On Temperature Dependence of Microstructure, Deformation Mechanisms and Tensile Properties in Austenitic Cr-Mn Steel with Ultrahigh Interstitial Content C + N = 1.9 Mass.%

Abstract

:1. Introduction

2. Materials and Methods

3. Results

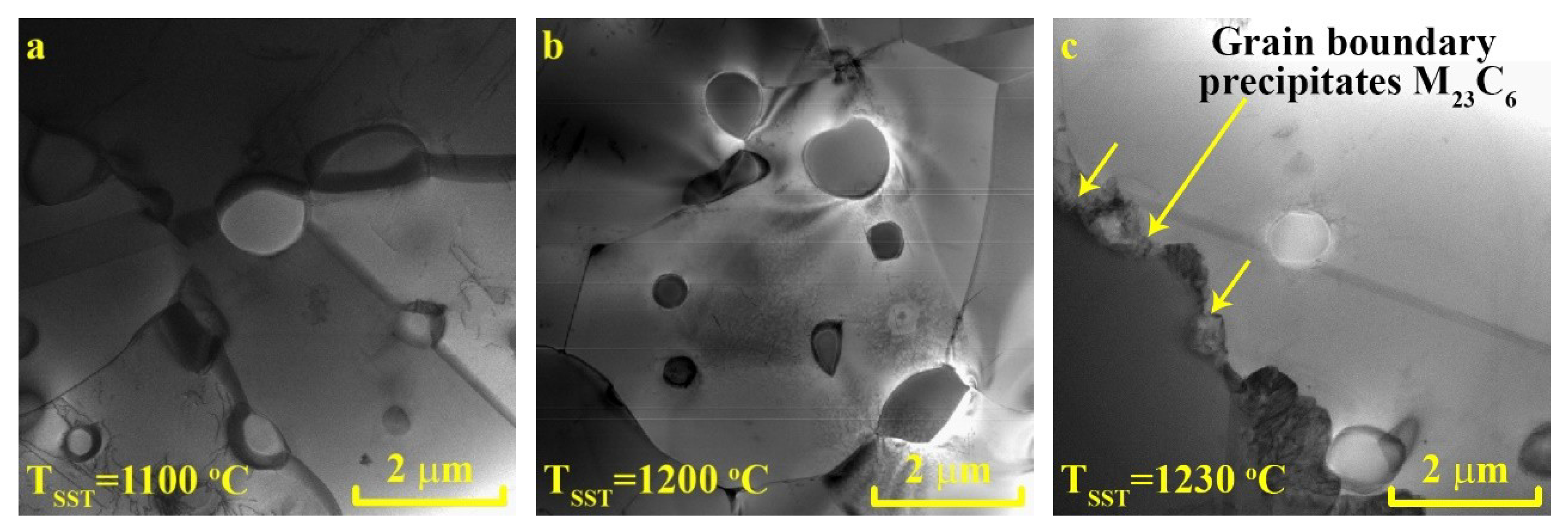

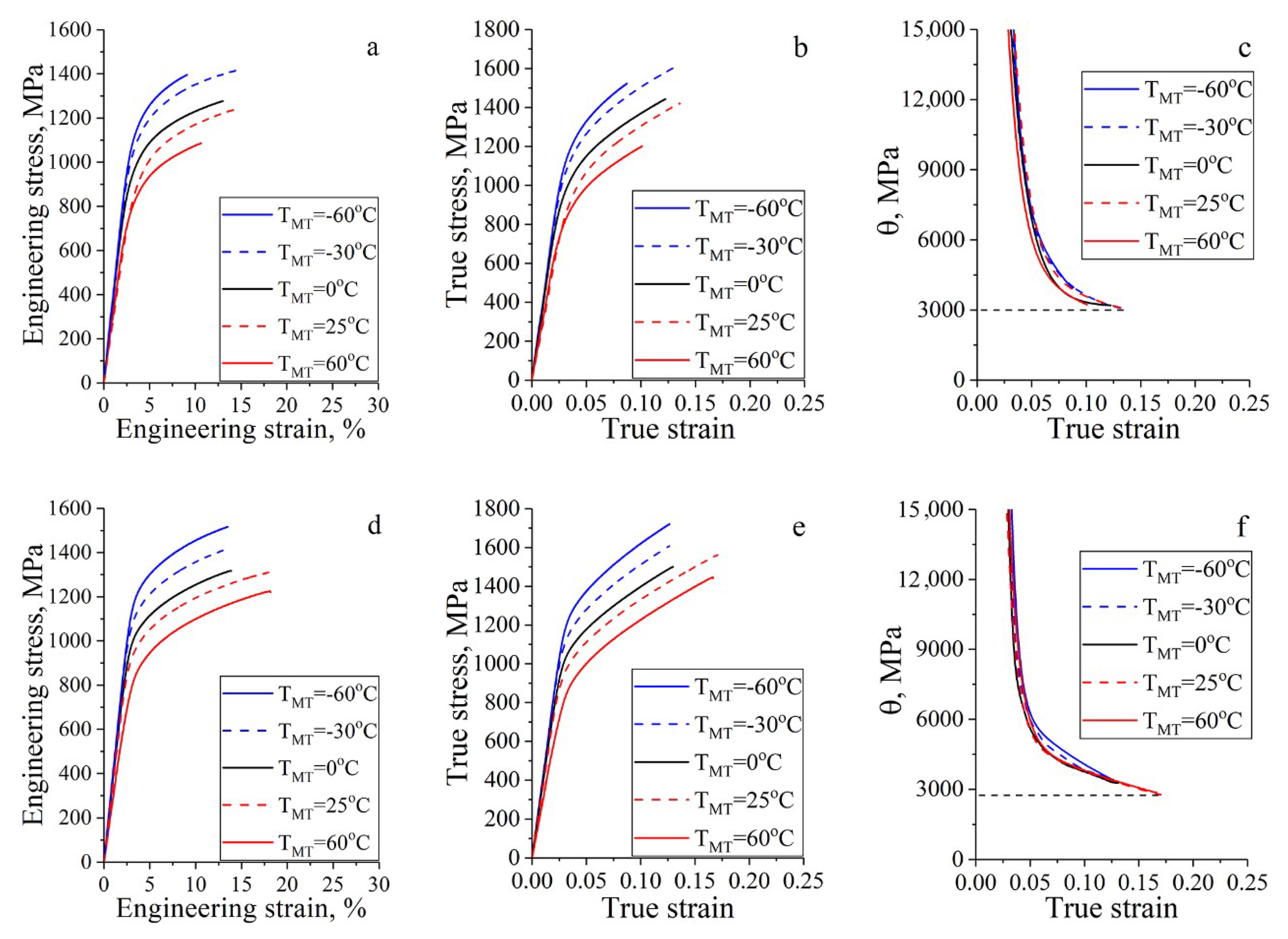

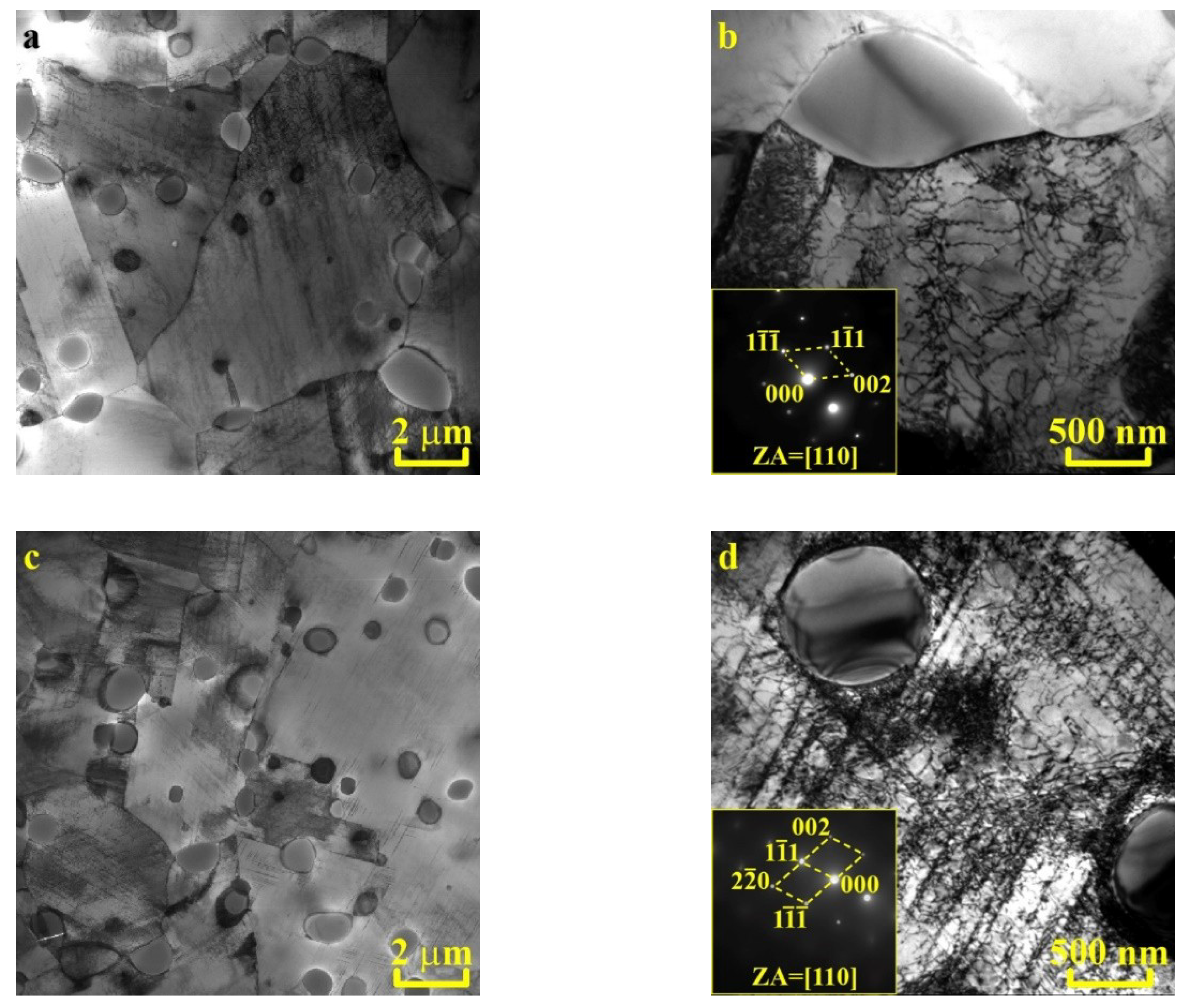

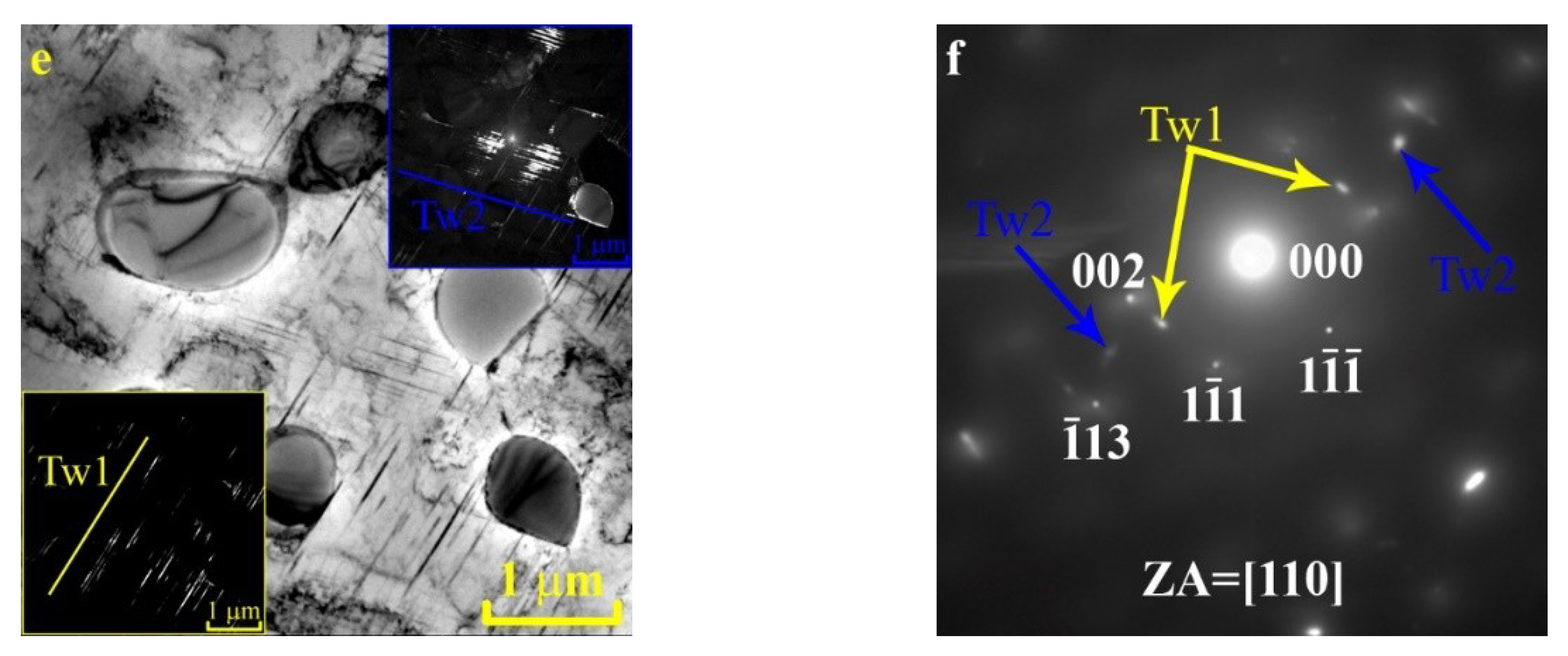

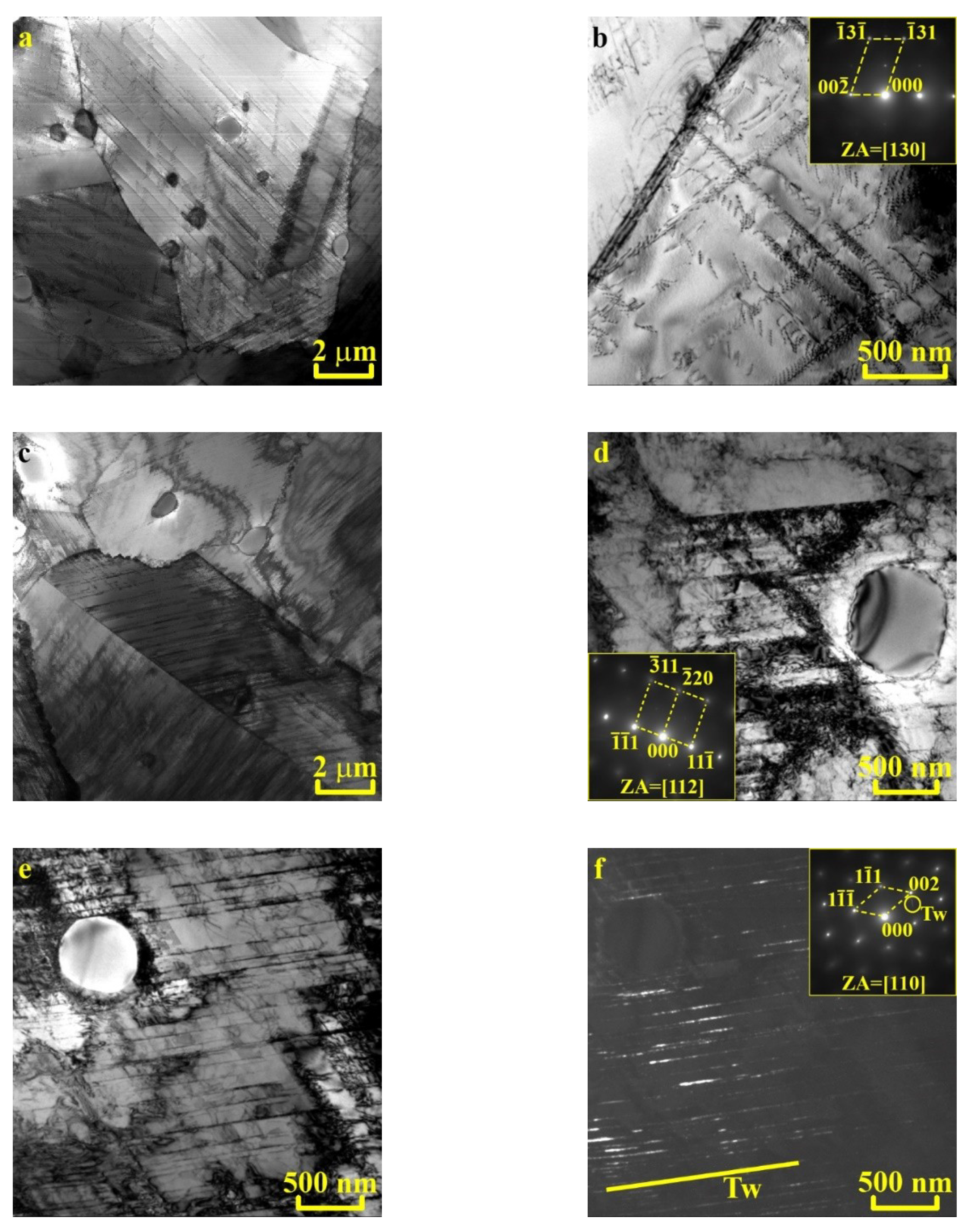

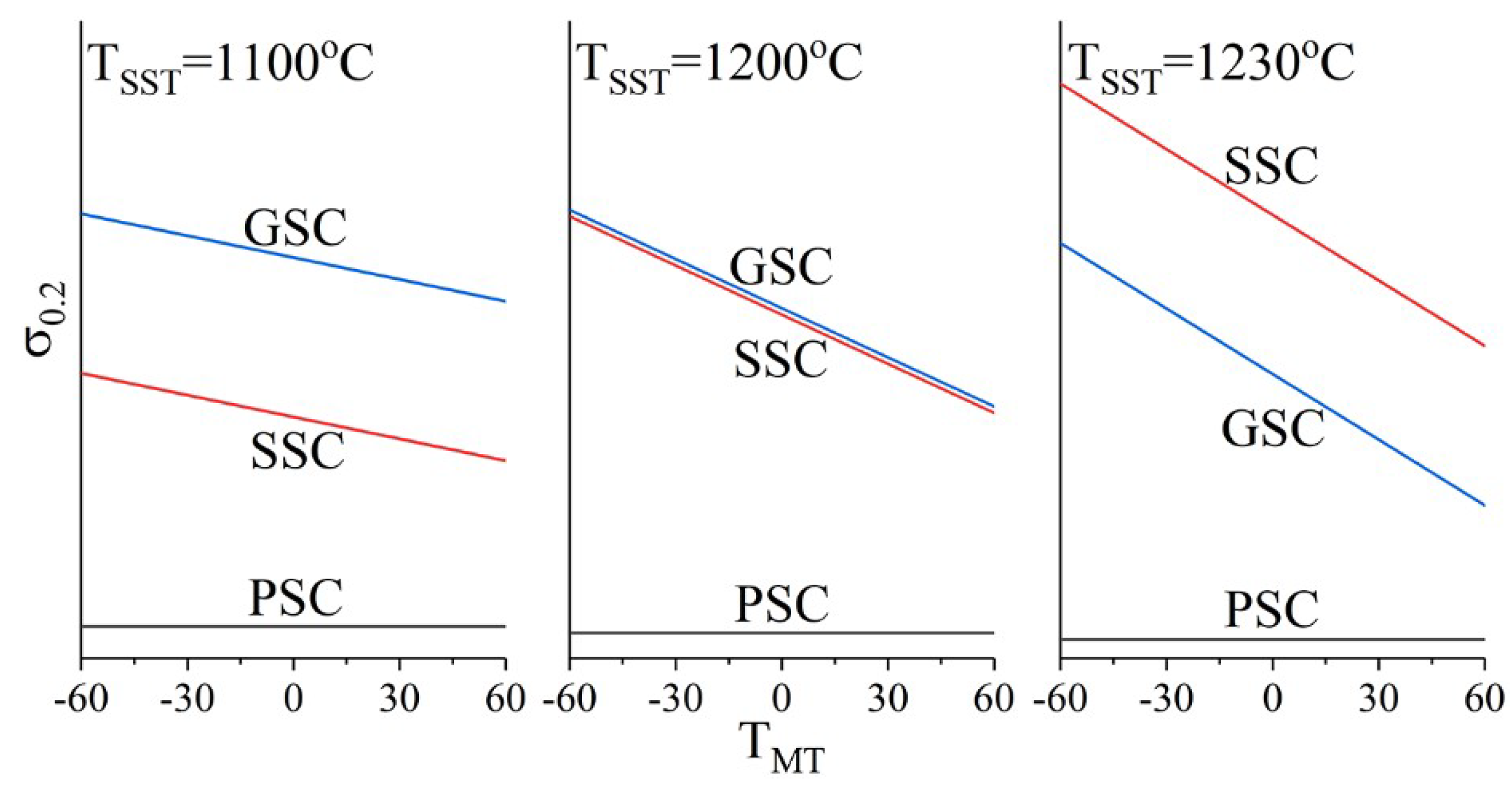

3.1. The Effect of Deformation Temperature in The Interval from −60 °C to +60 °C on Microstructure, Deformation Mechanisms and Tensile Properties in Cr-Mn UHIS

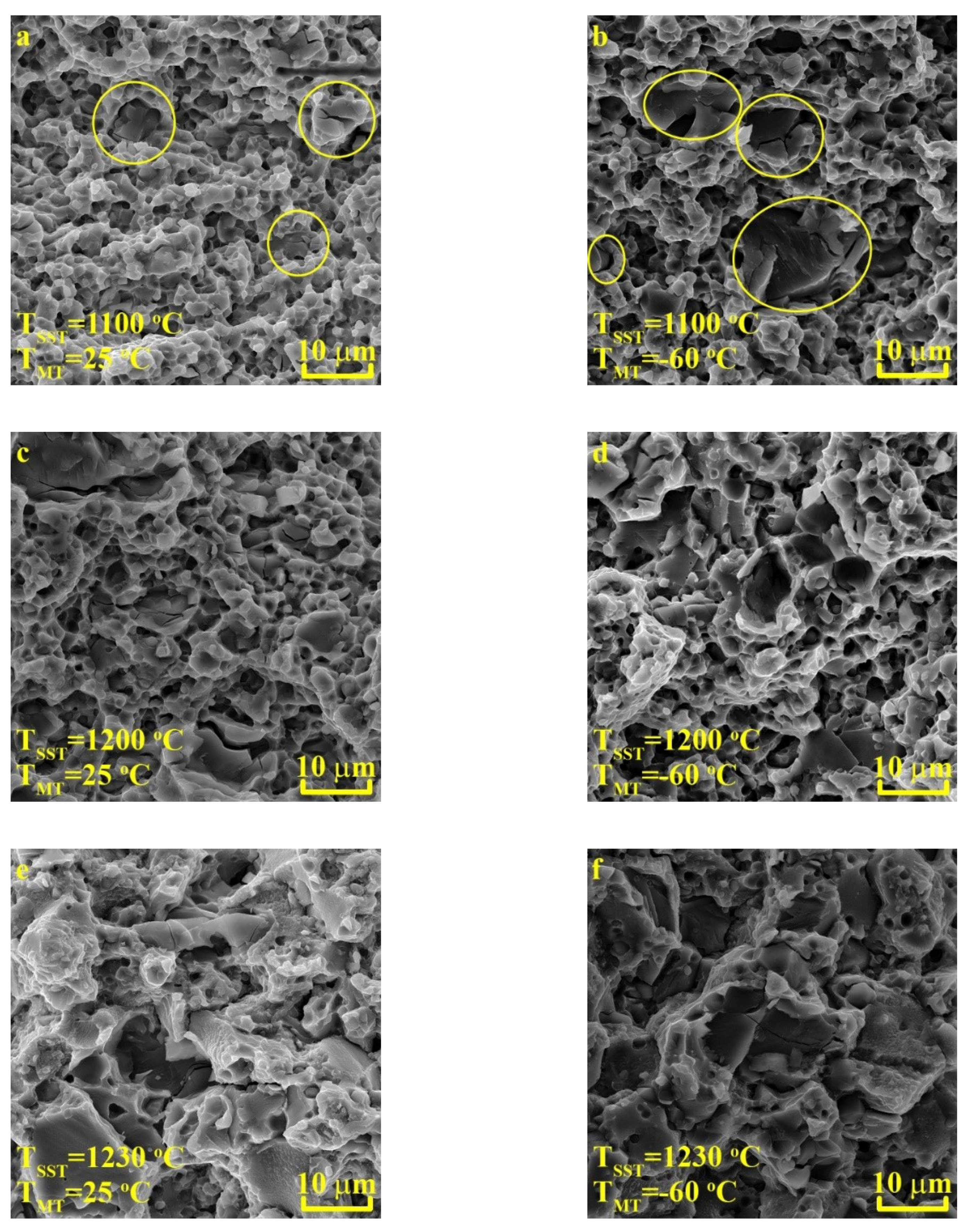

3.2. Fracture Micromechanisms in the Temperature Range from −60 °C to +60 °C

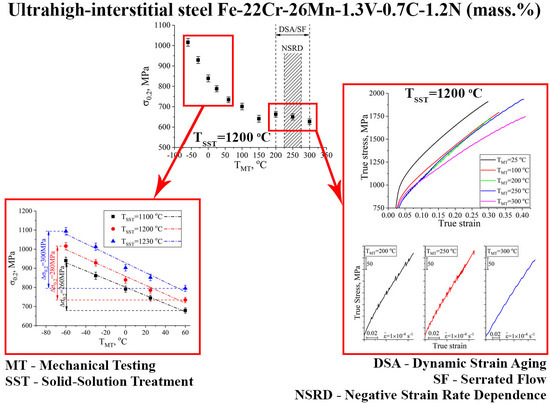

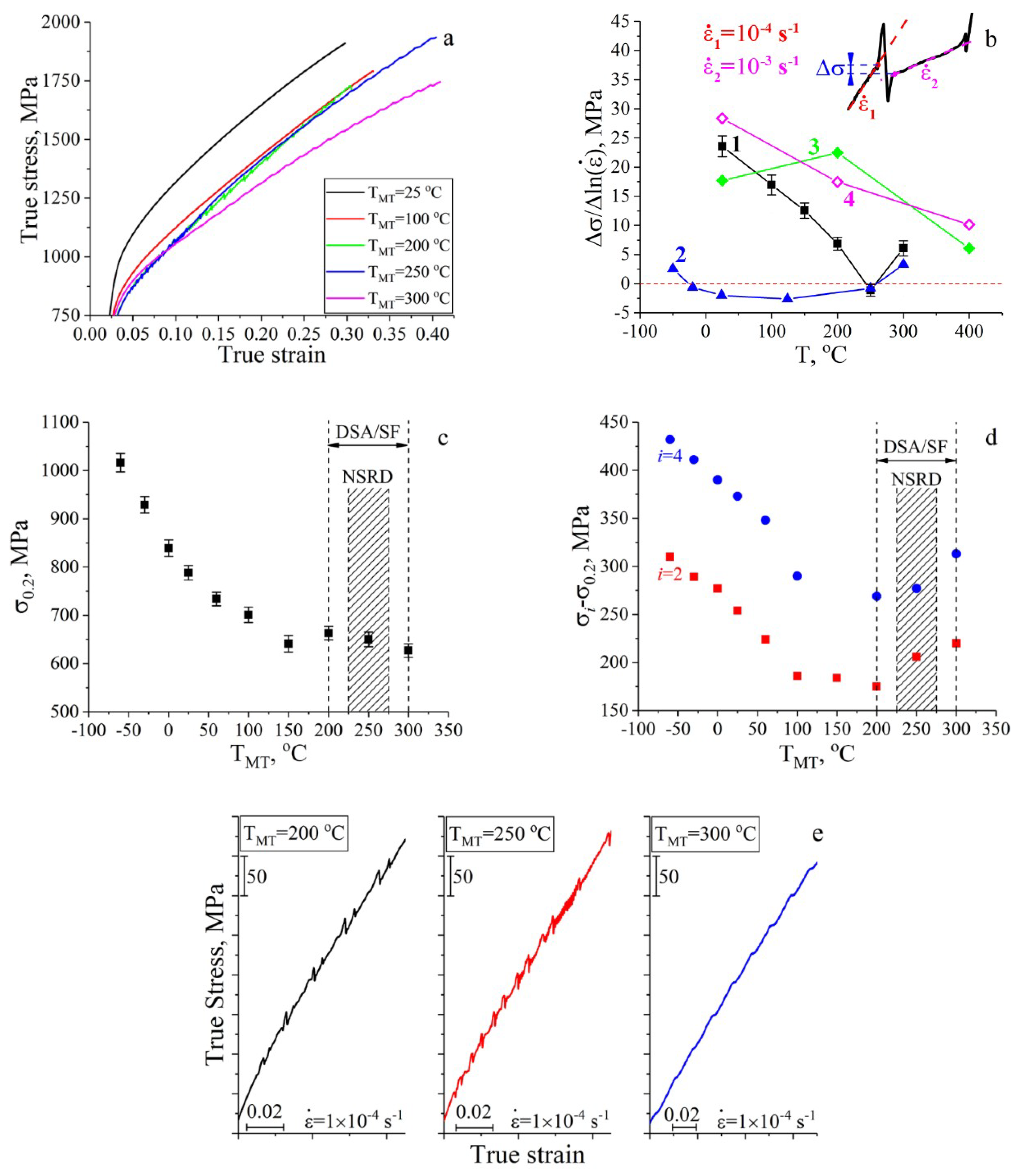

3.3. The Dynamic Strain Aging Phenomenon in the UHIS Solution Treated at 1200 °C

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent developments in stainless steels. Mater. Sci. Eng. R. 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Honeykombe, R.W.K. Steels: Microstructure and Properties; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Rajasekhara, S.; Ferreira, P.J.; Karjalainen, L.P.; Kyrolainen, A. Hall–Petch behavior in ultra-fine-grained AISI 301LN stainless steel. Metallurg. Mater. Trans. A 2007, 38A, 1202–1210. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Lugovskaya, A.; Belyakov, A.; Kaibyshev, R. Deformation microstructures and tensile properties of an austenitic stainless steel subjected to multiple warm rolling. Mater. Sci. Eng. A 2016, 667, 279–285. [Google Scholar] [CrossRef] [Green Version]

- Astafurova, E.G.; Melnikov, E.V.; Astafurov, S.V.; Ratochka, I.V.; Mishin, I.P.; Maier, G.G.; Moskvina, V.A.; Zakharov, G.N.; Smirnov, A.I.; Bataev, V.A. Hydrogen embrittlement effects on austenitic stainless steels with ultrafine-grained structure of different morphology. Phys. Mesomech. 2019, 22, 313–326. [Google Scholar] [CrossRef]

- Astafurov, S.V.; Maier, G.G.; Melnikov, E.V.; Moskvina, V.A.; Panchenko, M.Y.; Astafurova, E.G. The strain-rate dependence of the Hall-Petch effect in two austenitic stainless steels with different stacking fault energies. Mater. Sci. Eng. A 2019, 756, 365–372. [Google Scholar] [CrossRef]

- Karavaeva, M.V.; Abramova, M.M.; Enikeev, N.A.; Raab, G.I.; Valiev, R.Z. Superior strength of austenitic steel produced by combined processing, including equal-channel angular pressing and rolling. Metals 2016, 6, 310. [Google Scholar] [CrossRef] [Green Version]

- Gavriljuk, V.G.; Berns, H. High Nitrogen Steels; Springer: Berlin, Germany, 1999. [Google Scholar]

- Reed, R.P. Nitrogen in austenitic stainless steels. JOM 1989, 41, 16–21. [Google Scholar] [CrossRef]

- Stein, G.; Menzel, J.; Dörr, H. Industrial manufacture of massively nitrogen-alloyed steels. In High Nitrogen Steels, HNS-88; Foct, J., Hendry, A., Eds.; The Institute of Metals: London, UK, 1989; pp. 32–38. [Google Scholar]

- Pickering, F.B. Some beneficial effects of nitrogen in steel. In High Nitrogen Steels, HNS-88; Foct, J., Hendry, A., Eds.; The Institute of Metals: London, UK, 1989; pp. 10–31. [Google Scholar]

- Uggowitzer, P.J.; Harzenmozer, M. Strengthening of austenitic stainless steels by nitrogen. In High Nitrogen Steels, HNS-88; Foct, J., Hendry, A., Eds.; The Institute of Metals: London, UK, 1989; pp. 174–179. [Google Scholar]

- Berns, H.; Gavriljuk, V.; Riedner, S. High Interstitial Stainless Austenitic Steels; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Rawers, J.; Grujicic, M. Effect of metal composition and temperature on the yield strength of nitrogen strengthened stainless steels. Mater. Sci. Eng. A 1996, 207, 188–194. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Sozinov, A.L.; Foct, J.; Petrov, J.N.; Polushkin, Y.A. Effect of nitrogen on the temperature dependence of the yield strength of austenitic steels. Acta Mater. 1998, 46, 1157–1163. [Google Scholar] [CrossRef]

- Mullner, P.; Solenthaler, C.; Uggowitzer, P.J.; Spidel, M.O. Brittle fracture in austenitic steel. Acta Mater. 1994, 42, 2211–2217. [Google Scholar] [CrossRef]

- Tomota, Y.; Xia, Y.; Inoue, K. Mechanism of low temperature brittle fracture in high nitrogen bearing austenitic steels. Acta Mater. 1998, 46, 1577–1587. [Google Scholar] [CrossRef]

- Tobler, R.L.; Meyn, D. Cleavage-like fracture along slip planes in Fe-18Cr-3Ni-13Mn-0.37N austenitic stainless steel at liquid helium temperature. Metallurg. Trans. A 1988, 19A, 1626–1631. [Google Scholar] [CrossRef]

- Liu, S.; Liu, D.; Liu, S. Transgranular fracture in low temperature brittle fracture of high nitrogen austenitic steel. J. Mater. Sci. 2007, 42, 7514–7519. [Google Scholar] [CrossRef]

- Chumlyakov, Y.I.; Kireeva, I.V.; Sehitoglu, H.; Litvinova, E.I.; Zaharova, E.G.; Luzginova, N.V. High-strength single crystals of austenitic stainless steel with nitrogen content: Mechanisms of deformation and fracture. Mater. Sci. Forum. 1999, 318–320, 395–400. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, T.-H.; Kim, S.-J. Effects of deformation-induced martensite and grain size on ductile-to-brittle transition of austenitic 18Cr-10Mn-N stainless steels. Met. Mater. Int. 2010, 16, 905–911. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, T.-H.; Park, S.-J.; Oh, C.-S.; Kim, S.-J. Correlation of austenite stability and ductile-to-brittle transition behavior of high-nitrogen 18Cr-10Mn austenitic steels. Mater. Sci. Eng. A 2011, 528, 7257–7266. [Google Scholar] [CrossRef]

- Kireeva, I.V.; Chumlyakov, Y.I. Effect of nitrogen and stacking-fault energy on twinning in [111] single crystals of austenitic stainless steels. Phys. Met. Metallogr. 2009, 108, 298–309. [Google Scholar] [CrossRef]

- Mosecker, L.; Saeed-Akbari, A. Nitrogen in chromium-manganese stainless steels: A review on the evaluation of stacking fault energy by computational thermodynamics. Sci. Tech. Adv. Mater. 2013, 14, 033001. [Google Scholar] [CrossRef]

- Mullner, P.; Solenthaler, C.; Uggowitzer, P.; Speidel, M.O. On the effect of nitrogen on the dislocation structure of austenitic stainless steel. Mater. Sci. Eng. A 1993, 164, 164–169. [Google Scholar] [CrossRef]

- Panin, V.E.; Derevyagina, L.S.; Panin, S.V.; Shugurov, A.R.; Gordienko, A.I. The role of nanoscale strain-induced defects in the sharp increase of low-temperature toughness in low-carbon and low-alloy steels. Mater. Sci. Eng. A 2019, 768, 138491. [Google Scholar] [CrossRef]

- Akbari, A.; Mohammadzadeh, R. Effect of grain refinement on the mechanical properties of a nickel- and manganese-free high nitrogen austenitic stainless steel. Metallurg. Mater. Trans. A 2015, 46A, 1570–1579. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Shanina, B.D.; Berns, H. A physical concept for alloying steels with carbon + nitrogen. Mater. Sci. Eng. A 2008, 481–482, 707–712. [Google Scholar] [CrossRef]

- Shanina, B.; Gavriljuk, V.; Berns, H.; Schmalt, F. Concept of a new high-strength low-cost stainless steel. Steel Res. 2002, 73, 105–113. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Shanina, B.D.; Berns, H. Ab initio development of a high-strength corrosion resistant austenitic steel. Acta Mater. 2008, 56, 5071–5082. [Google Scholar] [CrossRef]

- Berns, H.; Nabiran, N.; Mujica, L. High-interstitial stainless austenitic steel castings. Steel Res. Int. 2013, 84, 119–128. [Google Scholar] [CrossRef]

- Mosecker, L.; Pierce, D.T.; Schwedt, A.; Beighmohamadi, M.; Mayer, J.; Bleck, W.; Wittig, J.E. Temperature effect on deformation mechanisms and mechanical properties of a high manganese C+N alloyed austenitic stainless steel. Mater. Sci. Eng. A 2015, 642, 71–83. [Google Scholar] [CrossRef]

- Yang, H.K.; Tian, Y.Z.; Zhang, Z.J.; Zhang, Z.F. Simultaneously improving the strength and ductility of Fe–22Mn–0.6C twinning-induced plasticity steel via nitrogen addition. Mater. Sci. Eng. A 2018, 715, 276–280. [Google Scholar] [CrossRef]

- Saenarjhan, N.; Kang, J.-H.; Kim, S.-J. Effect of carbon and nitrogen on austenite stability and tensile deformation behavior of 15Cr-15Mn-4Ni based austenitic stainless steels. Mater. Sci. Eng. A 2019, 742, 608–616. [Google Scholar] [CrossRef]

- Astafurova, E.G.; Moskvina, V.A.; Maier, G.G.; Gordienko, A.I.; Burlachenko, A.G.; Smirnov, A.I.; Bataev, V.A.; Galchenko, N.K.; Astafurov, S.V. Low-temperature tensile ductility by V-alloying of high-nitrogen CrMn and CrNiMn steels: Characterization of deformation microstructure and fracture micromechanisms. Mater. Sci. Eng. A 2019, 745, 265–278. [Google Scholar] [CrossRef]

- Astafurova, E.; Moskvina, V.; Maier, G.; Melnikov, E.; Galchenko, N.; Astafurov, S.; Gordienko, A.; Burlachenko, A.; Smirnov, A.; Bataev, V. The effect of test temperature on deformation microstructure and fracture mechanisms in CrMn high-nitrogen steels alloyed (0–3 wt.%) with vanadium. Mater. Sci. Forum. 2018, 941, 27–32. [Google Scholar] [CrossRef]

- Bannykh, O.A.; Blinov, V.M. On the effect of discontinuous decomposition on the structure and properties of high-nitrogen steels and on methods for suppression thereof. Steel Res. 1991, 62, 38–45. [Google Scholar] [CrossRef]

- Blinov, V.M. Progress in the study of high-nitrogen corrosion-resistant aging nonmagnetic vanadium steels. Russ. Metall. (Metally) 2007, 2, 127–135. [Google Scholar] [CrossRef]

- Astafurov, S.V.; Maier, G.G.; Tumbusova, I.A.; Melnikov, E.V.; Moskvina, V.A.; Panchenko, M.Y.; Smirnov, A.I.; Galchenko, N.K.; Astafurova, E.G. The effect of solid-solution temperature on phase composition, tensile characteristics and fracture mechanism of V-containing CrMn-steels with high interstitial content C + N > 1 mass. %. Mater. Sci. Eng. A 2020, 770, 138534. [Google Scholar] [CrossRef]

- Hirsch, P.B.; Howie, A.; Nicholson, R.B.; Pashley, D.W.; Whelan, M.J. Electron Microscopy of Thin Crystals; Butterworths: London, UK, 1965. [Google Scholar]

- Dastur, Y.N.; Leslie, W.C. Mechanism of work hardening in Hadfield manganese steel. Metallurg. Trans. A 1981, 12, 749–759. [Google Scholar] [CrossRef]

- Ilola, R.; Kemppainen, M.; Hanninen, H. Dynamic strain aging of austenitic high-nitrogen Cr-Ni and Cr-Mn steels. Mater. Sci. Forum. 1999, 318–320, 407–412. [Google Scholar] [CrossRef]

- Rodriguez, P. Serrated plastic flow. Bull. Mater. Sci. 1984, 6, 653–663. [Google Scholar] [CrossRef]

- Tanaka, M.; Onomoto, T.; Tsuchiyama, T.; Higashida, K. Brittle-to-ductile transition in nickel-free austenitic stainless steels with high nitrogen. ISIJ Int. 2012, 52, 915–921. [Google Scholar] [CrossRef] [Green Version]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels. A review of the microstructure properties relationship. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

- Byrnes, M.L.G.; Grujicic, M.; Owen, W.S. Nitrogen strengthening of a stable austenitic stainless steel. Acta Metallurg. 1987, 35, 1853–1862. [Google Scholar] [CrossRef]

- Lee, S.-J.; Kim, J.; Kane, S.N.; De Cooman, B.C. On the origin of dynamic strain aging in twinning-induced plasticity steels. Acta Mater. 2011, 59, 6809–6819. [Google Scholar] [CrossRef]

- Ganesan, V.; Laha, K.; Nandagopal, M.; Parameswaran, P.; Mathew, M.D. Effect of nitrogen content on dynamic strain ageing behaviour of type 316LN austenitic stainless steel during tensile deformation. Mater. High. Temp. 2014, 31, 162–170. [Google Scholar] [CrossRef]

| Parameter | Solid-Solution Temperature | ||

|---|---|---|---|

| 1100 °C | 1200 °C | 1230 °C | |

| Phase composition | Austenite, Me2X (hcp), MeX (fcc) | Austenite, Me2X (hcp), MeX (fcc) | Austenite, MeX (fcc), Me23C6 (fcc), Me23C6 * (fcc) |

| Austenite lattice parameter, Å | 3.6373 | 3.6486 | 3.6535 |

| Austenite grain size, µm | 7.0 ± 2.1 | 10.4 ± 5.2 | 15.0 ± 7.5 |

| Particle mean size/volume fraction, µm/% | 670/9.0 | 570/6.5 | 750/4.1 |

| Concentration of Cr/Mn/V in austenite | 18–19/26/0.4–0.5 | 19–20/25–26/0.5–0.6 | 21–22/25-26/0.9–1.0 |

| Stacking fault energy of austenite, mJ/m2 (TEM) | 45 ± 3 | 51 ± 13 | 25 ± 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Astafurova, E.; Astafurov, S.; Maier, G.; Tumbusova, I.; Melnikov, E.; Moskvina, V.; Panchenko, M.; Reunova, K.; Galchenko, N. On Temperature Dependence of Microstructure, Deformation Mechanisms and Tensile Properties in Austenitic Cr-Mn Steel with Ultrahigh Interstitial Content C + N = 1.9 Mass.%. Metals 2020, 10, 786. https://doi.org/10.3390/met10060786

Astafurova E, Astafurov S, Maier G, Tumbusova I, Melnikov E, Moskvina V, Panchenko M, Reunova K, Galchenko N. On Temperature Dependence of Microstructure, Deformation Mechanisms and Tensile Properties in Austenitic Cr-Mn Steel with Ultrahigh Interstitial Content C + N = 1.9 Mass.%. Metals. 2020; 10(6):786. https://doi.org/10.3390/met10060786

Chicago/Turabian StyleAstafurova, Elena, Sergey Astafurov, Galina Maier, Irina Tumbusova, Eugene Melnikov, Valentina Moskvina, Marina Panchenko, Kseniya Reunova, and Nina Galchenko. 2020. "On Temperature Dependence of Microstructure, Deformation Mechanisms and Tensile Properties in Austenitic Cr-Mn Steel with Ultrahigh Interstitial Content C + N = 1.9 Mass.%" Metals 10, no. 6: 786. https://doi.org/10.3390/met10060786

APA StyleAstafurova, E., Astafurov, S., Maier, G., Tumbusova, I., Melnikov, E., Moskvina, V., Panchenko, M., Reunova, K., & Galchenko, N. (2020). On Temperature Dependence of Microstructure, Deformation Mechanisms and Tensile Properties in Austenitic Cr-Mn Steel with Ultrahigh Interstitial Content C + N = 1.9 Mass.%. Metals, 10(6), 786. https://doi.org/10.3390/met10060786