A Methodology for Incorporating the Effect of Grain Size on the Energy Efficiency Coefficient for Fatigue Crack Initiation Estimation in Polycrystalline Metal

Abstract

1. Introduction

2. Methods

2.1. Microstructure Characterization and Sample Design

2.2. Tensile Testing

2.3. Fatigue Testing

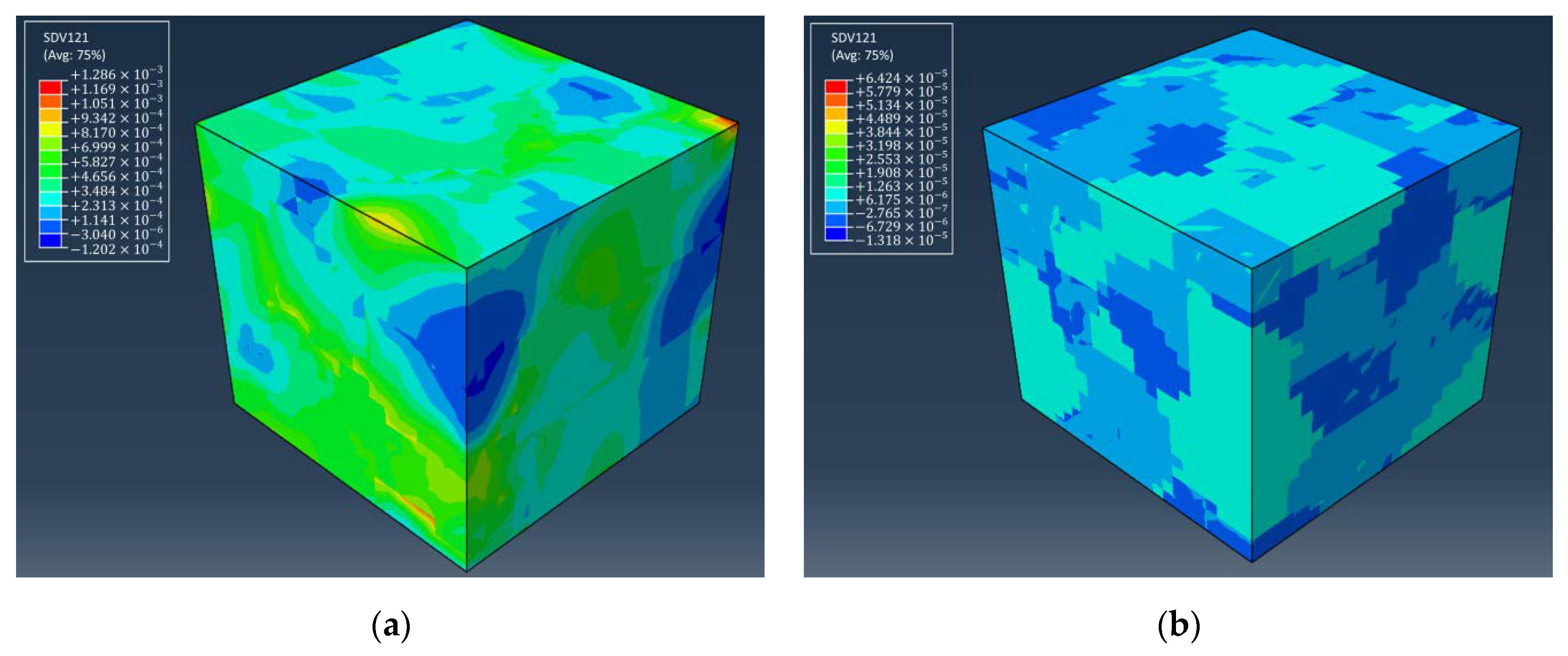

2.4. Crystal Plasticity Finite Element Model

2.5. Determination of the Elastic Constant and Critical Resolved Shear Stress

2.6. Determination of the Energy Efficiency Coefficient

3. Results and Discussion

3.1. Elastic Constants and Critical Resolved Shear Stress

3.2. Effect of Grain Size on the Energy Efficiency Coefficient (ρ)

3.3. Crack Initiation Prediction Improvement

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Choi, Y.; Liu, C.R. Rolling Contact Fatigue Life of Finish Hard Machined Surfaces: Part 1. Model Development. Wear 2006, 261, 485–491. [Google Scholar] [CrossRef]

- Mughrabi, H. Microstructural Mechanisms of Cyclic Deformation, Fatigue Crack Initiation and Early Crack Growth. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140132. [Google Scholar] [CrossRef] [PubMed]

- Kazymyrovych, V.; Bergström, J.; Burman, C. The Significance of Crack Initiation Stage in Very High Cycle Fatigue of Steels. Steel Res. Int. 2010, 81, 308–314. [Google Scholar] [CrossRef]

- Everaerts, J.; Verlinden, B.; Wevers, M. The Influence of the Alpha Grain Size on Internal Fatigue Crack Initiation in Drawn Ti-6Al-4V Wires. In Procedia Structural Integrity, Proceedings of the 21st European Conference on Fracture, ECF21, Catania, Italy, 20–24 June 2016; Elsevier: Amsterdam, The Netherlands, 2016; Volume 2, pp. 1055–1062. [Google Scholar] [CrossRef]

- Cruzado, A.; Lucarini, S.; Llorca, J.; Segurado, J. Crystal Plasticity Simulation of the Effect of Grain Size on the Fatigue Behavior of Polycrystalline Inconel 718. Int. J. Fatigue 2018, 113, 236–245. [Google Scholar] [CrossRef]

- Alexandre, F.; Deyber, S.; Pineau, A. Modelling the optimum grain size on the low cycle fatigue life of a Ni based superalloy in the presence of two possible crack initiation sites. Scr. Mater. 2004, 50, 25–30. [Google Scholar] [CrossRef]

- Prithivirajan, V.; Sangid, M.D. The role of defects and critical pore size analysis in the fatigue response of additively manufactured IN718 via crystal plasticity. Mater. Des. 2018, 150, 139–153. [Google Scholar] [CrossRef]

- Minaii, K.; Farrahi, G.H.; Karimpour, M.; Bahai, H.; Majzoobi, G.H. Investigation of microstructure effect on fretting fatigue crack initiation using crystal plasticity. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 640–650. [Google Scholar] [CrossRef]

- Signor, L.; Villechaise, P.; Ghidossi, T.; Lacoste, E.; Gueguen, M.; Courtin, S. Influence of local crystallographic configuration on microcrack initiation in fatigued 316LN stainless steel: Experiments and crystal plasticity finite elements simulations. Mater. Sci. Eng. A 2016, 649, 239–249. [Google Scholar] [CrossRef]

- Manonukul, A.; Dunne, F.P.E. High- and Low-Cycle Fatigue Crack Initiation Using Polycrystal Plasticity. In Proceedings of the Royal Society of London, London, UK, 8 July 2004; Series A: Mathematical, Physical and Engineering Sciences; The Royal Society: London, UK, 2004; Volume 460, pp. 1881–1903. [Google Scholar] [CrossRef]

- Hochhalter, J.D.; Littlewood, D.J.; Christ, R.J.; Veilleux, M.G.; Bozek, J.E.; Ingraffea, A.R.; Maniatty, A.M. A Geometric approach to modeling microstructurally small fatigue crack formation: II. physically based modeling of microstructure-dependent slip localization and actuation of the crack nucleation mechanism in AA 7075-T651. Model. Simul. Mater. Sci. Eng. 2010, 18, 045004. [Google Scholar] [CrossRef]

- Bhat Shrikant, P.; Fine Morris, E. Fatigue crack nucleation in iron and a high strength low alloy steel. Mater. Sci. Eng. A 2001, 314, 90–96. [Google Scholar] [CrossRef]

- Tanaka, K.; Mura, T. A Dislocation model for fatigue crack initiation. J. Appl. Mech. 1981, 48, 97–103. [Google Scholar] [CrossRef]

- Fine Morris, E.; Bhat Shrikant, P. A model of fatigue crack nucleation in single crystal iron and copper. Mater. Sci. Eng. A 2007, 468, 64–69. [Google Scholar] [CrossRef]

- Voothaluru, R.; Richard Liu, C. Determination of lattice level energy efficiency for fatigue crack initiation. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 70–78. [Google Scholar] [CrossRef]

- Voothaluru, R.; Liu, C.R. A Crystal plasticity based methodology for fatigue crack initiation life prediction in polycrystalline copper. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 671–681. [Google Scholar] [CrossRef]

- Voothaluru, R. A Crystal Plasticity Based Methodology for Modeling Fatigue Crack Initiation and Estimating Material Coefficients to Predict Fatigue Crack Initiation Life at Micro, Nano and Macro Scales. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2014. [Google Scholar]

- Lin, M.R.; Fine, M.E.; Mura, T. Fatigue crack initiation on slip bands: Theory and experiment. Acta Metall. 1986, 34, 619–628. [Google Scholar] [CrossRef]

- Li, L.; Shen, L.; Proust, G. Fatigue Crack Initiation Life Prediction for Aluminium Alloy 7075 Using Crystal Plasticity Finite Element Simulations. Mech. Mater. 2015, 81, 84–93. [Google Scholar] [CrossRef]

- Wan, V.V.C.; Cuddihy, M.A.; Jiang, J.; MacLachlan, D.W.; Dunne, F.P.E. An HR-EBSD and Computational Crystal Plasticity Investigation of Microstructural Stress Distributions and Fatigue Hotspots in Polycrystalline Copper. Acta Mater. 2016, 115, 45–57. [Google Scholar] [CrossRef]

- Wan, V.V.C.; Jiang, J.; MacLachlan, D.W.; Dunne, F.P.E. Microstructure-Sensitive Fatigue Crack Nucleation in a Polycrystalline Ni Superalloy. Int. J. Fatigue 2016, 90, 181–190. [Google Scholar] [CrossRef]

- Dabiri, M.; Laukkanen, A.; Bjork, T. Fatigue Microcrack Nucleation Modeling: A Survey of the State of the Art. Int. Rev. Mech. Eng. 2015, 9, 368–376. [Google Scholar] [CrossRef]

- Naderi, M.; Amiri, M.; Iyyer, N.; Kang, P.; Phan, N. Prediction of Fatigue Crack Nucleation Life in Polycrystalline AA7075-T651 Using Energy Approach. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 167–179. [Google Scholar] [CrossRef]

- Li, D.F.; Barrett, R.A.; O’Donoghue, P.E.; O’Dowd, N.P.; Leen, S.B. A Multi-Scale Crystal Plasticity Model for Cyclic Plasticity and Low-Cycle Fatigue in a Precipitate-Strengthened Steel at Elevated Temperature. J. Mech. Phys. Sol. 2017, 101, 44–62. [Google Scholar] [CrossRef]

- Verma, R.K.; Biswas, P. Crystal Plasticity-Based Modelling of Grain Size Effects in Dual Phase Steel. Mater. Sci. Technol. 2016, 32, 1553–1558. [Google Scholar] [CrossRef]

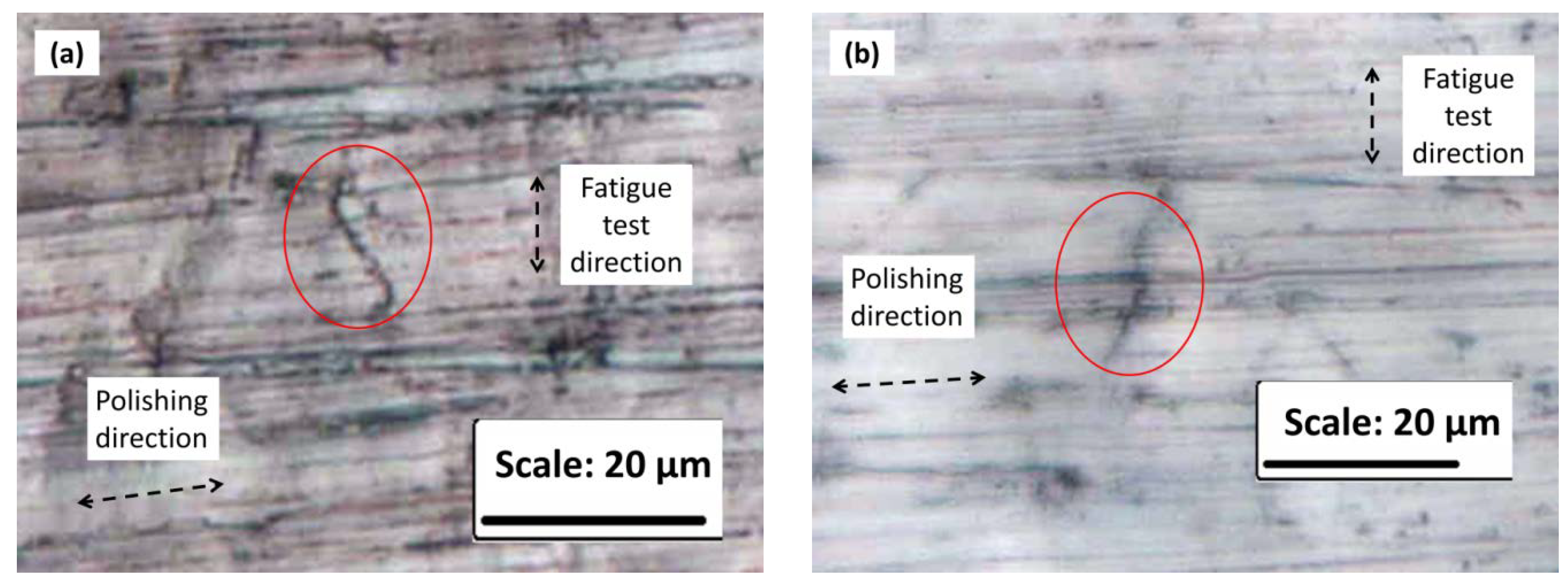

- Ou, C.Y.; Liu, C.R. The Effects of Grain Size and Strain Amplitude on Persistent Slip Band Formation and Fatigue Crack Initiation. Metall. Mater. Trans. A 2019, 50, 5056–5065. [Google Scholar] [CrossRef]

- ASTM International: ASTM E606/E606M-12; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM E8/E8M-16a, Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM International: ASTM E3; ASTM International: West Conshohocken, PA, USA, 2017.

- Taylor, G.I. Plastic Strain in Metals. Inst. Met. 1938, 62, 307. [Google Scholar]

- Asaro, R.J. Crystal Plasticity. J. Appl. Mech. 1983, 50, 921–934. [Google Scholar] [CrossRef]

- Huang, Y. A User-Material Subroutine Incorporating Single Crystal Plasticity in the ABAQUS Finite Element Program; Harvard University Research Report; Harvard University: Cambridge, MA, USA, 1991. [Google Scholar]

- Liu, B.; Raabe, D.; Roters, F.; Eisenlohr, P.; Lebensohn, R.A. Comparison of Finite Element and Fast Fourier Transform Crystal Plasticity Solvers for Texture Prediction. Modell. Simul. Mater. Sci. Eng. 2010, 18, 085005. [Google Scholar] [CrossRef]

- Voothaluru, R.; Bedekar, V.; Xie, Q.; Stoica, A.D.; Hyde, R.S.; An, K. In-Situ Neutron Diffraction and Crystal Plasticity Finite Element Modeling to Study the Kinematic Stability of Retained Austenite in Bearing Steels. Mater. Sci. Eng. A 2018, 711, 579–587. [Google Scholar] [CrossRef]

- Voothaluru, R.; Bedekar, V.; Yu, D.; Xie, Q.; An, K.; Pauskar, P.; Hyde, R.S. Investigating the Difference in Mechanical Stability of Retained Austenite in Bainitic and Martensitic High-Carbon Bearing Steels Using in Situ Neutron Diffraction and Crystal Plasticity Modeling. Metals 2019, 9, 482. [Google Scholar] [CrossRef]

- Smit, R.J.M.; Brekelmans, W.A.M.; Meijer, H.E.H. Prediction of the mechanical behavior of nonlinear heterogeneous systems by multi-level finite element modeling. Comput. Methods Appl. Mech. Eng. 1998, 155, 181–192. [Google Scholar] [CrossRef]

- Kumar, R.S.; Wang, A.J.; Mcdowell, D.L. Effects of Microstructure Variability on Intrinsic Fatigue Resistance of Nickel-Base Superalloys—A Computational Micromechanics Approach. Int. J. Fract. 2006, 137, 173–210. [Google Scholar] [CrossRef]

- Zhang, J.; Prasannavenkatesan, R.; Shenoy, M.M.; McDowell, D.L. Modeling Fatigue Crack Nucleation at Primary Inclusions in Carburized and Shot-Peened Martensitic Steel. Eng. Fract. Mech. 2009, 76, 315–334. [Google Scholar] [CrossRef]

- Suiker, A.S.; Turteltaub, S. Computational modelling of plasticity induced by martensitic phase transformations. Int. J. Numer. Methods Eng. 2005, 63, 1655–1693. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Bounds and Self-Consistent Estimates for Creep of Polycrystalline Materials. Proc. R. Soc. Lond. A 1976, 348, 101. [Google Scholar]

- Brown, S.B.; Kim, K.H.; Anand, L. An Internal Variable Constitutive Model for Hot Working of Metals. Int. J. Plast. 1989, 5, 95–130. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Argon, A.S. Strengthening Mechanismi Crystal Plasticity; Oxford University: New York, NY, USA, 2008. [Google Scholar]

- Fleck, N.A.; Muller, M.F.; Ashby, M.F.; Hutchinson, J.W. Strain gradient plasticity: Theory and experiment. Acta Metall. Mater. 1994, 42, 475–487. [Google Scholar] [CrossRef]

- Kwon, I.B. Fatigue Crack Initiation in Copper at Room and Cryogenic Temperatures. Ph.D. Thesis, Northwestern University, Evanston, IL, USA, 1987. [Google Scholar]

| W—Width of Narrow Section | 3.18 (mm) |

| T—Thickness | 1.5875 (mm) |

| L—Length of narrow section | 9.53 (mm) |

| WO—Width overall, min | 12.7 (mm) |

| LO—Length overall, min | 63.5 (mm) |

| G—Gage length | 7.62 (mm) |

| D—Distance between grips | 25.4 (mm) |

| R—Radius of fillet | 12.7 (mm) |

| Material Grade | Heat Treatment Procedures | Grain Size Distribution (μm) |

|---|---|---|

| Coarse grain | Annealing: Heated to 700 °C in a vacuum for 1 h, then furnace-cooled to room temperature | Average diameter: 104.2 Standard deviation: 10 |

| Fine grain | Stress-relieving: Heated to 200 °C in a vacuum for 30 min, and then furnace-cooled to room temperature | Average diameter: 14.2 Standard deviation: 2 |

| Grain Distribution | CRSS (MPa) | |||

|---|---|---|---|---|

| Coarse grain (average grain size104.2 µm) | 181 | 142 | 69 | 45.9 |

| Fine grain (average grain size14.2 µm) | 181 | 142 | 69 | 78.2 |

| Grain Distribution | Applied Stress (MPa) | Shear Stress Amplitude (MPa) | Plastic Slip per Cycle | Computed Energy Efficiency Coefficient |

|---|---|---|---|---|

| Coarse grain (average grain size104.2 µm) | 64 | 66.1 | 0.778 | |

| Fine grain (average grain size14.2 µm) | 64 | 40.8 | 0.986 |

| Normal Stress Amplitude (MPa) | 150 | 110 | 100 |

| Plastic strain amplitude | |||

| Crack initiation life by experiment (cycles) | 150 | 70,000 | 100,000 |

| Life predicted by Fine and Bhat [14] | - | 1131 | 6345 |

| % improvement using the new model () | - | 97.78% | 92.94% |

| Life predicted by Voothaluru and Liu [16,17] | Benchmark | 63,291 | 89,222 |

| % improvement using the new model () | - | 8.98% | 10.06% |

| Life predicted by the new model | Benchmark | 70425 | 99,280 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ou, C.-Y.; Voothaluru, R.; Liu, C.R. A Methodology for Incorporating the Effect of Grain Size on the Energy Efficiency Coefficient for Fatigue Crack Initiation Estimation in Polycrystalline Metal. Metals 2020, 10, 355. https://doi.org/10.3390/met10030355

Ou C-Y, Voothaluru R, Liu CR. A Methodology for Incorporating the Effect of Grain Size on the Energy Efficiency Coefficient for Fatigue Crack Initiation Estimation in Polycrystalline Metal. Metals. 2020; 10(3):355. https://doi.org/10.3390/met10030355

Chicago/Turabian StyleOu, Chun-Yu, Rohit Voothaluru, and C. Richard Liu. 2020. "A Methodology for Incorporating the Effect of Grain Size on the Energy Efficiency Coefficient for Fatigue Crack Initiation Estimation in Polycrystalline Metal" Metals 10, no. 3: 355. https://doi.org/10.3390/met10030355

APA StyleOu, C.-Y., Voothaluru, R., & Liu, C. R. (2020). A Methodology for Incorporating the Effect of Grain Size on the Energy Efficiency Coefficient for Fatigue Crack Initiation Estimation in Polycrystalline Metal. Metals, 10(3), 355. https://doi.org/10.3390/met10030355