Fatigue Design of Dental Implant Assemblies: A Nominal Stress Approach

Abstract

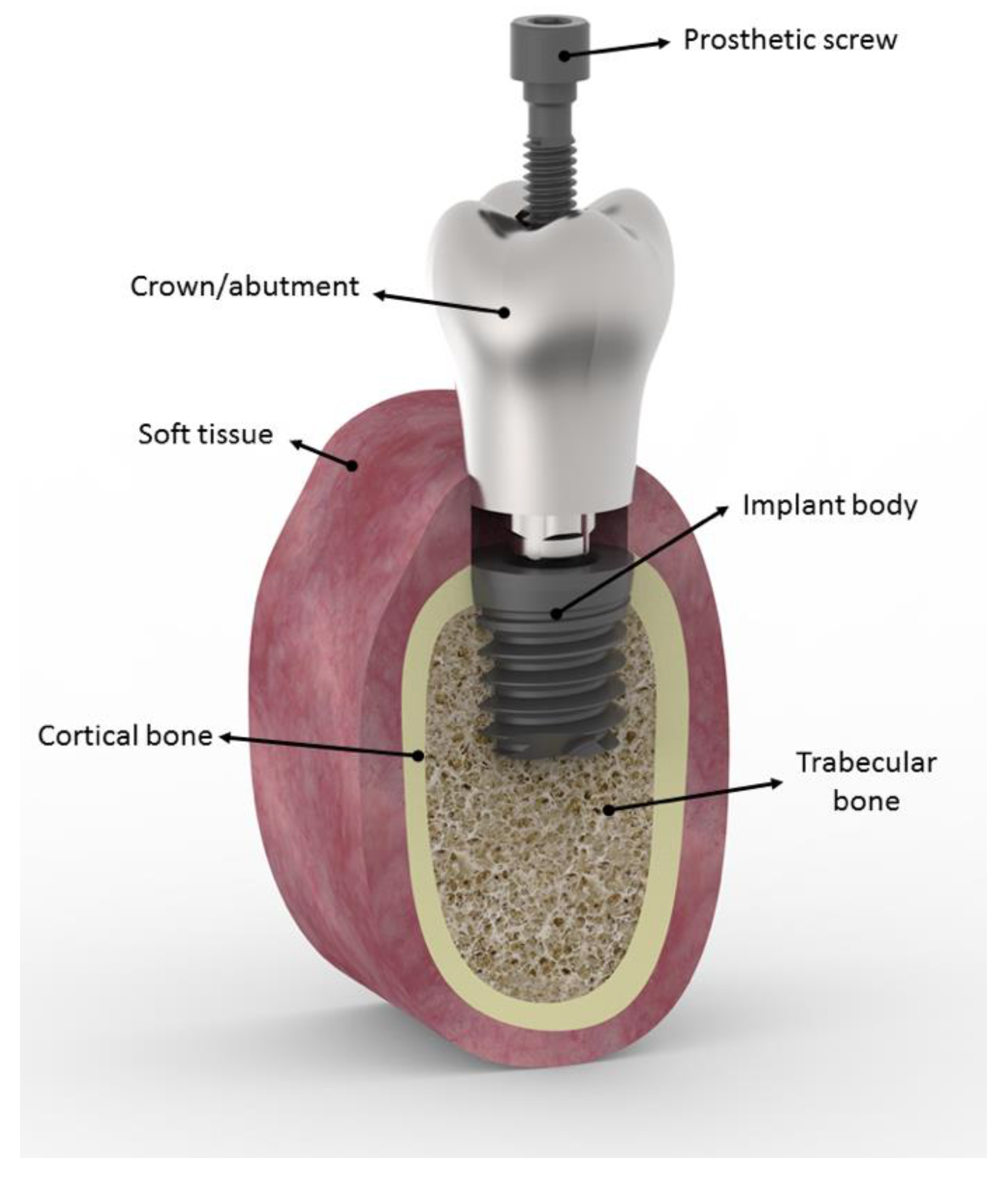

:1. Introduction

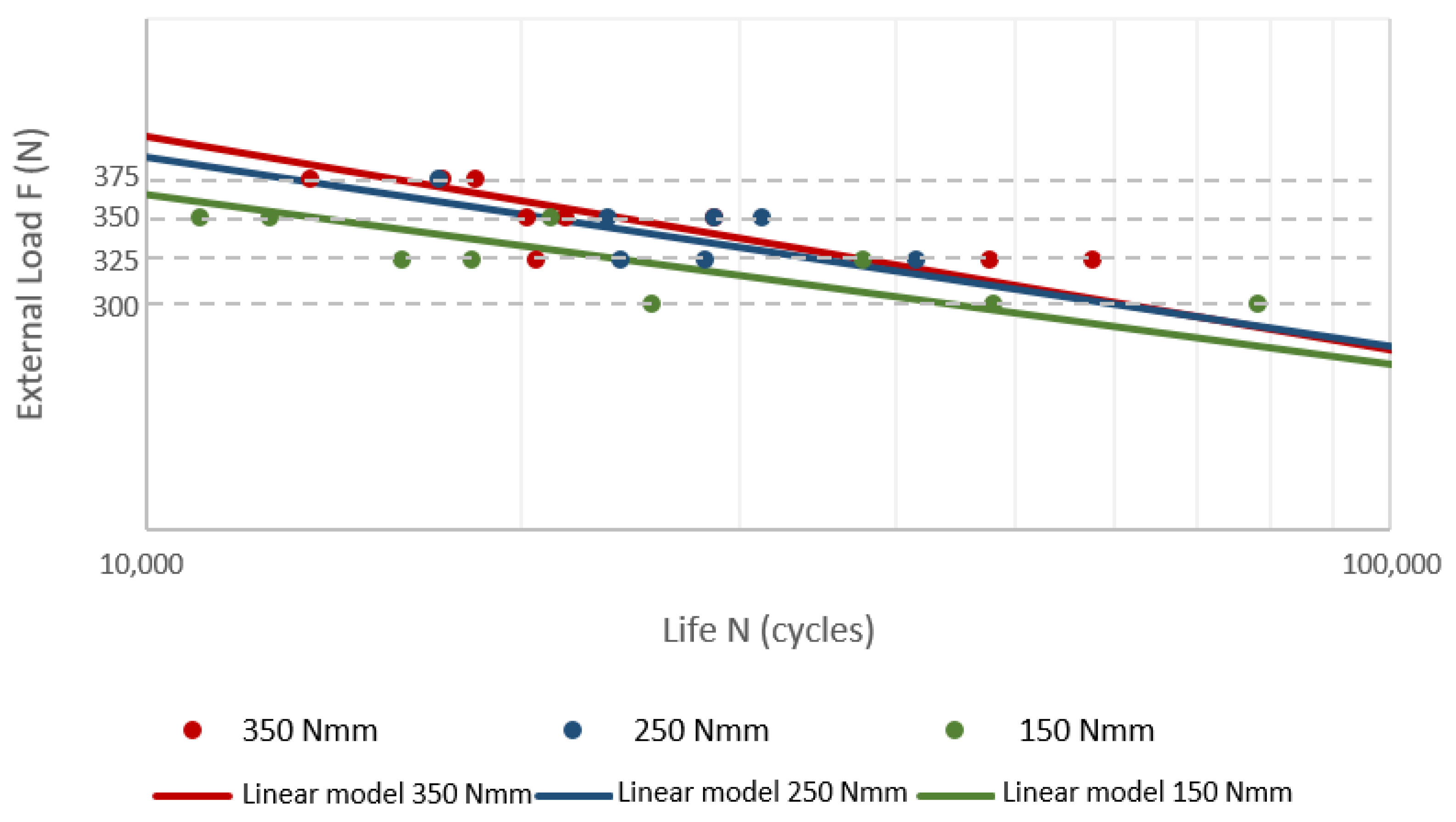

2. Materials and Methods

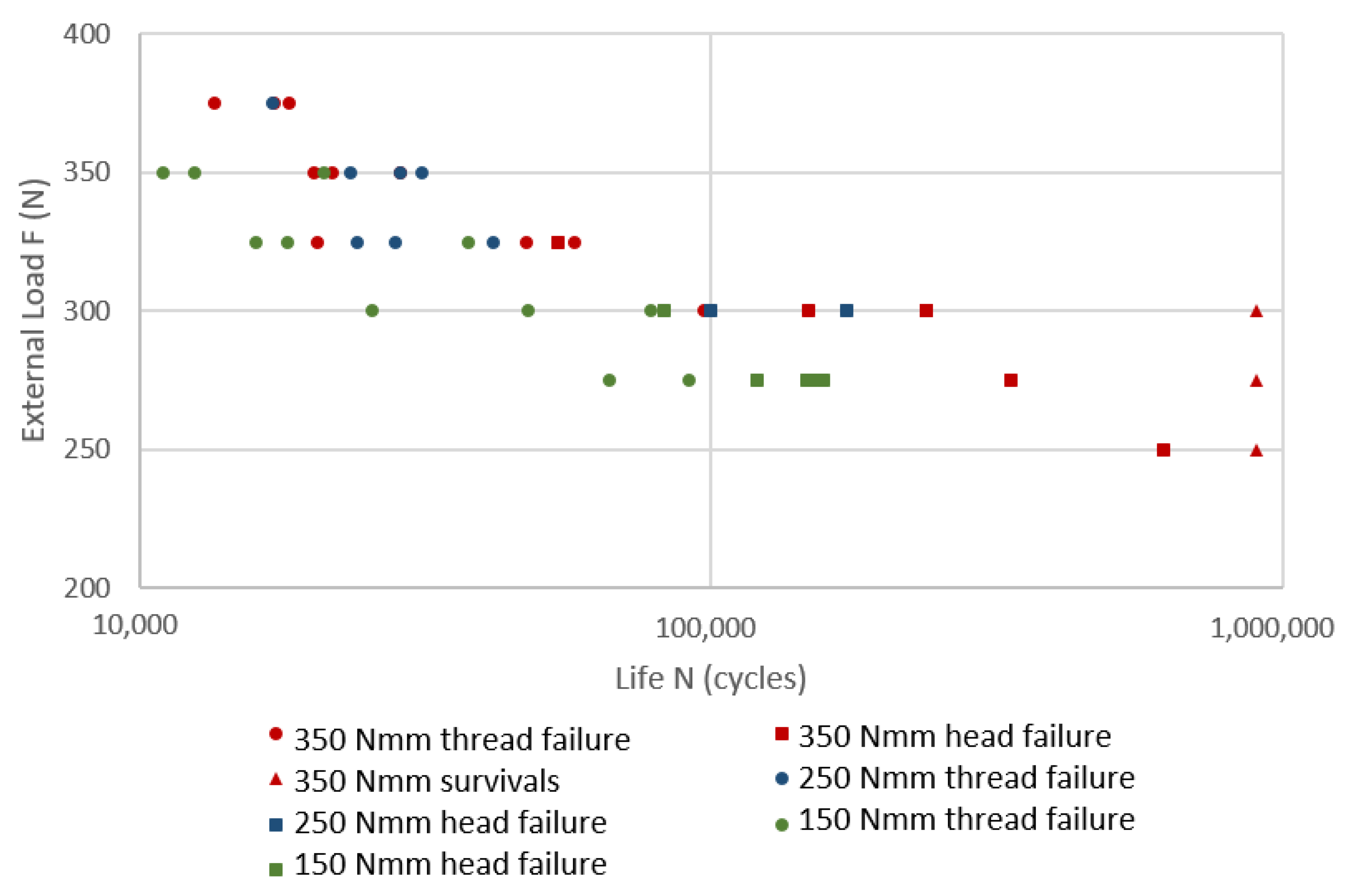

2.1. Experimental Tests

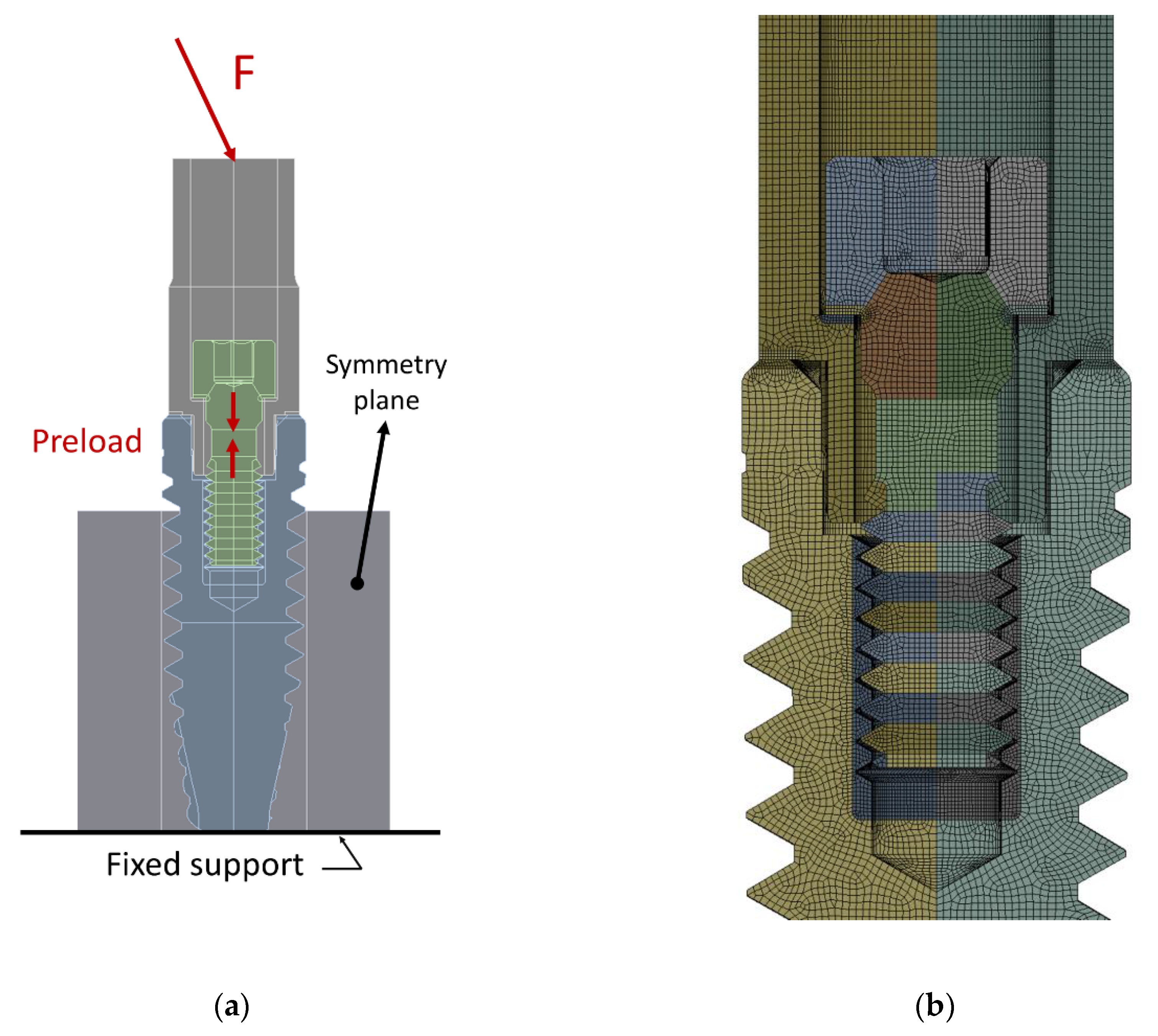

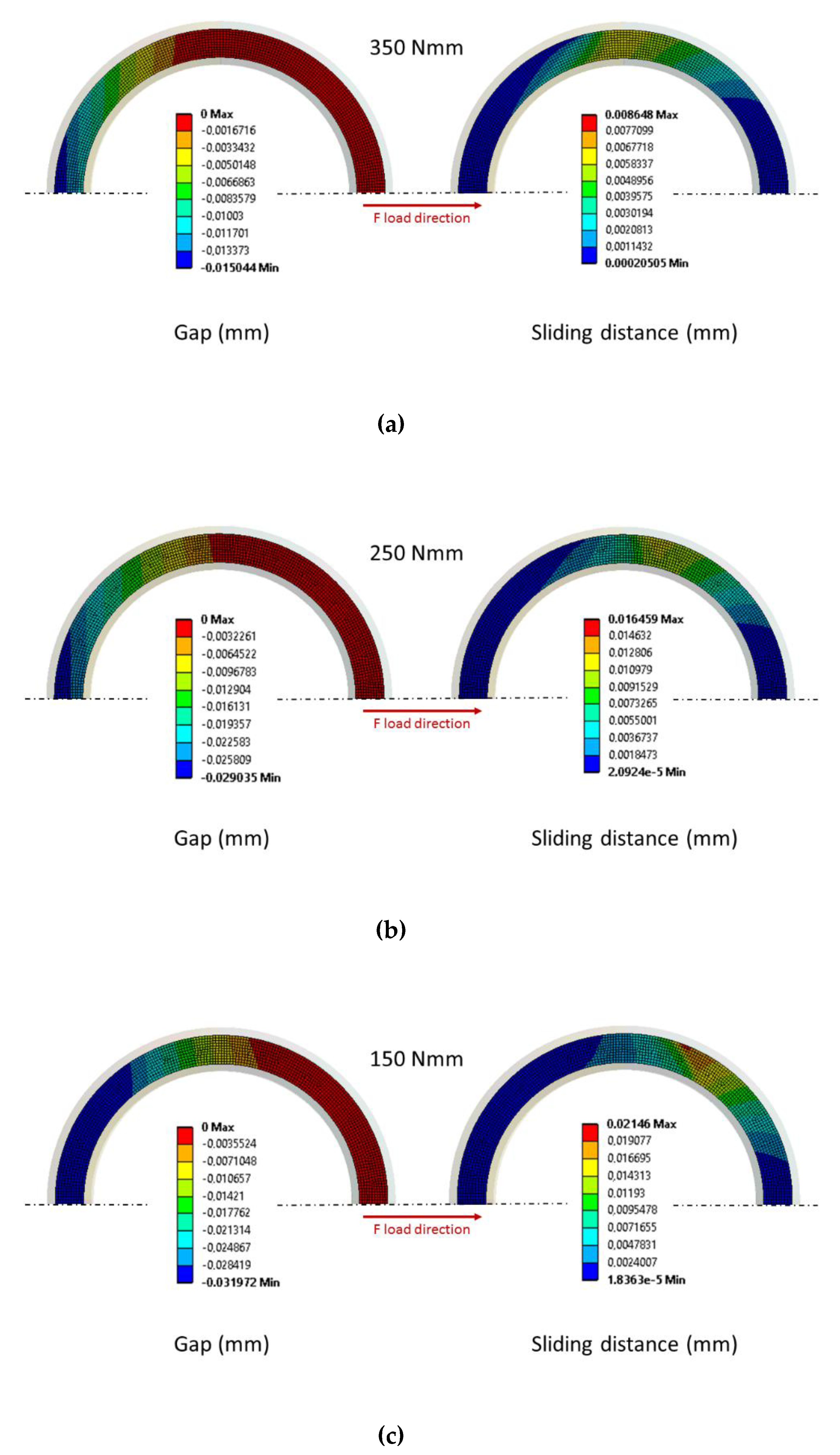

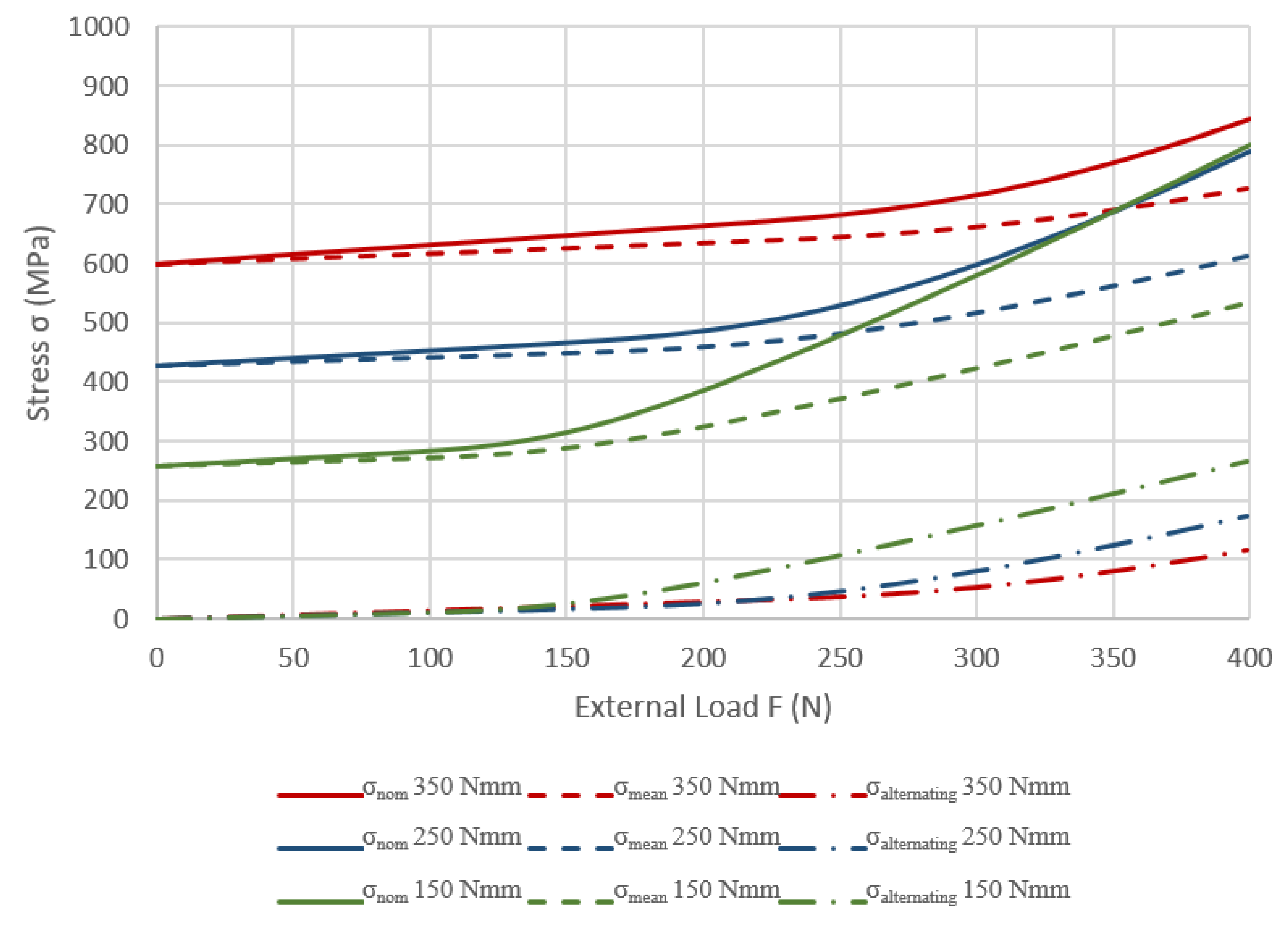

2.2. Finite Element Model

2.3. Measurement of the Friction Coefficients

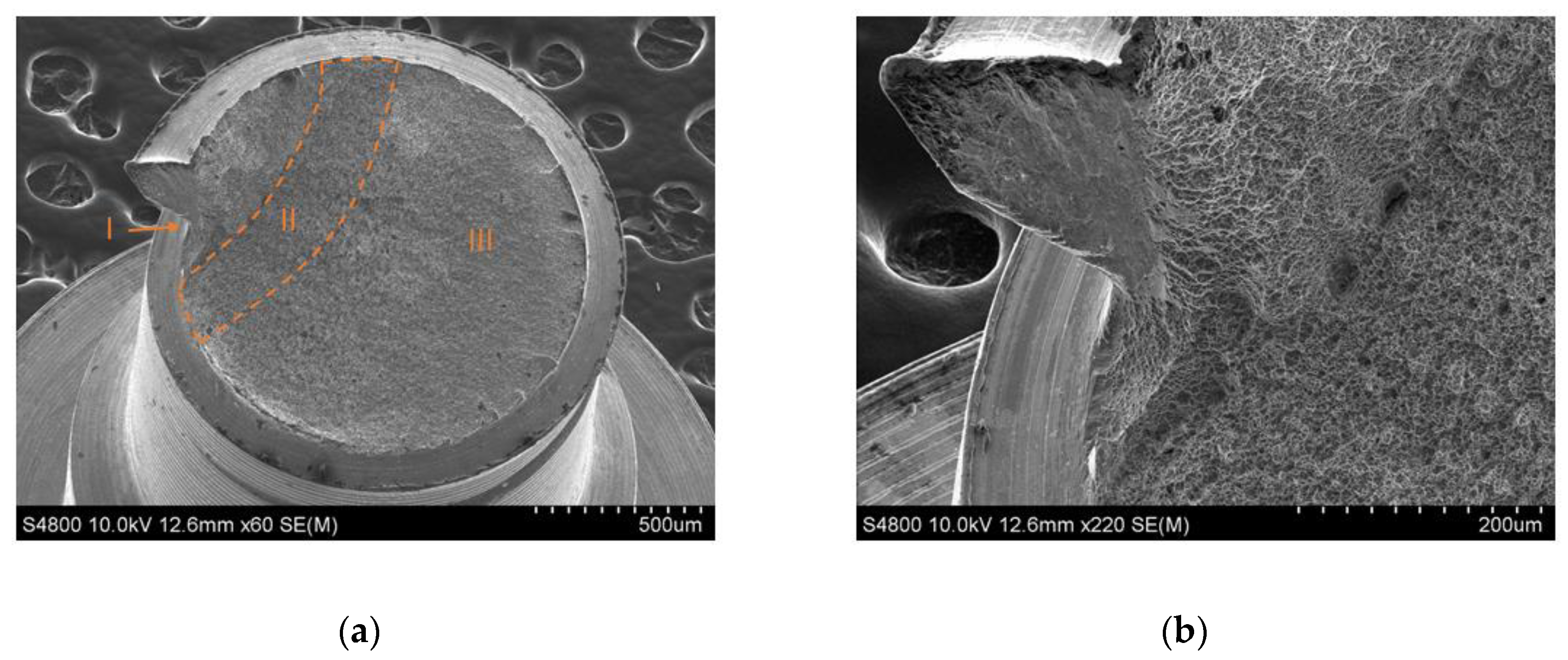

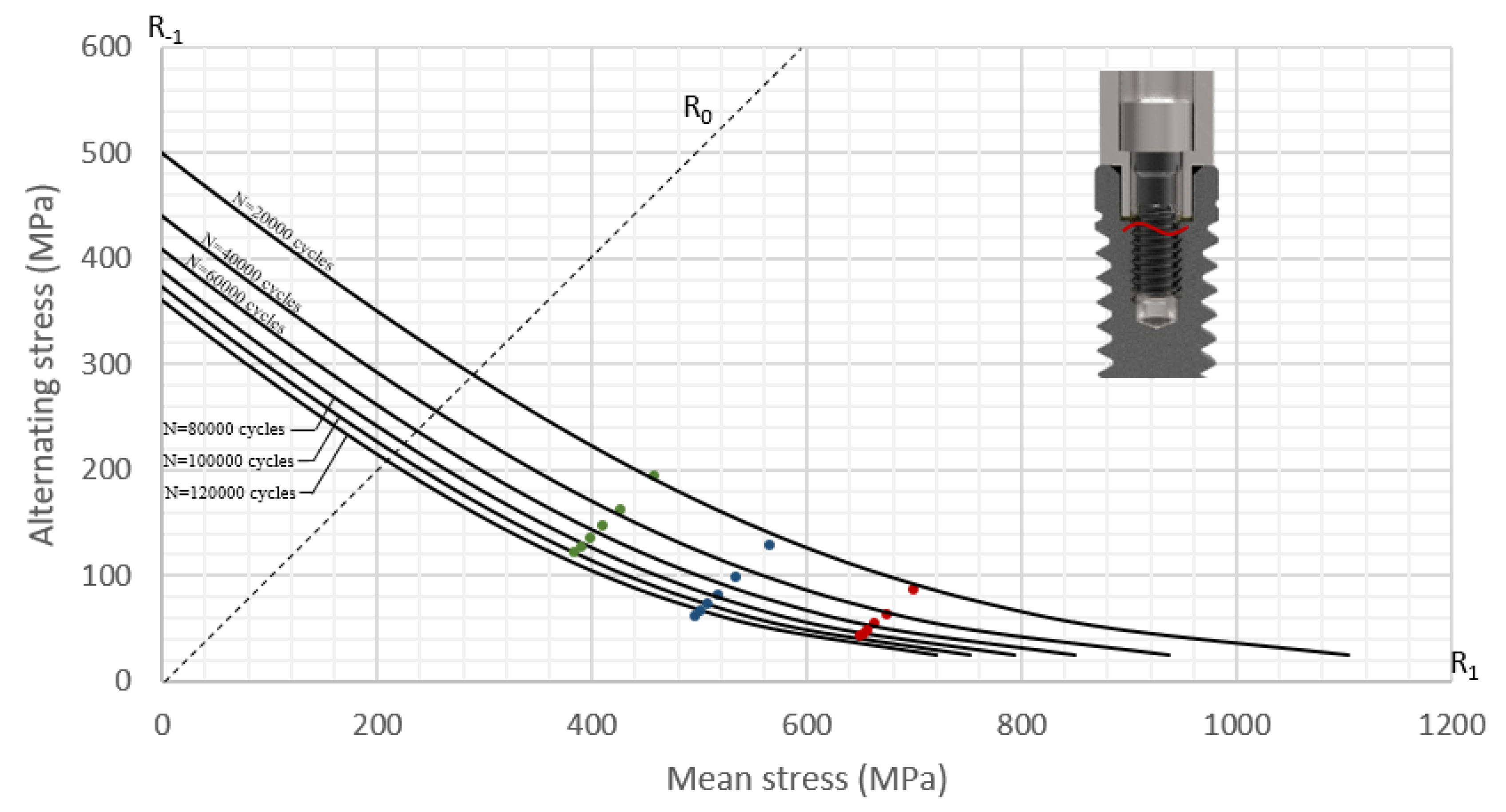

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Warreth, A.; Fesharaki, H.; McConville, R.; McReynolds, D. An introduction to single implant abutments. Dent. Update 2013, 40, 7–17. [Google Scholar] [CrossRef] [PubMed]

- Patterson, E.A.; Johns, R.B. Theoretical analysis of the fatigue life of fixture screws in osseointegrated dental implants. Int. J. Oral Maxillofac. Implant. 1992, 7, 26–33. [Google Scholar]

- Bickford, J.H. Introduction to the Design and Behavior of Bolted Joints. In Introduction to the Design and Behavior of Bolted Joints; CRC Press: New York, NY, USA, 2008; pp. 1–14. [Google Scholar]

- Stüker, R.A.; Teixeira, E.R.; Beck, J.C.P.; Da Costa, N.P. Preload and torque removal evaluation of three different abutment screws for single standing implant restorations. J. Appl. Oral Sci. 2008, 16, 55–58. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lang, L.A.; Kang, B.; Wang, R.F.; Lang, B.R. Finite element analysis to determine implant preload. J. Prosthet. Dent. 2003, 90, 539–546. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, G.S.; da Silva-Neto, J.P.; Simamoto-Júnior, P.C.; das Neves, F.D.; da Gloria, C.; de Mattos, M.; Ribeiro, R.F. Evaluation of screw loosening on new abutment screws and after successive tightening. Braz. Dent. J. 2011, 22, 51–55. [Google Scholar] [CrossRef] [Green Version]

- Budynas, R.; Nisbett, J.K. Shigley’s Mechanical Engineering Design; McGraw-Hill: New York, NY, USA, 2015; ISBN 9780070568990. [Google Scholar]

- Shemtov-Yona, K.; Rittel, D. Fatigue of Dental Implants: Facts and Fallacies. Dent. J. 2016, 4, 16. [Google Scholar] [CrossRef] [Green Version]

- Pjetursson, B.; Asgeirsson, A.; Zwahlen, M.; Sailer, I. Improvements in Implant Dentistry over the Last Decade: Comparison of Survival and Complication Rates in Older and Newer Publications. Int. J. Oral Maxillofac. Implant. 2014, 29, 308–324. [Google Scholar] [CrossRef] [Green Version]

- Dhima, M.; Paulusova, V.; Lohse, C.; Salinas, T.J.; Carr, A.B. Practice-based evidence from 29-year outcome analysis of management of the edentulous jaw using osseointegrated dental implants. J. Prosthodont. 2014, 23, 173–181. [Google Scholar] [CrossRef]

- Pérez, M.A. Life prediction of different commercial dental implants as influence by uncertainties in their fatigue material properties and loading conditions. Comput. Methods Programs Biomed. 2012, 108, 1277–1286. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 14801:2007 Dentistry. Implants. Dynamic fatigue test for endosseous dental implants; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Darshith, R.B.K.; Manjunath, S.S. Comprehensive Study of Cut and Roll Threads. IOSR J. Mech. Civ. Eng. 2014, 11, 91–96. [Google Scholar]

- Javier Gil, F.; Planell, J.A.; Padrós, A.; Aparicio, C. The effect of shot blasting and heat treatment on the fatigue behavior of titanium for dental implant applications. Dent. Mater. 2007, 23, 486–491. [Google Scholar] [CrossRef] [PubMed]

- Park, J.K.; Choi, J.U.; Jeon, Y.C.; Choi, K.S.; Jeong, C.M. Effects of abutment screw coating on implant preload. J. Prosthodont. 2010, 19, 458–464. [Google Scholar] [CrossRef]

- Jeng, M.D.; Liu, P.Y.; Kuo, J.H.; Lin, C.L. Load fatigue performance evaluation on two internal tapered abutment-implant connection implants under different screw tightening torques. J. Oral Implantol. 2017, 43, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Quek, H.; Tan, K.; Nicholls, J. Load fatigue performance of four implant-abutment interface designs: Effect of torque level and implant system. J. Prosthet. Dent. 2008, 23, 253–262. [Google Scholar]

- Xia, D.; Lin, H.; Yuan, S.; Bai, W.; Zheng, G. Dynamic fatigue performance of implantabutment assemblies with different tightening torque values. Biomed. Mater. Eng. 2014, 24, 2143–2149. [Google Scholar]

- Yao, K.T.; Kao, H.C.; Cheng, C.K.; Fang, H.W.; Yip, S.W.; Hsu, M.L. The effect of clockwise and counterclockwise twisting moments on abutment screw loosening. Clin. Oral Implant. Res. 2012, 23, 1181–1186. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Yamanishi, Y.; Machado, L.S.; Matsumoto, S.; Tovar, N.; Coelho, P.G.; Thompson, V.P.; Imazato, S. In vitro fatigue tests and in silico finite element analysis of dental implants with different fixture/abutment joint types using computer-aided design models. J. Prosthodont. Res. 2018, 62, 24–30. [Google Scholar] [CrossRef]

- Khraisat, A.; Stegaroiu, R.; Nomura, S.; Miyakawa, O. Fatigue resistance of two implant/abutment joint designs. J. Prosthet. Dent. 2002, 88, 604–610. [Google Scholar] [CrossRef]

- Bicudo, P.; Reis, J.; Deus, A.M.; Reis, L.; Vaz, M.F. Performance evaluation of dental implants: An experimental and numerical simulation study. Theor. Appl. Fract. Mech. 2016, 85, 74–83. [Google Scholar] [CrossRef]

- Lee, J.H.; Frias, V.; Lee, K.W.; Wright, R.F. Effect of implant size and shape on implant success rates: A literature review. J. Prosthet. Dent. 2005, 94, 377–381. [Google Scholar] [CrossRef]

- Shemtov-Yona, K.; Rittel, D.; Levin, L.; Machtei, E.E. Effect of dental implant diameter on fatigue performance. Part I: Mechanical behavior. Clin. Implant Dent. Relat. Res. 2014, 16, 172–177. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Gan, X.; Zhu, Z. Evaluation of dental implant fatigue performance under loading conditions in two kinds of physiological environment. Int. J. Clin. Exp. Med. 2017, 10, 6369–6377. [Google Scholar]

- Janeček, M.; Nový, F.; Harcuba, P.; Stráský, J.; Trško, L.; Mhaede, M.; Wagner, L. The very high cycle fatigue behaviour of Ti-6Al-4V alloy. Acta Phys. Pol. A 2015, 128, 497–503. [Google Scholar] [CrossRef]

- Carrion, P.E.; Shamsaei, N.; Daniewicz, S.R.; Moser, R.D. Fatigue behavior of Ti-6Al-4V ELI including mean stress effects. Int. J. Fatigue 2017, 99, 87–100. [Google Scholar] [CrossRef] [Green Version]

- Carrion, P.E.; Shamsaei, N. Strain-based fatigue data for Ti-6Al-4V ELI under fully-reversed and mean strain loads. Data Br. 2016, 7, 12–15. [Google Scholar] [CrossRef] [Green Version]

- Baragetti, S. Notch corrosion fatigue behavior of Ti-6Al-4V. Materials (Basel) 2014, 7, 4349–4366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hosseini, S.; Limooei, M.B. Investigation of fatigue behaviour and notch sensitivity of Ti-6Al-4V. Appl. Mech. Mater. 2011, 80–81, 7–12. [Google Scholar] [CrossRef]

- Susmel, L. The theory of critical distances: A review of its applications in fatigue. Eng. Fract. Mech. 2008, 75, 1706–1724. [Google Scholar] [CrossRef]

- Lanning, D.B.; Nicholas, T.; Palazotto, A. The effect of notch geometry on critical distance high cycle fatigue predictions. Int. J. Fatigue 2005, 27, 10–12. [Google Scholar] [CrossRef]

- Yamashita, Y.; Ueda, Y.; Kuroki, H.; Shinozaki, M. Fatigue life prediction of small notched Ti-6Al-4V specimens using critical distance. Eng. Fract. Mech. 2010, 77, 1439–1453. [Google Scholar] [CrossRef]

- Sivaraman, K.; Chopra, A.; Narayan, A.I.; Balakrishnan, D. Is zirconia a viable alternative to titanium for oral implant? A critical review. J. Prosthodont. Res. 2018, 62, 121–133. [Google Scholar] [CrossRef]

- Niinomi, M. Fatigue characteristics of metallic biomaterials. Int. J. Fatigue 2007, 29, 992–1000. [Google Scholar] [CrossRef]

- Gehrke, S.A.; da Silva, P.M.P.; Guirado, J.L.C.; Delgado-Ruiz, R.A.; Dedavid, B.A.; Nagasawa, M.A.; Shibli, J.A. Mechanical behavior of zirconia and titanium abutments before and after cyclic load application. J. Prosthet. Dent. 2016, 116, 529–535. [Google Scholar] [CrossRef] [PubMed]

- Prados-Privado, M.; Bea, J.A.; Rojo, R.; Gehrke, S.A.; Calvo-Guirado, J.L.; Prados-Frutos, J.C. A New Model to Study Fatigue in Dental Implants Based on Probabilistic Finite Elements and Cumulative Damage Model. Appl. Bionics Biomech. 2017, 2017, 3726361. [Google Scholar] [CrossRef] [PubMed]

- Prados-Privado, M.; Prados-Frutos, J.C.; Manchón, Á.; Rojo, R.; Felice, P.; Bea, J.A. Dental implants fatigue as a possible failure of implantologic treatment: The importance of randomness in fatigue behaviour. Biomed Res. Int. 2015, 2015, 825402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Motosh, N. Development of design charts for bolts preloaded up to the plastic range. J. Manuf. Sci. Eng. Trans. ASME 1976, 98, 849–951. [Google Scholar] [CrossRef]

- Houpert, L. An engineering approach to hertzian contact elasticity-part I. J. Tribol. 2001, 123, 582–588. [Google Scholar] [CrossRef]

- ASTM International ASTM E739-91. Standard Practice for Statistical Analysis of Linear or Linearized Stress-Life (S–N) and Strain-Life (e–N) Fatigue Data; ASTM: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Walker, K. The Effect of Stress Ratio During Crack Propagation and Fatigue for 2024-T3 and 7075-T6 Aluminum. In Effects of Environment and Complex Load History on Fatigue Life; ASTM: West Conshohocken, PA, USA, 1970. [Google Scholar]

- Dowling, N.E.; Calhoun, C.A.; Arcari, A. Mean stress effects in stress-life fatigue and the Walker equation. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 163–179. [Google Scholar] [CrossRef]

| Ti 6Al 4V ELI (TI GR5) | TI CP4 | ||

|---|---|---|---|

| Composition | Wt. % | Composition | Wt. % |

| Al | 5.5–6.5 | N(max) | 0.05 |

| V | 3.5–4.5 | C(max) | 0.08 |

| Fe(max) | 0.25 | Fe(max) | 0.5 |

| O(max) | 0.13 | O(max) | 0.4 |

| C(max) | 0.08 | H(max) | 0.0125 |

| N(max) | 0.05 | - | - |

| H(max) | 0.012 | - | - |

| Friction Coef. in Implant-Abutment | Friction Coef. in Screw | ||

|---|---|---|---|

| Test Number | Friction Coefficient | Test Number | Friction Coefficient |

| 1 | 0.220 | 1 | 0.162 |

| 2 | 0.208 | 2 | 0.237 |

| 3 | 0.237 | 3 | 0.151 |

| 4 | 0.189 | 4 | 0.134 |

| 5 | 0.196 | 5 | 0.175 |

| 6 | 0.197 | 6 | 0.162 |

| 7 | 0.201 | 7 | 0.237 |

| 8 | 0.224 | - | - |

| 9 | 0.181 | - | - |

| Mean value: | 0.21 | Mean value: | 0.17 |

| Std Dev: | 0.02 | Std Dev: | 0.04 |

| Screw Tightening Torque TT | Screw Preload Fp |

|---|---|

| 350 Nmm | 814 N |

| 250 Nmm | 581 N |

| 150 Nmm | 349 N |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Armentia, M.; Abasolo, M.; Coria, I.; Albizuri, J. Fatigue Design of Dental Implant Assemblies: A Nominal Stress Approach. Metals 2020, 10, 744. https://doi.org/10.3390/met10060744

Armentia M, Abasolo M, Coria I, Albizuri J. Fatigue Design of Dental Implant Assemblies: A Nominal Stress Approach. Metals. 2020; 10(6):744. https://doi.org/10.3390/met10060744

Chicago/Turabian StyleArmentia, Mikel, Mikel Abasolo, Ibai Coria, and Joseba Albizuri. 2020. "Fatigue Design of Dental Implant Assemblies: A Nominal Stress Approach" Metals 10, no. 6: 744. https://doi.org/10.3390/met10060744

APA StyleArmentia, M., Abasolo, M., Coria, I., & Albizuri, J. (2020). Fatigue Design of Dental Implant Assemblies: A Nominal Stress Approach. Metals, 10(6), 744. https://doi.org/10.3390/met10060744