Synthesis and Morphological Characterization of Electroless-Deposited Ni-P Coatings on Diamond Abrasives

Abstract

1. Introduction

2. Materials and Methods

2.1. Pretreatment

2.2. Electroless Deposition

2.3. Morphological Characterizations

3. Results and Discussion

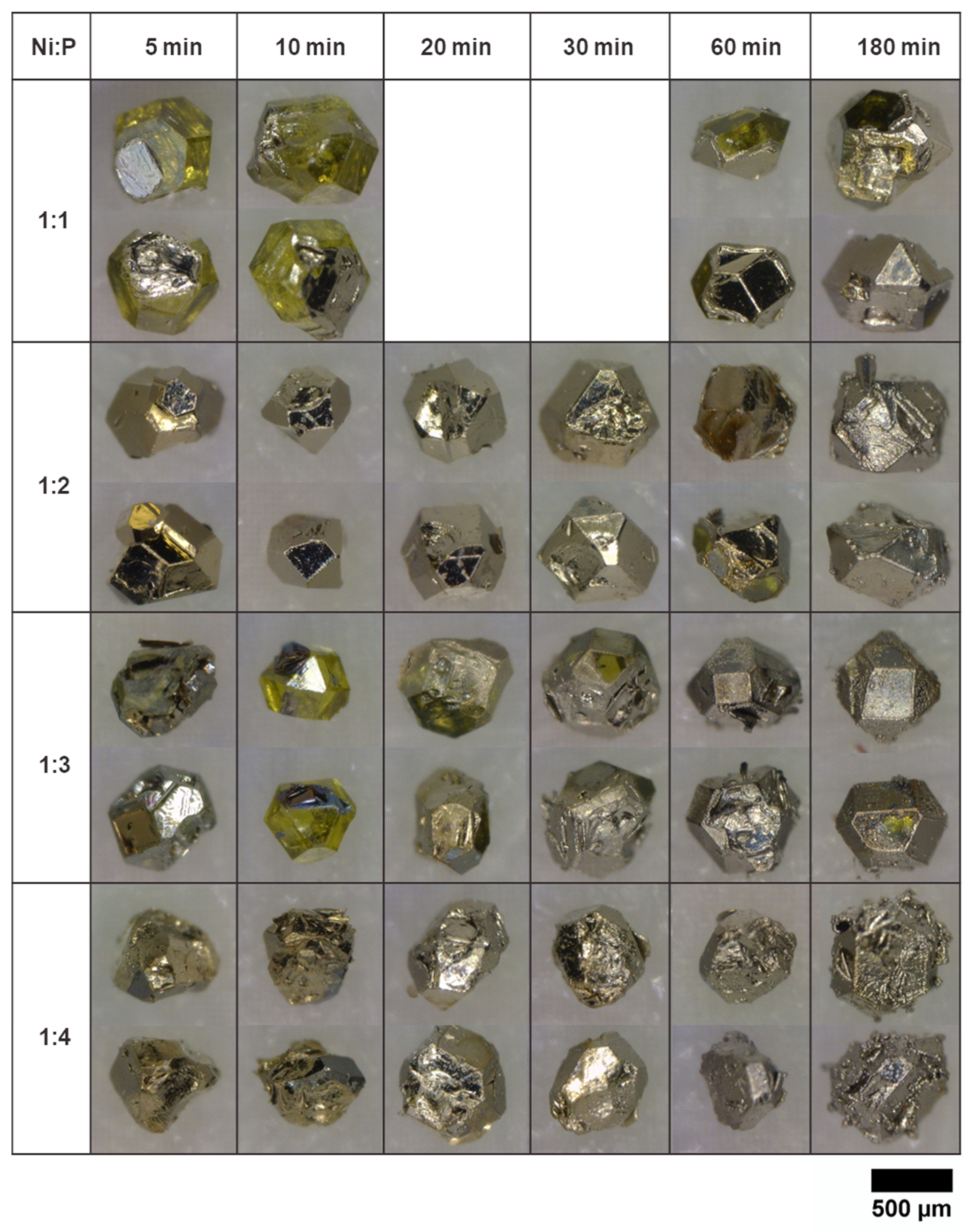

3.1. Coating Coverage Rate

3.1.1. Deposition Time

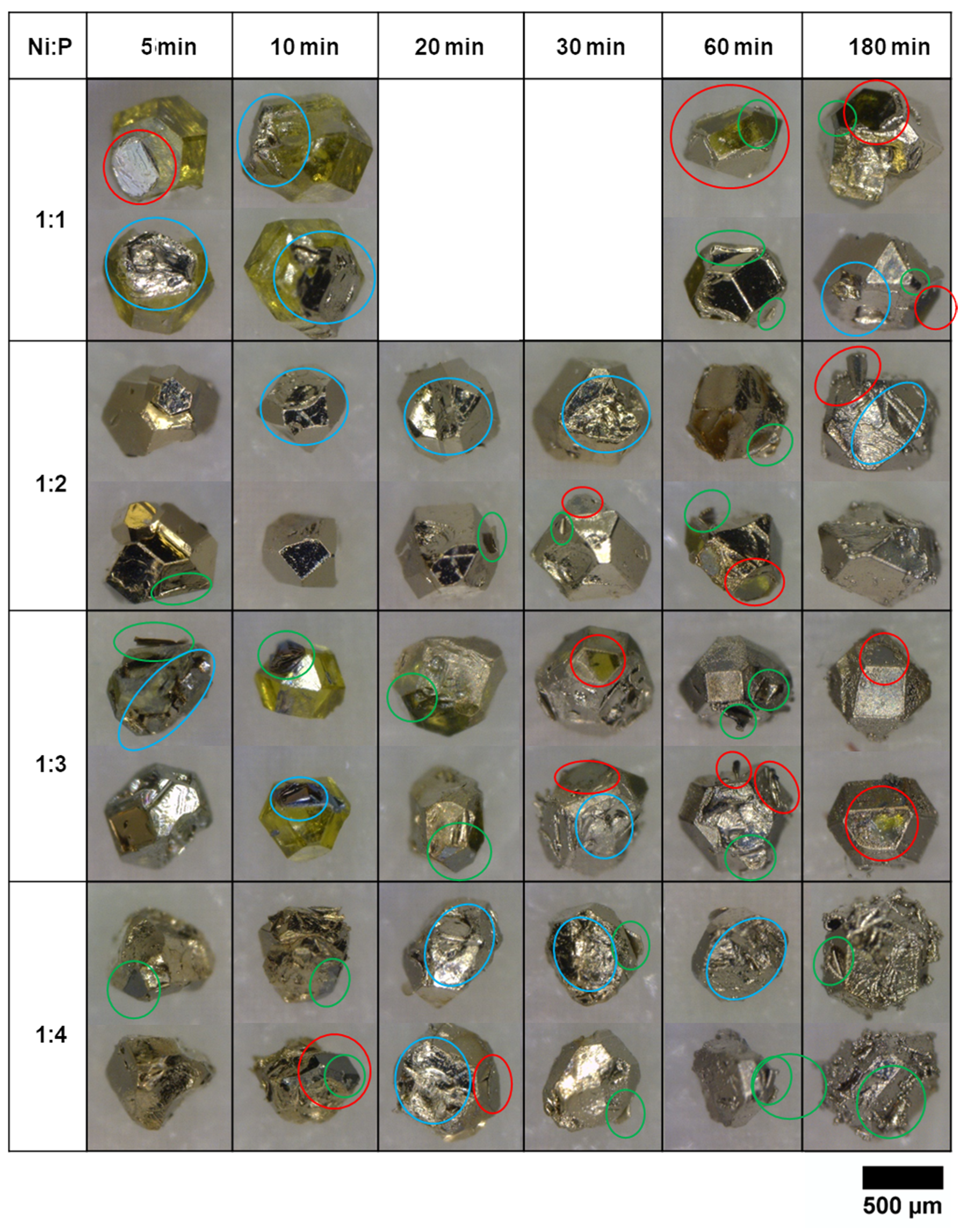

3.1.2. Substrate Morphology

3.1.3. Concentration of Reducing Agent

3.1.4. Processing Factors Affecting Coverage

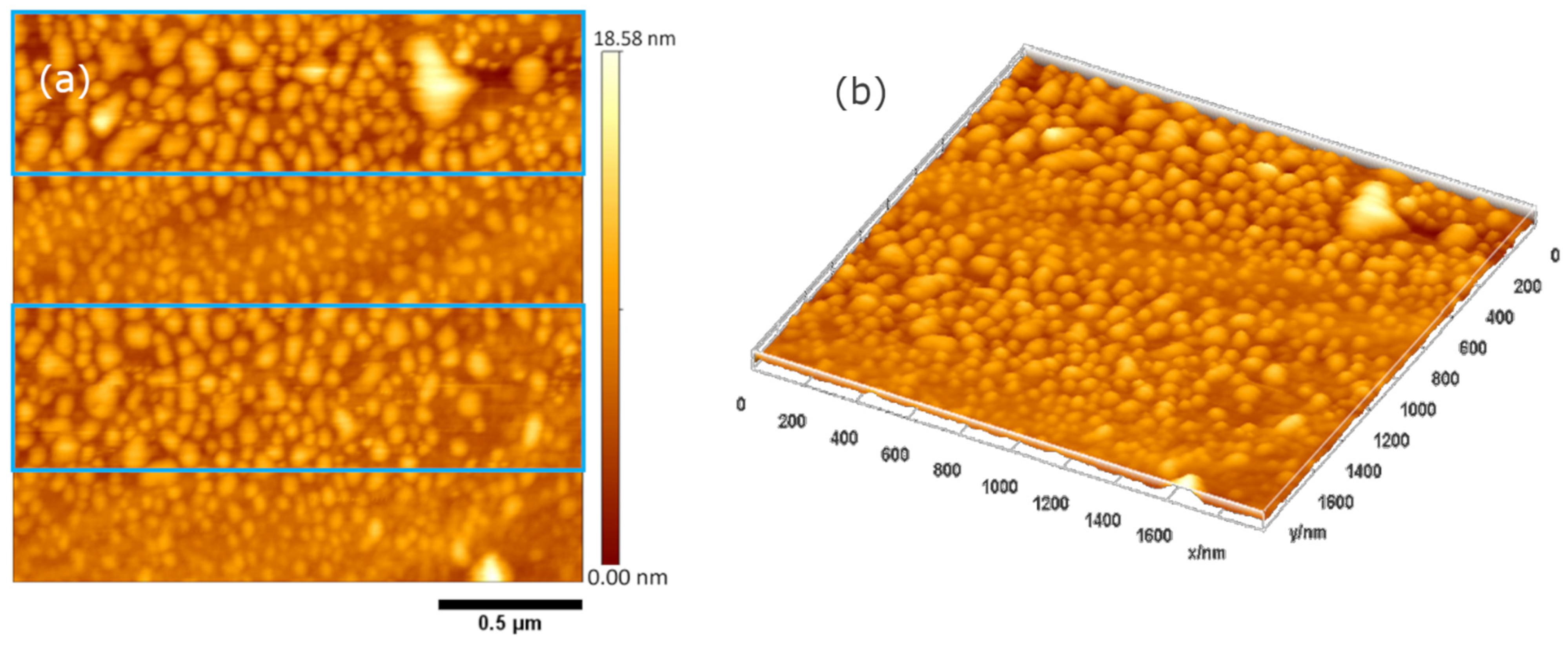

3.2. Coating Morphology

3.2.1. Deposition Parameters

3.2.2. Coating Integrity

3.2.3. Substrate Morphology

3.2.4. Process Parameters Affecting Morphology

3.3. Deposition Kinetics

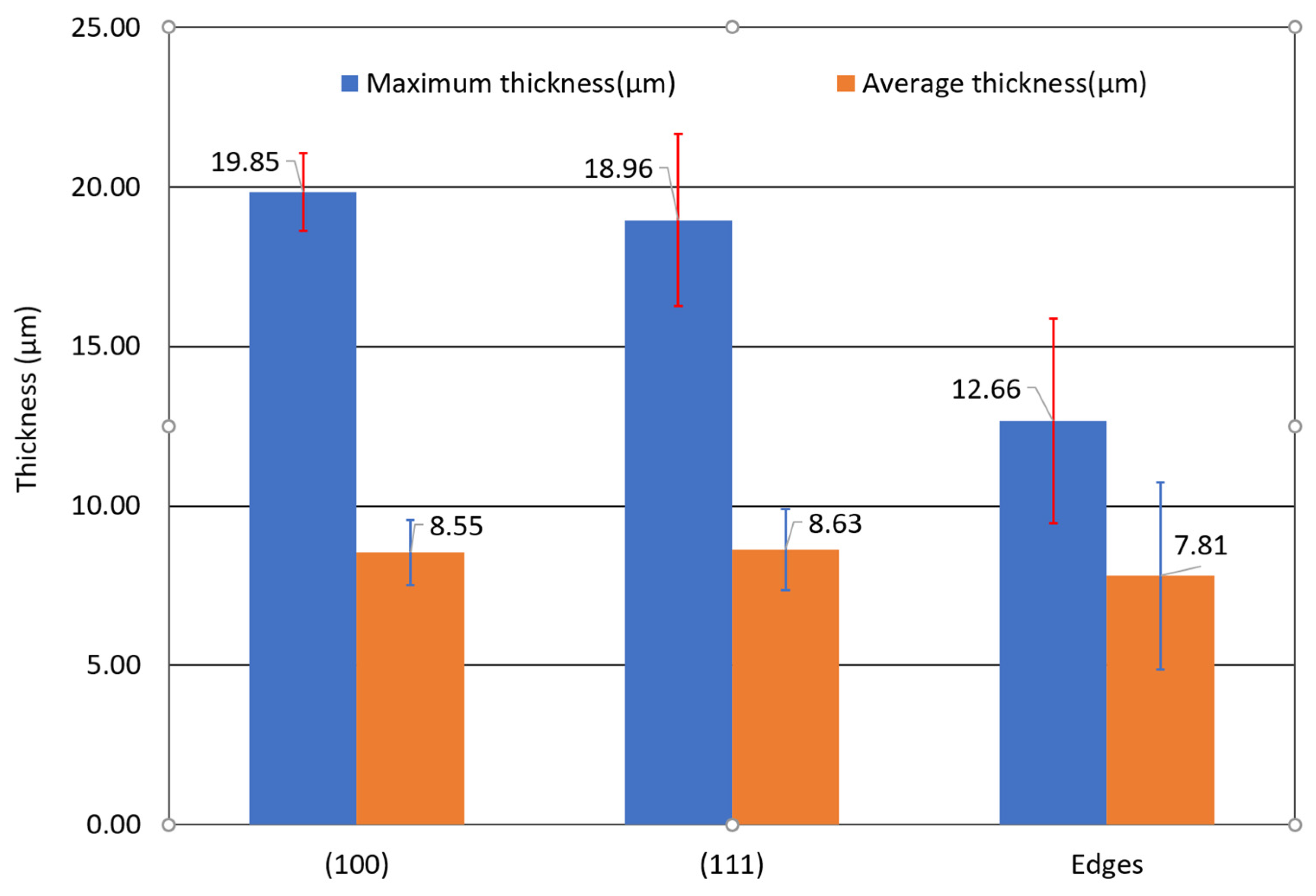

3.3.1. Influence of Crystallographic Orientation

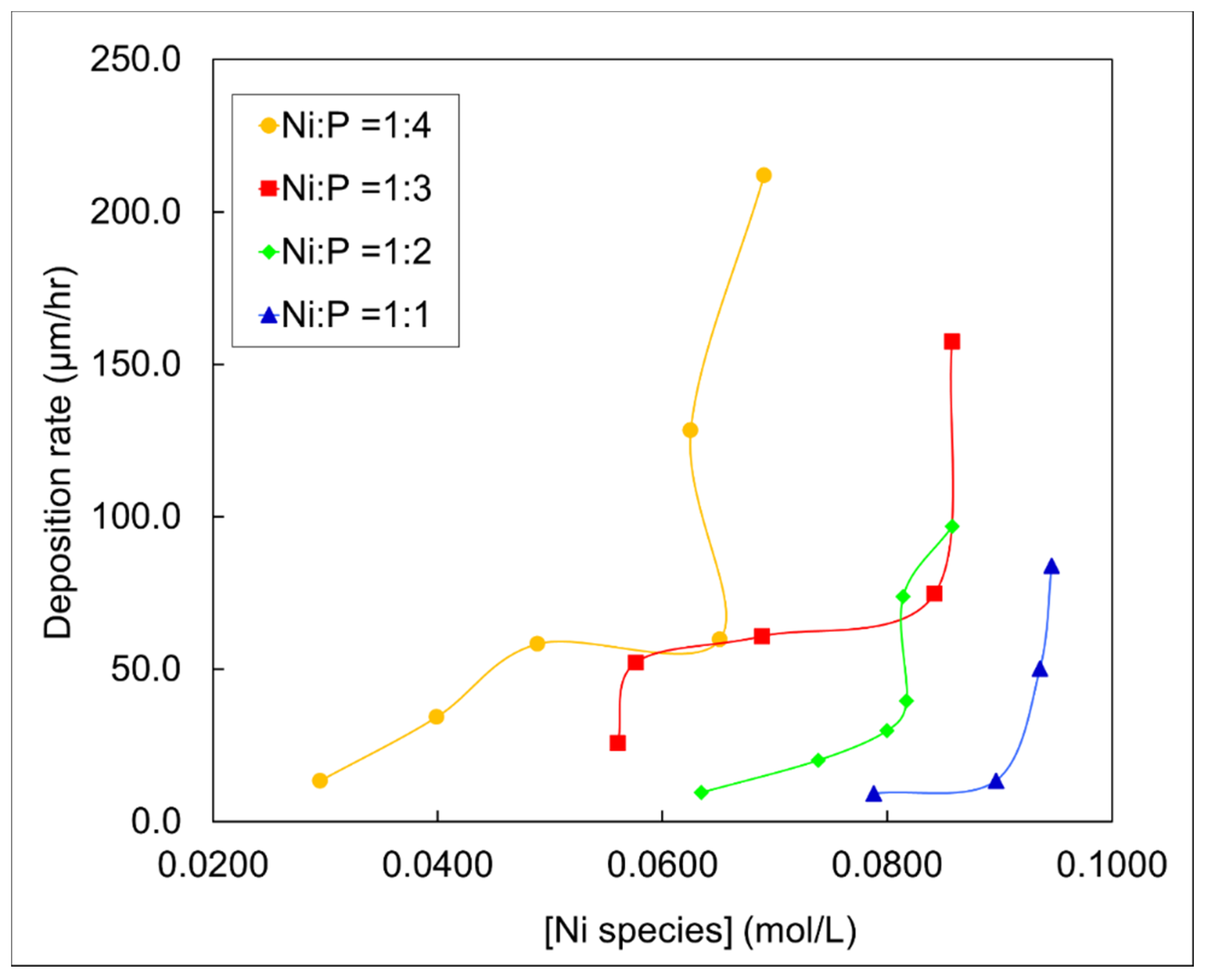

3.3.2. Influence of Reactants’ Concentration

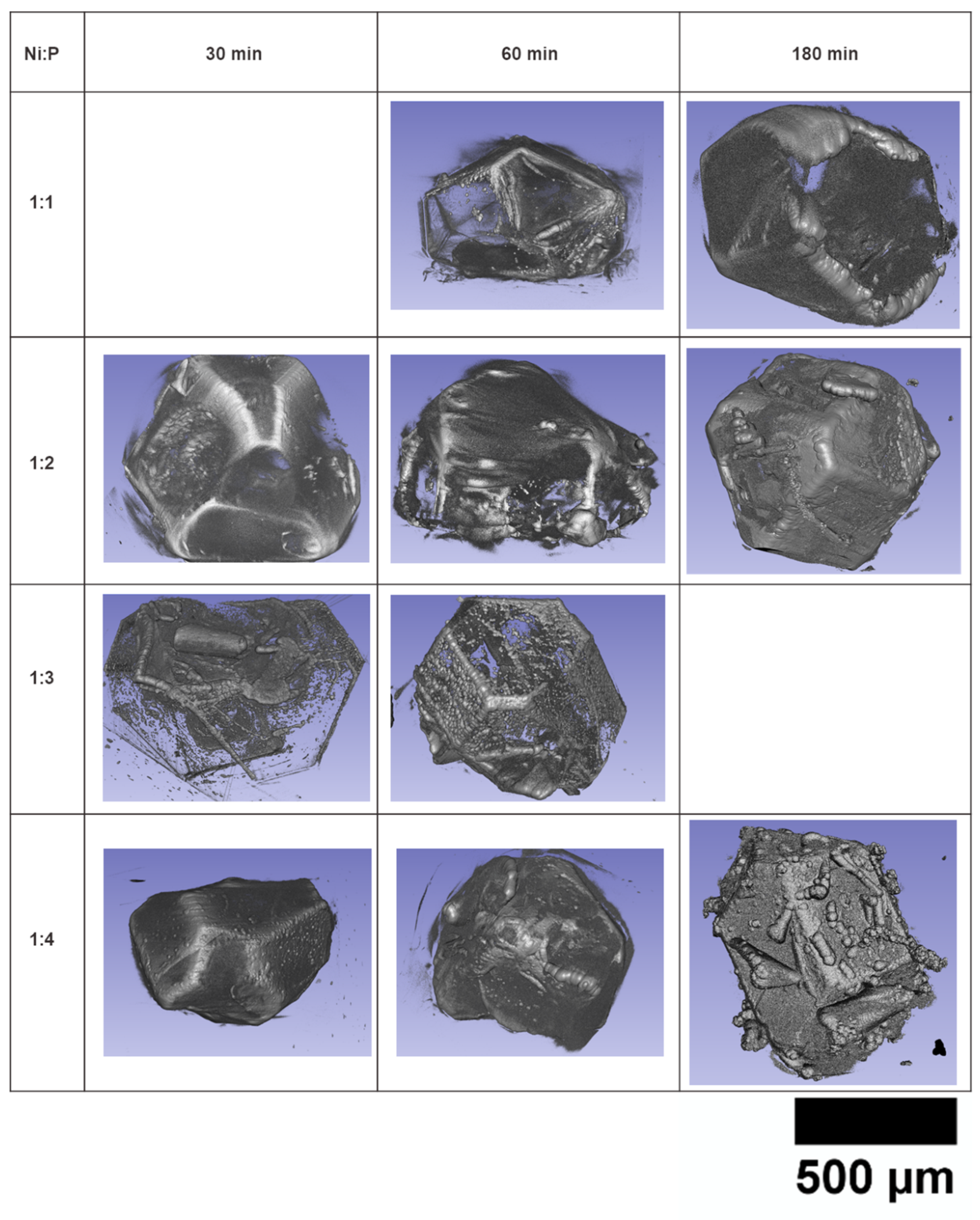

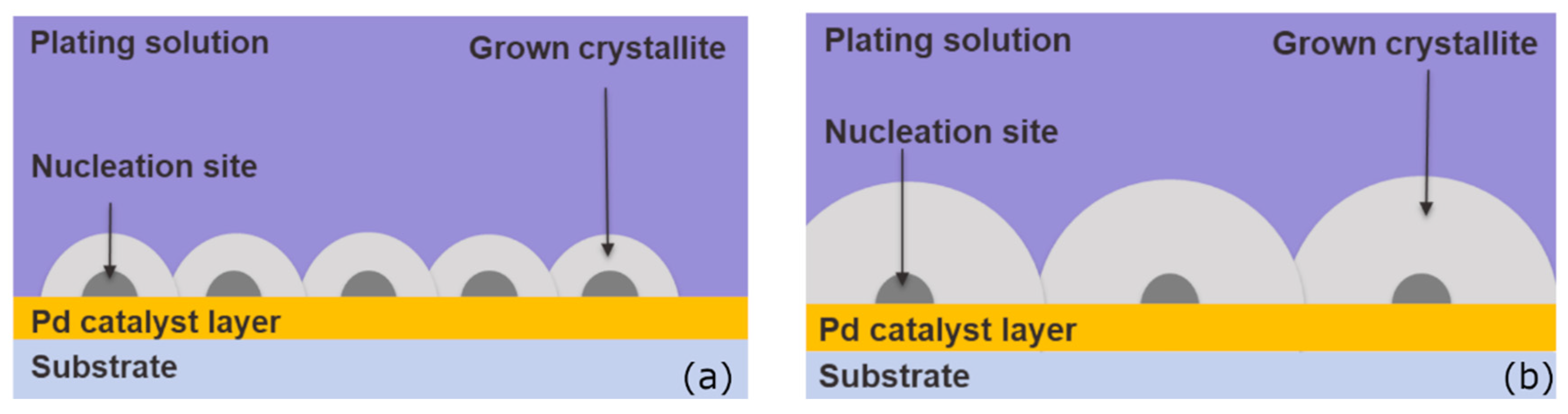

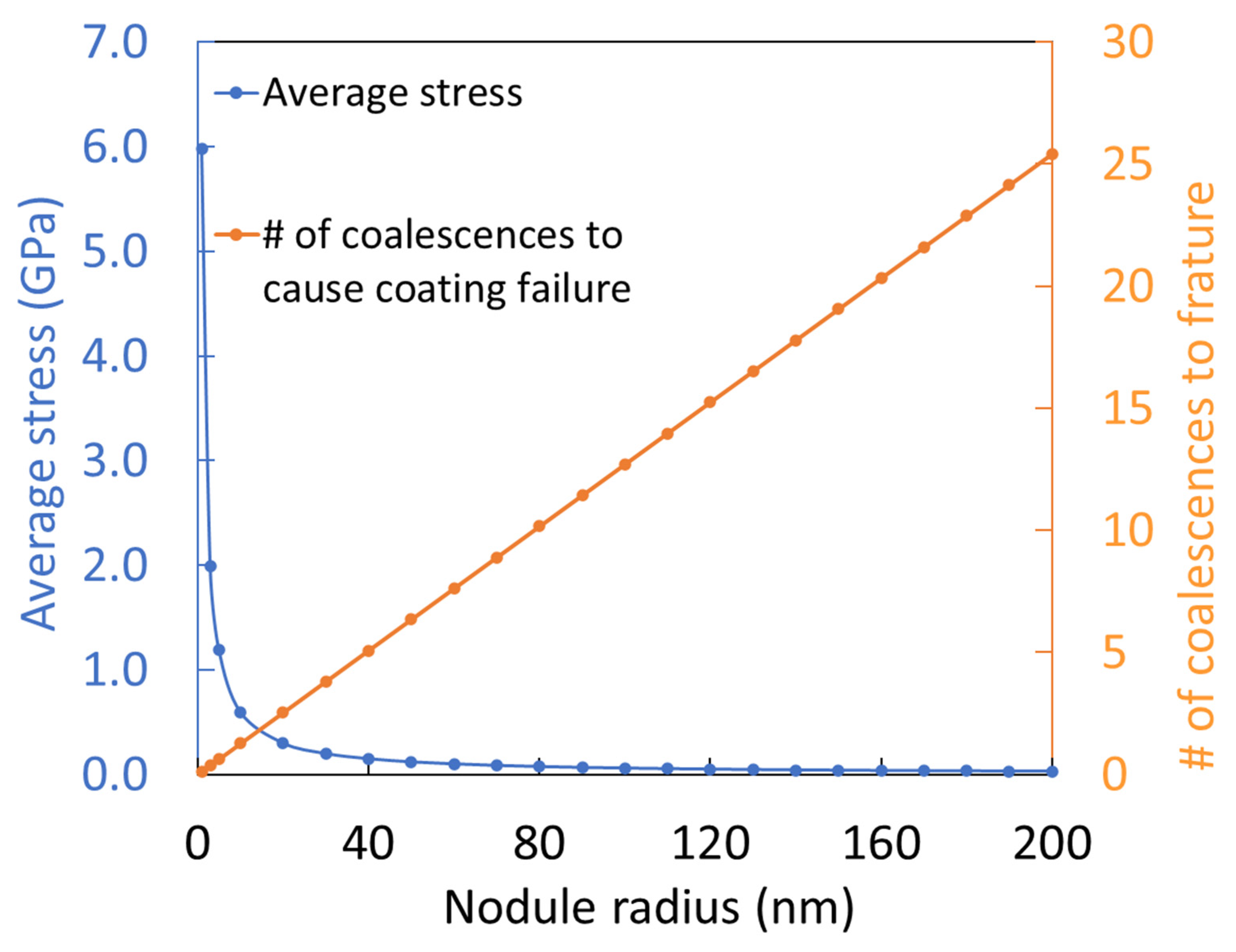

3.4. Physical Model for Coating Failure

3.4.1. Coating Failure Locations

3.4.2. Origins of Residual Stresses

3.4.3. Estimation of the Residual Stress

3.4.4. Coating Failure Mechanisms

4. Conclusions

- The coating coverage rate on diamond particles is affected by the synergistic action of the deposition time, substrate morphology, and reducing agent concentration.

- The two major morphological features of the coating: nodular and smooth, are influenced by the deposition parameters, coating integrity, and substrate morphology.

- The deposition rate was found to be dependent on the concentrations of the reactants.

- The morphological features of the substrate, which affect the coating failures tendencies, were recognized. Flat smooth surface and corner areas promote the coating failure, while rough surfaces retain the coating.

- The coating’s fracture is caused by the residual stress developed during the deposition process.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brenner, A.R.G. Nickel Plating by Chemical Reduction. U.S. Patent US2532283A, 5 December 1950. [Google Scholar]

- Shacham-Diamand, Y.Y. Electroless copper deposition using glyoxylic acid as reducing agent for ultralarge scale integration metallization. Electrochem. Solid State Lett. 2000, 3, 279–282. [Google Scholar] [CrossRef]

- Yoshino, M.; Nonaka, Y.; Sasano, J.; Matsuda, I.; Shacham-Diamand, Y.; Osaka, T. All-wet fabrication process for ULSI interconnect technologies. Electrochim. Acta 2005, 51, 916–920. [Google Scholar] [CrossRef]

- Vossen, J.L.; Schnable, G.L.; Kern, W. Processes for multilevel metallization. J. Vac. Sci. Technol. 1974, 11, 60–70. [Google Scholar] [CrossRef]

- Sricharoenchaikit, P.; Calabrese, G.S.; Gulla, M. Controlled Electroless Plating. US Patent US5203911A, 20 April 1993. [Google Scholar]

- Aal, A.A.; Shaaban, A.; Hamid, Z.A. Nanocrystalline soft ferromagnetic Ni–Co–P thin film on Al alloy by low temperature electroless deposition. Appl. Surf. Sci. 2008, 254, 1966–1971. [Google Scholar] [CrossRef]

- Balaraju, J.N.; Selvi, V.E.; Grips, V.K.W.; Rajam, K.S. Electrochemical studies on electroless ternary and quaternary Ni–P based alloys. Electrochim. Acta 2006, 52, 1064–1074. [Google Scholar] [CrossRef]

- Georgieva, J.; Armyanov, S. Electroless deposition and some properties of Ni–Cu–P and Ni–Sn–P coatings. J. Solid State Electr. 2007, 11, 869–876. [Google Scholar] [CrossRef]

- Shashikala, A.R.; Mayanna, S.M.; Sharma, A.K. Studies and characterisation of electroless Ni–Cr–P alloy coating. Trans. IMF 2013, 85, 320–324. [Google Scholar] [CrossRef]

- Fukumuro, N.; Nishiyama, J.; Shigeta, K.; Takagami, H.; Yae, S.; Matsuda, H. Confirmation of hydroxide in electroless cobalt alloy films by GDOES. Trans. IMF 2013, 85, 111–112. [Google Scholar] [CrossRef]

- Nwosu, N.O.; Davidson, A.M.; Hindle, C.S. Effect of Sodium Dodecyl Sulphate on the Composition of Electroless Nickel—Yttria Stabilized Zirconia Coatings. Adv. Chem. Eng. Sci. 2011, 1, 118–124. [Google Scholar] [CrossRef]

- Fayyad, E.; Abdullah, A.; Hassan, M.; Mohamed, A.; Wang, C.; Jarjoura, G.; Farhat, Z. Synthesis, Characterization, and Application of Novel Ni-P-Carbon Nitride Nanocomposites. Coatings 2018, 8, 37. [Google Scholar] [CrossRef]

- Winowlin Jappes, J.T.; Ramamoorthy, B.; Kesavan Nair, P. Novel approaches on the study of wear performance of electroless Ni–P/diamond composite deposites. J. Mater. Process. Tech. 2009, 209, 1004–1010. [Google Scholar] [CrossRef]

- Alexis, J.; Gaussens, C.; Etcheverry, B.; Bonino, J.-P. Development of nickel–phosphorus coatings containing micro particles of talc phyllosilicates. Mater. Chem. Phys. 2013, 137, 723–733. [Google Scholar] [CrossRef][Green Version]

- Balaraju, J.N.; Kalavati; Rajam, K.S. Influence of particle size on the microstructure, hardness and corrosion resistance of electroless Ni–P–Al2O3 composite coatings. Surf. Coat. Technol. 2006, 200, 3933–3941. [Google Scholar] [CrossRef]

- Mafi, I.R.; Dehghanian, C. Comparison of the coating properties and corrosion rates in electroless Ni–P/PTFE composites prepared by different types of surfactants. Appl. Surf. Sci. 2011, 257, 8653–8658. [Google Scholar] [CrossRef]

- Huang, Y.S.; Zeng, X.T.; Annergren, I.; Liu, F.M. Development of electroless NiP–PTFE–SiC composite coating. Surf. Coat. Technol. 2003, 167, 207–211. [Google Scholar] [CrossRef]

- Ankita, S.; Singh, A.K. Corrosion and wear resistance study of Ni-P and Ni-P-PTFE nanocomposite coatings. Cent. Eur. J. Eng. 2011, 1, 234–243. [Google Scholar] [CrossRef]

- Okumiya, M.; Tsunekawa, Y.; Saida, T.; Ichino, R. Creation of high strength bonded abrasive wheel with ultrasonic aided composite plating. Surf. Coat. Technol. 2003, 169–170, 112–115. [Google Scholar] [CrossRef]

- Dong, Y.-H.; He, X.-B.; Ud-Din, R.; Guo, C.-Y.; Xu, L.; Huang, Y.-T.; Qu, X.-H. Fabrication and thermal stability of Ni-P coated diamond powder using electroless plating. Int. J. Miner. Metall. Mater. 2011, 18, 479. [Google Scholar] [CrossRef]

- Petrova, M.; Noncheva, Z.; Dobreva, E. Electroless deposition of diamond powder dispersed nickel—Phosphorus coatings on steel substrate. Trans. IMF 2013, 89, 89–94. [Google Scholar] [CrossRef]

- Ma, L.; He, X.; Fang, A.; Liang, H. Electrochemical Characterization of a Nickel-Phosphorus Coating on Diamond Grits. Mater. Perform. Charact. 2018, 7, 266–280. [Google Scholar] [CrossRef]

- Loto, C.A. Electroless Nickel Plating—A Review. Silicon 2016, 8, 177–186. [Google Scholar] [CrossRef]

- Lambert, R.M.; Pacchioni, G.; North Atlantic Treaty Organization, Scientific Affairs Division. Chemisorption and Reactivity on Supported Clusters and Thin Films: Towards an Understanding of Microscopic Processes in Catalysis; Kluwer Academic Publishers: Dordrecht, The Netherlands; Boston, MA, USA, 1997. [Google Scholar]

- Pietsch, P.; Wood, V. X-ray tomography for lithium ion battery research: A practical guide. Annu. Rev. Mater. Res. 2017, 47, 451–479. [Google Scholar] [CrossRef]

- Beamline 8.3.2 Manual. Available online: http://microct.lbl.gov/manual (accessed on 13 February 2021).

- de Oliveira, M.C.L.; Correa, O.V.; da Silva, R.M.P.; de Lima, N.B.; de Oliveira, J.T.D.; de Oliveira, L.A.; Antunes, R.A. Structural, Adhesion and Electrochemical Characterization of Electroless Plated Ni-P-Carbon Black Composite Films on API 5L X80 Steel. J. Mater. Eng. Perform. 2019, 28, 4751–4761. [Google Scholar] [CrossRef]

- Parkinson, R. Properties and Applications of Electroless Nickel; Technical Series No. 10081; Nickel Development Institute: Toronto, ON, Canada, 1997; pp. 5–6. Available online: https://nickelinstitute.org/media/1769/propertiesandapplicationsofelectrolessnickel_10081_.pdf (accessed on 13 February 2021).

- Uchiyama, H.; Endo, T.; Sone, M. Direct Observation of Nodule Growth on Electroless Ni-P Deposition in Supercritical CO2 Emulsion. J. Electrochem. Soc. 2012, 159, D114–D118. [Google Scholar] [CrossRef]

- Hadipour, A.; Monirvaghefi, S.M.; Bahrololoom, M.E. Electroless deposition of graded Ni-P coatings. Surf. Eng. 2015, 31, 399–405. [Google Scholar] [CrossRef]

- Zhong, L.L.; Liu, C.C.; Mawla, S.A.; John, J.D.S.; Petrehn, J.L. Nodule-Free Electroless Nip Plating. US Patent US6685990B1, 3 February 2004. [Google Scholar]

- Son, K.S.; Lee, J.H.; Choi, Y.J.; Jung, U.C.; Chung, W.S. Effect of Intermediate Layer Coated Diamond Particles on Performance of Diamond Tool. J. Korean Inst. Surf. Eng. 2013, 46, 216–222. [Google Scholar] [CrossRef]

- Webster, J.; Tricard, M. Innovations in Abrasive Products for Precision Grinding. CIRP Ann. Manuf. Technol. 2004, 53, 597–617. [Google Scholar] [CrossRef]

- Xi, X.; Miao, H.; Zhang, R.; Cheng, J. Effect of phosphorus content on the properties of Ni-P coated diamond. Surf. Coat. Technol. 2016, 297, 27–33. [Google Scholar] [CrossRef]

- Ahn, J.G.; Kim, D.J.; Lee, J.R.; Chung, H.S.; Kim, C.O.; Hai, H.T. Improving the adhesion of electroless-nickel coating layer on diamond powder. Surf. Coat. Technol. 2006, 201, 3793–3796. [Google Scholar] [CrossRef]

- Marton, J.; Schlesinger, M. The Nucleation, Growth, and Structure of Thin Ni-P Films. J. Electrochem. Soc. 1968, 115, 16–21. [Google Scholar] [CrossRef]

- Baldwin, C.; Such, T.E. The Plating Rates and Physical Properties of Electroless Nickel/Phosphorus Alloy Deposits. Trans. IMF 1968, 46, 73–80. [Google Scholar] [CrossRef]

- Mallory, G.O.; Hajdu, J.B. Electroless Plating: Fundamentals and Applications; ASCE: Reston, VA, USA, 1990. [Google Scholar]

- Schmetterer, C.; Vizdal, J.; Ipser, H. A new investigation of the system Ni–P. Intermetallics 2009, 17, 826–834. [Google Scholar] [CrossRef]

- Vlassak, J. Thin Film Mechanics. 2004. Available online: https://www.mrsec.harvard.edu/education/ap298r2004/Vlassak%20AP298presentation.pdf (accessed on 13 February 2021).

- Freund, L.; Chason, E. Model for stress generated upon contact of neighboring islands on the surface of a substrate. J. Appl. Phys. 2001, 89, 4866–4873. [Google Scholar] [CrossRef]

- Clark, E.; Yeske, R.; Birnbaum, H. The effect of hydrogen on the surface energy of nickel. Metall. Trans. A 1980, 11, 1903–1908. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Vijayaraghavan, L. Investigation of the surface properties of heat treated electroless Ni–P coating. Trans. IMF 2016, 94, 265–273. [Google Scholar] [CrossRef]

- Krishnan, K.H.; John, S.; Srinivasan, K.N.; Praveen, J.; Ganesan, M.; Kavimani, P.M. An overall aspect of electroless Ni-P depositions—A review article. Metall. Mater. Trans. A 2006, 37, 1917–1926. [Google Scholar] [CrossRef]

- Taheri, R. Evaluation of Electroless Nickel-Phosphorus (EN) Coatings. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2002. [Google Scholar]

- Panagopoulos, C.; Papachristos, V.; Sigalas, C. Tensile behaviour of as deposited and heat-treated electroless Ni-P deposits. J. Mater. Sci. 1999, 34, 2587–2600. [Google Scholar] [CrossRef]

| Treatment | Chemicals | Concentration | Immersion Time (min) |

|---|---|---|---|

| Sensitization | SnCl2∙2H2O | 20 g/L | 2 |

| HCl | 40 mL/L | ||

| Activation | PdCl2 | 0.5 g/L | 1 |

| HCl | 10 mL/L |

| Chemicals | Concentration (mol/L) |

|---|---|

| Nickel Sulfate hexahydrate, NiSO4∙6H2O | 0.1 |

| Sodium hypophosphite monohydrate, NaH2PO2∙H2O | 0.1, 0.2, 0.3, 0.4 |

| Trisodium citrate dihydrate, C6H5Na3O7∙2H2O | 0.1 |

| Ammonium sulfate, (NH4)2SO4 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Chen, Y.; Renner, P.; Parkinson, D.; Fang, A.; Liang, H. Synthesis and Morphological Characterization of Electroless-Deposited Ni-P Coatings on Diamond Abrasives. Lubricants 2021, 9, 20. https://doi.org/10.3390/lubricants9020020

Ma L, Chen Y, Renner P, Parkinson D, Fang A, Liang H. Synthesis and Morphological Characterization of Electroless-Deposited Ni-P Coatings on Diamond Abrasives. Lubricants. 2021; 9(2):20. https://doi.org/10.3390/lubricants9020020

Chicago/Turabian StyleMa, Lian, Yan Chen, Peter Renner, Dilworth Parkinson, Alex Fang, and Hong Liang. 2021. "Synthesis and Morphological Characterization of Electroless-Deposited Ni-P Coatings on Diamond Abrasives" Lubricants 9, no. 2: 20. https://doi.org/10.3390/lubricants9020020

APA StyleMa, L., Chen, Y., Renner, P., Parkinson, D., Fang, A., & Liang, H. (2021). Synthesis and Morphological Characterization of Electroless-Deposited Ni-P Coatings on Diamond Abrasives. Lubricants, 9(2), 20. https://doi.org/10.3390/lubricants9020020