On the Effect of Electron Beam Melted Ti6Al4V Part Orientations during Milling

Abstract

:1. Introduction

2. Experimental Work

3. Results and Discussions

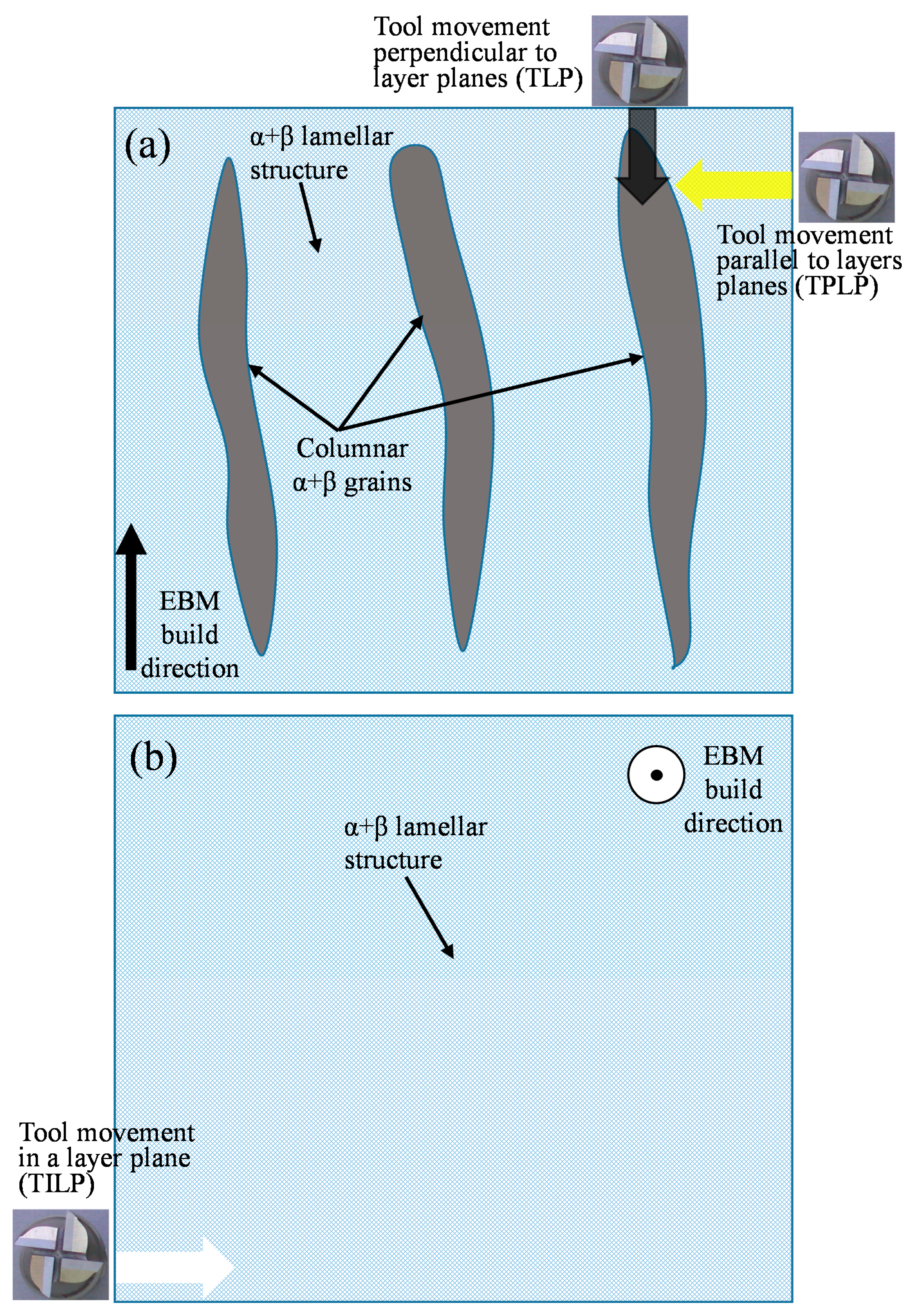

3.1. Electron Beam Melting of Ti6Al4V

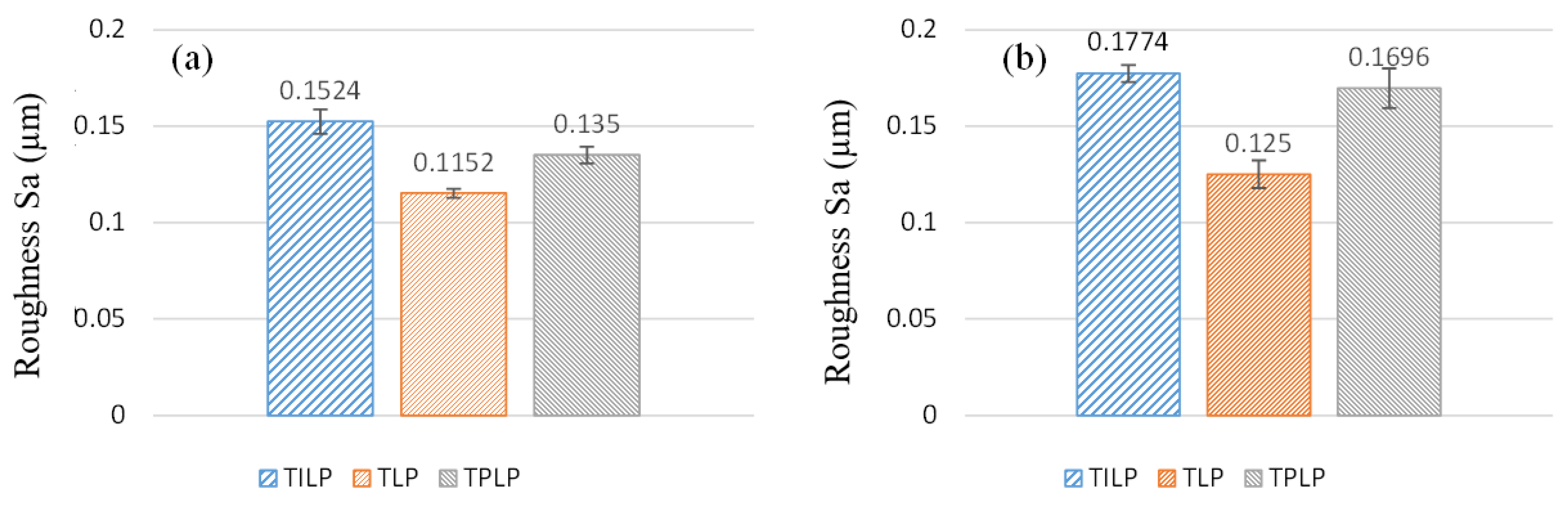

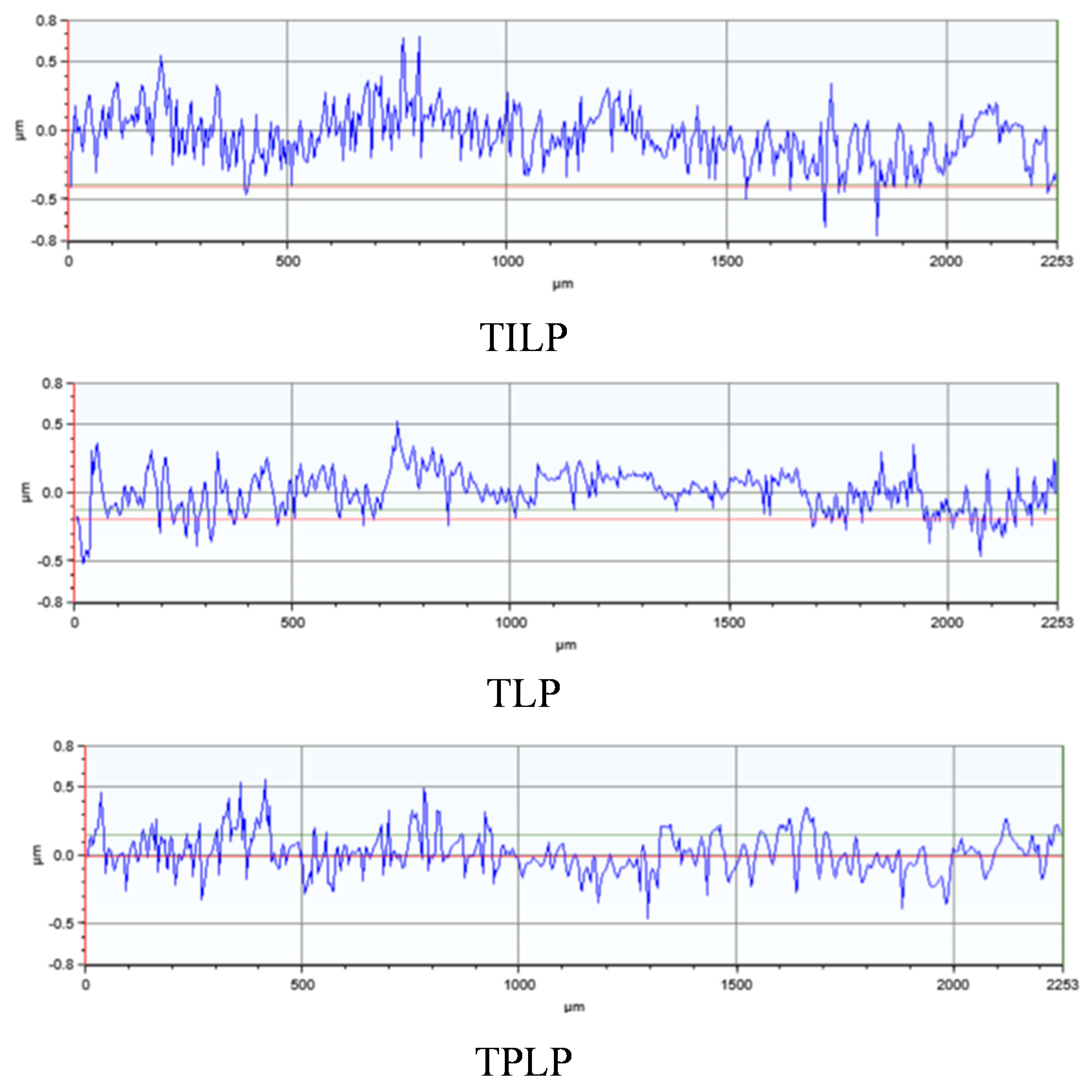

3.2. Surface Roughness Evaluation

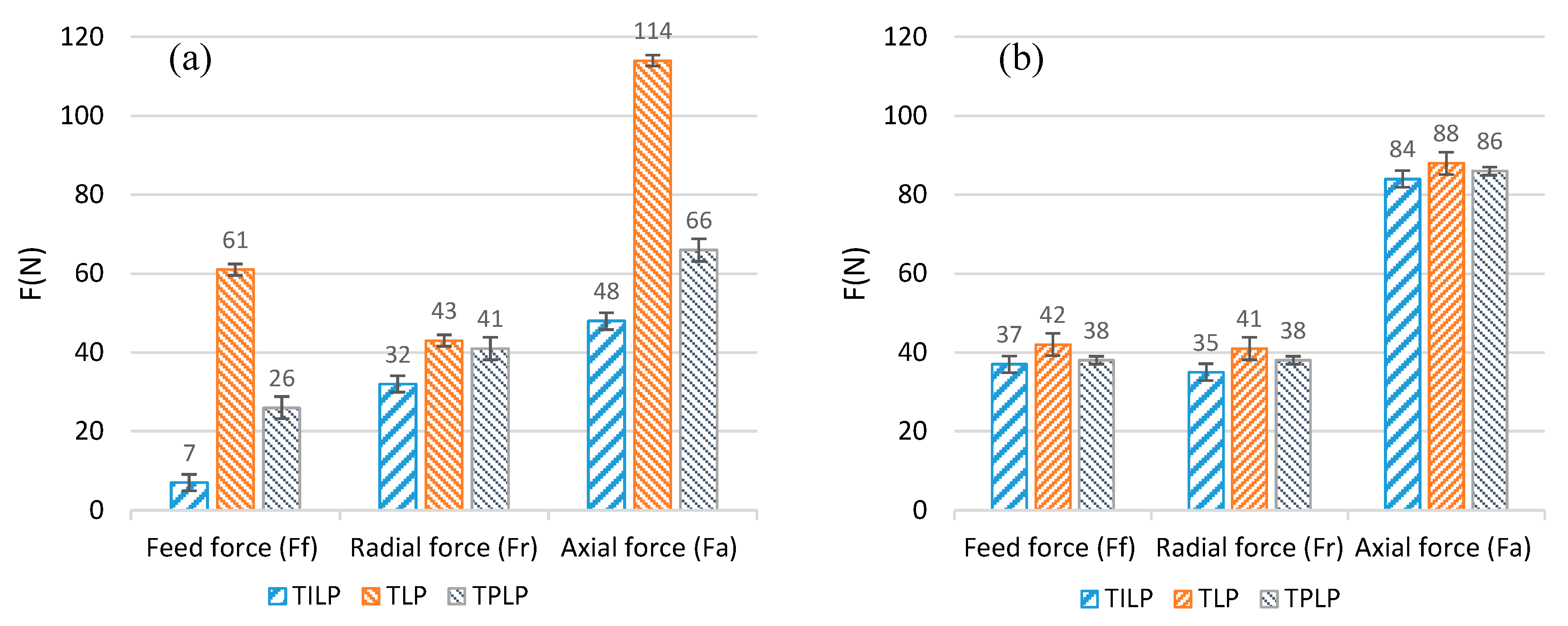

3.3. Cutting Force Evaluation

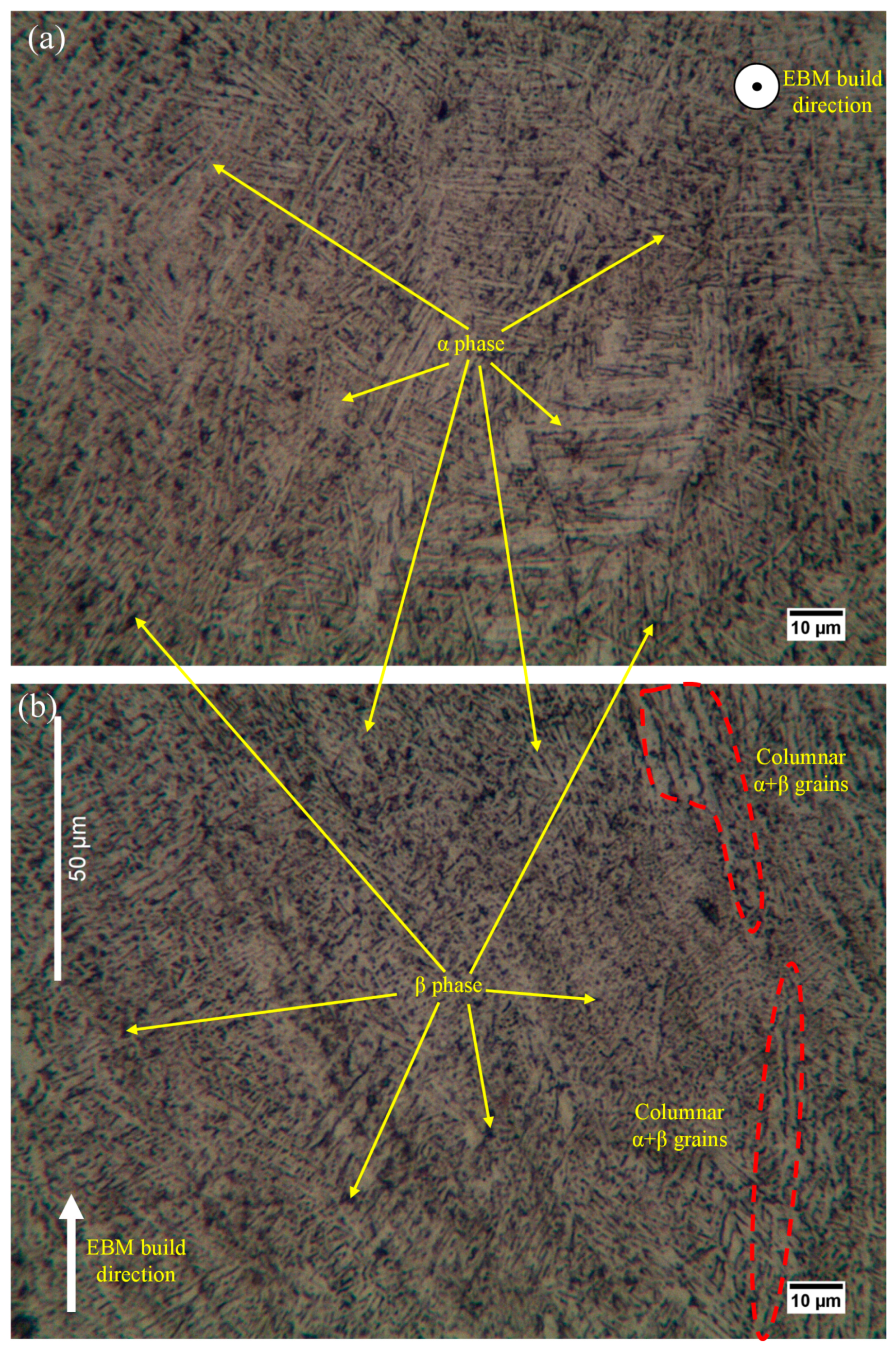

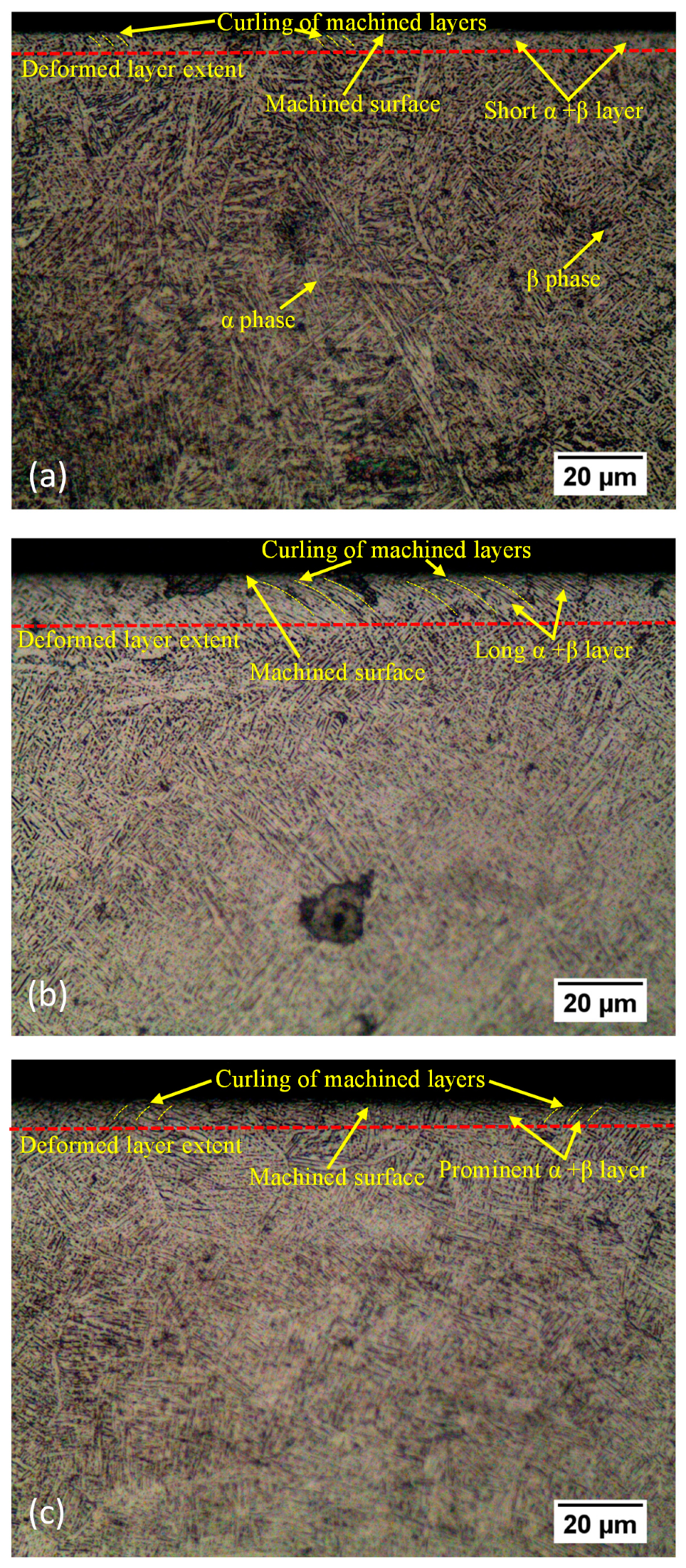

3.4. Microstructures

3.5. Micro-Hardness

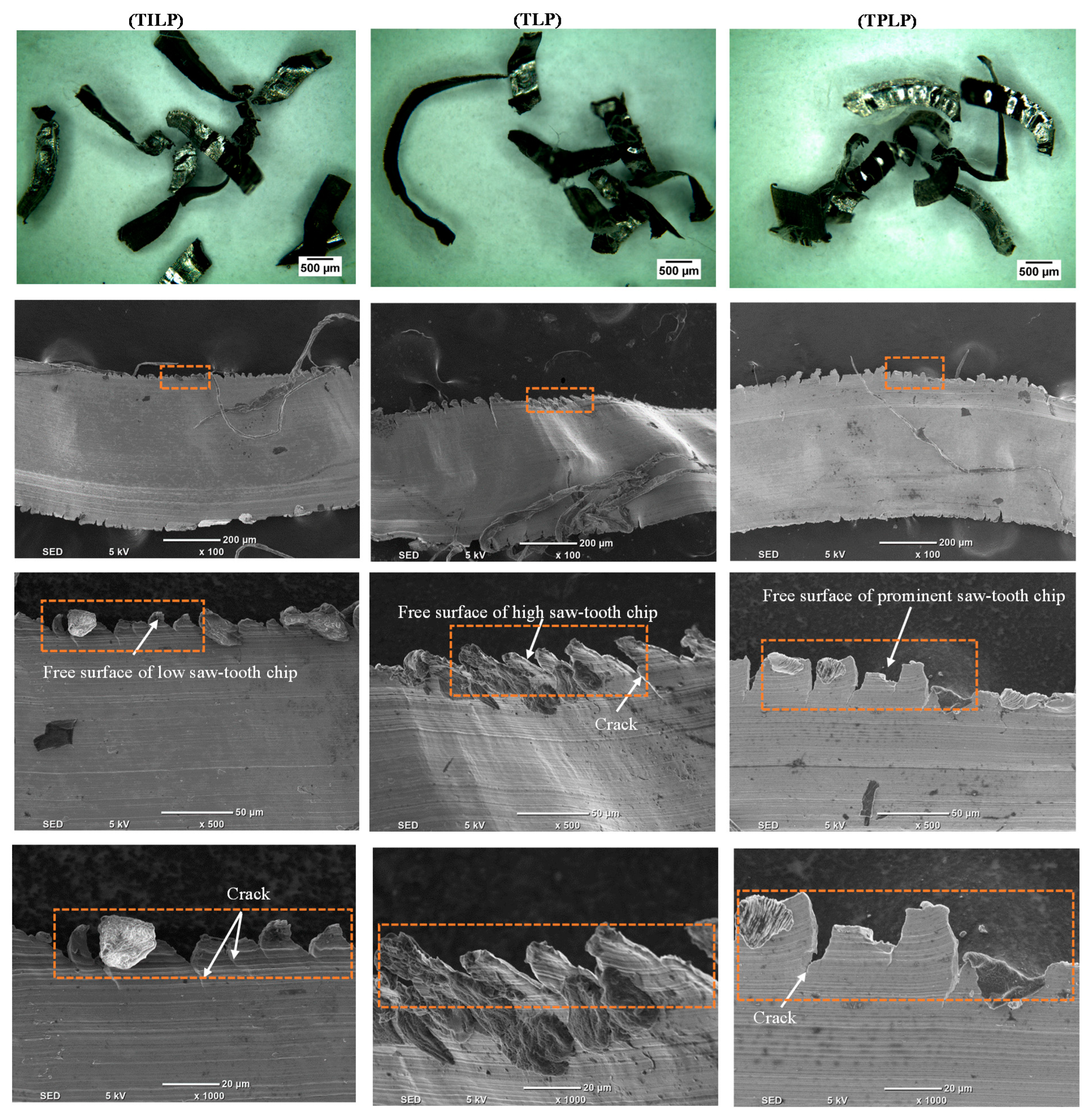

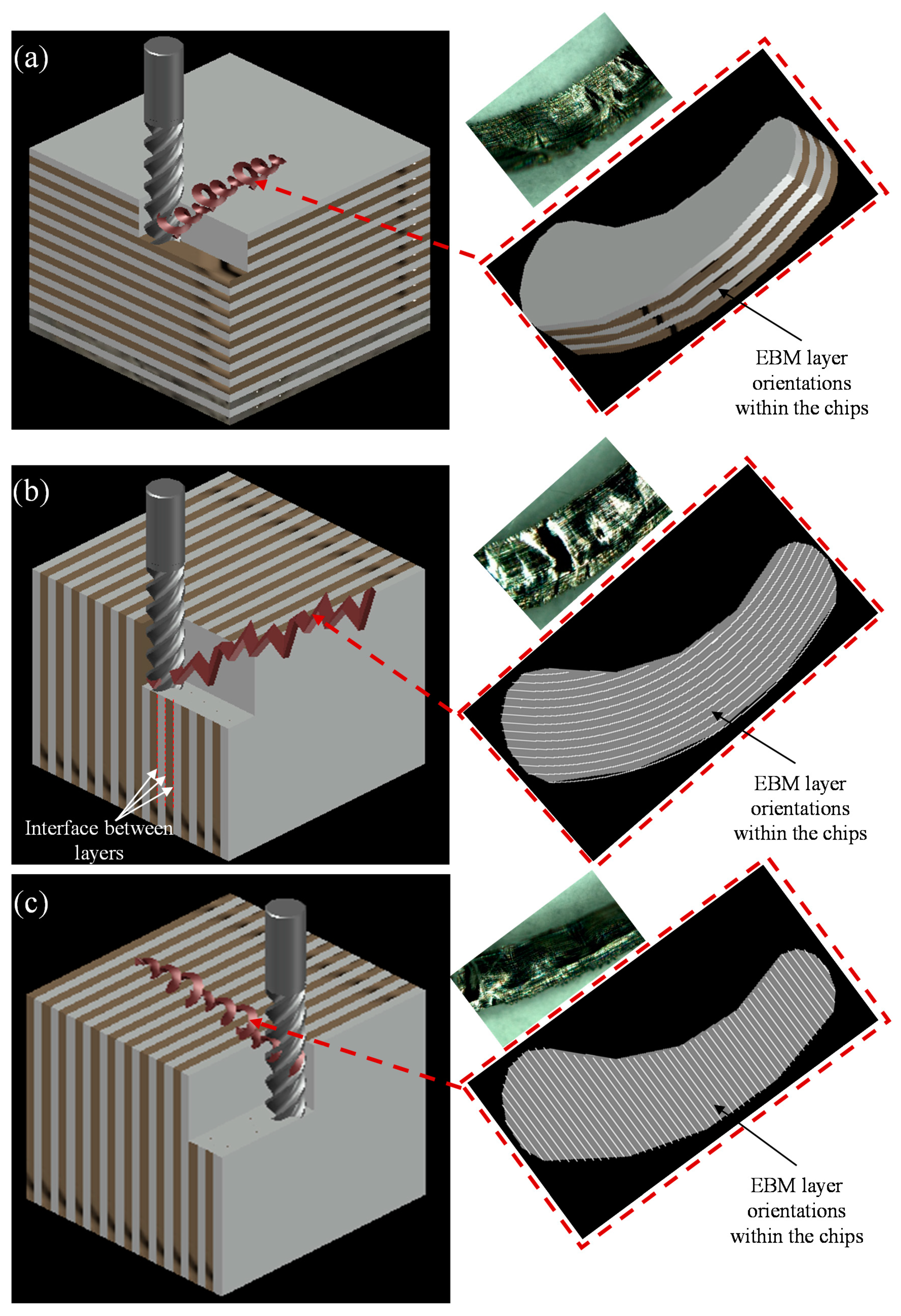

3.6. Chip Morphology Evaluation

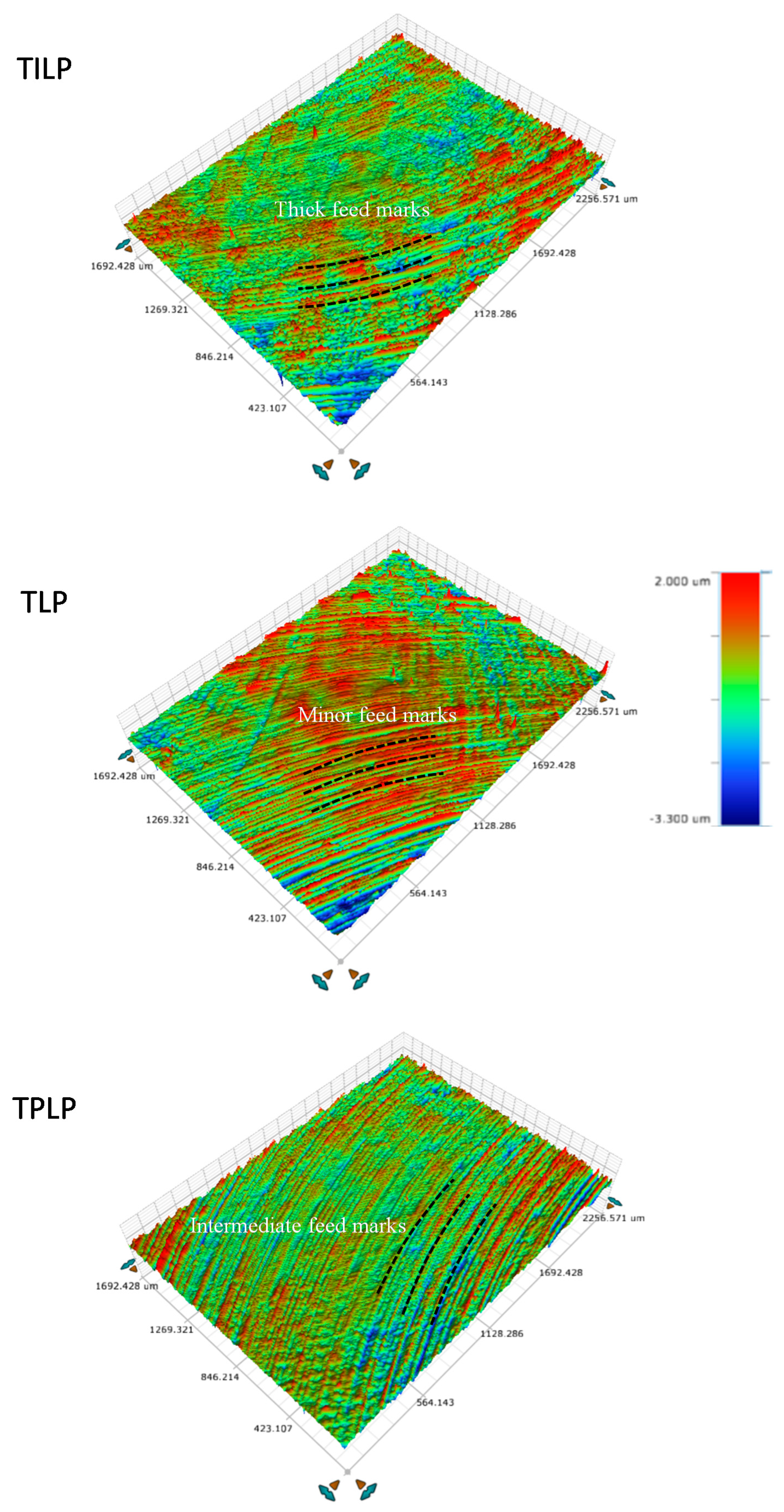

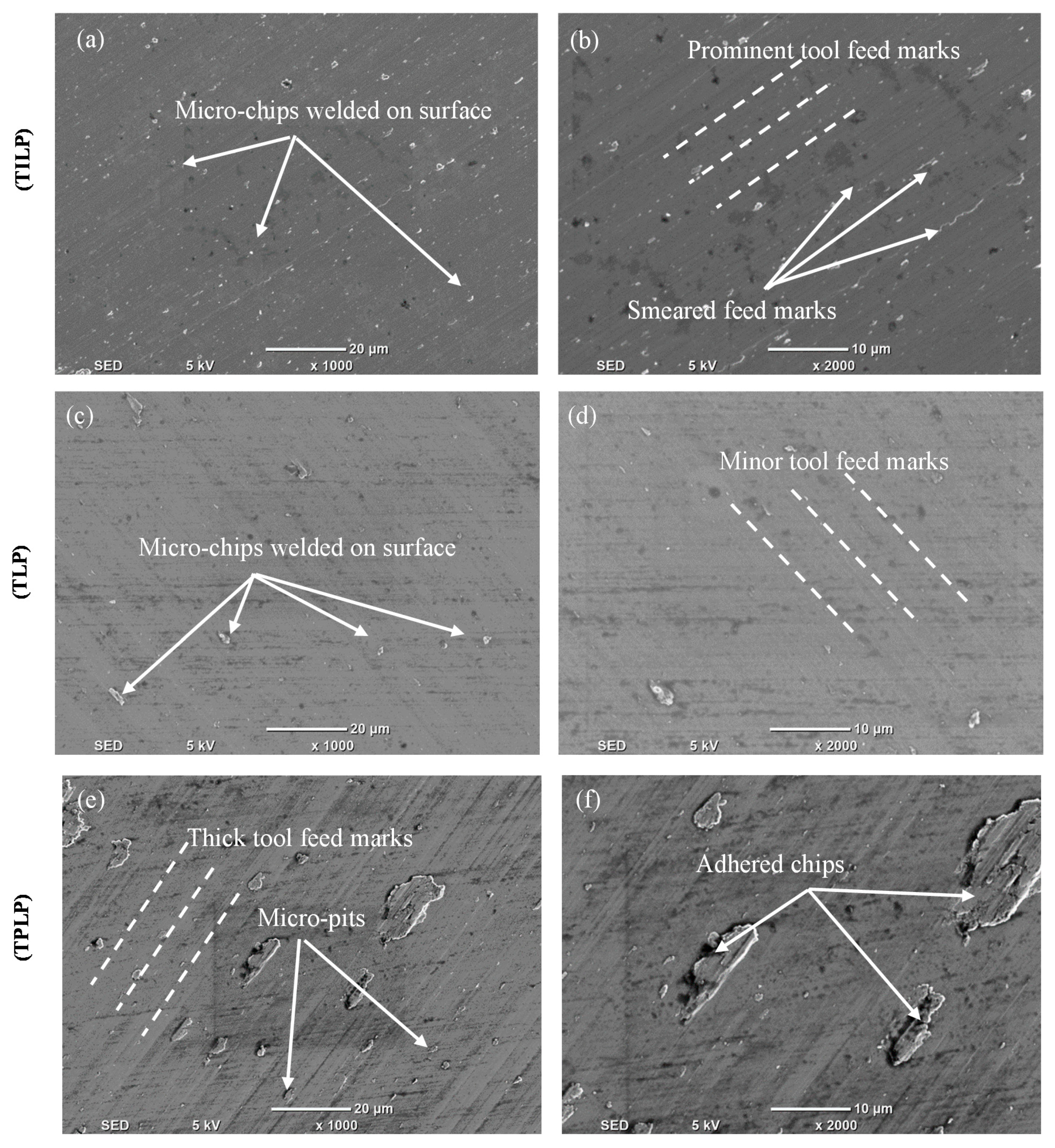

3.7. Surface Morphology of EBM Machined Parts

4. Conclusions

- (1)

- EBM Ti6Al4V parts exhibited significantly higher surface roughness values on the side (Sa = 21 µm) and top faces (Sa = 6 µm) despite using the optimized ARCAM recommended process parameters.

- (2)

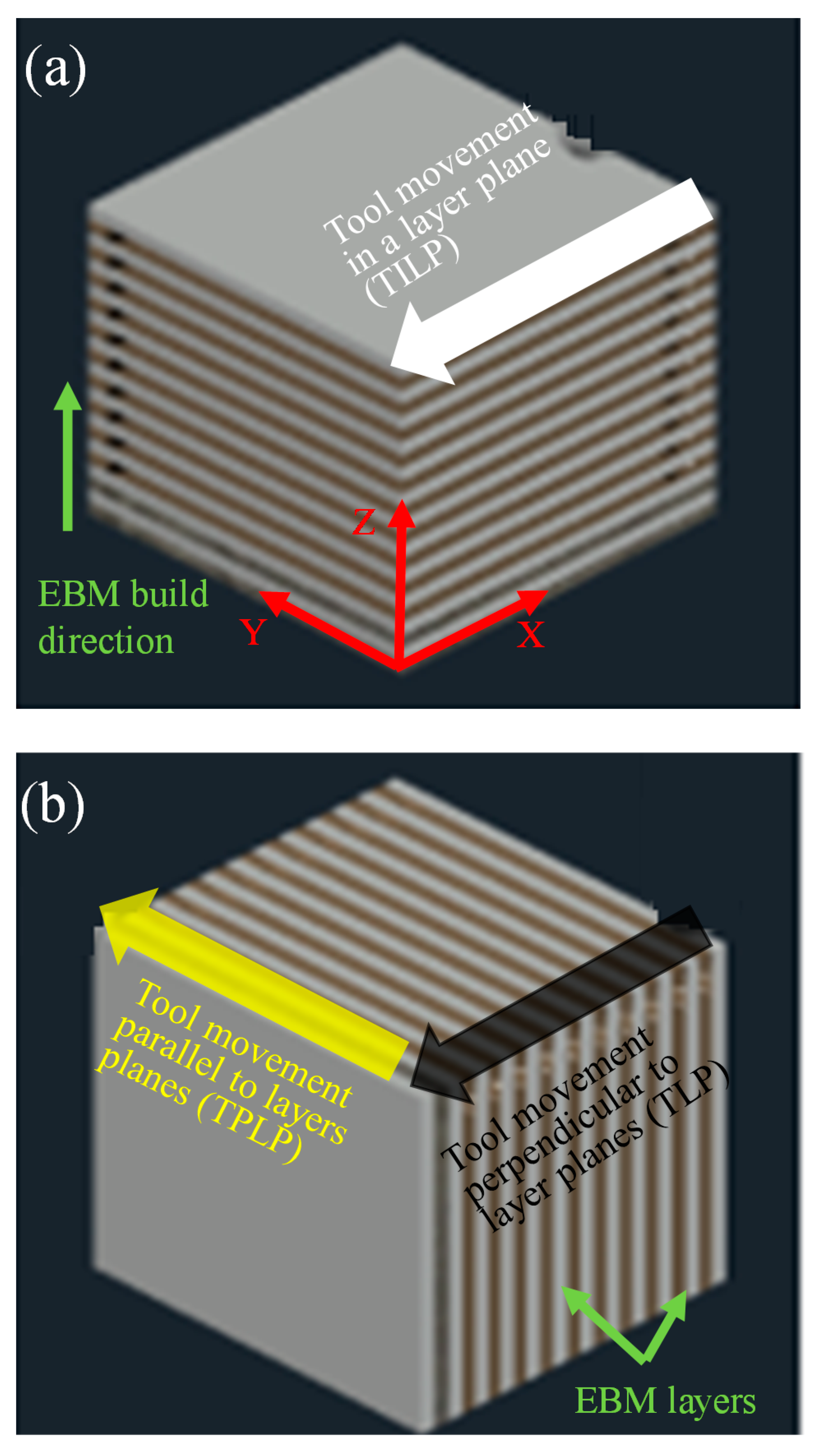

- For improving the surface quality, milling was performed on the EBM Ti6Al4V parts in three orientations, namely “tool movement in a layer plane” (TILP), “tool movement perpendicular to layer planes” (TLP), and “tool movement parallel to layers planes” (TPLP).

- (3)

- The results showed that considerably lower (improved) surface roughness (Sa = 0.11 µm) was achieved when the milling tool was fed along the TLP orientation as compared to the TILP (Sa = 0.13 µm) and TPLP (Sa = 0.15 µm) orientations, respectively. This is mainly due to the effect of the EBM layers, and α and β grains directionality.

- (4)

- Regarding the cutting forces, the highest cutting forces were observed when the parts were machined along the TLP orientation. In comparison, the intermediate forces were observed for the TPLP orientation, and the lowest cutting forces were recorded in the case of TILP orientation. For example, at the same milling parameters of V = 80 m/min, f = 30 mm/min, and dR = 4.8 mm, the cutting force in the case of TLP was 114 N, which was 42% and 57% higher compared to the forces recorded for TPLP and TILP orientations, respectively.

- (5)

- It was observed that the extent of the deformed microstructure beneath the machined surface varies for different part orientations. The highest depth of the deformation was found in the case of the TLP and then for TPLP, and the lowest deformation was found in the case of TILP. These results were in line with the trend of the cutting forces, i.e., the higher the cutting force produced more deformed microstructure. The increase in the sub-surface microhardness also followed the same trend as the deformation in the microstructure.

- (6)

- Regarding the chip formation, TLP produced the highest saw-tooth chips because of the large cutting force, followed by TPLP and then TILP.

- (7)

- The surface morphology of the machined parts showed grooves, smeared feed marks, micro-chips deposition, micro-pits, and tool feed marks, which were minimum in the case of TLP.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wally, Z.J.; van Grunsven, W.; Claeyssens, F.; Goodall, R.; Reilly, G.C. Porous titanium for dental implant applications. Metals 2015, 5, 1902–1920. [Google Scholar] [CrossRef]

- Iqbal, A.; Suhaimi, H.; Zhao, W.; Jamil, M.; Nauman, M.M.; He, N.; Zaini, J. Sustainable Milling of Ti-6Al-4V: Investigating the effects of milling orientation, cutter′s helix angle, and type of cryogenic coolant. Metals 2020, 10, 258. [Google Scholar] [CrossRef] [Green Version]

- Schulz, H.; Annals, T.M.-C. High-speed machining. CIRP Ann.-Manuf. Technol. 1992, 41, 637–643. [Google Scholar] [CrossRef]

- Ezugwu, E.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Sharif, S. EA Rahim Performance of coated-and uncoated-carbide tools when drilling titanium alloy—Ti–6Al4V. J. Mater. Process. Technol. 2007, 185, 72–76. [Google Scholar] [CrossRef] [Green Version]

- Safari, H.; Sharif, S.; Izman, S.; Jafari, H.; Kurniawan, D. Cutting force and surface roughness characterization in cryogenic high-speed end milling of Ti–6Al-4V ELI. Mater. Manuf. Process. 2014, 29, 350–356. [Google Scholar] [CrossRef]

- Additive Manufacturing for the Aerospace Industry—Google Books. Available online: https://books.google.com.sa/books?hl=en&lr=&id=IlSIDwAAQBAJ&oi=fnd&pg=PP1&dq=Additive+manufacturing+for+aerospace+industry&ots=BAIj8xFuVn&sig=t5np9Q3NDRF8-ws8NJRZSFbkfiA&redir_esc=y#v=onepage&q=Additivemanufacturingforaerospaceindustry&f=false (accessed on 22 August 2020).

- Hassanin, H.; Finet, L.; Cox, S.C.; Jamshidi, P.; Grover, L.M.; Shepherd, D.E.T.; Addison, O.; Attallah, M.M. Tailoring selective laser melting process for titanium drug-delivering implants with releasing micro-channels. Addit. Manuf. 2018, 20, 144–155. [Google Scholar] [CrossRef] [Green Version]

- Layer by Layer|MIT Technology Review. Available online: https://www.technologyreview.com/2011/12/19/20869/layer-by-layer/ (accessed on 22 August 2020).

- An Epiphany Of Disruption: GE Additive Chief Explains How 3D Printing Will Upend Manufacturing|GE News. Available online: https://www.ge.com/news/reports/epiphany-disruption-ge-additive-chief-explains-3d-printing-will-upend-manufacturing (accessed on 22 August 2020).

- A World First: Additively Manufactured Titanium Components Now Onboard the Airbus A350 XWB. Available online: https://www.etmm-online.com/a-world-first-additively-manufactured-titanium-components-now-onboard-the-airbus-a350-xwb-a-486310/ (accessed on 22 August 2020).

- Maloney, K.J.; Fink, K.D.; Schaedler, T.A.; Kolodziejska, J.A.; Jacobsen, A.J.; Roper, C.S. Multifunctional heat exchangers derived from three-dimensional micro-lattice structures. Int. J. Heat Mass Transf. 2012, 55, 2486–2493. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Heinl, P.; Müller, L.; Körner, C.; Singer, R.F.; Müller, F.A. Cellular Ti-6Al-4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater. 2008, 4, 1536–1544. [Google Scholar] [CrossRef]

- Harrysson, O.L.A.; Cormier, D.R.; Marcellin-Little, D.J.; Jajal, K. Rapid prototyping for treatment of canine limb deformities. Rapid Prototyp. J. 2003, 9, 37–42. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S.; Christensen, A. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 2009, 3, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Ameen, W.; Khan Mohammed, M.; Al-Ahmari, A. Evaluation of support structure removability for additively manufactured Ti6Al4V overhangs via electron beam melting. Metals 2019, 9, 1211. [Google Scholar] [CrossRef] [Green Version]

- Dolimont, A.; Michotte, S.; Rivière-Lorphèvre, E.; Ducobu, F.; Vivès, S.; Godet, S.; Henkes, T.; Filippi, E. Influence on surface characteristics of electron beam melting process (EBM) by varying the process parameters. AIP Conf. Proc. 2017, 1896, 040010. [Google Scholar] [CrossRef] [Green Version]

- Safdar, A.; He, H.Z.; Wei, L.Y.; Snis, A.; Chavez De Paz, L.E. Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp. J. 2012, 18, 401–408. [Google Scholar] [CrossRef]

- Wang, P.; Sin, W.J.; Nai, M.L.S.; Wei, J. Effects of processing parameters on surface roughness of additive manufactured Ti-6Al-4V via electron beam melting. Materials 2017, 10, 1121. [Google Scholar] [CrossRef] [Green Version]

- Greitemeier, D.; Dalle Donne, C.; Syassen, F.; Eufinger, J.; Melz, T. Effect of surface roughness on fatigue performance of additive manufactured Ti–6Al–4V. Mater. Sci. Technol. 2016, 32, 629–634. [Google Scholar] [CrossRef]

- Wennerberg, A.; Albrektsson, T. Effects of titanium surface topography on bone integration: A systematic review. Clin. Oral Implant. Res. 2009, 20, 172–184. [Google Scholar] [CrossRef]

- Ramesh, S.; Karunamoorthy, L.; Palanikumar, K. Measurement and analysis of surface roughness in turning of aerospace titanium alloy (gr5). Meas. J. Int. Meas. Confed. 2012, 45, 1266–1276. [Google Scholar] [CrossRef]

- Masuo, H.; Tanaka, Y.; Morokoshi, S.; Yagura, H.; Uchida, T.; Yamamoto, Y.; Murakami, Y. Effects of Defects, Surface Roughness and HIP on Fatigue Strength of Ti-6Al-4V manufactured by Additive Manufacturing. Procedia Struct. Integr. 2017, 7, 19–26. [Google Scholar] [CrossRef]

- Anwar, S.; Ahmed, N.; Abdo, B.M.; Pervaiz, S.; Chowdhury, M.A.K.; Alahmari, A.M. Electron beam melting of gamma titanium aluminide and investigating the effect of EBM layer orientation on milling performance. Int. J. Adv. Manuf. Technol. 2018, 96, 3093–3107. [Google Scholar] [CrossRef]

- Biffi, C.A.; Fiocchi, J.; Ferrario, E.; Fornaci, A.; Riccio, M.; Romeo, M.; Tuissi, A. Effects of the scanning strategy on the microstructure and mechanical properties of a TiAl6V4 alloy produced by electron beam additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 4913–4924. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, A.; Ji, H.; Song, Q.; Liu, Z.; Cai, W.; Mia, M.; Khanna, N. Impact of layer rotation on micro-structure, grain size, surface integrity and mechanical behaviour of SLM Al-Si-10Mg alloy. Integr. Med. Res. 2020, 9, 9506–9522. [Google Scholar] [CrossRef]

- Hassanin, H.; Essa, K.; Qiu, C.; Abdelhafeez, A.M.; Adkins, N.J.E.; Attallah, M.M. Net-shape manufacturing using hybrid selective laser melting/hot isostatic pressing. Rapid Prototyp. J. 2017, 4, 720–726. [Google Scholar] [CrossRef] [Green Version]

- Qiu, C.; Adkins, N.J.E.; Hassanin, H.; Attallah, M.M.; Essa, K. In-situ shelling via selective laser melting: Modelling and microstructural characterisation. Mater. Des. 2015, 87, 845–853. [Google Scholar] [CrossRef]

- Sun, J.; Guo, Y.B. A comprehensive experimental study on surface integrity by end milling Ti-6Al-4V. J. Mater. Process. Technol. 2009, 209, 4036–4042. [Google Scholar] [CrossRef]

- Milton, S.; Morandeau, A.; Chalon, F.; Leroy, R. Influence of finish machining on the surface integrity of ti6al4v produced by selective laser melting. Procedia CIRP 2016, 45, 127–130. [Google Scholar] [CrossRef] [Green Version]

- Bordin, A.; Bruschi, S.; Ghiotti, A.; Bucciotti, F.; Facchini, L. Comparison between wrought and EBM Ti6Al4V machinability characteristics. Key Eng. Mater. 2014, 611–612, 1186–1193. [Google Scholar] [CrossRef]

- Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of titanium alloys fabricated using rapid prototyping technologies—Electron beam melting and laser beam melting. Materials 2011, 4, 1776–1792. [Google Scholar] [CrossRef]

- Zhang, W.; Qin, P.; Wang, Z.; Yang, C.; Kollo, L.; Grzesiak, D.; Prashanth, K.G. Superior wear resistance in EBM-Processed TC4 alloy compared with SLM and forged samples. Materials 2019, 12, 782. [Google Scholar] [CrossRef] [Green Version]

- Ginta, T.L. Development of surface roughness models in end milling titanium alloy Ti-6Al-4V Using uncoated tungsten carbide inserts. Eur. J. Sci. Res. 2009, 28, 542–551. [Google Scholar]

- Zhang, S.; Li, J. Tool wear criterion, tool life, and surface roughness during high-speed end milling Ti-6Al-4V alloy. J. Zhejiang Univ.-Sci. A 2010, 11, 587–595. [Google Scholar] [CrossRef]

- Al-rubaie, K.S.; Melotti, S.; Rabelo, A.; Paiva, J.M. Machinability of SLM-produced Ti6Al4V titanium alloy parts. J. Manuf. Process. 2020, 57, 768–786. [Google Scholar] [CrossRef]

- Thesiya, D.; Rajurkar, A.; Patel, S. Heat affected zone and recast layer of Ti-6Al-4V alloy in the EDM process through scanning electron microscopy (SEM). J. Manuf. Technol. Res. 2014, 6, 1–2. [Google Scholar]

- Bruschi, S.; Bertolini, R.; Bordin, A.; Medea, F.; Ghiotti, A. Influence of the machining parameters and cooling strategies on the wear behavior of wrought and additive manufactured Ti6Al4V for biomedical applications. Tribol. Int. 2016, 102, 133–142. [Google Scholar] [CrossRef]

- Bordin, A.; Sartori, S.; Bruschi, S.; Ghiotti, A. Experimental investigation on the feasibility of dry and cryogenic machining as sustainable strategies when turning Ti6Al4V produced by Additive Manufacturing. J. Clean. Prod. 2017, 142, 4142–4151. [Google Scholar] [CrossRef]

- Al-Ahmari, A.; Ashfaq, M.; Alfaify, A.; Abdo, B.; Alomar, A.; Dawud, A. Predicting surface quality of γ-TiAl produced by additive manufacturing process using response surface method. J. Mech. Sci. Technol. 2016, 30, 345–352. [Google Scholar] [CrossRef]

- Kyzioł, K.; Kaczmarek, Ł.; Brzezinka, G.; Kyzioł, A. Structure, characterization and cytotoxicity study on plasma surface modified Ti-6Al-4V and γ-TiAl alloys. Chem. Eng. J. 2014, 240, 516–526. [Google Scholar] [CrossRef]

- Ameen, W.; Al-Ahmari, A.; Mohammed, M.K. Self-supporting overhang structures produced by additive manufacturing through electron beam melting. Int. J. Adv. Manuf. Technol. 2019, 104, 2215–2232. [Google Scholar] [CrossRef]

- Umer, U.; Ameen, W.; Abidi, M.H.; Moiduddin, K.; Alkhalefah, H.; Alkahtani, M.; Al-Ahmari, A. Modeling the effect of different support structures in electron beam melting of titanium alloy using finite element models. Metals 2019, 9, 806. [Google Scholar] [CrossRef] [Green Version]

- Ameen, W.; Al-Ahmari, A.; Mohammed, M.K.; Abdulhameed, O.; Umer, U.; Moiduddin, K. Design, finite element analysis (FEA), and fabrication of custom titanium alloy cranial implant using electron beam melting additive manufacturing. Adv. Prod. Eng. Manag. 2018, 13, 267–278. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Wu, C.; Phenomena, R.C.-S.S. Effects of cutting parameters on the surface roughness of Ti6Al4V titanium alloys in side milling. In Solid State Phenomena; Trans Tech Publications Ltd.: Xiamen, China, 2011; Volume 175, pp. 289–293. [Google Scholar]

- Oosthuizen, G.A.; Nunco, K.; Conradie, P.J.T.; Dimitrov, D.M. The effect of cutting parameters on surface integrity in milling TI6AL4V. S. Afr. J. Ind. Eng. 2016, 27, 115–123. [Google Scholar] [CrossRef] [Green Version]

- Wu, H.; Zhang, S. Effects of cutting conditions on the milling process of titanium alloy Ti6Al4V. Int. J. Adv. Manuf. Technol. 2015, 77, 2235–2240. [Google Scholar] [CrossRef]

- Todai, M.; Nakano, T.; Liu, T.; Yasuda, H.Y.; Hagihara, K.; Cho, K.; Ueda, M.; Takeyama, M. Effect of building direction on the microstructure and tensile properties of Ti-48Al-2Cr-2Nb alloy additively manufactured by electron beam melting. Addit. Manuf. 2017, 13, 61–70. [Google Scholar] [CrossRef] [Green Version]

- Mohammadhosseini, A.; Fraser, D.; Masood, S.H.; Jahedi, M. Microstructure and mechanical properties of Ti-6Al-4V manufactured by electron beam melting process. Mater. Res. Innov. 2013, 17. [Google Scholar] [CrossRef]

- Lenz, M. 1. Introduction. In Arms Are Necessary; Böhlau Verlag: Köln, Germany, 2010; pp. 1–20. [Google Scholar] [CrossRef]

- Galarraga, H.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of the microstructure and porosity on properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Addit. Manuf. 2016, 10, 47–57. [Google Scholar] [CrossRef] [Green Version]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Raghavan, S.; Ling, M.; Nai, S.; Wang, P.; Sin, W.J.; Li, T.; Wei, J. Heat treatment of electron beam melted (EBM) Ti-6Al-4V: Microstructure to mechanical property correlations. Rapid Prototyp. J. 2018, 24, 774–783. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, J.; Li, A.; Zhao, J. Cutting forces and surface roughness in high-speed end milling of Ti6Al4V. Key Eng. Mater. 2014, 589–590, 76–81. [Google Scholar] [CrossRef]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of heat treatments on microstructure and properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Mater. Sci. Eng. A 2017, 685, 417–428. [Google Scholar] [CrossRef] [Green Version]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti-6Al-4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Calamaz, M.; Coupard, D.; Girot, F. A new material model for 2D numerical simulation of serrated chip formation when machining titanium alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2008, 48, 275–288. [Google Scholar] [CrossRef] [Green Version]

| Chemical Element | Content in (%) |

|---|---|

| Aluminum | 6.04 |

| Vanadium | 4.05 |

| Carbon | 0.013 |

| Iron | 0.0107 |

| Oxygen | 0.13 |

| Titanium | Balance/Base |

| EBM Parameters | Values |

|---|---|

| Beam current | 15 mA |

| Electron beam diameter | 200 μm |

| Acceleration voltage | 60 kV |

| Focus offset | 3 mA |

| Line offset | 0.1 Mm |

| Scan speed | 4530 mm/s |

| Powder layer thickness | 0.05 mm |

| Liquidus temperature | 1928 K |

| Preheat temperature | 750 °C |

| Solidus temperature | 1878 K |

| Process Parameters | Values |

|---|---|

| Feed rate, (f) mm/min | 30, 60 |

| Radial depth of cut, (dR) mm | 2.4, 4.8 |

| Depth of cut, (d) mm | 0.4 |

| Cutting speed, (V) m/min | 50, 80 |

| Tool feed direction, (TFD) | TLP, TPLP, TILP |

| Defects | TILP | TLP | TPLP |

|---|---|---|---|

| Adhered material | ●● | ○ | ●●● |

| Grooves | ●● | ● | ●●● |

| Smeared feed marks | ●●● | ○ | ○ |

| Micro-chips welded on the surface | ●●● | ●● | ● |

| Micro-pits | ●● | ● | ●●● |

| Thick tool feed marks | ●● | ● | ●●● |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dabwan, A.; Anwar, S.; M. Al-Samhan, A.; M. Nasr, M. On the Effect of Electron Beam Melted Ti6Al4V Part Orientations during Milling. Metals 2020, 10, 1172. https://doi.org/10.3390/met10091172

Dabwan A, Anwar S, M. Al-Samhan A, M. Nasr M. On the Effect of Electron Beam Melted Ti6Al4V Part Orientations during Milling. Metals. 2020; 10(9):1172. https://doi.org/10.3390/met10091172

Chicago/Turabian StyleDabwan, Abdulmajeed, Saqib Anwar, Ali M. Al-Samhan, and Mustafa M. Nasr. 2020. "On the Effect of Electron Beam Melted Ti6Al4V Part Orientations during Milling" Metals 10, no. 9: 1172. https://doi.org/10.3390/met10091172