Dilution Ratio and the Resulting Composition Profile in Dissimilar Laser Powder Bed Fusion of AlSi10Mg and Al99.8

Abstract

:1. Introduction

2. Materials and Methods

3. Theory Composition Profile Model for LPBF

4. Results and Discussion

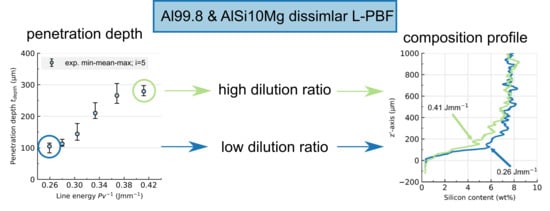

4.1. Influence of the Process Parameter on the Penetration Depth

4.2. Influence of Process Parameter on the Composition Profile

4.3. Comparison of Experiment and Model

4.4. Limitations of the Developed Theoretical Model

5. Implications for Process Design

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shribman, V.; Nahmany, M.; Levi, S.; Atiya, O.; Ashkenazi, D.; Stern, A. MP Welding of dissimilar materials: AM laser powder-bed fusion AlSi10Mg to wrought AA6060-T6. Prog. Addit. Manuf. 2020, 5, 171–181. [Google Scholar] [CrossRef]

- Ostermann, F. Anwendungstechnologie Aluminium; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 978-3-662-43806-0. [Google Scholar]

- DIN EN 573-3, Aluminium and Aluminium Alloys—Chemical Composition and Form of Wrought Products—Part 3: Chemical Composition and Form of Products; German Version EN 573-3:2019. Available online: https://www.beuth.de/de/norm/din-en-573-3/307211401 (accessed on 2 September 2020).

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2003; ISBN 0471434914. [Google Scholar]

- Enz, J.; Kumar, M.; Riekehr, S.; Ventzke, V.; Huber, N.; Kashaev, N. Mechanical properties of laser beam welded similar and dissimilar aluminum alloys. J. Manuf. Process. 2017, 29, 272–280. [Google Scholar] [CrossRef]

- Pinto, L.A.; Quintino, L.; Miranda, R.M.; Carr, P. Laser welding of dissimilar aluminium alloys with filler materials. Weld. World 2010, 54, 333–341. [Google Scholar] [CrossRef]

- Hinojos, A.; Mireles, J.; Reichardt, A.; Frigola, P.; Hosemann, P.; Murr, L.E.; Wicker, R.B. Joining of Inconel 718 and 316 Stainless Steel using electron beam melting additive manufacturing technology. Mater. Des. 2016, 94, 17–27. [Google Scholar] [CrossRef] [Green Version]

- Sing, S.L.; Lam, L.P.; Zhang, D.Q.; Liu, Z.H.; Chua, C.K. Interfacial characterization of SLM parts in multi-material processing: Intermetallic phase formation between AlSi10Mg and C18400 copper alloy. Mater. Charact. 2015, 107, 220–227. [Google Scholar] [CrossRef]

- Nguyen, D.S.; Park, H.S.; Lee, C.M. Applying selective laser melting to join Al and Fe: An investigation of dissimilar materials. Appl. Sci. 2019, 9, 3031. [Google Scholar] [CrossRef] [Green Version]

- Cyr, E.; Asgari, H.; Shamsdini, S.; Purdy, M.; Hosseinkhani, K.; Mohammadi, M. Fracture behaviour of additively manufactured MS1-H13 hybrid hard steels. Mater. Lett. 2018, 212, 174–177. [Google Scholar] [CrossRef]

- Zhang, S.; Pan, M.; Jia, Y.; Yu, Z.; Sokkalingam, R.; Shi, X.; Ji, P.; Eckert, J.; Prashanth, K.G. Microstructure and Mechanical Properties of Al–(12-20)Si Bi-Material Fabricated by Selective Laser Melting. Materials 2019, 12, 2126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fahrenwaldt, H.J.; Schuler, V.; Twrdek, J. Praxiswissen Schweißtechnik; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 9783658031404. [Google Scholar]

- Aversa, A.; Moshiri, M.; Librera, E.; Hadi, M.; Marchese, G.; Manfredi, D.; Lorusso, M.; Calignano, F.; Biamino, S.; Lombardi, M.; et al. Single scan track analyses on aluminium based powders. J. Mater. Process. Technol. 2018, 255, 17–25. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Analysis of processing parameters and characteristics of selective laser melted high strength Al-Cu-Mg alloys: From single tracks to cubic samples. J. Mater. Process. Technol. 2018, 256, 69–77. [Google Scholar] [CrossRef]

- Matilainen, V.; Piili, H.; Salminen, A.; Syvänen, T.; Nyrhilä, O. Characterization of process efficiency improvement in laser additive manufacturing. Phys. Procedia 2014, 56, 317–326. [Google Scholar] [CrossRef] [Green Version]

- Campanelli, S.L.; Angelastro, A.; Signorile, C.G.; Casalino, G. Investigation on direct laser powder deposition of 18 Ni (300) marage steel using mathematical model and experimental characterisation. Int. J. Adv. Manuf. Technol. 2017, 89, 885–895. [Google Scholar] [CrossRef]

| Material | Si | Fe | Cu | Mn | Mg | Zn | V + Ti | Al |

|---|---|---|---|---|---|---|---|---|

| AlSi10Mg (EN AC-43000) | 9.84 | 0.10 | <0.01 | <0.01 | 0.32 | <0.01 | <0.01 | balance |

| Al99.8 (P1020) | 0.026 | 0.079 | 0.001 | <0.01 | <0.01 | <0.01 | <0.01 | 99.88 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Böhm, C.; Werz, M.; Weihe, S. Dilution Ratio and the Resulting Composition Profile in Dissimilar Laser Powder Bed Fusion of AlSi10Mg and Al99.8. Metals 2020, 10, 1222. https://doi.org/10.3390/met10091222

Böhm C, Werz M, Weihe S. Dilution Ratio and the Resulting Composition Profile in Dissimilar Laser Powder Bed Fusion of AlSi10Mg and Al99.8. Metals. 2020; 10(9):1222. https://doi.org/10.3390/met10091222

Chicago/Turabian StyleBöhm, Constantin, Martin Werz, and Stefan Weihe. 2020. "Dilution Ratio and the Resulting Composition Profile in Dissimilar Laser Powder Bed Fusion of AlSi10Mg and Al99.8" Metals 10, no. 9: 1222. https://doi.org/10.3390/met10091222

APA StyleBöhm, C., Werz, M., & Weihe, S. (2020). Dilution Ratio and the Resulting Composition Profile in Dissimilar Laser Powder Bed Fusion of AlSi10Mg and Al99.8. Metals, 10(9), 1222. https://doi.org/10.3390/met10091222