Detection of Lubrication State in a Field Operational Wind Turbine Gearbox Bearing Using Ultrasonic Reflectometry

Abstract

1. Introduction

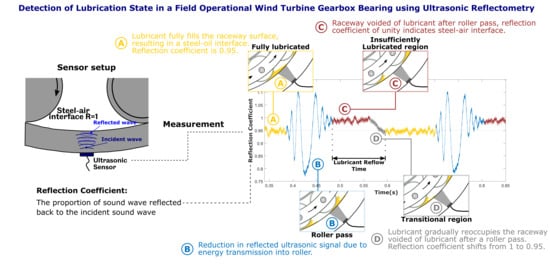

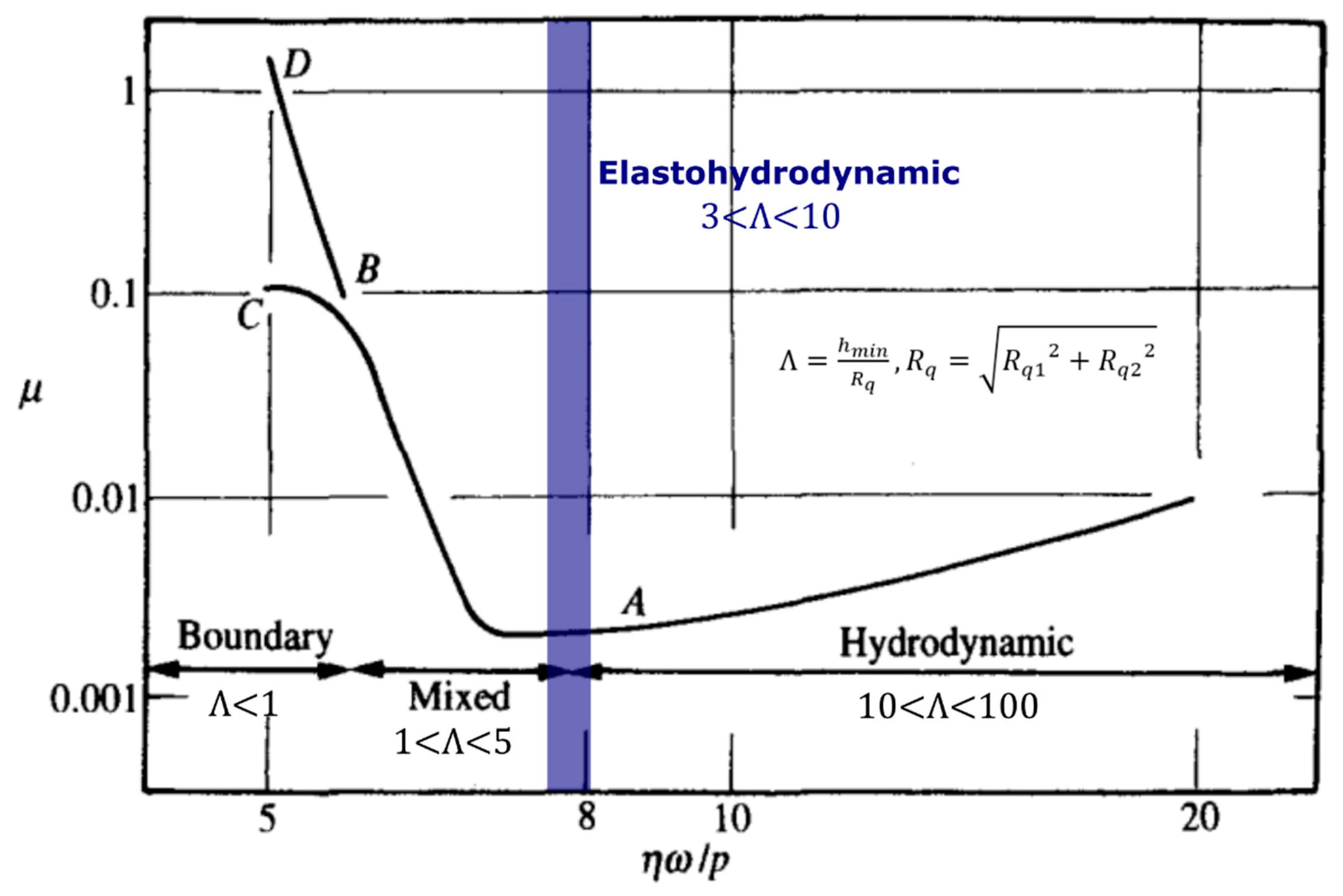

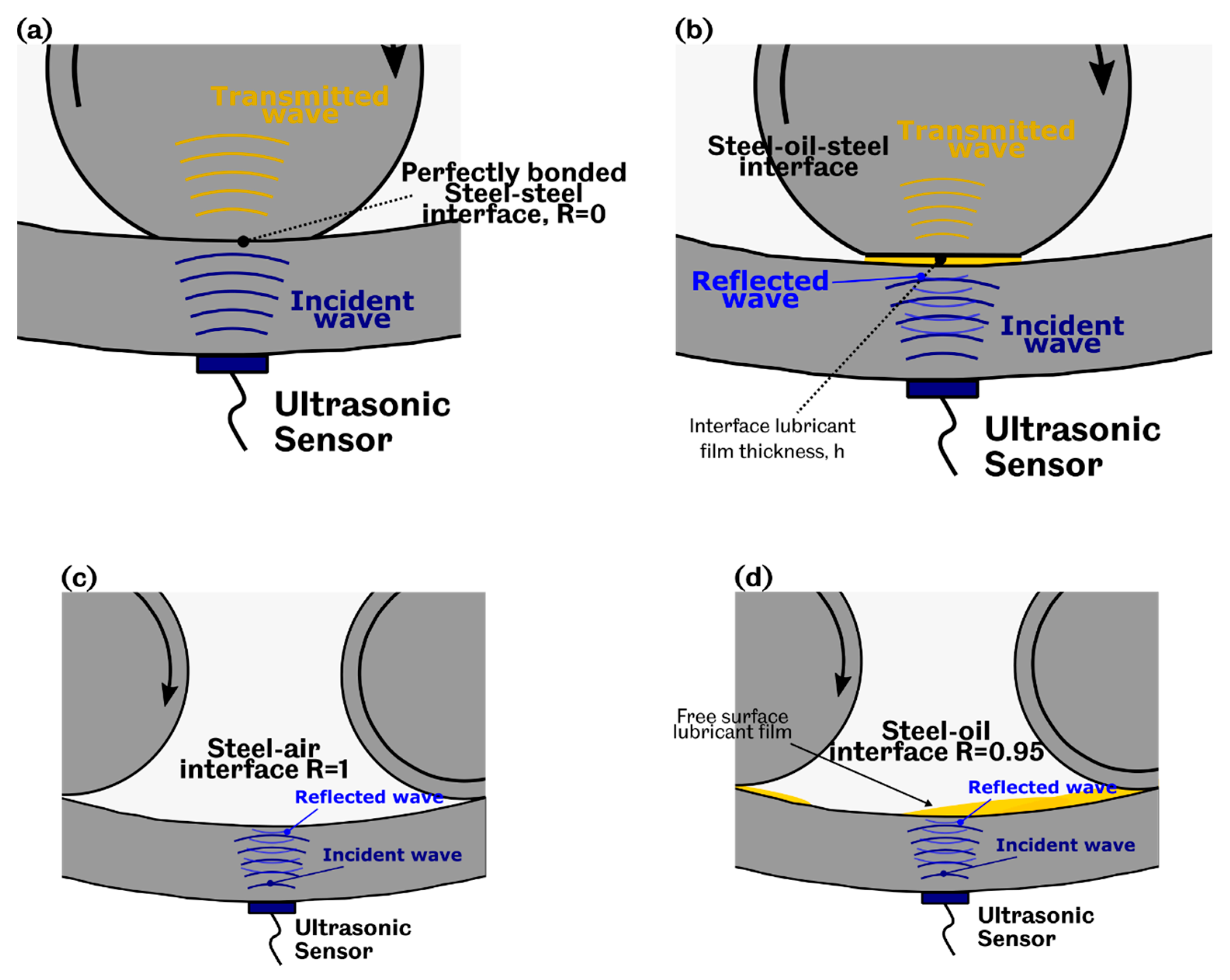

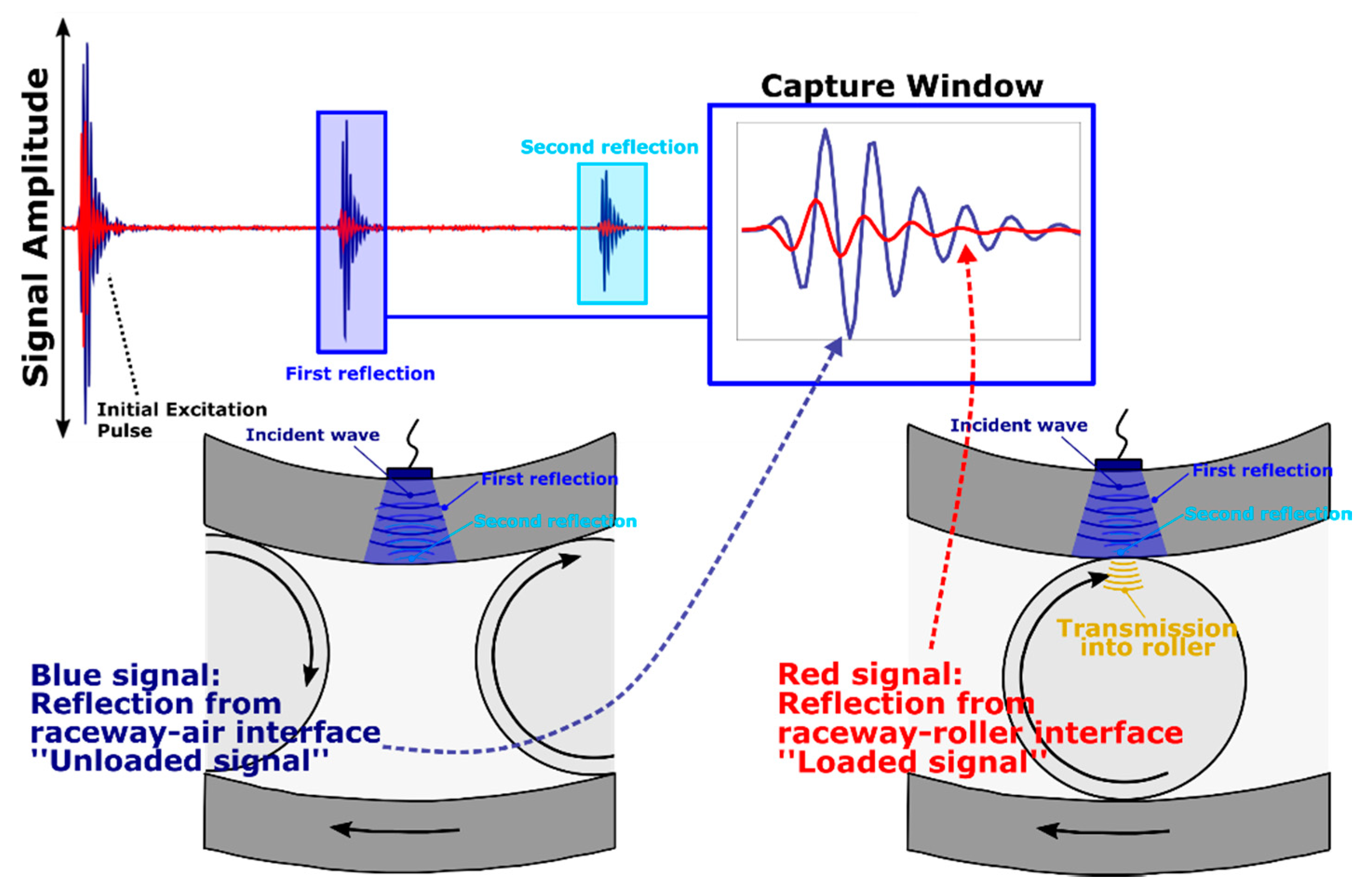

2. Measurement Methodology

3. Instrumentation and Methodology

3.1. Full Scale Cylindrical Roller Bearing Test Rig

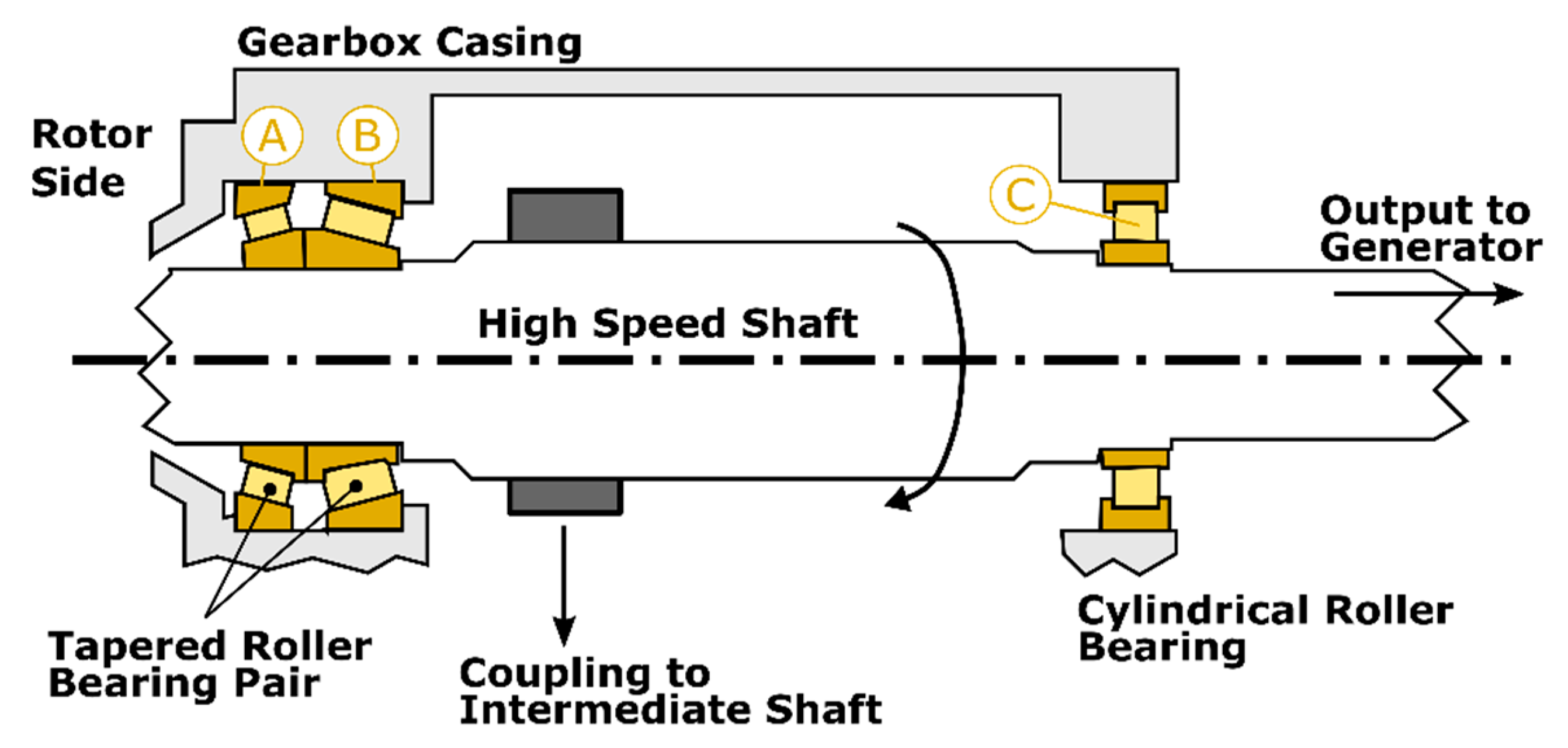

3.2. Wind Turbine High-Speed Shaft Gearbox Bearing Field Test

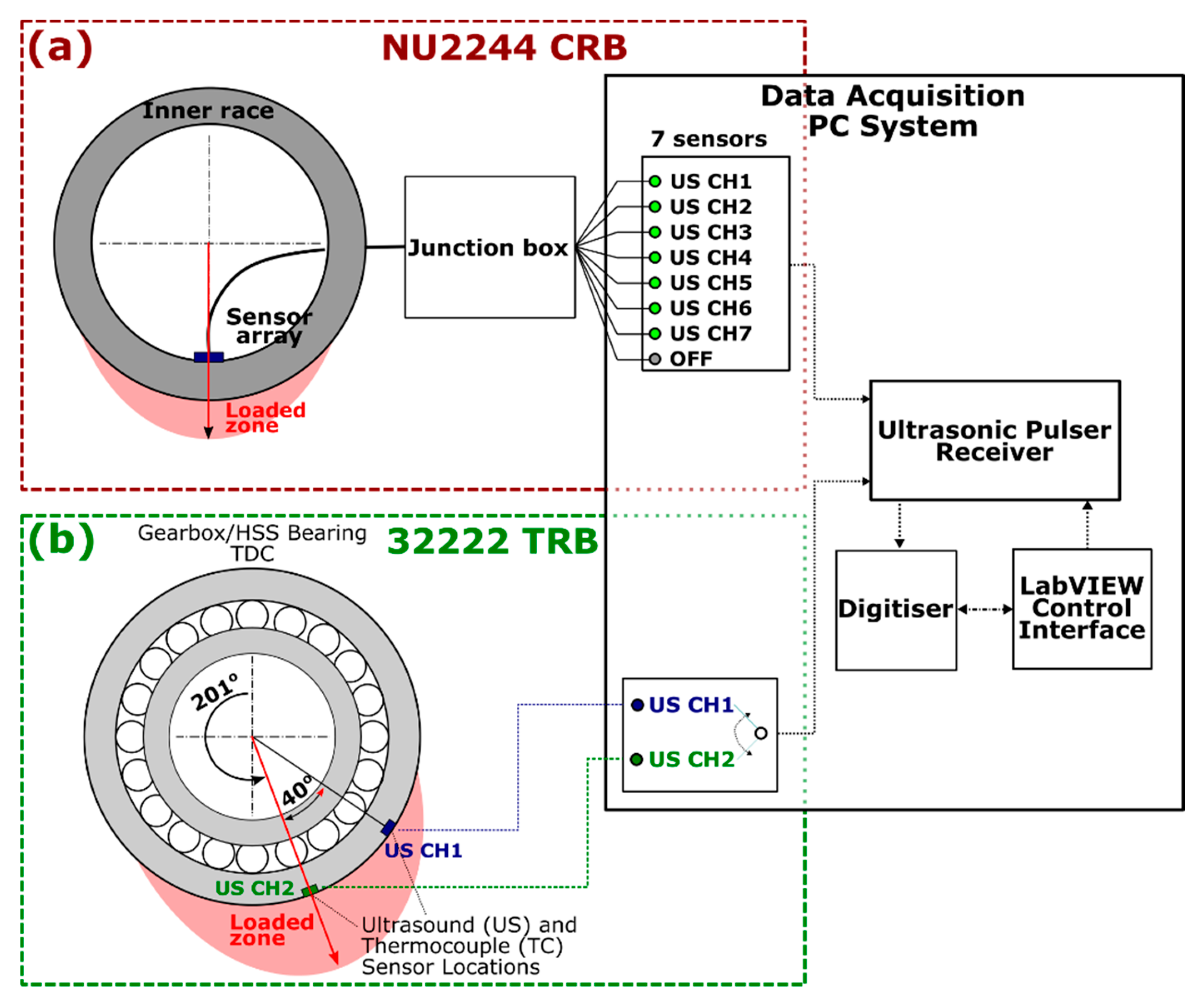

3.3. Sensor Instrumentation and Data Acquisition

3.3.1. Full-Scale Cylindrical Roller Bearing

3.3.2. Field Tapered Roller Bearing

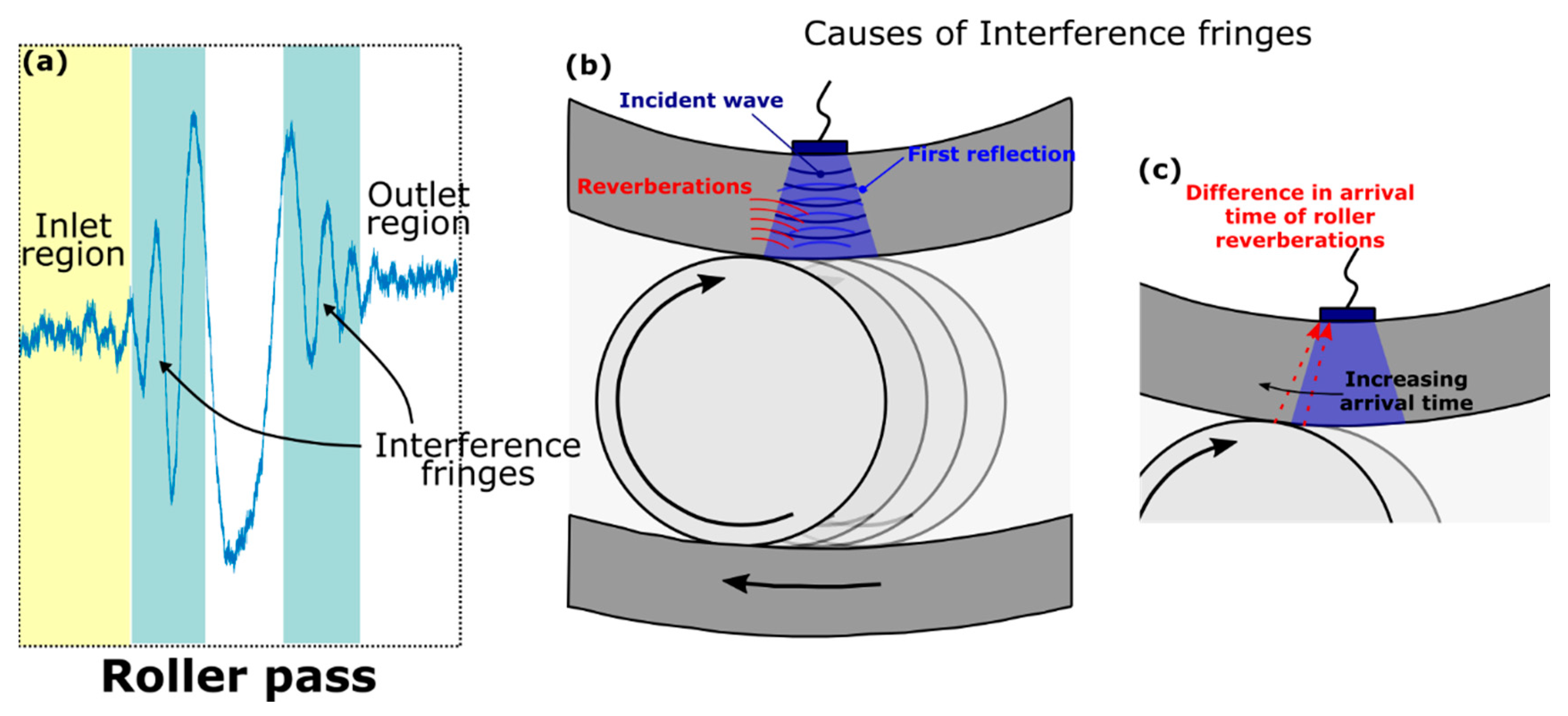

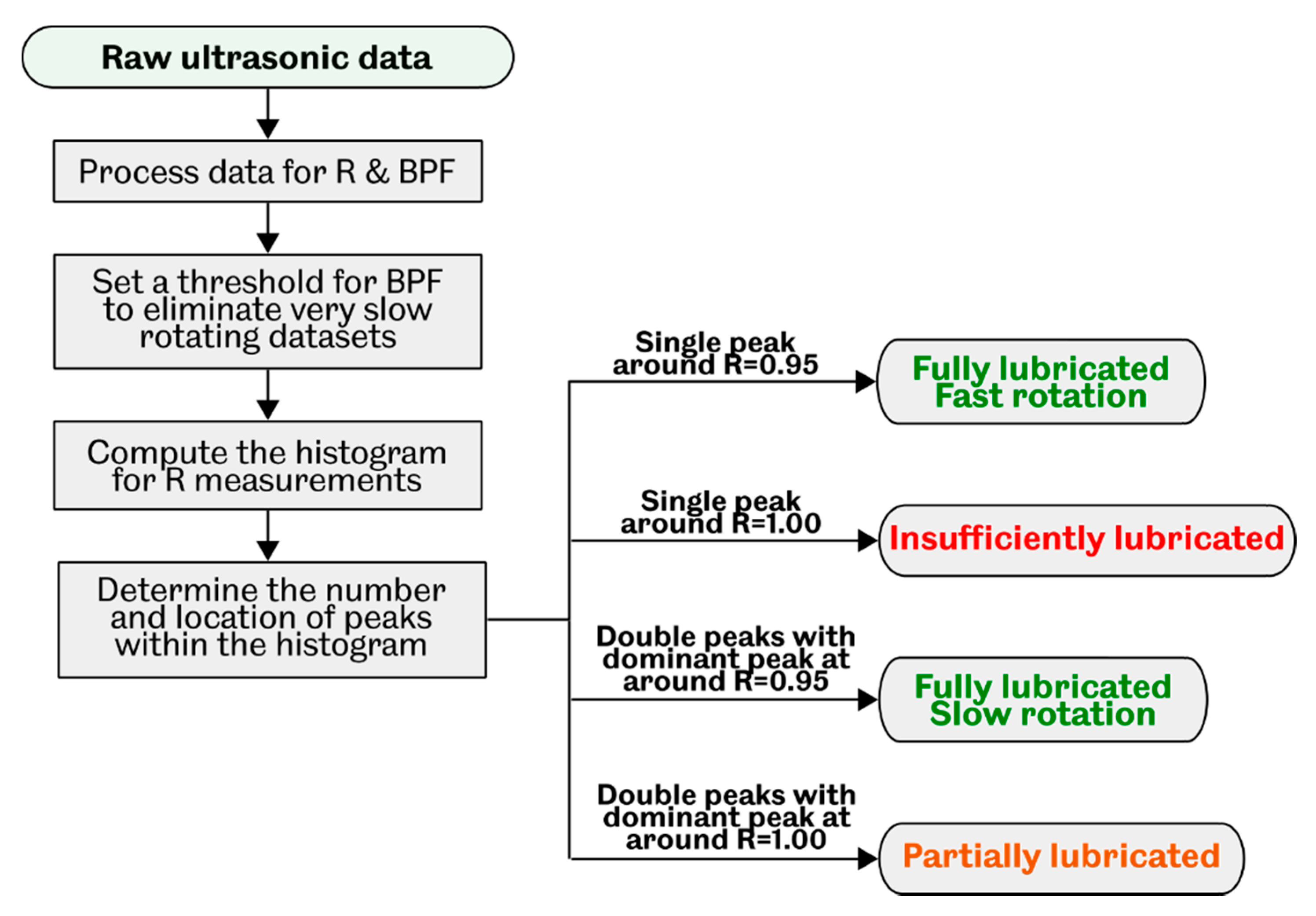

4. Analysis Procedure

5. Results

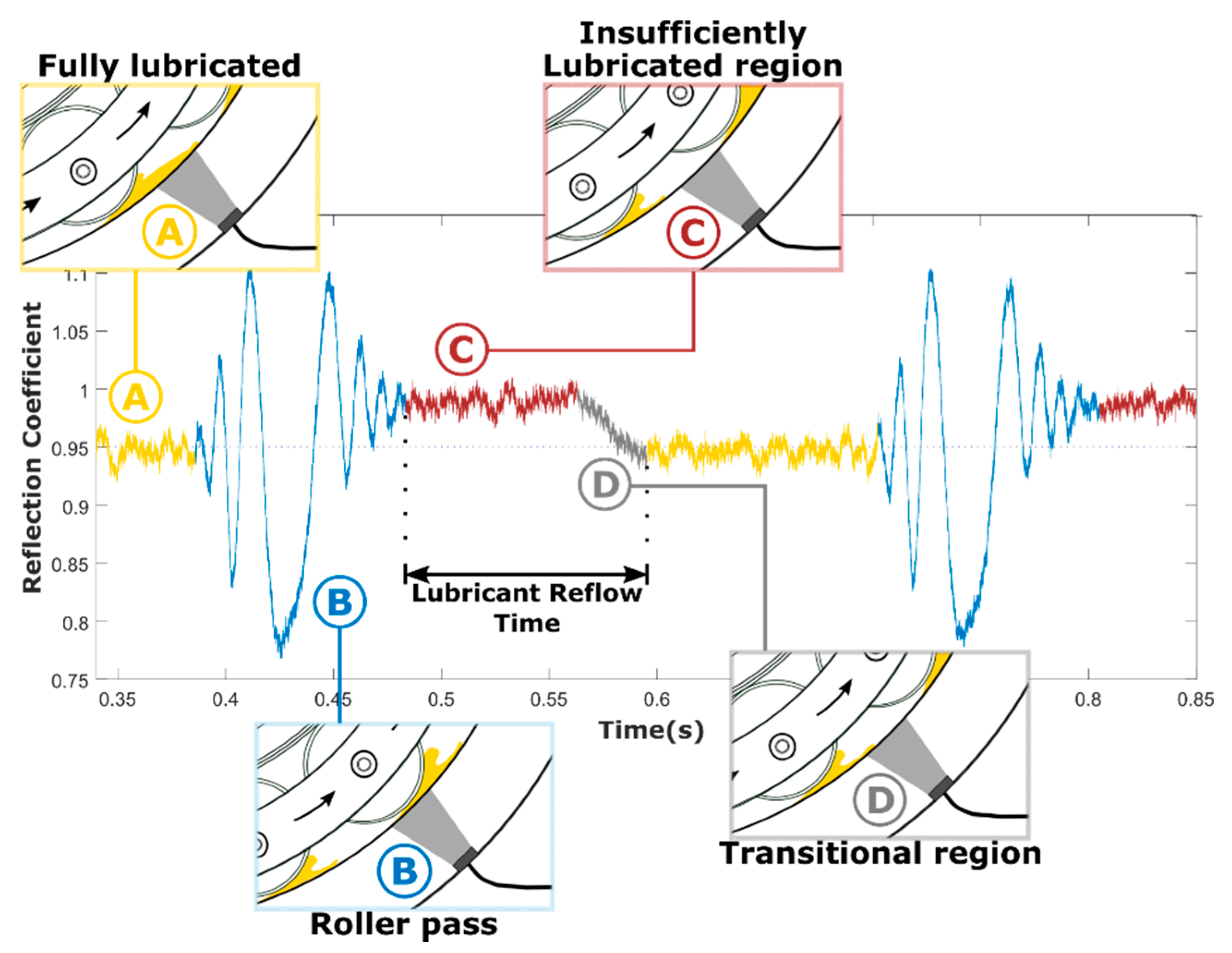

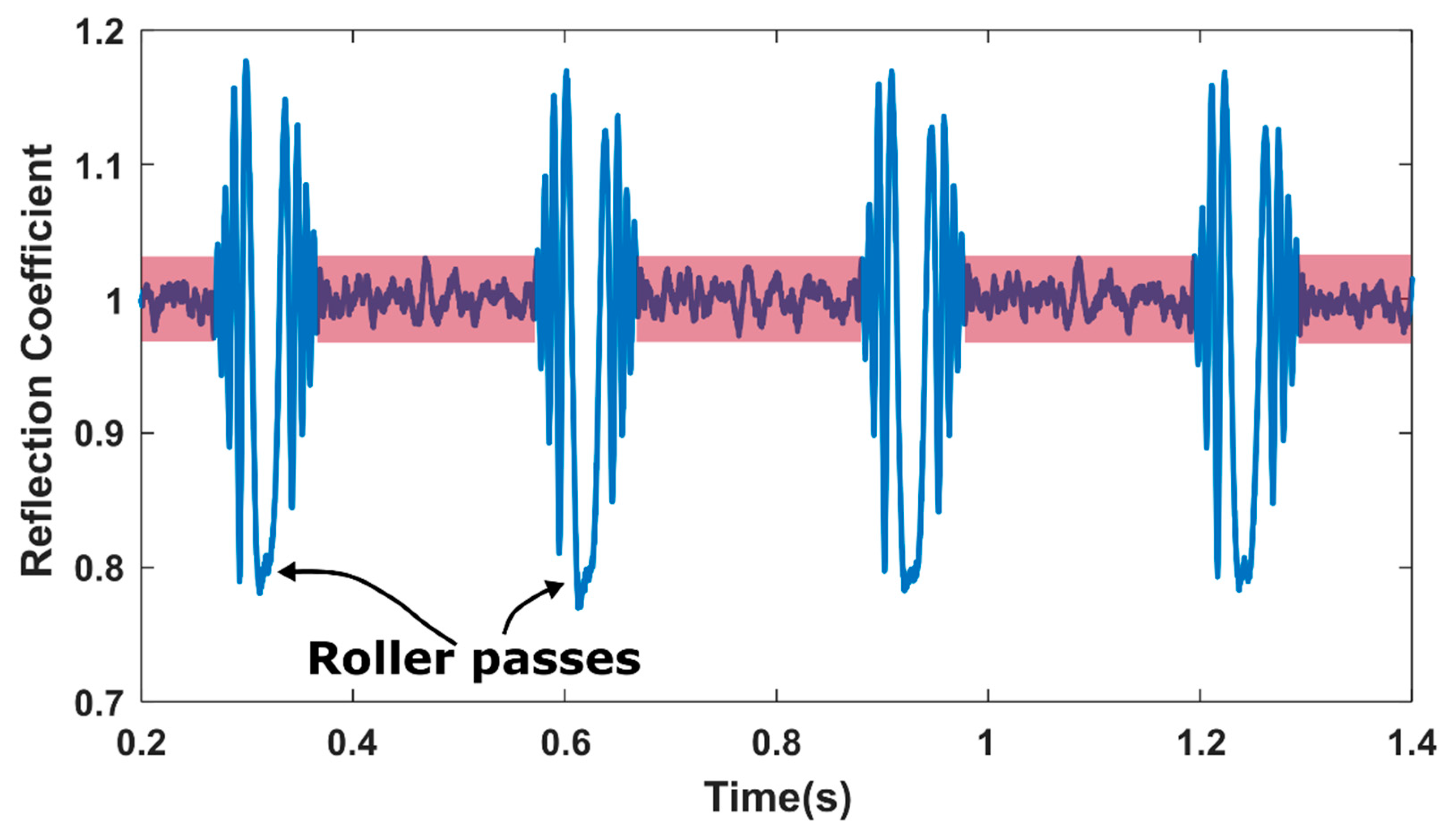

5.1. Measurements from the Full-Scale CRB Test Rig

5.2. Measurements from the Field Operational HSS Gearbox Bearing

5.2.1. Identification of Bearing Lubrication Condition

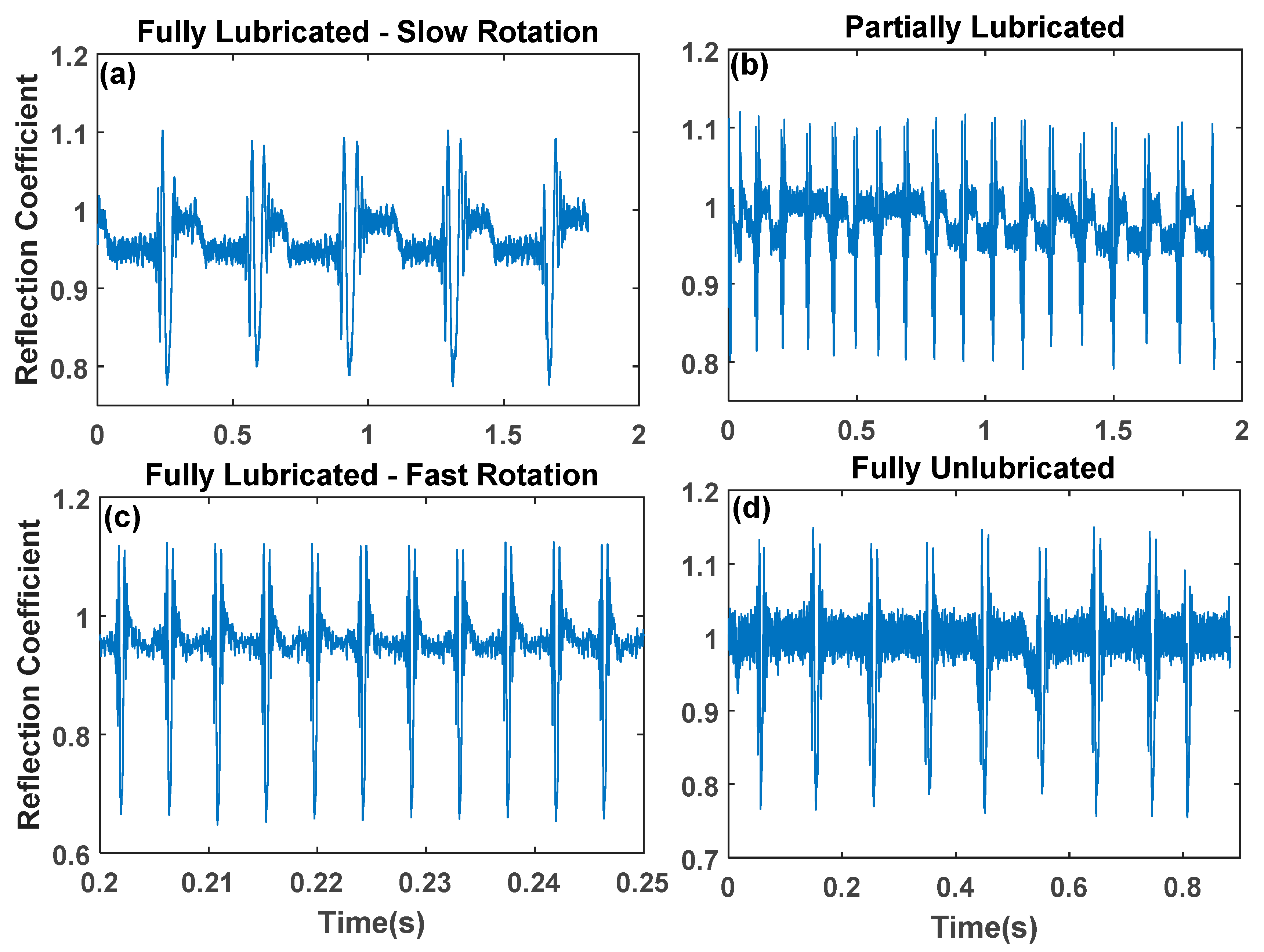

- Fully lubricated—slow rotation (Figure 14a). The alternating “zig-zag” pattern is evident within all the measurements between roller passes. The reflection coefficient for each roller inlet region is 0.95, indicating the raceway surface is lubricated before a roller traverses across the region.

- Partially lubricated (Figure 14b). The alternating pattern is not evident within all the measurements between roller passes and a mixture of roller inlet reflection coefficient values exist, varying between unity and 0.95.

- Fully lubricated—fast rotation (Figure 14c). A quicker transition from unity to 0.95 at the roller outlet was observed. The roller inlet reflection coefficient is 0.95.

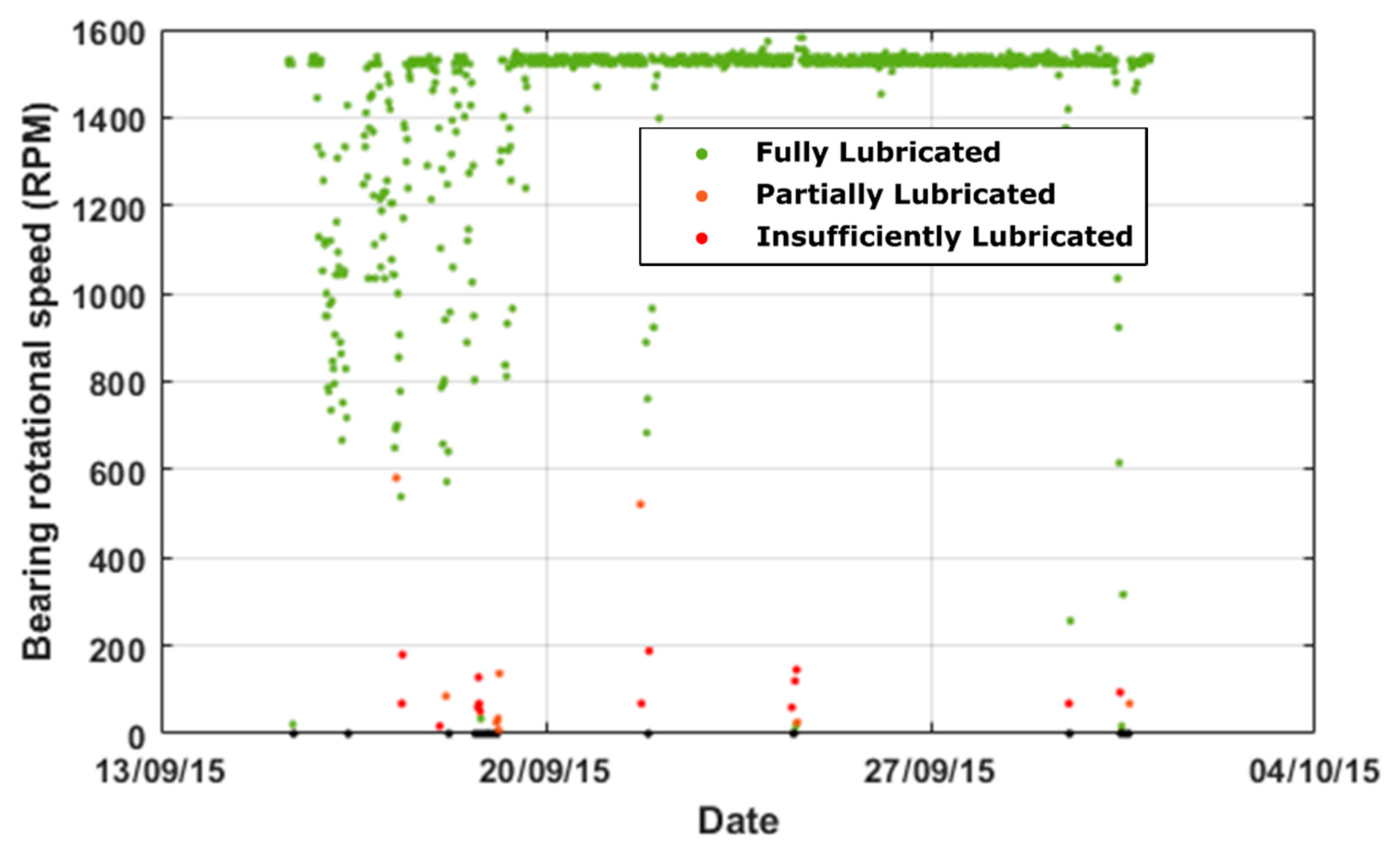

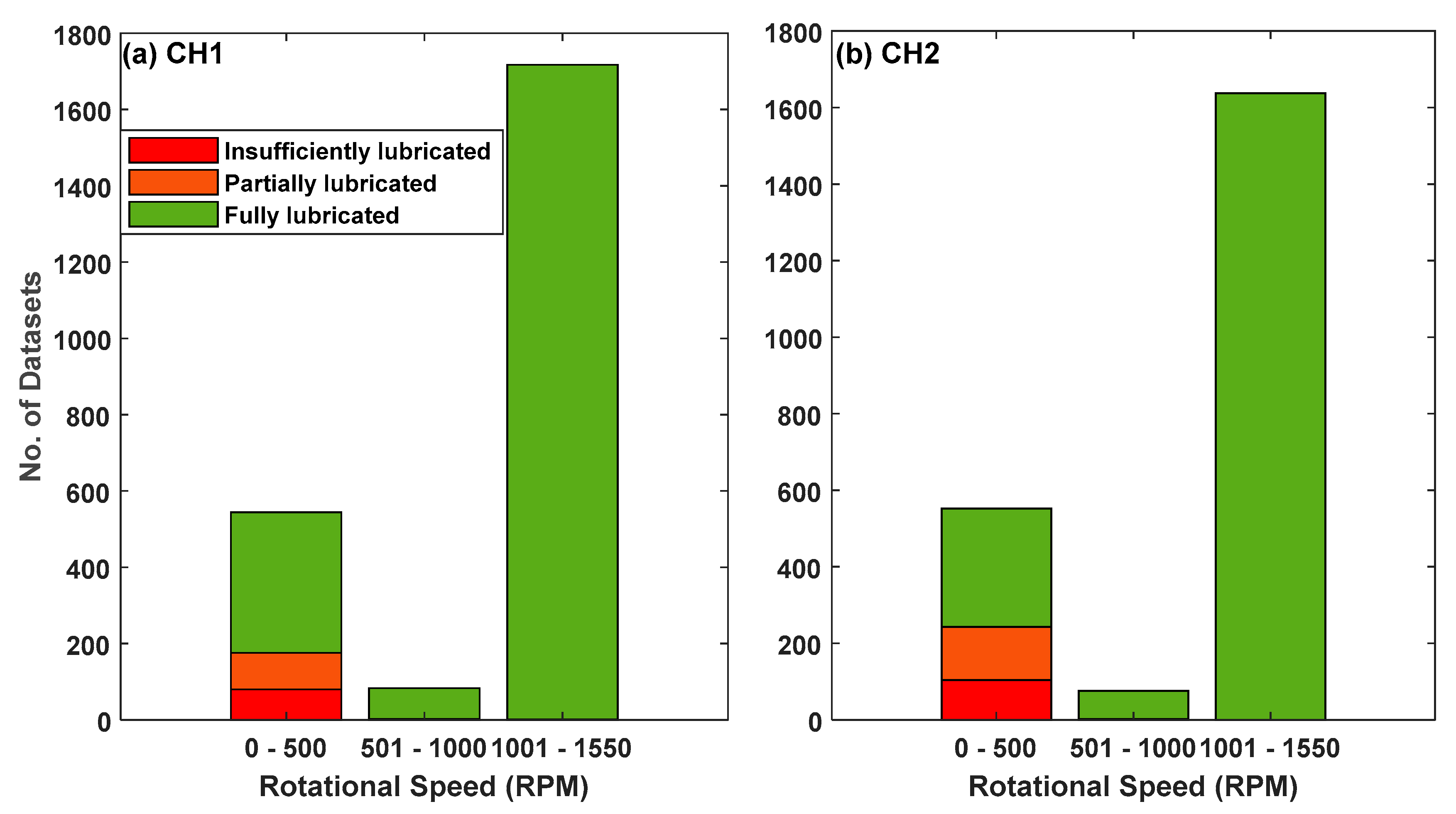

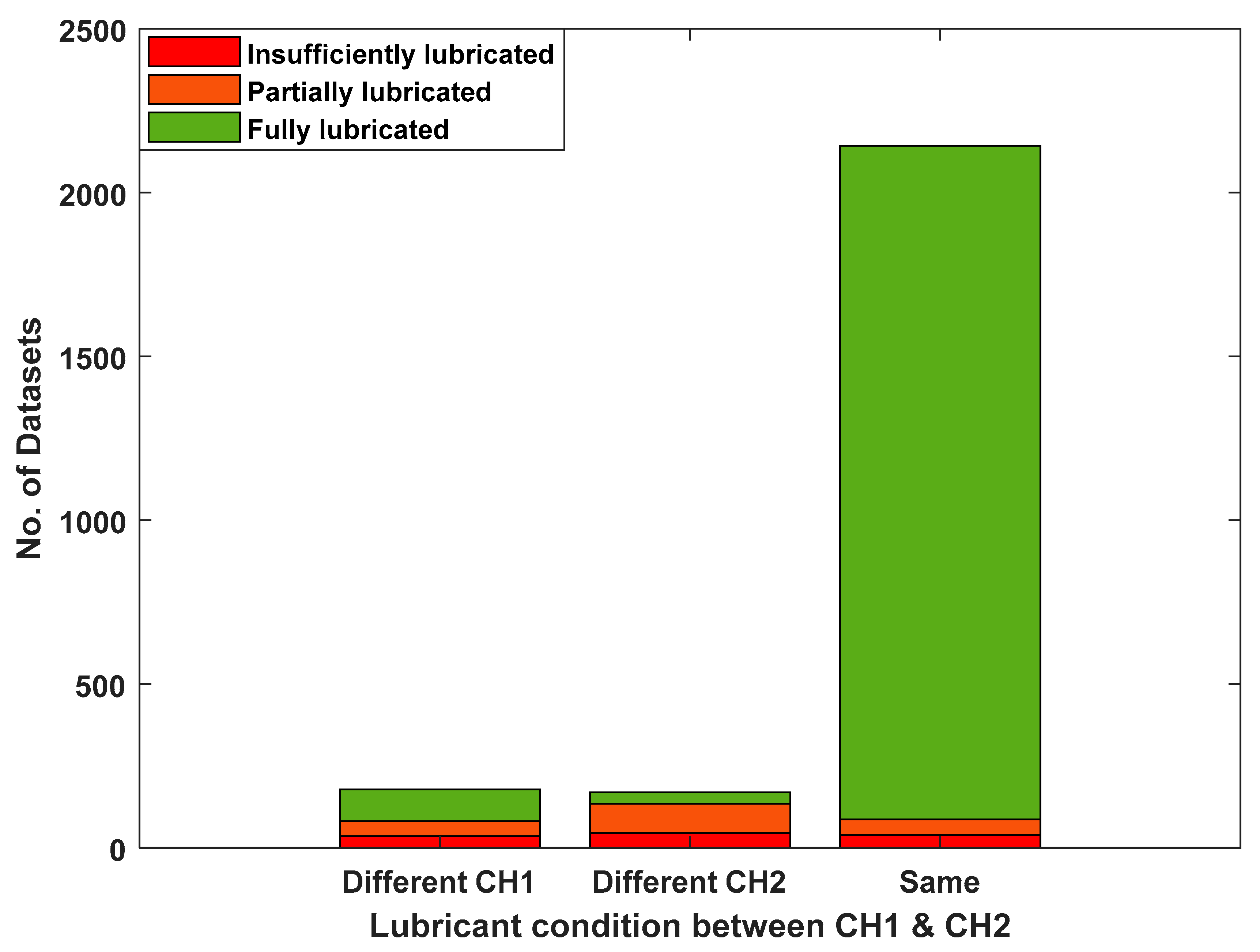

5.2.2. Bearing Lubrication Condition Variation with Turbine Operation

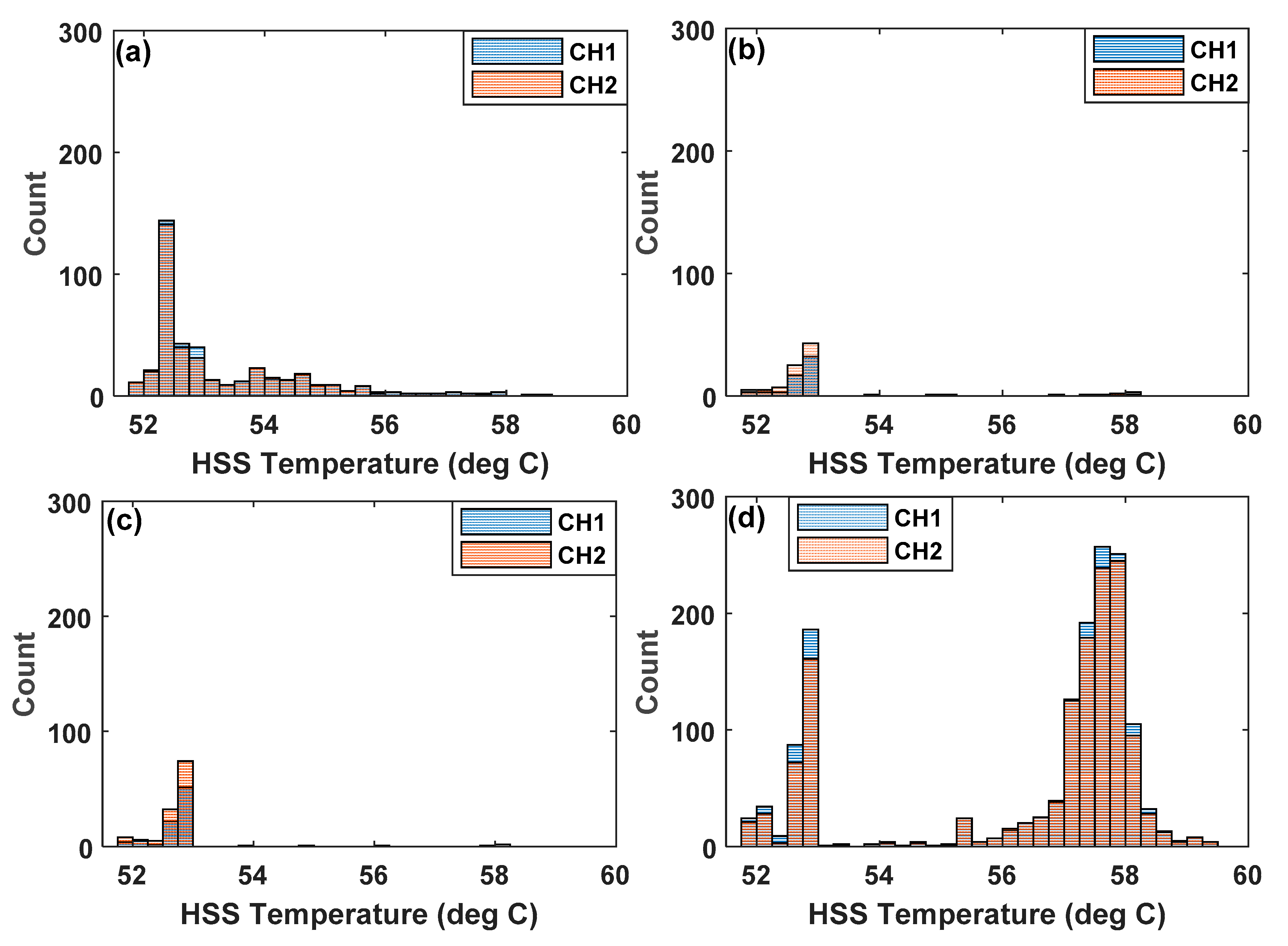

5.2.3. Lubrication Condition at Edge and Centre of Bearing Loaded Region

6. Discussion

6.1. Principal Findings

6.2. Limitations and Assumptions

7. Conclusions

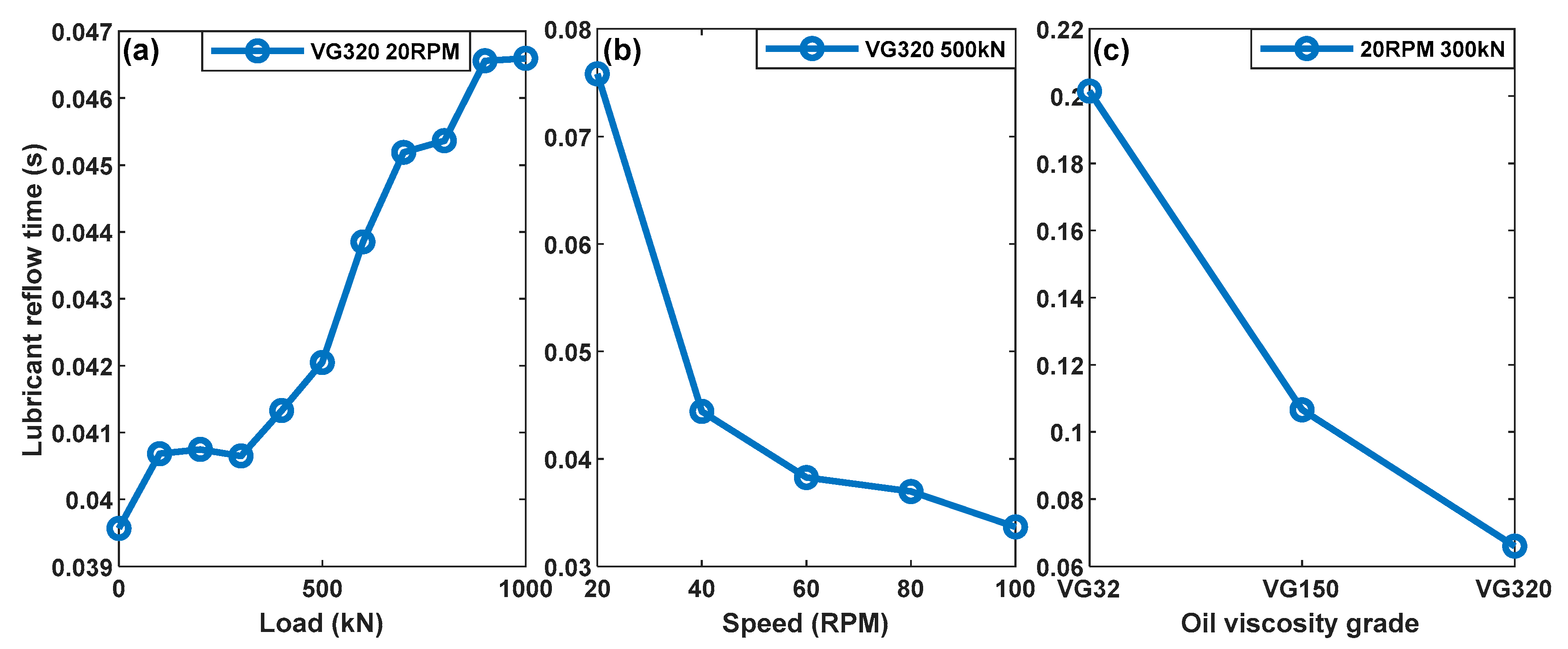

- The lubricant reflow time was found to be positively influenced with increasing bearing rotational speed and lubricant viscosity and negatively with bearing load.

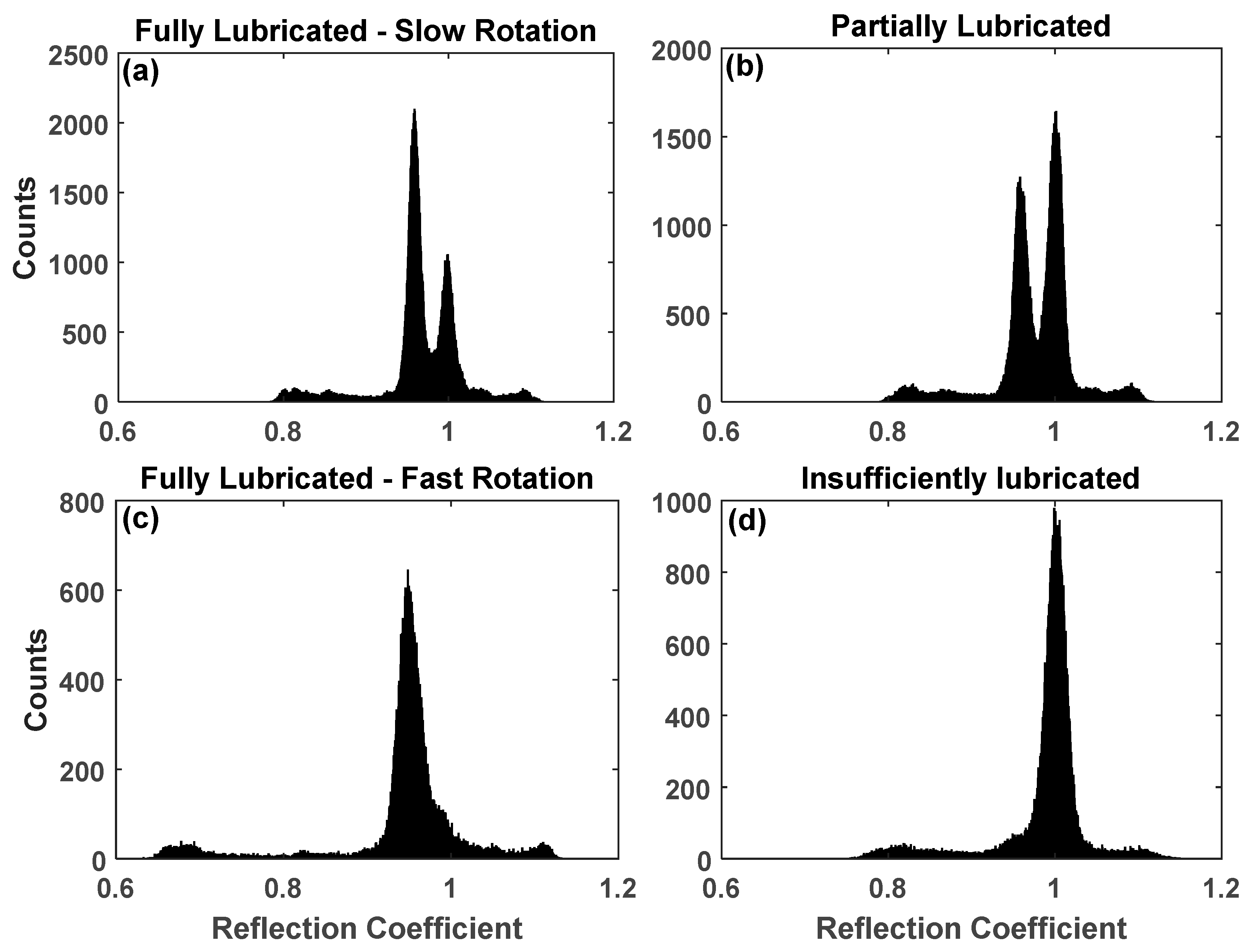

- Three bearing lubrication conditions were observed from the field measurements: fully, partially, and insufficiently lubricated.

- Unique features within the reflection coefficient histogram measurements for each lubrication condition enabled automatic categorization of field datasets.

- For medium (500–1000 RPM) and high (1001–1550 RPM) rotational speeds, most datasets were fully lubricated.

- Partially lubricated and insufficiently lubricated measurements were found to be recorded mostly during transient operation, with rotational speeds of ~200 RPM and HSS temperatures close to idle (53 °C, 0.5 °C higher than idle shaft temperature).

- As transient operation is often accompanied with overloading and torque reversals, issues with bearing lubrication could potentially risk premature failure through modes such as adhesive or abrasive wear, scuffing, and fretting. Thus, it is crucial that sufficient lubrication is provided to the bearings at both transient and steady-state turbine operation to avoid premature bearing failure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Evans, M. White structure flaking (WSF) in wind turbine gearbox bearings: Effects of ‘butterflies’ and white etching cracks (WECs). J. Mater. Sci. Technol. 2012, 28, 3–22. [Google Scholar] [CrossRef]

- Sheng, S. Report on Wind Turbine Subsystem Reliability–A Survey of Various Databases: 2013. NREL/PR-5000–59111. Available online: https://www.nrel.gov/docs/fy13osti/59111.pdf (accessed on 5 January 2021).

- Kotzalas, M.; Doll, G. Tribological advancements for reliable wind turbine performance. Philos. Trans. R. Soc. A 2010, 368, 4829–4850. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Parthasarathy, G.; Uluyol, O.; Foslien, W.; Sheng, S.; Fleming, P. Use of SCADA Data for Failure Detection in Wind Turbines. In Proceedings of the ASME 2011 5th International Conference on Energy Sustainability, Washington, DC, USA, 7–10 August 2011. [Google Scholar]

- Musial, W.; Butterfield, S.; McNiff, B. Improving Wind Turbine Gearbox Reliability. In Proceedings of the European Wind Energy Conference, Milan, Italy, 7–10 May 2007. [Google Scholar]

- Zepeng, L.; Long, Z. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar]

- INA. Failure Analysis. INA Bearing Failure Mode Archive, Sach Nr. 009-694-480/TPI 109 GB-D 03012. Available online: https://www.schaeffler.de/content.schaeffler.de/en/news_media/media_library/downloadcenter-detail-page.jsp?id=98147 (accessed on 5 January 2021).

- FAG. Rolling Bearing Damage—Recognition of Damage and Bearing Inspection. Publication No. WL 82102/2 EA. Available online: https://rolling.hu/pdf/FAG/FAG_meghibasodas.pdf (accessed on 5 January 2021).

- Ernesto, A.; Mazuyer, D.; Cayer-Barrioz, J. From Full-Film Lubrication to Boundary Regime in Transient Kinematics. Tribol. Lett. 2015, 59, 23–33. [Google Scholar] [CrossRef]

- Williams, J. Engineering Tribology; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Stachowiak, G.; Batchelor, A. Engineering Tribology, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Chevalier, F.; Lubrecht, A.; Cann, P.; Colin, F.; Dalmaz, G. Film thickness in starved EHL point contacts. Trans. ASME 1998, 120, 126–133. [Google Scholar] [CrossRef]

- Cann, P.; Damiens, B.; Lubrecht, A. The transition between fully flooded and starved regimes in EHL. Tribol. Int. 2004, 37, 859–864. [Google Scholar] [CrossRef]

- Berthe, L.; Adams-Chaves, A.; Lubrecht, A. Friction measurement indicating the transition between fully flooded and starved regimes in elasto-hydrodynamic lubrication. Proc. Inst. Mech. Eng. Part J 2014, 228, 1403–1409. [Google Scholar] [CrossRef]

- Litwin, W.; Dymarski, C. Experimental research on water-lubricated marine stern tube bearings in conditions of improper lubrication and cooling causing rapid bush wear. Tribol. Int. 2016, 95, 449–455. [Google Scholar] [CrossRef]

- Bearing Failure: Causes and Cures. Available online: Shorturl.at/hpwyB (accessed on 22 December 2020).

- Bearing Failure Prevention Guide. Available online: Shorturl.at/fzJVY (accessed on 22 December 2020).

- Spikes, H.; Cann, P. The development and application of the spacer layer imaging method for measuring lubricant film thickness. Proc. Inst. Mech. Eng. Part J 2001, 215, 261–277. [Google Scholar] [CrossRef]

- Astridge, D.; Longfield, M. Capacitance measurement and oil film thickness in a large radius disc and ring machine. Proc. Inst. Mech. Eng. 1967, 182, 89–96. [Google Scholar] [CrossRef]

- El-Sisi, S.; Shawki, G. Measurement of oil-film thickness between disks by electrical conductivity. J. Fluids Eng. 1960, 82, 12–16. [Google Scholar] [CrossRef]

- Hameed, Z.; Hong, Y.; Cho, Y.; Ahn, S.; Song, C. Condition Monitoring and Fault Detection of Wind Turbines and Related Algorithms: A Review. Renew. Sustain. Energy Rev. 2009, 13, 1–39. [Google Scholar] [CrossRef]

- Mills, R.; Avan, E.; Dwyer-Joyce, R. Piezoelectric sensors to monitor lubricant film thickness at piston-cylinder contacts in a fired engine. Proc. Inst. Mech. Eng. Part J 2013, 227, 100–111. [Google Scholar] [CrossRef]

- Dwyer-Joyce, R.; Reddyhoff, T.; Drinkwater, B. Operating limits for acoustic measurement of rolling bearing oil film thickness. Tribol. Trans. 2004, 47, 366–375. [Google Scholar] [CrossRef]

- Dwyer-Joyce, R.; Reddyhoff, T.; Zhu, J. Ultrasonic measurement for film thickness and solid contact in elastohydrodynamic lubrication. J. Tribol. 2011, 133, 031501. [Google Scholar] [CrossRef]

- Zhang, J.; Drinkwater, B.; Dwyer-Joyce, R. Monitoring of lubricant film failure in a ball bearing using ultrasound. J. Tribol. Trans. ASME 2006, 128, 612–618. [Google Scholar] [CrossRef]

- Zhang, J.; Drinkwater, B.; Dwyer-Joyce, R. Acoustic measurement of lubricant-film thickness distribution in ball bearings. J. Acoust. Soc. Am. 2006, 119, 863–871. [Google Scholar] [CrossRef]

- Zhang, K.; Meng, Q.; Zhao, W. Measurement of oil film thickness in cylindrical roller bearing by ultrasound. In Proceedings of the ASME 2014 12th Biennial Conference on Engineering Systems Design and Analysis, Copenhagen, Denmark, 25–27 July 2014. [Google Scholar]

- Li, M.; Jing, M.; Chen, Z.; Liu, H. An improved ultrasonic method for lubricant-film thickness measurement in cylindrical roller bearings under light radial load. Tribol. Int. 2014, 78, 35–40. [Google Scholar] [CrossRef]

- Li, M.; Liu, H.; Xu, C.; Jing, M.; Dong, G. Ultrasonic Measurement of Cylindrical Roller-Bearing Lubricant Film Distribution with Two Juxtaposed Transducers. Tribol. Trans. 2017, 60, 79–86. [Google Scholar] [CrossRef]

- Nicholas, G.; Howard, T.; Long, H.; Wheals, J.; Dwyer-Joyce, R. Measurement of roller load, load variation and lubrication in a wind turbine gearbox high-speed shaft bearing in the field. Tribol. Int. 2020, 148, 106322. [Google Scholar] [CrossRef]

- Pialucha, T.; Guyott, C.; Cawley, P. Amplitude spectrum method for the measurement of phase velocity. Ultrasonics 1989, 27, 270–279. [Google Scholar] [CrossRef]

- Dwyer-Joyce, R.; Drinkwater, B.; Donohoe, C. The measurement of lubricant-film thickness using ultrasound. Proc. R. Soc. A 2003, 459, 957–976. [Google Scholar] [CrossRef]

- Reddyhoff, T.; Kasolang, S.; Dwyer-Joyce, R. The phase shift of an ultrasonic pulse at an oil layer and determination of film thickness. Proc. Inst. Mech. Eng. 2005, 219, 387–400. [Google Scholar] [CrossRef]

- Geng, T.; Meng, Q.; Chen, Z.; Wang, P. Ultrasonic monitoring of lubricating conditions of hydrodynamic bearings. J. Phys. 2011, 305, 012065. [Google Scholar] [CrossRef]

- Dwyer-Joyce, R.; Reddyhoff, T. Ultrasonic Measurement of EHL Oil Films in a Mixed Regime Contact. In Proceedings of the STLE/ASME 2006 International Joint Tribology Conference, San Antonio, TX, USA, 23–25 October 2006. [Google Scholar]

- Howard, T. Development of a Novel Bearing Concept for Improved Wind Turbine Gearbox Reliability. Ph.D. Thesis, The University of Sheffield, Sheffield, UK, 2016. [Google Scholar]

- Hunter, A.; Dwyer-Joyce, R.; Harper, P. Calibration and validation of ultrasonic reflection methods for thin-film measurement in tribology. Meas. Sci. Technol. 2012, 23, 105605. [Google Scholar] [CrossRef]

- Troubleshooting Wind Gearbox Problems. Available online: Shorturl.at/rvCDQ (accessed on 17 September 2020).

- Heege, A.; Betran, J.; Radovcic, Y. Fatigue load computation of wind turbine gearboxes by coupled finite element, multi-body system and aerodynamic analysis. Wind Energy 2007, 10, 395–413. [Google Scholar] [CrossRef]

- Bruce, T.; Long, H.; Dwyer-Joyce, R. Dynamic modelling of wind turbine gearbox bearing loading during transient events. IET Renew. Power Gener. 2015, 9, 821–830. [Google Scholar] [CrossRef]

- Bruce, T.; Rounding, E.; Long, H.; Dwyer-Joyce, R. Characterisation of white etching crack damage in wind turbine gearbox bearings. Wear 2015, 338, 164–177. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nicholas, G.; Clarke, B.P.; Dwyer-Joyce, R.S. Detection of Lubrication State in a Field Operational Wind Turbine Gearbox Bearing Using Ultrasonic Reflectometry. Lubricants 2021, 9, 6. https://doi.org/10.3390/lubricants9010006

Nicholas G, Clarke BP, Dwyer-Joyce RS. Detection of Lubrication State in a Field Operational Wind Turbine Gearbox Bearing Using Ultrasonic Reflectometry. Lubricants. 2021; 9(1):6. https://doi.org/10.3390/lubricants9010006

Chicago/Turabian StyleNicholas, G., B. P. Clarke, and R. S. Dwyer-Joyce. 2021. "Detection of Lubrication State in a Field Operational Wind Turbine Gearbox Bearing Using Ultrasonic Reflectometry" Lubricants 9, no. 1: 6. https://doi.org/10.3390/lubricants9010006

APA StyleNicholas, G., Clarke, B. P., & Dwyer-Joyce, R. S. (2021). Detection of Lubrication State in a Field Operational Wind Turbine Gearbox Bearing Using Ultrasonic Reflectometry. Lubricants, 9(1), 6. https://doi.org/10.3390/lubricants9010006