Fabrication of Single Crystals through a µ-Helix Grain Selection Process during Electron Beam Metal Additive Manufacturing

Abstract

:1. Introduction

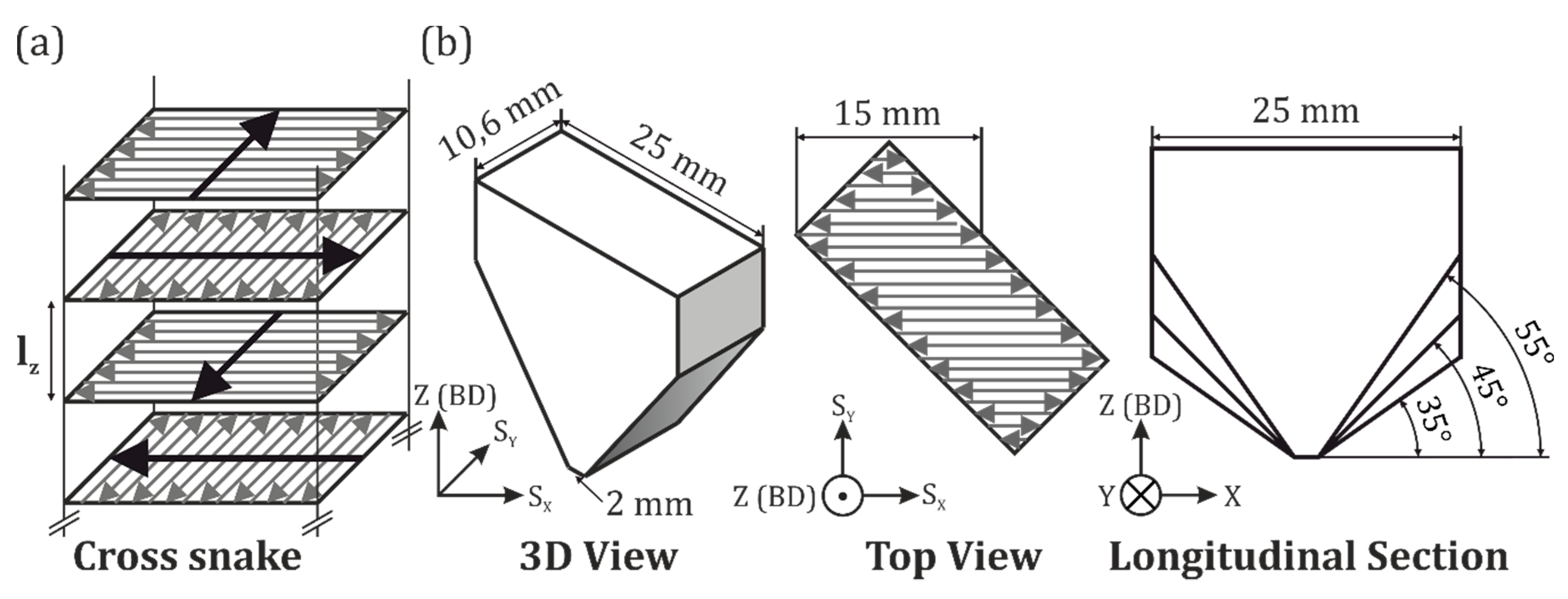

2. Materials and Methods

3. Results and Discussion

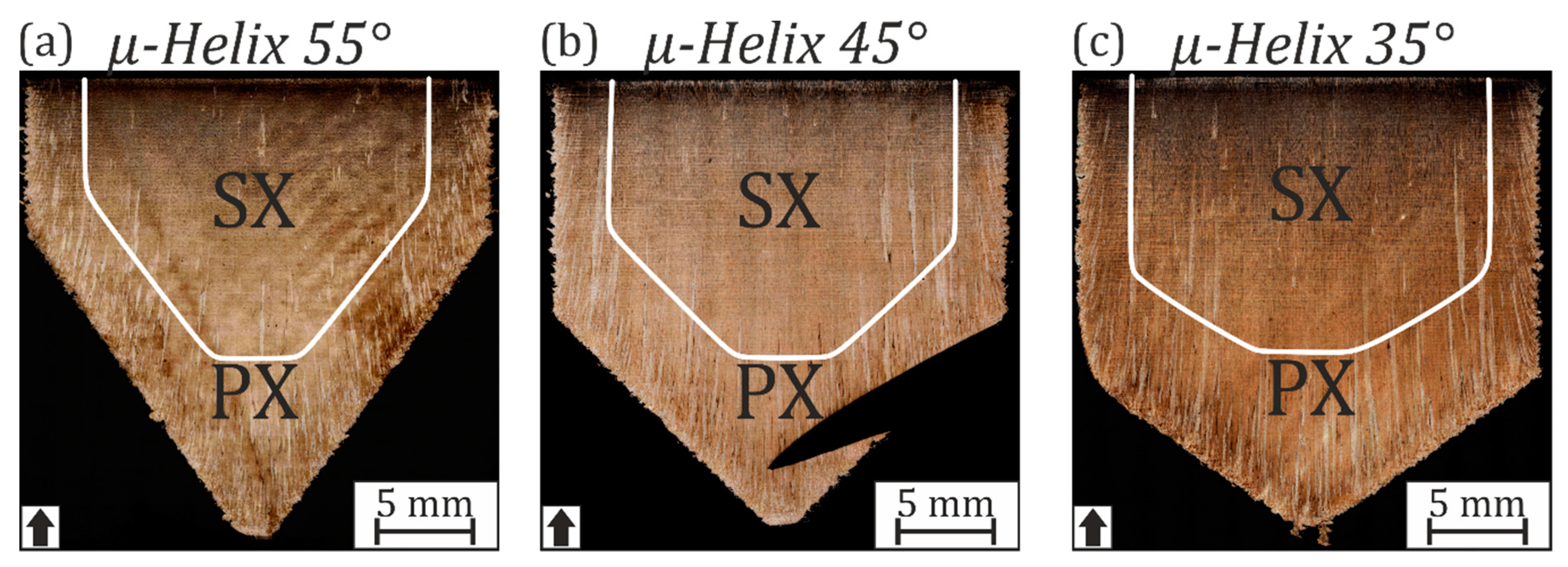

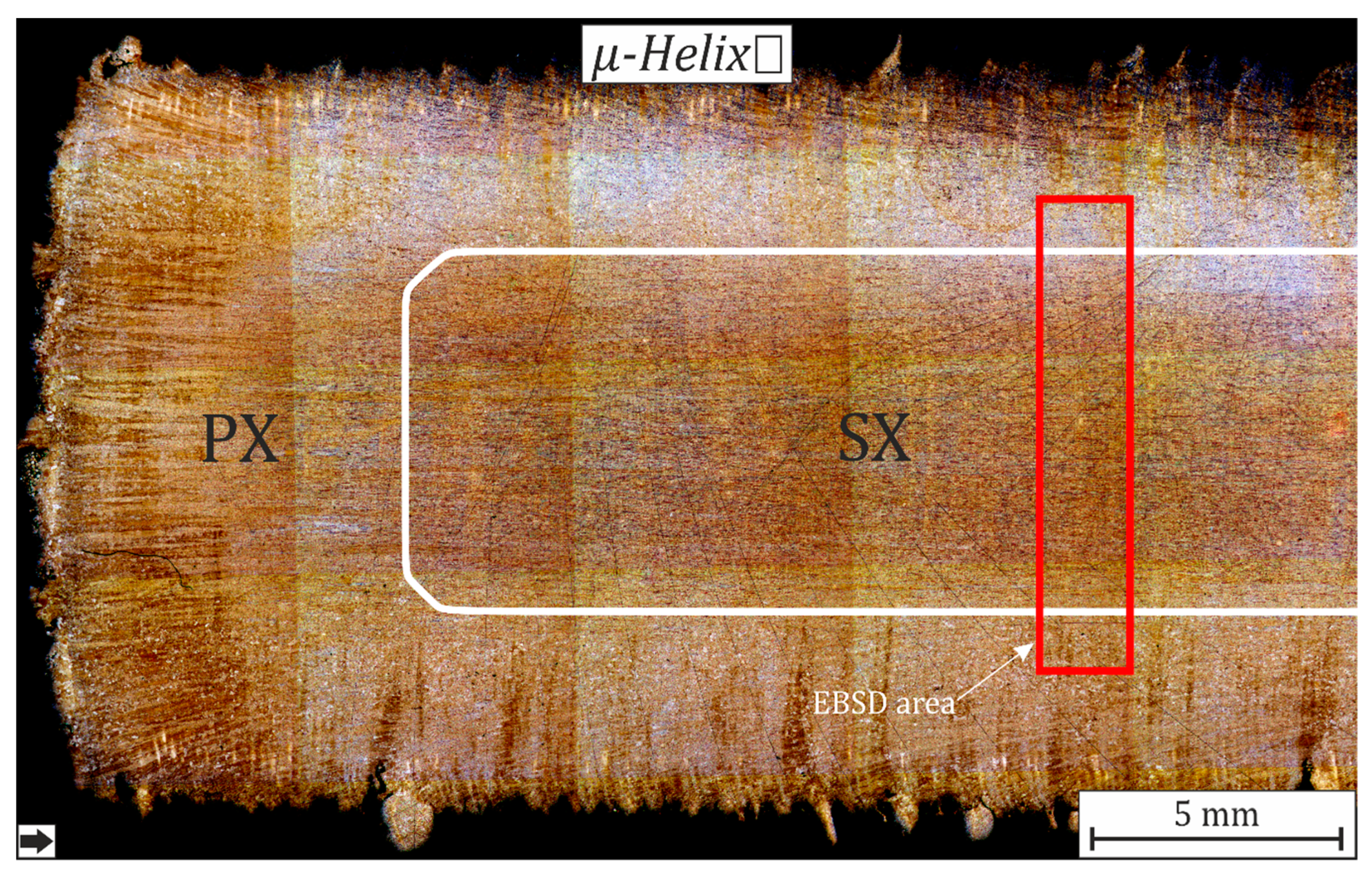

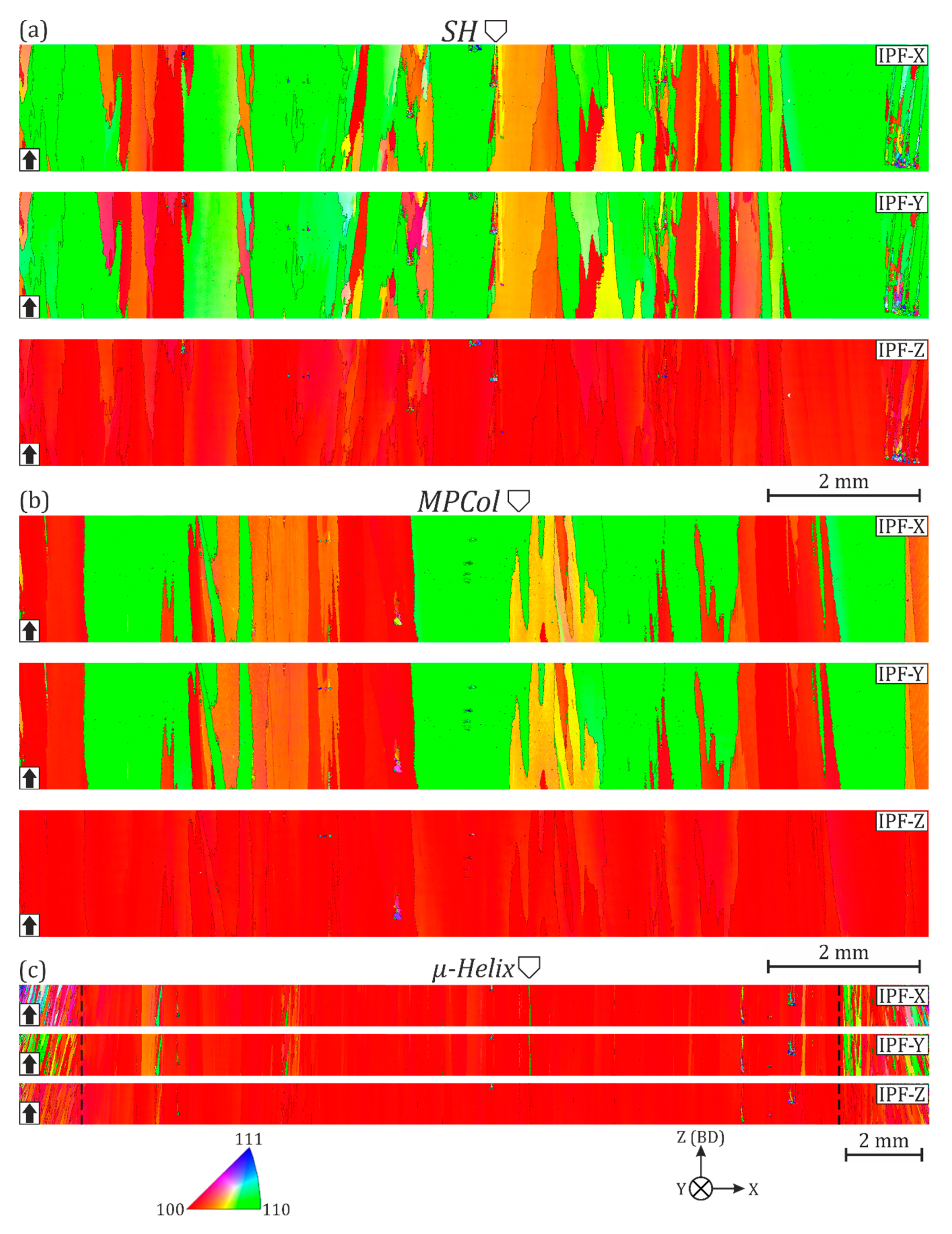

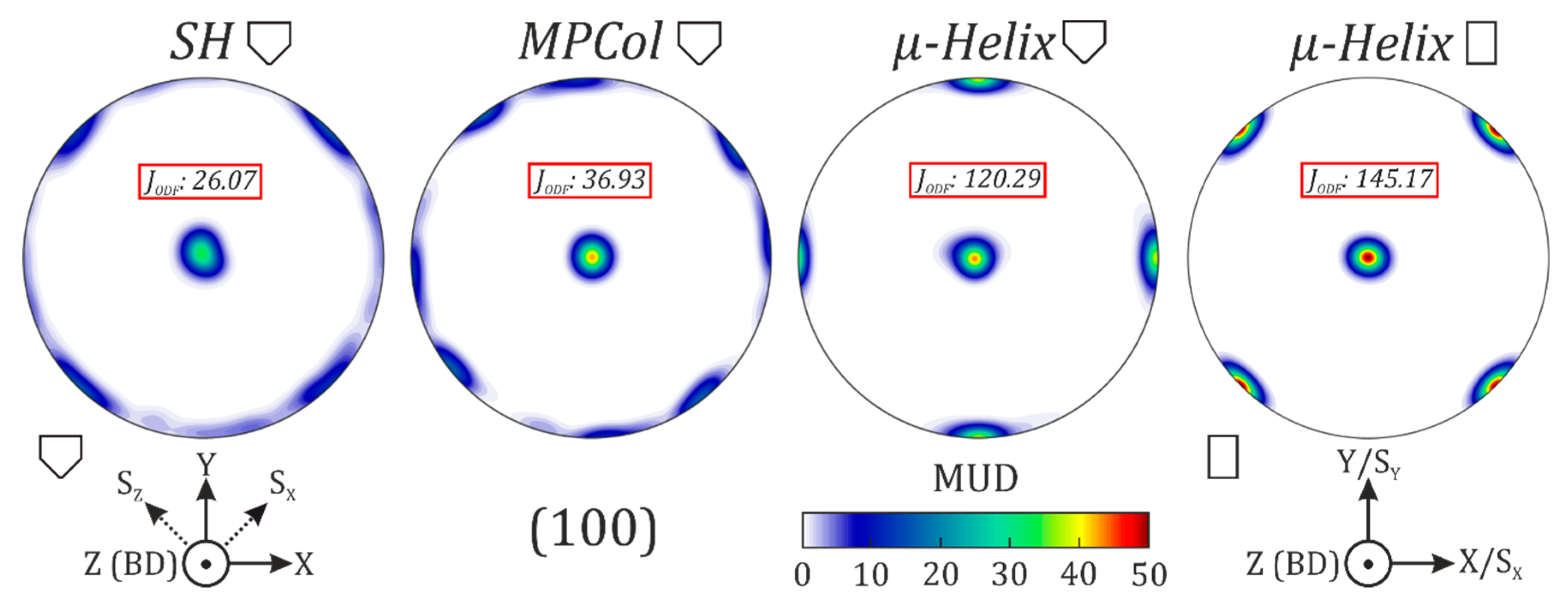

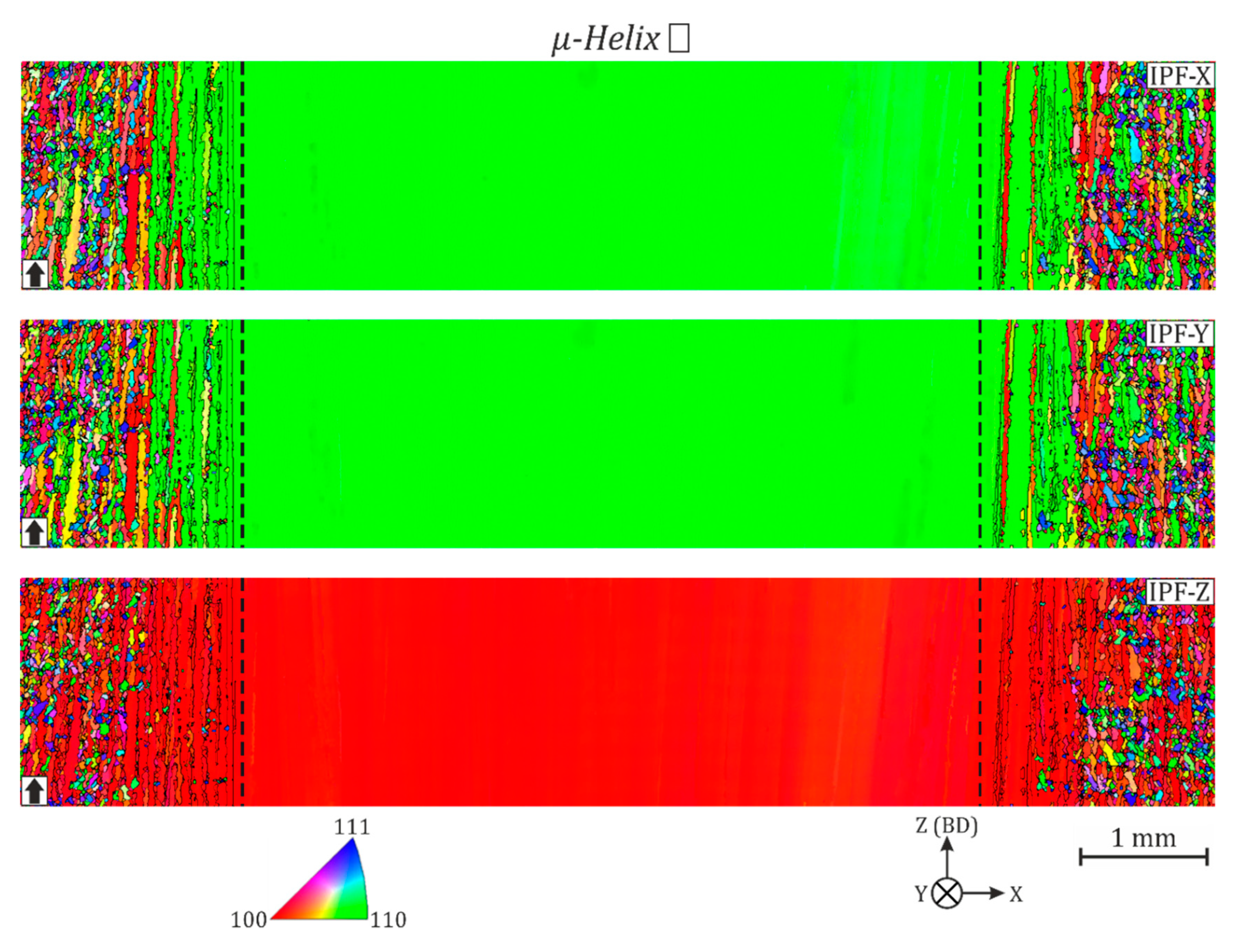

3.1. Grain Structure Characterization

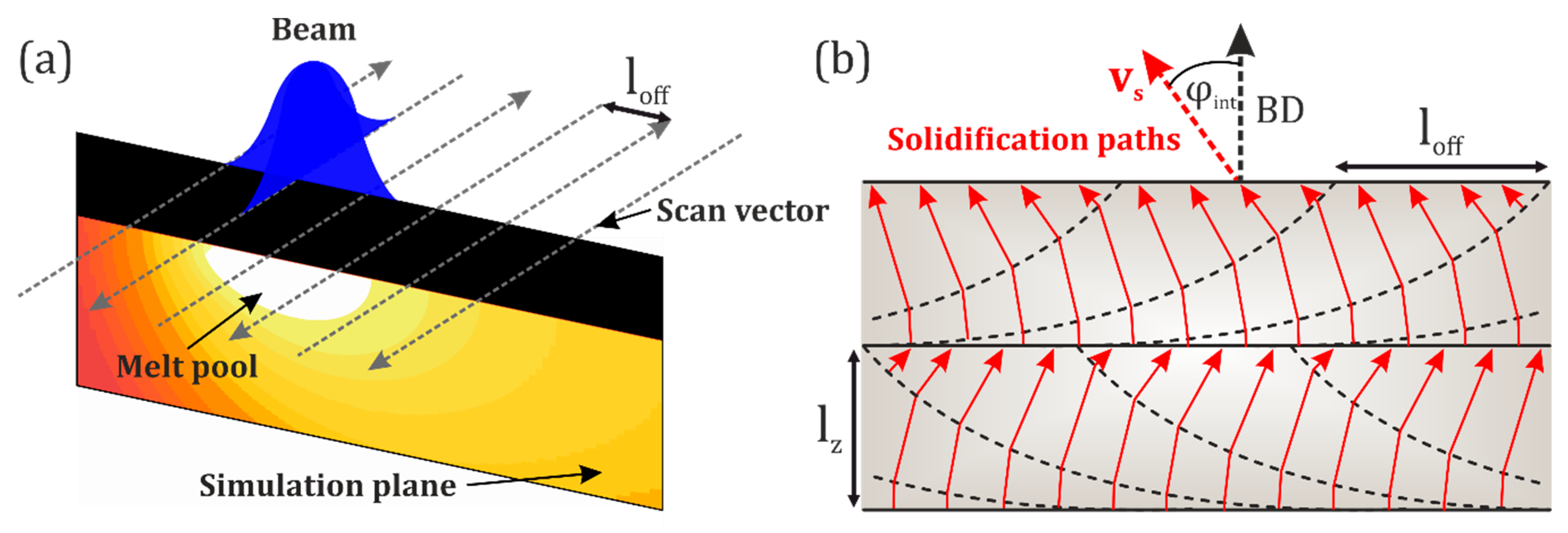

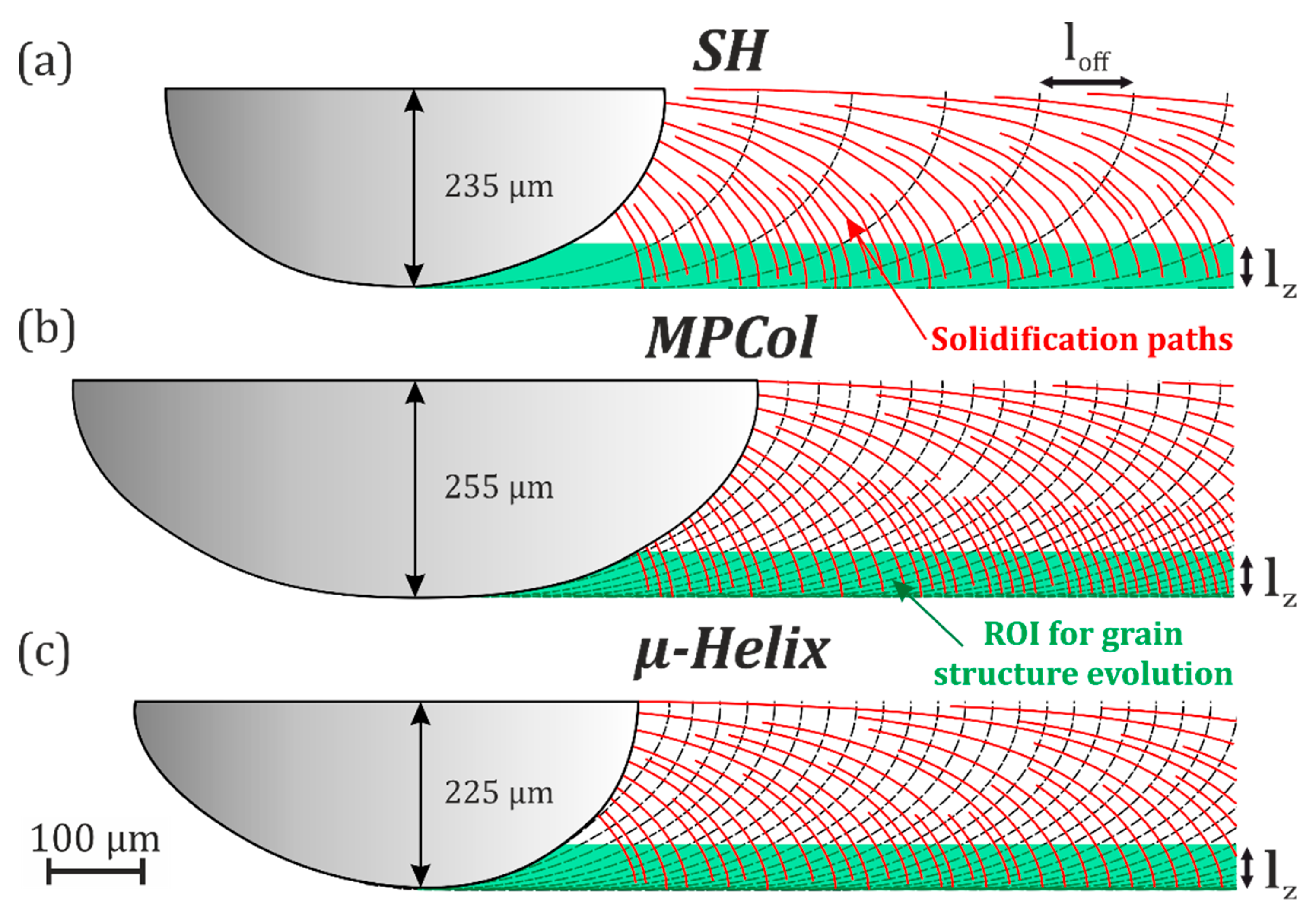

3.2. Numerical Simulation

4. Discussion

5. Conclusions

- Standard hatching and multi passing yield columnar grains with a pronounced <100> fiber texture along the build direction. The novel µ-Helix parameter setting, a special variant of multi passing, allowed for the fabrication of technical single crystals (SXs), which were surrounded by a polycrystalline shell. Within the SX section, minor agglomerations of stray grains were still present. This was overcome in a second build job with improved temperature control, which resulted in high quality cuboid SX samples.

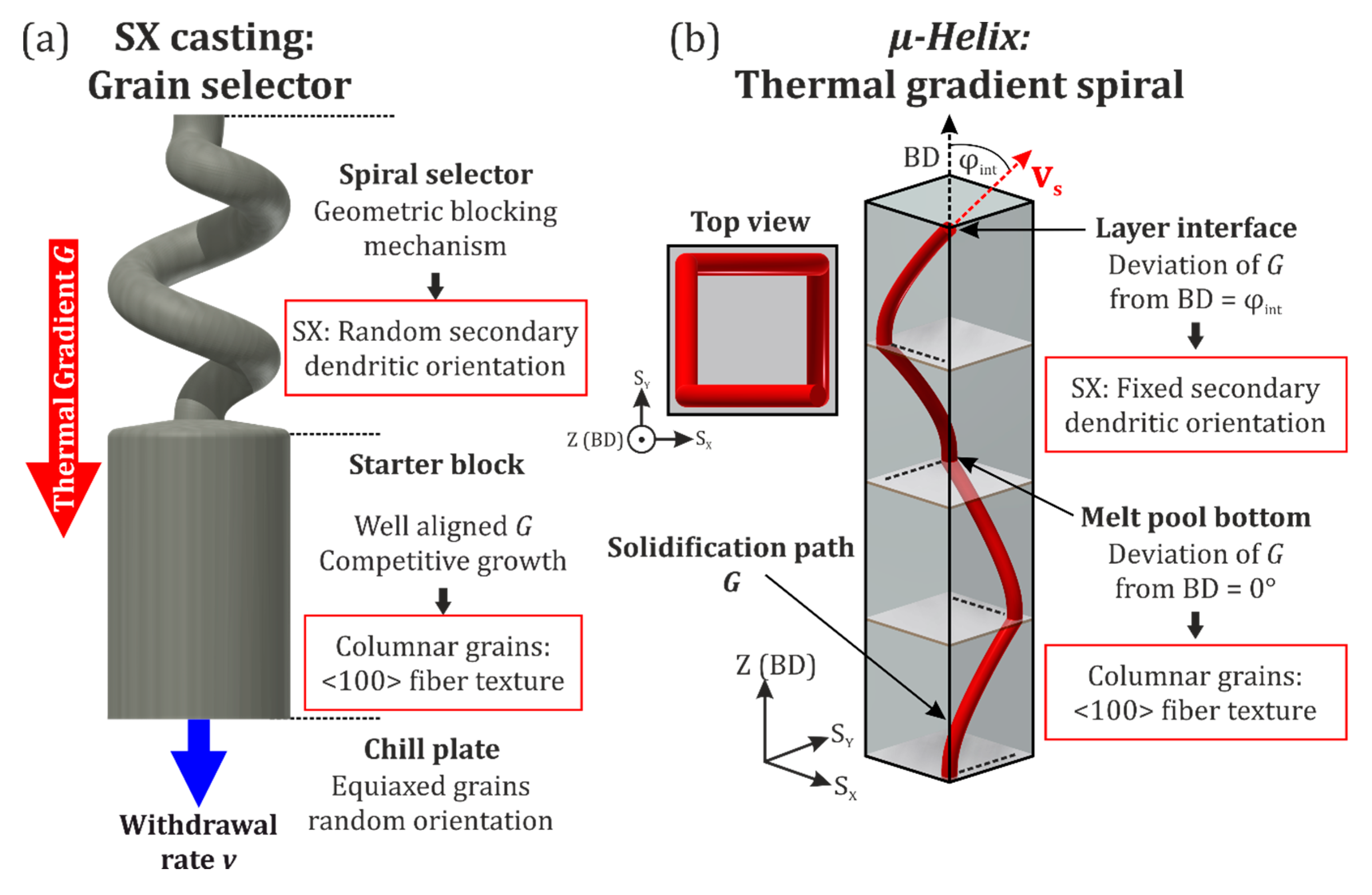

- In contrast to investment casting, where the secondary orientation of single crystals produced by a spiral grain selector is random, SEBM leads to a defined and reproducible secondary orientation. All SXs show a primary orientation of <100> parallel to the build direction, and a secondary orientation of <110> along the scan vectors.

- The aperture angle of the trapezoidal prisms determines the height where the SX region reaches its maximum width as new grain orientations emerge as long as the sample cross section still increases.

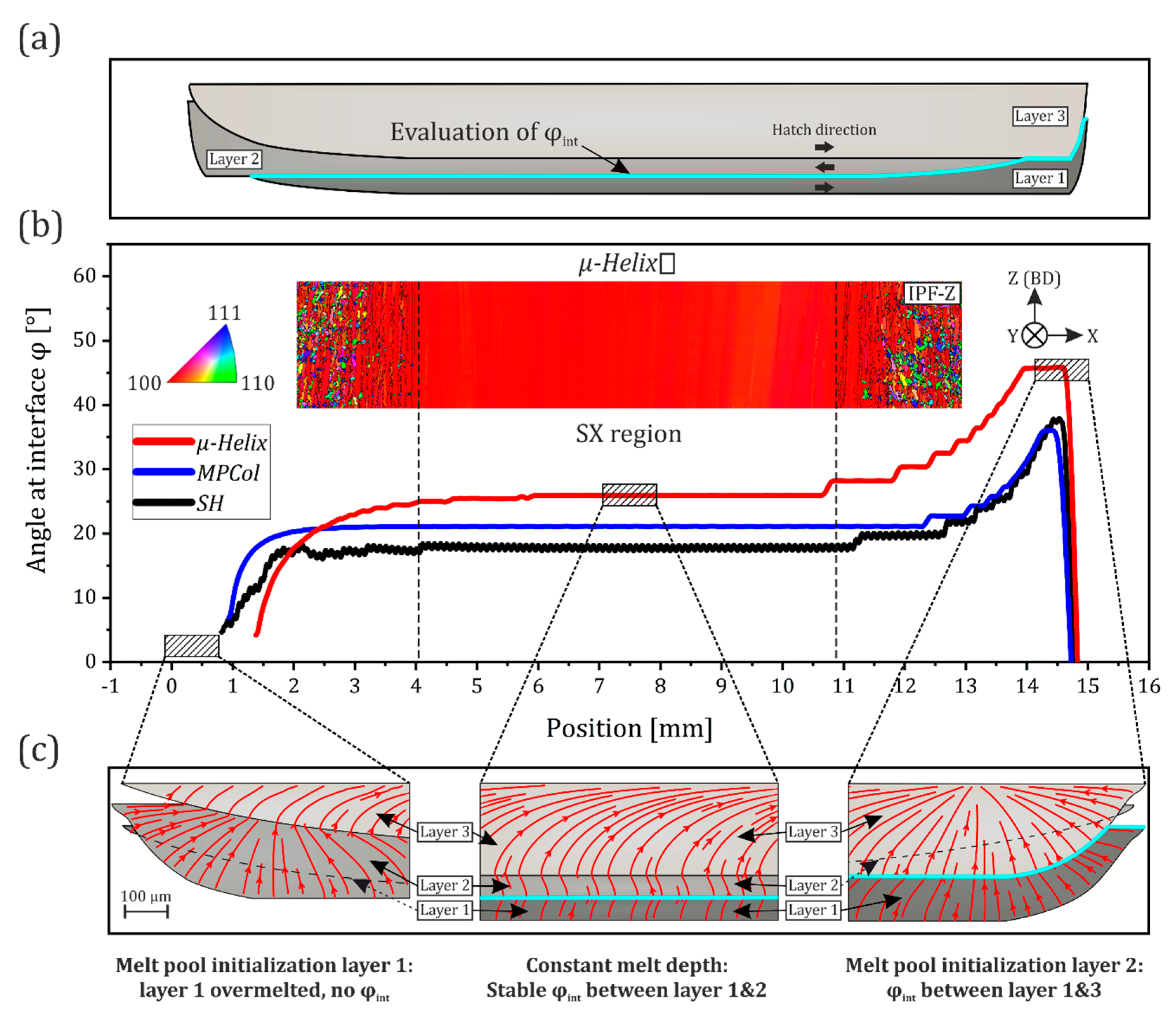

- Numerical simulations using our in-house software suite revealed that the deviation of the thermal gradient G from the build direction, right at the interface between two layers, φint, correlates with the effectiveness of grain selection. The higher φint, the stronger the grain selection. The µ-Helix parameter setting forces the solidification paths along a µm-sized helix over the course of multiple layers.

- The grain selection mechanisms leading to an SX are two-fold. As G deviates only slightly at the bottom of each melt pool, competitive growth between the grains based on their primary dendritic orientation is triggered, yielding a columnar grain structure. The increasing deviation of G from the BD closer to the layer interface leads to grain selection based on the secondary dendritic orientation. This mechanism is not yet fully understood and still under investigation.

Author Contributions

Funding

Conflicts of Interest

References

- Körner, C. Additive manufacturing of metallic components by selective electron beam melting—A review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar] [CrossRef] [Green Version]

- Strondl, A.; Palm, M.; Gnauk, J.; Frommeyer, G. Microstructure and mechanical properties of nickel based superalloy IN718 produced by rapid prototyping with electron beam melting (EBM). Mater. Sci. Technol. 2011, 27, 876–883. [Google Scholar] [CrossRef]

- Helmer, H.E.; Hartmann, N.; Körner, C.; Singer, R.F. Relation Between Processing Strategy, Grain Structure and Mechanical Properties in Superalloy Inconel 718 Processed by Selective Electron Beam Melting. In Proceedings of the DDMC 2014, Fraunhofer Direct Digital Manufacturing Conference, Berlin, Germany, 12–13 March 2014. [Google Scholar]

- Sun, S.-H.; Koizumi, Y.; Saito, T.; Yamanaka, K.; Li, Y.-P.; Cui, Y.; Chiba, A. Electron beam additive manufacturing of Inconel 718 alloy rods: Impact of build direction on microstructure and high-temperature tensile properties. Addit. Manuf. 2018, 23, 457–470. [Google Scholar] [CrossRef]

- Strondl, A.; Fischer, R.; Frommeyer, G.; Schneider, A. Investigations of MX and γ′/γ″ precipitates in the nickel-based superalloy 718 produced by electron beam melting. Mater. Sci. Eng. A 2008, 480, 138–147. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V. MMTA 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti6Al4V by selective electron beam melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- Helmer, H.; Bauereiß, A.; Singer, R.F.; Körner, C. Grain structure evolution in Inconel 718 during selective electron beam melting. Mater. Sci. Eng. A 2016, 668, 180–187. [Google Scholar] [CrossRef]

- Raghavan, N.; Dehoff, R.; Pannala, S.; Simunovic, S.; Kirka, M.; Turner, J.; Carlson, N.; Babu, S.S. Numerical modeling of heat-transfer and the influence of process parameters on tailoring the grain morphology of IN718 in electron beam additive manufacturing. Acta Mater. 2016, 112, 303–314. [Google Scholar] [CrossRef] [Green Version]

- Kirka, M.M.; Lee, Y.; Greeley, D.A.; Okello, A.; Goin, M.J.; Pearce, M.T.; Dehoff, R.R. Strategy for Texture Management in Metals Additive Manufacturing. JOM 2017, 69, 523–531. [Google Scholar] [CrossRef] [Green Version]

- Ramsperger, M.; Carolin, K. Selective Electron Beam Melting Of The Single Crystalline Nickel-Base Superalloy Cmsx-4®: From Columnar Grains To A Single Crystal. In Superalloys 2016; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Chauvet, E.; Tassin, C.; Blandin, J.-J.; Dendievel, R.; Martin, G. Producing Ni-base superalloys single crystal by selective electron beam melting. Scr. Mater. 2018, 152, 15–19. [Google Scholar] [CrossRef]

- Mainprice, D.; Bachmann, F.; Hielscher, R.; Schaeben, H. Descriptive tools for the analysis of texture projects with large datasets using MTEX: Strength, symmetry and components. Geol. Soc. Lond. Spec. Publ. 2014, 409, SP409. [Google Scholar] [CrossRef]

- Markl, M.; Rausch, A.M.; Küng, V.E.; Körner, C. SAMPLE: A Software Suite to Predict Consolidation and Microstructure for Powder Bed Fusion Additive Manufacturing. Adv. Eng. Mater. 2019, 1901270. [Google Scholar] [CrossRef] [Green Version]

- Pottlacher, G.; Hosaeus, H.; Kaschnitz, E.; Seifter, A. Thermophysical properties of solid and liquid Inconel 718 Alloy *. Scand. J. Metall. 2002, 31, 161–168. [Google Scholar] [CrossRef]

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead: Cambridge, UK, 2002. [Google Scholar]

- Mills, K.C.; Youssef, Y.M.; Li, Z.; Su, Y. Calculation of Thermophysical Properties of Ni-based Superalloys. ISIJ Int. 2006, 46, 623–632. [Google Scholar] [CrossRef] [Green Version]

- Walton, D.; Chalmers, B. The origin of the preferred orientation in the columnar zone of ingots. Trans. Metall. Soc. AIME 1959, 215, 447–457. [Google Scholar]

- Harald, E.H. Additive Fertigung durch Selektives Elektronenstrahlschmelzen der Nickelbasis Superlegierung IN718: Prozessfenster, Mikrostruktur und Mechanische Eigenschaften. Ph.D. Thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg, Erlangen, Germany, 2017. [Google Scholar]

- Dehoff, R.R.; Kirka, M.M.; List, F.A.; Unocic, K.A.; Sames, W.J. Crystallographic texture engineering through novel melt strategies via electron beam melting: Inconel 718. Mater. Sci. Technol. 2015, 31, 939–944. [Google Scholar] [CrossRef]

- Koepf, J.A.; Gotterbarm, M.R.; Markl, M.; Körner, C. 3D multi-layer grain structure simulation of powder bed fusion additive manufacturing. Acta Materialia 2018, 152, 119–126. [Google Scholar] [CrossRef]

- Dai, H.J.; D’Souza, N.; Dong, H.B. Grain Selection in Spiral Selectors During Investment Casting of Single-Crystal Turbine Blades: Part I. Experimental Investigation. Metall. Mater. Trans. A 2011, 42, 3430–3438. [Google Scholar] [CrossRef]

- Dai, H.J.; Dong, H.B.; D’Souza, N.; Gebelin, J.-C.; Reed, R.C. Grain Selection in Spiral Selectors During Investment Casting of Single-Crystal Components: Part II. Numerical Modeling. Metall. Mater. Trans. A 2011, 42, 3439–3446. [Google Scholar] [CrossRef]

- Rausch, A.M.; Gotterbarm, M.R.; Markl, M.; Körner, C. Nucleation Mechanism in Powder Bed Fusion Additive Manufacturing; 2020; Manuscript in preparation. [Google Scholar]

| Parameter Setting | Scan Strategy | Scan Speed [m/s] | Line Offset [µm] | Beam Power [W] | Build Temperature [°C] | Layer Thickness [µm] |

|---|---|---|---|---|---|---|

| Standard hatching (SH) | Cross snake | 3 | 100 | 660 | 950 | 50 |

| Multi passing (MPCol) | Cross snake | 13 | 30 | 858 | 950 | 50 |

| Multi passing (µ-Helix) | Cross snake | 7 | 30 | 546 | 950 | 50 |

| Fe | Ni | Cr | Nb | Mo | Ti | Al | Co | C |

|---|---|---|---|---|---|---|---|---|

| Bal. | 53.6 | 18.1 | 5.38 | 3.07 | 0.97 | 0.6 | 0.22 | 0.024 |

| Parameter | Value | Unit |

|---|---|---|

| Density | 7580 | Kgm−3 |

| Dynamic Viscosity | 4.0 × 10−3 | Pas |

| Atomic Mass | 26.73 | u |

| Surface Tension | 1.73 | Nm−1 |

| Solidus Temperature | 1528 | K |

| Liquidus Temperature | 1610 | K |

| Heat Capacity (solid) | 652 | JKg−1K−1 |

| Heat Capacity (liquid) | 778 | JKg−1K1 |

| Thermal Conductivity (solid) | 1.66 × 10−2 T + 5.80 | Wm−1K−1 |

| Thermal Conductivity (liquid) | 1.35 × 10−2 T + 5.15 | Wm−1K−1 |

| Latent Heat of Fusion | 2.27∙105 | JK−1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gotterbarm, M.R.; Rausch, A.M.; Körner, C. Fabrication of Single Crystals through a µ-Helix Grain Selection Process during Electron Beam Metal Additive Manufacturing. Metals 2020, 10, 313. https://doi.org/10.3390/met10030313

Gotterbarm MR, Rausch AM, Körner C. Fabrication of Single Crystals through a µ-Helix Grain Selection Process during Electron Beam Metal Additive Manufacturing. Metals. 2020; 10(3):313. https://doi.org/10.3390/met10030313

Chicago/Turabian StyleGotterbarm, Martin R., Alexander M. Rausch, and Carolin Körner. 2020. "Fabrication of Single Crystals through a µ-Helix Grain Selection Process during Electron Beam Metal Additive Manufacturing" Metals 10, no. 3: 313. https://doi.org/10.3390/met10030313