Improved Operating Behavior of Self-Lubricating Rolling-Sliding Contacts under High Load with Oil-Impregnated Porous Sinter Material

Abstract

:1. Introduction

2. Materials and Methods

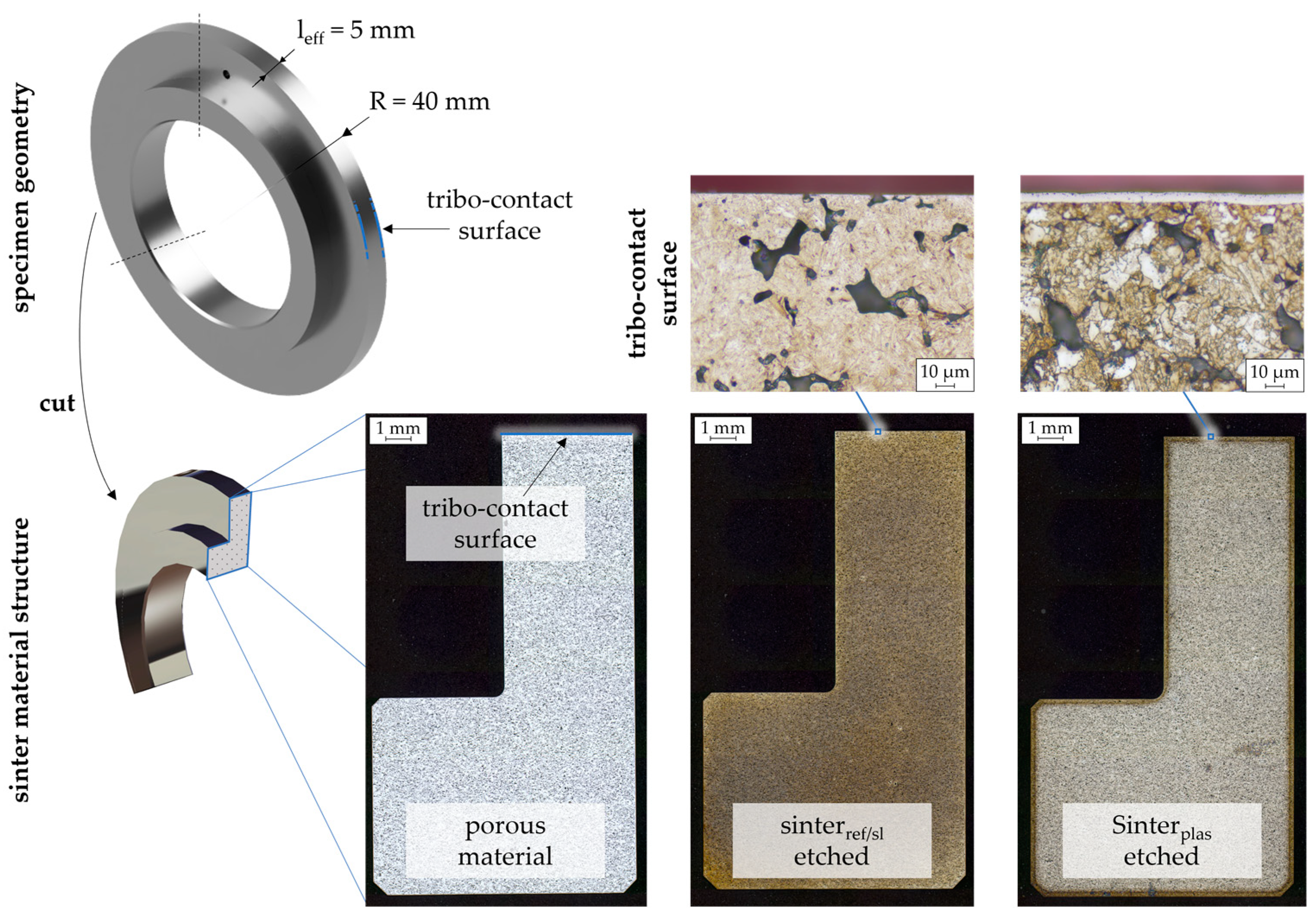

2.1. Specimen

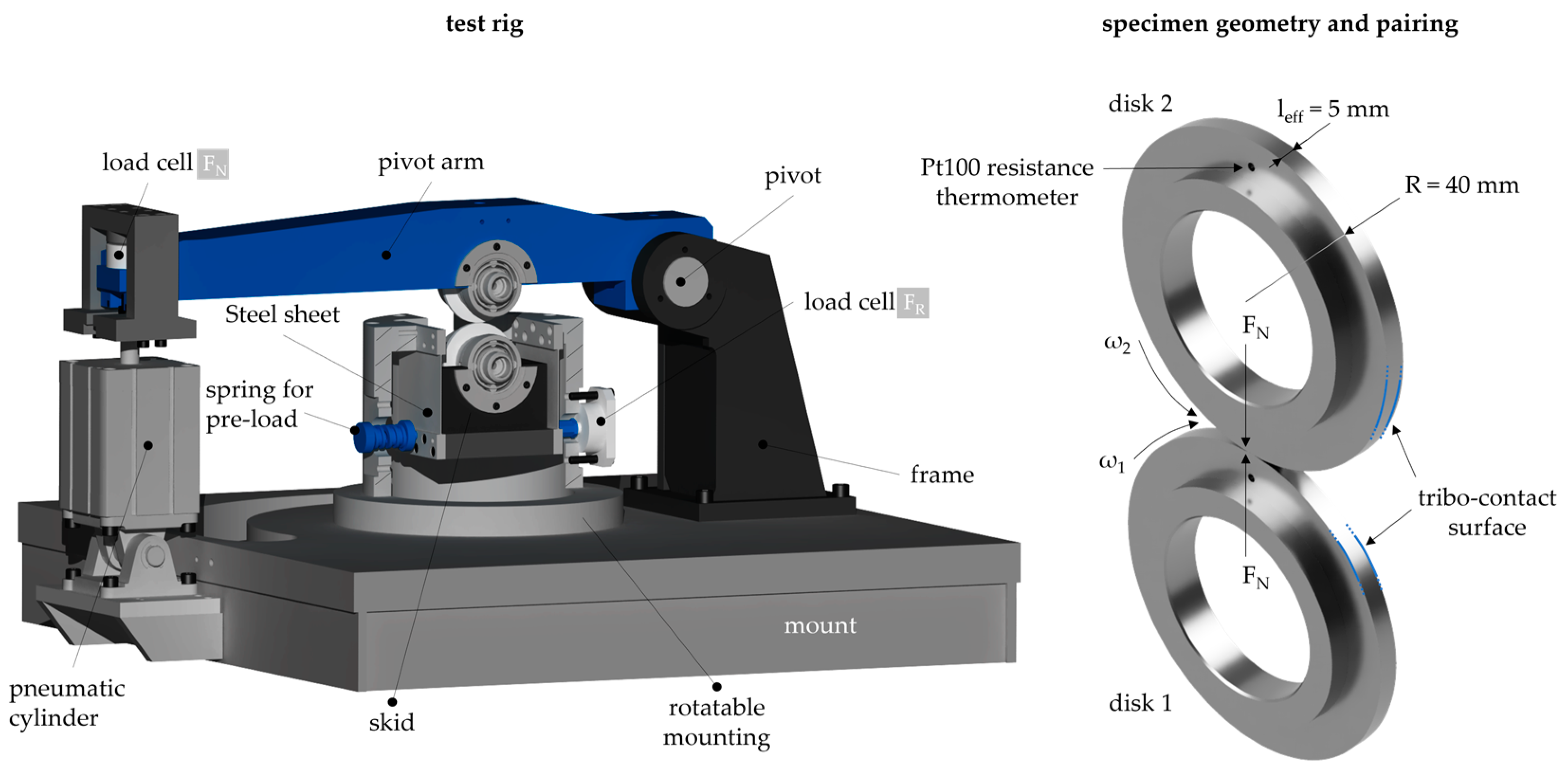

2.2. Test Rig

2.3. Test Method

2.3.1. Friction Curves

- Demonstration of the functionality of self-lubricating rolling-sliding contacts across a wide range of operating points and comparison with injection-lubricated rolling-sliding contacts.

- Determination of the tribologically optimal number of oil-impregnated elements in a self-lubricating rolling-sliding contact.

- Investigation of the influence of surface condition and finish on self-lubricating rolling-sliding contacts.

2.3.2. Long-Term Tests

- Demonstration of long-term durability of self-lubricating contacts and comparison with injection-lubricated contacts.

- Investigation of the influence of surface finish on the frictional and stress behavior in self-lubricating contacts.

- Investigation of the improvement of the frictional behavior in self-lubricating contacts through solid lubricant additives in the sinter material.

- Determination of the performance of self-lubricating contacts under higher load and speed.

- Evaluation of the transferability to gear applications with typical tooth flank surfaces.

3. Results

3.1. Friction Curve Tests

3.1.1. Demonstration of Self-Lubricating Rolling-Sliding Contacts and Comparison with Injection-Lubricated Rolling-Sliding Contacts

3.1.2. Determination of the Tribologically Optimal Number of Oil-Impregnated Sinter Elements in Self-Lubricating Rolling-Sliding Contacts

3.1.3. Investigation of the Influence of Surface Finish on Self-Lubricating Rolling-Sliding Contacts

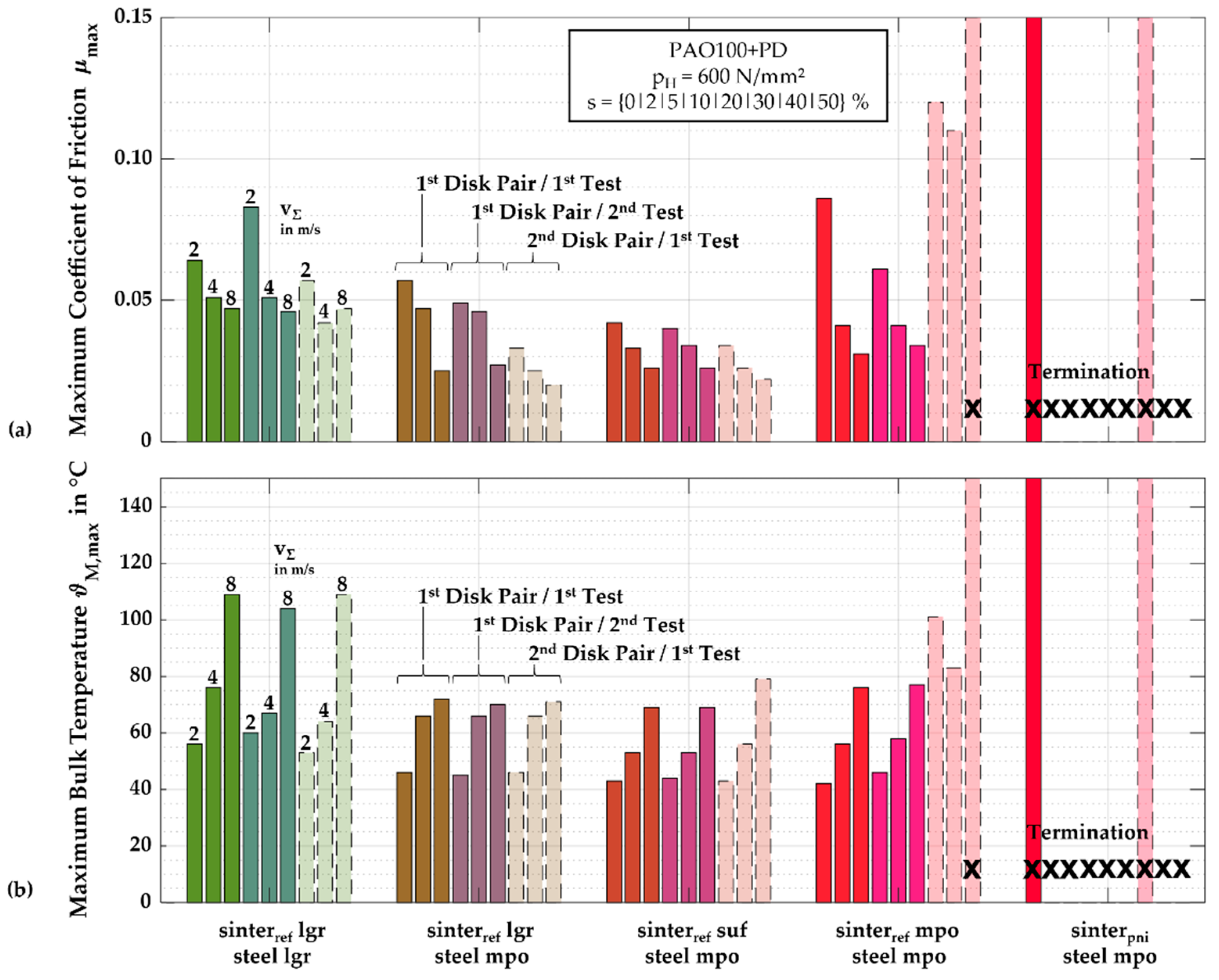

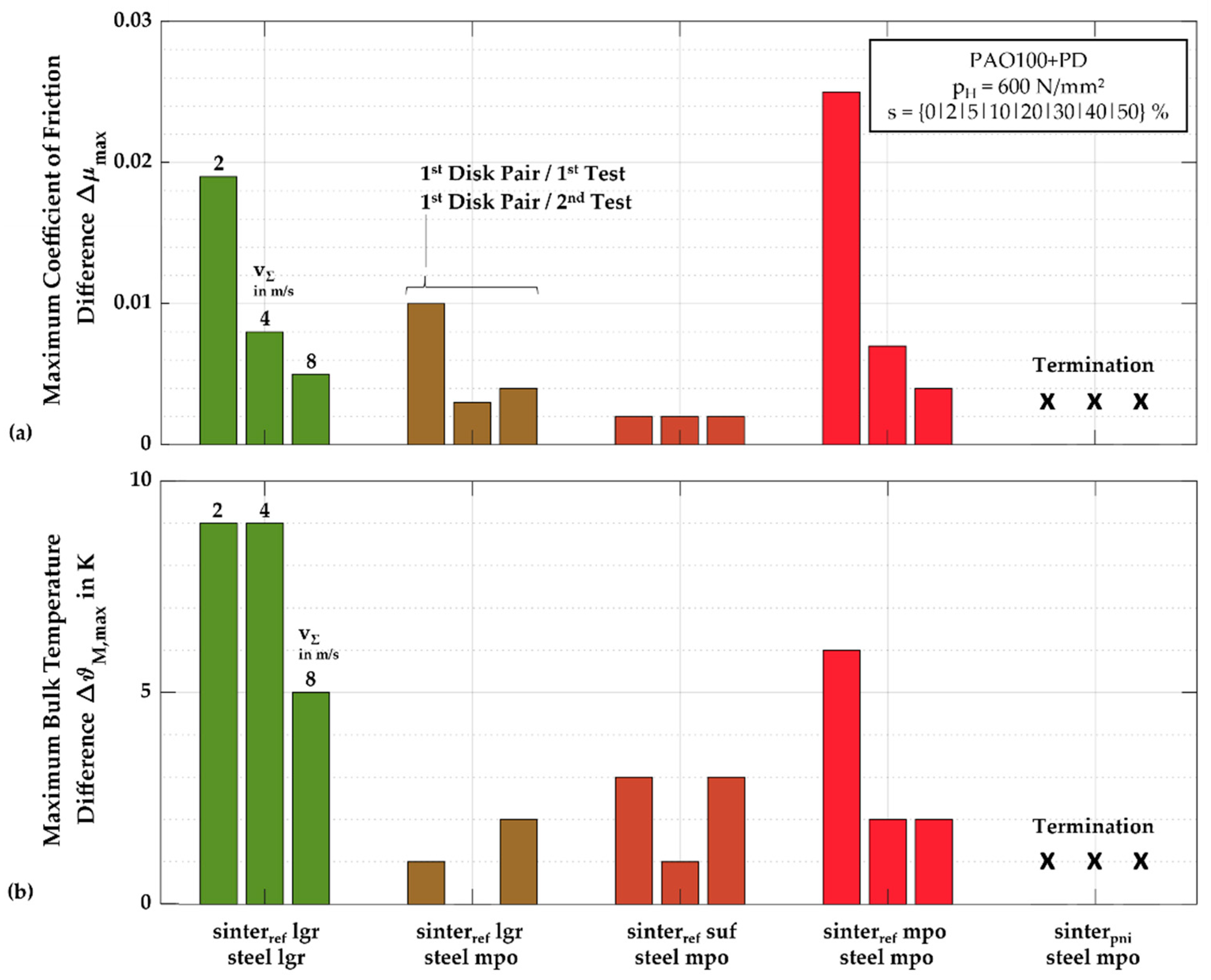

3.1.4. Summary of the Friction Curve Tests

3.2. Long-Term Tests

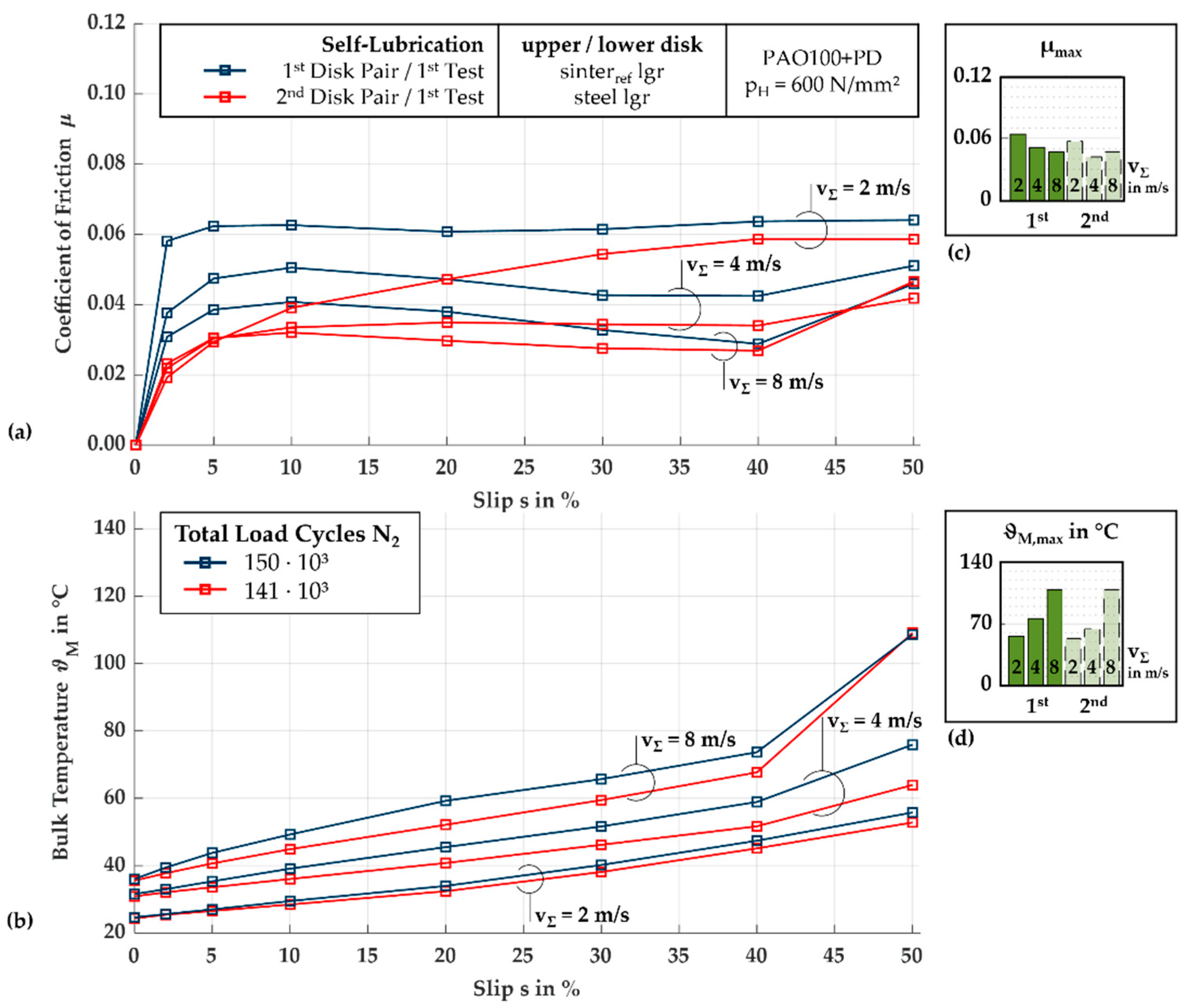

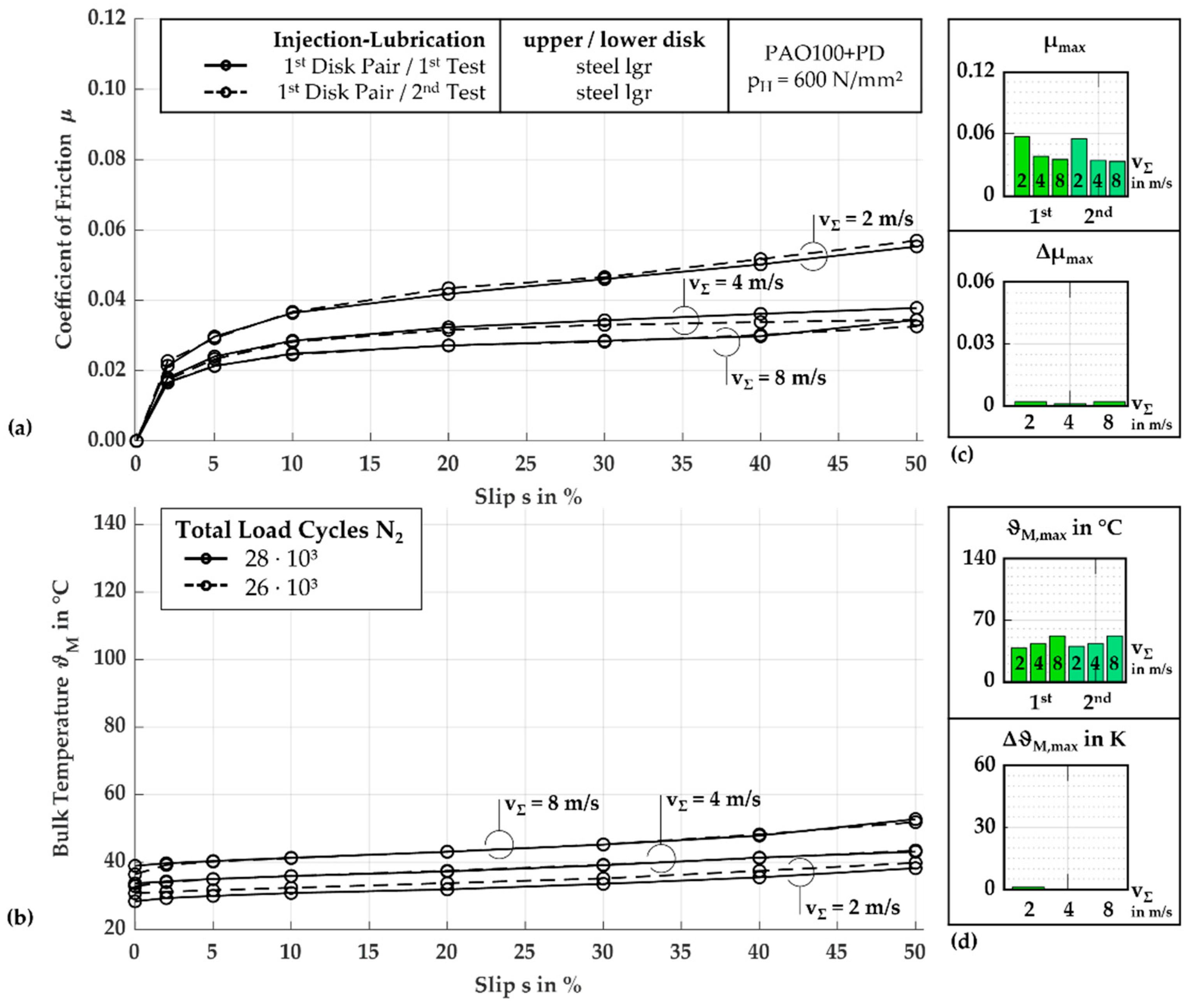

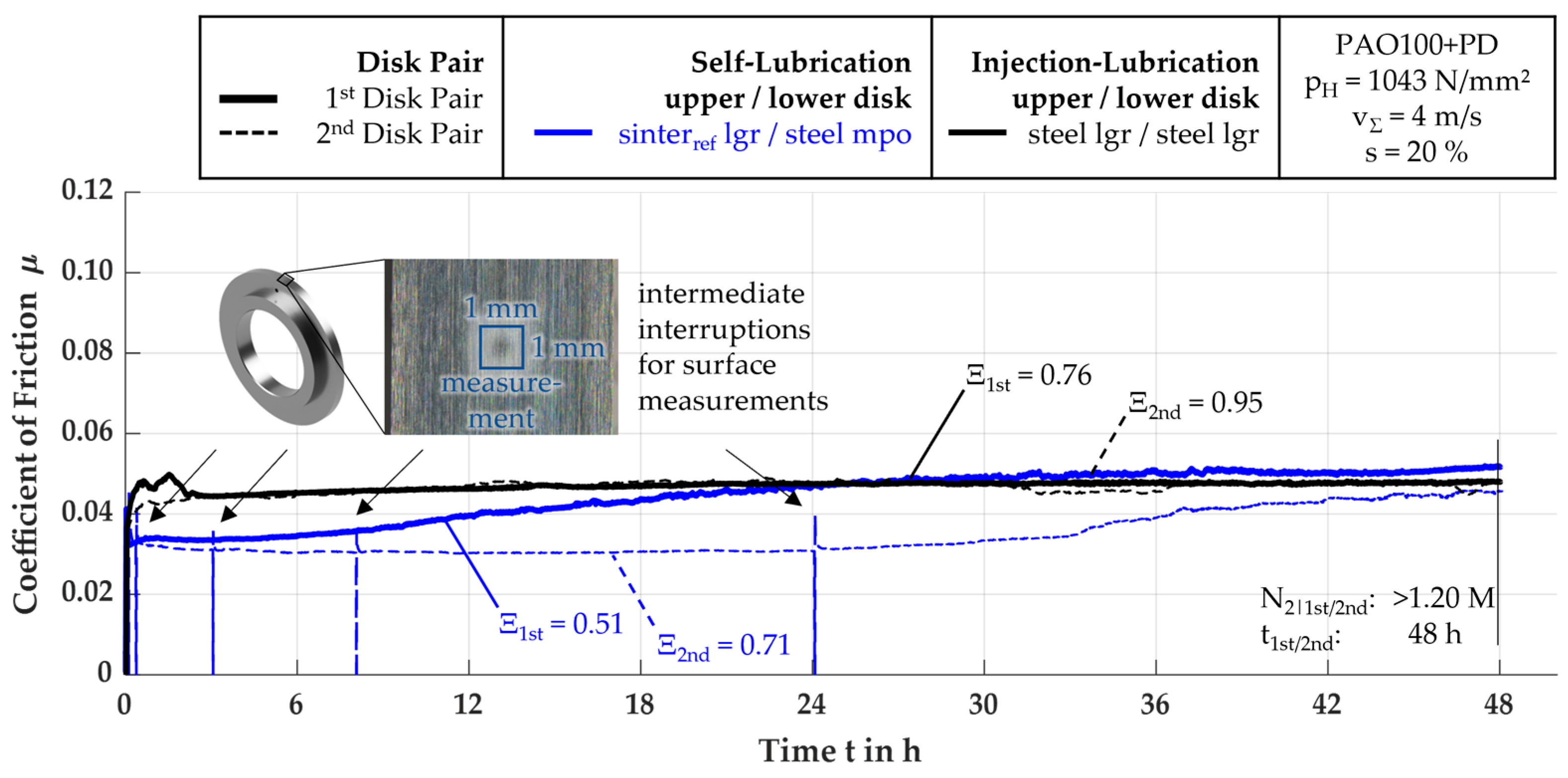

3.2.1. Demonstration of Long-Term Durability of Self-Lubricating Contacts and Comparison to Injection Lubrication

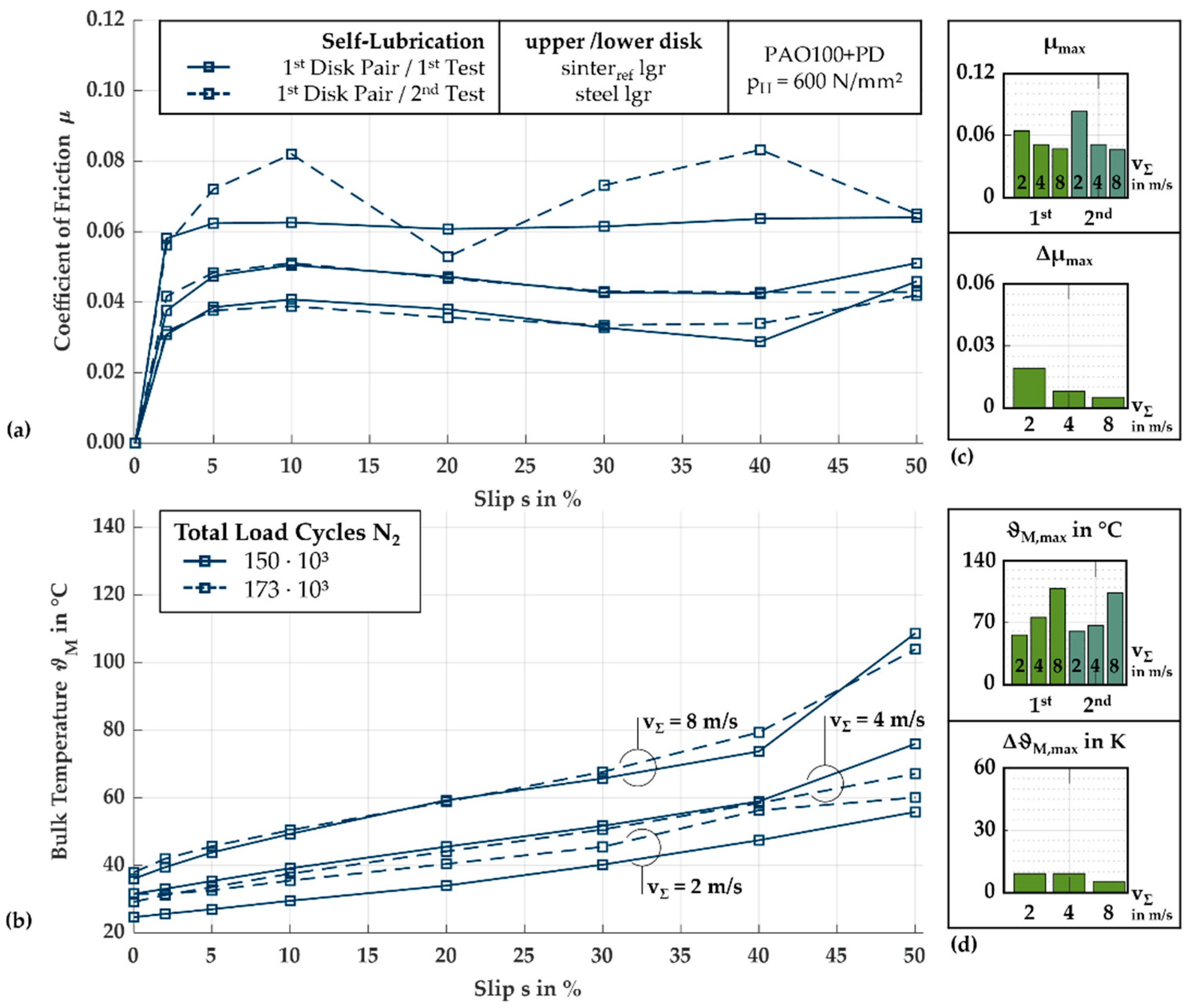

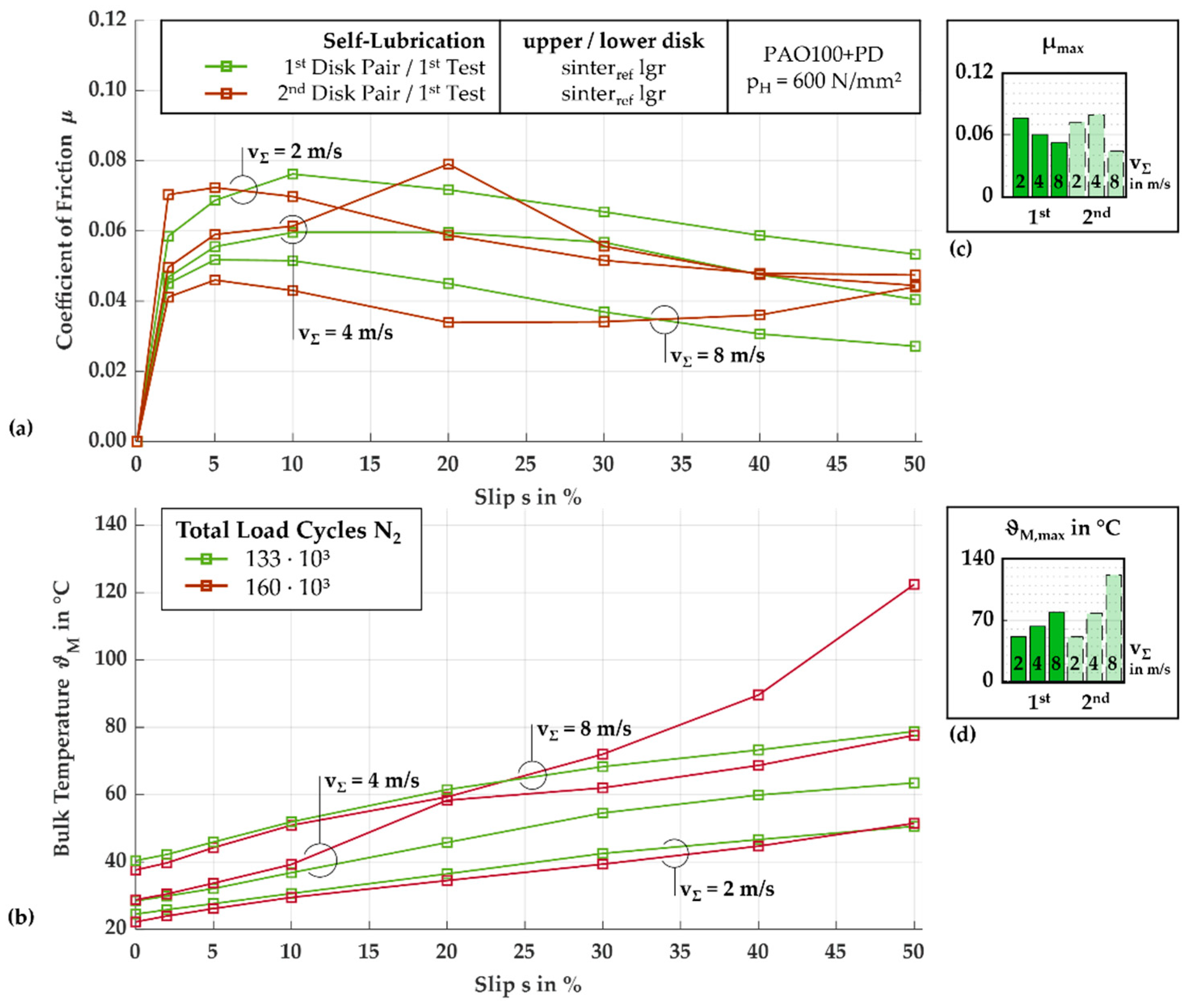

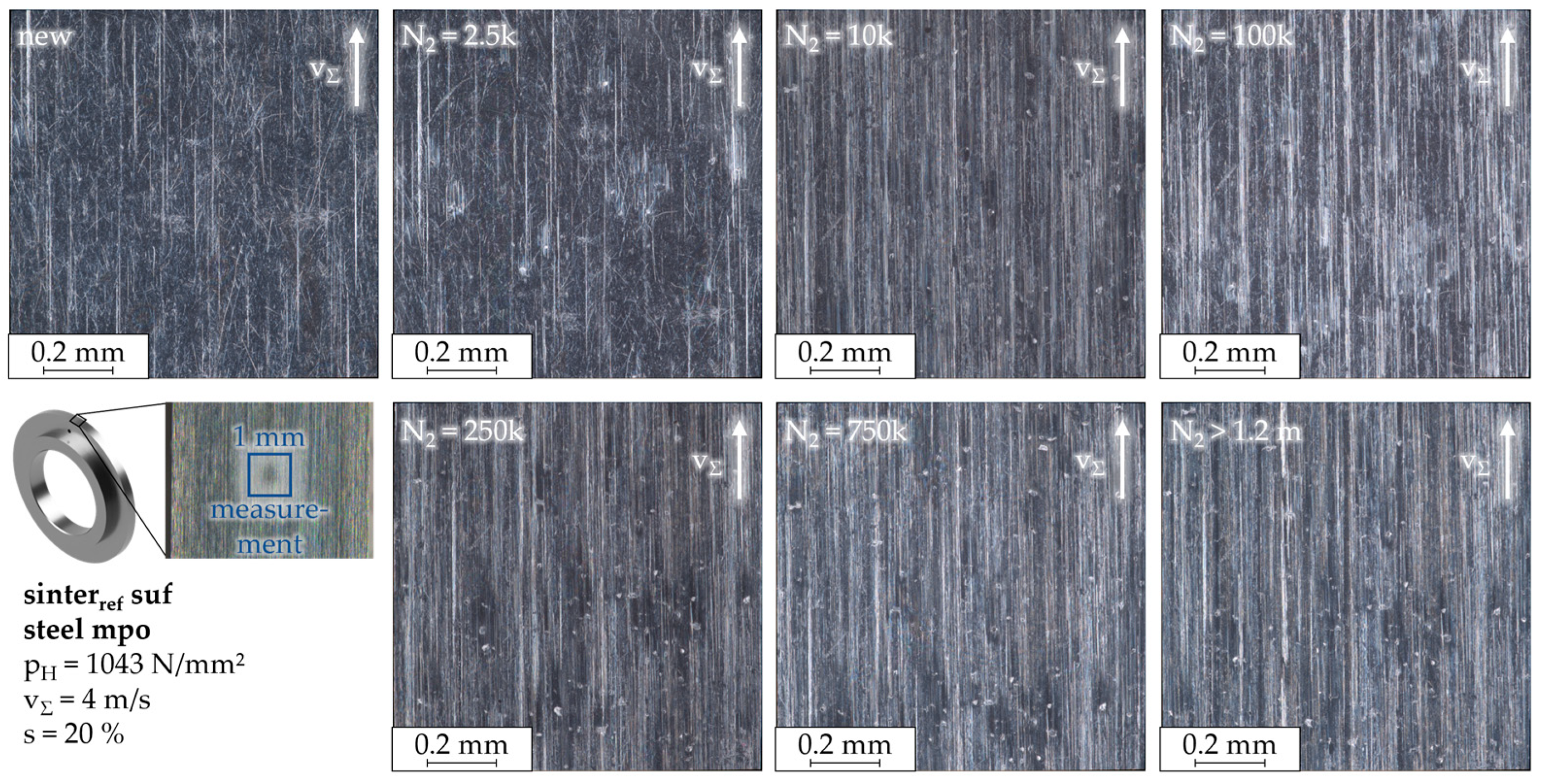

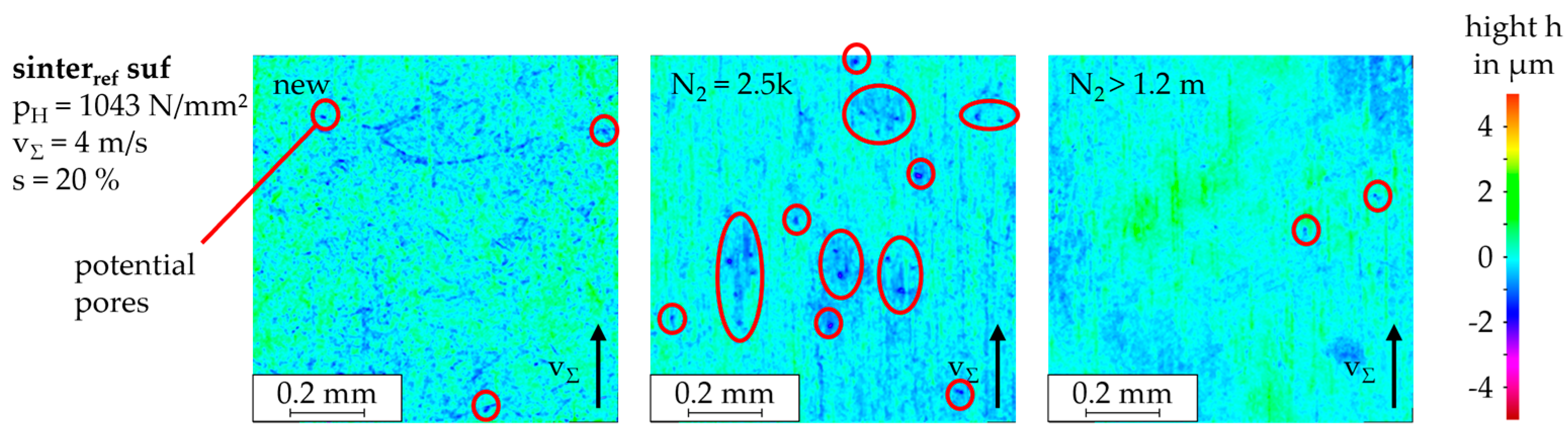

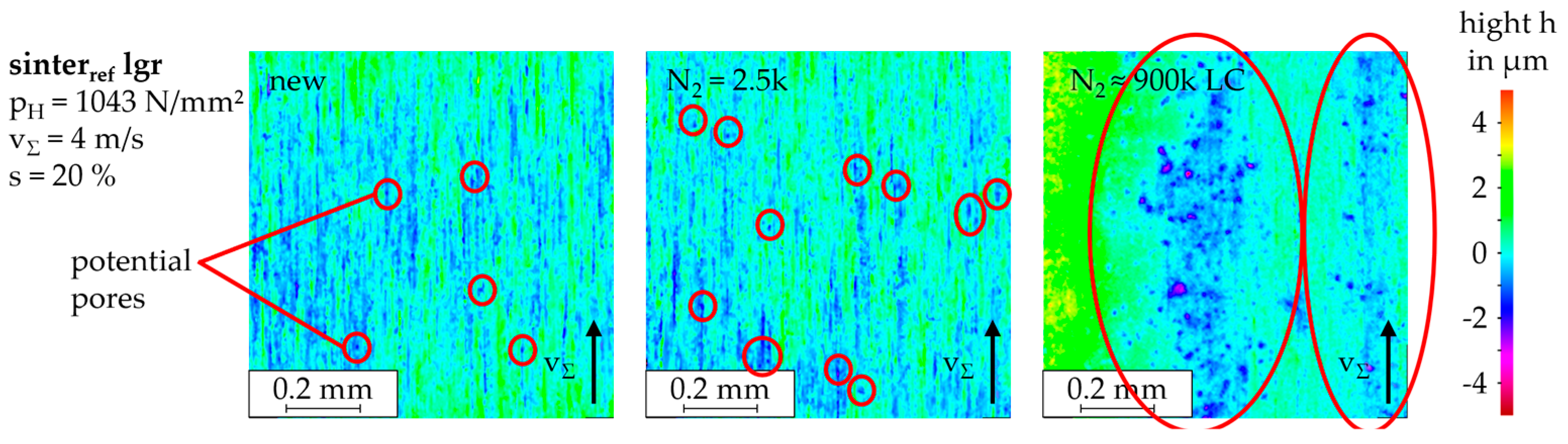

3.2.2. Investigation of the Influence of Surface Finish on the Frictional and Stress Behavior in Self-Lubricating Contacts

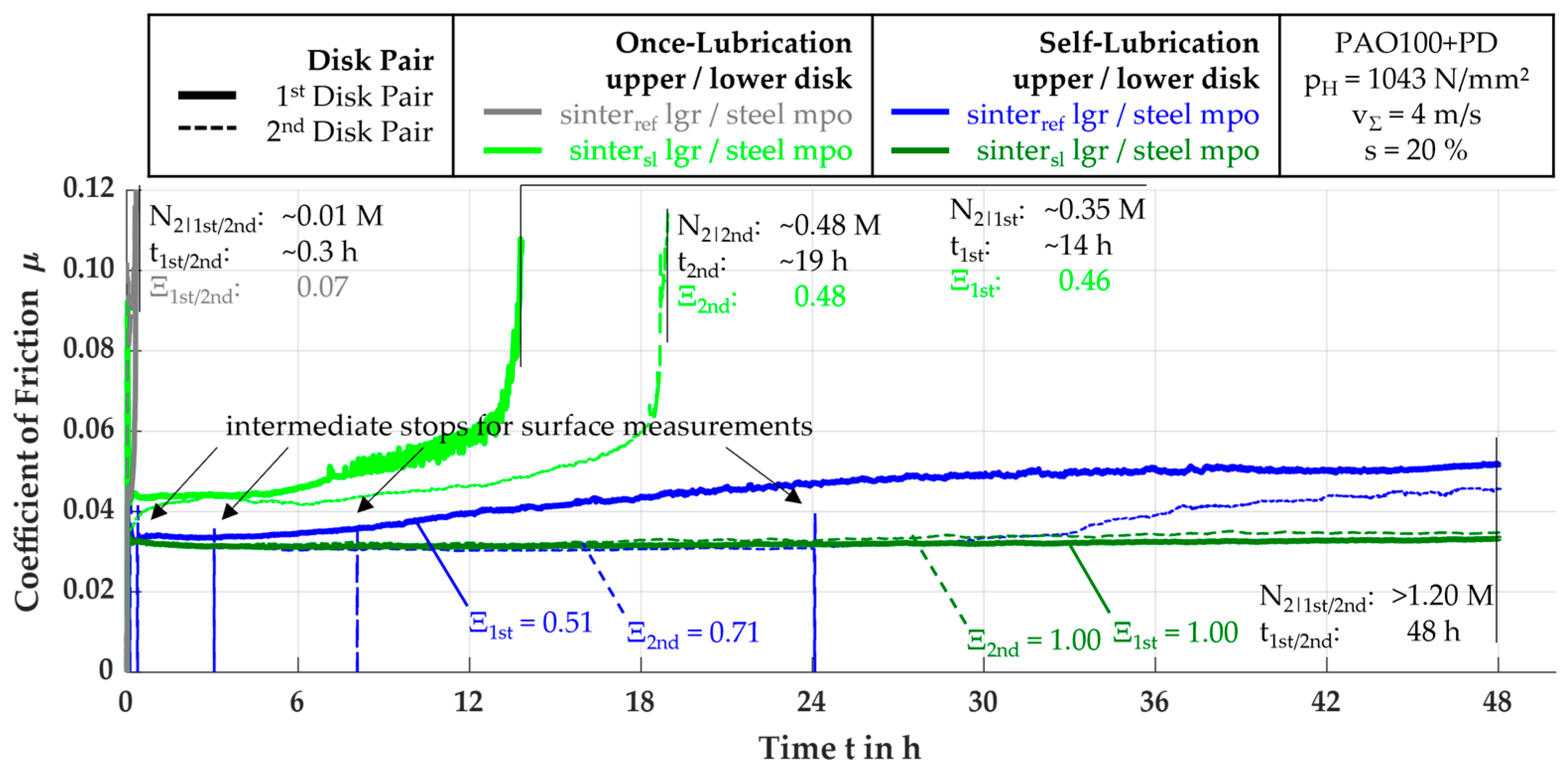

3.2.3. Investigation of the Improvement of the Frictional Behavior in Self-Lubricating Contacts through Solid Lubricant Additives in the Sinter Material

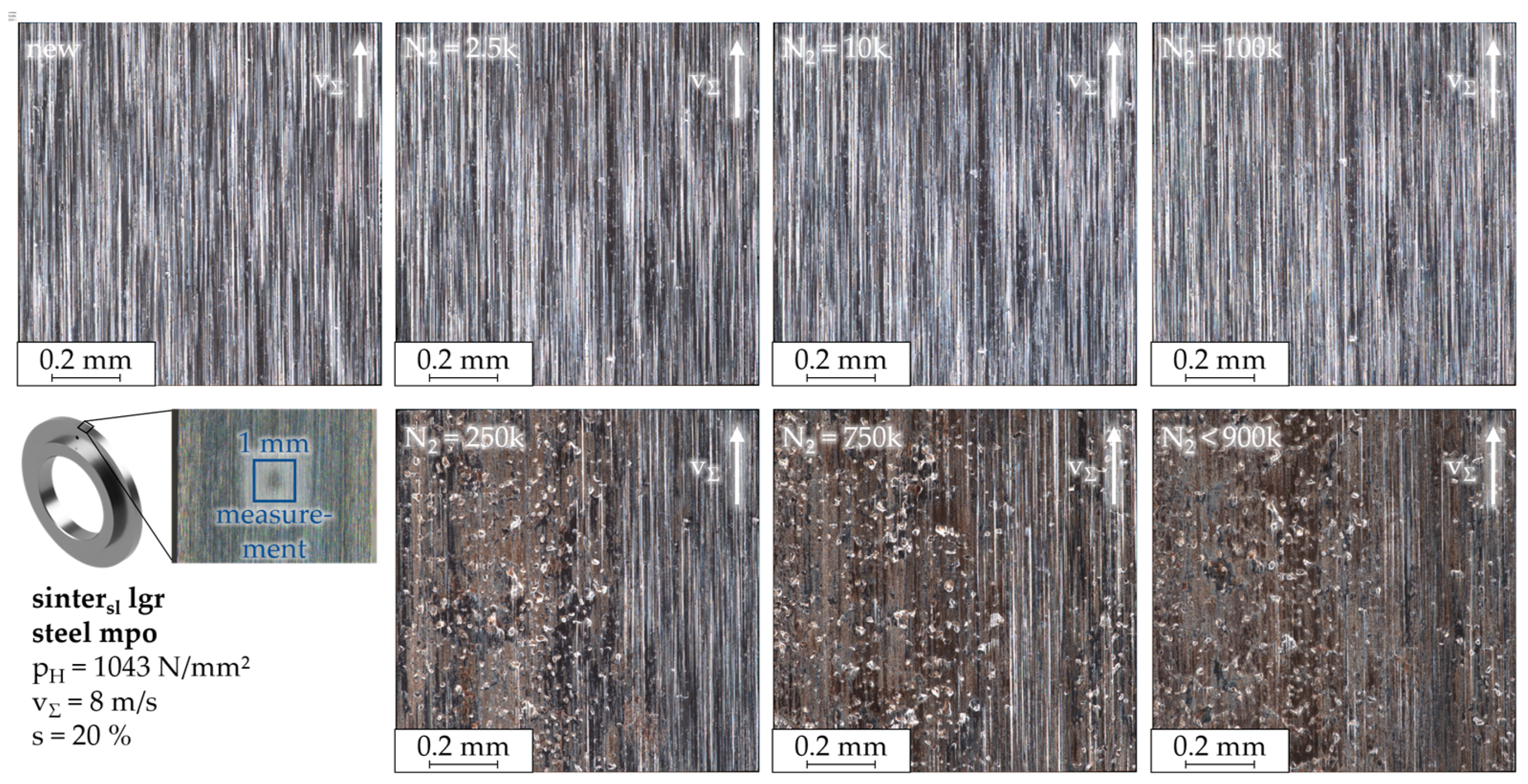

3.2.4. Determination of the Performance of Self-Lubricating Contacts under Higher Load and Speed

3.2.5. Evaluation of the Functionality of Self-Lubrication with Tooth Flank Similar Surfaces

3.2.6. Summary of the Long-Term Tests

4. Discussion

4.1. Influence of the Material on the Operating Behavior

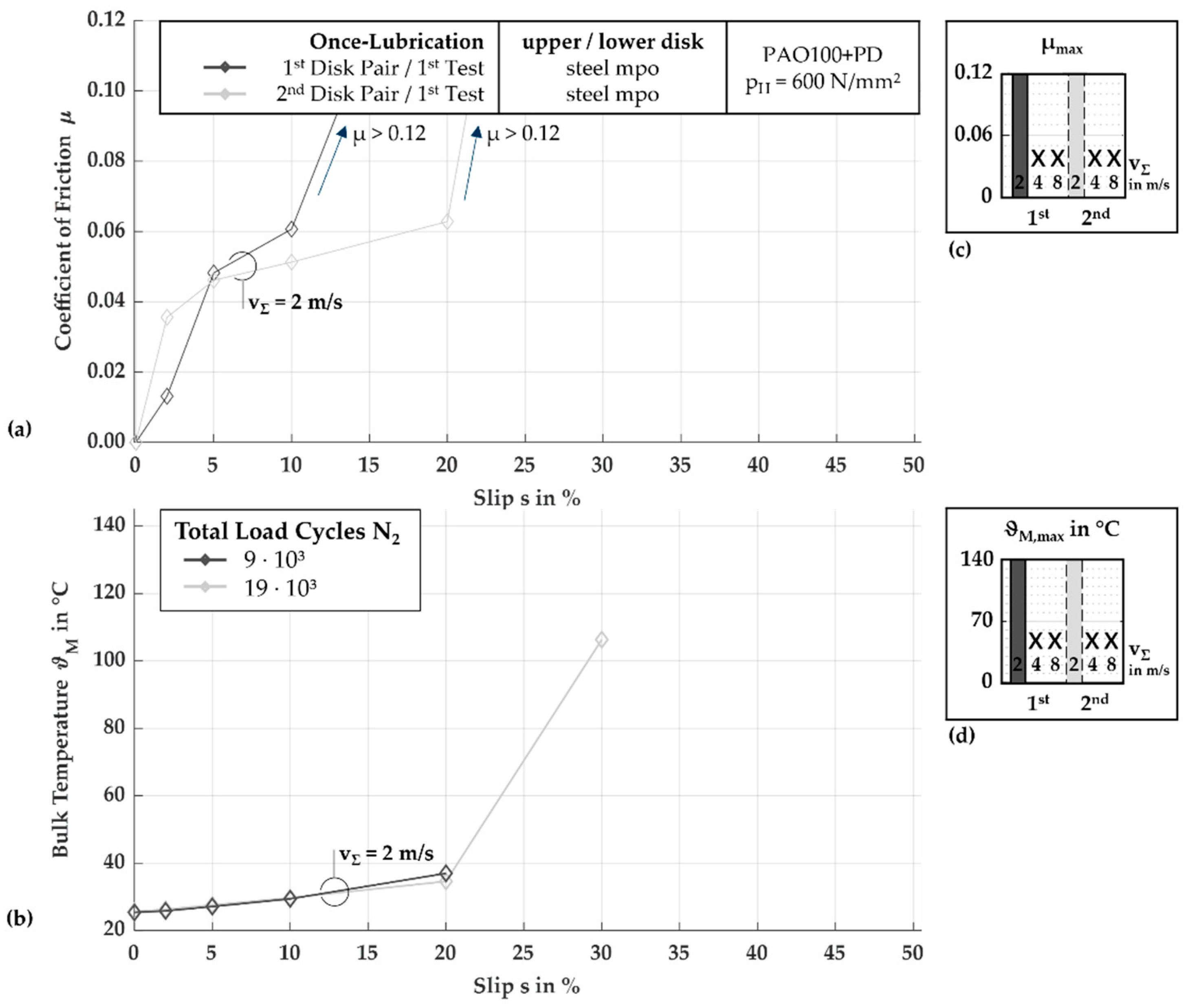

4.1.1. EHL Tribosystem without Oil-Impregnated Sinter Disks under Once-Lubrication and with One Oil-Impregnated sinterref Disk under Self-Lubrication

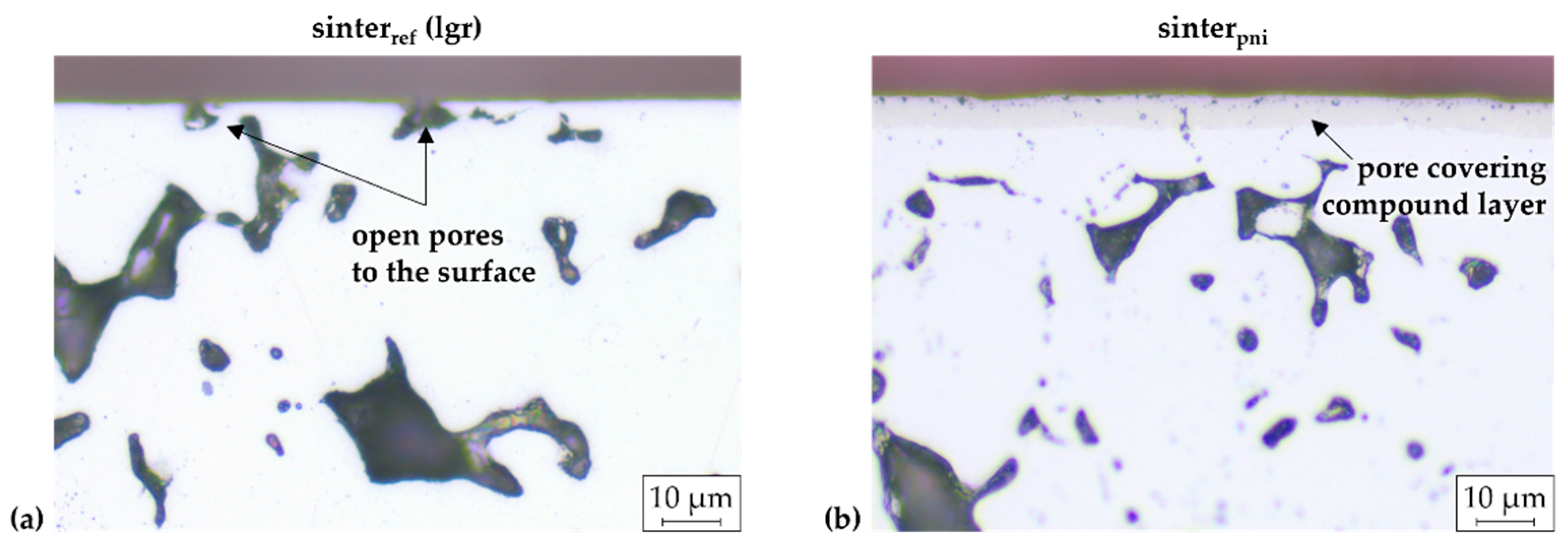

4.1.2. EHL Tribosystem with One Oil-Impregnated sinterpni Disk under Self-Lubrication

4.1.3. EHL Tribosystem with Two Oil-Impregnated sinterref Disks under Self-Lubrication

4.1.4. EHL Tribosystem with One Non-Impregnated sintersl Disk under Once-Lubrication or One Oil-Impregnated sintersl Disk under Self-Lubrication

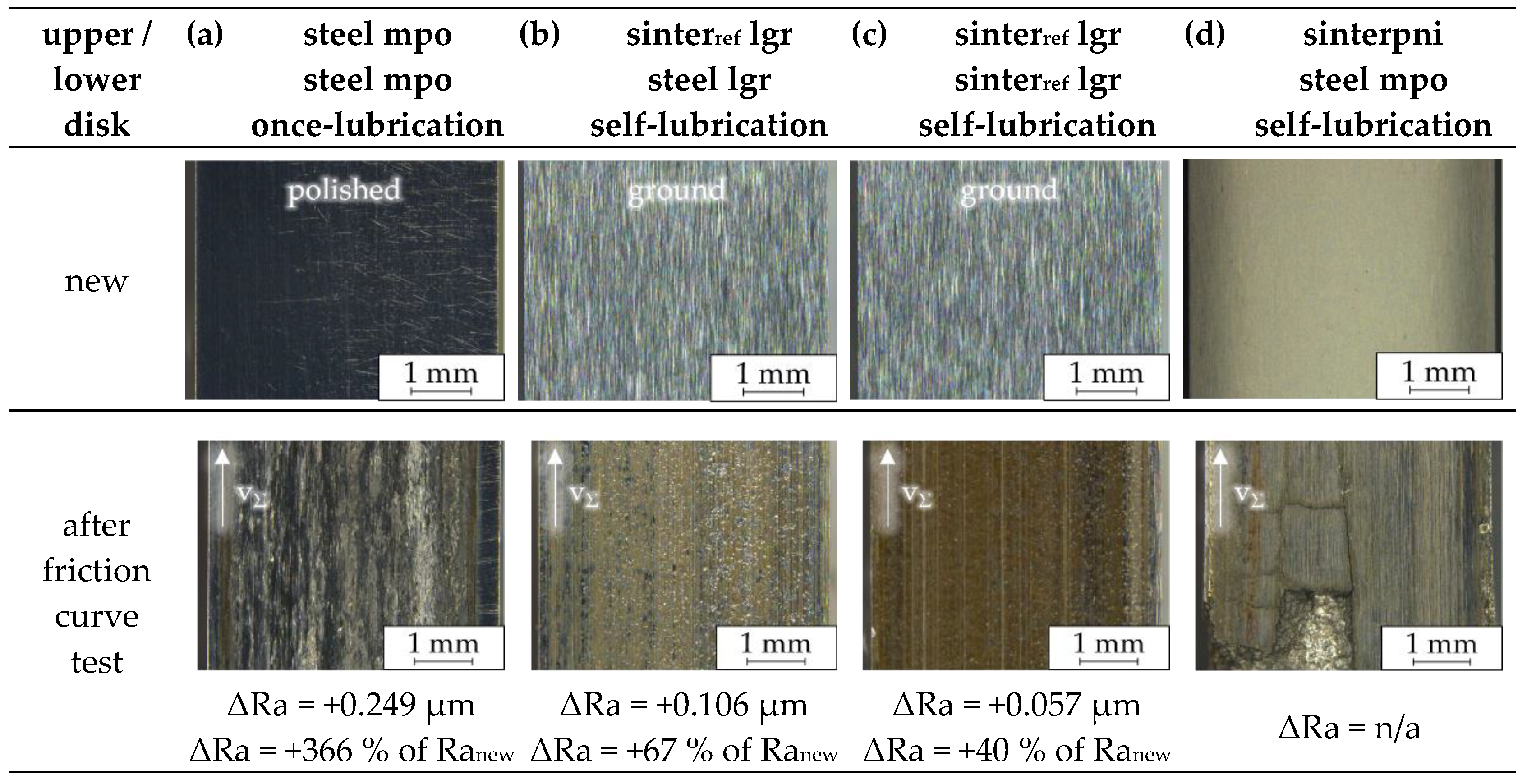

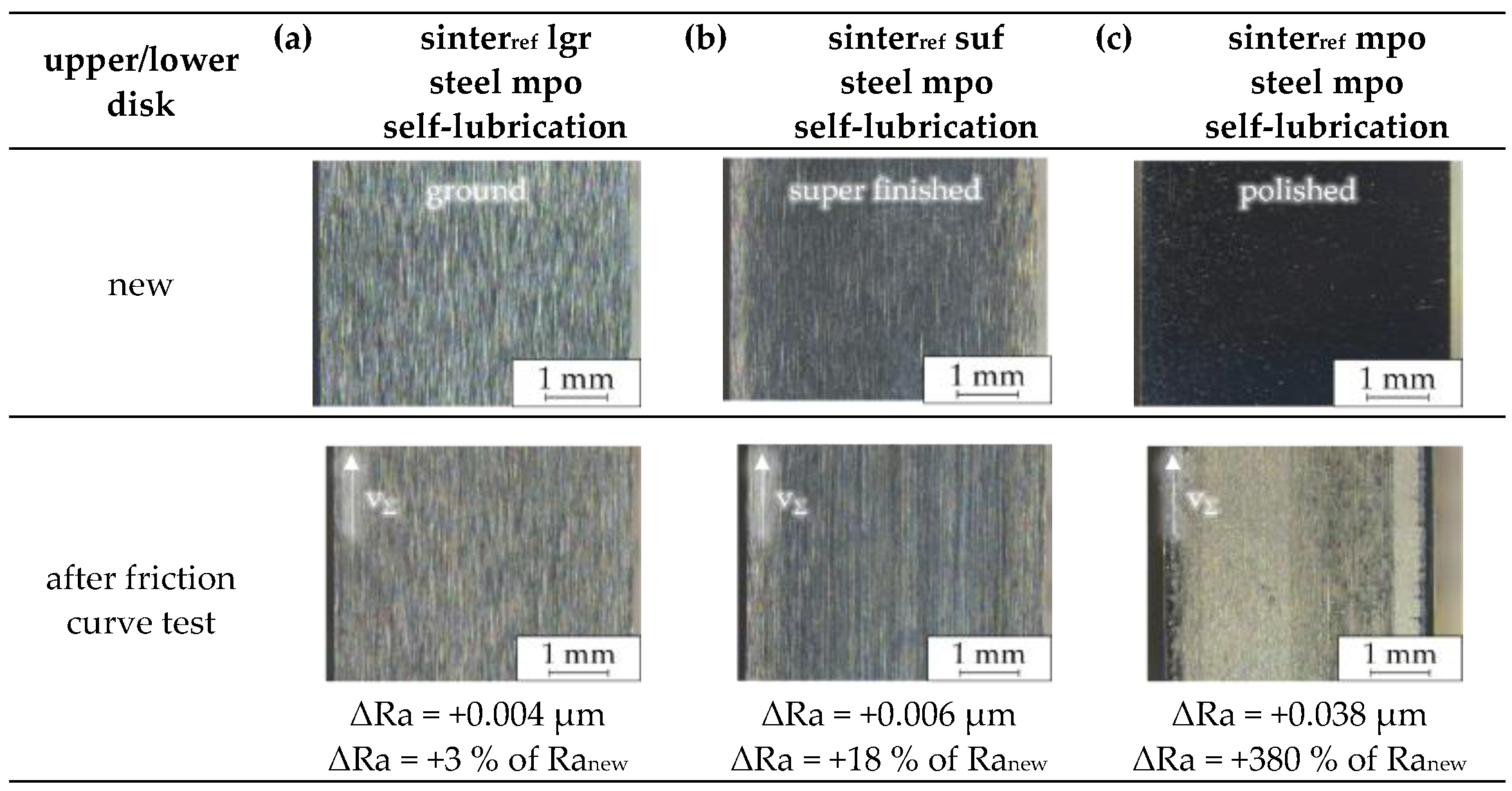

4.2. Influence of the Surface on the Operating Behavior

4.2.1. EHL Tribosystem with Ground Steel Disk and Sinter Disk Surfaces under Self-Lubrication

4.2.2. EHL Tribosystem with a Smoothed Steel Disk Surface Paired with a Longitudinally Ground Sinter Disk Surface under Self-Lubrication

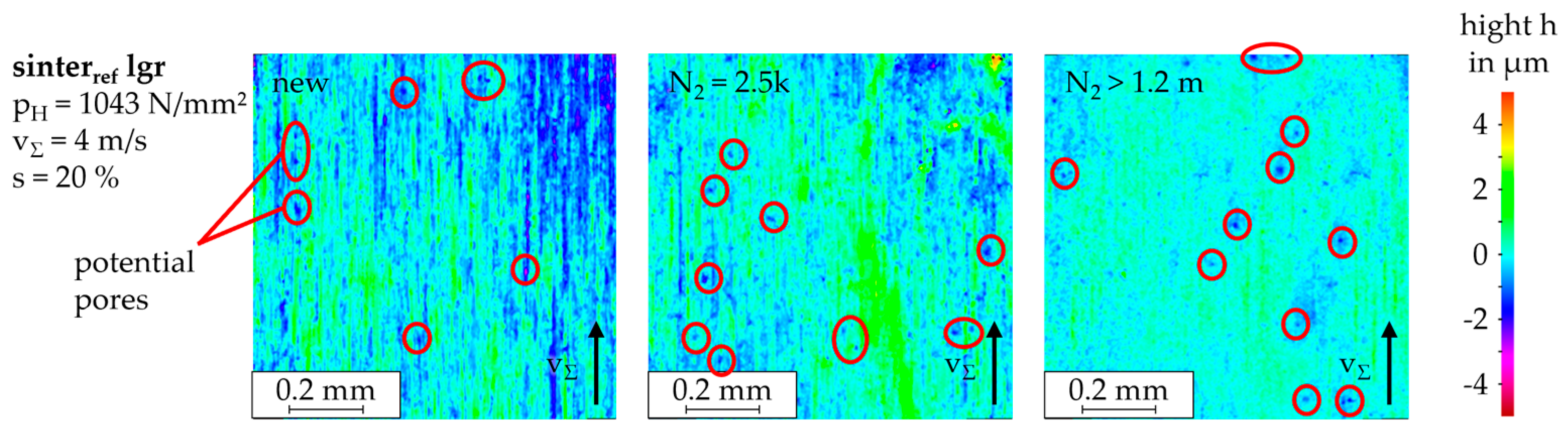

4.2.3. EHL Tribosystem with a Smoothed Steel Disk Surface Paired with a Smoothed sinterref Disk Surface under Self-Lubrication

Superfinishing of the sinterref Disk Surface

Mechanical Polishing of the sinterref Disk Surface

4.3. Influence of the Operating Conditions on the Operating Behavior

4.3.1. EHL Tribosystem under Comparably Higher Load

4.3.2. EHL Tribosystem under Comparably Higher Sum Velocity

5. Conclusions

- A once-lubricated EHL tribosystem without external oil lubrication performs better when a solid lubricant is added to the sintering powder prior to sintering.

- A self-lubricating EHL tribosystem with longitudinally ground surfaces and one oil-impregnated sinter disk exhibits adequate friction behavior and, thus, mostly stable operating behavior during the tests. Two oil-impregnated sinter disks show worse tribological performance.

- Smoothing the surface of the steel disk in the self-lubricating EHL tribosystem improves tribological performance, while finishing both contact partner surfaces by mechanical polishing of the steel disk and superfinishing of the sinter disk provides the best repeatable tribological performance.

- For axially ground surfaces similar to typical gear tooth flanks, the best tribological performance of a self-lubricating EHL tribosystem can be achieved with a solid lubricant addition to the sintered material prior to sintering.

- The surface alteration during the tests with EHL tribosystems with good tribological performance is characterized by a consistent running-in-like increase in pore size and quantity within the initial load cycles and an only slight additional change during the further lifetime.

- Nevertheless, great differences in operating behavior and surface alteration are observed for disk pairs manufactured with identical requirements for mechanical properties and surface conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ebner, M.; Lohner, T.; Michaelis, K.; Höhn, B.-R.; Stahl, K. Self-Lubricating Gears with Oil-Impregnated Sintered Materials. Forsch. Im Ingenieurwesen 2017, 2, 13–28. [Google Scholar]

- Niemann, G.; Winter, H. Maschinenelemente 2: Getriebe Allgemein, Zahnradgetriebe—Grundlagen, Stirnradgetriebe, 2nd ed.; revised; Springer: Berlin/Heidelberg, Germany, 2003; ISBN 978-3-662-11874-0. [Google Scholar]

- DIN 51509-1; Selection of Lubricants for Gears; Gear Lubricating Oils. Beuth GmbH: Berlin, Germany, 1976.

- Bartel, D. Simulation von Tribosystemen: Grundlagen und Anwendungen; Postdoctoral Thesis; 1st ed.; Vieweg + Teubner; University of Magdeburg: Wiesbaden, Germany, 2010; ISBN 978-3-8348-1241-4. [Google Scholar]

- Conrades, V. Proteins of the Matrix in Tissue Engineered Meniscus. Ph.D. Thesis, Technical University of Munich, München, Germany, 2007; pp. 12–20. [Google Scholar]

- Schatt, W. Pulvermetallurgie: Technologien und Werkstoffe, 2nd ed.; revised and extended; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 3-540-23652-X. [Google Scholar]

- DIN 1850-3; Plain Bearings: Part 3: Sintermetal Bushes. Beuth GmbH: Berlin, Germany, 1998.

- Roberts, M. A Study of Oil Circulation in the R4 Spin-Axis Bearing with Sintered Nylon Ball Retainer: Proc. Gyro. Spin-Axis Hydrodynamic; Massachusetts Institute of Technology: Cambridge, UK, 1966. [Google Scholar]

- Fote, A.A.; Slade, B.A.; Feuerstein, S. The behavior of thin oil films in the presence of porous lubricant reservoirs. Wear 1978, 46, 377–385. [Google Scholar] [CrossRef]

- Bertrand, P.A.; Carré, D.J. Oil Exchange between Ball Bearings and Porous Polyimide Ball Bearing Retainers. Tribol. Trans. 1997, 40, 294–302. [Google Scholar] [CrossRef]

- Marchetti, M.; Meurisse, M.-H.; Vergne, P.; Sicre, J.; Durand, M. Lubricant Supply by Porous Reservoirs in Space Mechanisms. In Proceedings of the 26th Leeds-Lyon Symposium on Tribology, Leeds, UK, 14-17 September 1999; Volume 38, pp. 777–785. [Google Scholar] [CrossRef]

- Marchetti, M.; Meurisse, M.-H.; Vergne, P.; Sicre, J.; Durand, M. Analysis of oil supply phenomena by sintered porous reservoirs. Tribol. Lett. 2001, 10, 163–170. [Google Scholar] [CrossRef]

- Bertrand, P.A.; Carré, D.J.; Bauer, R. Oil Exchange Between Ball Bearings and Cotton-Phenolic Bail-Bearing Retainers. Tribol. Trans. 1995, 38, 342–352. [Google Scholar] [CrossRef]

- Scheichl, B.; Neacsu, I.A.; Kluwick, A. A novel view on lubricant flow undergoing cavitation in sintered journal bearings. Tribol. Int. 2015, 88, 189–209. [Google Scholar] [CrossRef]

- Morgan, V.T.; Cameron, A. Mechanism of lubrication in porous metal bearings. In Proceedings of the Conference on Lubrication and Wear, London, UK, 1–3 October 1957; Volume 89, pp. 151–157. [Google Scholar]

- Dizdar, S. Pitting Resistance of Sintered Small-Module Gears: Proceedings of the institution of Mechanical Engineers. Part J J. Eng. Tribol. 2013, 227, 1225–1240. [Google Scholar] [CrossRef]

- Lipp, K. Rolling Contact Fatigue of Sintered Steels under Constant and Variable Hertzian Pressure and Sliding; LBF: Darmstadt, Germany, 1997. [Google Scholar]

- Dlapka, M.; Danninger, H.; Gierl, C.; Lindqvist, B. Defining the pores in PM components. Met. Powder Rep. 2010, 65, 30–33. [Google Scholar] [CrossRef]

- Li, X.; Olofsson, U. A study on friction and wear reduction due to porosity in powder metallurgic gear materials. Tribol. Int. 2017, 110, 86–95. [Google Scholar] [CrossRef]

- Balasoiu, A.M.; Braun, M.J.; Moldovan, S.I. A parametric study of a porous self-circulating hydrodynamic bearing. Tribol. Int. 2013, 61, 176–193. [Google Scholar] [CrossRef]

- Manoylov, A.V.; Borodich, F.M.; Evans, H.P. Modelling of Elastic Properties of Sintered Materials. Proc. R. Soc. A 2013, 469. [Google Scholar] [CrossRef]

- Zapf, G. Handbook of Manufacturing Technology Vol. 1: Handbuch der Fertigungstechnik; Carl Hanser, München Wien: München, Germany, 1981. [Google Scholar]

- Ebner, M.; Lohner, T.; Michaelis, K.; Stemplinger, J.-P.; Höhn, B.-R.; Stahl, K. Self-Lubricated Elastohydrodynamic (EHL) Contacts with Oil-Impregnated Sintered Materials. In TAE 2016; Technische Akademie Esslingen: Ostfildern, Germany, 2016. [Google Scholar]

- Ebner, M.; Lohner, T.; Weigl, A.; Michaelis, K.; Stemplinger, J.-P.; Höhn, B.-R.; Stahl, K. Hochbelastete und schmierstoffgetränkte Wälzpaarungen aus Sintermaterial ohne externe Schmierstoffzuführung. Tribol. Schmier. 2016, 63, 22–30. [Google Scholar]

- Ebner, M. Self-Lubrication of Highly-Loaded Gear Contacts with Oil-Impregnated Porous Ferrous Metals. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2021. [Google Scholar]

- Ebner, M.; Lohner, T.; Stahl, K. Konstruktionselemente mit Hertz’scher Punkt- oder Linienlast und Schlupf in der Kontaktfläche ohne äußere Schmierung: DFG Koselleck Final Report; German Research Foundation: München, Germany, 2019. [Google Scholar]

- Ebner, M.; Schwarz, A. Einfluss Poröser Oberflächen auf die Selbstschmierung: 2. Tribologie-Kolloquium des GfT-Arbeitskreises München; Gesellschaft für Tribologie e.V.: Jülich, Germany, 2019. [Google Scholar]

- Omasta, M.; Ebner, M.; Sperka, P.; Lohner, T.; Krupka, I.; Hartl, M.; Höhn, B.-R.; Stahl, K. Film formation in EHL contacts with oil-impregnated sintered materials. Ind. Lubr. Tribol. 2018, 70, 612–619. [Google Scholar] [CrossRef]

- Ebner, M.; Schwarz, A. Selbstschmierende hochbelastete Wälzpaarungen: 2. Tribologie-Kolloquium des GfT-Arbeitskreises München; Gesellschaft für Tribologie e.V.: Jülich, Germany, 2019. [Google Scholar]

- Zhang, S.; Li, Y.; Hu, L.; Feng, D.; Wang, H. AntiWear Effect of Mo and W Nanoparticles as Additives for Multialkylated Cyclopentanes Oil in Vacuum. J. Tribol. 2017, 139, 021607. [Google Scholar] [CrossRef]

- Rabaso, P.; Ville, F.; Dassenoy, F.; Diaby, M.; Afanasiev, P.; Cavoret, J.; Vacher, B.; Le Mogne, T. Boundary lubrication: Influence of the size and structure of inorganic fullerene-like MoS2 nanoparticles on friction and wear reduction. Wear 2014, 320, 161–178. [Google Scholar] [CrossRef]

- Srinivas, V.; Rao, C.K.R.; Abyudaya, M.; Jyothi, E.S. Extreme Pressure Properties of 600 N Base Oil Dispersed with Molybdenum Disulphide Nano Particles. Univers. J. Mech. Eng. 2014, 2, 220–225. [Google Scholar] [CrossRef]

- Bakunin, V.N.; Suslov, A.Y.; Kuzmina, G.N.; Parenago, O.P.; Topchiev, A.V. Synthesis and Application of Inorganic Nanoparticles as Lubricant Components ÔÇô a Review. J. Nanoparticle Res. 2004, 6, 273–284. [Google Scholar] [CrossRef]

- Zhu, S.; Cheng, J.; Qiao, Z.; Yang, J. High temperature solid-lubricating materials: A review. Tribol. Int. 2019, 133, 206–223. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Fushchich, O.I.; Danyluk, S. The tribological properties and mechanism of wear of Cu-based sintered powder materials containing molybdenum disulfide and molybdenum diselenite under unlubricated sliding against copper. Wear 2012, 290, 106–123. [Google Scholar] [CrossRef]

- Dhanasekaran, S.; Gnanamoorthy, R. Dry sliding friction and wear characteristics of Fe–C–Cu alloy containing molybdenum di sulphide. Mater. Des. 2007, 28, 1135–1141. [Google Scholar] [CrossRef]

- DIN 30910-6; Sintered Metal Materials: Sint-Material Specifications: Hot-Forged Sintered Steels for Structural Parts. Beuth GmbH: Berlin, Germany, 1990.

- DIN EN ISO 5755; Sintered Metal Material: Specifications. Beuth GmbH: Berlin, Germany, 2022.

- DIN EN ISO 13565-1; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Surfaces Having Stratified Functional Properties: Part 1: Filtering and General Measurement Conditions. Beuth GmbH: Berlin, Germany, 1998.

- Cai, J.; Jin, T.; Kou, J.; Zou, S.; Xiao, J.; Meng, Q. Lucas-Washburn Equation-Based Modeling of Capillary-Driven Flow in Porous Systems. Langmuir 2021, 37, 1623–1636. [Google Scholar] [CrossRef] [PubMed]

- Hamraoui, A.; Nylander, T. Analytical approach for the Lucas-Washburn equation. J. Colloid Interface Sci. 2002, 250, 415–421. [Google Scholar] [CrossRef] [PubMed]

- Lados, D.; Apelian, D.; Semel, F.J. Open and Closed Porosity in P/M Materials: Measurement and Variation with Density Levels and Sintering Conditions; Euro PM 2005 Tools for Improving PM; European Powder Metallurgy Association: Prague, Czech Republic, 2005. [Google Scholar]

- Lohner, T.; Merz, R.; Mayer, J.; Michaelis, K.; Kopnarski, M.; Stahl, K. On the Effect of Plastic Deformation (PD) Additives in Lubricants. Tribol. Und Schmier. 2015, 62, 13–24. [Google Scholar]

- UK Castrol Ltd. Castrol Optigear Synthetic PD…ES: Product Data Sheet; BP Europa SE: Hamburg, Germany, 2019. [Google Scholar]

- Vojacek, H. Das Reibungsverhalten von Fluiden unter Elastohydrodynamischen Bedingungen. Einfluss der Chemischen Struktur des Fluides, der Werkstoffe und der Makro- und Mikrogeometrie der Gleit/Wälzkörper. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 1984. [Google Scholar]

- Ebner, M.; Omasta, M.; Lohner, T.; Sperka, P.; Krupka, I.; Hartl, M.; Michaelis, K.; Höhn, B.-R.; Stahl, K. Local Effects in EHL Contacts with Oil-Impregnated Sintered Materials. Lubricants 2019, 7, 1. [Google Scholar] [CrossRef]

| Material | Young’s Modulus E in GPa | Poisson’s Ratio ν | Surface Hardness | Density ρ in g/cm3 |

|---|---|---|---|---|

| steel | 210 | 0.30 | 745 HV5 | 7.8 |

| sinterref/sl | 130 | 0.27 | 755 HV5 | 7.0 |

| sinterpni | 140 | 0.27 | 785 HV5 | 7.0 |

| Longitudinally Ground (lgr) | Axially Ground (agr) | Superfinished (suf) | Mechanically Polished (mpo) | Plasma Nitride (pni) |

|---|---|---|---|---|

|  |  |  |  |

| ISO VG | Density ρoil at 15 °C in kg/m3 | Kin. Viscosity η40°C at 40 °C in mm2/s | Kin. Viscosity η100°C at 100 °C in mm2/s |

|---|---|---|---|

| 100 | 849 | 105.0 | 15.7 |

| Measurement Intervals | |||||||

|---|---|---|---|---|---|---|---|

| Load cycle number N2 | >2.5 k | >10 k | >30 k | <100 k | >250 k | >750 k | >1200 k |

| Time t in h | 0.08 | 0.33 | 1 | 3 | 8 | 24 | 48 |

| Lubrication Method Upper/Lower Disk pH = 600 N/mm2 s = 0…50% | µmax at vΣ | ϑM,max in °C at vΣ | N2 in M | |||||

|---|---|---|---|---|---|---|---|---|

| 2 m/s | 4 m/s | 8 m/s | 2 m/s | 4 m/s | 8 m/s | Total | ||

| once-lubrication steel mpo/steel mpo | 1.1 4 | >0.120 1 | x 2 | x 2 | >140 1 | x 2 | x 2 | x 2 |

| 1.2 5 | x 2 | x 2 | x 2 | x | x 2 | x 2 | x 2 | |

| Δµmax | x 2 | x 2 | x 2 | x | x 2 | x 2 | ||

| 2.1 6 | >0.120 1 | x 2 | x 2 | >140 1 | x 2 | x 2 | x 2 | |

| injection lubrication steel lgr/steel lgr | 1.1 4 | 0.057 | 0.038 | 0.035 | 38 | 43 | 52 | 0.03 |

| 1.2 5 | 0.055 | 0.034 | 0.033 | 40 | 43 | 52 | 0.03 | |

| Δµmax | 0.002 | 0.001 | 0.002 | 1 | 0 | 0 | ||

| 2.1 6 | - 3 | - 3 | - 3 | - 3 | - 3 | - 3 | - 3 | |

| self-lubrication sinterref lgr/steel lgr | 1.1 4 | 0.064 | 0.051 | 0.047 | 56 | 76 | 109 | 0.15 |

| 1.2 5 | 0.083 | 0.051 | 0.046 | 60 | 67 | 104 | 0.17 | |

| Δµmax | 0.019 | 0.008 | 0.005 | 9 | 9 | 5 | ||

| 2.1 6 | 0.057 | 0.042 | 0.047 | 53 | 64 | 109 | 0.14 | |

| self-lubrication sinterref lgr/sinterref lgr | 1.1 4 | 0.076 | 0.060 | 0.052 | 51 | 63 | 79 | 0.13 |

| 1.2 5 | 0.120 | 0.063 | 0.062 | 66 | 90 | 90 | 0.20 | |

| Δµmax | 0.055 | 0.023 | 0.033 | 17 | 17 | 15 | ||

| 2.16 | 0.072 | 0.079 | 0.044 | 51 | 88 | 122 | 0.16 | |

| self-lubrication sinterref lgr/steel mpo | 1.1 4 | 0.057 | 0.047 | 0.025 | 46 | 66 | 72 | 0.13 |

| 1.2 5 | 0.049 | 0.046 | 0.027 | 45 | 66 | 70 | 0.13 | |

| Δµmax | 0.010 | 0.003 | 0.004 | 1 | 0 | 2 | ||

| 2.1 6 | 0.033 | 0.025 | 0.020 | 46 | 66 | 71 | 0.13 | |

| self-lubrication sinterref suf/steel mpo | 1.1 4 | 0.042 | 0.033 | 0.026 | 43 | 53 | 69 | 0.12 |

| 1.2 5 | 0.040 | 0.034 | 0.026 | 44 | 53 | 69 | 0.12 | |

| Δµmax | 0.002 | 0.002 | 0.002 | 3 | 1 | 3 | ||

| 2.1 6 | 0.034 | 0.026 | 0.022 | 43 | 56 | 79 | 0.13 | |

| self-lubrication sinterref mpo/steel mpo | 1.1 4 | 0.086 | 0.041 | 0.031 | 42 | 56 | 76 | 0.14 |

| 1.2 5 | 0.061 | 0.041 | 0.034 | 46 | 58 | 77 | 0.13 | |

| Δµmax | 0.025 | 0.007 | 0.004 | 6 | 2 | 2 | ||

| 2.1 6 | 0.120 | 0.110 | >0.120 1 | 101 | 83 | >140 1 | 0.08 1 | |

| self-lubrication sinterpni/steel mpo | 1.1 4 | >0.120 1 | x 2 | x 2 | >140 1 | x 2 | x 2 | x 2 |

| 1.2 5 | x 2 | x 2 | x 2 | x 2 | x 2 | x 2 | x 2 | |

| Δµmax | x 2 | x 2 | x 2 | x 2 | x 2 | x 2 | ||

| 2.1 6 | >0.120 1 | x 2 | x 2 | >140 1 | x 2 | x 2 | x 2 | |

| Lubrication Method Upper/Lower Disk pH = 1043 N/mm2 vΣ = 4 m/s s = 20% | 1st 2nd | Δµmax | M|1st M|2nd in °C | N2|1st/N2|48h N2|2nd/N2|48h in % | Ξ1st Ξ2nd |

|---|---|---|---|---|---|

| once-lubrication sinterref lgr/steel mpo | 0.094 0.052 | 0.059 | 92 52 | <1 <1 | 0.07 0.07 |

| once-lubrication sintersl lgr/steel mpo | 0.051 0.047 | 0.057 | 93 86 | ≈29 ≈40 | 0.46 0.48 |

| injection lubrication steel lgr/steel lgr | 0.047 0.047 | 0.005 | 56 56 | 100 100 | 0.76 0.95 |

| self-lubrication sinterref lgr/steel lgr | 0.051 0.043 | 0.013 | 85 78 | 100 100 | 0.45 0.38 |

| self-lubrication sinterref lgr/steel mpo | 0.045 0.035 | 0.020 | 82 70 | 100 100 | 0.51 0.71 |

| self-lubrication sinterref suf/steel mpo | 0.031 0.036 | 0.008 | 62 70 | 100 100 | 1.00 0.69 |

| self-lubrication sintersl lgr/steel mpo | 0.032 0.033 | 0.002 | 65 68 | 100 100 | 1.00 1.00 |

| self-lubrication sinterref agr/steel agr | 0.073 0.057 | 0.041 | 110 92 | ≈73 ≈21 | 0.30 0.15 |

| self-lubrication sintersl agr/steel agr | 0.053 0.047 | 0.010 | 91 87 | 100 100 | 0.27 0.56 |

| self-lubrication 1 sintersl lgr/steel mpo | 0.045 0.039 | 0.011 | 86 87 | 100 100 | 0.46 0.43 |

| self-lubrication 2 sintersl lgr/steel mpo | 0.042 0.042 | 0.016 | 117 116 | ≈90 ≈37 | 0.48 0.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sprogies, N.; Lohner, T.; Stahl, K. Improved Operating Behavior of Self-Lubricating Rolling-Sliding Contacts under High Load with Oil-Impregnated Porous Sinter Material. Lubricants 2024, 12, 259. https://doi.org/10.3390/lubricants12070259

Sprogies N, Lohner T, Stahl K. Improved Operating Behavior of Self-Lubricating Rolling-Sliding Contacts under High Load with Oil-Impregnated Porous Sinter Material. Lubricants. 2024; 12(7):259. https://doi.org/10.3390/lubricants12070259

Chicago/Turabian StyleSprogies, Nicolai, Thomas Lohner, and Karsten Stahl. 2024. "Improved Operating Behavior of Self-Lubricating Rolling-Sliding Contacts under High Load with Oil-Impregnated Porous Sinter Material" Lubricants 12, no. 7: 259. https://doi.org/10.3390/lubricants12070259

APA StyleSprogies, N., Lohner, T., & Stahl, K. (2024). Improved Operating Behavior of Self-Lubricating Rolling-Sliding Contacts under High Load with Oil-Impregnated Porous Sinter Material. Lubricants, 12(7), 259. https://doi.org/10.3390/lubricants12070259