Development of a Resistance Spot Welding Process Using Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

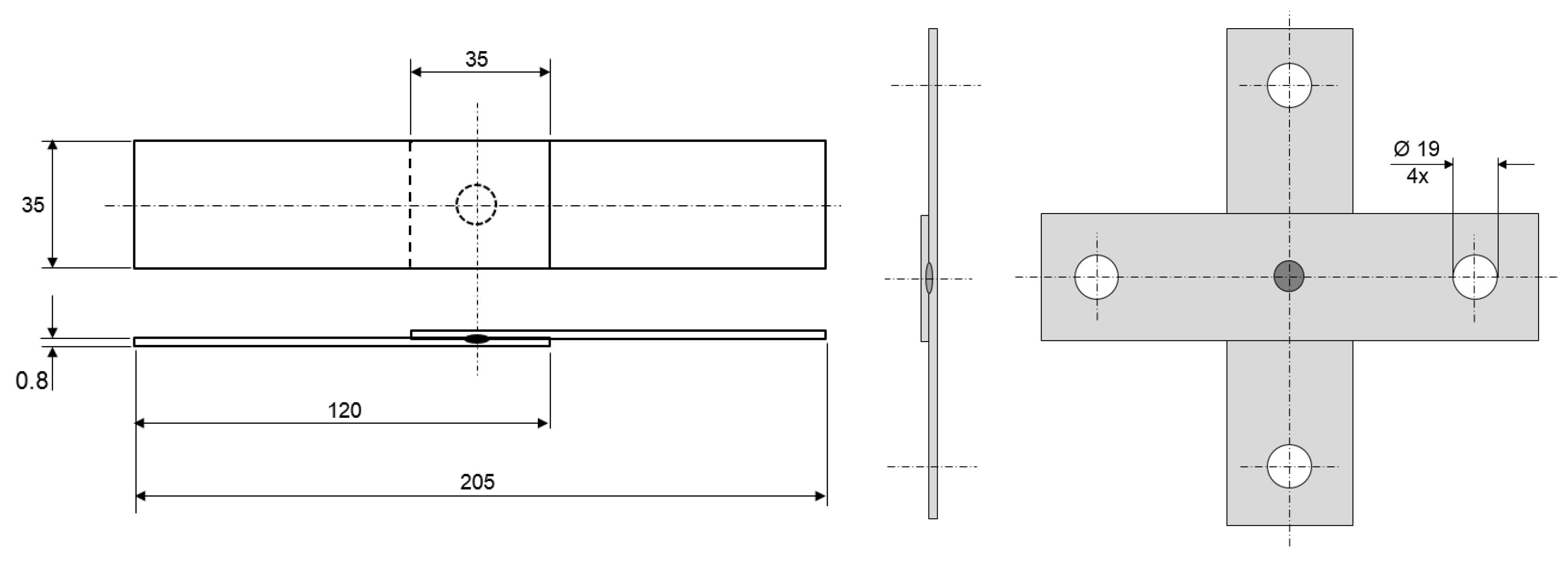

2.1. Characteristics of the Test Speciments

2.2. Characteristics of the Metallic Powder for the Laser Deposition (Additive Manufacturing) Used in the Experiments

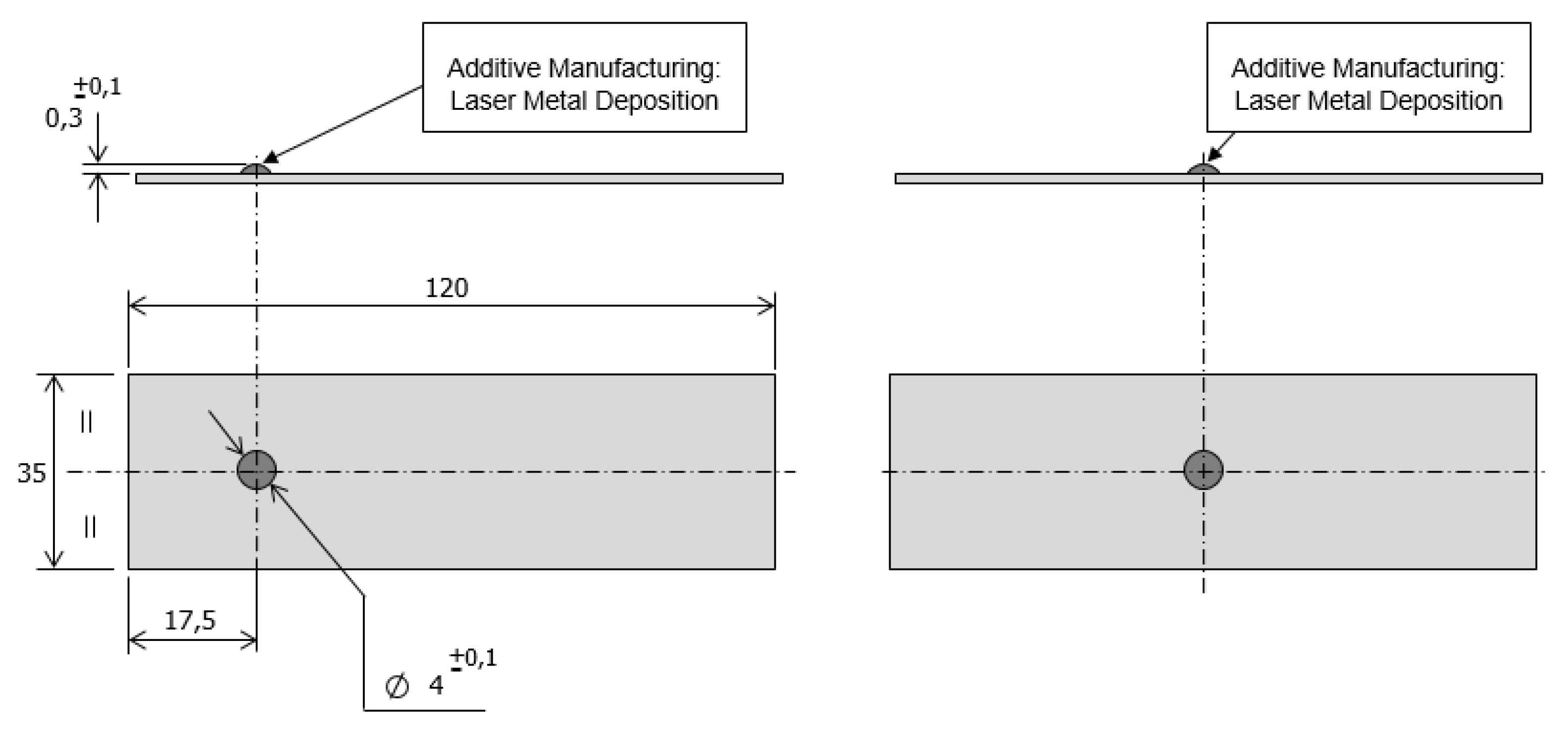

2.3. Additive Manufacturing Process for Laser Powder Deposition Used in Experiments

2.4. Characteristics of the Resistance Spot Welding Equipment Used in the Experiments

2.5. Welding Spot Acceptance Criteria

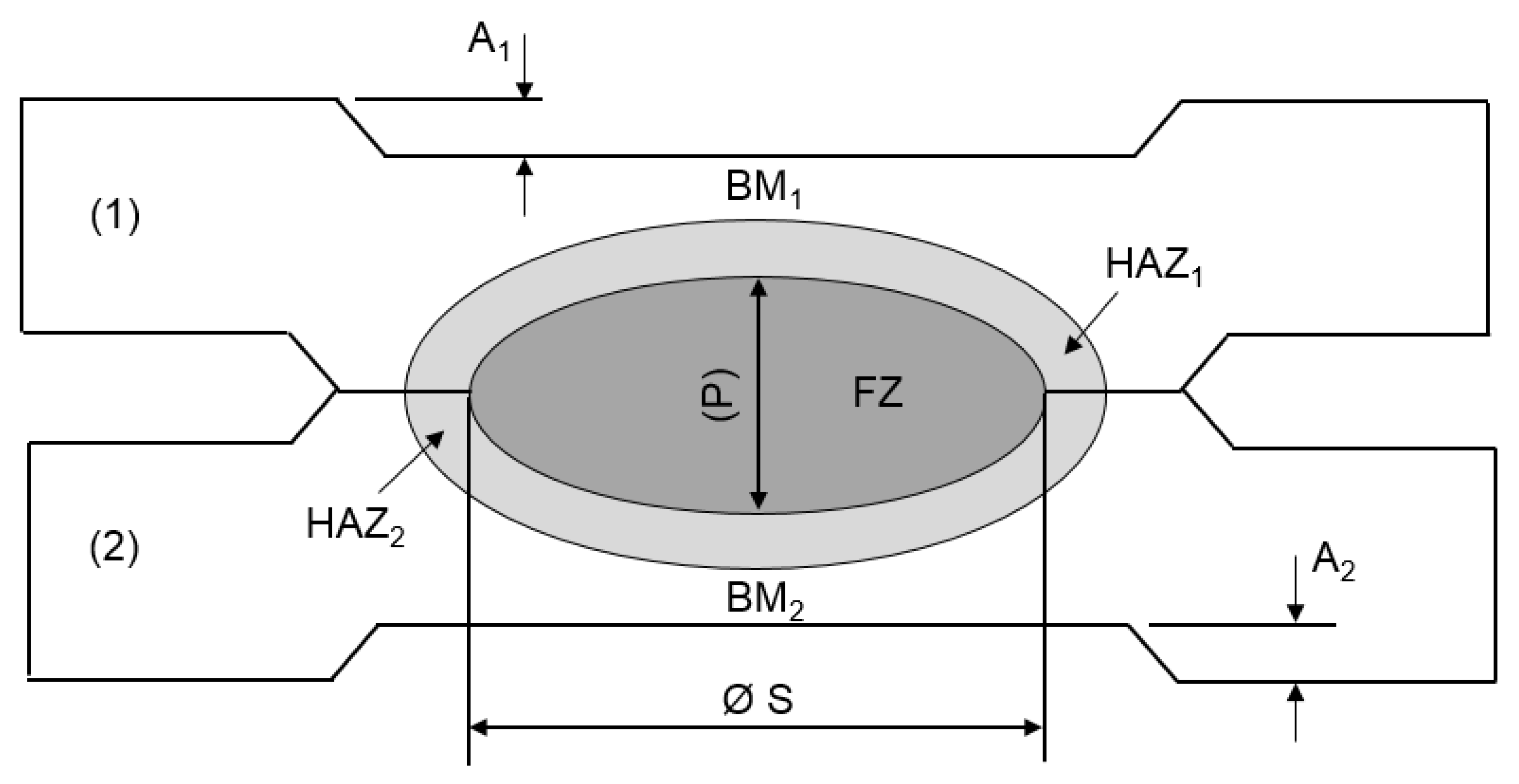

2.6. Characterization of the Spot Welding Joint Geometry

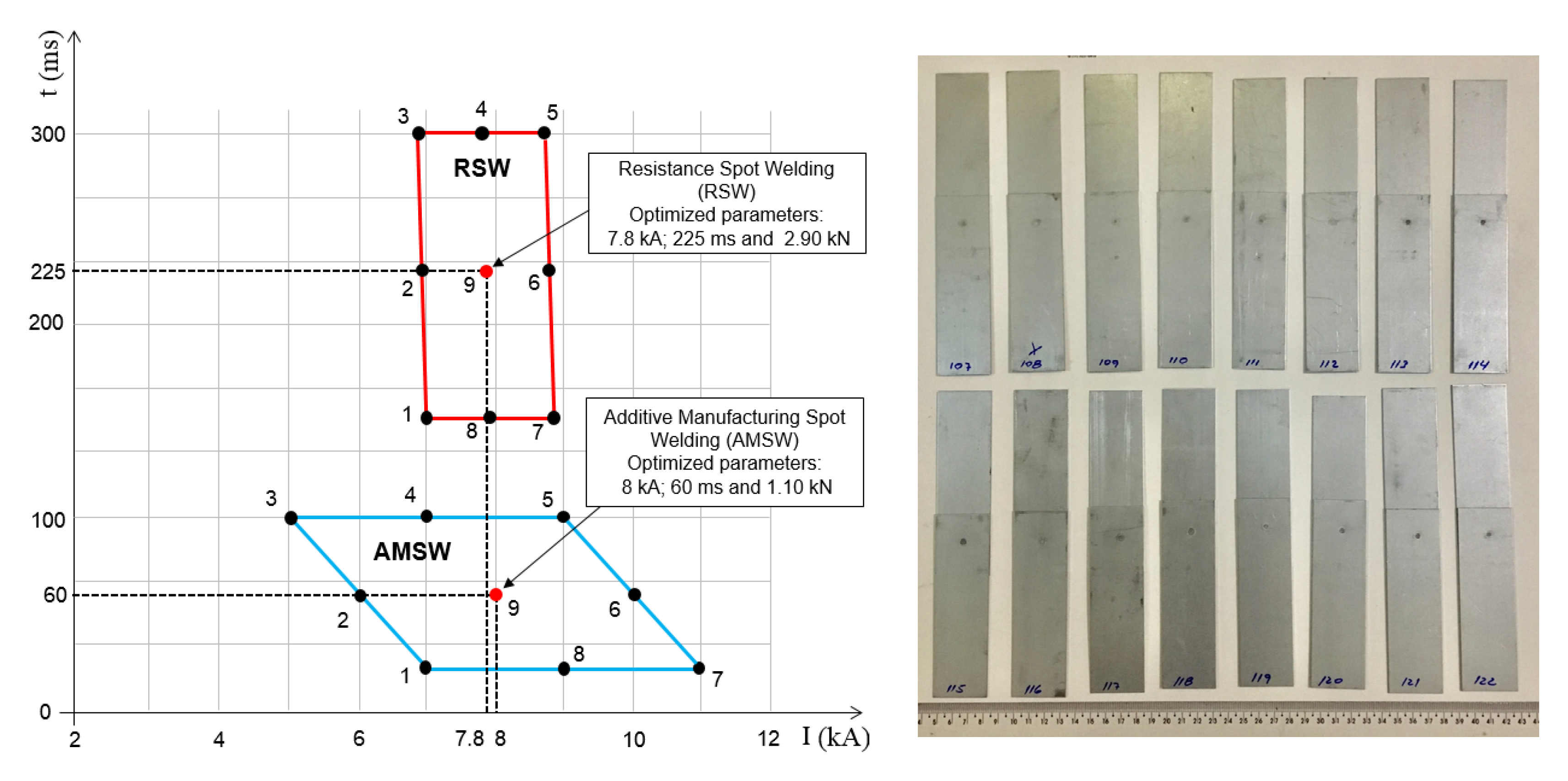

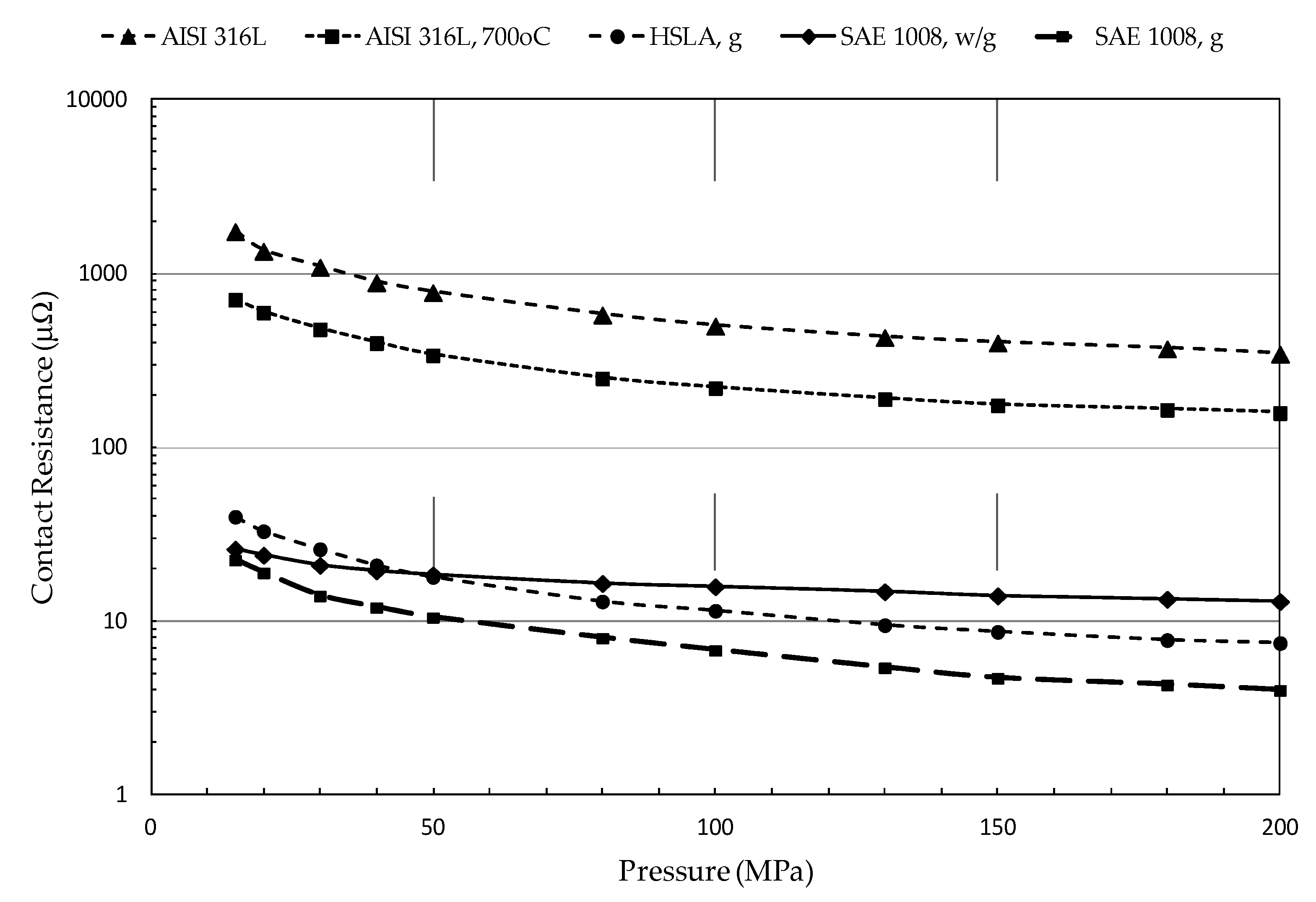

2.7. Determination of Weldability Diagrams and Optimized Welding Parameters

3. Results and Discussion

3.1. Weldability Diagrams

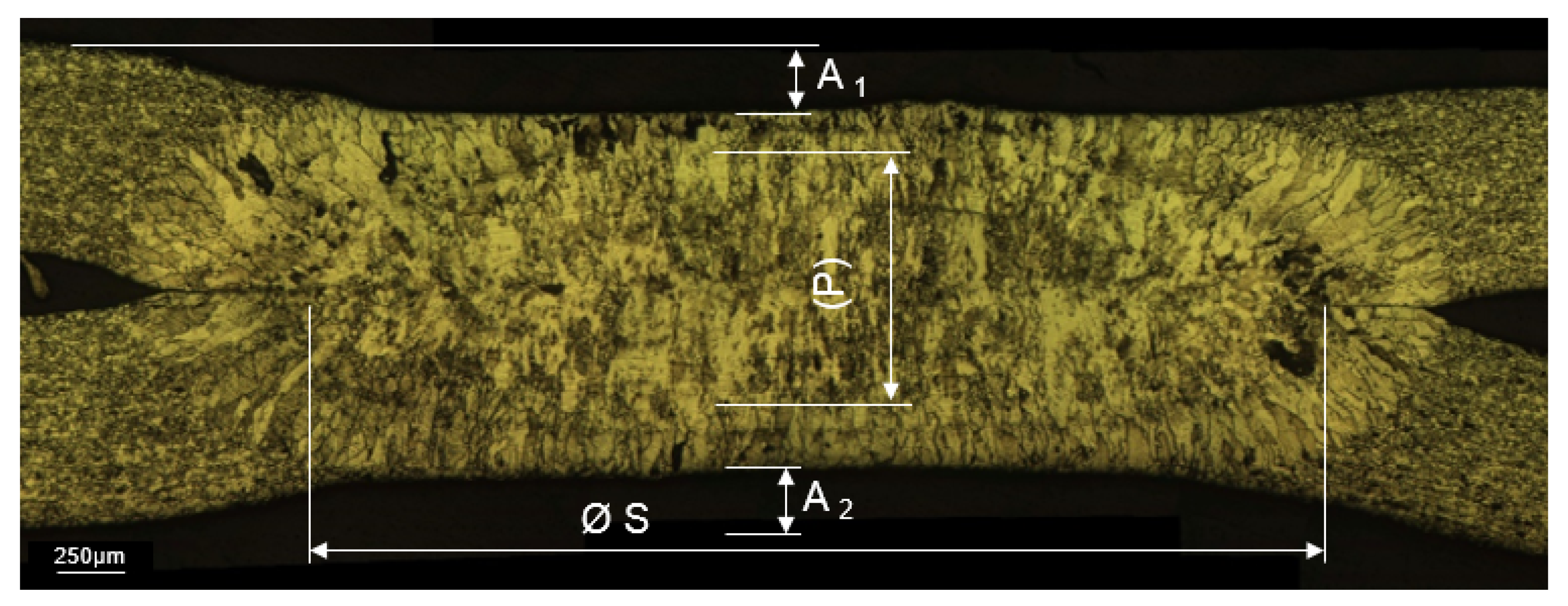

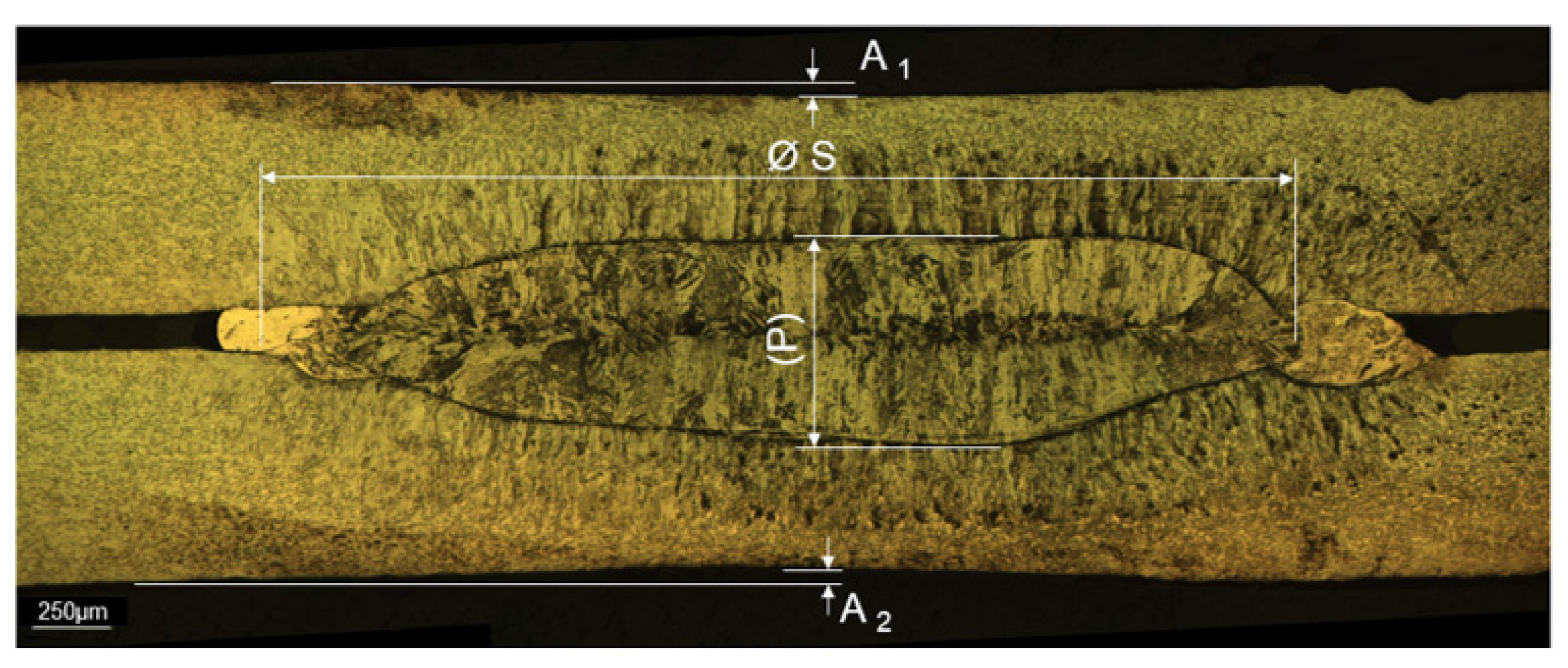

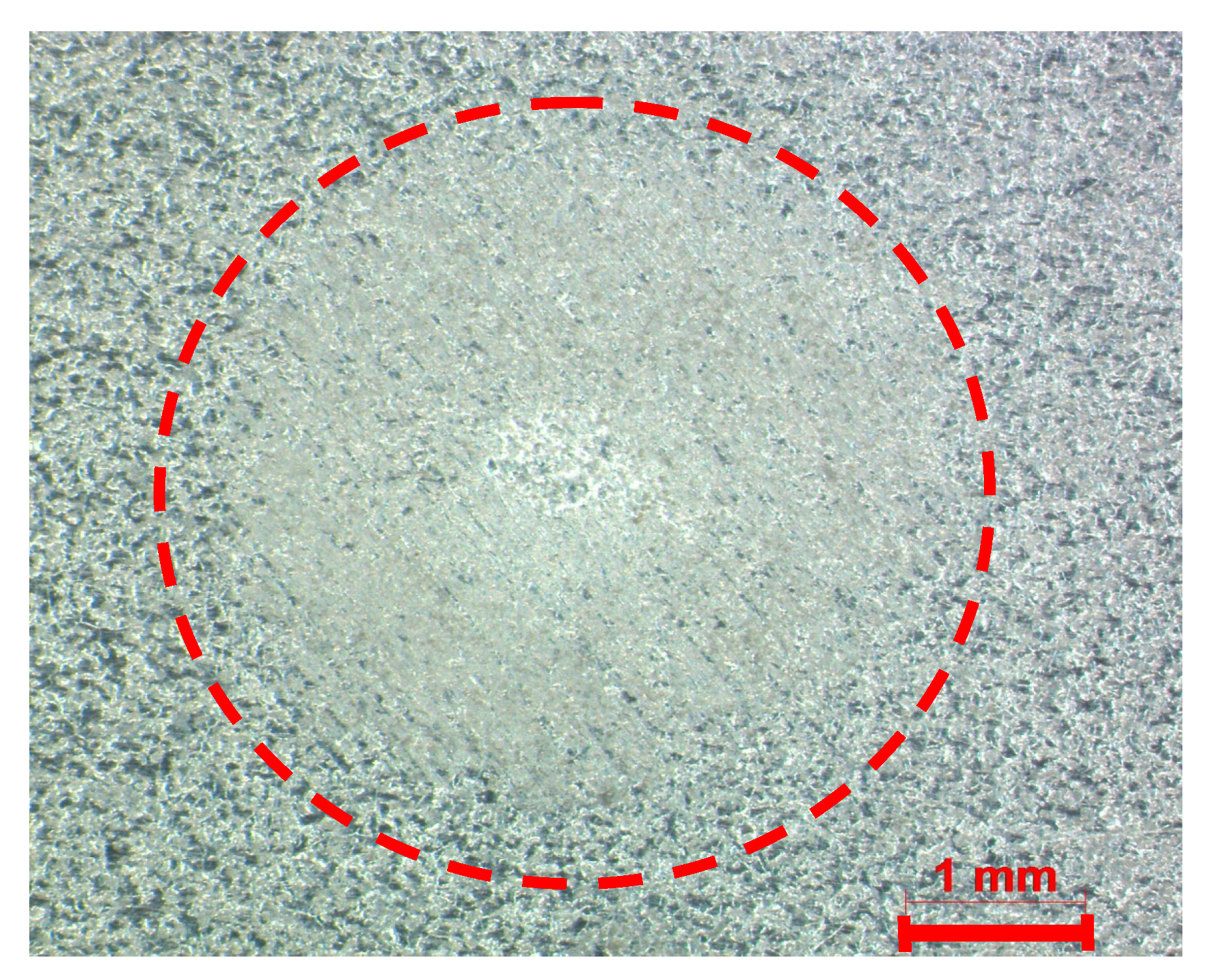

3.2. Dimensions of the Weld Spots through the Macrography Tests

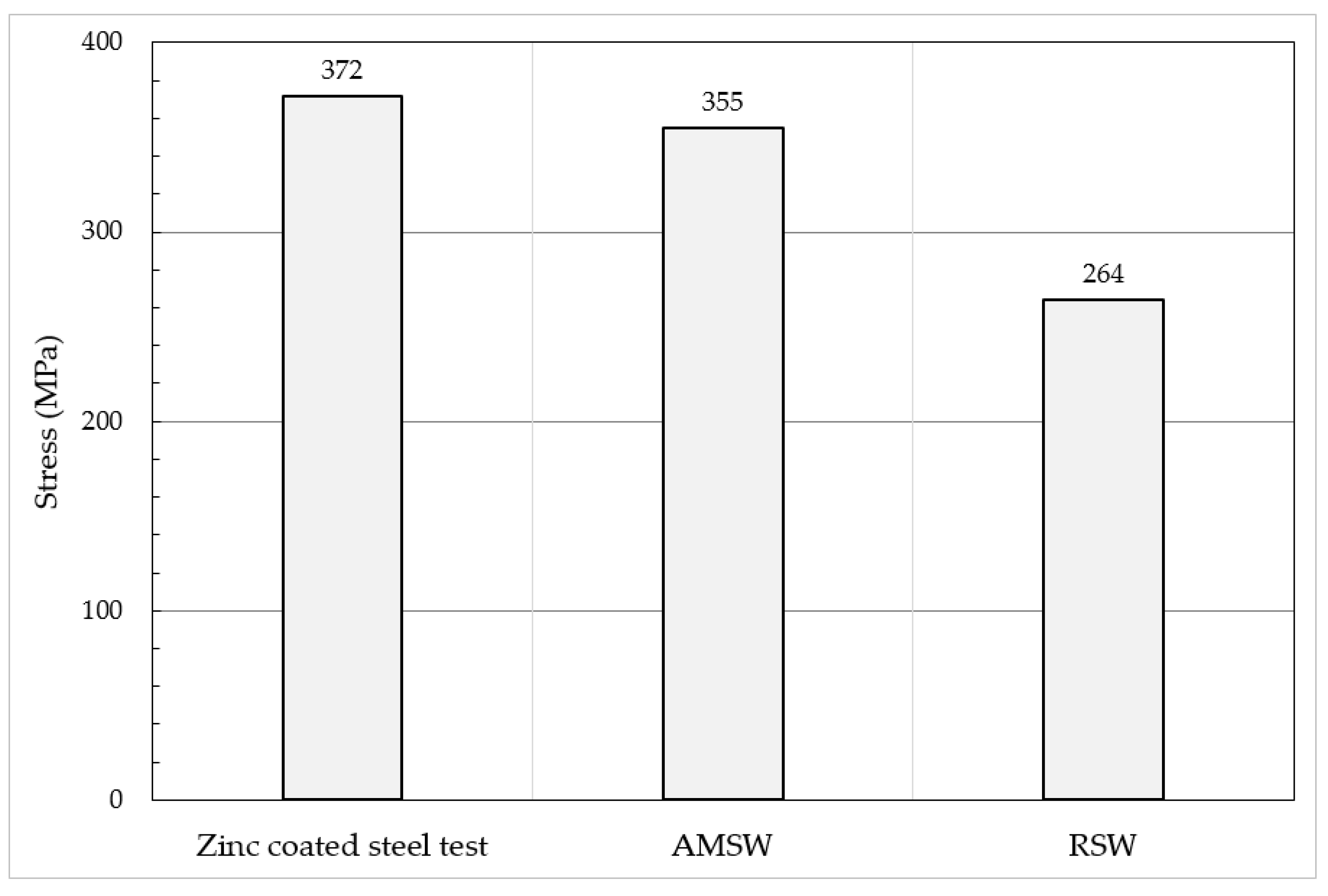

3.3. Maximum Tensile Shear Stress

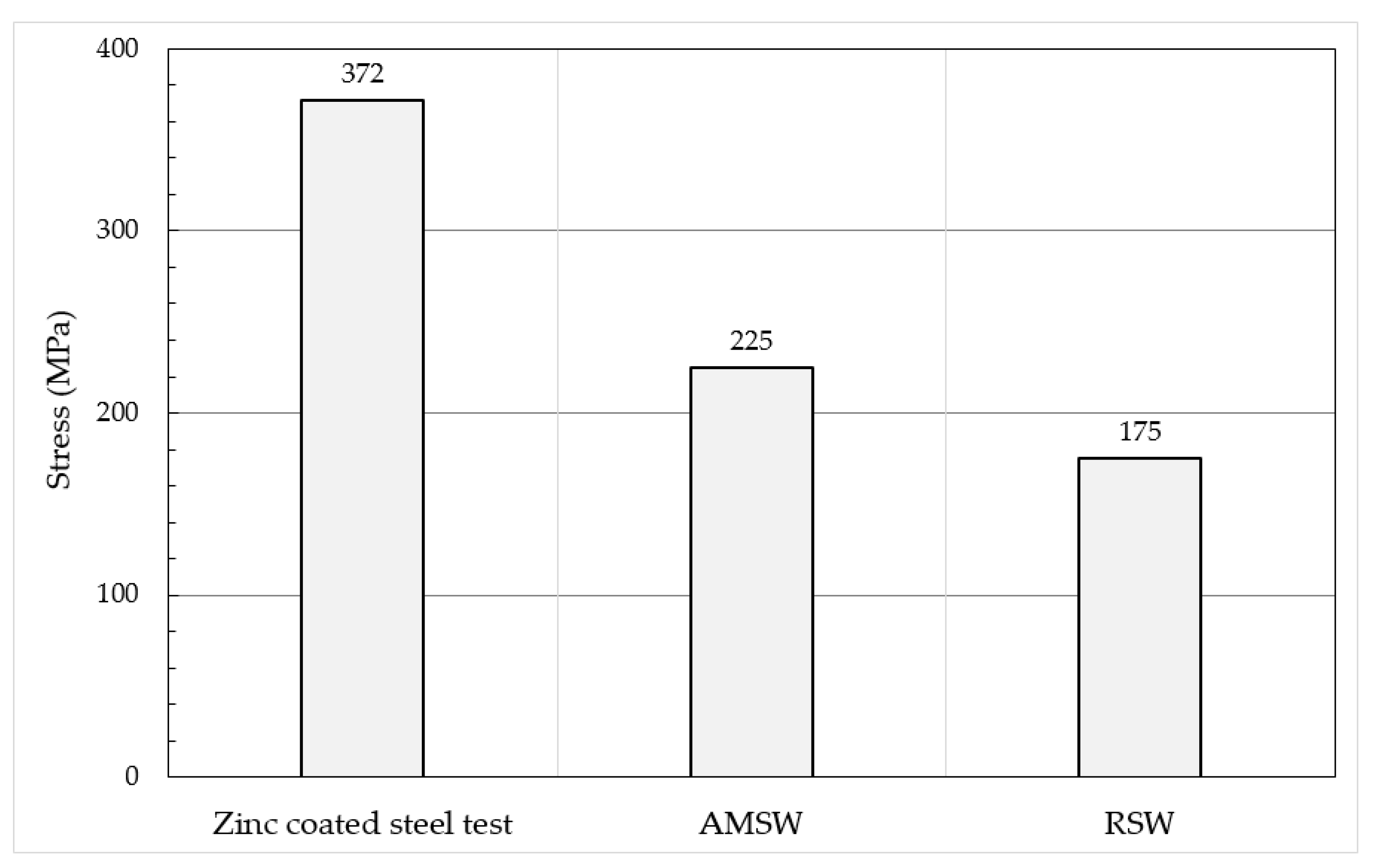

3.4. Maximum Tensile Stress for Cross-Tension Test

4. Conclusions

- In general, the dilution between the deposited metal and the base material was total, using the optimized parameters, in zinc coated sheets, it can be concluded that this new process of spot welding using additive manufacturing (AMWS) is by melting and pressing.

- The welding time for the optimized parameters, by the resistance spot welding process (RSW), was higher by 275% when compared to the time of the optimized parameters of the spot welding process using additive manufacturing (AMSW). This result is related to the higher concentration of thermal energy in a predetermined area, performed through the laser deposition, as well as, with the higher electrical resistivity, and lower thermal conductivity of the deposited material compared to the base material. Therefore, one can conclude that these facts result in lower losses and greater efficiency in the generation of thermal energy, when compared to the resistance spot welding process (RWS).

- The strength between the electrodes in relation to the optimized parameters, by the resistance welding process (RSW), was higher by 163.6%, compared to the strength of the optimized parameters of the spot welding process using additive manufacturing (AMSW), it can be concluded that this new process of spot welding requires smaller equipment, and consequently lower costs.

- The maximum stress of the weld spot in relation to the tensile shear tests and the cross-tension tests, referring to the spot welding process using additive manufacturing (AMSW), was 34.47% and 28.57% higher respectively, in comparison to the resistance spot welding process (RSW). These results are related to the lower HAZ (heat-affected zone), the absence of indentation and also the greater mechanical resistance of the alloy deposited in relation to the base material. It can be concluded that this new process of spot welding using additive manufacturing, under optimized conditions, has higher mechanical resistance in static shear stresses and static stresses perpendicular to the weld spot compared to the resistance spot welding process (RSW).

- The indentation or thermomechanical mark on the surface of the sheet, referring to the spot welding process using additive manufacturing (AMSW), through the optimized parameters, were imperceptible to the visual inspection. It can be concluded that this new welding process, in relation to aesthetics, can be used on apparent surface.

5. Patent

Author Contributions

Funding

Conflicts of Interest

References

- Pouranvari, M. Susceptibility to interfacial failure mode in similar and dissimilar resistance spot welds of DP600 dual phase steel and low carbon steel during cross-tension and tensile-shear loading conditions. Mater. Sci. Eng. A 2012, 546, 129–138. [Google Scholar] [CrossRef]

- Martín, O.; Ahedo, V.; Santos, J.I.; Tiedra, P.; Galán, J.M. Quality assessment of resistance spot welding joints of AISI 304 stainless steel based on elastic nets. Mater. Sci. Eng. A 2016, 676, 173–181. [Google Scholar] [CrossRef] [Green Version]

- Anijdana, S.H.M.; Sabzib, M.; Hasabc, G.M.; Ghiyas, R.A. Optimization of spot welding process parameters in dissimilar joint of dual phase steel DP600 and AISI 304 stainless steel to achieve the highest level of shear-tensile strength. Mater. Sci. Eng. A 2018, 726, 120–125. [Google Scholar] [CrossRef]

- Marashi, P.; Pouranvari, M.; Amirabdollahian, S.; Abedi, A.; Goodarzi, M. Microstructure and failure behavior of dissimilar resistance spot welds between low carbon galvanized and austenitic stainless steels. Mater. Sci. Eng. A 2008, 480, 175–180. [Google Scholar] [CrossRef]

- Brauser, S.; Pepke, L.A.; Weber, G.; Rethmeier, M. Deformation behaviour of spot-welded high strength steels for automotive applications. Mater. Sci. Eng. A 2010, 527, 7099–7108. [Google Scholar] [CrossRef]

- Babu, N.K.; Brauser, S.; Rethmeier, M.; Cross, C.E. Characterization of microstructure and deformation behaviour of resistance spot welded AZ31 magnesium alloy. Mater. Sci. Eng. A 2012, 549, 149–156. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Abdurakhmanov, A.; Abbasi, M.; Prahl, U. Characterization of Microstructure and Mechanical Properties of Resistance Spot Welded DP600 Steel. Metals 2015, 5, 1704–1716. [Google Scholar] [CrossRef] [Green Version]

- Pouranvari, M. Fracture toughness of martensitic stainless steel resistance spot welds. Mater. Sci. Eng. A 2017, 680, 97–107. [Google Scholar] [CrossRef]

- Huin, T.; Dancette, S.; Fabrègue, D.; Dupuy, T. Investigation of the Failure of Advanced High Strength Steels Heterogeneous Spot Welds. Metals 2016, 6, 111. [Google Scholar] [CrossRef]

- Emre, H.E.; Kaçar, R. Resistance Spot Weldability of Galvanize Coated and Uncoated TRIP Steels. Metals 2016, 6, 299. [Google Scholar] [CrossRef] [Green Version]

- Fukumoto, S.; Fujiwara, K.; Toji, S.; Yamamoto, A. Small-scale resistance spot welding of austenitic stainless steels. Mater. Sci. Eng. A 2008, 492, 243–249. [Google Scholar] [CrossRef]

- Han, J.H.; Shan, P.; Hu, S.S. Contact analysis of fractal surfaces in earlier stage of resistance spot welding. Mater. Sci. Eng. A 2006, 436, 204–211. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H.; Safanama, D.S. Failure mode transition in AHSS resistance spot welds. Part II: Experimental investigation and model validation. Mater. Sci. Eng. A 2011, 528, 8344–8352. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H. Failure mode transition in AHSS resistance spot welds. Part I. Controlling factors. Mater. Sci. Eng. A 2011, 528, 8337–8343. [Google Scholar] [CrossRef]

- Spena, P.R.; Maddis, M.; D’Antonio, G.; Lombardi, F. Weldability and Monitoring of Resistance Spot Welding of Q&P and TRIP Steels. Metals 2016, 6, 270. [Google Scholar]

- Tutar, M.; Aydin, H.; Bayram, A. Effect of Weld Current on the Microstructure and Mechanical Properties of a Resistance Spot-Welded TWIP Steel Sheet. Metals 2017, 7, 519. [Google Scholar] [CrossRef] [Green Version]

- Arrizubieta, J.I.; Ruiz, J.E.; Martinez, S.; Ukar, E.; Lamikiz, A. Intelligent nozzle design for the Laser Metal Deposition process in Industry 4.0. ScienceDirect–Procedia Manuf. 2017, 13, 1237–1244. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Ukar, E.; Lacalle, L.N.; Angulo, C.; Urbikain, G. Numerical simulation and experimental validation of powder flux distribution in coaxial laser cladding. Mater. Process. Technol. 2010, 210, 2125–2134. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Junker, D.; Hentschel, O.; Schmidt, M.; Merklein, M. Investigation of Heat Treatment Strategies for Additively-Manufactured Tools of X37CrMoV5-1. Metals 2018, 8, 854. [Google Scholar] [CrossRef] [Green Version]

- Batista, M.; Brandi, S.D. Use of dynamic resistance and dynamic energy to compare two resistance spot welding equipments for automotive industry in zinc coated and uncoated sheets. Am. J. Eng. Res. 2013, 2, 79–93. [Google Scholar]

- Nielsen, C.V.; Zhang, W.; Alves, L.M.; Bay, N.; Martins, P. Modeling of Thermo-Electro-Mechanical Manufacturing Processes; Springer: London, UK, 2013; 120p. [Google Scholar]

| Alloy | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt % | 0.0030 | 0.6100 | 0.0330 | 0.0046 | 0.0770 | 0.0180 | 0.0056 | 0.0230 | 0.0020 | 0.0500 | 0.0480 |

| Mechanical Properties | Values |

|---|---|

| Yield Strength [MPa] | 188 |

| Tensile Strength [MPa] | 372 |

| Ductility [% Elongation] | 44 |

| Alloy | C | Mo | Ni | Mn | Cr | Si | Fe |

|---|---|---|---|---|---|---|---|

| wt % | 0.015 | 2.6 | 13.1 | 1.6 | 17.2 | 0.7 | Balance |

| Sheet Thickness (mm) | Spot Diameter (Macrography Test) (mm) | Spot Diameter (Peel Test) (mm) | Min. Strength: Tensile Shear Test (kN) | Min. Strength: Cross-Tension Tests (kN) |

|---|---|---|---|---|

| 0.8 | 3.1 | 3.6 | 2.30 | 1.38 |

| Welding Process | Spot Diameter | Indentation | Base Metal | HAZ Extension | Spot Thickness | |||

|---|---|---|---|---|---|---|---|---|

| Ø S | A1 | A2 | BM1 | BM2 | HAZ1 | HAZ2 | (P) | |

| RSW | 4.92 | 0.25 | 0.20 | 0.0 | 0.0 | 0.83 | 0.68 | 0.82 |

| AMSW | 3.60 | 0.05 | 0.07 | 0.23 | 0.18 | 0.17 | 0.33 | 0.71 |

| Welding Process | Ø S Spot Diameter (mm) | Max.Tensile Shear Load (kN) | Max. Tensile Shear Stresses of the Weld Spot (MPa) | Max. Tensile Stress of the Sheet (MPa) |

|---|---|---|---|---|

| RSW | 4.92 | 5.012 | 264 | 372 |

| AMSW | 3.60 | 3.613 | 355 | 372 |

| Welding Process | Ø S Spot Diameter (mm) | Max.Tensile Shear Load (kN) | Max. Tensile Stresses of the Spot (MPa) | Max. Tensile Stress of the Sheet (MPa) |

|---|---|---|---|---|

| RSW | 4.92 | 3.32 | 175 | 372 |

| AMSW | 3.60 | 2.29 | 225 | 372 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batista, M.; Furlanetto, V.; Duarte Brandi, S. Development of a Resistance Spot Welding Process Using Additive Manufacturing. Metals 2020, 10, 555. https://doi.org/10.3390/met10050555

Batista M, Furlanetto V, Duarte Brandi S. Development of a Resistance Spot Welding Process Using Additive Manufacturing. Metals. 2020; 10(5):555. https://doi.org/10.3390/met10050555

Chicago/Turabian StyleBatista, Márcio, Valdir Furlanetto, and Sérgio Duarte Brandi. 2020. "Development of a Resistance Spot Welding Process Using Additive Manufacturing" Metals 10, no. 5: 555. https://doi.org/10.3390/met10050555