1. Introduction

Cemented carbides are among the most researched and most developed representatives of materials that were obtained by powder metallurgy. Their main constituents, hard and brittle tungsten carbides (WC), and the softer and tougher cobalt (Co) matrix, are key for their specific properties. The field of cemented carbides application is continuously expanding due to high market demands and their favorable properties, such as: high hardness, wear resistance, high flexural and compressive strength, high modulus of elasticity, resistance to elevated temperatures, high corrosion resistance, etc. The development of cemented carbides in recent years is based on the application of ultrafine and nanoparticle powders that enable significant material properties improvement especially for applications such as cutting [

1]. Requirements for increasing cutting speeds in order to achieve a sustainable level of production are continuously increasing [

2]. Therefore, the materials are required to have high-temperature dimensional stability and reduced friction coefficient [

3], high strength, and high hardness [

4]. The most common wear mechanisms that affect cutting tool lifetime are abrasion and adhesion wear [

4], delamination wear [

5], and wear caused by tools and workpiece chemical incompatibility, which includes diffusion wear, wear that is caused by dissolution, and electrochemical wear. Cemented carbide has proven to be the optimal material for cutting tools in terms of properties, price, and durability [

6].

Numerous studies [

7] (p.9), [

8] (p.3), have proven that the use of nano-sized cemented carbides results in relatively high flexural strength and fracture toughness, while also showing high hardness values; therefore, contributing to the crack propagation resistance [

9]. All of the mentioned advantages of nanostructured cemented carbides can only be fully utilized if the carbide grain remains on the nanoscale after the consolidation process [

10]. Grain growth, which inevitably occurs in the sintering process, can be reduced by adding grain growth inhibitors (GGIs), such as carbides of vanadium, chromium, tantalum, and niobium [

11], and by sintering time and temperature optimization. Vanadium carbide (VC) has a positive effect on the hardness at elevated temperatures, while chromium carbide (Cr

3C

2) increases toughness. The combination of VC–Cr

3C

2 (TaC) yields an optimum ratio of hardness and toughness [

12]. Earlier studies have also shown that Co binder particles do not have to be nano-sized, since their primary function is filling the pores between carbides and enabling sintering at lower temperatures with shorter bonding times. This improves the microstructural characteristics of the sintered product [

13], indirectly preventing grain growth [

14].

By surface processing (modification and/or coating), it is possible to form a surface layer/base material (substrate) system with properties that can meet the modern expectations that are placed on these materials at an acceptable production cost.

Research of nanostructured cemented carbides with TiN, TiCN, TiBN, or TiB

2 coatings is a very interesting research area, due to specific, so far, unsolved issues regarding high reactivity of nano-sized cemented carbides, both in the sintering and coating phase. High-temperature coating processes, such as chemical vapor deposition (CVD), can cause microstructural defects in the surface layers, dependent on the Co content [

15]. On the one hand, eta (η)-phase, occurring at temperatures that are below 800 °C in the form of metal carbides (M

6C), and unbound carbon are the most common microstructural defects often significantly deteriorating fracture toughness and strength as well as the adhesiveness of the applied coating [

16]. On the other hand, vapor phase physical coating (PVD) processes that were carried out at lower temperatures result in thicker coatings, ultimately reducing their stability and adhesiveness [

17] while making the coating process more complex. In PVD procedures, the coating is directly applied to the sample surface (line of sight), so there is a need for sample rotation. Titanium nitride (TiN), titanium carbide (TiC), titanium carbonitride (TiCN), titanium boron nitride (TiBN), and alumina (Al

2O

3) are commonly used coatings available on the market. Recent studies have indicated the need for the development of complex architecture coatings, primarily of multilayer and gradient type, which were shown to have a significant effect on heat dissipation during tool heating [

18]. Multilayer gradient coatings are usually formed through three layers. The first is a thin layer, the main role of which is adhesion to the substrate. The middle layer gradually changes from the adhesion layer to the surface, creating a bond between the layers of lower and higher hardness. Besides increasing the wear resistance, the role of the top layer is to achieve high-temperature coating stability [

19,

20]. Plasma-assisted chemical vapor deposition (PACVD) is a process that combines most of the advantages of CVD coating with the PVD coating technique, which can result in coating formation at significantly lower temperatures. Nevertheless, the full range of its possibilities is still insufficiently explored.

This article presents an investigation of nanostructured cemented carbides and the possibility of applying the PACVD as coating process of hard thin coatings and the development of a new, innovative coating with improved properties.

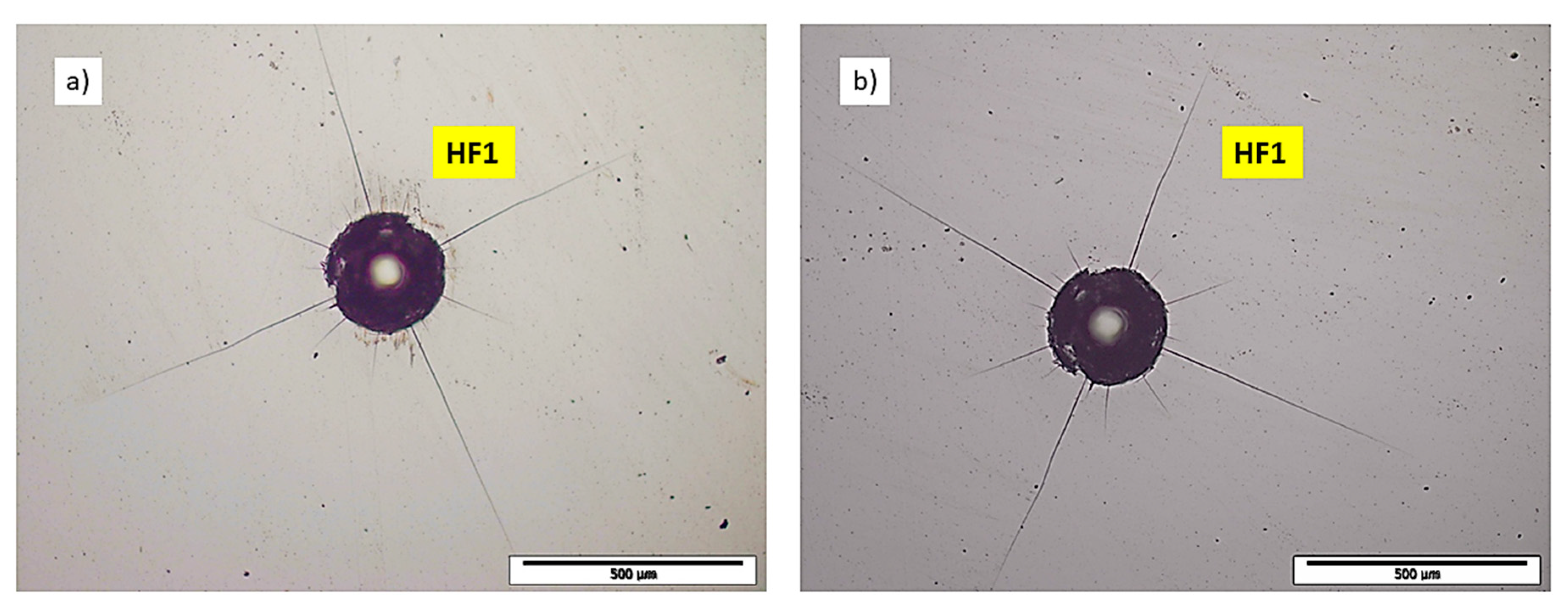

For the purpose of investigating properties, microstructure and quality of the substrate/coating interface tests were performed on both uncoated and coated samples. The characterization of the uncoated substrate cemented carbide material included density measurement, specific magnetization saturation test, hardness and fracture toughness determination, modulus of elasticity determination by nanoindentation method, microstructural analysis aimed at investigating the presence of the porosity, structural constituents, and possible irregularities. Microstructure analysis, surface roughness, coating adhesion, thickness, and microhardness were tested in order to give insight into complex multilayered coating properties, obtained by the described PACVD process.

For the actual validation of the superiority of this material in applications, such as cutting, it is necessary to conduct additional research in the form of abrasion and erosion resistance testing, dry sliding wear, and friction factor testing, along with exploitation tests in real turning conditions. Because of the demanding implementation and complexity of such testing, that type of testing is not included in this paper, since the research presented here is exclusively focused on the process of obtaining valuable data on the basic characteristics of both substrate and coated cemented carbide, and not the final product such as a removable cutting blade. Because data on this type of PACVD coated nanostructured WC-Co material have not been found in the recent literature, the key interest of this research was to create a basis for an overall understanding of material capability in order to answer all of the demands opposed on future products.