Influence of Solid Lubricants on the Tribological Performance of Photocurable Resins for Vat Photopolymerization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Formulation of the Resins

2.3. Sample Preparation

2.4. Characterization

2.4.1. FT-IR Spectroscopy

- C1 is a coefficient between the surface area of the double bond absorption band (810 cm−1) and the surface area of the carbonyl group absorption band (1724 cm−1) of the crosslinked specimen.

- C2 is a coefficient between the surface area of the double bond absorption band and surface area of the carbonyl group of the uncured resin.

2.4.2. Tensile Tests

2.4.3. Charpy Impact Tests

2.4.4. Shore D Hardness

2.4.5. Dynamic Mechanical Analysis

2.4.6. Tribological Testing

2.4.7. Optical Microscopy

3. Results and Discussion

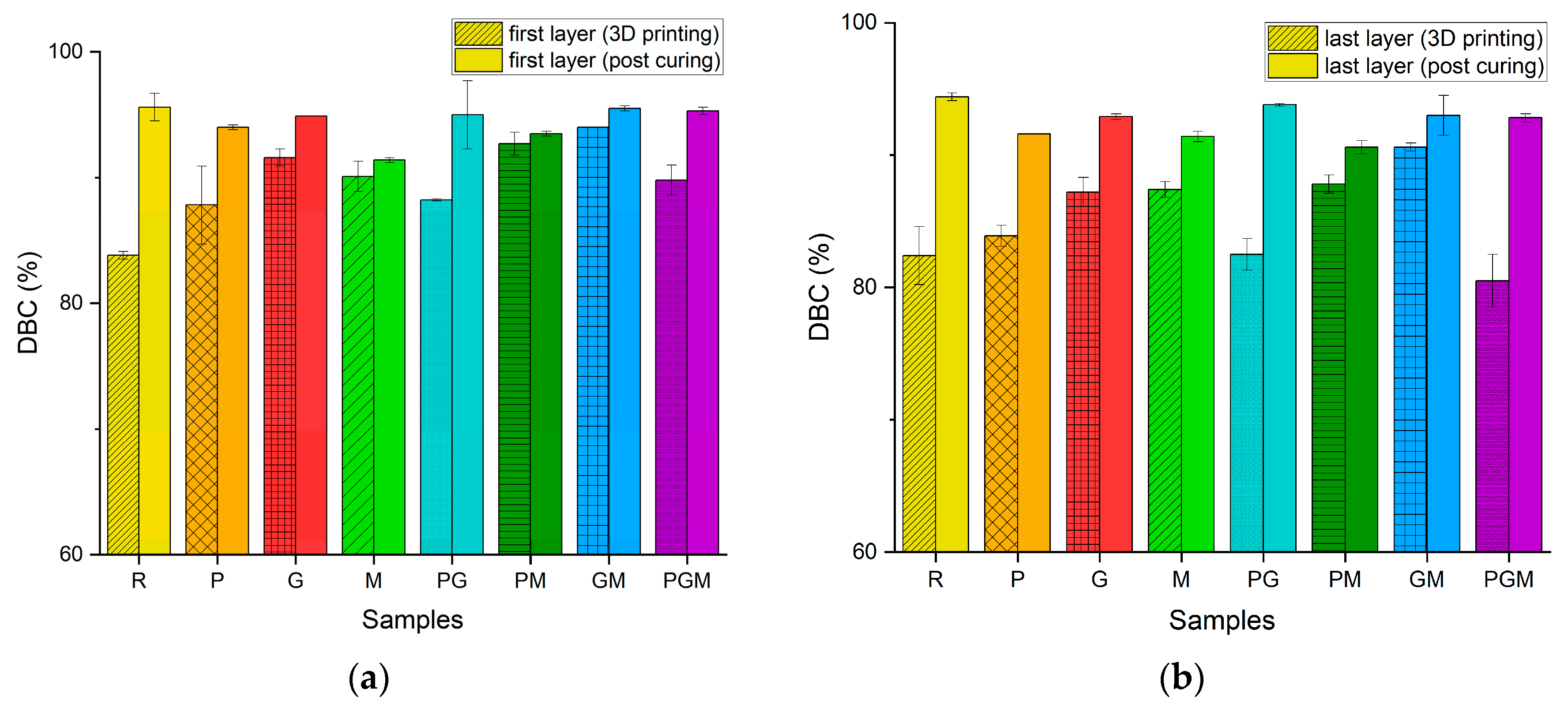

3.1. FT-IR Spectroscopy

3.2. Tensile Tests

3.3. Charpy Impact Tests

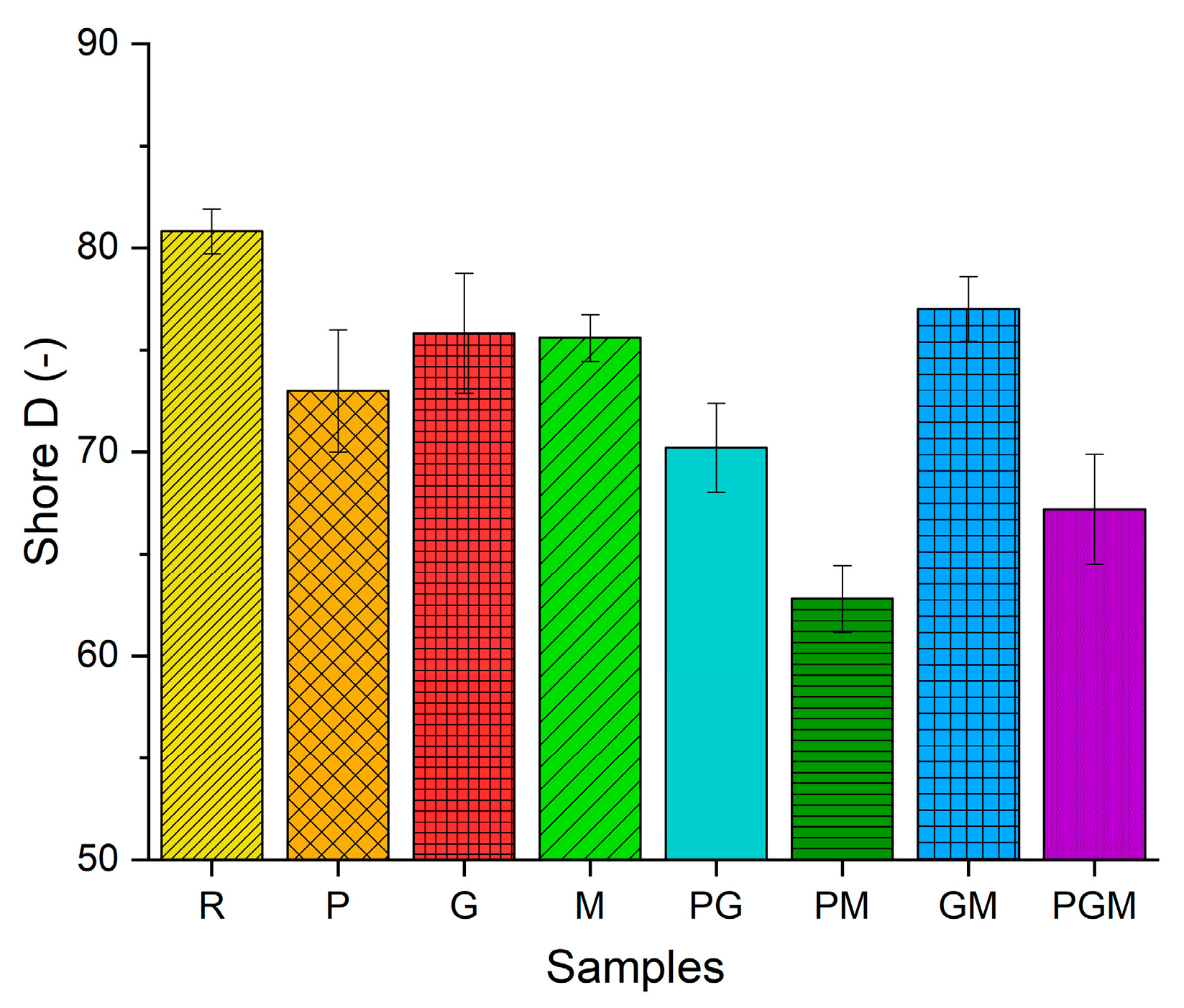

3.4. Shore D Hardness

3.5. Dynamic Mechanical Analysis

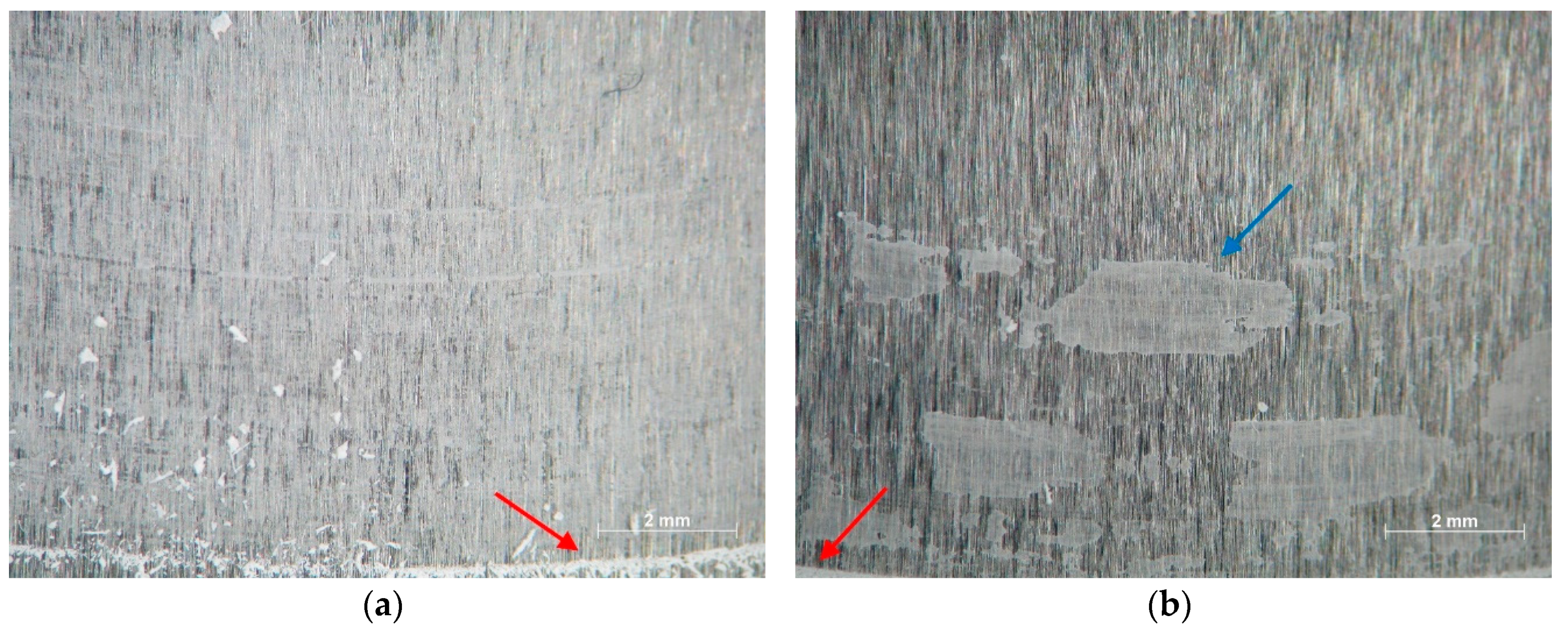

3.6. Tribological Testing and Damage Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bell, P.C. Mechanical Power Transmission; Bell, P.C., Ed.; Palgrave Macmillan Press Limited: London, UK, 1971; ISBN 978-1-349-01197-1. [Google Scholar]

- Hu, C.; Smith, W.A.; Randall, R.B.; Peng, Z. Development of a gear vibration indicator and its application in gear wear monitoring. Mech. Syst. Signal Process. 2016, 76–77, 319–336. [Google Scholar] [CrossRef]

- Radzevich, S.P. Dudley’s Handbook of Practical Gear Design and Manufacture, 2nd ed.; Radzevich, S.P., Ed.; CRC Press: Boca Raton, FL, USA, 2012; ISBN 9780429109065. [Google Scholar]

- Kirupasankar, S.; Gurunathan, C.; Gnanamoorthy, R. Transmission efficiency of polyamide nanocomposite spur gears. Mater. Des. 2012, 39, 338–343. [Google Scholar] [CrossRef]

- Senthilvelan, S.; Gnanamoorthy, R. Fiber reinforcement in injection molded nylon 6/6 spur gears. Appl. Compos. Mater. 2006, 13, 237–248. [Google Scholar] [CrossRef]

- Li, S.; Vaidyanathan, A.; Harianto, J.; Kahraman, A. Influence of design parameters on mechanical power losses of helical gear pairs. J. Adv. Mech. Des. Syst. Manuf. 2009, 3, 146–158. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.Y.; Shi, Z.Y.; Shu, Z.H.; Fu, S. Study on evaluation system of gear accuracy based on statistical analysis. In Proceedings of the International Gear Conference 2014, Lyon, France, 26–28 August 2014; pp. 905–913. [Google Scholar]

- Bhushan, B. Principles and Applications of Tribology, 2nd ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2013; ISBN 9781118403020. [Google Scholar]

- Plastics, G.E. A Guide to Plastic Gearing; General Electric Company: Boston, MA, USA, 2006. [Google Scholar]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in additive manufacturing on new materials. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY. USA, 2015; ISBN 9781493921133. [Google Scholar]

- ISO/ASTM 52900:2015 Standard Terminology for Additive Manufacturing–General Principles–Terminology; International Organization for Standardization: Geneva, Switzerland, 2015.

- Berger, U.; Mäule, B. Rapid manufacturing of high reduction polymer gears by use of stereolithography. In Proceedings of the 2009 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; pp. 613–617. [Google Scholar]

- Berger, U. Aspects of accuracy and precision in the additive manufacturing of plastic gears. Virtual Phys. Prototyp. 2015, 10, 49–57. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef] [Green Version]

- Ramadani, R.; Belsak, A.; Kegl, M.; Predan, J.; Pehan, S. Topology optimization based design of lightweight and low vibration gear bodies. Int. J. Simul. Model. 2018, 17, 92–104. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical behaviour of ABS: An experimental study using FDM and injection moulding techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Amiruddin, H.; Abdollah, M.F.B.; Norashid, N.A. Comparative study of the tribological behaviour of 3D-printed and moulded ABS under lubricated condition. Mater. Res. Express 2019, 6, 085328. [Google Scholar] [CrossRef]

- Boparai, K.; Singh, R.; Singh, H. Comparison of tribological behaviour for Nylon6-Al-Al2O3 and ABS parts fabricated by fused deposition modelling. Virtual Phys. Prototyp. 2016, 10, 59–66. [Google Scholar] [CrossRef]

- Singh, R.; Singh, S.; Fraternali, F. Development of in-house composite wire based feed stock filaments of fused deposition modelling for wear-resistant materials and structures. Compos. Part B 2016, 98, 244–249. [Google Scholar] [CrossRef]

- Golbang, A.; Harkin-Jones, E.; Wegrzyn, M.; Campbell, G.; Archer, E.; McIlhagger, A. Production and characterization of PEEK/IF-WS2 nanocomposites for additive manufacturing: Simultaneous improvement in processing characteristics and material properties. Addit. Manuf. 2020, 31, 100920. [Google Scholar] [CrossRef]

- Arif, M.F.; Alhashmi, H.; Varadarajan, K.M.; Koo, J.H.; Hart, A.J.; Kumar, S. Multifunctional performance of carbon nanotubes and graphene nanoplatelets reinforced PEEK composites enabled via FFF additive manufacturing. Compos. Part B Eng. 2020, 184, 107625. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Effect of processing parameters and graphite content on the tribological behaviour of 3D printed acrylonitrile butadiene styrene. Materwiss Werksttech 2015, 46, 1185–1195. [Google Scholar] [CrossRef]

- Bai, J.; Song, J.; Wei, J. Tribological and mechanical properties of MoS2 enhanced polyamide 12 for selective laser sintering. J. Mater. Process. Technol. 2019, 264, 382–388. [Google Scholar] [CrossRef]

- Esakki, B.; Rajamani, D.; Arunkumar, P. Modeling and prediction of optimal process parameters in wear behaviour of selective inhibition sintered high density polyethylene parts. Prog. Addit. Manuf. 2018, 3, 109–121. [Google Scholar] [CrossRef]

- Palma, T.; Munther, M.; Damasus, P.; Salari, S.; Beheshti, A.; Davami, K. Multiscale mechanical and tribological characterizations of additively manufactured polyamide 12 parts with different print orientations. J. Manuf. Process. 2019, 40, 76–83. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 4575330A, 11 March 1986. [Google Scholar]

- Shusteff, M.; Browar, A.E.M.; Kelly, B.E.; Henriksson, J.; Weisgraber, T.H.; Panas, R.M.; Fang, N.X.; Spadaccini, C.M. One-step volumetric additive manufacturing of complex polymer structures. Sci. Adv. 2017, 3, eaao5496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schwartz, J.J.; Boydston, A.J. Multimaterial actinic spatial control 3D and 4D printing. Nat. Commun. 2019, 10, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Maruo, S.; Ikuta, K. Submicron stereolithography for the production of freely movable mechanisms by using single-photon polymerization. Sensors Actuators A Phys. 2002, 100, 70–76. [Google Scholar] [CrossRef]

- Emons, M.; Obata, K.; Binhammer, T.; Ovsianikov, A.; Chichkov, B.N.; Morgner, U. Two-photon polymerization technique with sub-50 nm resolution by sub-10 fs laser pulses. Opt. Mater. Express 2012, 2, 942–947. [Google Scholar] [CrossRef]

- Stampfl, J.; Baudis, S.; Heller, C.; Liska, R.; Neumeister, A.; Kling, R.; Ostendorf, A.; Spitzbart, M. Photopolymers with tunable mechanical properties processed by laser-based high-resolution stereolithography. J. Micromech. Microeng. 2008, 18, 125014. [Google Scholar] [CrossRef]

- Slapnik, J.; Pulko, I. Tailoring properties of photopolymers for additive manufacturing with mixture design. Prog. Addit. Manuf. 2020. [Google Scholar] [CrossRef]

- Malas, A.; Isakov, D.; Couling, K.; Gibbons, G.J. Fabrication of high permittivity resin composite for vat photopolymerization 3D printing: Morphology, thermal, dynamic mechanical and dielectric properties. Materials 2019, 12, 3818. [Google Scholar] [CrossRef] [Green Version]

- Zuo, Y.; Yao, Z.; Lin, H.; Zhou, J.; Lu, J.; Ding, J. Digital light processing 3D printing of graphene/carbonyl iron/polymethyl methacrylate nanocomposites for efficient microwave absorption. Compos. Part B 2019, 179, 107533. [Google Scholar] [CrossRef]

- Markandan, K.; Lai, C.Q. Enhanced mechanical properties of 3D printed graphene-polymer composite lattices at very low graphene concentrations. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105726. [Google Scholar] [CrossRef]

- Gonçalves, M.W.; Salmoria, G.V.; Ahrens, C.H.; Pouzada, A.S. Study of tribological properties of moulds obtained by stereolithography. Virtual Phys. Prototyp. 2007, 2, 29–36. [Google Scholar] [CrossRef] [Green Version]

- Slapnik, J.; Gradec, S.; Stiller, T.; Competence, P.; Hausberger, A.; Competence, P. Stereolitografija: Pripravljena na izdelavo končnih izdelkov? In Vir Znanja in Izkušenj za Stroko: Zbornik Foruma, Proceedings of the 11. Industrijski Forum IRT, Portorož, Slovenia, 3–4 July 2019; Profidtp: Škofljica, Slovenia, 2010; pp. 47–250. [Google Scholar]

- Dunnigan, R.; Clemens, J.; Cavalli, M.N.; Kaabouch, N.; Gupta, S. Beneficial usage of recycled polymer particulates for designing novel 3D printed composites. Prog. Addit. Manuf. 2018, 3, 33–38. [Google Scholar] [CrossRef]

- Alajmi, M.; Alrashdan, K.R.; Alsaeed, T.; Shalwan, A. Tribological characteristics of graphite epoxy composites using adhesive wear experiments. J. Mater. Res. Technol. 2020, 9, 13671–13681. [Google Scholar] [CrossRef]

- Li, X.; Gao, Y.; Xing, J.; Wang, Y.; Fang, L. Wear reduction mechanism of graphite and MoS2 in epoxy composites. Wear 2004, 257, 279–283. [Google Scholar] [CrossRef]

- Padhan, M.; Marathe, U.; Bijwe, J. A complex interdependence of thermal conductivity and lubricity of two solid lubricants to control the tribo-performance of PAEK based composites. Wear 2020, 458–459, 203406. [Google Scholar] [CrossRef]

- Bajpai, A.; Saxena, P.; Kunze, K. Tribo-mechanical characterization of carbon fiber-reinforced cyanate ester resins modified with fillers. Polymers 2020, 12, 1725. [Google Scholar] [CrossRef]

- Zhang, X.; Liao, G.; Jin, Q.; Feng, X.; Jian, X. On dry sliding friction and wear behavior of PPESK filled with PTFE and graphite. Tribol. Int. 2008, 41, 195–201. [Google Scholar] [CrossRef]

- Halloran, J.W. Ceramic stereolithography: Additive manufacturing for ceramics by photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- Frankel, N.A.; Acrivos, A. On the viscosity of a concentrated suspension of solid spheres. Chem. Eng. Sci. 1967, 22, 847–853. [Google Scholar] [CrossRef]

- Salonitis, K. Stereolithography. Compr. Mater. Process. 2014, 10, 19–67. [Google Scholar]

- Dworak, C.; Kopeinig, S.; Hoffmann, H.; Liska, R. Photoinitiating monomers based on Di- and Triacryloylated hydroxylamine derivatives. J. Polym. Sci. Part A Polym. Chem. 2008, 47, 392–403. [Google Scholar] [CrossRef]

- Schuster, M.; Turecek, C.; Mateos, A.; Stampfl, J.; Liska, R.; Varga, F. Evaluation of Biocompatible Photopolymers II: Further Reactive Diluents. Monatshefte Für Chemie-Chem. Mon. 2007, 138, 261–268. [Google Scholar] [CrossRef]

- Skorb, E.V.; Ustinovich, E.A.; Kulak, A.I.; Sviridov, D.V. Photocatalytic activity of TiO2:In2O3 nanocomposite films towards the degradation of arylmethane and azo dyes. J. Photochem. Photobiol. A Chem. 2008, 193, 97–102. [Google Scholar] [CrossRef]

- Chand, N.; Sharma, P.; Fahim, M. Correlation of mechanical and tribological properties of organosilane modified cenosphere filled high density polyethylene. Mater. Sci. Eng. A 2010, 527, 5873–5878. [Google Scholar] [CrossRef]

- Alajmi, M.; Shalwan, A. Correlation between mechanical properties with specific wear rate and the coefficient of friction of graphite/epoxy composites. Materials 2015, 8, 4162–4175. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ligon-Auer, S.C.; Schwentenwein, M.; Gorsche, C.; Stampfl, J.; Liska, R. Toughening of photo-curable polymer networks: A review. Polym. Chem. 2016, 7, 257–286. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Raju, B.S.; Shekar, U.C.; Venkateswarlu, K.; Drakashayani, D.N. Establishment of process model for rapid prototyping technique (stereolithography) to enhance the part quality by Taguchi method. Procedia Technol. 2014, 14, 380–389. [Google Scholar] [CrossRef] [Green Version]

- Dorfinger, P.; Stampfl, J.; Liska, R. Toughening of photopolymers for stereolithography (SL). Mater. Sci. Forum 2015, 825–826, 53–59. [Google Scholar] [CrossRef]

- Steyrer, B.; Busetti, B.; Harakály, G.; Liska, R.; Stampfl, J. Hot Lithography vs. room temperature DLP 3D-printing of a dimethacrylate. Addit. Manuf. 2018, 21, 209–214. [Google Scholar] [CrossRef]

- Sathees Kumar, S.; Kanagaraj, G. Investigation on mechanical and tribological behaviors of PA6 and graphite-reinforced PA6 polymer composites. Arab. J. Sci. Eng. 2016, 41, 4347–4357. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Nguen Suan, T.; Ivanova, L.R.; Poltaranin, M.A.; Shil’ko, S.V. Wear resistance of composites based on ultrahigh molecular weight polyethylene filled with graphite and molybdenum disulfide microparticles. J. Frict. Wear 2014, 35, 290–296. [Google Scholar] [CrossRef]

- Diani, J.; Gall, K. Microstructure, thermal, physico–mechanical and tribological characteristics of molybdenum disulphide-filled polyamide 66/carbon black composites. Polym. Eng. Sci. 2013, 53, 1676–1686. [Google Scholar]

- Menard, K. Dynamic Mechanical Analysis: A Practical Introduction, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008; ISBN 9781420053128. [Google Scholar]

| Sample | PTFE (%) | Graphite (%) | MoS2 (%) |

|---|---|---|---|

| R | / | / | / |

| P | 5 | / | / |

| G | / | 1 | / |

| M | / | / | 1.6 |

| PG | 5 | 1 | 0 |

| PM | 5 | / | 1.6 |

| GM | / | 0.5 | 0.8 |

| PGM | 5 | 0.5 | 0.8 |

| Parameter | Value |

|---|---|

| Vat floor | Fluorinated ethylene propylene |

| Layer height | 50 µm |

| Curing time of first layers | 30 s |

| Number of first layers | 3 |

| Curing time | 15 s |

| Resting time before curing | 2 s |

| Build platform lift height | 3 mm |

| Lift speed | 30 mm/s |

| Retraction speed | 150 mm/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slapnik, J.; Stiller, T.; Wilhelm, T.; Hausberger, A. Influence of Solid Lubricants on the Tribological Performance of Photocurable Resins for Vat Photopolymerization. Lubricants 2020, 8, 104. https://doi.org/10.3390/lubricants8120104

Slapnik J, Stiller T, Wilhelm T, Hausberger A. Influence of Solid Lubricants on the Tribological Performance of Photocurable Resins for Vat Photopolymerization. Lubricants. 2020; 8(12):104. https://doi.org/10.3390/lubricants8120104

Chicago/Turabian StyleSlapnik, Janez, Tanja Stiller, Thomas Wilhelm, and Andreas Hausberger. 2020. "Influence of Solid Lubricants on the Tribological Performance of Photocurable Resins for Vat Photopolymerization" Lubricants 8, no. 12: 104. https://doi.org/10.3390/lubricants8120104

APA StyleSlapnik, J., Stiller, T., Wilhelm, T., & Hausberger, A. (2020). Influence of Solid Lubricants on the Tribological Performance of Photocurable Resins for Vat Photopolymerization. Lubricants, 8(12), 104. https://doi.org/10.3390/lubricants8120104