Comparative Study of Flank Cams Manufactured by WEDM and Milling Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Selection of a Reference Cam-Follower Mechanism

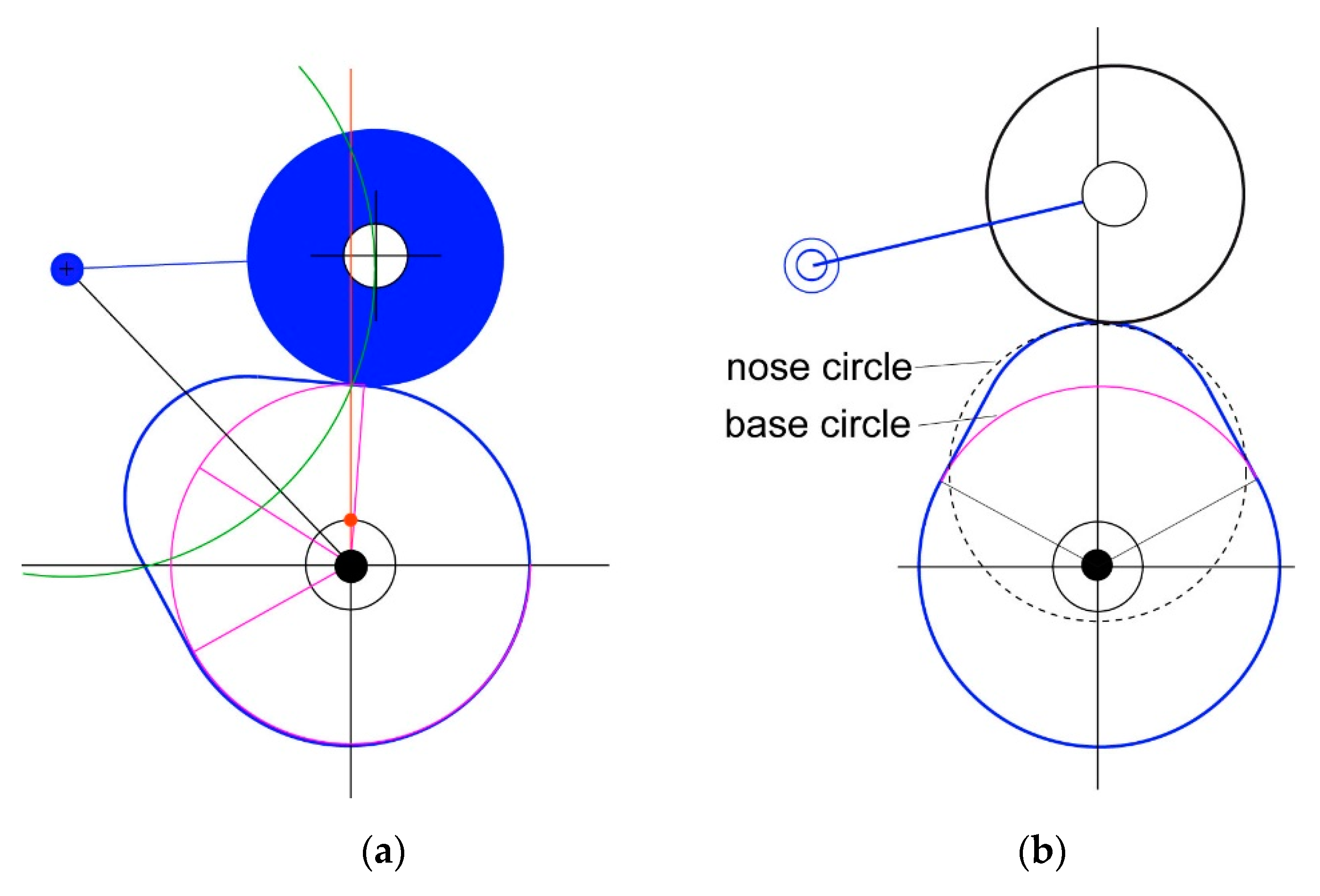

2.2. Design of a New Cam Profile

- (a)

- to design the follower displacement law,

- (b)

- to obtain the cam profile according to the designed displacement law, and

- (c)

- to check that the curvature of the cam profile guarantees a correct cam-follower contact.

2.3. Manufacturing of a Prototype of the Cam and Validation of the Design

2.4. Design of the Manufacturing Processes to Obtain the Cams

2.4.1. Machining Process

2.4.2. WEDM

2.5. Roughness and Shape Measurement

2.5.1. Roughness Measurement

2.5.2. Shape Measurement

3. Results

3.1. Visual Inspection

3.2. Roughness

3.2.1. Roughness of the Milled Cam

3.2.2. Roughness of the WEDM Cam

3.3. Shape Error

3.3.1. Shape Error of the Milled Cam

3.3.2. Shape Error of the WEDM Cam

4. Discussion

5. Conclusions

- -

- The milled cam, obtained with subsequent rough and finish contour milling operations, meets both the requirements about surface roughness (average Ra = 0.269 μm < 0.4 μm) and shape error (shape error = 18 μm < 50 μm) for cams.

- -

- The WEDM cam, obtained with a rough operation, complies with the shape requirements (shape error = 48 μm < 50 μm), but not with the roughness requirements, with an average Ra value of 1.212. For this reason, a finish operation would be recommended, with a special clamping system to ensure the proper alignment of the part.

- -

- WEDM is a potential process for the manufacture of cams, especially in short production batches. Some advantages of this technique are the possibility to obtain complex shapes in different conductive materials, and the fact that, if WEDM is used in rough operations, the quantity of material to be removed in subsequent operations can be reduced.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Angeles, J.; López-Cajún, C.S. Optimization of Cam Mechanisms; Springer: Berlin/Heidelberg, Germany, 1991. [Google Scholar]

- Norton, R.L. Cam Design and Manufacturing Handbook; Industrial Press Inc.: New York, NY, USA, 2002. [Google Scholar]

- Grant, B.; Soni, A.H. A survey of cam manufacture methods. J. Mech. Des. Trans. ASME 1979, 101, 455–464. [Google Scholar] [CrossRef]

- Luis Pérez, C.J.; Luri Irigoyen, R.; Fuertes Bonel, J.P.; León Iriarte, J.; Salcedo Pérez, D.; Puertas Arbizu, I. Experimental and fem analysis of wear behaviour in AA5083 ultrafine-grained cams. Metals 2020, 10, 479. [Google Scholar] [CrossRef] [Green Version]

- Purohit, R.; Sagar, R. Fabrication of a cam using metal matrix composites. Int. J. Adv. Manuf. Technol. 2001, 17, 644–648. [Google Scholar] [CrossRef]

- Mouralova, K.; Zahradnicek, R.; Benes, L.; Prokes, T.; Hrdy, R.; Fries, J. Study of micro structural material changes after WEDM based on TEM lamella analysis. Metals 2020, 10, 949. [Google Scholar] [CrossRef]

- Kumar, S.; Grover, S.; Walia, R.S. Effect of hybrid wire EDM conditions on generation of residual stresses in machining of HCHCr D2 tool steel under ultrasonic vibration. Int. J. Interact. Des. Manuf. 2018, 12, 1119–1137. [Google Scholar] [CrossRef]

- Klink, A.; Guo, Y.B.; Klocke, F. Surface integrity evolution of powder metallurgical tool steel by main cut and finishing trim cuts in wire-EDM. Proc. Procedia Eng. 2011, 19, 178–183. [Google Scholar] [CrossRef] [Green Version]

- Ahuja, N.; Sharma, N.; Hegab, H.; Khanna, R.; Khan, A.M. Bioactivity measurement of commercially pure titanium processed by micro-electric discharge drilling. Int. J. Adv. Manuf. Technol. 2020, 107, 2797–2805. [Google Scholar] [CrossRef]

- Sharma, N.; Singh, G.; Gupta, M.; Hegab, H.; Mia, M. Investigations of surface integrity, bio-activity and performance characteristics during wire-electrical discharge machining of Ti-6Al-7Nb biomedical alloy. Mater. Res. Express 2019, 6, 9. [Google Scholar] [CrossRef]

- Mohd Abbas, N.; Solomon, D.G.; Fuad Bahari, M. A review on current research trends in electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2007, 47, 1214–1228. [Google Scholar] [CrossRef]

- García-Hernández, C.; Gella-Marín, R.M.; Huertas-Talón, J.L.; Efkolidis, N.; Kyratsis, P. WEDM manufacturing method for noncircular gears, using CAD/CAM software. Stroj. Vestn. J. Mech. Eng. 2016, 62, 137–144. [Google Scholar] [CrossRef] [Green Version]

- Sanchez, J.A.; Plaza, S.; De Lacalle, L.N.L.; Lamikiz, A. Computer simulation of wire-EDM taper-cutting. Int. J. Comput. Integr. Manuf. 2006, 19, 727–735. [Google Scholar] [CrossRef]

- Ho, K.H.; Newman, S.T.; Rahimifard, S.; Allen, R.D. State of the art in wire electrical discharge machining (WEDM). Int. J. Mach. Tools Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Klocke, F.; Zeis, M.; Klink, A.; Veselovac, D. Technological and economical comparison of roughing strategies via milling, sinking-EDM, wire-EDM and ECM for titanium- and nickel-based blisks. CIRP J. Manuf. Sci. Technol. 2013, 6, 198–203. [Google Scholar] [CrossRef]

- Hegab, H.A.; Gadallah, M.H.; Esawi, A.K. Modeling and optimization of Electrical Discharge Machining (EDM) using statistical design. Manuf. Rev. 2015, 2, 21. [Google Scholar] [CrossRef]

- Sonawane, S.A.; Kulkarni, M.L. Optimization of machining parameters of WEDM for Nimonic-75 alloy using principal component analysis integrated with Taguchi method. J. King Saud Univ. Eng. Sci. 2018, 30, 250–258. [Google Scholar] [CrossRef]

- Magabe, R.; Sharma, N.; Gupta, K.; Paulo Davim, J. Modeling and optimization of Wire-EDM parameters for machining of Ni55.8Ti shape memory alloy using hybrid approach of Taguchi and NSGA-II. Int. J. Adv. Manuf. Technol. 2019, 102, 1703–1717. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Prabu, S.S.M.; Palani, I.A.; Patel, V.K.; Parikh, D.M.; de Lacalle, L.N.L. Multi-response optimization of WEDM process parameters for machining of superelastic nitinol shape-memory alloy using a heat-transfer search algorithm. Materials 2019, 12, 1277. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.G.; Han, S. Measurement and evaluation of form deviation error of disk cam with an exclusively built profile-measuring machine. Proc. Robot. Comput. Integr. Manuf. 2010, 26, 686–693. [Google Scholar] [CrossRef]

- Hsieh, J.F.; Lin, P.D. Application of homogenous transformation matrix to measurement of cam profiles on coordinate measuring machines. Int. J. Mach. Tools Manuf. 2007, 47, 1593–1606. [Google Scholar] [CrossRef]

- Chang, W.T.; Wu, L.I. Computerized tolerance analysis of disk cam mechanisms with a roller follower. Eng. Comput. 2009, 25, 247–260. [Google Scholar] [CrossRef]

- Le, C.; Tan, K.N. Reconstruction of planar cam profile function and its follower displacement using B-spline curve based on inverse subdivision method and theory of contact relations—Application to cam mechanism of oscillating follower with roller. Appl. Sci. Eng. Prog. 2011, 4, 51–58. [Google Scholar]

- Werner, A. Method for enhanced accuracy in machining curvilinear profiles on wire-cut electrical discharge machines. Precis. Eng. 2016, 44, 75–80. [Google Scholar] [CrossRef]

- Gupta, K.; Jain, N.K. Comparative study of wire-EDM and hobbing for manufacturing high-quality miniature gears. Mater. Manuf. Process. 2014, 29, 1470–1476. [Google Scholar] [CrossRef]

- Gupta, K.; Jain, N.K. On surface integrity of miniature spur gears manufactured by wire electrical discharge machining. Int. J. Adv. Manuf. Technol. 2014, 72, 1735–1745. [Google Scholar] [CrossRef]

- ul Islam, T.; Khurram, M.; Umar, M.; Mufti, R.A.; Akhtar, K. Experimental and theoretical evaluation of friction in roller follower valve train. Meas. J. Int. Meas. Confed. 2020, 160, 107808. [Google Scholar] [CrossRef]

- Torabi, A.; Akbarzadeh, S.; Salimpour, M.; Khonsari, M.M. On the running-in behavior of cam-follower mechanism. Tribol. Int. 2018, 118, 301–313. [Google Scholar] [CrossRef]

- Björklund, S. The influence of surface roughness in elliptical contacts. Tribol. Int. 2001, 34, 841–845. [Google Scholar] [CrossRef]

- Agulló, J.; Cardona, S. Assessment of Surface Roughness (Valoración de la Rugosidad Superficial); Asociación Nacional de la Máquina—Herramienta: Spain, 1974. [Google Scholar]

- Veera Ajay, C.; Pradeep, B.A.; Boopathi, C.; Sanjeev, R.K.; Meganathan, V. Comparison of geometrical accuracy and surface finish of cam profile generated by wire-EDM and CNC milling machine. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Volume 764, International Conference on Advances in Materials Processing and Characterization, Sathyamangalam, India, 10–11 September 2019. [Google Scholar]

- Bouquet, J.; Hensgen, L.; Klink, A.; Jacobs, T.; Klocke, F.; Lauwers, B. Fast production of gear prototypes—A comparison of technologies. Proc. Procedia CIRP 2014, 14, 77–82. [Google Scholar] [CrossRef]

- Zayas, E.E.; Cardona, S.; Jordi, L. Analysis and synthesis of the displacement function of the follower in constant-breadth cam mechanisms. Mech. Mach. Theory 2009, 44, 1938–1949. [Google Scholar] [CrossRef]

- Norton, R.L. Design of machinery: An Introduction to the Synthesis and Analysis of Mechanisms and Machines, 3rd ed.; Mc Graw Hill: New York, NY, USA, 2004; p. 856. [Google Scholar]

- Zayas, E.E.; Parra, F.; Jordi, L.; Cardona, S. QtCAM: Free software for the design and the analysis of flat cam-follower mechanisms (QtCAM: Software libre para el diseño y el análisis de mecanismos planos de leva-palpador). In Proceedings of the XXII National Conference of Mechanical Engineering of Spain, Madrid, Spain, 18–21 September 2018; pp. 875–884. [Google Scholar]

- DIN 6885-1: 1968. Key, Hub Keyway, Shaft Keyway Details and Dimensions; Deutsches Institut für Normung (DIN): Berlin, Germany, 1968. [Google Scholar]

- ISO/R 773:1969. Rectangular or Square Parallel Keys and Their Corre((Sponding Keyways (Dimensions in Millimetres); International Organization for Standardization: Geneva, Switzerland, 1969. [Google Scholar]

- ISO 4957:2018. Tool Steels; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- ISO 4288:1996. Geometrical Product Specifications (GPS)-Surface Texture: Profile Method-Rules and Procedures for the Assessment of Surface Texture; International Organization for Standardization: Geneva, Switzerland, 1996. [Google Scholar]

- Rothbart, H.A.; Klipp, D.L. Cam Design Handbook. J. Mech. Des. 2004, 126, 375. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Vivancos-Calvet, J.; Domínguez-Fernández, A. Surface topography in ball-end milling processes as a function of feed per tooth and radial depth of cut. Int. J. Mach. Tools Manuf. 2012, 53, 151–159. [Google Scholar] [CrossRef]

- Sanchez, J.A.; Rodil, J.L.; Herrero, A.; de Lacalle, L.N.L.; Lamikiz, A. On the influence of cutting speed limitation on the accuracy of wire-EDM corner-cutting. J. Mater. Process. Technol. 2007, 182, 574–579. [Google Scholar] [CrossRef]

- Sommer, C. Non-Traditional Machining Handbook, 2nd ed.; Advance Publishing Inc.: Houston, TX, USA, 2009. [Google Scholar]

- Buj-Corral, I.; Ortiz-Marzo, J.A.; Costa-Herrero, L.; Vivancos-Calvet, J.; Luis-Pérez, C. Optimal machining strategy selection in ball-end milling of hardened steels for injection molds. Materials 2019, 16, 860. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Parameter | Value |

|---|---|

| Maximum angle of displacement of the rotating follower θmáx (°) | 12.13 |

| Base radius of the cam Rb (mm) | 14.04 |

| Number of sections of the profile (according to the movement law) | 3 |

| Length of the follower arm lb (mm) | 24.25 |

| Radius of the roller Rr (mm) | 10.00 |

| Distance between rotation centers d (mm) | 32.82 |

| Parameter | Value |

|---|---|

| Maximum pressure angle βmax (°) | 27.7 (limit value = 35) |

| Minimum radius of curvature of the cam profile Rcmin (mm) | 17.89 (greater than the radius of the follower) |

| Process | NC Milling | WEDM |

|---|---|---|

| Machine | Haas VM-2 Machining Center | ONA UE205 |

| Tools | End milling cutter of diameter 20 mm and 3 teeth (rough contour milling) + end milling cutter of diameter 10 mm and 4 teeth (finish contour milling) | Brass wire of diameter 0.25 mm |

| Fixture system | Conventional vice + adaptable fixture | Clamp + magnets |

| Cutting conditions | Cutting speed 120 m/min, feed 0.15 mm (rough), feed 0.05 mm (finish), axial depth of cut 1 mm (rough), axial depth of cut 14 mm (finish), radial depth of cut 0.15 mm (finish) | Voltage 130 V, feed speed 1.75 mm/min, cutting speed 2.25 mm/min |

| Manufacturing Process | x’ Translation (mm) | y’ Translation (mm) | Rotation θ (°) |

|---|---|---|---|

| Milled cam | −0.508 | −0.153 | 114.342 |

| WEDM cam | 0.018 | 0.040 | 118.227 |

| Segment | 1 | 2 | 3 | 4 | Average |

|---|---|---|---|---|---|

| Ra (μm) | 0.144 | 0.409 | 0.229 | 0.295 | 0.269 |

| Segment | 1 | 2 | 3 | 4 | Average |

|---|---|---|---|---|---|

| Ra (μm) | 1.075 | 1.132 | 1.533 | 1.108 | 1.212 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buj-Corral, I.; Zayas-Figueras, E.; Montaña-Faiget, À. Comparative Study of Flank Cams Manufactured by WEDM and Milling Processes. Metals 2020, 10, 1159. https://doi.org/10.3390/met10091159

Buj-Corral I, Zayas-Figueras E, Montaña-Faiget À. Comparative Study of Flank Cams Manufactured by WEDM and Milling Processes. Metals. 2020; 10(9):1159. https://doi.org/10.3390/met10091159

Chicago/Turabian StyleBuj-Corral, Irene, Enrique Zayas-Figueras, and Àngels Montaña-Faiget. 2020. "Comparative Study of Flank Cams Manufactured by WEDM and Milling Processes" Metals 10, no. 9: 1159. https://doi.org/10.3390/met10091159

APA StyleBuj-Corral, I., Zayas-Figueras, E., & Montaña-Faiget, À. (2020). Comparative Study of Flank Cams Manufactured by WEDM and Milling Processes. Metals, 10(9), 1159. https://doi.org/10.3390/met10091159