Laser Beam Welding of Feconicrmn High-Entropy Alloys with Preplaced Powders

Abstract

:1. Introduction

2. Experiments

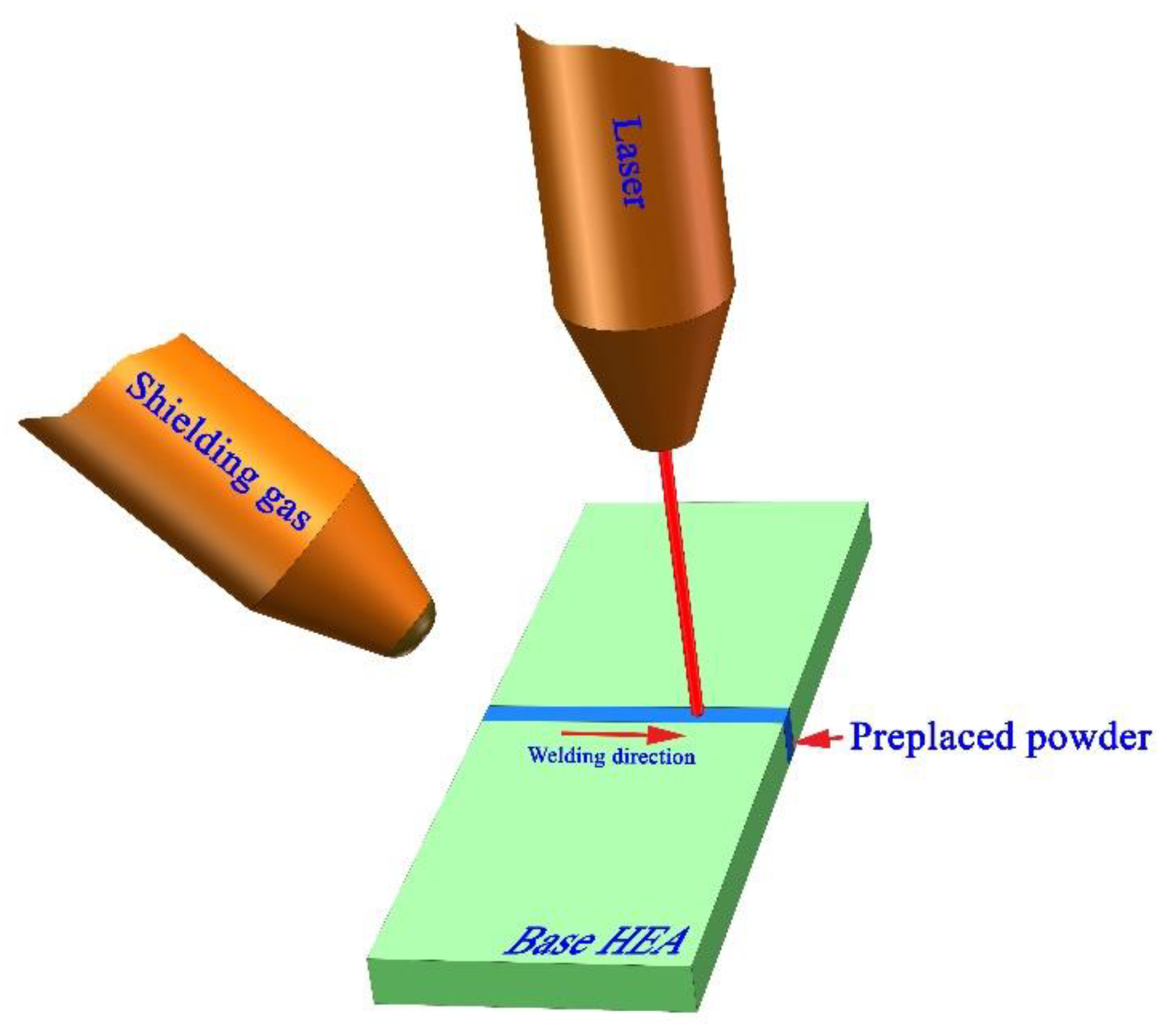

2.1. Preparation of Materials and Laser Welding

2.2. Characterization and Tensile Tests

3. Results and Discussion

4. Conclusions

- (1)

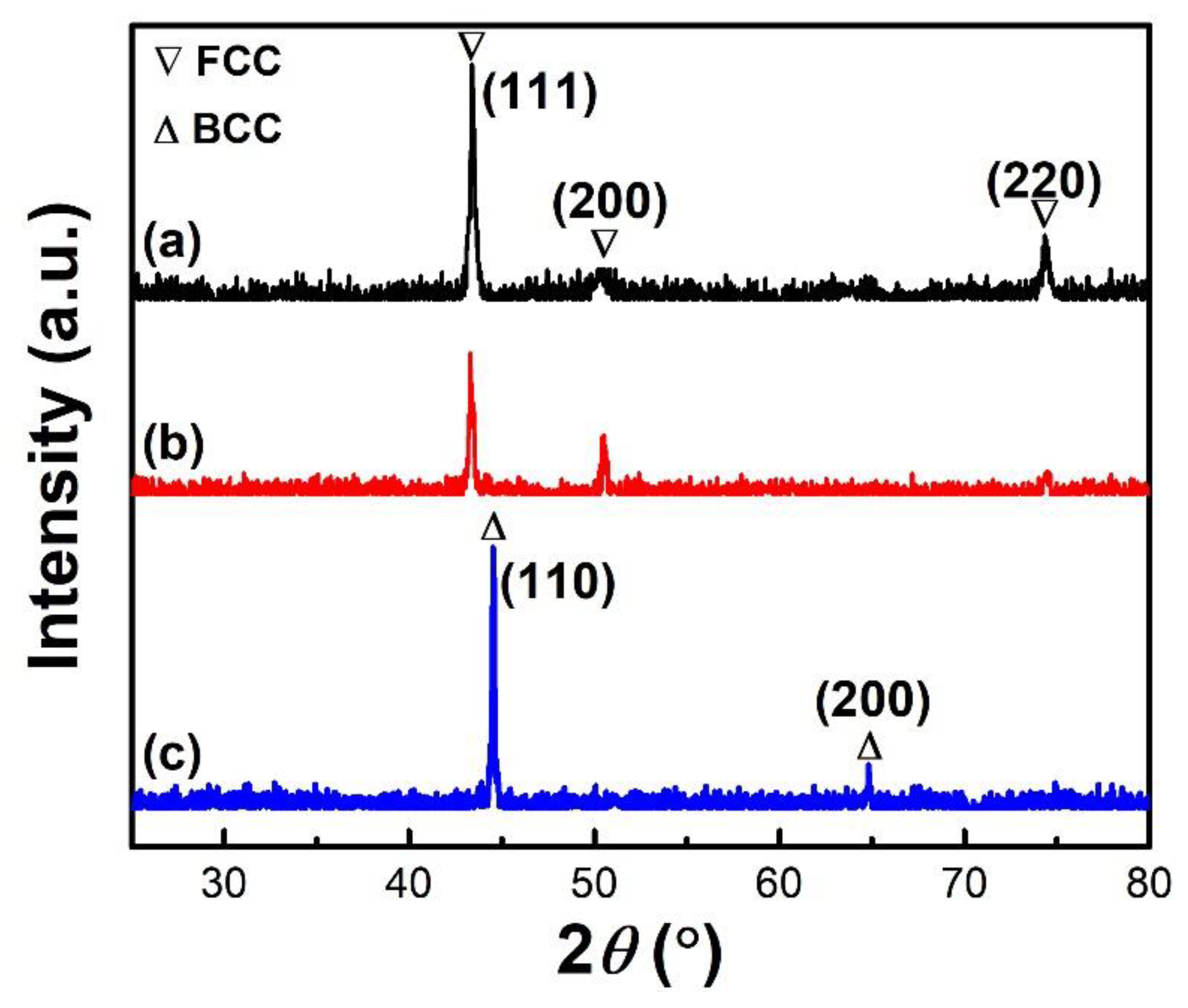

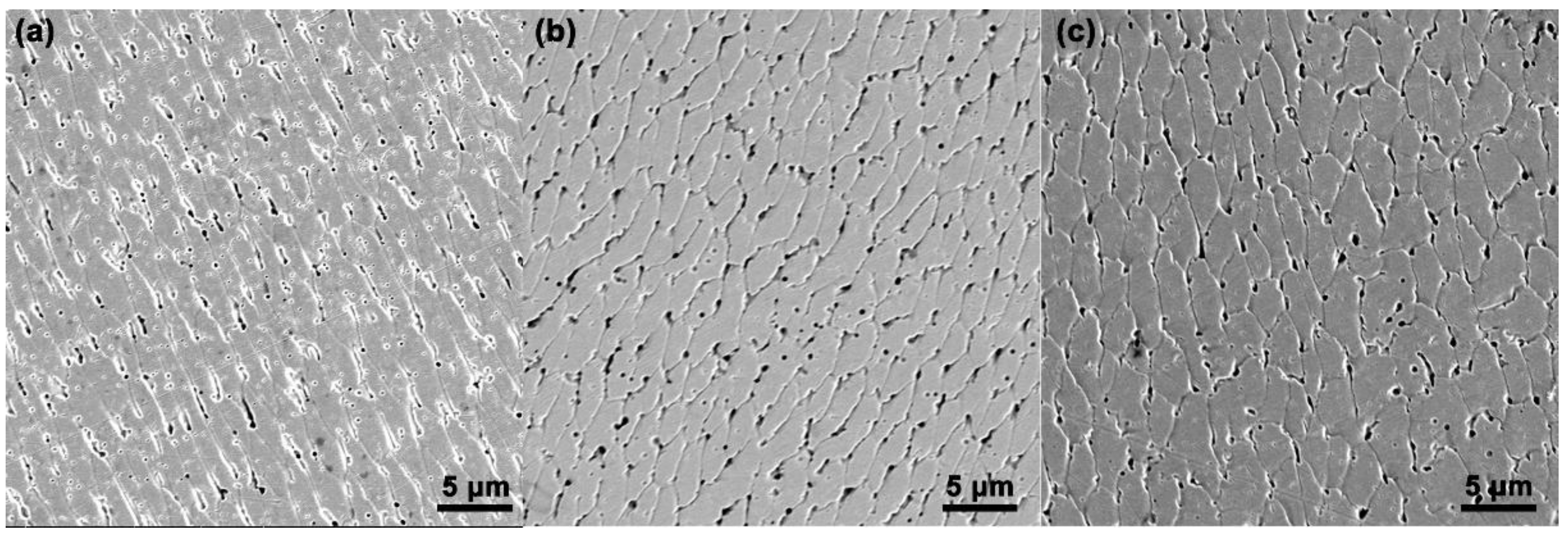

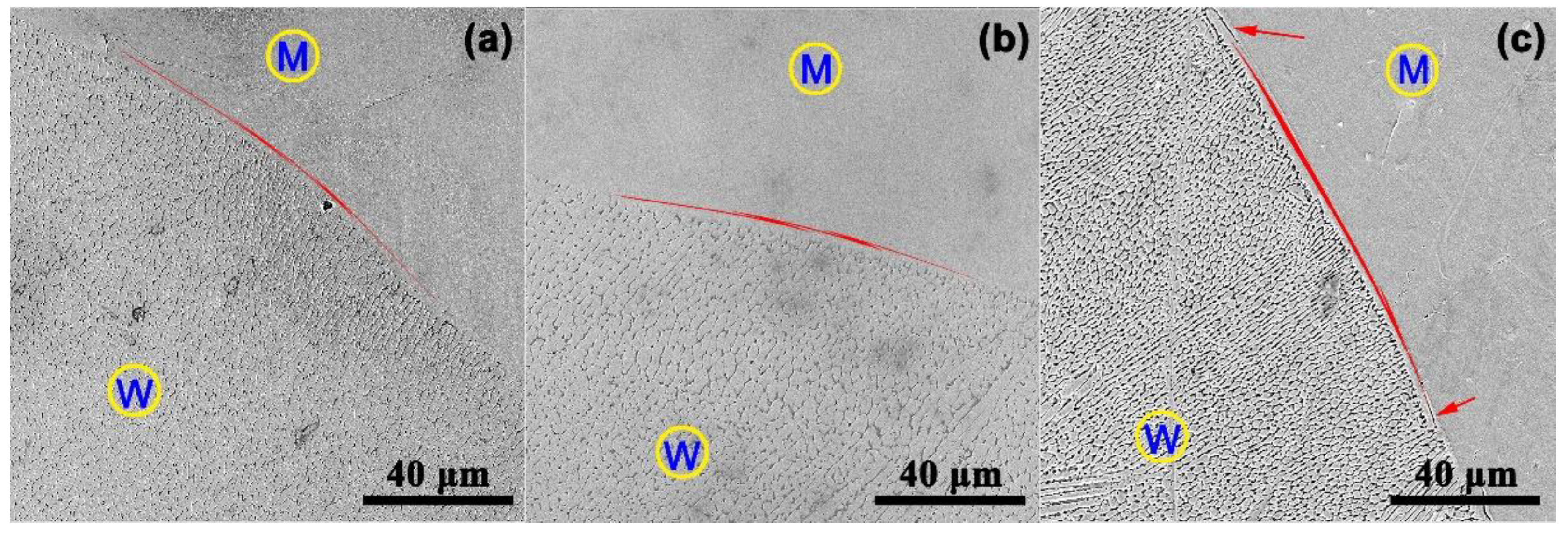

- The fusion zone of W1 indicates elongated grains, but the aspect ratio of the fusion zone of W2 has been remarkably reduced, and W3 presents relative equiaxed grains. Noticeable deviation of compositions is observed in the Mn and Al elements, implying that even in this rapid processing technique, the loss of the Mn element can still occur.

- (2)

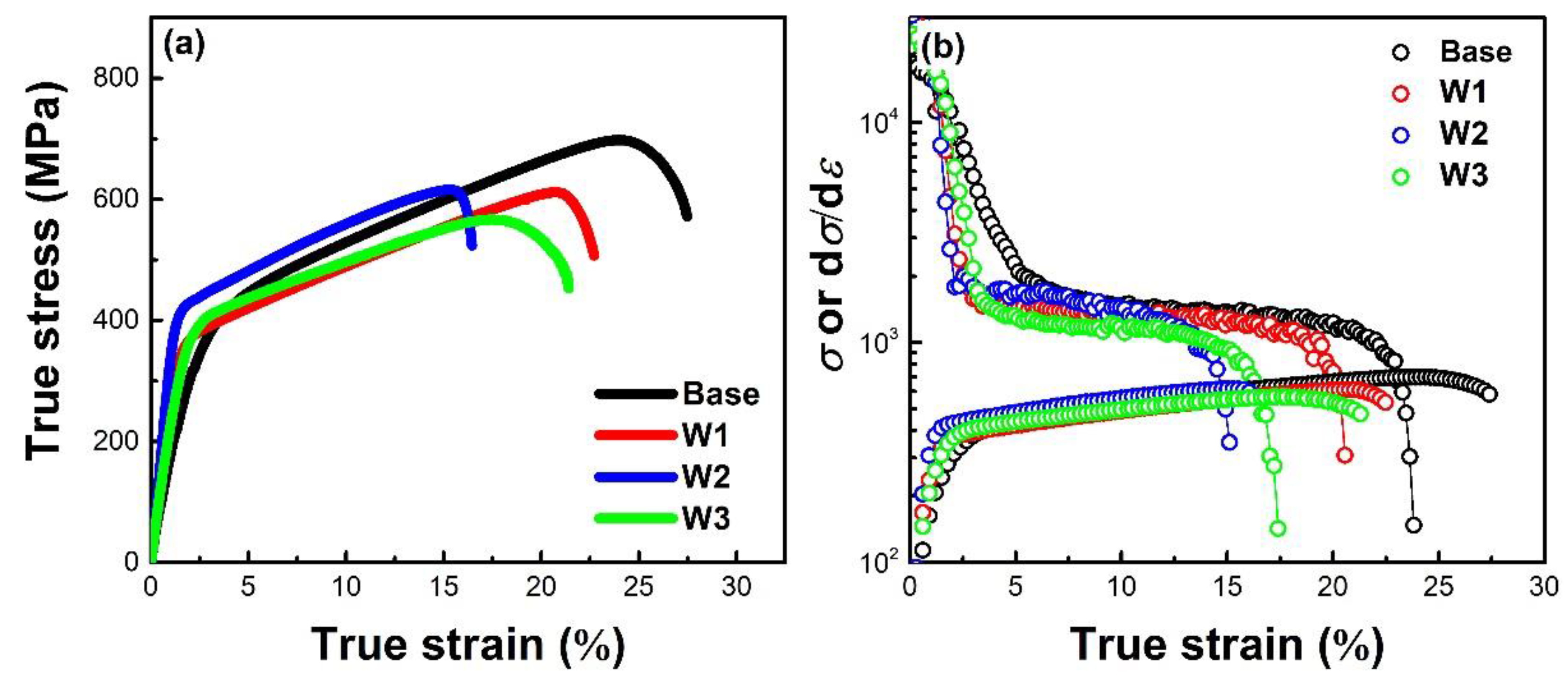

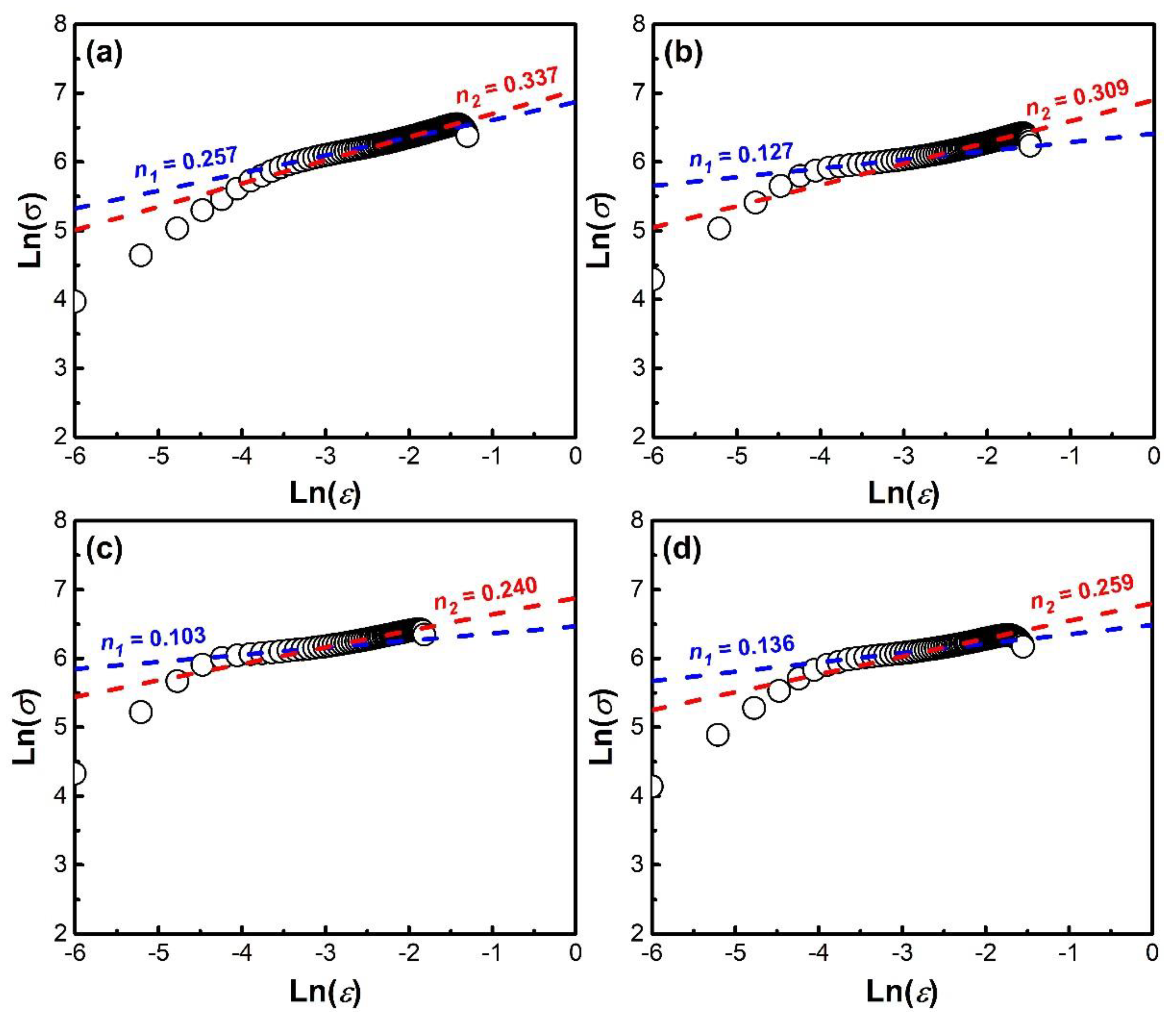

- The yield strength (σy) of each weldment has been remarkably enhanced and the maximum value can be reached for W2 (330.5 MPa). The σUTS of W1, W2 and W3 reaches 87.8%, 88.5% and 81.7% when referring to the base. Laser welding with preplaced powders can promote tensile properties.

- (3)

- The fractographies of W1 are similar to those of the base, but the size of the dimples of the base is larger than that of W1. However, the fractographies of both W2 and W3 indicate a cleavage feature, agreeing with the reduction in elongation.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Chen, Z.; Shi, J.C.; Wang, Z.Y.; Zhang, J.Y. The effect of Al content on microstructures and comprehensive properties in AlxCoCrCuFeNi high entropy alloys. Vacuum 2019, 161, 143–149. [Google Scholar] [CrossRef]

- Bernd, G.; Anton, H.; Dhiraj, C.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153. [Google Scholar]

- Wu, Z.; David, S.A.; Feng, Z.; Bei, H. Weldability of a high entropy CrMnFeCoNi alloy. Scr. Mater. 2016, 124, 81–85. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Tang, C.; Rothwell, G.; Li, L.S.; Wang, Y.C.; Yang, Q.X.; Ren, X.J. Welding of high entropy alloys A Review. Entropy 2019, 21, 431. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Sun, H.T.; Wang, S.; Hao, X.H.; Dong, H.G. Rotary friction welding of AlCoCrFeNi2.1 eutectic high entropy alloy. J. Alloy. Compd. 2020, 814, 152322. [Google Scholar] [CrossRef]

- Arab, A.; Guo, Y.S.; Zhou, Q.; Chen, P.W. Joining AlCoCrFeNi high entropy alloys and Al-6061 by explosive welding method. Vacuum 2020, 174, 109221. [Google Scholar] [CrossRef]

- Reddy, C.K.; Krishna, M.G.; Srikant, P. Brief evolution story and some basic limitations of high entropy alloys (heas)–A review. Mater. Today Proc. 2019, 18, 436–439. [Google Scholar] [CrossRef]

- Sokkalingam, R.; Sivaprasad, K.; Duraiselvam, M.; Muthupandi, V.; Prashanth, K.G. Novel welding of Al0.5CoCrFeNi high-entropy alloy: Corrosion behavior. J. Alloy. Compd. 2020, 817, 153163. [Google Scholar] [CrossRef]

- Benyounis, K.Y.; Olabi, A.G.; Hashmi, M.S.J. Effect of laser welding parameters on the heat input and weld-bead profile. J. Mater. Process. Technol. 2005, 164, 978–985. [Google Scholar] [CrossRef] [Green Version]

- Kashaev, N.; Ventzke, V.; Stepanov, N.; Shaysultanov, D.; Sanin, V.; Zherebtsov, S. Laser beam welding of a CoCrFeNiMn-type high entropy alloy produced by self-propagating high-temperature synthesis. Intermetallics 2018, 96, 63–71. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, B.F.; Duan, B.H.; Zhang, X.Y. Mechanical properties and microstructure of laser welded FeCoNiCrMn high-entropy alloy. Mater. Lett. 2020, 262, 127060. [Google Scholar] [CrossRef]

- Nam, H.; Park, C.; Moon, J.; Na, Y.; Kim, H.; Kang, N. Laser weldability of cast and rolled high-entropy alloys for cryogenic applications. Mater. Sci. Eng. A 2019, 742, 224–230. [Google Scholar] [CrossRef]

- Nam, H.; Park, S.; Chun, E.-J.; Kim, H.; Na, Y.; Kang, N. Laser dissimilar weldability of cast and rolled CoCrFeMnNi high-entropy alloys for cryogenic applications. Sci. Technol. Weld. Join. 2019, 2, 1–8. [Google Scholar] [CrossRef]

- Nam, H.; Park, S.; Park, N.; Na, Y.; Kim, H.; Yoo, S.J.; Moon, H.Y.; Kang, N. Weldability of cast CoCrFeMnNi high-entropy alloys using various filler metals for cryogenic applications. J. Alloy. Compd. 2020, 819, 153278. [Google Scholar] [CrossRef]

- Dong, K.W.; Kong, J.; Yang, Y.; Peng, Y.; Zhou, Q.; Wang, K.H. Achieving high-strength joining of TiAl- and Ni-based alloys at room temperature and 750 degrees via utilizing a quinary FeCoNi-based amorphous filler. J. Mater. Res. Technol. JMRT 2020, 9, 1955–1965. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y.Z. Grain refinement and boundary misorientation transition by annealing in the laser rapid solidified 6FeNiCoCrAlTiSi multicomponent ferrous alloy coating. Surf. Coat. Technol. 2011, 205, 4068–4072. [Google Scholar] [CrossRef]

- Attar, H.; Bonisch, M.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium-titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Bayraktar, E.; Kaplan, D.; Devillers, L.; Chevalier, J.P. Grain growth mechanism during the welding of interstitial free (IF) steels. J. Mater. Process. Technol. 2007, 189, 114–125. [Google Scholar] [CrossRef]

- Kurz, W.; Bezencon, C.; Gaumann, M. Columnar to equiaxed transition in solidification processing. Sci. Technol. Adv. Mater. 2001, 2, 185–191. [Google Scholar] [CrossRef]

- Cao, X.; Jahazi, M.; Immarigeon, J.P.; Wallace, W. A review of laser welding techniques for magnesium alloys. J. Mater. Process. Technol. 2006, 171, 188–204. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Cam, G. Prospects of laser beam welding and friction stir welding processes for aluminum airframe structural applications. J. Manuf. Process. 2018, 36, 571–600. [Google Scholar] [CrossRef]

- Martin, A.C.; Fink, C. Initial weldability study on Al0.5CrCoCu0.1FeNi high-entropy alloy. Weld. World 2019, 63, 739–750. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Chen, B.; Moon, S.K.; Yao, X.; Bi, G.; Shen, J.; Umeda, J.; Kondoh, K. Strength and strain hardening of a selective laser melted AlSi10Mg alloy. Scr. Mater. 2017, 141, 45–49. [Google Scholar] [CrossRef]

| Sample | Fe | Co | Ni | Cr | Mn | Al |

|---|---|---|---|---|---|---|

| Base | 23.97 | 19.97 | 19.27 | 20.18 | 16.62 | / |

| W1 | 25.90 | 20.70 | 18.58 | 21.83 | 12.98 | / |

| W2 | 26.06 | 20.94 | 19.15 | 20.80 | 13.04 | / |

| W3 | 25.40 | 20.58 | 18.26 | 20.72 | 11.93 | 3.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Zhang, F.; Wu, J.; Pi, J.; Chen, F. Laser Beam Welding of Feconicrmn High-Entropy Alloys with Preplaced Powders. Metals 2020, 10, 1402. https://doi.org/10.3390/met10111402

Zhou Z, Zhang F, Wu J, Pi J, Chen F. Laser Beam Welding of Feconicrmn High-Entropy Alloys with Preplaced Powders. Metals. 2020; 10(11):1402. https://doi.org/10.3390/met10111402

Chicago/Turabian StyleZhou, Ziyi, Feng Zhang, Jili Wu, Jinhong Pi, and Fei Chen. 2020. "Laser Beam Welding of Feconicrmn High-Entropy Alloys with Preplaced Powders" Metals 10, no. 11: 1402. https://doi.org/10.3390/met10111402

APA StyleZhou, Z., Zhang, F., Wu, J., Pi, J., & Chen, F. (2020). Laser Beam Welding of Feconicrmn High-Entropy Alloys with Preplaced Powders. Metals, 10(11), 1402. https://doi.org/10.3390/met10111402