A New 3D Creep-Fatigue-Elasticity Damage Interaction Diagram Based on the Total Tensile Strain Energy Density Model

Abstract

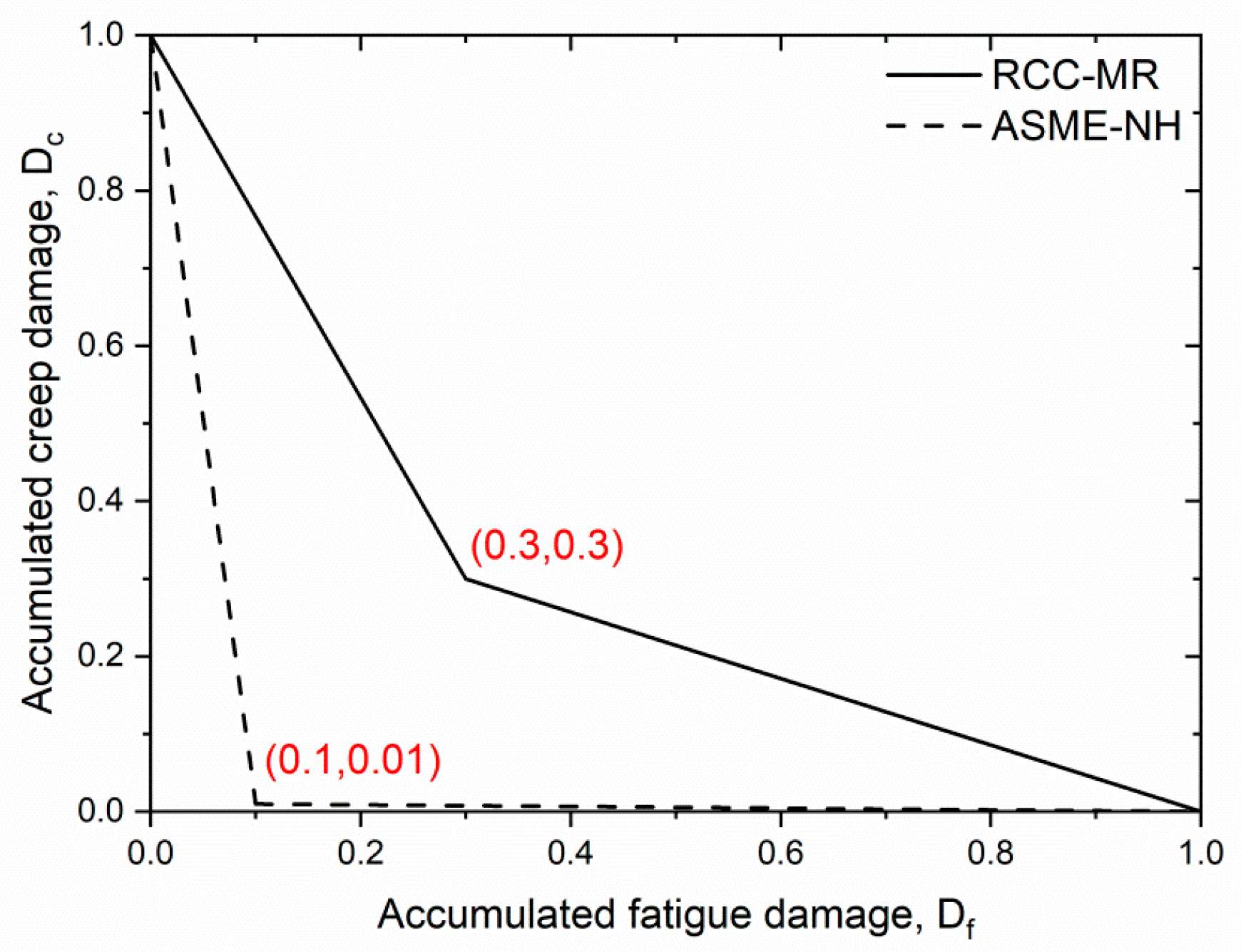

:1. Introduction

2. The Proposed Total Tensile Strain Energy-Based Life Prediction Model

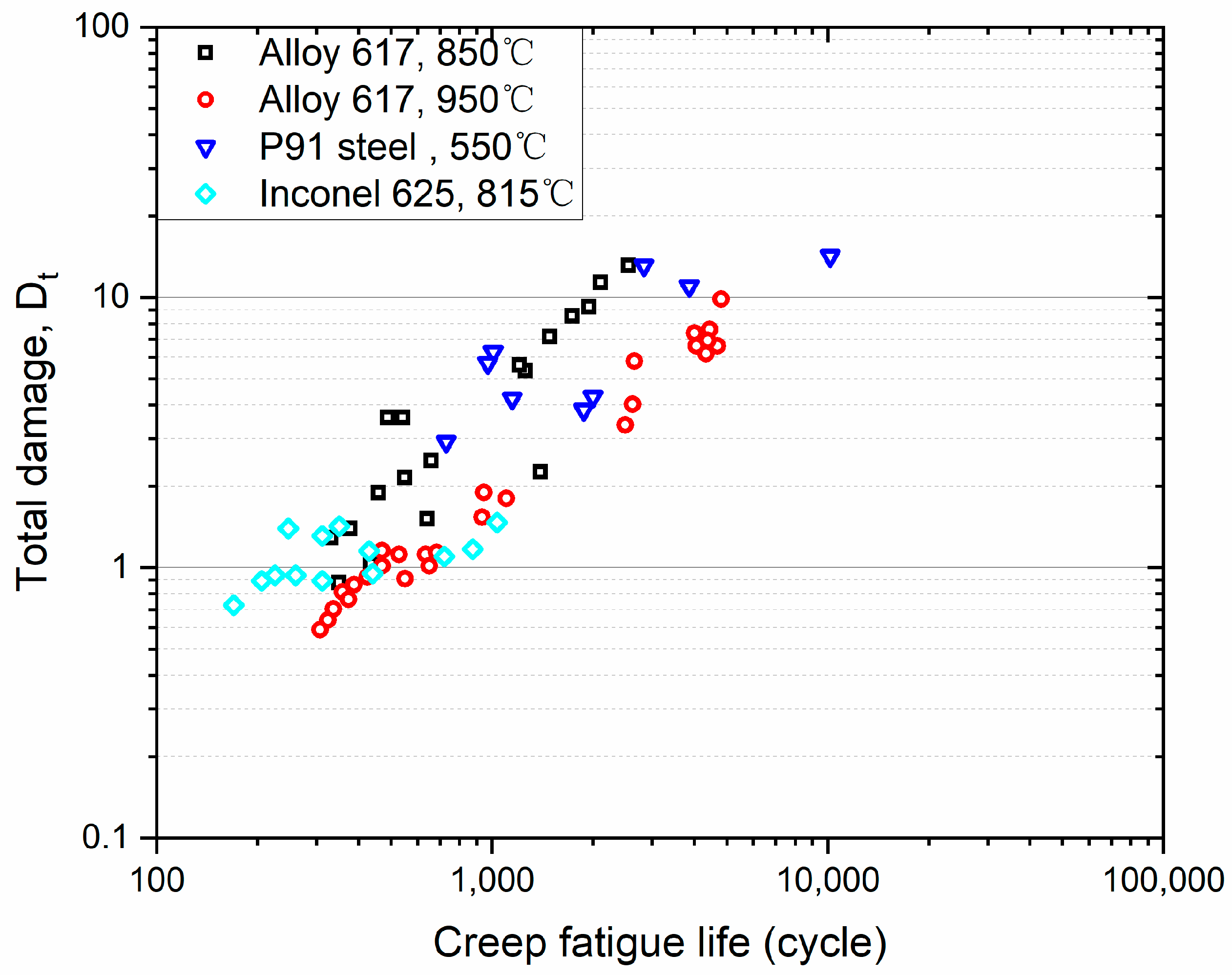

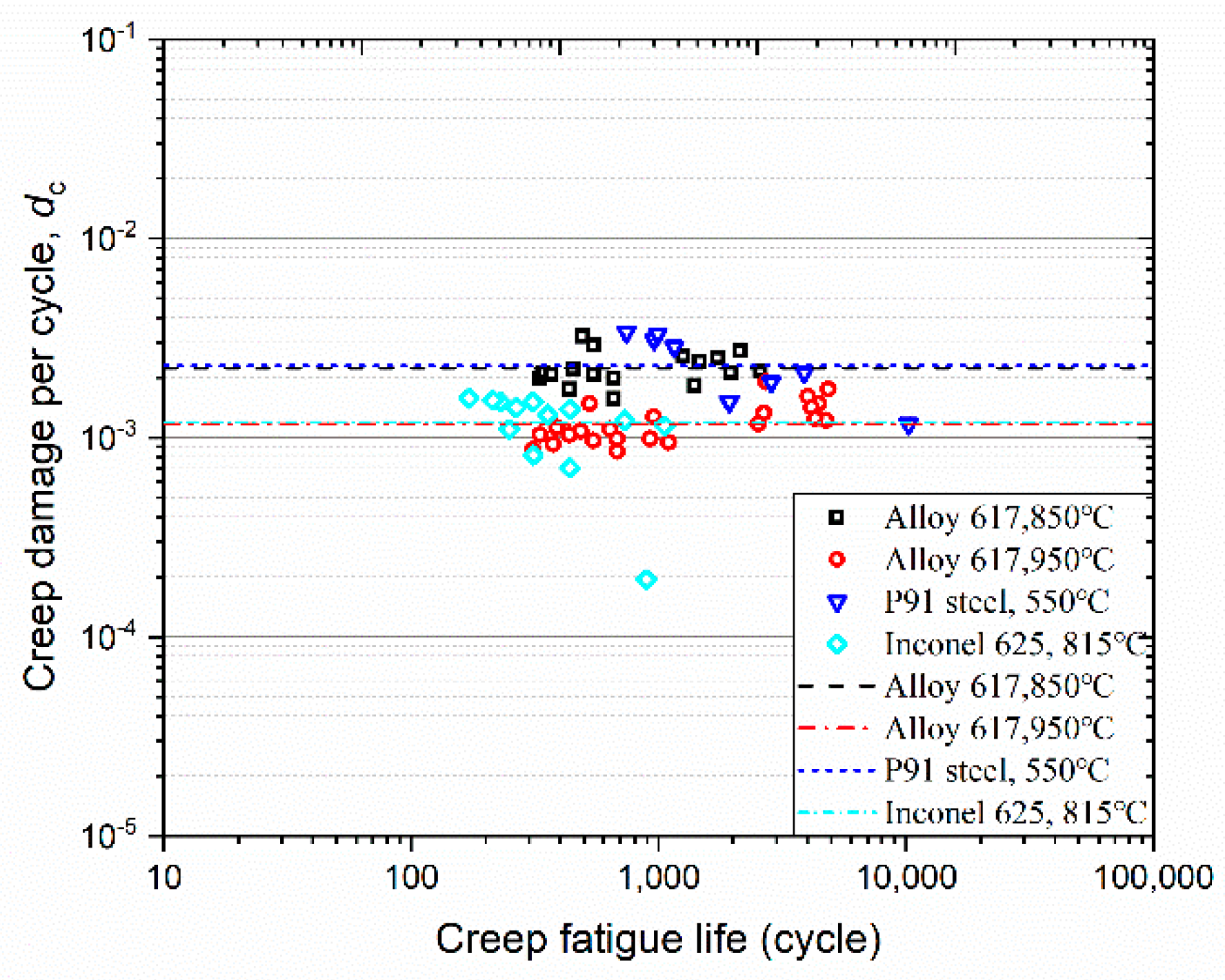

3. Construction of 3D Damage Interaction Diagram

4. Results and Discussions

4.1. Data Collection

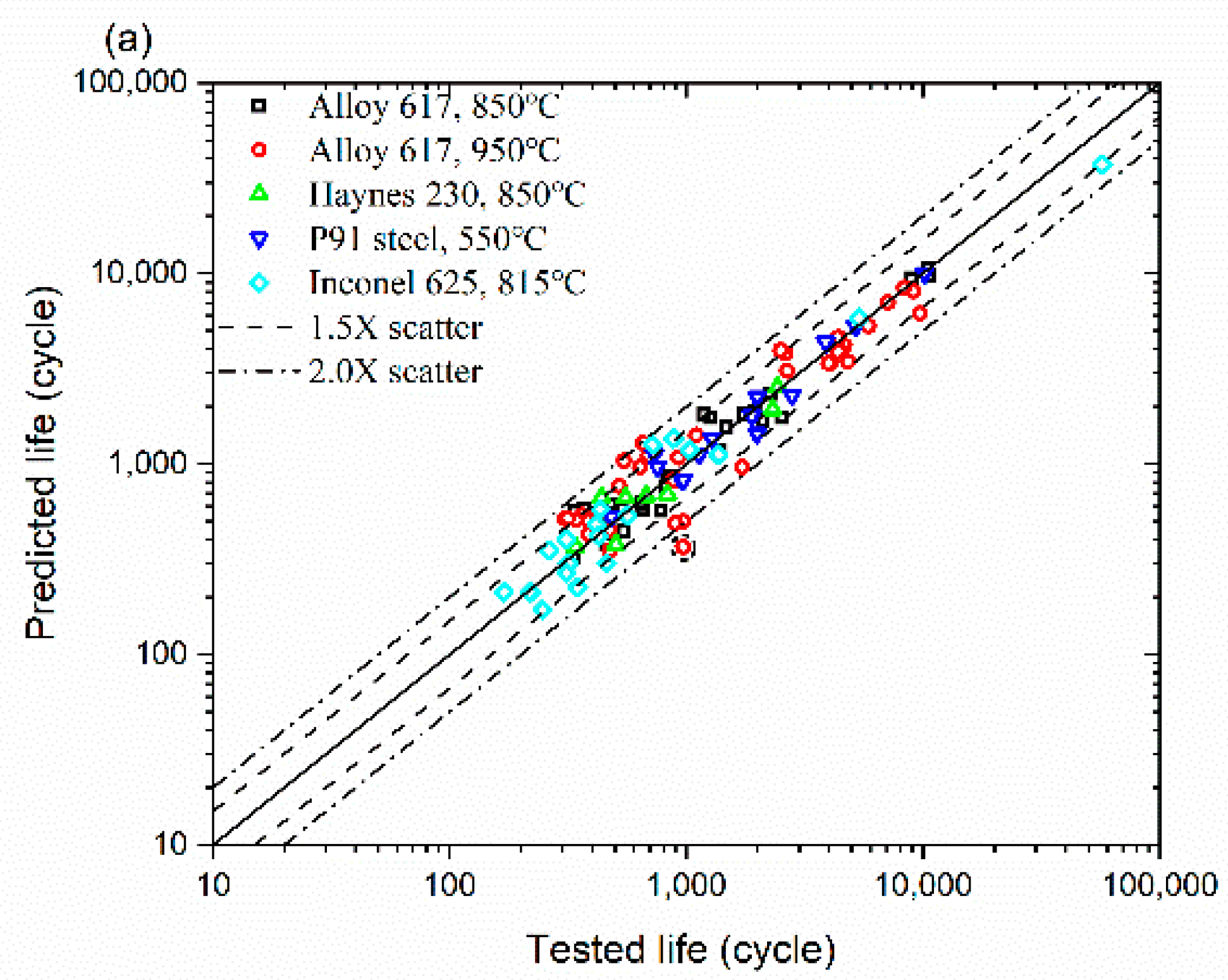

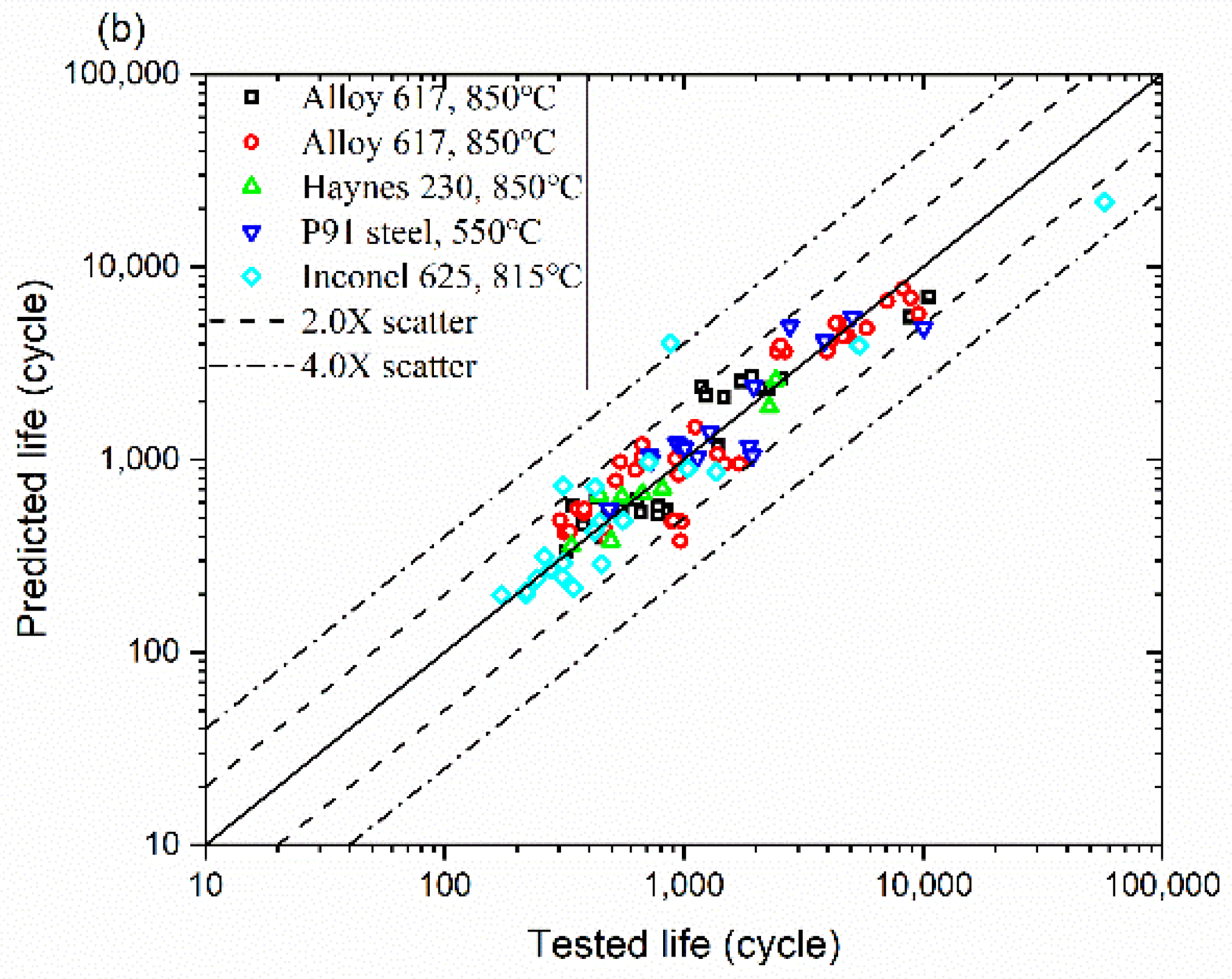

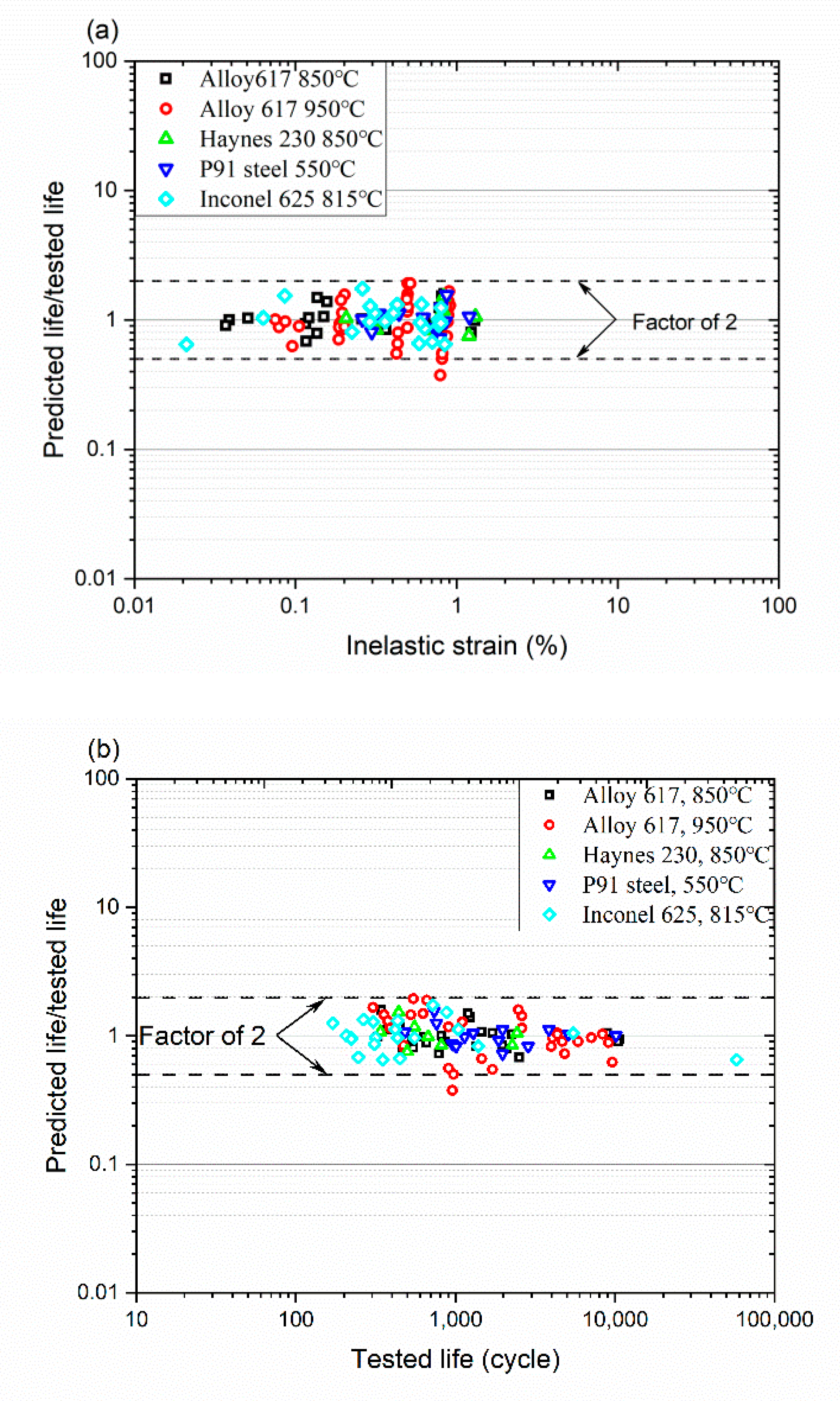

4.2. Fitting Procedure and Prediction Results

4.3. Damage Interaction Diagram by the Present Model

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- ASME. Section III, Division 1, Subsection NH; ASME: New York, NY, USA, 2007. [Google Scholar]

- RCC-MR. Construction Rules for Mechanical Components of FBR Nuclear Islands; RCC-MR, Appendix A: Paris, France, 2002. [Google Scholar]

- Ainsworth, R.A. R5: Assessment Procedure for the High Temperature Response of Structures; British Energy Generation Ltd.: London, UK, 2003. [Google Scholar]

- Robinson, E.L. Effect of Temperature Variation on the Long-Time Rupture Strength of Steels; Trans. ASME: New York, NY, USA, 1952. [Google Scholar]

- Priest, R.H.; Ellison, E.G. A combined deformation map-ductility exhaustion approach to creep-fatigue analysis. Mater. Sci. Eng. 1981, 49, 7–17. [Google Scholar] [CrossRef]

- Asayama, T.; Tachibana, Y. Collect Available Creep-Fatigue Data and Study Existing Creep-Fatigue Evaluation Procedures for Grade 91 and Hastelloy XR; ASME Standards Technology, LLC.: New York, NY, USA, 2007. [Google Scholar]

- Takahashi, Y. Study on creep-fatigue evaluation procedures for high-chromium steels—Part I: Test results and life prediction based on measured stress relaxation. Int. J. Press. Vessels. Pip. 2008, 85, 406–422. [Google Scholar] [CrossRef]

- Yan, X.L.; Zhang, X.C.; Tu, S.T.; Mannan, S.L.; Xuan, F.Z.; Lin, Y.C. Review of creep–fatigue endurance and life prediction of 316 stainless steels. Int. J. Press. Vessels. Pip. 2015, 126, 17–28. [Google Scholar] [CrossRef]

- Wang, X.W.; Zhang, W.; Gong, J.M.; Wahab, M.A. Low cycle fatigue and creep fatigue interaction behavior of 9Cr-0.5 Mo-1.8 WV-Nb heat-resistant steel at high temperature. J. Nucl. Mater. 2018, 505, 73–84. [Google Scholar] [CrossRef]

- Mannan, S.L.; Valsan, M. High-temperature low cycle fatigue, creep–fatigue and thermomechanical fatigue of steels and their welds. Int. J. Mech. Sci. 2006, 48, 160–175. [Google Scholar] [CrossRef]

- Date, S.; Ishikawa, H.; Otani, T.; Takahashi, Y.; Nakazawa, T. Study on environmental effect on fatigue and creep-fatigue strength of 316FR stainless steel in sodium at elevated temperature. Nucl. Eng. Des. 2008, 238, 353–367. [Google Scholar] [CrossRef]

- Carroll, L.J.; Lloyd, W.R.; Simpson, J.A.; Wright, R.N. The influence of dynamic strain aging on fatigue and creep-fatigue characterization of nickel-base solid solution strengthened alloys. Mater. High. Temp. 2010, 27, 313–323. [Google Scholar] [CrossRef]

- Reddy, G.P.; Mariappan, K.; Kannan, R.; Sandhya, R.; Sankaran, S.; Rao, K.B.S. Effect of strain rate on low cycle fatigue of 316LN stainless steel with varying nitrogen content: Part-II fatigue life and fracture. Int. J. Fatigue 2015, 81, 309–317. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, W.; Gong, J.; Jiang, Y. Experimental and numerical characterization of low cycle fatigue and creep fatigue behaviour of P92 steel welded joint. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 611–624. [Google Scholar] [CrossRef]

- Golanski, G.; Zielinska-Lipiec, A.; Zielinski, A.; Sroka, M. Effect of long-term service on microstructure and mechanical properties of martensitic 9% Cr Steel. J. Mater. Eng. Perform. 2017, 26, 1101–1107. [Google Scholar] [CrossRef] [Green Version]

- Zieliński, A.; Dobrzański, J.; Purzyńska, H.; Golański, G. Properties, structure and creep resistance of austenitic steel Super 304H. Mater. Test. 2015, 57, 859–865. [Google Scholar] [CrossRef]

- Coffin, J.L. Fatigue at high temperature-prediction and interpretation. Proc. Inst. Mech. Eng. 1974, 188, 109–127. [Google Scholar] [CrossRef]

- Coffin, J.L. Fatigue at High Temperature, Fatigue at Elevated Temperatures; ASTM International: New York, NY, USA, 1973. [Google Scholar]

- Halford, G.R.; Hirschberg, M.H.; Manson, S.S. Creep fatigue analysis by strain-range partitioning. In Proceedings of the First symposium on design for elevated temperature environment, San Francisco, CA, USA, 10–12 May 1971; pp. 12–28. [Google Scholar]

- Callaghan, M.D.; Humphries, S.; Law, M.; Ho, M.; Bendeich, P.; Li, H.; Yeung, W. Energy-based approach for the evaluation of low cycle fatigue behaviour of 2.25 Cr–1Mo steel at elevated temperature. Mater. Sci. Eng. A 2010, 527, 5619–5623. [Google Scholar] [CrossRef]

- Lee, K.O.; Hong, S.G.; Lee, S.B. A new energy-based fatigue damage parameter in life prediction of high-temperature structural materials. Mater. Sci. Eng. A 2008, 496, 471–477. [Google Scholar] [CrossRef]

- Oldham, J.; Abou-Hanna, J. A numerical investigation of creep-fatigue life prediction utilizing hysteresis energy as a damage parameter. Int. J. Press. Vessels. Pip. 2011, 88, 149–157. [Google Scholar] [CrossRef]

- Payten, W.M.; Dean, D.W.; Snowden, K.U. A strain energy density method for the prediction of creep–fatigue damage in high temperature components. Mater. Sci. Eng. A 2010, 527, 1920–1925. [Google Scholar] [CrossRef]

- Skelton, R. The energy density exhaustion method for assessing the creep-fatigue lives of specimens and components. Mater. High. Temp. 2013, 30, 183–201. [Google Scholar] [CrossRef]

- Takahashi, Y.; Dogan, B.; Gandy, D. Systematic evaluation of creep-fatigue life prediction methods for various alloys. J. Press. Vessel. Technol. 2013, 135, 061204. [Google Scholar] [CrossRef]

- Wang, R.Z.; Zhang, X.C.; Tu, S.T.; Zhu, S.P.; Zhang, C.C. A modified strain energy density exhaustion model for creep–fatigue life prediction. Int. J. Fatigue 2016, 90, 12–22. [Google Scholar] [CrossRef]

- Wang, R.Z.; Zhu, X.M.; Zhang, X.C.; Tu, S.T.; Gong, J.G.; Zhang, C.C. A generalized strain energy density exhaustion model allowing for compressive hold effect. Int. J. Fatigue 2017, 104, 61–71. [Google Scholar] [CrossRef]

- Zhu, S.P.; Huang, H.Z.; He, L.P.; Liu, Y.; Wang, Z. A generalized energy-based fatigue–creep damage parameter for life prediction of turbine disk alloys. Eng. Fract. Mech. 2012, 90, 89–100. [Google Scholar] [CrossRef]

- Zhu, S.P.; Huang, H.Z. A generalized frequency separation–strain energy damage function model for low cycle fatigue–creep life prediction. Fatigue Fract. Eng. Mater. Struct. 2010, 33, 227–237. [Google Scholar] [CrossRef]

- Fan, Y.N.; Shi, H.J.; Tokuda, K. A generalized hysteresis energy method for fatigue and creep-fatigue life prediction of 316L (N). Mater. Sci. Eng. A 2015, 625, 205–212. [Google Scholar] [CrossRef]

- Ellyin, F.; Kujawski, D. An energy-based fatigue failure criterion. Microstruct. Mech. Behav. Mater. 1985, 2, 591–600. [Google Scholar]

- Golos, K.; Ellyin, F. A total strain energy density theory for cumulative fatigue damage. J. Press. Vessel. Technol. 1988, 110, 36–41. [Google Scholar] [CrossRef]

- Golos, K.; Ellyin, F. Total Strain Energy Density as a Fatigue Damage Parameter; Advances in Fatigue Science and Technology; Springer: Dordrecht, The Netherlands, 1989; pp. 849–858. [Google Scholar]

- Fournier, B.; Sauzay, M.; Caës, C.; Noblecourt, M.; Mottot, M.; Bougault, A.; Rabeau, V.; Pineau, A. Creep-fatigue-oxidation interactions in a 9Cr–1Mo martensitic steel. Part II: Effect of compressive holding period on fatigue lifetime. Int. J. Fatigue 2018, 30, 663–676. [Google Scholar] [CrossRef]

- Li, S.X.; Smith, D.J. High temperature fatigue-creep behaviour of single crystal SRR99 nickel base superalloys: Part ii—Fatigue-creep life behaviour. Fatigue Fract. Eng. Mater. Struct. 1995, 18, 631–643. [Google Scholar] [CrossRef]

- Ostergren, W. A damage function and associated failure equations for predicting hold time and frequency effects in elevated temperature, low cycle fatigue. J. Test. Eval. 1976, 4, 327–339. [Google Scholar]

- Choudhary, B.K.; Christopher, J. Influence of temperature and strain rate on tensile deformation and fracture behaviour of boron added P91 steel. Int. J. Press. Vessels. Pip. 2019, 171, 153–161. [Google Scholar] [CrossRef]

- Choudhary, B.K.; Srinivasan, V.S.; Mathew, M.D. Influence of strain rate and temperature on tensile properties of 9Cr–1Mo ferritic steel. Mater. High. Temp. 2011, 28, 155–161. [Google Scholar] [CrossRef]

- Führer, U.; Aktaa, J. Modeling the cyclic softening and lifetime of ferritic-martensitic steels under creep-fatigue loading. Int. J. Mech. Sci. 2018, 136, 460–474. [Google Scholar] [CrossRef]

- Ruggles, M.; Ogata, T. Creep-Fatigue Criteria and Inelastic Behavior of Modified 9Cr-1Mo Steel at Elevated Temperatures; Final Report; Oak Ridge National Lab, Electric Power Research Instituion: Palo Alto, CA, USA, 1994. [Google Scholar]

- Bui-Quoc, T.; Gomuc, R.; Biron, A.; Nguyen, H.; Masounave, J. Elevated Temperature Fatigue-Creep Behavior of Nickel-Base Superalloy IN 625, Low Cycle Fatigue; ASTM International: West Conshohocken, PA, USA, 1988. [Google Scholar]

- Carroll, L.; Carroll, M. Creep-Fatigue Behavior of Alloy 617 at 850 and 950; Idaho National Laboratory (INL): Idaho Falls, ID, USA, 2013. [Google Scholar]

- Chen, X. High Temperature Creep-Fatigue Behavior of Alloy 617 and Alloy 230; University of Illinois at Urbana-Champaign: Illinois, IL, USA, 2012. [Google Scholar]

- Dundulis, G.; Janulionis, R.; Grybėnas, A.; Makarevičius, V.; Dundulis, R. Numerical and experimental investigation of low cycle fatigue behaviour in P91 steel. Eng. Fail. Anal. 2017, 79, 285–295. [Google Scholar] [CrossRef]

- Purohit, A.; Burke, W.F. Elevated Temperature Creep Behavior of Inconel Alloy 625; Argonne National Lab.: Illinois, IL, USA, 1984. [Google Scholar]

- Special Metals Corporation. Available online: https://www.specialmetals.com/assets/smc/documents/alloys/inconel/inconel-alloy-625.pdf (accessed on 13 August 2013).

- Kim, W.G.; Park, J.Y.; Lee, G.G.; Hong, S.D.; Kim, Y.W. Temperature effect on the creep behavior of alloy 617 in air and helium environments. Nucl. Eng. Des. 2014, 271, 291–300. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Denlinger, E.; Michaleris, P.; Stoica, A.D.; Ma, D.; Beese, A.M. Residual stress mapping in Inconel 625 fabricated through additive manufacturing: Method for neutron diffraction measurements to validate thermomechanical model predictions. Mater. Des. 2017, 113, 169–177. [Google Scholar] [CrossRef] [Green Version]

| Material | T (°C) | ∆εt (%) | th (min) | Life Ranges (cycles) | Reference | ||

|---|---|---|---|---|---|---|---|

| T | C | S | |||||

| P91 steel | 550 | 0.50–1.50 | 0/10/60 | 10/60 | 10/60 | 488–10120 | [39,40] |

| Inconel 625 | 815 | 0.37–1.22 | 0/1/5/10/15/30 | 5/15 | 0 | 170–57342 | [41] |

| Alloy 617 | 850 | 0.30–1.50 | 0/3/10/30 | 0 | 0 | 332–10631 | [42,43] |

| Alloy 617 | 950 | 0.30–1.00 | 0/3/10/30/150 | 0 | 0 | 308–9641 | [42] |

| Haynes 230 | 850 | 0.50–1.50 | 0/3/10/30 | 0 | 0 | 340–2295 | [43] |

| Material | T (°C) | n’ | K’ | |

|---|---|---|---|---|

| P91 steel | 550 | 0.1 | 0.0899 | 479.38 |

| Inconel 625 | 815 | 1.0 | 0.1710 | 1338.40 |

| Alloy 617 | 850 | 0.1 | 0.0645 | 360.34 |

| Alloy 617 | 850 | 0.025 | 0.0352 | 294.48 |

| Alloy 617 | 950 | 0.1 | −0.1100 | 117.77 |

| Haynes 230 | 850 | 0.025 | 0.0463 | 376.02 |

| Material | T (°C) | γ | a | b | |

|---|---|---|---|---|---|

| P91 steel | 550 | 0.1 | −2.2 | 2450.4 | −1.392 |

| Inconel 625 | 815 | 1.0 | 0.3 | 672.0 | −1.218 |

| Alloy 617 | 850 | 0.1 | 11.7 | 1156.1 | −0.800 |

| Alloy 617 | 850 | 0.025 | 30.0 | 1766.9 | −0.861 |

| Alloy 617 | 950 | 0.1 | 3.2 | 658.4 | −1.365 |

| Haynes 230 | 850 | 0.025 | 0.1 | 1243.5 | −1.047 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhang, N.; Wang, X. A New 3D Creep-Fatigue-Elasticity Damage Interaction Diagram Based on the Total Tensile Strain Energy Density Model. Metals 2020, 10, 274. https://doi.org/10.3390/met10020274

Wang Q, Zhang N, Wang X. A New 3D Creep-Fatigue-Elasticity Damage Interaction Diagram Based on the Total Tensile Strain Energy Density Model. Metals. 2020; 10(2):274. https://doi.org/10.3390/met10020274

Chicago/Turabian StyleWang, Qiang, Naiqiang Zhang, and Xishu Wang. 2020. "A New 3D Creep-Fatigue-Elasticity Damage Interaction Diagram Based on the Total Tensile Strain Energy Density Model" Metals 10, no. 2: 274. https://doi.org/10.3390/met10020274