Study of the Environmental Implications of Using Metal Powder in Additive Manufacturing and Its Handling

Abstract

:1. Introduction

2. Methodology Applied for the Literature Review

3. Metal AM processes

- (1)

- Liquid-based processes: Stereolithography, Jetting Systems, Direct Light processingTM technologies, High-Viscosity Jetting, and Maple process.

- (2)

- Powder-based processes: Selective Laser Sintering (polymers), Selective Laser Sintering (Ceramics and Metals), Direct Metal Laser Sintering, Three-Dimensional Printing, Fused Metal Deposition Systems, Electron Beam Melting, Selective Laser Melting, Selective Masking Sintering, Selective Inhibition Sintering, Electrophotographic Layered Manufacturing, and High-Speed Sintering.

- (3)

- Solid-based processes: Fused Deposition Modelling and Sheet Stacking Technologies.

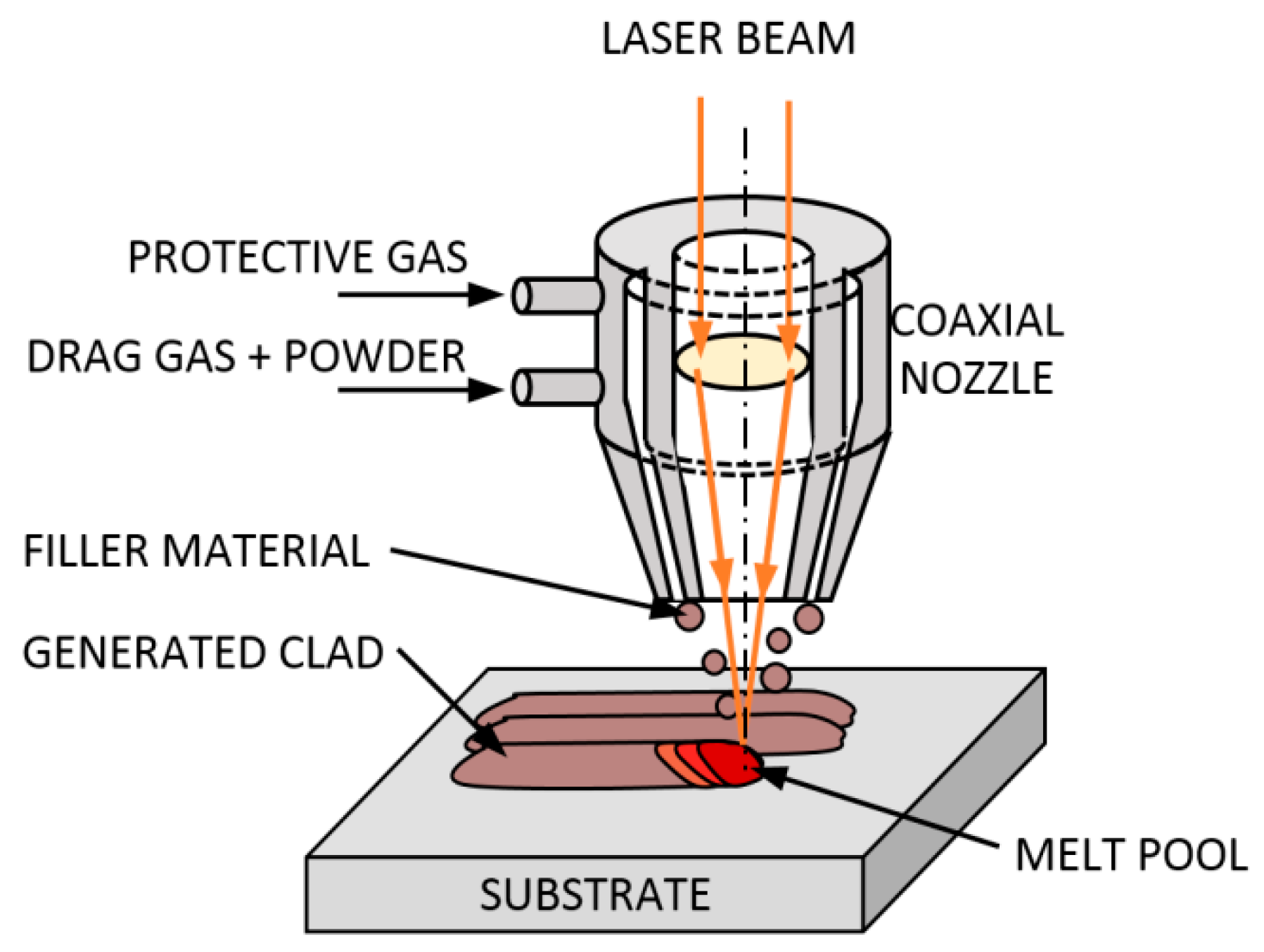

3.1. Fundamentals of the DED Process

3.2. Fundamentals of the PBF Process

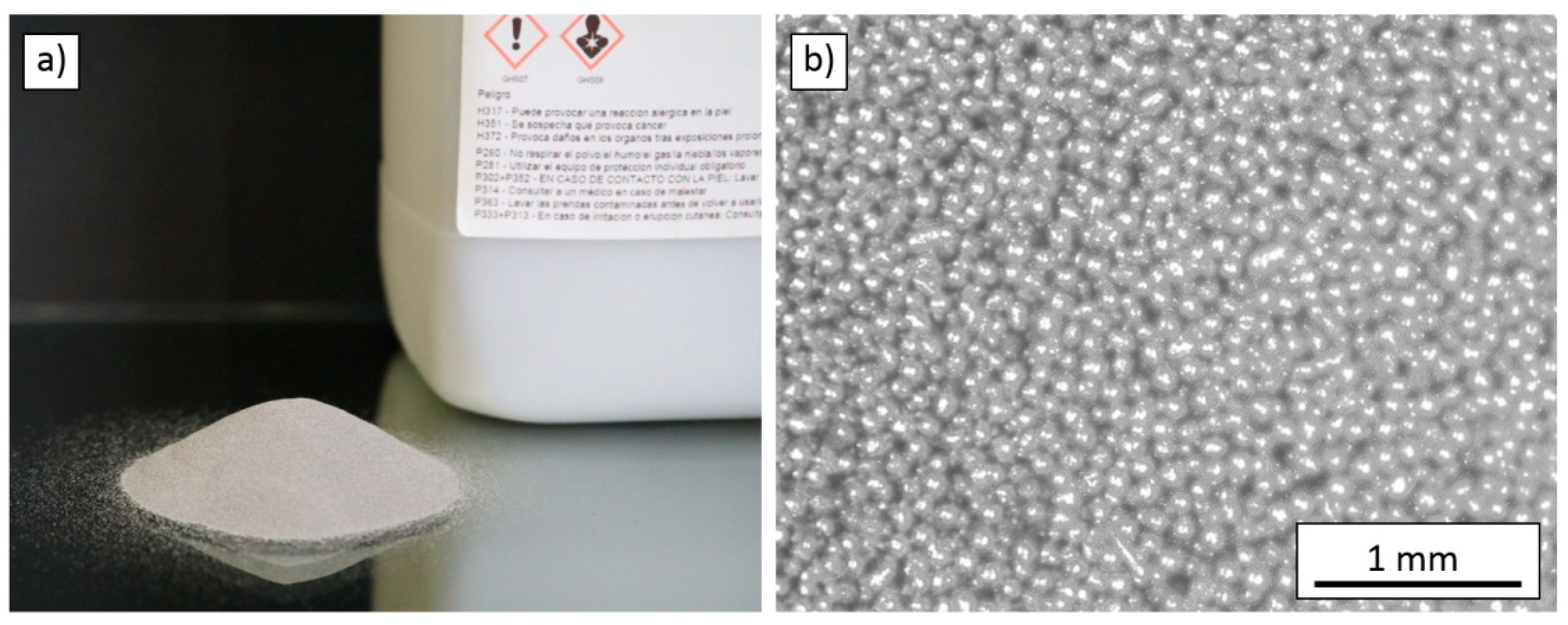

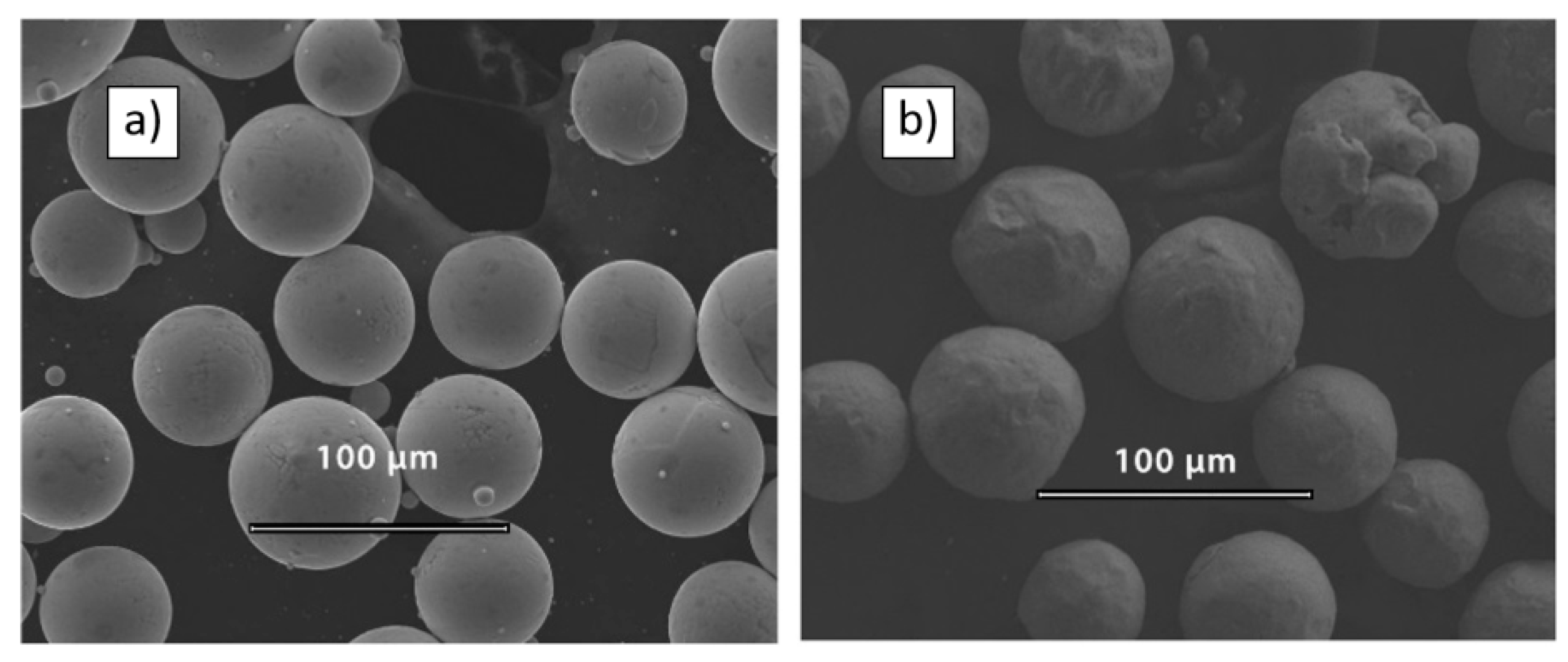

3.3. Powder Employed in Metal AM and Its Health Issues

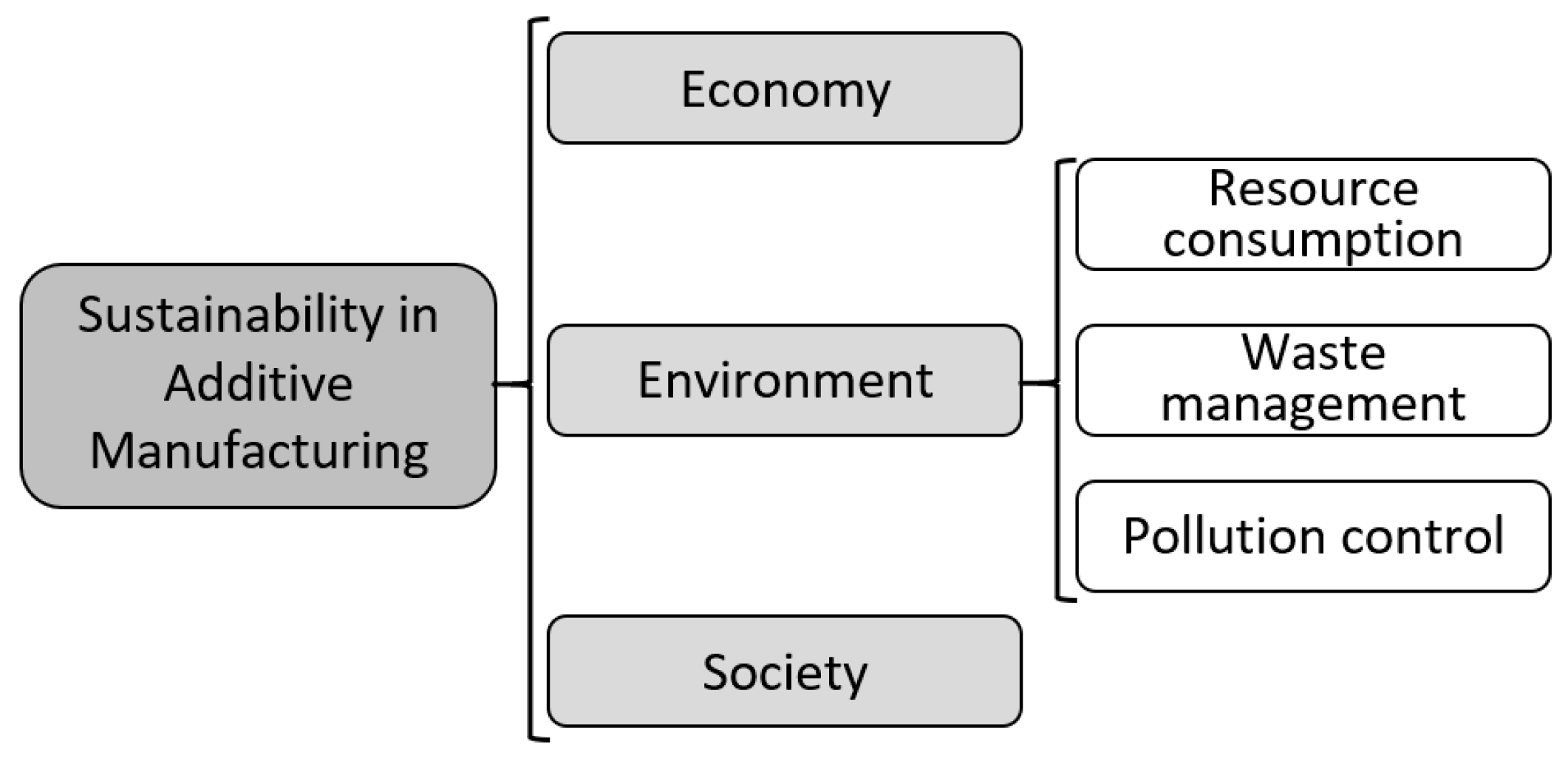

4. AM—A Sustainable Manufacturing Process

4.1. Life Cycle Analysis

4.2. Ecodesign and Circular Economy

5. Handling of Powder in Metal AM

5.1. Risks in the Workplace

Preventive Actions

- (1)

- Ventilation: The exposure can be considerably reduced by the implementation of good general ventilation which allows for the reduction of particles and fibers in the working environment [114]. It can be further improved by point ventilation placed at strategic emission sources. Furthermore, to protect the outdoor environment, particle/fiber collection filters should be installed.

- (2)

- Protective mask: Machine operators should wear a personal protective mask in the working environment where emission occurs. The mask is considered the most effective personal protective equipment [114].

- (3)

- Machine enclosure: A proper cabinet is required to prevent particles from spreading through the workshop [116].

5.2. Treatment of Waste Material

5.2.1. Reuse

5.2.2. Waste Disposal

6. Conclusions

- (1)

- In order to consider the manufacturing impact, it is necessary to analyze the whole AM product supply-chain, from cradle to grave. So, more research work considering design, production, use, and end-of-life is needed.

- (2)

- The prevailing environmental issue is resource consumption, and more specifically energy consumption. But there are other factors that should be considered such as resource use, pollution, impact on human health, and social impact. To assess the sustainability of the AM process and its environmental impact, all these aspects must be considered equally. The weighted quantification of the economic impact of each factor could be a possibility to consider all of them with the same relevance.

- (3)

- Several authors focused their research efforts in studying the behavior of reused powder:

- (i)

- The protective atmosphere plays an important role in powder reuse. The correct design of the protective atmosphere allows the powder-shaped material to maintain its original properties and chemical composition. Therefore, the powder can be reused efficiently in AM.

- (ii)

- As a global trend, the oxygen content in the powder increases progressively as the number of reuses increases and the particles become less spherical. Consequently, this influences the powder flowability and the material oxidation in the final part.

- (iii)

- Most research states that the UTS and yield strength values of the reused powder do not vary with regard to the new powder. Nevertheless, it is widely accepted that parts manufactured with recycled powder present a more brittle nature. Nonetheless, uneven results were obtained even for the same material and AM process. This means that a proper procedure for evaluating the reusability of the powder in AM is needed to ensure reliable results.

- (iv)

- It is important to define a standardized particle recycling procedure. However, opposed conclusions were reached by different authors regarding powder recyclability. Results depended on the process and the employed powder, and therefore, it is not possible to make general statements.

- (4)

- Once that powder cannot be longer reused, it has to be disposed of according to the law in force in each country. This last step is of great importance in minimizing the environmental impact of AM.

- (5)

- The LCA and ecodesign concepts should be applied in the early stages of product development design to improve the viability of end-of-life strategies. In addition to the final price, the quality, production time, and factors such as human health and environmental impact need to be taken into account.

Author Contributions

Funding

Conflicts of Interest

References

- Wohlers Associates. Wholers Report 2018: 3D Printing and Additive Manufacturing State of the Industry; Wohlers Associates: Fort Collins, CO, USA, 2018. [Google Scholar]

- Süss, M. Adding It up: The Economic Impact of Additive Manufacturing; Agency for Science, Technology and Research (A*STAR): Singapore, 2018. [Google Scholar]

- Bonneau, V.; Yi, H.; Probst, L.; Pedersen, B.; Lonkeu, O.K. The Disruptive Nature of 3D Printing; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Huang, Y.; Leu, M.; Mazumder, J.; Donmez, M. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 14001. [Google Scholar] [CrossRef] [Green Version]

- Roca, J.B.; Vaishnav, P.; Mendoza, J.; Morgan, M.G. Getting Past the Hype About 3-D Printing, Although Additive Manufacturing Techniques Hold Great Promise, Near-Term Expectations for Them Are Overoptimistic; MIT: Cambridge, MA, USA, 2017; Volume 58. [Google Scholar]

- Jurrens, K. Measurement Science Roadmap for Metal-Based Additive Manufacturing; NIST: Gaithersburg, MD, USA, 2013. [Google Scholar]

- Verhoef, L.A.; Budde, B.W.; Chockalingam, C.; García Nodar, B.; van Wijk, A.J.M. The effect of additive manufacturing on global energy demand: An assessment using a bottom-up approach. Energy Policy 2018, 112, 349–360. [Google Scholar] [CrossRef]

- Crozet, V. SmarTech Issues New Report on Opportunities for AM in Automotive Production, Sees $5.3 Billion Market in 2023; SmarTech Markets Publishing: Crozet, VA, USA, 2018. [Google Scholar]

- European Commission. Support Action for Standardisation in Additive Manufacturing (SASAM); European Commission: Brussels, Belgium, 2014; Available online: https://cordis.europa.eu/project/id/319167 (accessed on 7 February 2020).

- Kitchenham, B. Procedures for Performing Systematic Reviews. Keele Univ. 2004, 33, 1–26. [Google Scholar]

- Thorpe, R.; Holt, R. The SAGE Dictionary of Qualitative Management Research; SAGE Publications Ltd: London, UK, 2008. [Google Scholar]

- Littel, J.H.; Corcoran, J.; Pilla, V. Systematic Reviews and Meta-Analysis; Oxford University Press: New York, NY, USA, 2008. [Google Scholar]

- Wohlin, C. Guidelines for snowballing in systematic literature studies and a replication in software engineering. In Proceedings of the 18th International Conference on Evaluation Assessment in Software Engineering, Berlin, Germany, 30 March 2014; p. 38. [Google Scholar]

- ASTM International. ASTM, F2792-12a Standard Terminology for Additive Manufacturing Technologies; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Hopkinson, N.; Hague, R.J.M.; Dickens, P.M. Rapid Manufacturing: An Industrial Revolution for the Digital Age; John Wiley & Sons Ltd: Chischester, UK; West Sussex, UK, 2006. [Google Scholar]

- Arcam. EBM® Electron Beam Melting—In the forefront of Additive Manufacturing; Arcam: Cambridge, UK, 2019; Available online: http://www.arcam.com/ (accessed on 7 February 2020).

- EOS. Systems and Solutions for Metal Additive Manufacturing; EOS: Chengdu, China, 2019; Available online: https://www.eos.info/en (accessed on 7 February 2020).

- Fraunhofer Institute for Laser Technology ILT. Available online: https://www.ilt.fraunhofer.de/en.html (accessed on 7 February 2020).

- Castells, R. DMLS vs. SLM 3D Printing for Metal Manufacturing; Element Materials Technology: London, UK, 2016; Available online: https://www.element.com/nucleus/2016/06/29/dmls-vs-slm-3d-printing-for-metal-manufacturing (accessed on 7 February 2020).

- Sandia National Laboratories. Creating a Complex Metal Part in a Day is Goal of Commercial Consortium; Sandia National Laboratories: Livermore, CA, USA, 1997. Available online: https://www.sandia.gov/media/lens.htm (accessed on 7 February 2020).

- Manyika, J.; Chui, M.; Bughin, J. Disruptive Technologies: Advances That Will Transform Life, Business, and the Global Economy; McKinsey & Company: New York, NY, USA, 2013. [Google Scholar]

- Toyserkani, E.; Khajepour, A.; Corbin, S. Laser Cladding; CRC Press LLC: Boca Raton, FL, USA, 2005. [Google Scholar]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Klocke, F.; Klingbeil, N.; Lamikiz, A.; Martinez, S. Evaluation of efficiency and mechanical properties of Inconel 718 components built by wire and powder laser material deposition. Rapid Prototyp. J. 2017, 23, 965–972. [Google Scholar] [CrossRef]

- Gasser, A. Tailored Light 2: Laser Metal Deposition, RWTH Edition; Poprawe, R., Ed.; Springer: New York, NY, USA, 2011. [Google Scholar]

- Caiazzo, F. Laser-aided Directed Metal Deposition of Ni-based superalloy powder. Opt. Laser Technol. 2018, 103, 193–198. [Google Scholar] [CrossRef]

- Ren, L.; Padathu, A.P.; Ruan, J.; Sparks, T.; Liou, F. Three dimensional die repair using a hybrid manufacturing system. In Proceedings of the 17th Solid Freeform Fabrication Symposium, SFF 2006, Austin, TX, USA, 14–16 August 2006; pp. 14–16. [Google Scholar]

- Navas, C.; Conde, A.; Fernández, B.J.; Zubiri, F.; de Damborenea, J. Laser coatings to improve wear resistance of mould steel. Surf. Coat. Technol. 2005, 194, 136–142. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Li, L. Multiple-layer cladding of stainless steel using a high-powered diode laser: An experimental investigation of the process characteristics and material properties. Thin Solid Film 2004, 453–454, 471–476. [Google Scholar] [CrossRef]

- Richter, K.-H.; Orban, S.; Nowotny, S. Laser cladding of the titanium alloy TI6242 to restore damaged blades. In Proceedings of the 23rd International Congress on Applications of Lasers & Electro-Optics, San Francisco, CA, USA, 4–7 October 2004; p. 1506. [Google Scholar]

- Kong, C.Y.; Scudamore, R.J.; Allen, J. High-rate laser metal deposition of Inconel 718 component using low heat-input approach. Phys. Procedia 2010, 5, 379–386. [Google Scholar] [CrossRef] [Green Version]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Lima, D.D.; Mantri, S.A.; Mikler, C.V.; Contieri, R.; Yannetta, C.J.; Campo, K.N.; Lopes, E.S.; Styles, M.J.; Borkar, T.; Caram, R.; et al. Laser additive processing of a functionally graded internal fracture fixation plate. Mater. Des. 2017, 130, 8–15. [Google Scholar] [CrossRef]

- Hwang, T.; Woo, Y.Y.; Han, S.W.; Moon, Y.H. Functionally graded properties in directed-energy-deposition titanium parts. Opt. Laser Technol. 2018, 105, 80–88. [Google Scholar] [CrossRef]

- Priarone, P.C.; Ingarao, G. Towards criteria for sustainable process selection: On the modelling of pure subtractive versus additive/subtractive integrated manufacturing approaches. J. Clean. Prod. 2017, 144, 57–68. [Google Scholar] [CrossRef]

- Allen, J.S. An Investigation into the Comparative Costs of Additive Manufacture vs. Machine from Solid for Aero Engine Parts; Rolls-Royce PLC: Derby, UK, 2006. [Google Scholar]

- Caiazzo, F.; Alfieri, V.; Corrado, G.; Argenio, P.; Barbieri, G.; Acerra, F.; Innaro, V. Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction. Metals 2017, 7, 183. [Google Scholar] [CrossRef]

- Exequiel Ruiz, J.; Gonzalez Barrio, H.; Cortina, M.; Arrizubieta Arrate, J.I.; Lamikiz Mentxaka, A. Desarrollo de estrategia y sensorizacion en proceso de LMD para reparacion de geometrias tipo blisk. Rev. Iberoam. Ing. Mec. 2018, 22, 13–18. [Google Scholar]

- Abdulrahman, K.O.; Akinlabi, E.T.; Mahamood, R.M. Laser metal deposition technique: Sustainability and environmental impact. Procedia Manuf. 2018, 21, 109–116. [Google Scholar] [CrossRef]

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing—Enabling Circular Economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef] [Green Version]

- Kumar, L.J.; Nair, C.G.K. Laser metal deposition repair applications for Inconel 718 alloy. Mater. Today Proc. 2017, 4, 11068–11077. [Google Scholar] [CrossRef]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J. Clean. Prod. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- Jhavar, S.; Paul, C.P.; Jain, N.K. Causes of failure and repairing options for dies and molds: A review. Eng. Fail. Anal. 2013, 34, 519–535. [Google Scholar] [CrossRef]

- Mazumder, J. Laser Assisted Surface Coatings BT—Metallurgical and Ceramic Protective Coatings; Stern, K.H., Ed.; Springer: Dordrecht, The Netherlands, 1996; pp. 74–111. [Google Scholar]

- Flynn, J.M.; Shokrani, A.; Newman, S.T.; Dhokia, V. Hybrid additive and subtractive machine tools –Research and industrial developments. Int. J. Mach. Tools Manuf. 2016, 101, 79–101. [Google Scholar] [CrossRef] [Green Version]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Mazumder, J. Laser-aided direct metal deposition of metals and alloys. In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 21–53. [Google Scholar]

- McAndrew, A.R.; Rosales, M.A.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of Ti-6Al-4V wire+arc additively manufactured features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Qin, S.; Dunbar, A.; Michaleris, P.; Beese, A.M. Characterization of the strength of support structures used in powder bed fusion additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2017, 14, 60–68. [Google Scholar] [CrossRef]

- Mueller, B. Additive Manufacturing Technologies—Rapid Prototyping to Direct Digital Manufacturing. Assem Autom 2012, 32. [Google Scholar] [CrossRef]

- Wally, Z.J.; Haque, A.M.; Feteira, A.; Claeyssens, F.; Goodall, R.; Reilly, G.C. Selective laser melting processed Ti6Al4V lattices with graded porosities for dental applications. J. Mech. Behav. Biomed. Mater. 2019, 90, 20–29. [Google Scholar] [CrossRef] [Green Version]

- Ataee, A.; Li, Y.; Brandt, M.; Wen, C. Ultrahigh-strength titanium gyroid scaffolds manufactured by selective laser melting (SLM) for bone implant applications. Acta Mater. 2018, 158, 354–368. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace applications of laser additive manufacturing. In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 351–371. [Google Scholar]

- Arrizubieta, J.I. Laser Metal Deposition Enhancement by Holistic Simulation of Powder Mass Flow and Deposition into the Melt Pool. Ph.D. Thesis, University of the Basque Country (UPV/EHU), Leioa, Spain, 2017. [Google Scholar]

- Sciaky Inc. Sciaky EBAM; Sciaky Inc.: Bedford Park, IL, USA, 2019; Available online: https://www.sciaky.com/ (accessed on 7 February 2020).

- Zhu, H.H.; Lu, L.; Fuh, J.Y.H. Development and characterisation of direct laser sintering Cu-based metal powder. J. Mater. Process. Technol. 2003, 140, 314–317. [Google Scholar] [CrossRef]

- Mumtaz, K.; Hopkinson, N. Top surface and side roughness of Inconel 625 Parts processed using selective laser melting. Rapid Prototyp. J. 2009, 15, 96–103. [Google Scholar] [CrossRef]

- Mazumder, J.; Dutta, D.; Kikuchi, N.; Ghosh, A. Closed loop direct metal deposition: Art to part. Opt. Lasers Eng. 2000, 34, 397–414. [Google Scholar] [CrossRef]

- Milewski, J.O.; Lewis, G.K.; Thoma, D.J.; Keel, G.I.; Nemec, R.B.; Reinert, R.A. Directed light fabrication of a solid metal hemisphere using 5-axis powder deposition. J. Mater. Process. Technol. 1998, 75, 165–172. [Google Scholar] [CrossRef]

- Oerlikon Metco. Inconel 718 Datasheet. Available online: https://www.oerlikon.com/ecomaXL/files/metco/oerlikon_DSMW-0002.6_NiSuperalloys_LaserCladding.pdf%26download=1 (accessed on 7 February 2020).

- Oerlikon Metco. Stellite 6 Datasheet. Available online: https://www.oerlikon.com/ecomaXL/files/metco/oerlikon_DSM-0218.0_CoSuperalloy_StelliteType.pdf&download=1 (accessed on 7 February 2020).

- Carpenter Additive. Ti6Al4V Datasheet. Available online: https://cdn2.hubspot.net/hubfs/6205315/carpenter_additive/image/Resources/Datasheets/CT-PowderRange-Ti64-E.pdf (accessed on 7 February 2020).

- Eramet. Pearl®Micro 316L. Available online: https://www.aubertduval.com/wp-media/uploads/2018/05/316L_PearlMicro_AM_GB.pdf (accessed on 7 February 2020).

- FST. Laser Cladding Powders. Available online: https://www.fst.nl/thermal-spray-material/laser-cladding-powders/pdf/80/laser-cladding-powders.pdf (accessed on 7 February 2020).

- Oerlikon Metco. Available online: https://www.oerlikon.com/metco/en/ (accessed on 7 February 2020).

- Carpenter Additive. Carpenter Technology Corporation. Available online: https://www.carpenteradditive.com/technical-library/ (accessed on 7 February 2020).

- FST. Flame Spray Technologies. Available online: https://www.fst.nl/ (accessed on 7 February 2020).

- Eramet. Auvert&Duval. Available online: https://www.aubertduval.com/products/powders-for-additive-manufacturing/ (accessed on 7 February 2020).

- ECHA. European Chemicals Agency. Available online: https://echa.europa.eu/es/home (accessed on 7 February 2020).

- Instituto Nacional de Seguridad y Salud en el Trabajo (INSST). O.A., M.P. Límites de Exposición Profesional Para Agentes Químicos En España. 2019. Available online: https://www.insst.es/documents/94886/188493/Límites+de+exposición+profesional+para+agentes+químicos+2019/7b0b9079-d6b5-4a66-9fac-5ebf4e4d83d1 (accessed on 7 February 2020).

- Occupational Safety and Health Administration. OSHA Occupational Chemical Database. United Stated Department of Labor. Available online: https://www.osha.gov/chemicaldata/ (accessed on 7 February 2020).

- Centers for Disease Control and Prevention. NIOSH Pocket Guide to Chemical Hazards. 2007. Available online: https://www.cdc.gov/niosh/docs/2005-149/pdfs/2005-149.pdf (accessed on 7 February 2020).

- ECHA. Guidance on the Application of the CLP Criteria. 2017. Available online: https://echa.europa.eu/documents/10162/23036412/clp_en.pdf/58b5dc6d-ac2a-4910-9702-e9e1f5051cc5 (accessed on 7 February 2020).

- Salonitis, K.; Ball, P. Energy Efficient Manufacturing from Machine Tools to Manufacturing Systems. Procedia CIRP 2013, 7, 634–639. [Google Scholar] [CrossRef] [Green Version]

- He, Q.; Silliman, B.R. Climate Change, Human Impacts, and Coastal Ecosystems in the Anthropocene. Curr. Biol. 2019, 29, R1021–R1035. [Google Scholar] [CrossRef] [PubMed]

- Le Bourhis, F.; Kerbrat, O.; Hascoet, J.Y.; Mognol, P. Sustainable manufacturing: Evaluation and modeling of environmental impacts in additive manufacturing. Int. J. Adv. Manuf. Technol. 2013, 69, 1927–1939. [Google Scholar] [CrossRef] [Green Version]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of additive manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Laurin, L. Overview of LCA—History, Concept, and Methodology. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Fratila, D.; Rotaru, H. Additive manufacturing—A sustainable manufacturing route. MATEC Web Conf. 2017, 94. [Google Scholar] [CrossRef] [Green Version]

- Kafara, M.; Süchting, M.; Kemnitzer, J.; Westermann, H.; Steinhilper, R. Comparative Life Cycle Assessment of Conventional and Additive Manufacturing in Mold Core Making for CFRP Production. Procedia Manuf. 2017, 8, 223–230. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Giannoulis, C.; Papacharalampopoulos, A. Life cycle analysis: Comparison between different methods and optimization challenges. Procedia CIRP 2016, 41, 626–631. [Google Scholar] [CrossRef] [Green Version]

- Salieri, B.; Turner, D.A.; Nowack, B.; Hischier, R. Life cycle assessment of manufactured nanomaterials: Where are we? NanoImpact 2018, 10, 108–120. [Google Scholar] [CrossRef]

- Baumers, M.; Duflou, J.R.; Flanagan, W.; Gutowski, T.G.; Kellens, K.; Lifset, R. Charting the Environmental Dimensions of Additive Manufacturing and 3D Printing. J. Ind. Ecol. 2017, 21, S9–S14. [Google Scholar] [CrossRef] [Green Version]

- Rejeski, D.; Zhao, F.; Huang, Y. Research needs and recommendations on environmental implications of additive manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef] [Green Version]

- Saade, M.R.M.; Yahia, A.; Amor, B. How has LCA been applied to 3D printing? A systematic literature review and recommendations for future studies. J. Clean. Prod. 2020, 244, 118803. [Google Scholar] [CrossRef]

- Machado, C.G.; Despeisse, M.; Winroth, M.; Ribeiro da Silva, E.H.D. Additive manufacturing from the sustainability perspective: Proposal for a self-assessment tool. Procedia CIRP 2019, 81, 482–487. [Google Scholar] [CrossRef]

- Niaki, M.K.; Torabi, S.A.; Nonino, F. Why manufacturers adopt additive manufacturing technologies: The role of sustainability. J. Clean. Prod. 2019, 222, 381–392. [Google Scholar] [CrossRef]

- Ma, J.; Harstvedt, J.D.; Dunaway, D.; Bian, L.; Jaradat, R. An exploratory investigation of Additively Manufactured Product life cycle sustainability assessment. J. Clean. Prod. 2018, 192, 55–70. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Bourell, D.L.; Sreenivasan, R.; Hague, R. Sustainability of additive manufacturing: Measuring the energy consumption of the laser sintering process. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2011, 225, 2228–2239. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Wildman, R.; Ashcroft, I.; Hague, R. Shape Complexity and Process Energy Consumption in Electron Beam Melting: A Case of Something for Nothing in Additive Manufacturing? J. Ind. Ecol. 2017, 21, S157–S167. [Google Scholar] [CrossRef] [Green Version]

- Jackson, M.A.; Van Asten, A.; Morrow, J.D.; Min, S.; Pfefferkorn, F.E. Energy Consumption Model for Additive-Subtractive Manufacturing Processes with Case Study. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 459–466. [Google Scholar] [CrossRef]

- Nagarajan, H.P.N.; Haapala, K.R. Characterizing the influence of resource-energy-exergy factors on the environmental performance of additive manufacturing systems. J. Manuf. Syst. 2018, 48, 87–96. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008. In A Life Cycle Impact Assess Method which Comprises Harmon Categ Indic Midpoint Endpoint Lev; Ruimte en Milieu: Zoetermeer, The Netherlands, 2009; Volume 1, pp. 1–126. [Google Scholar]

- Minetola, P.; Eyers, D. Energy and Cost Assessment of 3D Printed Mobile Case Covers. Procedia CIRP 2018, 69, 130–135. [Google Scholar] [CrossRef]

- Drizo, A.; Pegna, J. Environmental impacts of rapid prototyping: An overview of research to date. Rapid Prototyp. J. 2006, 12, 64–71. [Google Scholar] [CrossRef]

- Bours, J.; Adzima, B.; Gladwin, S.; Cabral, J.; Mau, S. Addressing Hazardous Implications of Additive Manufacturing: Complementing Life Cycle Assessment with a Framework for Evaluating Direct Human Health and Environmental Impacts. J. Ind. Ecol. 2017, 21, S25–S36. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Li, L. Total volatile organic compound emission evaluation and control for stereolithography additive manufacturing process. J. Clean. Prod. 2018, 170, 1268–1278. [Google Scholar] [CrossRef]

- Faludi, J.; Bayley, C.; Bhogal, S.; Iribarne, M. Comparing Environmental Impacts of Additive Manufacturing vs. Traditional Machining via Life-Cycle Assessment Introduction. Rapid Prototyp. J. 2015, 21, 14–33. [Google Scholar] [CrossRef] [Green Version]

- Gao, W.; Li, T.; Tang, Z.; Peng, S.; Zhang, H.C. Investigation on the Comparative Life Cycle Assessment between Newly Manufacturing and Remanufacturing Turbochargers. Procedia CIRP 2017, 61, 750–755. [Google Scholar] [CrossRef]

- Böckin, D.; Tillman, A.M. Environmental assessment of additive manufacturing in the automotive industry. J. Clean. Prod. 2019, 226, 977–987. [Google Scholar] [CrossRef]

- Gebler, M.; Schoot Uiterkamp, A.J.M.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Wits, W.W.; García, J.R.R.; Becker, J.M.J. How Additive Manufacturing Enables more Sustainable End-user Maintenance, Repair and Overhaul (MRO) Strategies. Procedia CIRP 2016, 40, 693–698. [Google Scholar] [CrossRef] [Green Version]

- Pigosso, D.C.A.; Zanette, E.T.; Filho, A.G.; Ometto, A.R.; Rozenfeld, H. Ecodesign methods focused on remanufacturing. J. Clean. Prod. 2010, 18, 21–31. [Google Scholar] [CrossRef]

- Lahrour, Y.; Brissaud, D. A Technical Assessment of Product/Component Re-manufacturability for Additive Remanufacturing. Procedia CIRP 2018, 69, 142–147. [Google Scholar] [CrossRef]

- Ünal, E.; Shao, J. A taxonomy of circular economy implementation strategies for manufacturing firms: Analysis of 391 cradle-to-cradle products. J. Clean. Prod. 2019, 212, 754–765. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.P.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef] [Green Version]

- Kravchenko, M.; Pigosso, D.C.; McAloone, T.C. Towards the ex-ante sustainability screening of circular economy initiatives in manufacturing companies: Consolidation of leading sustainability-related performance indicators. J. Clean. Prod. 2019, 241, 118318. [Google Scholar] [CrossRef]

- Sauerwein, M.; Doubrovski, E.; Balkenende, R.; Bakker, C. Exploring the potential of additive manufacturing for product design in a circular economy. J. Clean. Prod. 2019, 226, 1138–1149. [Google Scholar] [CrossRef]

- Ljunggren, S.A.; Karlsson, H.; Ståhlbom, B.; Krapi, B.; Fornander, L.; Karlsson, L.E.; Bergström, B.; Nordenberg, E.; Ervik, T.K.; Graff, P. Biomonitoring of Metal Exposure During Additive Manufacturing (3D Printing). Saf. Health Work 2019, 10, 518–526. [Google Scholar] [CrossRef]

- Mellin, P.; Jönsson, C.; Åkermo, M.; Fernberg, P.; Nordenberg, E.; Brodin, H.; Strondl, A. Nano-sized by-products from metal 3D printing, composite manufacturing and fabric production. J. Clean. Prod. 2016, 139, 1224–1233. [Google Scholar] [CrossRef]

- Rehfisch, P.; Anderson, M.; Berg, P.; Lampa, E.; Nordling, Y.; Svartengren, M.; Westberg, H.; Gunnarsson, L.G. Lung function and respiratory symptoms in hard metal workers exposed to cobalt. J. Occup. Environ. Med. 2012, 54, 409–413. [Google Scholar] [CrossRef]

- Afshar-Mohajer, N.; Wu, C.Y.; Ladun, T.; Rajon, D.A.; Huang, Y. Characterization of particulate matters and total VOC emissions from a binder jetting 3D printer. Build Environ. 2015, 93, 293–301. [Google Scholar] [CrossRef]

- Graff, P.; Ståhlbom, B.; Nordenberg, E.; Graichen, A.; Johansson, P.; Karlsson, H. Evaluating Measuring Techniques for Occupational Exposure during Additive Manufacturing of Metals: A Pilot Study. J. Ind. Ecol. 2017, 21, S120–S129. [Google Scholar] [CrossRef] [Green Version]

- Chen, D.; Heyer, S.; Ibbotson, S.; Salonitis, K.; Steingrímsson, J.G.; Thiede, S. Direct digital manufacturing: Definition, evolution, and sustainability implications. J. Clean. Prod. 2015, 107, 615–625. [Google Scholar] [CrossRef]

- Song, R.; Telenko, C. Material and energy loss due to human and machine error in commercial FDM printers. J. Clean. Prod. 2017, 148, 895–904. [Google Scholar] [CrossRef]

- EU Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098 (accessed on 7 February 2020).

- Dotchev, K. Recycling of polyamide 12 based powders in the laser sintering process. Rapid Prototyp. J. 2009, 15, 192. [Google Scholar] [CrossRef]

- Petrovic, V.; Vicente Haro Gonzalez, J.; Jordá Ferrando, O.; Delgado Gordillo, J.; Ramón Blasco Puchades, J.; Portolés Griñan, L. Additive layered manufacturing: Sectors of industrial application shown through case studies. Int. J. Prod. Res. 2011, 49, 1061–1079. [Google Scholar] [CrossRef]

- Tang, H.P.; Qian, M.; Liu, N.; Zhang, X.Z.; Yang, G.Y.; Wang, J. Effect of Powder Reuse Times on Additive Manufacturing of Ti-6Al-4V by Selective Electron Beam Melting. JOM 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Gorji, N.E.; O’Connor, R.; Mussatto, A.; Snelgrove, M.; González, P.G.M.; Brabazon, D. Recyclability of stainless steel (316L) powder within the additive manufacturing process. Materialia 2019, 8, 100489. [Google Scholar] [CrossRef]

- Popov, V.V.; Katz-Demyanetz, A.; Garkun, A.; Bamberger, M. The effect of powder recycling on the mechanical properties and microstructure of electron beam melted Ti-6Al-4V specimens. Addit. Manuf. 2018, 22, 834–843. [Google Scholar] [CrossRef]

- Vojislav, P. Powder recyclability in electron beam melting for aeronautical use. Aircr. Eng. Aerosp. Technol. 2015, 87, 147–155. [Google Scholar]

- Heiden, M.J.; Deibler, L.A.; Rodelas, J.M.; Koepke, J.R.; Tung, D.J.; Saiz, D.J.; Jared, B.H. Evolution of 316L stainless steel feedstock due to laser powder bed fusion process. Addit. Manuf. 2019, 25, 84–103. [Google Scholar] [CrossRef]

- Pinto, F.C.; Souza Filho, I.R.; Sandim, M.J.R.; Sandim, H.R.Z. Defects in parts manufactured by selective laser melting caused by δ-ferrite in reused 316L steel powder feedstock. Addit. Manuf. 2020, 31, 100979. [Google Scholar] [CrossRef]

- Sutton, A.T.; Kriewall, C.S.; Karnati, S.; Leu, M.C.; Newkirk, J.W. Characterization of AISI 304L stainless steel powder recycled in the laser powder-bed fusion process. Addit. Manuf. 2020, 32, 100981. [Google Scholar] [CrossRef]

- Clayton, J. Optimising metal powders for additive manufacturing. Met. Powder Rep. 2014, 69, 14–17. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Elbestawi, M.; Dosbaeva, G.K.; Veldhuis, S.C. Thermal post-processing of AlSi10Mg parts produced by Selective Laser Melting using recycled powder. Addit. Manuf. 2018, 21, 234–247. [Google Scholar] [CrossRef]

- ASTM International. ASTM F3187-16, Standard Guide for Directed Energy Deposition of Metals; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Rousseau, J.N.; Bois-Brochu, A.; Blais, C. Effect of oxygen content in new and reused powder on microstructural and mechanical properties of Ti6Al4V parts produced by directed energy deposition. Addit. Manuf. 2018, 23, 197–205. [Google Scholar] [CrossRef]

- Renderos, M.; Torregaray, A.; Gutierrez-Orrantia, M.E.; Lamikiz, A.; Saintier, N.; Girot, F. Microstructure characterization of recycled IN718 powder and resulting laser clad material. Mater. Charact. 2017, 134, 103–113. [Google Scholar] [CrossRef] [Green Version]

- Renderos, M.; Girot, F.; Lamikiz, A.; Torregaray, A.; Saintier, N. Ni based powder reconditioning and reuse for LMD process. Phys. Procedia 2016, 83, 769–777. [Google Scholar] [CrossRef] [Green Version]

- Saboori, A.; Aversa, A.; Bosio, F.; Bassini, E.; Librera, E.; De Chirico, M.; Biamino, S.; Ugues, D.; Fino, P.; Lombardi, M. An investigation on the effect of powder recycling on the microstructure and mechanical properties of AISI 316L produced by Directed Energy Deposition. Mater. Sci. Eng. A 2019, 766, 138360. [Google Scholar] [CrossRef]

- EU Commission. EU Commission Decision 2000/532/EC. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32000D0532 (accessed on 7 February 2020).

- Gobierno Vasco/Eusko Jaurlaritza. Gestión de Los Residuos; Gobierno Vasco/Eusko Jaurlaritza: Vitoria-Gasteiz, Spain, 2018; Available online: https://www.euskadi.eus/gobierno-vasco/residuos/ (accessed on 7 February 2020).

- Gobierno Vasco/Eusko Jaurlaritza. Operadores de Instalaciones de Tratamiento de Residuos; Gobierno Vasco/Eusko Jaurlaritza: Vitoria-Gasteiz, Spain, 2018; Available online: https://www.euskadi.eus/operadores-de-instalaciones-de-tratamiento-de-residuos/web01-a2inghon/es/ (accessed on 7 February 2020).

| Keyword strings | Science Direct | Scopus | Used for |

|---|---|---|---|

| Laser Metal + AM | 792 | 811 | Introduction |

| Metal AM + LCA | 17 | 19 | Sustainability study |

| Metal AM + Sustainability | 34 | 20 | Sustainability study |

| AM + Recycle | 23 | 8 | Handling of powder |

| AM + Reuse | 37 | 35 | Handling of powder |

| Metal AM + Hazard | 2 | 5 | Handling of powder |

| AM Process Type | Brief Description | Technologies |

|---|---|---|

| Powder Bed Fusion (PBF) | Thermal energy selectively fuses regions of a powder bed | Electron Beam Melting (EBM) Selective Laser Sintering (SLS) Direct Metal Laser Sintering (DMLS) Selective Laser Melting (SLM) |

| Directed Energy Deposition (DED) | Focused thermal energy is used to fuse material by melting as it is being deposited | Fused Metal Deposition Systems (FMD) Laser Metal Deposition (LMD) Selective Laser Cladding (SLC) |

| AM Process Type | Powder Particle Size (µm) | Deposition Rate (g/min) | Dimensional Accuracy (µm) | Surface Roughness (µm) | References |

|---|---|---|---|---|---|

| Powder Bed Fusion (PBF) | 45–150 | 2–3 | ±0.05 | 9–16 | [55,56,57,58] |

| Direct Energy Deposition (DED) | 10–30 | 5–30 | ±0.13 | ≈40 | [55,56,59,60] |

| Material | Main Characteristics | Main Application |

|---|---|---|

| Inconel 718 |

| Turbine blades, heavy industry, etc. |

| Titanium Ti6Al4V |

| Aerospace industry and biomechanical applications (implants and prostheses) |

| AISI H13 |

| Injection molds, wear-resisting parts, hot stamping dies, etc. |

| AISI 316L |

| Corrosion-resistant applications, naval industry, intermediate soft layers, etc. |

| Stellite 6 |

| Crankshaft, bearing tracks, stamping dies, extrusion screws, etc. |

| Material | Manufacturer | Main Composition (wt.%) | Classification |

|---|---|---|---|

| Inconel 718 | Oerlikon Metco [66] | Ni: 53, Cr: 20, Fe: 17.4, Nb: 5.1, Mo: 3.1, Ti: 0.9, Al: 0.5 | H317 H351 H372 H412 |

| Titanium Ti6Al4V | LPW Technology [67] | Ti: 89.09, Al: 6.4, V: 3.9, Fe: 0.22, O: 0.07, C: 0.01 | H315 H319 H334 |

| AISI H13 | FST [68] | Fe: 90.41, Cr: 5.12, Mo: 1.33, V: 1.13, Si: 0.8, C: 0.41, Mn: 0.5 | H317 H351 H372 H412 |

| AISI 316L | Eramet [69] | Fe: 67.5, Cr: 18.2, Ni: 11.8, Mo: 2.3, Si: 0.34, C: 0.03, Mn: 0.08 | H317 H351 H372 H412 |

| Stellite 6 | Oerlikon Metco [66] | Co: 60.4, Cr: 28.5, W: 4.5, Si: 1.5, Fe: 1.5, C: 1, Mo: 1 | H319 H334 H317 H361 H400 H410 |

| Material | CAS Number | EC Number | Classification [70] | Limit Values According to Spanish Law 1/2014 ELV-DE [71] | 8 h Exposure Control TWA in mg/m3 |

|---|---|---|---|---|---|

| Titanium | 7440-32-6 | 231.142-3 | H228 H315 H335 | 1 mg/m3 in 8 h | 10 [73] |

| Aluminum | 7429-90-5 | 231-072-3 | H261 H228 | 10 | 10 |

| Vanadium | 7440-62-2 | 231-171-1 | H228 H315 H319 H335 H413 | 3 mg/m3 in 8 h (breathing) | 0.05 mg V2O5 [73] |

| Chromium | 7440-02-0 | 231-157-5 | H350 | 2 mg/m3 in 8 h | 0.5 |

| Nickel | 7440-02-0 | 231-111-4 | H317 H351 H372 H412 | 1 mg/m3 in 8 h | 1 |

| Niobium | 7440-03-1 | 231-113-5 | H228 H332 H250 | - | - |

| Molybdenum | 7439-98-7 | 231-107-2 | H225 H228 H361 | 3 mg/m3 in 8 h (breathing) | 10 [73] |

| Iron | 7439-89-6 | 231-096-4 | H228 H251 | - | 1 |

| Cobalt | 7440-48-4 | 231-157-5 | H332 H319 H317 H350i H361f H400 H410 | - | 0.1 |

| Tungsten | 7440-33-7 | 231-143-9 | H228 H252 | 10 mg/m3 in 15 min 5 mg/m3 in 8 h | 3 mg/m3 [72] |

| Manganese | 7439-96-5 | 231-105-1 | H319 H412 | 0.2 | 1 [73] |

| Code | Classification (Category) | Hazard Statement |

|---|---|---|

| H228 | 1 | Flammable solid |

| H252 | 2 | Self-heating in large quantities; may catch fire |

| H261 | 2 | In contact with water releases flammable gases |

| H315 | 2 | Causes skin irritation |

| H317 | 1 | Warning: May cause an allergic skin reaction |

| H319 | 2 | Causes serious eye irritation |

| H332 | 4 | Harmful if inhaled |

| H334 | 1 | May cause allergy or asthma symptoms or breathing difficulties if inhaled |

| H340 | 1 | May cause genetic defects |

| H341 | 2 | Suspected of causing genetic defects |

| H350 | 1 | May cause cancer |

| H350i | 1 | May cause cancer by inhalation |

| H351 | 2 | Suspected of causing cancer |

| H361 | 2 | Suspected of damaging fertility or the unborn child |

| H361f | 2 | Suspected of damaging fertility |

| H372 | 1 | Causes damage to organs (state all organs affected, if known) through prolonged or repeated exposure (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) |

| H400 | Aquatic Acute 1 | Very toxic to aquatic life |

| H410 | Aquatic Chronic 1 | Very toxic to aquatic life with long-lasting effects |

| H412 | Aquatic Chronic 3 | Harmful to aquatic life with long-lasting effects |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arrizubieta, J.I.; Ukar, O.; Ostolaza, M.; Mugica, A. Study of the Environmental Implications of Using Metal Powder in Additive Manufacturing and Its Handling. Metals 2020, 10, 261. https://doi.org/10.3390/met10020261

Arrizubieta JI, Ukar O, Ostolaza M, Mugica A. Study of the Environmental Implications of Using Metal Powder in Additive Manufacturing and Its Handling. Metals. 2020; 10(2):261. https://doi.org/10.3390/met10020261

Chicago/Turabian StyleArrizubieta, Jon Iñaki, Olatz Ukar, Marta Ostolaza, and Arantza Mugica. 2020. "Study of the Environmental Implications of Using Metal Powder in Additive Manufacturing and Its Handling" Metals 10, no. 2: 261. https://doi.org/10.3390/met10020261

APA StyleArrizubieta, J. I., Ukar, O., Ostolaza, M., & Mugica, A. (2020). Study of the Environmental Implications of Using Metal Powder in Additive Manufacturing and Its Handling. Metals, 10(2), 261. https://doi.org/10.3390/met10020261