On Additive Manufactured AlSi10Mg to Wrought AA6060-T6: Characterisation of Optimal- and High-Energy Magnetic Pulse Welding Conditions

Abstract

1. Introduction

2. Experimental Part

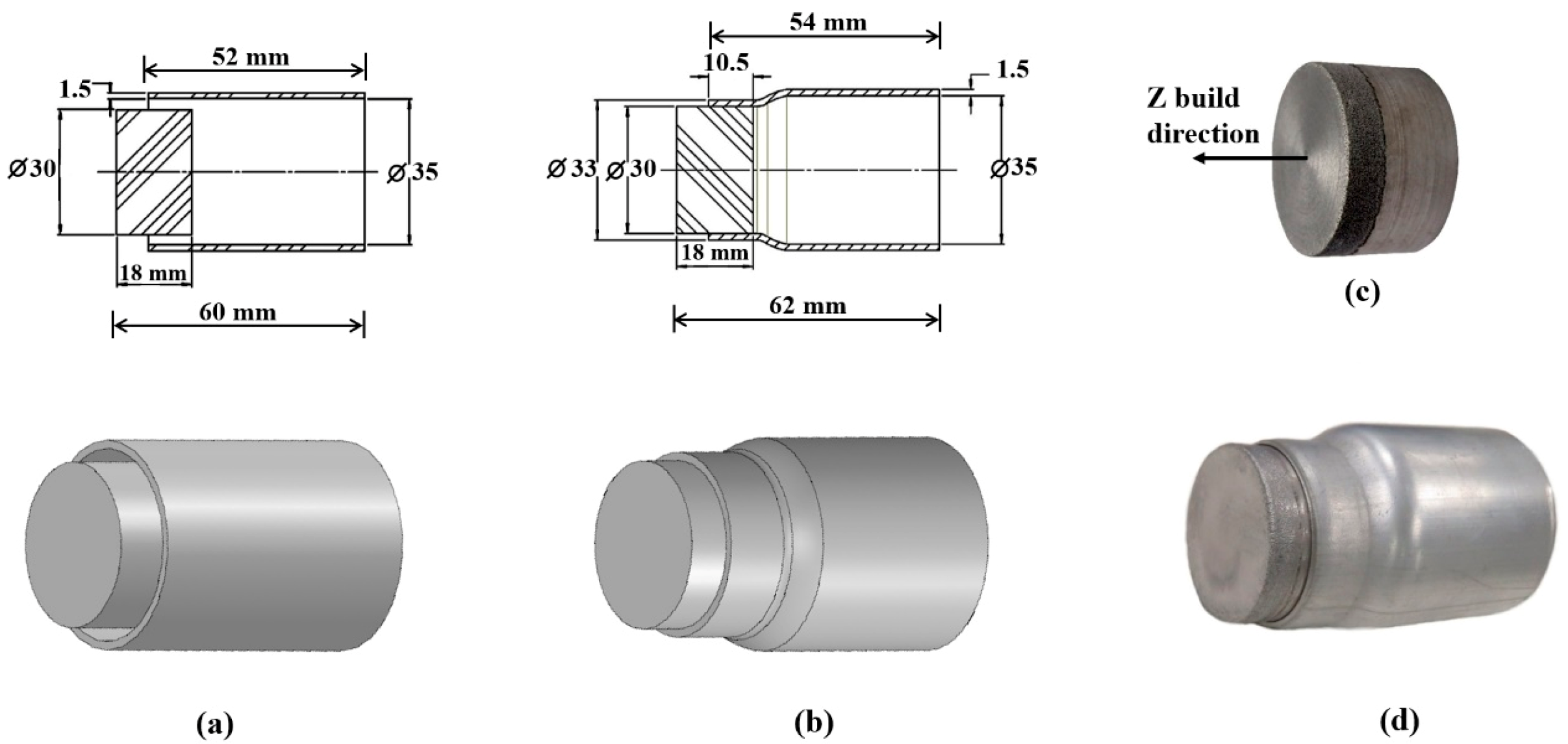

2.1. Materials and Magnetic Pulse Welding

2.2. MPW Joint Macro-Characterisation

- (a)

- The MPW specimens were visually tested (VT) to determine the existence of macroscopic discontinuities including jet residue on the AA6060-T6 tube inner surfaces.

- (b)

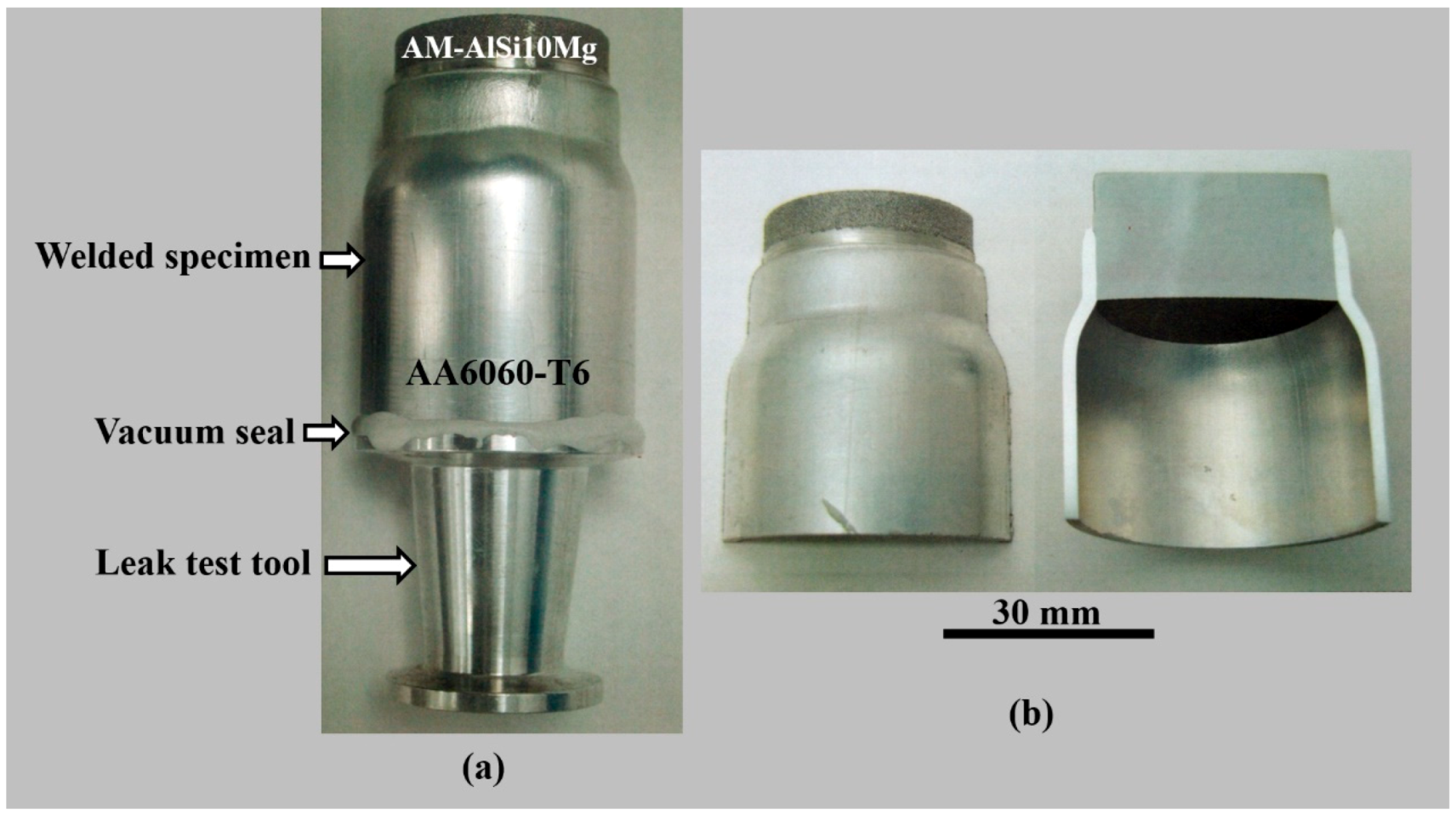

- The as-welded samples were cemented to a commercial vacuum connector shown in Figure 3a. The He leak tests were performed by the “spray-probe” technique to estimate the weld quality. An EDWARDS ELD500 Helium leak detector was coupled directly to the vacuum system, to evacuate the system including the sample. The external surface of the sample was finely sprayed with Helium, particularly around the joint zone. Any tiny leak caused by defective welds, damaged gaskets, etc., will allow helium to penetrate and be detected by the leak detector, as described in DIN EN 1779:1999-10, 2011 [41] standard, and as described and performed previously by Shribman, Nahmany et al. [14].

- (c)

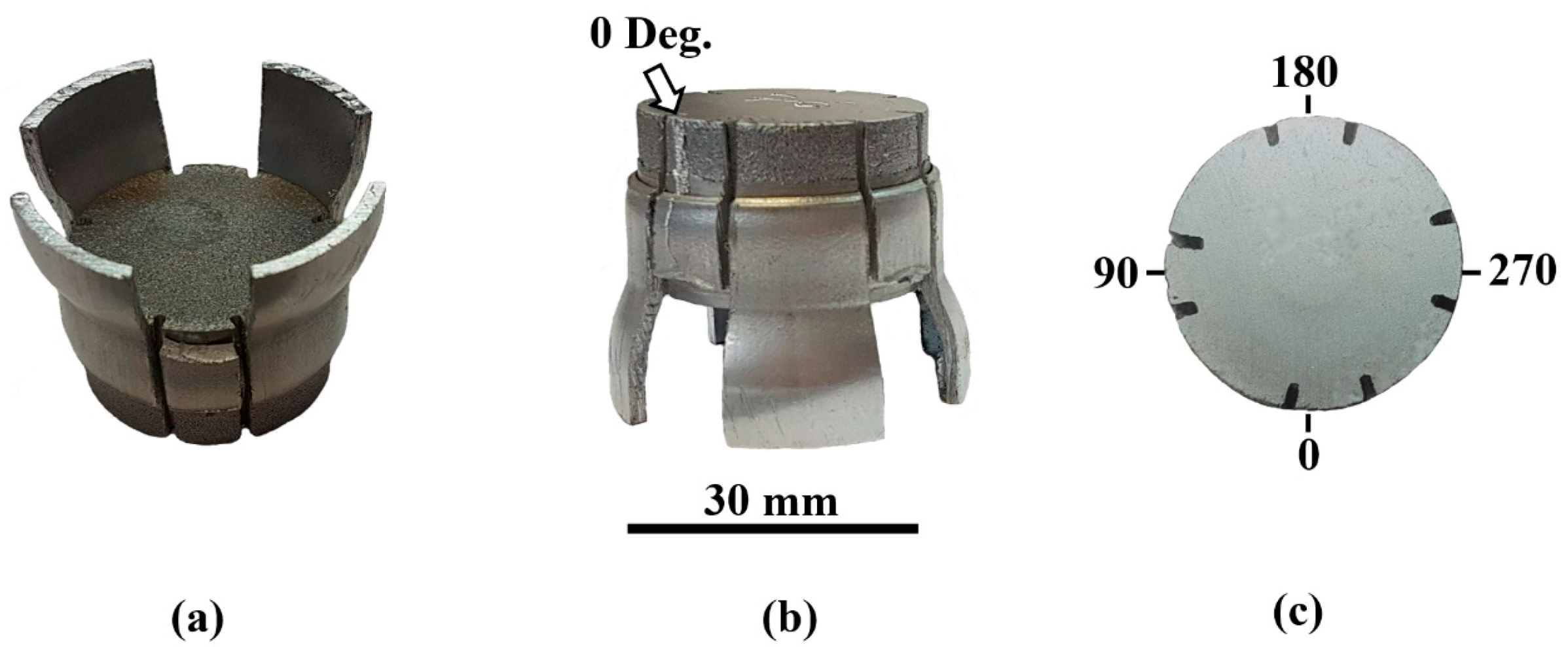

- Peel tests were performed to determine the quality and failure type of joints produced by diverse welding methods, such as resistance spot welding, etc.; ISO/AWI 23,598 standard [42] specifies the geometry of test specimens and the testing procedures for such a test. A manual peel test was used to assess the macro weld quality of the welded specimens at four positions around the circumference: 0°, 90°, 180°, and 270° (Figure 4). The isometric view of the specimen after a peel test is shown in Figure 4a,b. The position at the coil’s slot (0°) is of special interest during process parameter development, due to locally reduced magnetic field intensity in this specific region.

- (d)

- The macroscopic deformation of the flyer tube wall, after MPW, was measured at different positions along the joint and far enough to reach the initial wall’s tube thickness.

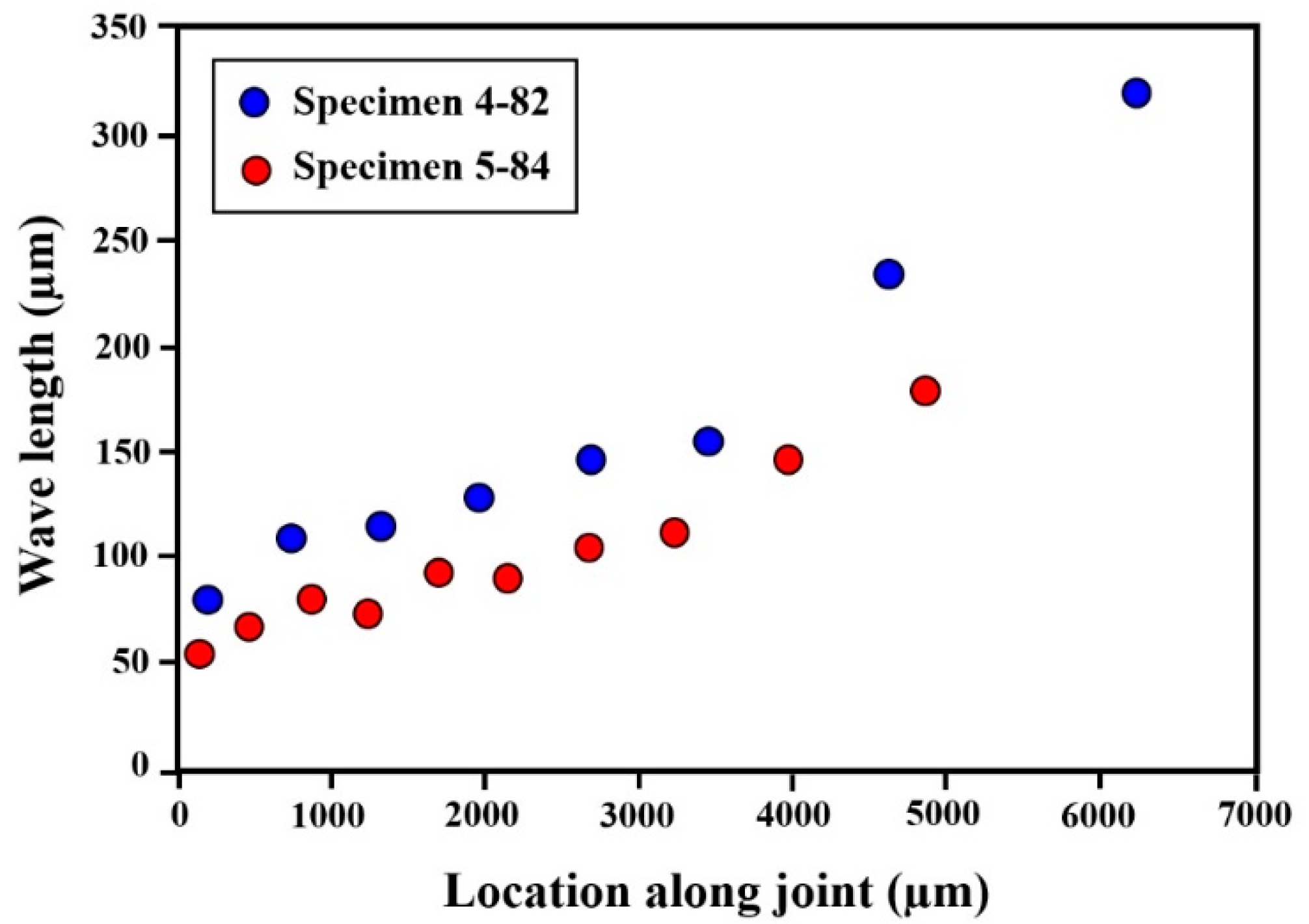

2.3. Material Characterisation

- (a)

- Metallographic samples of the welded parts were prepared according to the ASTM-E3 standard. The surface preparation included sectioning, grinding, and fine polishing steps (up to 0.05 µm). The microstructure was etched with a modified Flick’s reagent (10% HF-90% H2O).

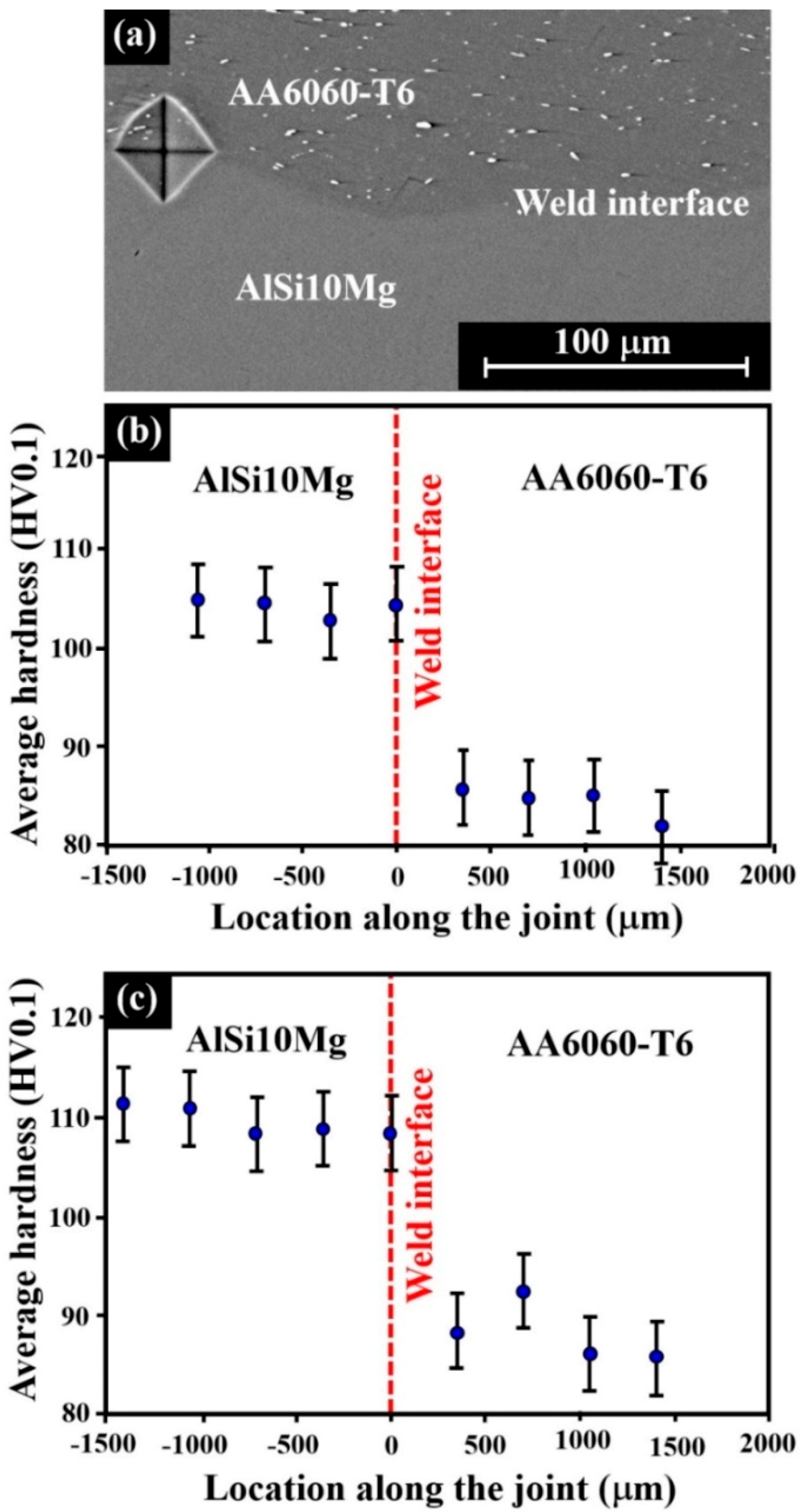

- (b)

- Light microscopy (LM) examination was carried out with a Zeiss, Aalen, Germany, metallographic microscope, in order to characterise the microstructure of the base materials and the joint, as well as to observe and estimate flyer tube deformation.

- (c)

- Vickers microhardness (HV) indentation tests were performed with a Buehler MMT-7 tester (Bühler, Uzwil, Switzerland), using a 100 g load and 10 s. duration load, in order to estimate joint mechanical properties.

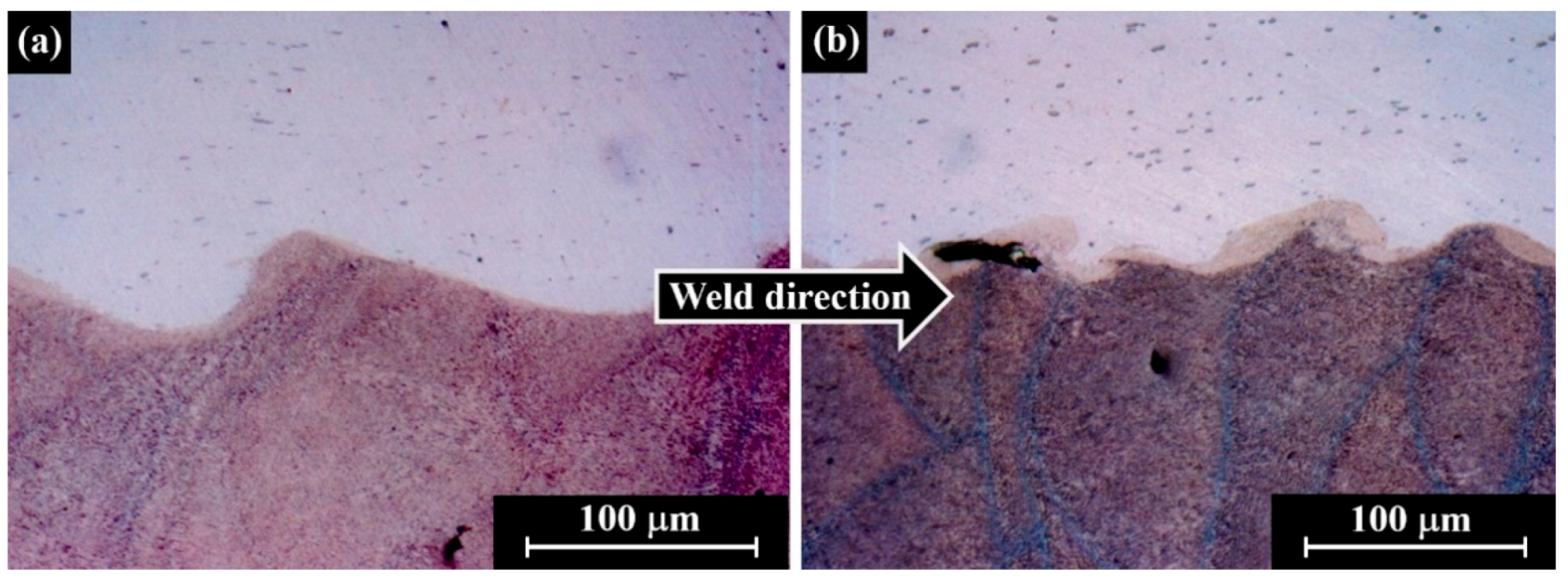

- (d)

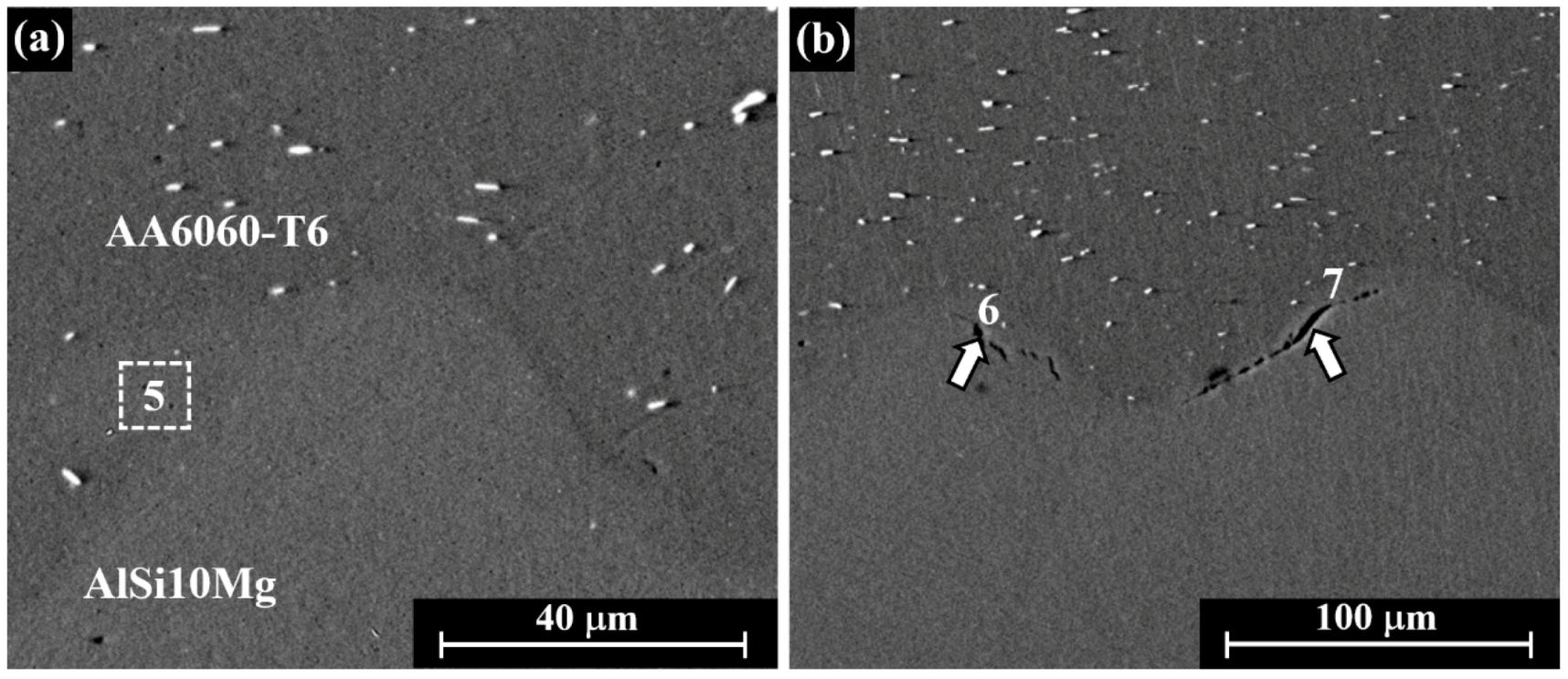

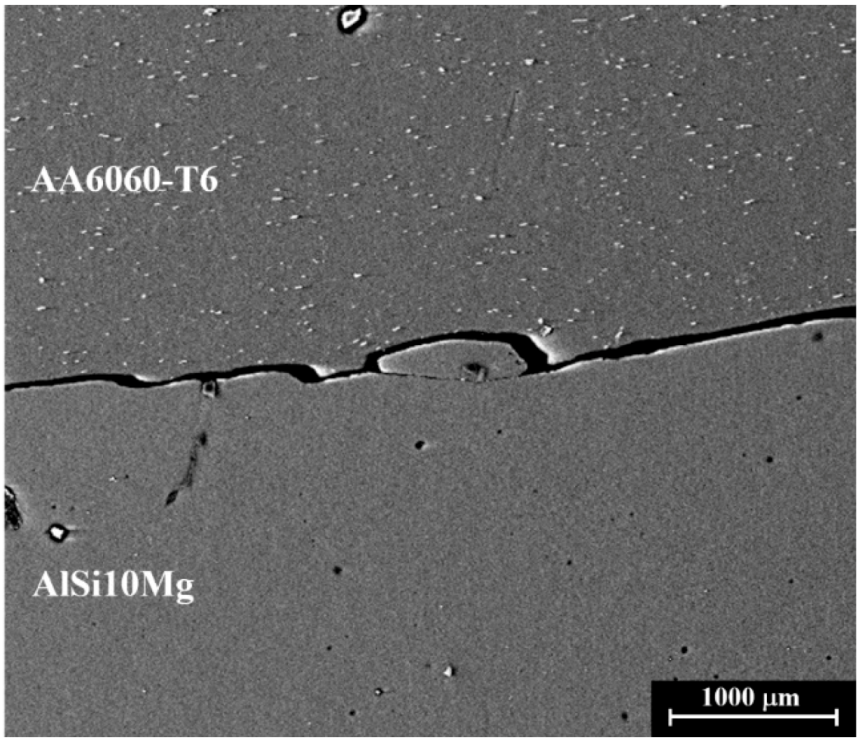

- Scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) were conducted with micro FA Quanta 200FEI SEM instrument and an environmental SEM (Quanta 200FEG E-SEM, Thermo Fisher Scientific, Waltham, Massachusetts, United States) in high vacuum condition and a secondary electron detector. The SEM-EDS analysis was performed to characterise the microstructure and composition of the base materials and the joint and detect discontinuities, such as molten “pockets” and cracks.

3. Results and Discussion

3.1. Leak and Peel Tests

3.1.1. Leak Tests

3.1.2. Peel Tests

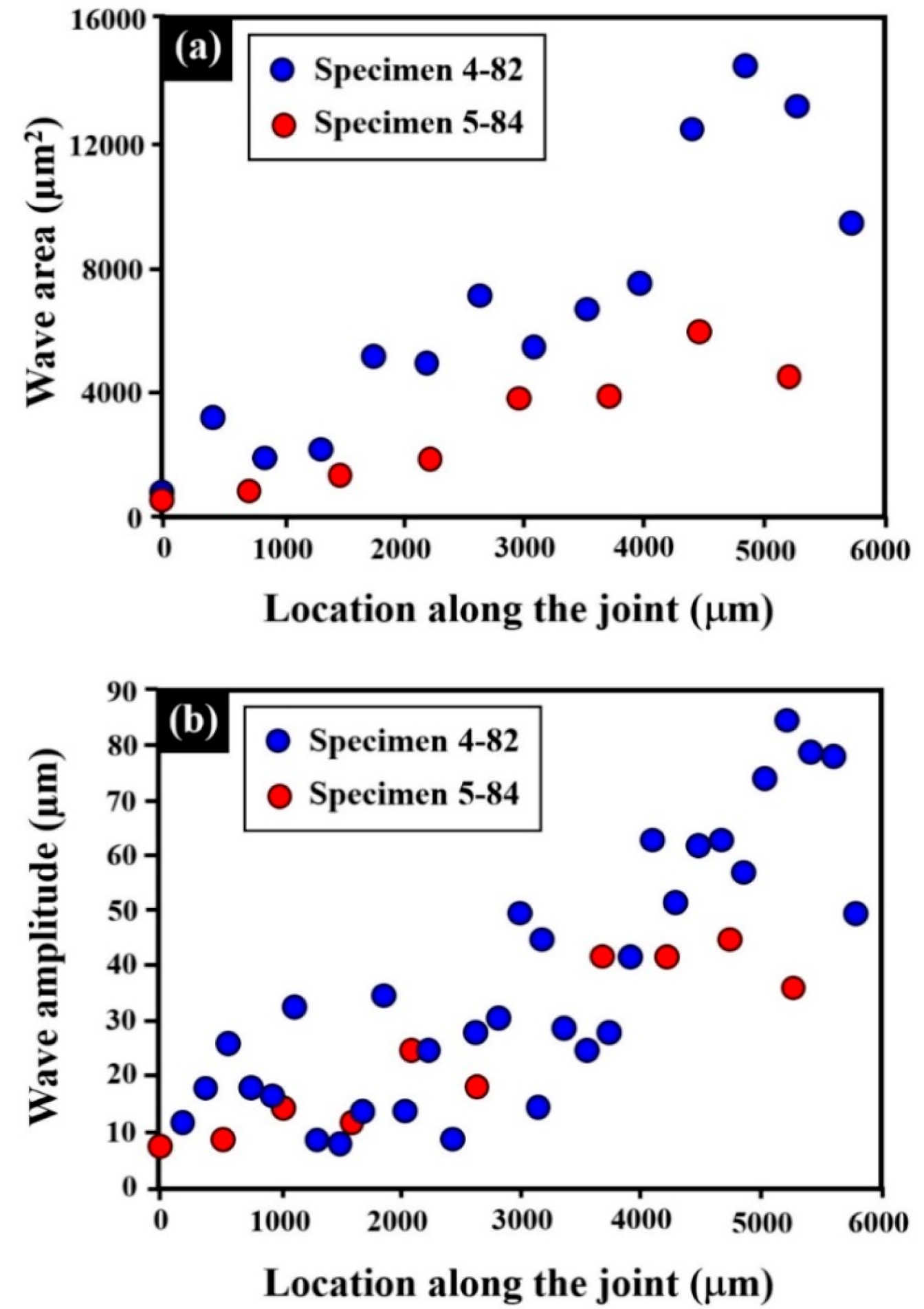

3.2. Flyer Tube Deformation

3.3. Microhardness Across the Interface

3.4. Microanalysis of the Joint

3.4.1. Interfacial Layers or “Pockets”

3.4.2. EDS of Interfacial Layers or “Pockets”

3.5. Jet Characterisation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bataev, I.A.; Ivanov, I.V.; Malyutina, Y.N.; Emurlaev, K.I.; Emurlaeva, Y.Y. High plastic deformations and high cooling rates at the interface of explosion-welded materials. Met. Sci. Heat Treat. 2019, 60, 674–679. [Google Scholar] [CrossRef]

- Lee, T.; Zhang, S.; Vivek, A.; Daehn, G.; Kinsey, B. Wave formation in impact welding: Study of the Cu–Ti system. CIRP Ann. 2019, 68, 261–264. [Google Scholar] [CrossRef]

- Nassiri, A.; Abke, T.; Daehn, G. Investigation of melting phenomena in solid-state welding processes. Scr. Mater. 2019, 168, 61–66. [Google Scholar] [CrossRef]

- Carlone, P.; Astarita, A. Dissimilar metal welding. Metals 2019, 9, 1206. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Sapanathan, T.; Buiron, N.M.; Rachik, M. Magnetic pulse welding of Al/Al and Al/Cu metal pairs: Consequences of the dissimilar combination on the interfacial behaviour during the welding process. J. Manuf. Process. 2015, 20, 112–127. [Google Scholar] [CrossRef]

- Stern, A.; Aizenshtein, M. Bonding zone formation in magnetic pulse welds. Sci. Tech. Weld. Join. 2002, 7, 339–342. [Google Scholar] [CrossRef]

- Stern, A.; Shribman, V.; Ben-Artzy, A.; Aizenshtein, M. Interface phenomena and bonding mechanism in magnetic pulse welding. J. Mater. Eng. Perform. 2014, 23, 3449–3458. [Google Scholar] [CrossRef]

- Kakizaki, S.; Watanabe, M.; Kumai, S. Simulation and experimental analysis of metal jet emission and weld interface morphology in impact welding. Mater. Trans. 2011, 152, 1104181357. [Google Scholar] [CrossRef]

- Stern, A.; Becher, O.; Nahmany, M.; Ashkenazi, D.; Shribman, V. Jet composition in magnetic pulse welding: Al–Al and Al-Mg couples. Weld. J. 2015, 94, 258s–264s. [Google Scholar]

- Wang, X.; Zheng, Y.; Liu, H.; Shen, Z.; Hu, Y.; Li, W.; Gao, Y.; Guo, C. Numerical study of the mechanism of explosive/impact welding using smoothed particle hydrodynamics method. Mater. Des. 2012, 35, 210–219. [Google Scholar] [CrossRef]

- Bellmann, J.; Beyer, E.; Lueg-Althoff, J.; Gies, S.; Tekkaya, A.E.; Schulze, S. Measurement of collision conditions in magnetic pulse welding processes. J. Phys. Sci. Appl. 2017, 7, 1–10. [Google Scholar] [CrossRef]

- Lueg-Althoff, J.; Bellmann, J.; Gies, S.; Schulze, S.; Tekkaya, A.E.; Beyer, E. Influence of the flyer kinetics on magnetic pulse welding of tubes. J. Mater. Process. Tech. 2018, 262, 189–203. [Google Scholar] [CrossRef]

- Pourabbas, M.; Abdollah-Zadeh, A.; Sarvari, M.; Pouranvari, M.; Miresmaeili, R. Investigation of structural and mechanical properties of magnetic pulse welded dissimilar aluminum alloys. J. Manuf. Processes 2019, 37, 292–304. [Google Scholar] [CrossRef]

- Shribman, V.; Nahmany, M.; Levi, S.; Atiya, O.; Ashkenazi, D.; Stern, A. MP welding of dissimilar materials: AM laser powder-bed fusion AlSi10Mg to wrought AA6060-T6. Prog. Addit. Manuf. 2019, 5, 71–181. [Google Scholar] [CrossRef]

- Debroy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure, and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Ben-Artzy, A.; Stern, A.; Frage, N.; Shribman, V.; Sadot, O. Wave formation mechanism in magnetic pulse welding. Int. J. Impact Eng. 2010, 37, 397–404. [Google Scholar] [CrossRef]

- Sridharan, N.; Poplawsky, J.; Vivek, A.; Bhattacharya, A.; Guo, W.; Meyer, H.; Mao, Y.; Lee, T.; Daehn, G. Cascading microstructures in aluminum-steel interfaces created by impact welding. Mater. Character. 2019, 151, 119–128. [Google Scholar] [CrossRef]

- Bellmann, J.; Lueg-Althoff, J.; Schulze, S.; Hahn, M.; Gies, S.; Beyer, E.; Tekkaya, A.E. Thermal effects in dissimilar magnetic pulse welding. Metals 2019, 9, 348. [Google Scholar] [CrossRef]

- Böhme, M.; Sharafiev, S.; Schumacher, E.; Böhm, S.; Wagner, M.F.X. On the microstructure and the origin of intermetallic phase seams in magnetic pulse welding of aluminum and steel. Mater. Werkst. 2019, 50, 958–964. [Google Scholar] [CrossRef]

- Geng, H.; Mao, J.; Zhang, X.; Li, G.; Cui, J. Formation mechanism of transition zone and amorphous structure in magnetic pulse welded Al-Fe joint. Mater. Lett. 2019, 245, 151–154. [Google Scholar] [CrossRef]

- Sapanathan, T.; Yang, K.; Chernikov, D.; Raoelison, R.N.; Gluschenkov, V.; Buiron, N.; Rachik, M. Thermal effect during electromagnetic pulse welding process. In Materials Science Forum; Trans Tech Publications: Stafa-Zurich, Switzerland, 2017; Volume 879, pp. 1662–1667. [Google Scholar]

- Sharafiev, S.; Pabst, C.; Wagner, M.F.; Groche, P. Microstructural characterization of interfaces in magnetic pulse welded aluminum/aluminum joints. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Rourkela, Bangalore, India, 14–16 July 2016; IOP Publishing: Bristol, UK, 2016; Volume 118, p. 012016. [Google Scholar]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of aluminium alloys: Additive manufacturing of aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, S.; Qiu, D.; Gibson, M.A.; Dargusch, M.S.; Brandt, M.; Qian, M.; Easton, M. Metal alloys for fusion based additive manufacturing. Adv. Eng. Mater. 2018, 20, 1700952. [Google Scholar] [CrossRef]

- Zuback, J.S.; DebRoy, T. The hardness of additively manufactured alloys. Materials 2018, 11, 2070. [Google Scholar] [CrossRef] [PubMed]

- Mertens, A.I.; Delahaye, J.; Lecomte-Beckers, J. Fusion-based additive manufacturing for processing aluminum alloys: State-of the-art and challenges. Adv. Eng. Mater. 2017, 19, 1700003. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Strain rate sensitivity and fracture mechanism of AlSi10Mg parts produced by selective laser melting. Mater. Sci. Eng. A 2017, 682, 509–517. [Google Scholar] [CrossRef]

- Awd, M.; Siddique, S.; Johannsen, J.; Emmelmann, C.; Walther, F. Very high-cycle fatigue properties and microstructural damage mechanisms of selective laser melted AlSi10Mg alloy. Int. J. Fatigue 2019, 124, 55–69. [Google Scholar] [CrossRef]

- Rosenthal, I.; Shneck, R.; Stern, A. Heat treatment effect on the mechanical properties and fracture mechanism in AlSi10Mg fabricated by additive manufacturing selective laser melting process. Mater. Sci. Eng. A 2018, 729, 310–322. [Google Scholar] [CrossRef]

- Tradowsky, U.; White, J.; Ward, R.M.; Read, N.; Reimers, W.; Attallah, M.M. Selective laser melting of AlSi10Mg: Influence of post-processing on the microstructural and tensile properties development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef]

- Biffi, C.A.; Fiocchi, J.; Tuissi, A. Laser weldability of AlSi10Mg alloy produced by selective laser melting: Microstructure and mechanical behavior. J. Mater. Eng. Perform. 2019, 28, 1–6. [Google Scholar] [CrossRef]

- Nahmany, M.; Hadad, Y.; Aghion, E.; Stern, A.; Frage, N. Microstructural assessment and mechanical properties of electron beam welding of AlSi10Mg specimens fabricated by selective laser melting. J. Mater. Process. Tech. 2019, 270, 228–240. [Google Scholar] [CrossRef]

- Zhang, C.; Bao, Y.; Zhu, H.; Nie, X.; Zhang, W.; Zhang, S.; Zeng, X. A comparison between laser and TIG welding of selective laser melted AlSi10Mg. Optic. Laser Tech. 2019, 120, 105696. [Google Scholar] [CrossRef]

- Nahmany, M.; Stern, A.; Benishti, I.; Rosenthal, I.; Frage, N. Electron beam welding of AlSil0Mg workpieces produced by selected laser melting additive manufacturing technology. Addit. Manuf. 2015, 8, 63–70. [Google Scholar]

- Nahmany, M.; Stern, A.; Aghion, E.; Frage, N. Structural properties of EB-welded AlSi10Mg thin-walled pressure vessels produced by AM-SLM technology. J. Mater. Eng. Perform. 2017, 26, 4813–4821. [Google Scholar] [CrossRef]

- Tavlovich, B.; Shirizly, A.; Katz, R. EBW and LBW of additive manufactured Ti6Al4V products. Weld. J. 2018, 97, 179S–190S. [Google Scholar]

- Wits, W.W.; Becker, J.J. Laser beam welding of titanium additive manufactured parts. Procedia CIRP 2015, 28, 70–75. [Google Scholar] [CrossRef]

- Adamczyk-Cieślak, B.; Mizera, J.; Kurzydłowski, K.J. Microstructures in the 6060 aluminium alloy after various severe plastic deformation treatments. Mater. Character. 2011, 62, 327–332. [Google Scholar] [CrossRef]

- Inberg, A.; Ashkenazi, D.; Kimmel, G.; Shacham-Diamand, Y.; Stern, A. Gold–silver electroless plating on laser powder-bed fusion additively printed AlSi10Mg parts. Metals 2020, 10, 557. [Google Scholar] [CrossRef]

- Inberg, A.; Ashkenazi, D.; Kimmel, G.; Shacham-Diamand, Y.; Stern, A. Gold plating of AlSi10Mg parts produced by a laser powder-bed fusion additive manufacturing technique. Prog. Addit. Manuf. 2020, 1–10. [Google Scholar] [CrossRef]

- DIN EN. 1779:1999-1. Non-destructive testing Leak testing-Criteria for the method and technique selection. In Din 1779, New European Standard for the Selection of A Suitable Method for Leak Detection and Leak Tightness Testing; Beuth: Berlin, Germany, 2011. [Google Scholar]

- ISO/AWI 23598 (under development). Mechanical Joining—Destructive Testing of Joints—Specimen Dimensions and Test Procedure for Mechanized Peel Testing of Single Joints; ISO: Geneva, Switzerland, 2019. [Google Scholar]

- Zhang, Y. Investigation of Magnetic Pulse Welding on Lap Joint of Similar and Dissimilar Materials. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2010. [Google Scholar]

| Alloy | Composition (wt%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al | Si | Mg | Fe | Cu | Mn | Zn | V | Ti | Ni | |

| AM L-PBF AlSi10Mg | Bal. | 9.63 | 0.32 | 0.14 | 0.01 | ≤0.01 | – | – | 0.01 | ≤0.01 |

| Wrought AA6060-T6 | Bal. | 0.51 | 0.40 | 0.21 | 0.03 | 0.05 | 0.02 | 0.02 | 0.02 | 0.01 |

| Specimen Type and No. | Energy (kJ) | Voltage (kV) | Current-Imax (kA) |

|---|---|---|---|

| High energy: 1, 2, 3, 4 | 9.7 | 11 | 478 |

| Optimal energy: 5, 6, 7 | 8.0 | 10 | 421 |

| Measured Distance | Specimen No. | |

|---|---|---|

| 4 (High Energy) | 5 (Optimal Energy) | |

| Joint length (µm) | 8029 | 5789 |

| Wavy length (µm) | 6049 | 4945 |

| Collapsed flyer thicknesses of welds (µm) | 1775 | 1827 |

| Element | Measurement Locations, (wt%) | ||||

|---|---|---|---|---|---|

| 5 | 6 | 7 | AA6060-BM | AM-BM | |

| Mg | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 |

| Al | 94.2 | 94.2 | 95.2 | 99.8 | 89.3 |

| Si | 5.7 | 5.7 | 4.7 | – | 10.6 |

| Element | Measurement Locations, (wt%) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 27 | 28 | 29 | 30 | 31 | 33 | 34 | 35 | 36 | 37 | 38 | 42 | 43 | 44 | |

| Mg | 0 | 0.2 | 0.1 | 0 | 0.1 | 0.2 | 0.3 | 0.3 | 0.3 | 0.1 | 0.1 | 0.2 | 0.4 | 0.13 |

| Al | 74.9 | 92.4 | 94.3 | 86.5 | 84.2 | 95.2 | 85.3 | 96.0 | 99.4 | 99.0 | 89.3 | 89.4 | 96.4 | 94.7 |

| Si | 4.5 | 2.7 | 5.5 | 8.1 | 3.8 | 4.6 | 6.2 | 3.7 | 0.3 | 0.9 | 10.6 | 8.8 | 3.3 | 4.1 |

| S | 7.1 | – | – | – | – | – | 3.0 | – | – | – | – | – | – | – |

| Cu | 13.6 | 4.8 | – | 4.9 | – | – | 5.2 | – | – | – | – | 1.6 | – | 1.1 |

| Fe | – | – | – | 1.5 | 11.9 | – | – | – | – | – | – | – | – | – |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nahmany, M.; Shribman, V.; Levi, S.; Ashkenazi, D.; Stern, A. On Additive Manufactured AlSi10Mg to Wrought AA6060-T6: Characterisation of Optimal- and High-Energy Magnetic Pulse Welding Conditions. Metals 2020, 10, 1235. https://doi.org/10.3390/met10091235

Nahmany M, Shribman V, Levi S, Ashkenazi D, Stern A. On Additive Manufactured AlSi10Mg to Wrought AA6060-T6: Characterisation of Optimal- and High-Energy Magnetic Pulse Welding Conditions. Metals. 2020; 10(9):1235. https://doi.org/10.3390/met10091235

Chicago/Turabian StyleNahmany, Moshe, Victor Shribman, Shlomo Levi, Dana Ashkenazi, and Adin Stern. 2020. "On Additive Manufactured AlSi10Mg to Wrought AA6060-T6: Characterisation of Optimal- and High-Energy Magnetic Pulse Welding Conditions" Metals 10, no. 9: 1235. https://doi.org/10.3390/met10091235

APA StyleNahmany, M., Shribman, V., Levi, S., Ashkenazi, D., & Stern, A. (2020). On Additive Manufactured AlSi10Mg to Wrought AA6060-T6: Characterisation of Optimal- and High-Energy Magnetic Pulse Welding Conditions. Metals, 10(9), 1235. https://doi.org/10.3390/met10091235