An Experimental Study on the Fretting Corrosion Behaviours of Three Material Pairs at Modular Interfaces for Hip Joint Implants

Abstract

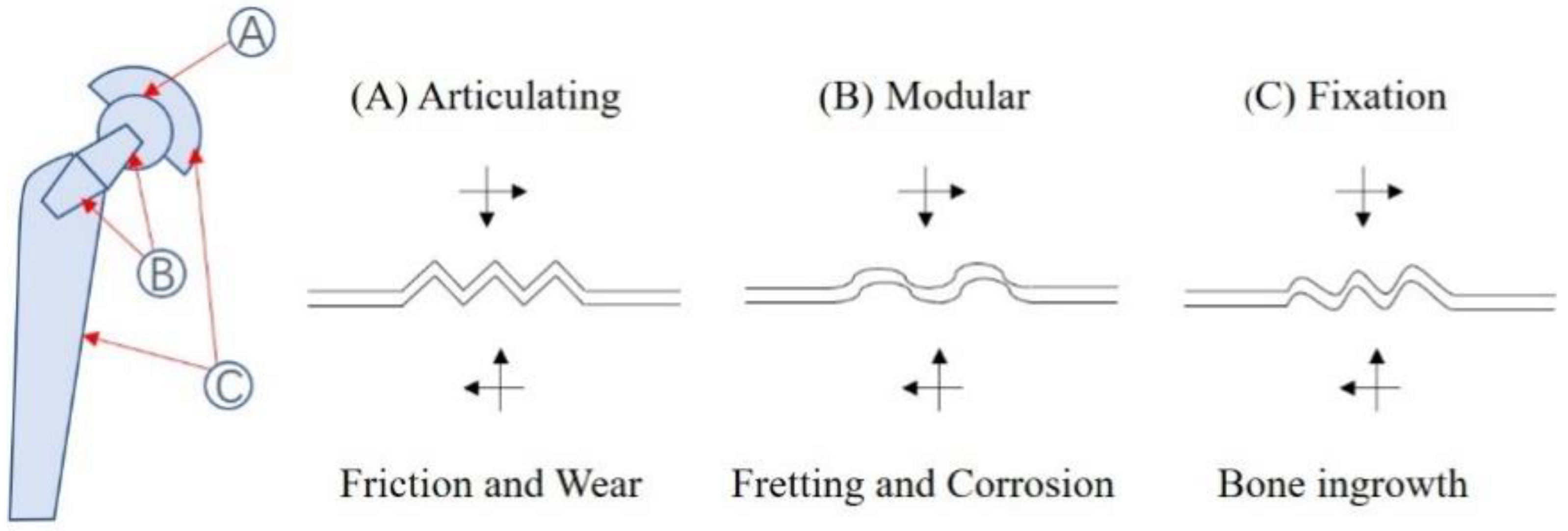

:1. Introduction

2. Materials and Methods

2.1. Materials

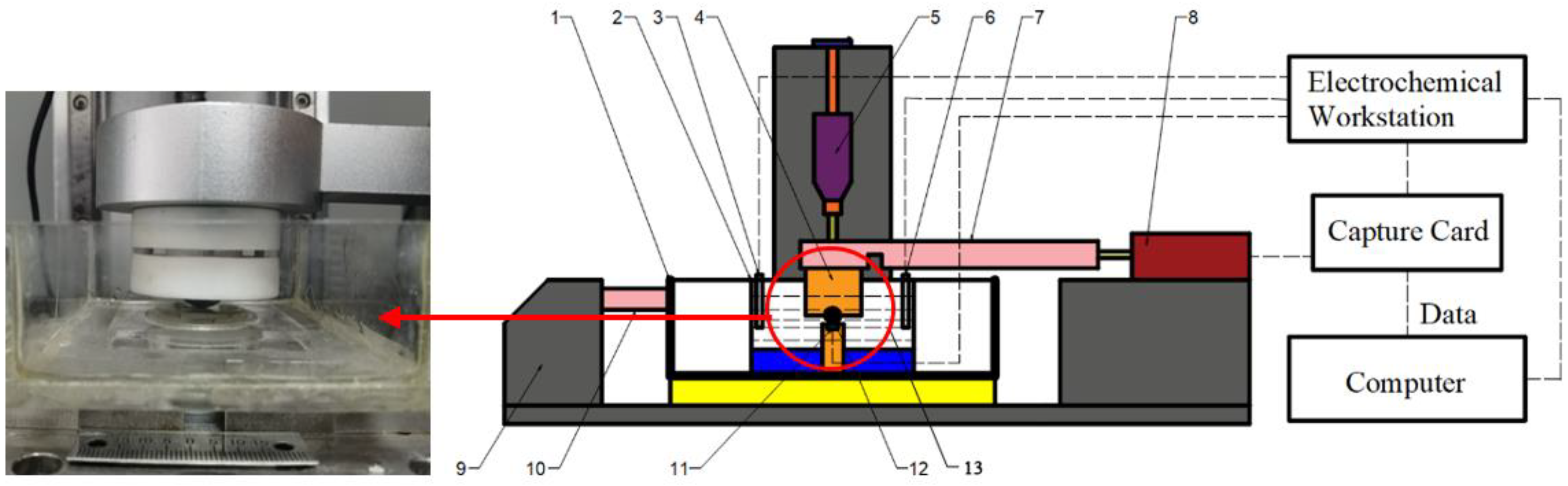

2.2. Methods and Devices

3. Results and Discussion

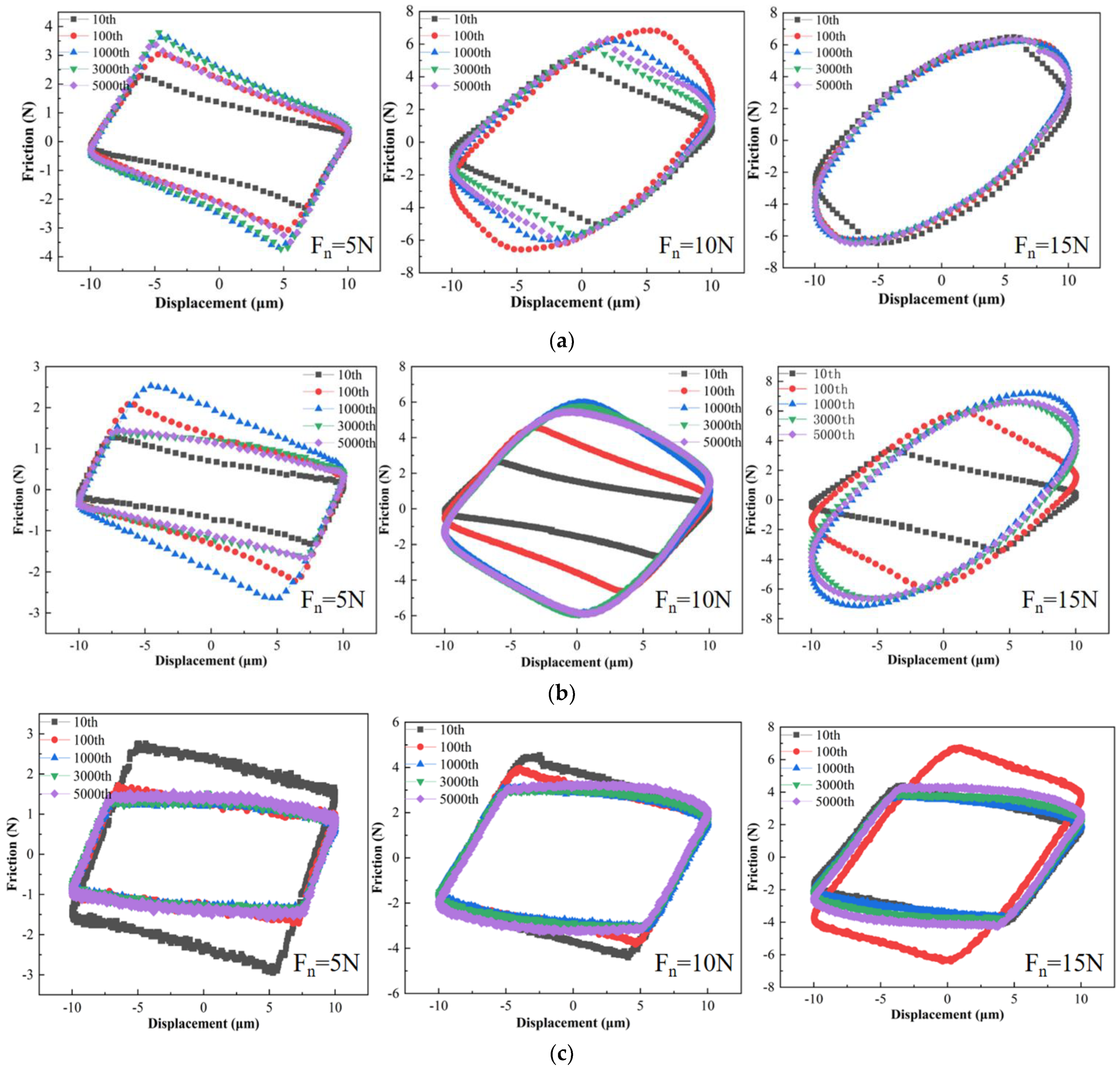

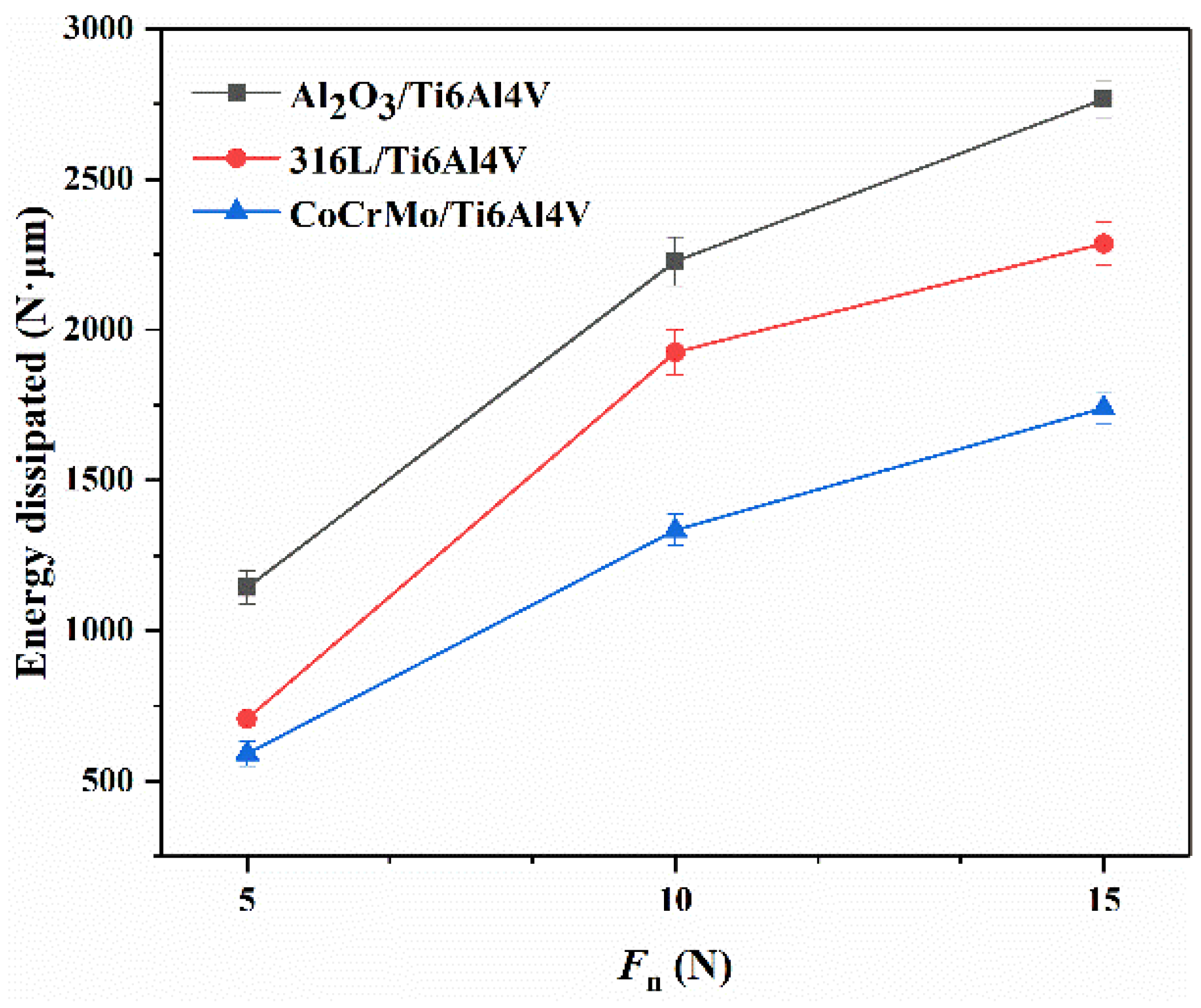

3.1. Fretting Running Characteristics

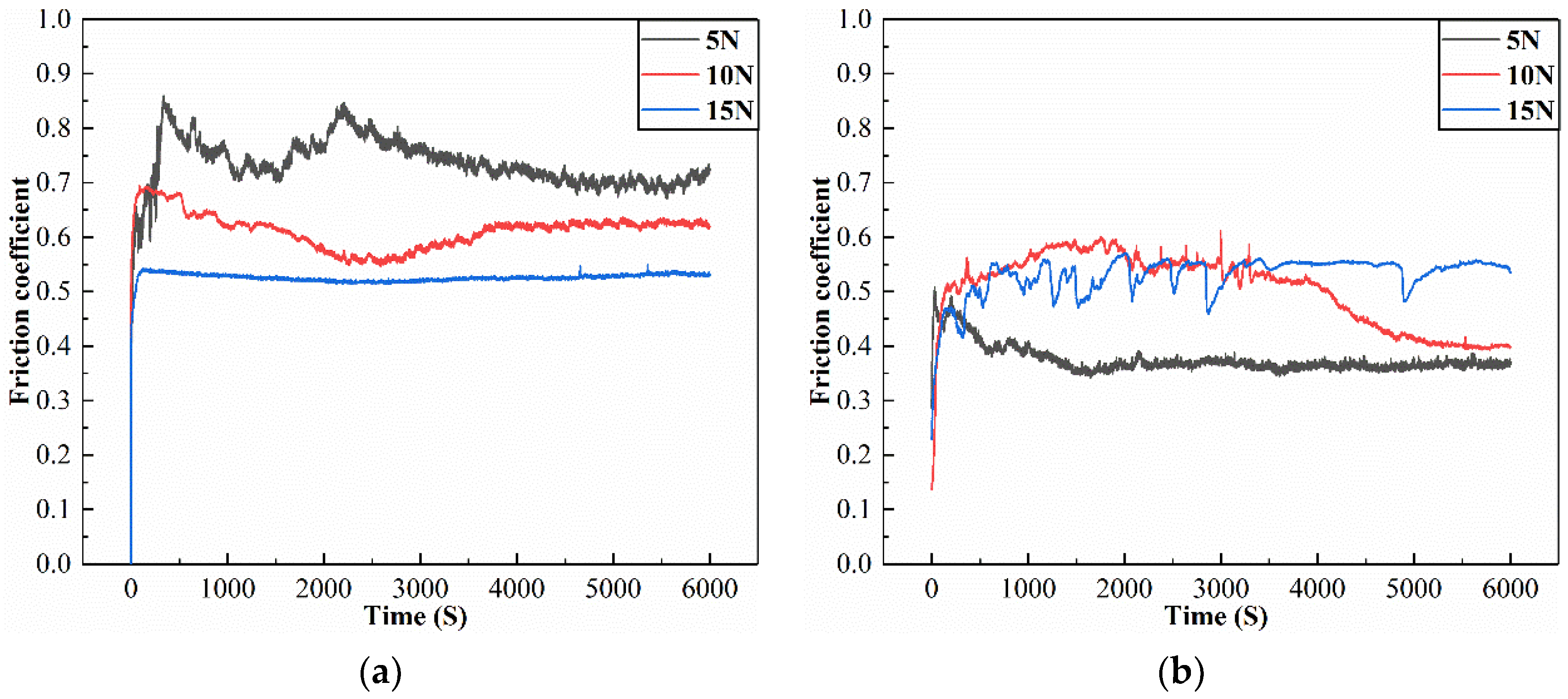

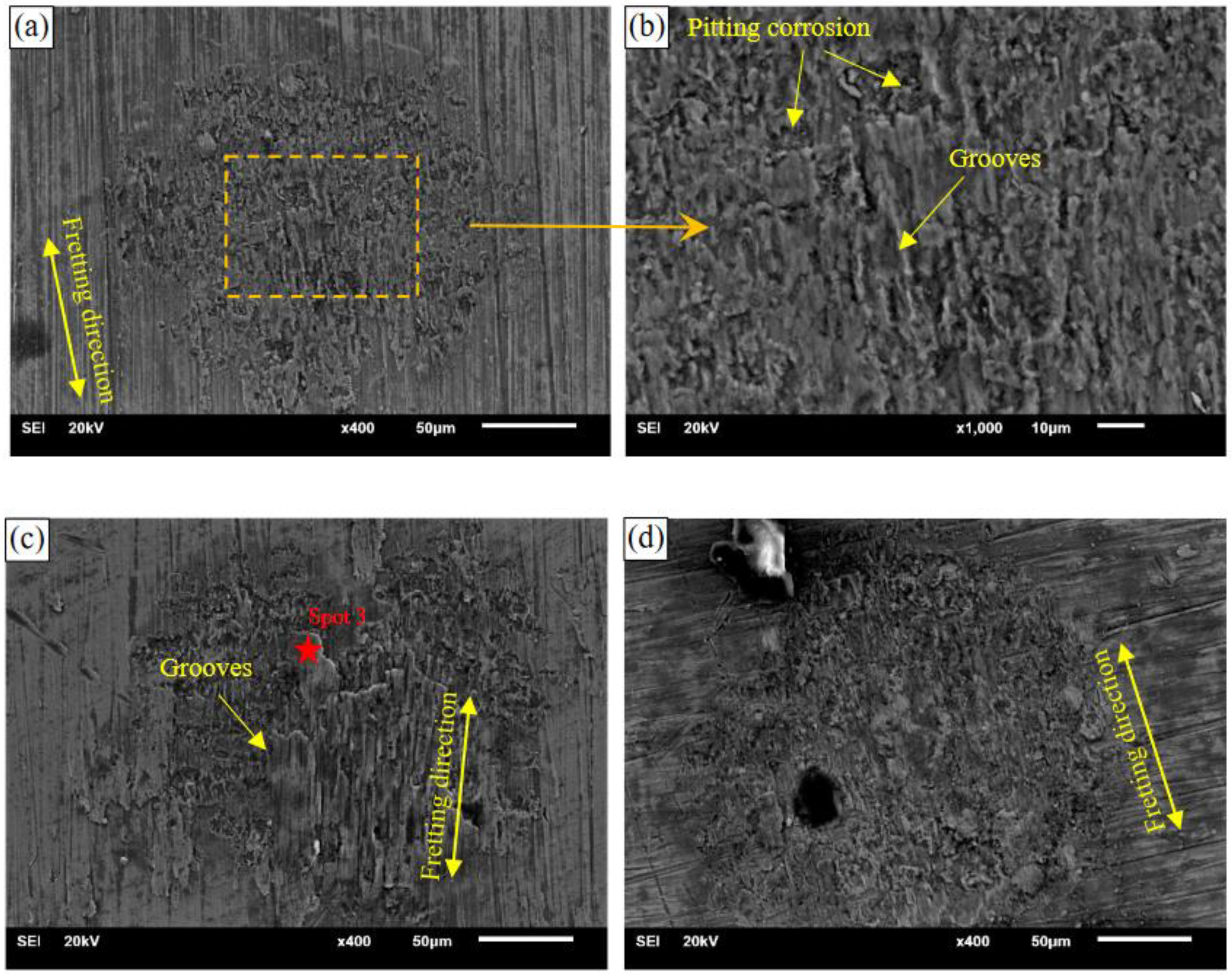

3.2. Analysis of Friction Coefficient

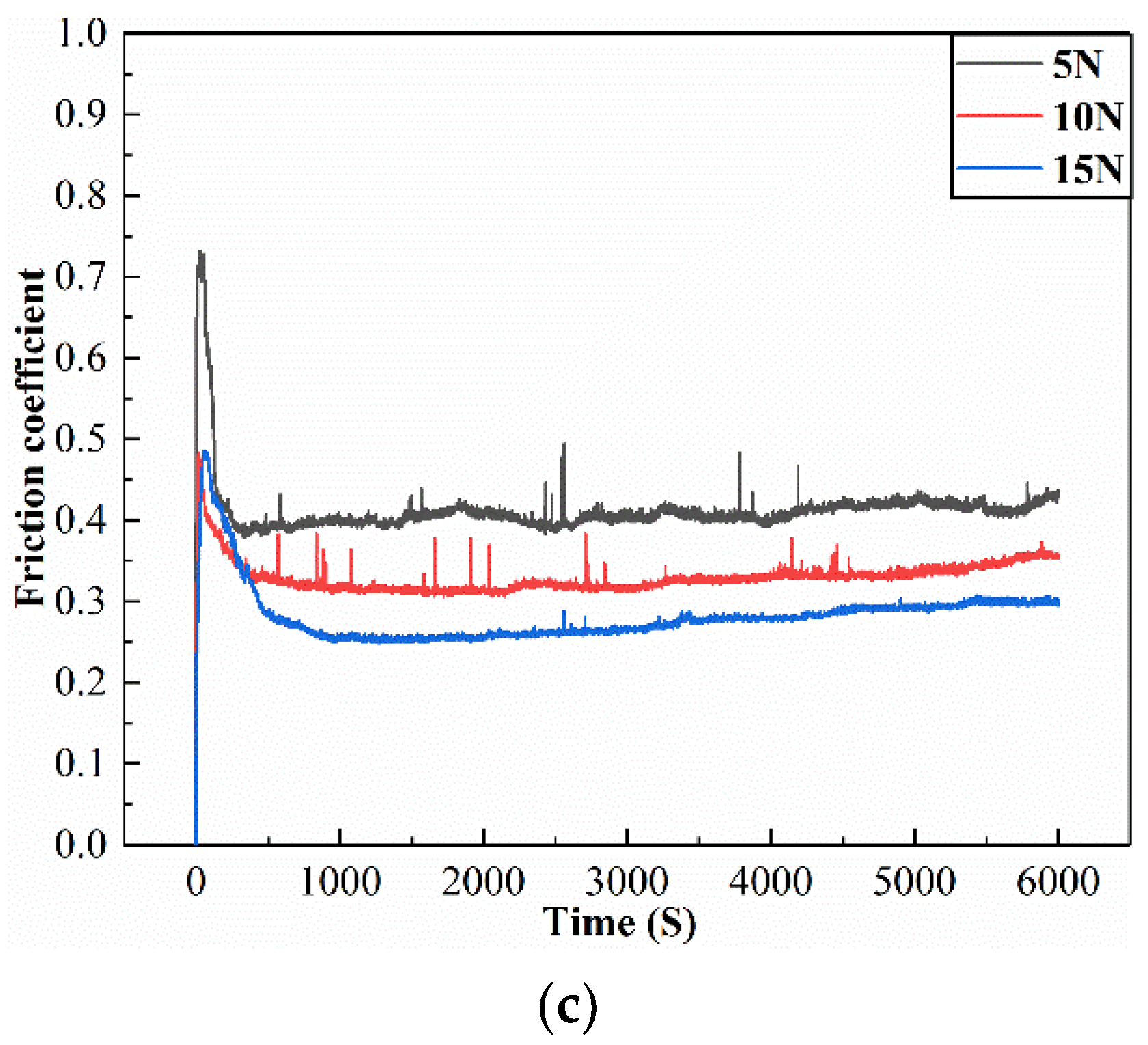

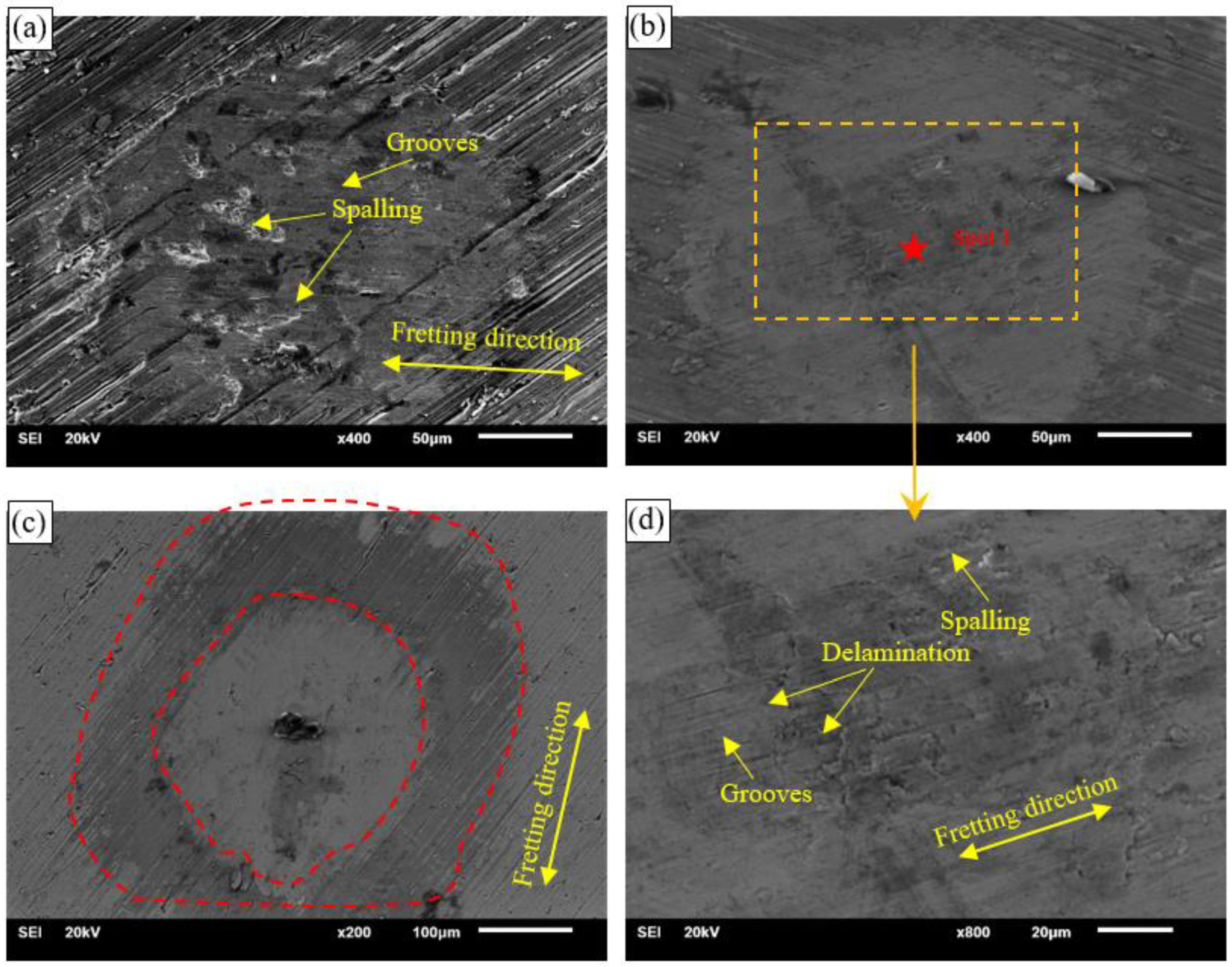

3.3. Analysis of Wear Morphology

3.4. Electrochemical Impedance Spectrum Analysis

3.5. Limitations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.; Haddouti, E.-M.; Welle, K.; Burger, C.; Kabir, K.; Schildberg, F.A. Local Cellular Responses to Metallic and Ceramic Nanoparticles from Orthopedic Joint Arthroplasty Implants. Int. J. Nanomed. 2020, 15, 6705–6720. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, C.T.; Barbosa, C.; Monteiro, M.J.; Abud, I.C.; Caminha, I.M.V.; Roesler, C.R.M. Characterization of the fretting corrosion behavior, surface and debris from head-taper interface of two different modular hip prostheses. J. Mech. Behav. Biomed. Mater. 2016, 62, 71–82. [Google Scholar] [CrossRef] [PubMed]

- McTighe, T.; Brazil, D.; Keppler, L.; Keggi, J.; McPherson, E. Metallic Modular Taper Junctions in Total Hip Arthroplasty. Reconstr. Rev. 2015, 5, 29–42. [Google Scholar] [CrossRef]

- Cooper, H.J.; Urban, R.M.; Wixson, R.L.; Meneghini, R.M.; Jacobs, J.J. Adverse Local Tissue Reaction Arising from Corrosion at the Femoral Neck-Body Junction in a Dual-Taper Stem with a Cobalt-Chromium Modular Neck. J. Bone Jt. Surg. Am. 2013, 95, 865–872. [Google Scholar] [CrossRef] [PubMed]

- Farhoudi, H.; Fallahnezhad, K.; Oskouei, R.H.; Taylor, M. A finite element study on the mechanical response of the head-neck interface of hip implants under realistic forces and moments of daily activities: Part 1, level walking. J. Mech. Behav. Biomed. Mater. 2017, 75, 470–476. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fallahnezhad, K.; Farhoudi, H.; Oskouei, R.H.; Taylor, M. A finite element study on the mechanical response of the head-neck interface of hip implants under realistic forces and moments of daily activities: Part 2. J. Mech. Behav. Biomed. Mater. 2018, 77, 164–170. [Google Scholar] [CrossRef] [Green Version]

- Ponthiaux, P.; Wenger, F.; Drees, D.; Celis, J.P. Electrochemical techniques for studying tribocorrosion processes. Wear 2004, 256, 459–468. [Google Scholar] [CrossRef]

- Ding, H.; Zhou, G.; Dai, Z.; Bu, Y.; Jiang, T. Corrosion wear behaviors of 2024Al in artificial rainwater and seawater at fretting contact. Wear 2009, 267, 292–298. [Google Scholar] [CrossRef]

- Salasi, M.; Stachowiak, G.B.; Stachowiak, G.W. New Experimental Rig to Investigate Abrasive–Corrosive Characteristics of Metals in Aqueous Media. Tribol. Lett. 2010, 40, 71–84. [Google Scholar] [CrossRef]

- Sivakumar, B.; Kumar, S.; Sankara Narayanan, T.S.N. Fretting corrosion behaviour of Ti–6Al–4V alloy in artificial saliva containing varying concentrations of fluoride ions. Wear 2011, 270, 317–324. [Google Scholar] [CrossRef]

- Dyrkacz, R.M.R.; Brandt, J.-M.; Ojo, O.A.; Turgeon, T.R.; Wyss, U.P. The Influence of Head Size on Corrosion and Fretting Behaviour at the Head-Neck Interface of Artificial Hip Joints. J. Arthroplast. 2013, 28, 1036–1040. [Google Scholar] [CrossRef] [PubMed]

- Panagiotidou, A.; Meswania, J.; Hua, J.; Muirhead-Allwood, S.; Hart, A.; Blunn, G. Enhanced wear and corrosion in modular tapers in total hip replacement is associated with the contact area and surface topography. J. Orthop. Res. 2013, 31, 2032–2039. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kao, Y.Y.J.; Koch, C.N.; Wright, T.M.; Padgett, D.E. Flexural Rigidity, Taper Angle, and Contact Length Affect Fretting of the Femoral Stem Trunnion in Total Hip Arthroplasty. J. Arthroplast. 2016, 31, S254–S258. [Google Scholar] [CrossRef] [PubMed]

- Jauch, S.Y.; Huber, G.; Sellenschloh, K.; Haschke, H.; Baxmann, M.; Grupp, T.M.; Morlock, M.M. Micromotions at the taper interface between stem and neck adapter of a bimodular hip prosthesis during activities of daily living. J. Orthop. Res. 2013, 31, 1165–1171. [Google Scholar] [CrossRef]

- Mann, M.A.; Tanzer, D.; Tanzer, M. Severe metal-induced osteolysis many years after unipolar hip endoprosthesis. Clin. Orthop. Relat. Res. 2013, 471, 2078–2082. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Svensson, O.; Mathiesen, E.B.; Reinholt, F.; Blomgren, G.J.J. Formation of a fulminant soft-tissue pseudotumor after uncemented hip arthroplasty. A case report. JBJS 1988, 70, 1238–1242. [Google Scholar] [CrossRef]

- Collier, J.P.; Surprenant, V.A.; Jensen, R.E.; Mayor, M.B.; Surprenant, H.P. Corrosion between the components of modular femoral hip prostheses. J. Bone Jt. Surg. Br. 1992, 74, 511–517. [Google Scholar] [CrossRef] [Green Version]

- Geringer, J.; Fridrici, V.; Ding, H.; Kim, K.; Taylor, T.; Semetse, L.; Ehsani-Majd, S.; Olubambi, P.; Fontaine, J.; Kapsa, P. Some Hard or Soft Coatings to Protect the Pristine Biometallic Substrates under Fretting-Corrosion Solicitations: What Should Be the Best Solution? Lubricants 2020, 8, 55. [Google Scholar] [CrossRef]

- Rasool, G.; El Shafei, Y.; Stack, M.M. Mapping Tribo-Corrosion Behaviour of TI-6AL-4V Eli in Laboratory Simulated Hip Joint Environments. Lubricants 2020, 8, 69. [Google Scholar] [CrossRef]

- Sadiq, K.; Sim, M.A.; Black, R.A.; Stack, M.M. Mapping the Micro-Abrasion Mechanisms of CoCrMo: Some Thoughts on Varying Ceramic Counterface Diameter on Transition Boundaries In Vitro. Lubricants 2020, 8, 71. [Google Scholar] [CrossRef]

- Brayda-Bruno, M.; Fini, M.; Pierini, G.; Giavaresi, G.; Rocca, M.; Giardino, R. Evaluation of Systemic Metal Diffusion after Spinal Pedicular Fixation with Titanium Alloy and Stainless Steel System: A 36-month Experimental Study in Sheep. Int. J. Artif. Organs 2018, 24, 41–49. [Google Scholar] [CrossRef]

- Kumar, S.; Sivakumar, B.; Sankara Narayanan, T.S.N.; Ganesh Sundara Raman, S.; Seshadri, S.K. Fretting-corrosion mapping of CP-Ti in Ringer’s solution. Wear 2010, 268, 1537–1541. [Google Scholar] [CrossRef]

- Eckert, J.A.; Mueller, U.; Jaeger, S.; Panzram, B.; Kretzer, J.P. Fretting and Corrosion in Modular Shoulder Arthroplasty: A Retrieval Analysis. BioMed Res. Int. 2016, 2016, 1695906. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Teeter, M.G.; Carroll, M.J.; Walch, G.; Athwal, G.S. Tribocorrosion in shoulder arthroplasty humeral component retrievals. J. Shoulder Elb. Surg. 2016, 25, 311–315. [Google Scholar] [CrossRef] [PubMed]

- Lukina, E.; Kollerov, M.; Meswania, J.; Khon, A.; Panin, P.; Blunn, G.W. Fretting corrosion behavior of nitinol spinal rods in conjunction with titanium pedicle screws. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 72, 601–610. [Google Scholar] [CrossRef]

- Mali, S.A.; Singh, V.; Gilbert, J.L. Effect of mixed alloy combinations on fretting corrosion performance of spinal screw and rod implants. J. Biomed. Mater. Res. B Appl. Biomater. 2017, 105, 1169–1177. [Google Scholar] [CrossRef]

- Kang, Y.-K.; Kim, M.-H.; Kim, J.-W.; Tien, T.N.; Lim, D.-H.; Chun, H.-J. Analysis on Wear Phenomenon of Artificial Knee Joint Based on FEM and Mechanical Test. Int. J. Precis. Eng. Manuf. 2018, 19, 1211–1217. [Google Scholar] [CrossRef]

- Swaminathan, V.; Gilbert, J.L. Fretting corrosion of CoCrMo and Ti6Al4V interfaces. Biomaterials 2012, 33, 5487–5503. [Google Scholar] [CrossRef]

- Royhman, D.; Patel, M.; Runa, M.J.; Jacobs, J.J.; Hallab, N.J.; Wimmer, M.A.; Mathew, M.T. Fretting-corrosion in hip implant modular junctions: New experimental set-up and initial outcome. Tribol. Int. 2015, 91, 235–245. [Google Scholar] [CrossRef] [Green Version]

- Barril, S.; Debaud, N.; Mischler, S.; Landolt, D. A tribo-electrochemical apparatus for in vitro investigation of fretting–corrosion of metallic implant materials. Wear 2002, 252, 744–754. [Google Scholar] [CrossRef]

- Barril, S.; Mischler, S.; Landolt, D. Influence of fretting regimes on the tribocorrosion behaviour of Ti6Al4V in 0.9wt.% sodium chloride solution. Wear 2004, 256, 963–972. [Google Scholar] [CrossRef]

- Royhman, D.; Patel, M.; Runa, M.J.; Wimmer, M.A.; Jacobs, J.J.; Hallab, N.J.; Mathew, M.T. Fretting-corrosion behavior in hip implant modular junctions: The influence of friction energy and pH variation. J. Mech. Behav. Biomed. Mater. 2016, 62, 570–587. [Google Scholar] [CrossRef]

- Royhman, D.; Patel, M.; Jacobs, J.J.; Wimmer, M.A.; Hallab, N.J.; Mathew, M.T. In vitro simulation of fretting-corrosion in hip implant modular junctions: The influence of pH. Med. Eng. Phys. 2018, 52, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.P.; Gilbert, J.L. The effect of simulated inflammatory conditions and pH on fretting corrosion of CoCrMo alloy surfaces. Wear 2017, 390–391, 302–311. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, D.; Hu, N.; Zhang, J. Effect of angular displacement amplitude on the torsional fretting corrosion behavior of CoCrMo alloy in different synovial fluid. RSC Adv. 2016, 6, 66087–66097. [Google Scholar] [CrossRef]

- Wang, S. Torsional Fretting Corrosion Behaviors of the CoCrMo/Ti6Al4V Couple. Int. J. Electrochem. Sci. 2018, 6414–6425. [Google Scholar] [CrossRef]

- Lin, X.-Z.; Zhu, M.-H.; Cai, Z.-B.; Dou, B.-J.; Cui, X.-J. Torsional fretting corrosion behaviours of Ti6Al4V alloys in Hank’s simulated body fluid. Corros. Eng. Sci. Technol. 2019, 54, 298–309. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Q.; Zhang, D.; Wang, J.; Zhang, X. Torsional Friction Behavior of Contact Interface between PEEK and CoCrMo in Calf Serum. J. Tribol. 2019, 141, 011602. [Google Scholar] [CrossRef]

- Gilbert, J.L.; Buckley, C.A.; Jacobs, J.J. In-Vivo Corrosion of Modular Hip-Prosthesis Components in Mixed and Similar Metal Combinations—The Effect of Crevice, Stress, Motion, and Alloy Coupling. J. Biomed. Mater. Res. 1993, 27, 1533–1544. [Google Scholar] [CrossRef]

- Mathiesen, E.B.; Lindgren, J.U.; Blomgren, G.G.A.; Reinholt, F.P. Corrosion of Modular Hip Prostheses. J. Bone Jt. Surg. Br. 1991, 73, 569–575. [Google Scholar] [CrossRef] [Green Version]

- Fouvry, S.; Liskiewicz, T.; Kapsa, P.; Hannel, S.; Sauger, E. An energy description of wear mechanisms and its applications to oscillating sliding contacts. Wear 2003, 255, 287–298. [Google Scholar] [CrossRef] [Green Version]

- Chaudhry, V.; Kailas, S.V. Fretting studies on self-mated stainless steel and chromium carbide coated surfaces under controlled environment conditions. Wear 2013, 301, 524–539. [Google Scholar] [CrossRef]

| Elements | Al | V | Fe | C | O | N | H | Ti |

|---|---|---|---|---|---|---|---|---|

| Percentage | 6.05 ± 0.63 | 3.95 ± 0.5 | 0.11 | 0.014 | 0.140 | 0.006 | 0.001 | Balance |

| Elements | Cr | Mo | Ni | Fe | Mn | Si | C | N | Co |

|---|---|---|---|---|---|---|---|---|---|

| percentage | 28.10 ± 2.10 | 5.90 ± 1.10 | 0.88 | 0.65 | 0.63 | 0.22 | 0.25 | 0.12 | Balance |

| Elements | Cr | Ni | Mo | Mn | Si | Co | C | Cu | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Percentage | 17.4 ± 1.6 | 13.0 ± 0.7 | 2.6 ± 0.4 | 1.73 ± 0.6 | 0.66 | 0.20 | 0.0165 | 0.097 | <0.001 | Balance |

| Elements | Al2O3 | Na2O | CaO | SiO2 | Magnetic |

|---|---|---|---|---|---|

| Percentage | ≥98.5 | ≤0.5 | ≤0.5 | ≤0.3 | ≤0.003 |

| Materials | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Elastic Modulus (GPa) | Poisson’s Ratio | Hardness (HV) |

|---|---|---|---|---|---|---|

| Al2O3 ceramic | / | / | / | 370 | 0.2 | 1500 |

| 316 L steel | 635 | 280 | 12 | 197 | 0.3 | 150 |

| CoCrMo alloy | 1507 | 962 | 20 | 200 | 0.3 | 320 |

| Ti6Al4V alloy | 860 | 795 | 12 | 110 | 0.3 | 260 |

| Parameter | Values |

|---|---|

| Displacement, D | D = 10 µm |

| Normal load, FN | FN,1 = 5 N; FN,2 = 10 N; FN,3 = 15 N |

| Frequency | 1 Hz |

| Test medium | physiological saline with 10% volume bovine serum (100 mL) |

| Element | O | Al | Si | Cl | Ti | V |

|---|---|---|---|---|---|---|

| Wt.% | 27.31 | 3.72 | 0.53 | 0.19 | 65.91 | 2.34 |

| Element | C | O | Na | Al | Si | Cl | K | Ti | V | Cr | Fe | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 4.14 | 45.4 | 0.65 | 0.19 | 0.59 | 2.7 | 0.34 | 4.52 | 0.3 | 25.11 | 11.32 | 3.66 | 1.07 |

| Element | C | O | Na | Al | Cl | K | Ca | Ti | V | Cr | Co | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 1.62 | 50.62 | 0.60 | 0.71 | 0.96 | 0.41 | 0.16 | 20.14 | 1.13 | 16.95 | 3.53 | 3.18 |

| Rs (Ω·cm−2) | CPE (F·cm−2) | n | Rfilm (Ω) | |

|---|---|---|---|---|

| Al2O3/Ti6Al4V | 47.85 ± 0.51 | 3.895 × 10−5 ± 9.69 × 10−7 | 0.9 | 2.592 × 104 ± 76.36 |

| 316 L/Ti6Al4V | 27.75 ± 0.17 | 2.348 × 10−5 ± 1.69 × 10−6 | 0.8 | 1.504 × 106 ± 1484.92 |

| CoCrMo/Ti6Al4V | 46.78 ± 0.43 | 2.792 × 10−5 ± 1.62 × 10−6 | 0.9 | 1.605 × 105 ± 989.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pu, J.; Wu, D.; Zhang, Y.; Zhang, X.; Jin, Z. An Experimental Study on the Fretting Corrosion Behaviours of Three Material Pairs at Modular Interfaces for Hip Joint Implants. Lubricants 2021, 9, 12. https://doi.org/10.3390/lubricants9020012

Pu J, Wu D, Zhang Y, Zhang X, Jin Z. An Experimental Study on the Fretting Corrosion Behaviours of Three Material Pairs at Modular Interfaces for Hip Joint Implants. Lubricants. 2021; 9(2):12. https://doi.org/10.3390/lubricants9020012

Chicago/Turabian StylePu, Jian, Dongsheng Wu, Yali Zhang, Xiaogang Zhang, and Zhongmin Jin. 2021. "An Experimental Study on the Fretting Corrosion Behaviours of Three Material Pairs at Modular Interfaces for Hip Joint Implants" Lubricants 9, no. 2: 12. https://doi.org/10.3390/lubricants9020012

APA StylePu, J., Wu, D., Zhang, Y., Zhang, X., & Jin, Z. (2021). An Experimental Study on the Fretting Corrosion Behaviours of Three Material Pairs at Modular Interfaces for Hip Joint Implants. Lubricants, 9(2), 12. https://doi.org/10.3390/lubricants9020012