Proteinaceous Spirulina Biomass as a Sustainable Drilling Fluid Additive for Lubricity

Abstract

:1. Introduction

2. Experimental Methods and Data Collection

2.1. Materials and Reagents

2.2. Sample Preparation of Drilling Fluids

2.3. Rheology

2.4. Fluid Loss

2.5. Lubricity

3. Results and Discussion

3.1. Rheology

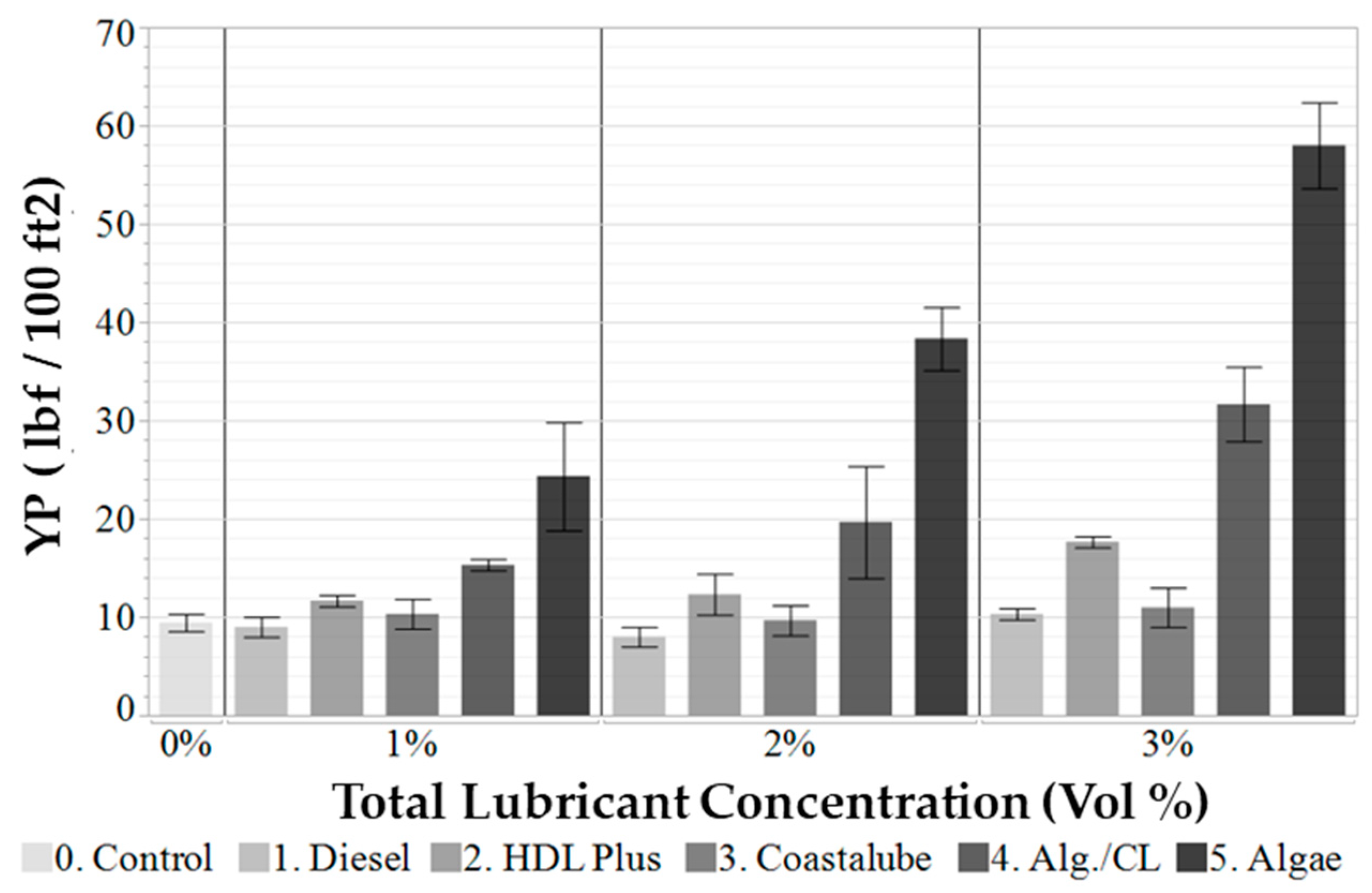

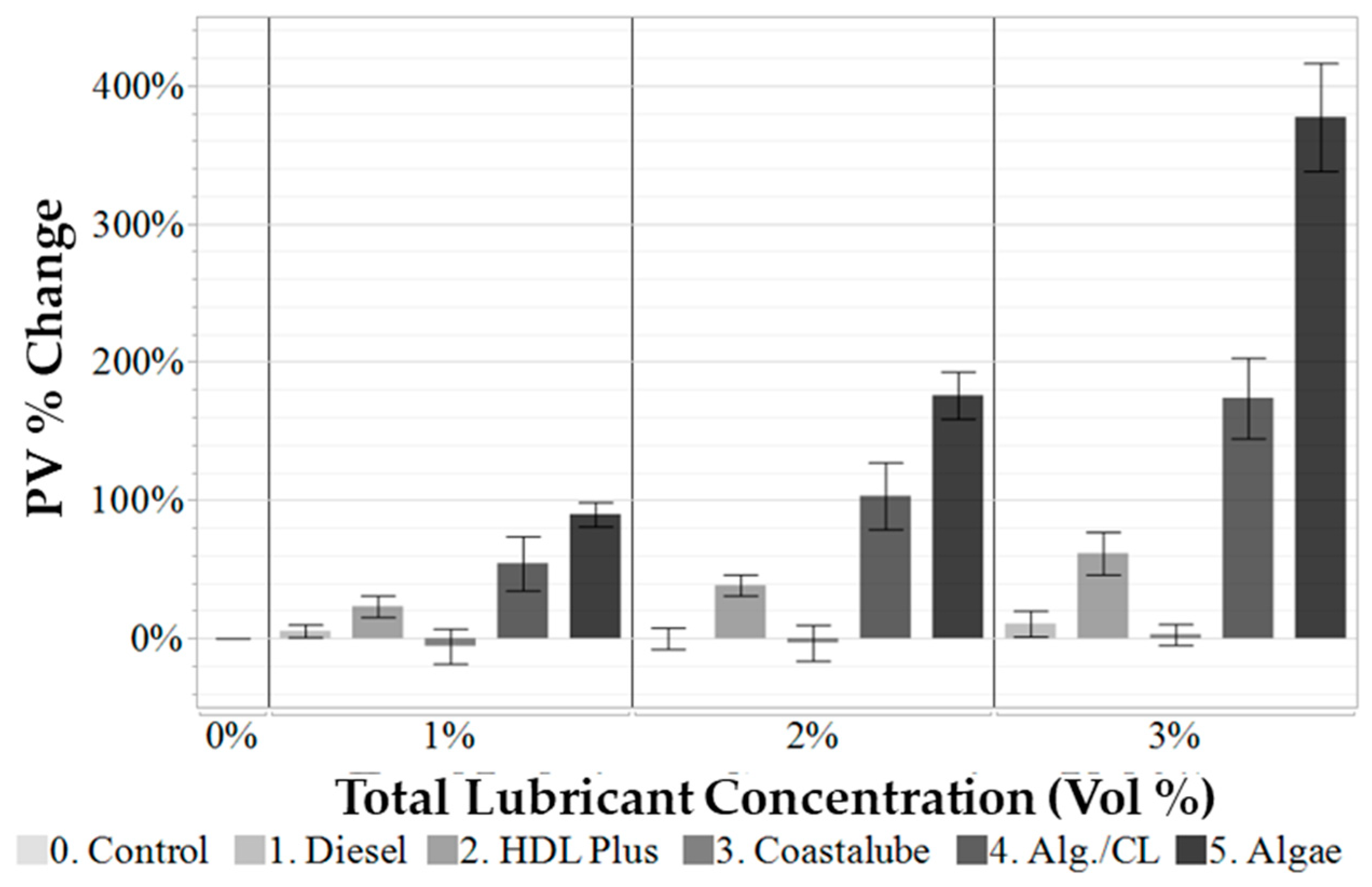

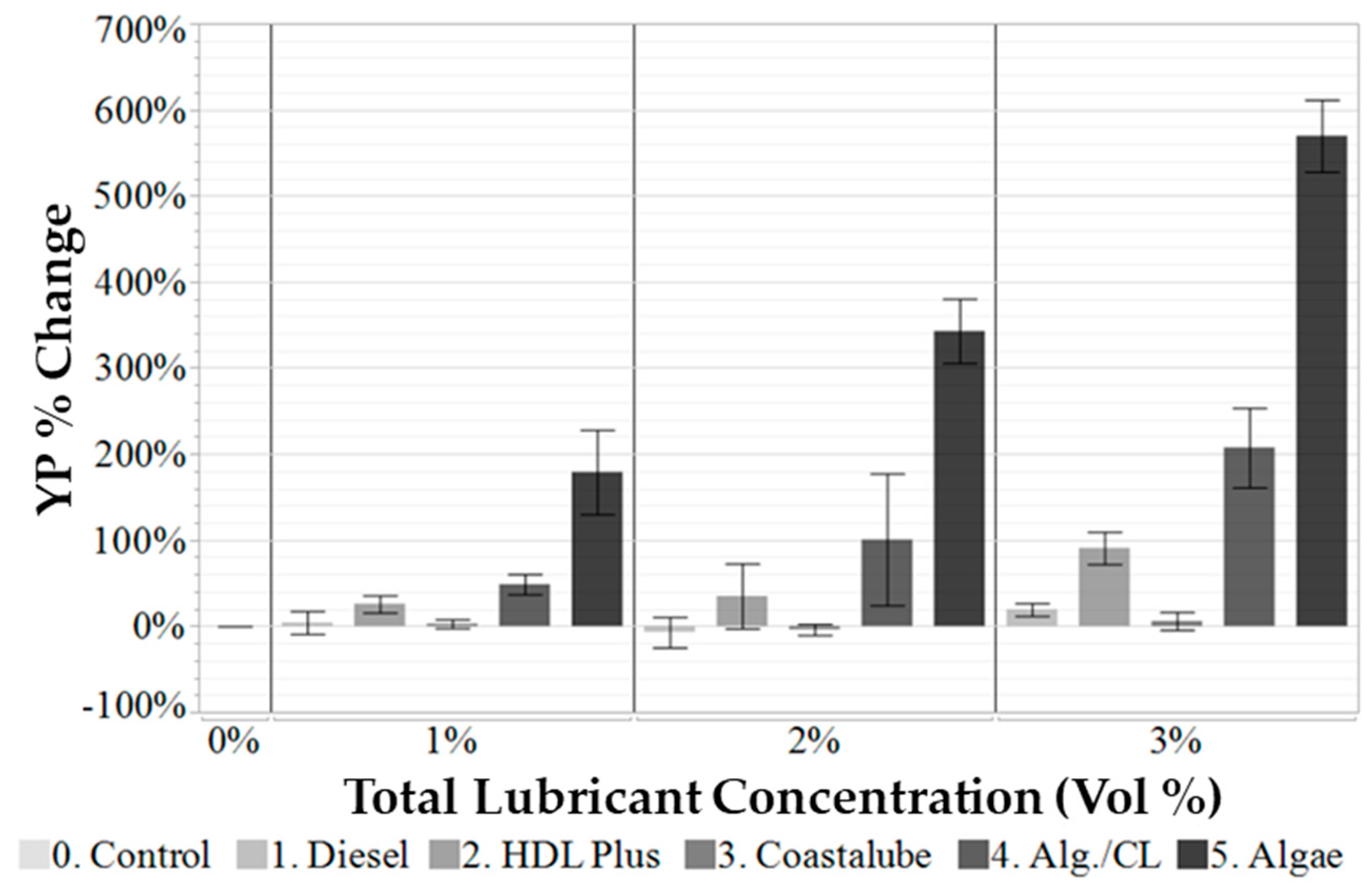

3.1.1. Bingham Plastic Model

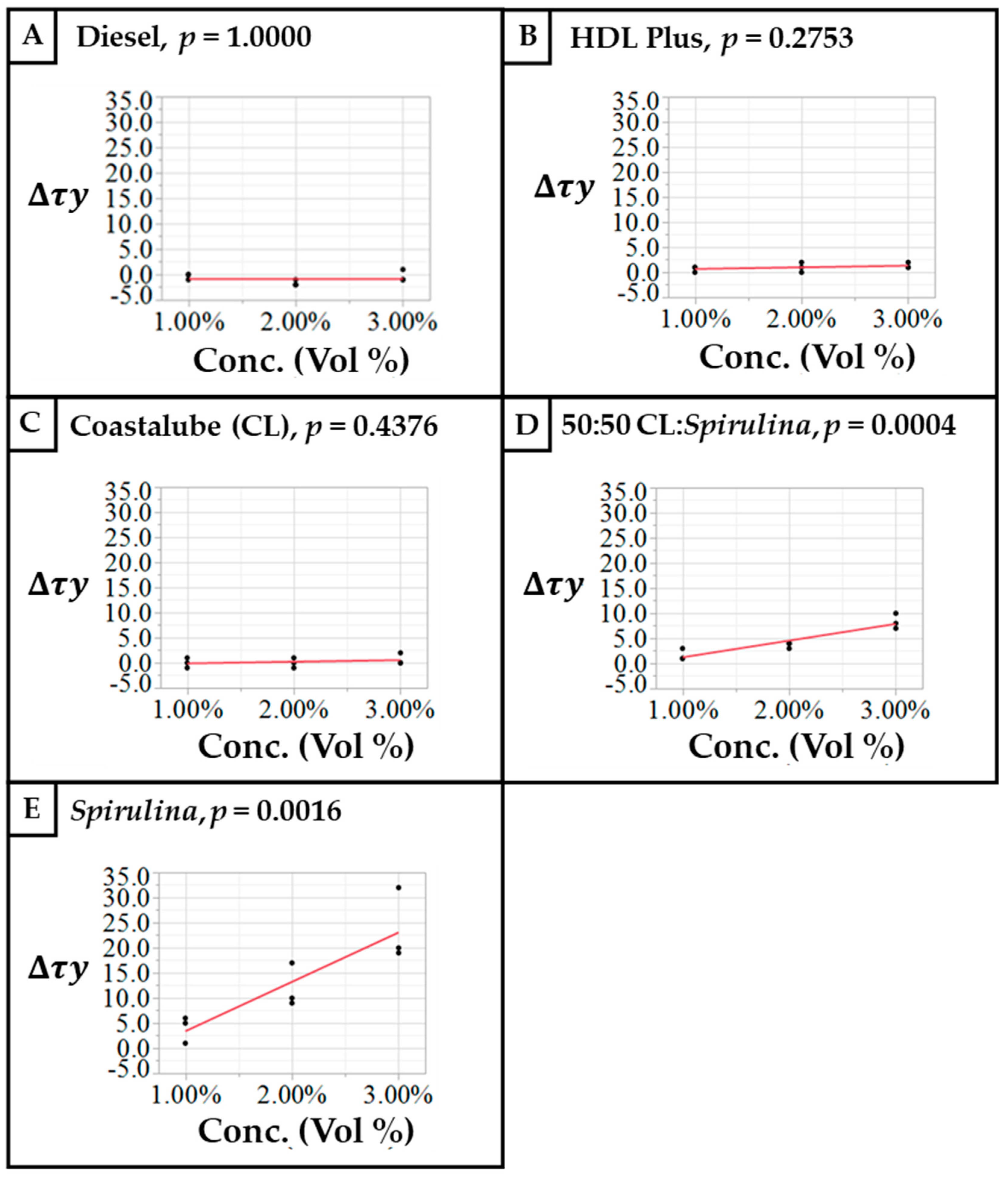

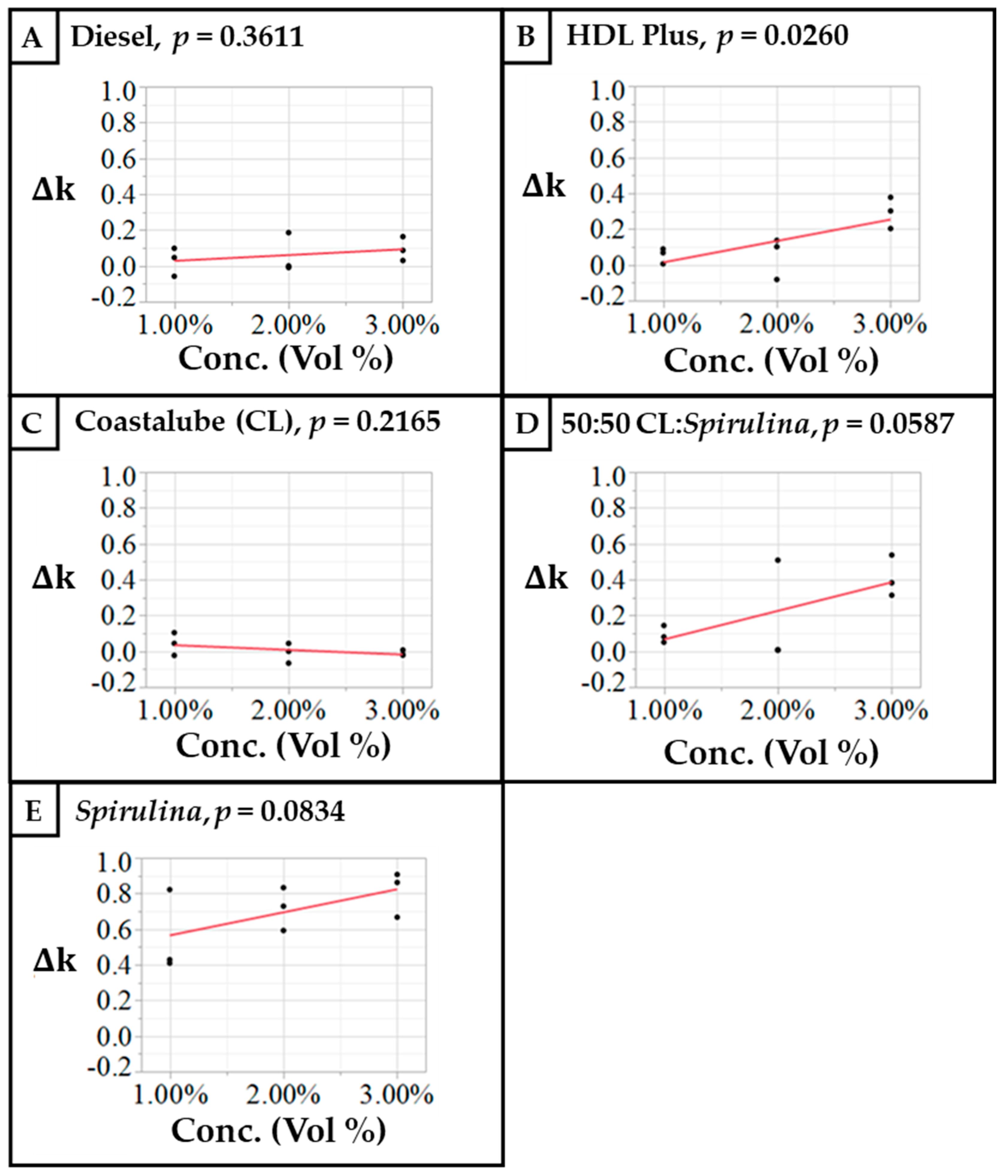

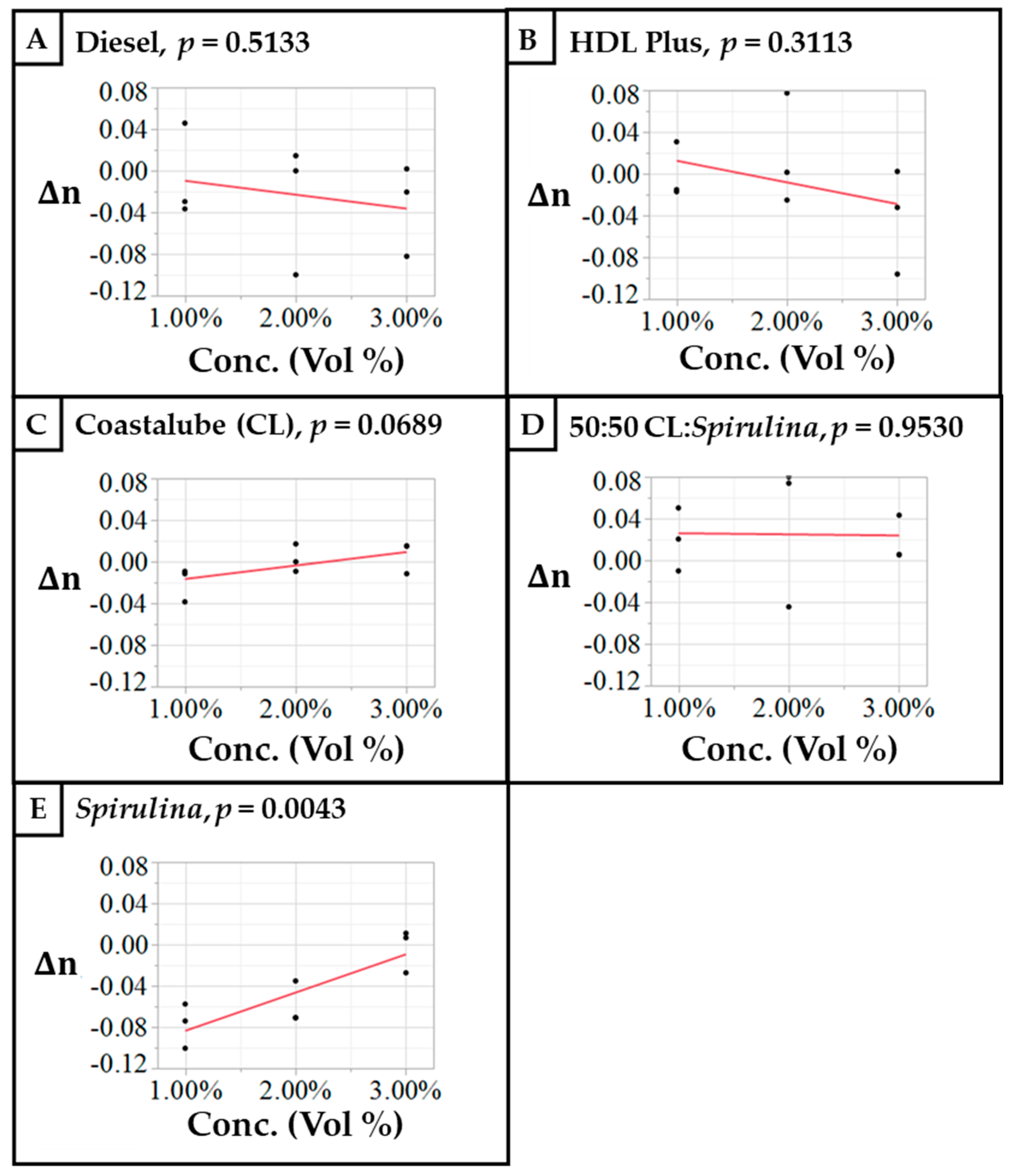

3.1.2. Herschel–Bulkley Model

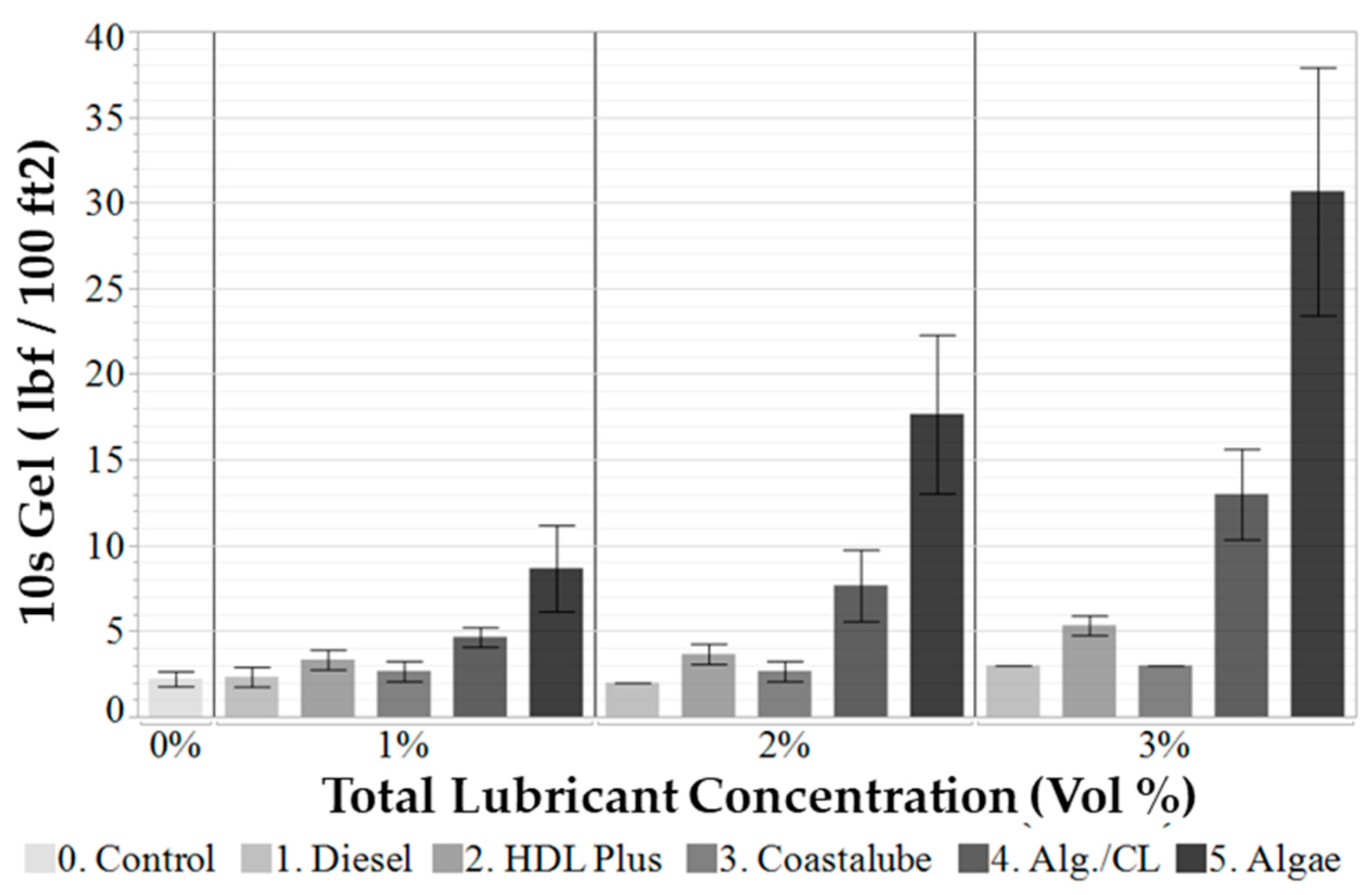

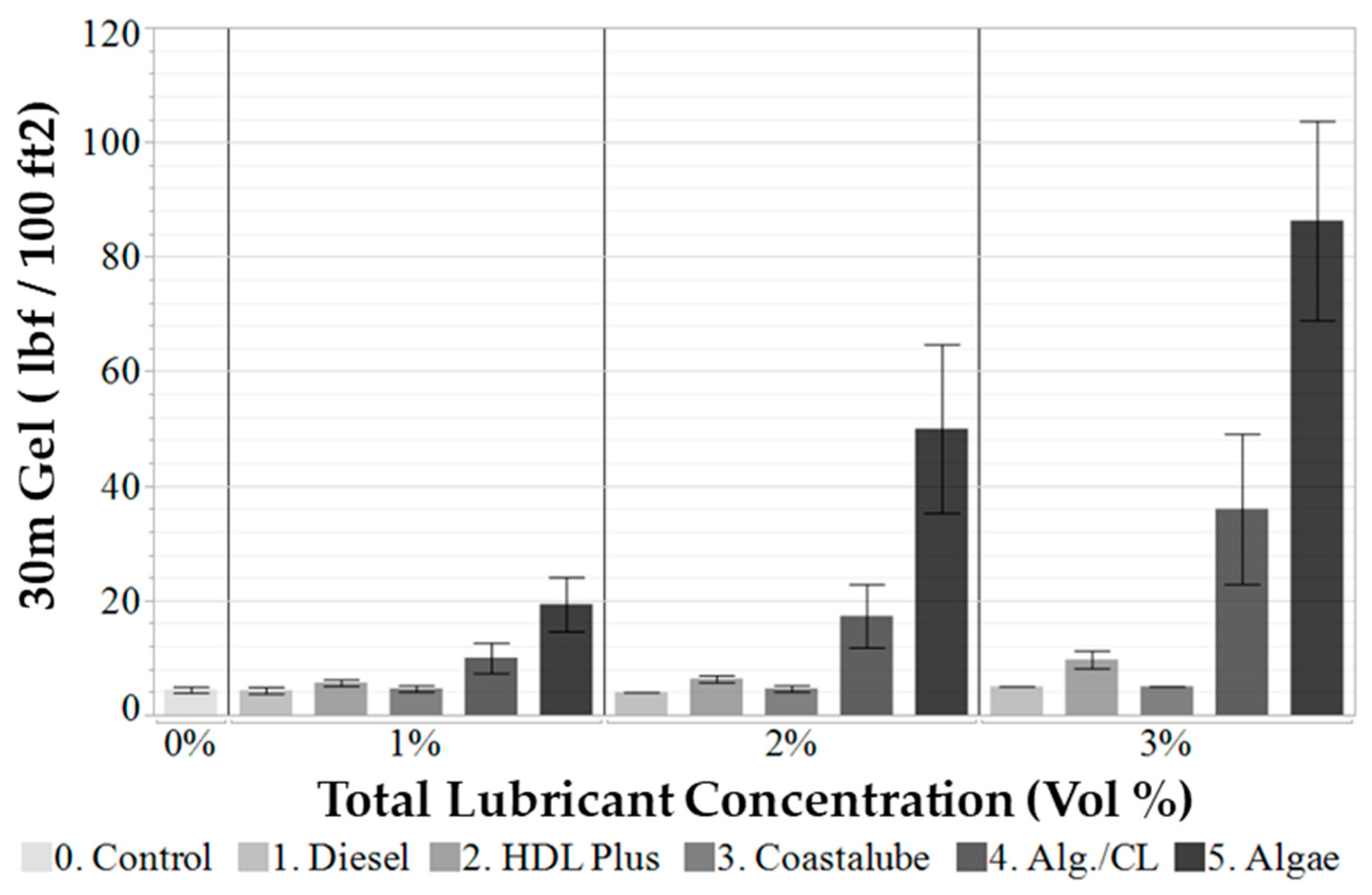

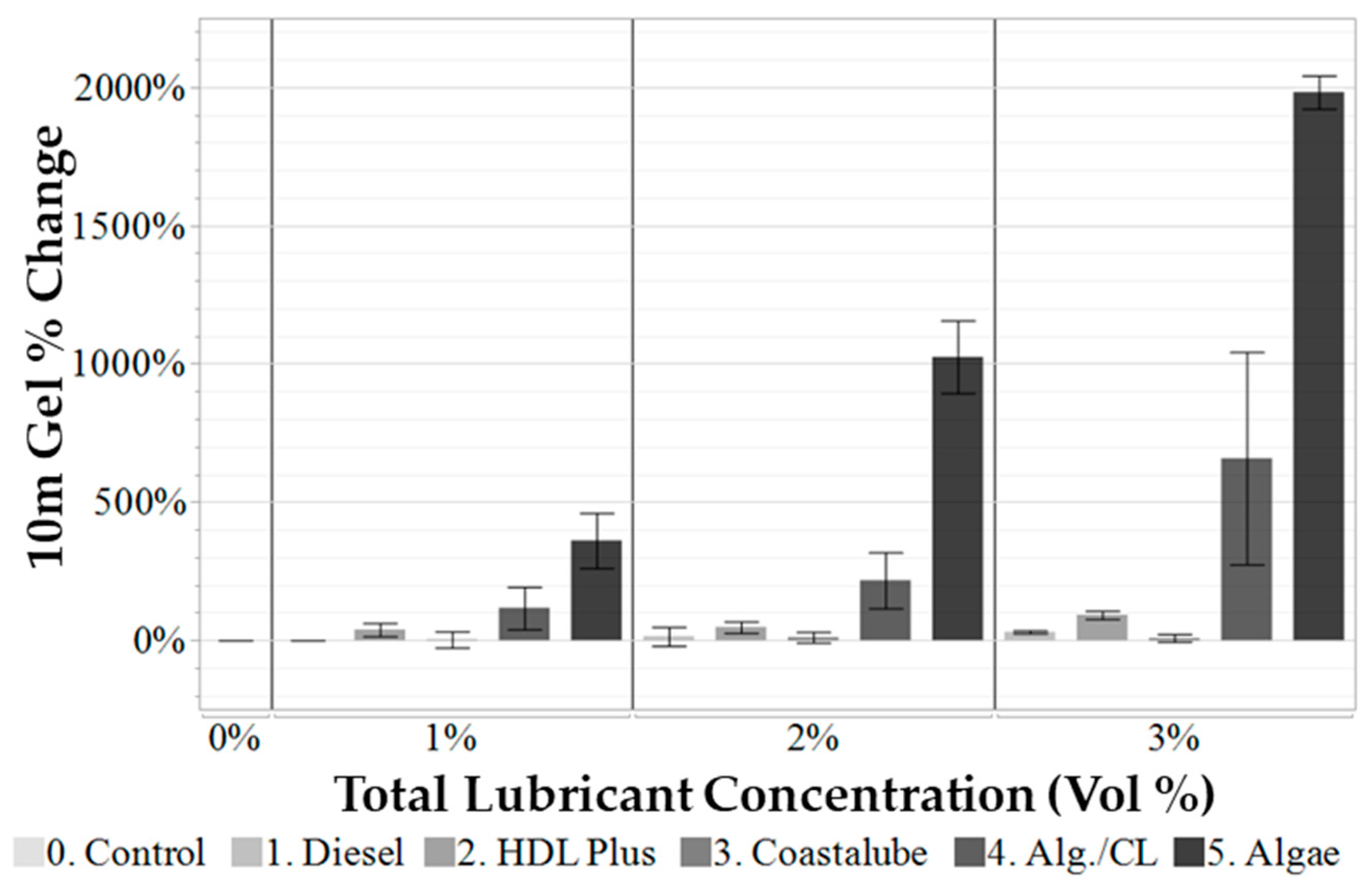

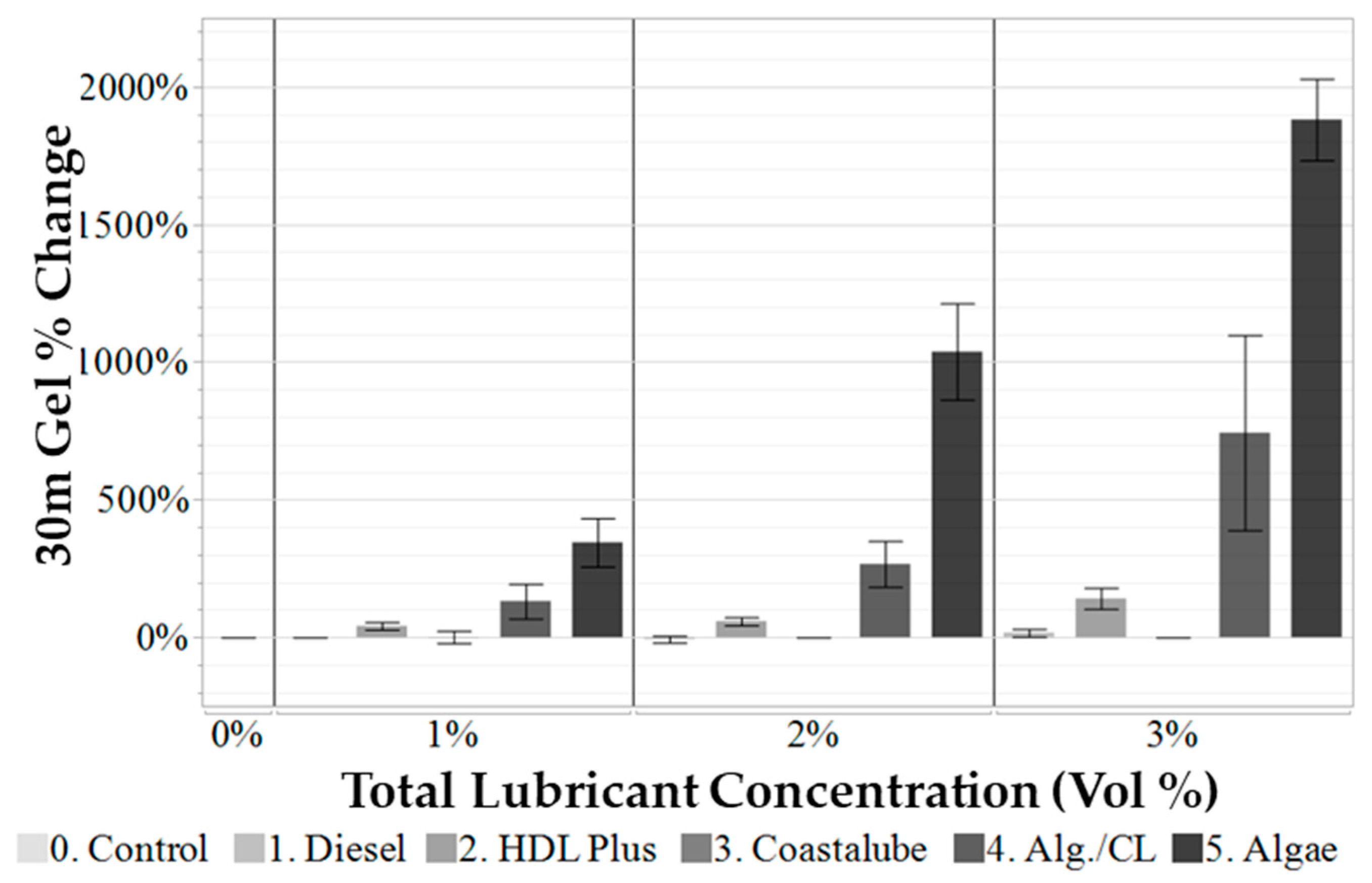

3.1.3. Gel Strength

3.2. Fluid Loss

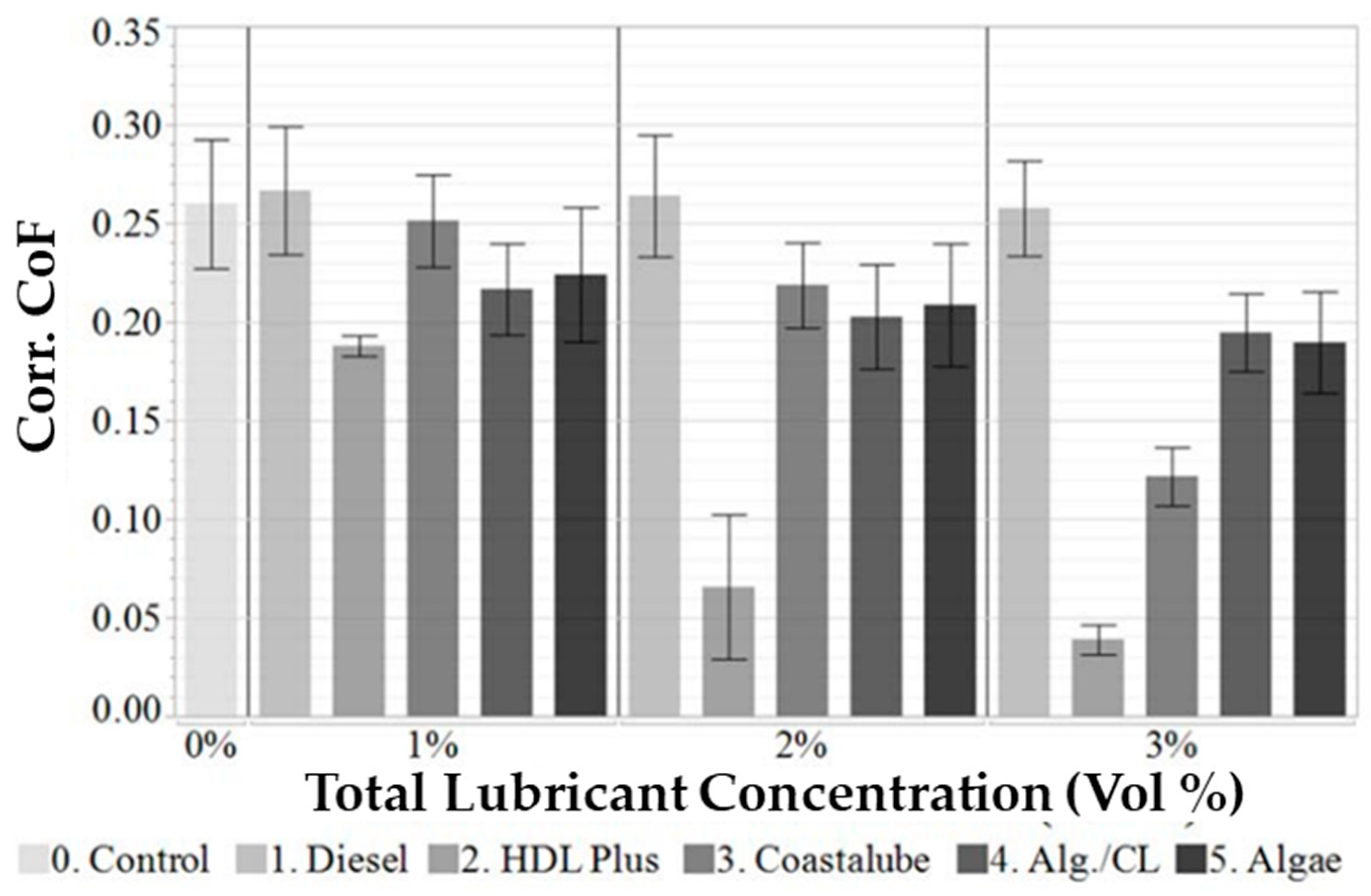

3.3. Lubricity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Batubara, M.; Purwanto, W.W.; Fauzi, A. Proposing a decision-making process for the development of sustainable oil and gas resources using the petroleum fund: A case study of the East Natuna gas field. Resour. Policy 2016, 49, 372–384. [Google Scholar] [CrossRef]

- Li, X.; Sun, L.; Lv, X.; Qi, J.; Lu, H.; Wu, Y.; Wang, B. Sustainable separation of petroleum hydrocarbons pollutant using hydrophobic deep eutectic solvents regulated by CO2. J. Environ. Chem. Eng. 2021, 9, 106280. [Google Scholar] [CrossRef]

- Tamala, J.K.; Maramag, E.I.; Simeon, K.A.; Ignacio, J.J. A bibliometric analysis of sustainable oil and gas production research using VOSviewer. Clean. Eng. Technol. 2022, 7, 100437. [Google Scholar] [CrossRef]

- Basik, M.; Mobin, M. 20—Environmentally sustainable corrosion inhibitors in the oil and gas industry. In Environmentally Sustainable Corrosion Inhibitors; Hussain, C.M., Verma, C., Aslam, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 405–421. [Google Scholar] [CrossRef]

- Defining Sustainability in the Oil and Gas Industry. Available online: https://www.hydrocarbonprocessing.com/conference-news/2019/10/defining-sustainability-in-the-oil-and-gas-industry (accessed on 19 March 2022).

- National Pollutant Discharge Elimination System (NPDES) | California State Water Quality Control Board. n.d. Available online: https://www.waterboards.ca.gov/water_issues/programs/npdes/drinkingwatersystems.html (accessed on 19 March 2022).

- Arthur, J.D.; Hochheiser, H.W. Sustainable Drilling of Onshore Oil and Gas Wells; Department of Energy: Washington, DC, USA, 2011; pp. 1–19. [Google Scholar]

- Zhou, S.; Song, J.; Xu, P.; He, M.; Xu, M.; You, F. A review on tribology, characterization and lubricants for water-based drilling fluids. Geoenergy Sci. Eng. 2023, 229, 212074. [Google Scholar] [CrossRef]

- Agwu, O.E.; Akpabio, J.U. Using agro-waste materials as possible filter loss control agents in drilling muds: A review. J. Pet. Sci. Eng. 2018, 163, 185–198. [Google Scholar] [CrossRef]

- Zaleski, P.L.; Derwin, D.J.; Weintritt, D.J.; Russel, G.W. Drilling Fluid Loss Prevention and Lubrication Additive. Available online: https://patents.google.com/patent/US582669A/en (accessed on 18 March 2025).

- Sönmez, A.; Verşan Kök, M.; Özel, R. Performance analysis of drilling fluid liquid lubricants. J. Pet. Sci. Eng. 2013, 108, 64–73. [Google Scholar] [CrossRef]

- Thibodeaux, G.M.; Baudoin, N.A.; Chirdon, W.M. Investigation of proteinaceous algal biomass as a drilling fluid component. Results Eng. 2023, 19, 101364. [Google Scholar] [CrossRef]

- Chirdon, W.M. Utilization of biorefinery waste proteins as feed, glues, composites, and other co-products. In Algal Biorefineries: Volume 2: Products and Refinery Design; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Schexnayder, P.; Baudoin, N.; Chirdon, W.M. Enhanced oil recovery from denatured algal biomass: Synergy between conventional and emergent fuels. Fuel 2020, 287, 119533. [Google Scholar] [CrossRef]

- EPA Office of Land U, Management E. List of Lists: Consolidated List of Chemicals Subject to the Emergency Planning and Community Right- To-Know Act (EPCRA), Comprehensive Environmental Response, Compensation and Liability Act (CERCLA) and Section 112(r) of the Clean Air Act. 1986. Available online: https://www.epa.gov/system/files/documents/2024-11/consolidated-list-of-lists_updated-october-2024.pdf (accessed on 18 March 2025).

- Com, S. Enhancing Your Value Horizons SUN’S COASTALUBE ® CT EXCEPTIONAL COIL TUBING LUBRICITY USING SUN’S PAO TECHNOLOGY. Available online: https://sunspecialtyproducts.com/coastalube-ct/ (accessed on 18 March 2025).

- Chirdon, W.M.; Schexnayder, P.F.; Thibodeaux, G.M.; Baudoin, N.A. Sustainable Agents for Enhanced Oil Recovery and Drilling Additives Derived from Microbial Biomass. U.S. Patent 11739253, 29 August 2023. [Google Scholar]

- OFITE. Model 900 Viscometer Instruction Manual 2015. Available online: https://www.manualslib.com/manual/1231559/Ofite-900.html (accessed on 18 March 2025).

- American Petroleum Institute. Recommended Practice for Field Testing of Water-based Drilling Fluids; API Recomm: Washington, DC, USA, 2016. [Google Scholar]

- Wiśniowski, R.; Skrzypaszek, K.; Małachowski, T. Selection of a suitable rheological model for drilling fluid using applied numerical methods. Energies 2020, 13, 3192. [Google Scholar] [CrossRef]

- OFITE. 4-Unit HTHP Filter Press with Load Cell Option Manual; OFITE: Aracaju, Brasil, 2015; Available online: https://www.manualslib.com/manual/1593603/Ofite-170-00-4s.html (accessed on 18 March 2025).

- OFITE. EP (Extreme Pressure) and Lubricity Tester Instruction Manual; OFI Testing Equipment, Inc.: Aracaju, Brasil, 2015; Available online: https://www.manualslib.com/manual/2060618/Ofite-112-00.html (accessed on 18 March 2025).

- American Petroleum Institute. Rheology and Hydraulics of Oil-Well Drilling Fluids; Api Recommended Practice: Washington, DC, USA, 2010. [Google Scholar]

- Chronakis, I.S. Gelation of edible blue-green algae protein isolate (Spirulina platensis Strain Pacifica): Thermal transitions, rheological properties, and molecular forces involved. J. Agric. Food Chem. 2001, 49, 888–898. [Google Scholar] [CrossRef] [PubMed]

- Murtaza, M.; Alarifi, S.A.; Abozuhairah, A.; Mahmoud, M.; Onaizi, S.A.; Al-Ajmi, M. Optimum Selection of H2S Scavenger in Light-Weight and Heavy-Weight Water-Based Drilling Fluids. ACS Omega 2021, 6, 24919–24930. [Google Scholar] [CrossRef] [PubMed]

- Amanullah, M.; Ramasamy, J.; Al-Arfaj, M.K.; Aramco, S. Application of an indigenous eco-friendly raw material as fluid loss additive. J. Pet. Sci. Eng. 2016, 139, 191–197. [Google Scholar] [CrossRef]

- Barry, M.M.; Jung, Y.; Lee, J.-K.; Phuoc, T.X.; Chyu, M.K. Fluid filtration and rheological properties of nanoparticle additive and intercalated clay hybrid bentonite drilling fluids. J. Pet. Sci. Eng. 2015, 127, 338–346. [Google Scholar] [CrossRef]

- Ismail, A.R.; Aftab, A.; Ibupoto, Z.H.; Zolkifile, N. The novel approach for the enhancement of rheological properties of water-based drilling fluids by using multi-walled carbon nanotube, nanosilica and glass beads. J. Pet. Sci. Eng. 2016, 139, 264–275. [Google Scholar] [CrossRef]

- Tripuraneni, G.C. Performance Analysis of Enhanced Activated Sludge as Drilling Mud Additive; University of Louisiana at Lafayette: Lafayette, LA, USA, 2017. [Google Scholar]

- Geng, Y.; Zhang, Z.; Yan, Z.; Yuan, Y.; Zhou, X.; Yue, W.; An, Y. A novel graphene/triolein complex-based lubricant for improving high temperature water-based drilling fluid. RSC Adv. 2023, 13, 34772–34781. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Wang, L.; Yang, X.; Lin, Y.; Xue, Y. Effect of ester based lubricant SMJH-1 on the lubricity properties of water based drilling fluid. J. Pet. Sci. Eng. 2015, 135, 161–167. [Google Scholar] [CrossRef]

- Ma, C.; Wen, R.; Zhou, F.; Zhao, H.; Bao, X.; Evelina, A.; Long, W.; Wei, Z.; Ma, L.; Liu, J.; et al. Preparation and application of an environmentally friendly compound lubricant based biological oil for drilling fluids. Arab. J. Chem. 2022, 15, 103610. [Google Scholar] [CrossRef]

- Mueller, H.; Herold, C.-P.; Von Tapavicza, S. Use of Selected Fatty Alcohols and Their Mixtures with Carboxylic Acid Esters As lubricant Components in Water-Based Drilling Fluid Systems for Soil Exploration. U.S. Patent 6,716,799, 6 April 2004. [Google Scholar]

- Liu, S.Q.; Chen, Z.R.; Meng, Q.N.; Zhou, H.L.; Li, C.; Liu, B.C. Effect of graphene and graphene oxide addition on lubricating and friction properties of drilling fluids. Nanosci. Nanotechnol. Lett. 2017, 9, 446–452. [Google Scholar] [CrossRef]

- Young, N. The NPDES General Permit for New and Existing Sources and New Dischargers in the Offshore Subcategory of the Oil and Gas Extraction Point Source Category for the Western Portion of the Outer Continental Shelf of the Gulf of Mexico (GMG290000). Available online: https://www.epa.gov/system/files/documents/2023-05/2023%20GMG290000%20Final%20Permit%20dated%20and%20signed_508.pdf (accessed on 18 March 2025).

| Component | Function | Concentration (lb/bbl) |

|---|---|---|

| Tap water | Base fluid | Varied |

| Gel NT (bentonite) | Viscosifier | 20.0 |

| Organic polymer | Defoamer | 0.99 |

| Caustic soda | pH modifier | 0.50 |

| Lignite | Thinner | 2.00 |

| Desco | Deflocculant | 2.00 |

| Xanthan gum | Viscosifier | 0.50 |

| Barite | Weighting agent | Varied |

| Lubricant—varied | Lubrication | See Table 2 |

| Fluid ID. | Lubricant Type | Concentration (vol.%) |

|---|---|---|

| 1 | None | 0.0 |

| 2 | Spirulina | 1.0 |

| 3 | Spirulina | 2.0 |

| 4 | Spirulina | 3.0 |

| 5 | Diesel | 1.0 |

| 6 | Diesel | 2.0 |

| 7 | Diesel | 3.0 |

| 8 | HDL Plus | 1.0 |

| 9 | HDL Plus | 2.0 |

| 10 | HDL Plus | 3.0 |

| 11 | Coastalube | 1.0 |

| 12 | Coastalube | 2.0 |

| 13 | Coastalube | 3.0 |

| 14 | Spirulina and Coastalube | 0.5 and 0.5 |

| 15 | Spirulina and Coastalube | 1.0 and 1.0 |

| 16 | Spirulina and Coastalube | 1.5 and 1.5 |

| Fluid ID | Lubricant Type | Concentration (vol.%) | τy | k | n |

|---|---|---|---|---|---|

| 1 | None | 0.0 | 1.778 | 0.254 | 0.712 |

| 2 | Spirulina | 1.0 | 6.000 | 0.763 | 0.649 |

| 3 | Spirulina | 2.0 | 14.000 | 0.928 | 0.668 |

| 4 | Spirulina | 3.0 | 25.667 | 1.022 | 0.723 |

| 5 | Diesel | 1.0 | 1.667 | 0.239 | 0.720 |

| 6 | Diesel | 2.0 | 0.333 | 0.269 | 0.698 |

| 7 | Diesel | 3.0 | 1.667 | 0.303 | 0.693 |

| 8 | HDL Plus | 1.0 | 2.667 | 0.297 | 0.713 |

| 9 | HDL Plus | 2.0 | 3.000 | 0.295 | 0.732 |

| 10 | HDL Plus | 3.0 | 3.333 | 0.537 | 0.672 |

| 11 | Coastalube | 1.0 | 1.333 | 0.341 | 0.682 |

| 12 | Coastalube | 2.0 | 1.333 | 0.292 | 0.704 |

| 13 | Coastalube | 3.0 | 1.667 | 0.324 | 0.697 |

| 14 | Spirulina and Coastalube | 0.5 and 0.5 | 3.333 | 0.400 | 0.709 |

| 15 | Spirulina and Coastalube | 1.0 and 1.0 | 5.333 | 0.464 | 0.735 |

| 16 | Spirulina and Coastalube | 1.5 and 1.5 | 10.000 | 0.719 | 0.707 |

| Lubricant Type | k | n | |

|---|---|---|---|

| Spirulina | VS | X | VS |

| Diesel | X | X | X |

| HDL Plus | X | S | X |

| Coastalube | X | X | X |

| Spirulina and Coastalube | VS | X | X |

| Lubricant Type | Source | Concentration (vol.%) | |||

|---|---|---|---|---|---|

| <1% | 1% | 2% | 3% | ||

| Diesel | - | - | −12% | −5% | −15% |

| HDL Plus | - | - | −7% | −14% | −1% |

| Coastalube | - | - | −16% | −17% | −19% |

| Spirulina and Coastalube | - | - | −16% | −31% | −33% |

| Spirulina | - | - | −28% | −33% | −51% |

| Date Seed Powder | [26] | - | −60% | - | - |

| Iron-oxide Nanoparticles | [27] | −28% | - | - | - |

| Iron-oxide Clay Hybrid | [27] | −47% | - | - | - |

| Aluminosilicate Clay Hybrid | [27] | −20% | - | - | - |

| Lubricant Type | Source | Concentration (vol.%) | |||

|---|---|---|---|---|---|

| <1% | 1% | 2% | 3% | ||

| Diesel | - | - | −2% | −3% | −5% |

| HDL Plus | - | - | −24% | −75% | −84% |

| Coastalube | - | - | −2% | −14% | −56% |

| Spirulina and Coastalube | - | - | −19% | −24% | −28% |

| Spirulina | - | - | −18% | −23% | −30% |

| Nanosilica nanoparticles | [28] | −15% | - | - | - |

| Carbon nanotubes | [28] | −22% | - | - | - |

| Enhanced activated sludge | [29] | - | - | −38% | - |

| Raw activated sludge | [29] | - | - | −31% | - |

| Graphene/triolein complex | [30] | - | −41.4% | - | −60% |

| SMJH-1 | [31] | - | −91.4% | - | - |

| F-1 | [32] | −88% | - | - | - |

| Polyethylene glycol | [33] | −44.5% | - | - | - |

| Graphene oxide | [34] | −12.5% | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thibodeaux, G.M.; Baudoin, N.A.; Chirdon, W.M. Proteinaceous Spirulina Biomass as a Sustainable Drilling Fluid Additive for Lubricity. Lubricants 2025, 13, 149. https://doi.org/10.3390/lubricants13040149

Thibodeaux GM, Baudoin NA, Chirdon WM. Proteinaceous Spirulina Biomass as a Sustainable Drilling Fluid Additive for Lubricity. Lubricants. 2025; 13(4):149. https://doi.org/10.3390/lubricants13040149

Chicago/Turabian StyleThibodeaux, Garrett M., Nicholas A. Baudoin, and William M. Chirdon. 2025. "Proteinaceous Spirulina Biomass as a Sustainable Drilling Fluid Additive for Lubricity" Lubricants 13, no. 4: 149. https://doi.org/10.3390/lubricants13040149

APA StyleThibodeaux, G. M., Baudoin, N. A., & Chirdon, W. M. (2025). Proteinaceous Spirulina Biomass as a Sustainable Drilling Fluid Additive for Lubricity. Lubricants, 13(4), 149. https://doi.org/10.3390/lubricants13040149