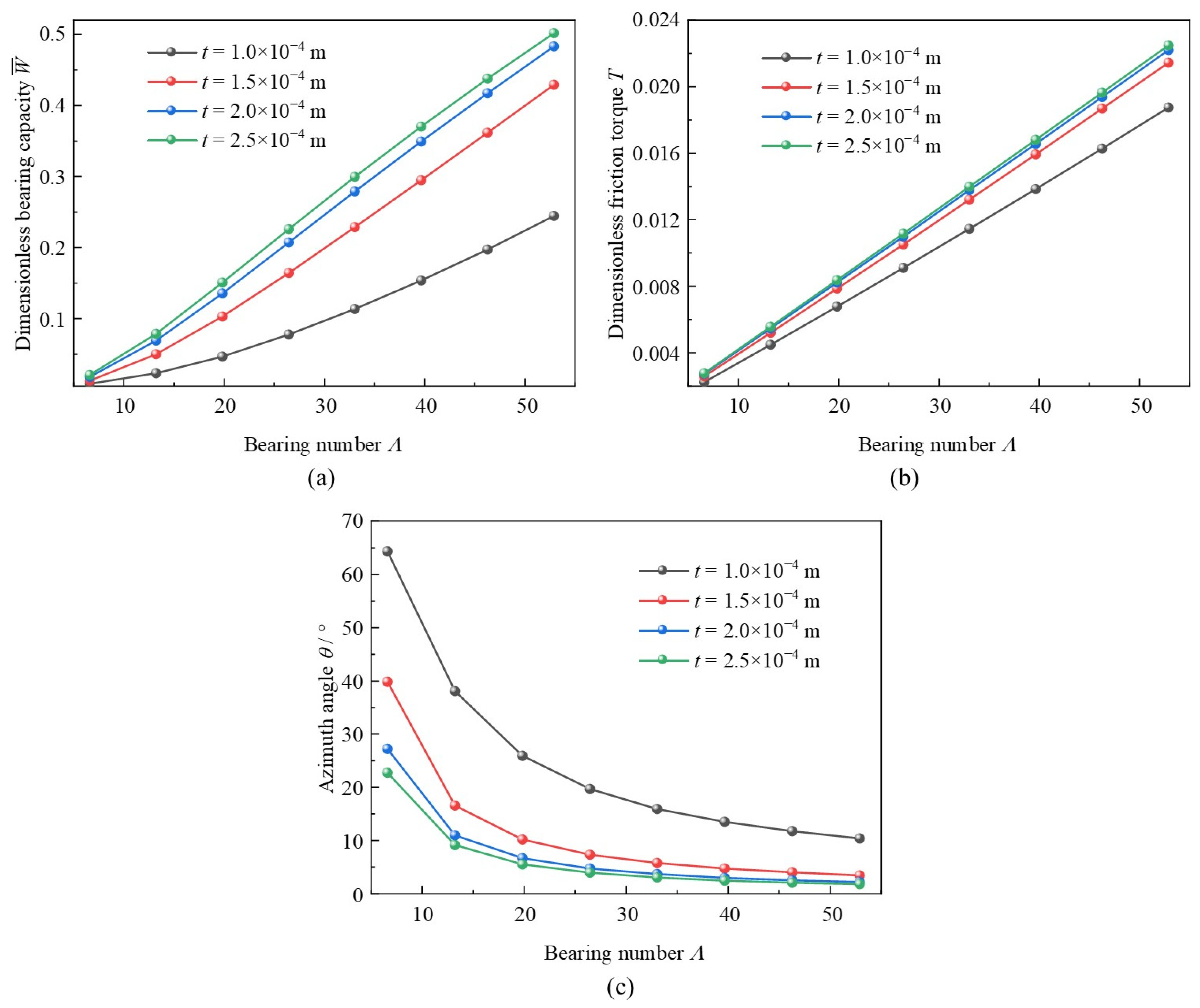

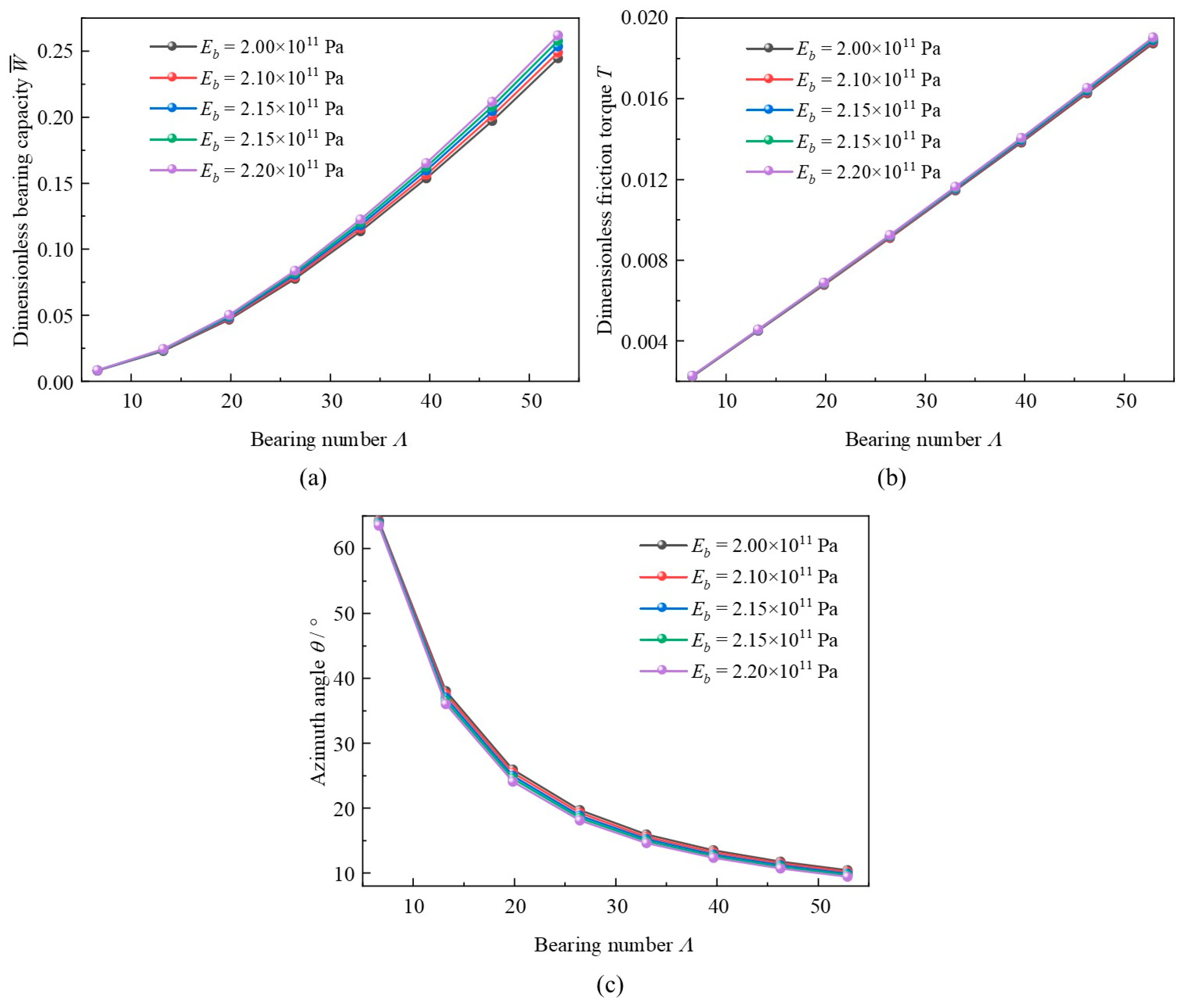

3.6. Bearing Number

4. Conclusions

- (1)

- Under larger eccentricity ratio, air film pressure on the foil surface around minimum clearance is significantly higher than that of other foils. The bearing capacity and friction torque could be increased; however, not as prominently as traditional rigid bearings or rolling bearings. The azimuth angle is decreased with the increase in eccentricity ratio and bearing numbers, while at the decreasing declining trend.

- (2)

- Influenced by the acceleration of bearing speed, the maximum pressure peak and bearing capacity are rapidly increased, which is more evident than the eccentricity ratio. The azimuth angle could be decreased with the increase in bearing speed and eccentricity ratio, while at an overall declining trend. Notably, the decrease could be receding when it surpasses a high eccentricity ratio threshold under large bearing speed.

- (3)

- Increased foil thickness could lead to friction torque promoting and azimuth angle decreasing at reducing amplitude. However, an optimal value of foil thickness may exist for the improvement of bearing load capacity. Foil thickness affects more obviously than bearing speed on friction torque. Increased bearing number could improve the bearing capacity and friction torque linearly, yet decrease the azimuth angle rapidly. However, the influence of typical elastic modulus is not so obvious.

- (4)

- Higher L/D could hinder capacity, although magnify friction torque and azimuth angle. At the same incremental vertical bearing load, a smaller bearing number signifies a larger variation in eccentricity ratio. With an appropriate low length-to-diameter ratio, large vertical bearing load, and high bearing number, balance between the suitable static characteristics and the requirements of practical applications could be more easily struck.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Gu, L.L.; Guenat, E.; Schiffmann, J. A review of grooved dynamic gas bearings. Appl. Mech. Rev. 2020, 72, 010802. [Google Scholar] [CrossRef]

- Pattnayak, M.R.; Ganai, P.; Pandey, R.K. An overview and assessment on aerodynamic journal bearings with important findings and scope for explorations. Tribol. Int. 2022, 174, 107778. [Google Scholar] [CrossRef]

- Samanta, P.; Murmu, N.C.; Khonsari, M.M. The evolution of foil bearing technology. Tribol. Int. 2019, 135, 305–323. [Google Scholar] [CrossRef]

- Hu, H.; Feng, M.; Ren, T. Study on the performance of gas foil journal bearings with bump-type shim foil. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 509–523. [Google Scholar] [CrossRef]

- Hou, Y.; Zhao, Q.; Guo, Y.; Ren, X.; Lai, T.; Chen, S. Application of gas foil bearings in China. Appl. Sci. 2021, 11, 6210. [Google Scholar] [CrossRef]

- Peng, Z.C.; Khonsari, M.M. A thermohydrodynamic analysis of foil journal bearings. J. Tribol.-T. ASME 2006, 128, 534–541. [Google Scholar] [CrossRef]

- Xiong, C.; Xu, B.; Yu, H.C. Thermal failure optimization of foil thrust bearings. Int. J. Mech. Sci. 2024, 267, 109026. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Wang, R.X.; Lyu, Y.W.; Huang, P.; Zhang, J.Z.; Huang, Z.W.; Cheng, F.N. Thermal effect induced by viscous dissipation on characteristics of aerodynamic foil journal bearing with aero-thermo-elastic coupling. Therm. Sci. Eng. Progr. 2024, 50, 102511. [Google Scholar] [CrossRef]

- Pattnayak, M.R.; Dutt, J.K.; Pandey, R.K. Rotordynamics of an accelerating rotor supported on aerodynamic journal bearings. Tribol. Int. 2022, 176, 107883. [Google Scholar] [CrossRef]

- San Andrés, L. A Review of Turbine and Compressor Aerodynamic Forces in Turbomachinery. Lubricants 2023, 11, 26. [Google Scholar] [CrossRef]

- Jiang, Y.L.; Xu, B.; Xiong, C.; Lu, X.; Yu, H.; Chen, Z. Influence of slip effect on viscous dissipation heat and lubrication characteristics of gas journal bearing: A multiscale analysis. Numer. Heat Tr. A-Appl. 2023, 83, 1285–1302. [Google Scholar] [CrossRef]

- Du, J.J.; Zhu, J.J.; Li, B.; Liu, D. Hydrodynamic analysis of multileaf gas foil bearing with backing springs. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 529–547. [Google Scholar] [CrossRef]

- Jiang, Y.L.; Xu, B.; Lu, X.; Liu, D. Multiscale simulation of flow in gas-lubricated journal bearings: A comparative study between the Reynolds equation and lattice Boltzmann methods. Eng. Appl. Comp. Fluid 2021, 15, 1792–1810. [Google Scholar] [CrossRef]

- Heshmat, H.; Walowit, J.A.; Pinkus, O. Analysis of gas lubricated foil journal bearings. J. Lubri. Technol. 1983, 108, 647–655. [Google Scholar] [CrossRef]

- Heshmat, C.A.; Xu, D.S.; Heshmat, H. Analysis of gas lubricated foil thrust bearings using coupled finite element and finite difference methods. J. Tribol.-T. ASME 2000, 122, 199–204. [Google Scholar] [CrossRef]

- Peng, Z.C.; Khonsari, M.M. Hydrodynamic analysis of compliant foil bearings with compressible air flow. J. Tribol.-T. ASME 2004, 126, 542–546. [Google Scholar] [CrossRef]

- Lee, Y.B.; Park, D.J. Operating characteristics of the bump foil journal bearings with top foil bending phenomenon and correlation among bump foils. Tribol. Int. 2008, 41, 221–223. [Google Scholar] [CrossRef]

- Andres, L.S.; Kim, D.J. Analysis of gas foil bearings integrating FE top foil models. Tribol. Int. 2009, 42, 111–120. [Google Scholar] [CrossRef]

- Andres, L.S.; Chirathadam, T. A metal mesh foil bearing and a bump-type foil bearing: Comparison of performance for two similar size gas bearings. J. Eng. Gas Turb. Power 2012, 134, 102501. [Google Scholar] [CrossRef]

- Zhang, G.H.; Liu, Z.S. Dynamic study of journal gas bearings-flexible rotor coupling system. J. Aerosp. Power 2010, 25, 1417–1426. [Google Scholar]

- Hou, Y.; Chen, S.T.; Chen, R.G.; Zhang, Q.; Zhao, H. Numerical study on foil journal bearing with protuberant foil structure. Tribol. Int. 2011, 44, 1061–1070. [Google Scholar]

- Larsen, J.S.; Santos, I.F.; Osmanski, S.V. Stability of rigid rotors supported by air foil bearings: Comparison of two fundamental approaches. J. Sound Vib. 2016, 381, 179–191. [Google Scholar] [CrossRef]

- Gu, Y.P.; Ren, G.X.; Zhou, M. A fully coupled elastohydrodynamic model for static performance analysis of gas foil bearings. Tribol. Int. 2020, 147, 106297. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Li, C.L.; Du, J.J. Modeling and static characteristics study of the double-layer bump gas foil bearing. Tribol. Int. 2021, 164, 107202. [Google Scholar] [CrossRef]

- Szeri, A.Z. Fluid Film Lubrication; Cambridge University Press: New York, NY, USA, 2010; pp. 466–510. [Google Scholar]

- Chi, C.Z. Hydrodynamic Lubrication; National Deference Industry Press: Beijing, China, 1998; pp. 485–487. [Google Scholar]

- Pilkey, W.D. Formulas for Stress, Strain, and Structural Matrices; John Wiley and Sons Incorporation: Hoboken, NJ, USA, 1994; pp. 878–879. [Google Scholar]

- Iordanoff, I. Analysis of an aerodynamic compliant foil thrust bearing: Method for a rapid design. J. Tribol.-T ASME 1999, 121, 816–822. [Google Scholar] [CrossRef]

- Strom, T. Advanced Gas Turbine (AGT) Technology Development Project: Final Report. (Report No. CR-180891); NASA: Pasadena, CA, USA, 1988.

- Koepsel, W.F. Gas Lubricated Foil Bearing Development for Advanced Turbomachines; AFAPL-TR-76-114; PN: London, UK, 1977. [Google Scholar]

- Du, J.J.; Zhu, J.J.; Li, B.; Liu, D.; Chao, S. The effect of area contact on the static performance of multileaf foil bearings. Tribol. T. 2015, 58, 592–601. [Google Scholar] [CrossRef]

- Li, C.L.; Du, J.J.; Zhu, J.J.; Yao, Y. Effects of structural parameters on the load carrying capacity of the multileaf gas foil journal bearing based on contact mechanics. Tribol. Int. 2019, 131, 318–331. [Google Scholar] [CrossRef]

| Parameter Name | Value |

|---|---|

| Bearing length (L) | 38.1 × 10−3 m |

| Shaft radius (Rj) | 19.05 × 10−3 m |

| Bearing clearance (C) | 20 × 10−5 m |

| Foil thickness (t) | 10.16 × 10−5 m |

| Foil elastic modulus (Eb) | 2.14 × 1011 Pa |

| Foil Poisson’s ratio (υb) | 0.3 |

| Ambient pressure (pa) | 1.01325 × 105 Pa |

| Dynamic viscosity of gas (μ) | 1.932 × 10−5 Pa·s |

| Bearing capacity (W) | 134.1 N |

| Bearing speed (ω) | 3.0 × 104 rpm |

| Parameter Name | Value |

|---|---|

| Bearing length (L) | 15.24 × 10−3 m |

| Shaft radius (Rj) | 57.15 × 10−3 m |

| Bearing radius (Rb) | 57.9628 × 10−3 m |

| Incircle radius (Ri) | 57.4548 × 10−3 m |

| Foil radius (Rf) | 59.50 × 10−3 m |

| Foil thickness (t) | 25.40 × 10−4 m |

| Foil elastic modulus (Eb) | 2.0685 × 1011 Pa |

| Foil number (N) | 8 |

| Ambient pressure (pa) | 1.01325 × 105 Pa |

| Dynamic viscosity of gas (μ) | 2.953 × 10−5 Pa·s |

| Bearing clearance (C) | 30.48 × 10−5 m |

| Bearing speed (ω) | 3.3 × 104 rpm |

| Parameter Name | Value |

|---|---|

| Bearing length (L) | 30.0 × 10−3~70.0 × 10−3 m |

| Shaft radius (Rj) | 23.49 × 10−3 m |

| Bearing radius (Rb) | 26.25 × 10−3 m |

| Incircle radius (Ri) | 23.5 × 10−3 m |

| Foil radius (Rf) | 25.25 × 10−3 m |

| Foil thickness (t) | 1.0 × 10−4~2.5 × 10−4 m |

| Foil elastic modulus (Eb) | 2.00 × 1011~2.20 × 1011 Pa |

| Foil number (N) | 4~8 |

| Ambient pressure (pa) | 1.01325 × 105 Pa |

| Dynamic viscosity of gas (μ) | 1.932 × 10−5 Pa·s |

| Specific heat ratio of gas (Cp/Cv) | 1.401 |

| Eccentricity ratio (ε) | 0.1~0.7 |

| Bearing speed (ω) | 3.0 × 104~1.2 × 105 rpm |

| Foil Poisson’s ratio (υb) | 0.3 |

| Span of bump foil (s) | 4.2 × 10−3 m |

| Half-length of bump foil (l) | 1.75 × 10−3 m |

| Thickness of bump foil (tb) | 1.016 × 10−4 m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Xu, B.; Zhu, Q.; Huang, Z.; Gao, D. Parameter Effects on the Static Characteristics of the Multi-Foil Aerodynamic Journal Bearing with Bump-Backing Foils. Lubricants 2024, 12, 246. https://doi.org/10.3390/lubricants12070246

Jiang Y, Xu B, Zhu Q, Huang Z, Gao D. Parameter Effects on the Static Characteristics of the Multi-Foil Aerodynamic Journal Bearing with Bump-Backing Foils. Lubricants. 2024; 12(7):246. https://doi.org/10.3390/lubricants12070246

Chicago/Turabian StyleJiang, Yulong, Bo Xu, Qianjing Zhu, Zhongwen Huang, and Dongyan Gao. 2024. "Parameter Effects on the Static Characteristics of the Multi-Foil Aerodynamic Journal Bearing with Bump-Backing Foils" Lubricants 12, no. 7: 246. https://doi.org/10.3390/lubricants12070246

APA StyleJiang, Y., Xu, B., Zhu, Q., Huang, Z., & Gao, D. (2024). Parameter Effects on the Static Characteristics of the Multi-Foil Aerodynamic Journal Bearing with Bump-Backing Foils. Lubricants, 12(7), 246. https://doi.org/10.3390/lubricants12070246