Analysis of the Properties of Hardox Extreme Steel and Possibilities of Its Applications in Machinery

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Chemical Composition Analysis

3.2. Microstructure Analysis

3.3. Static Tensile Test

3.4. Impact Tests

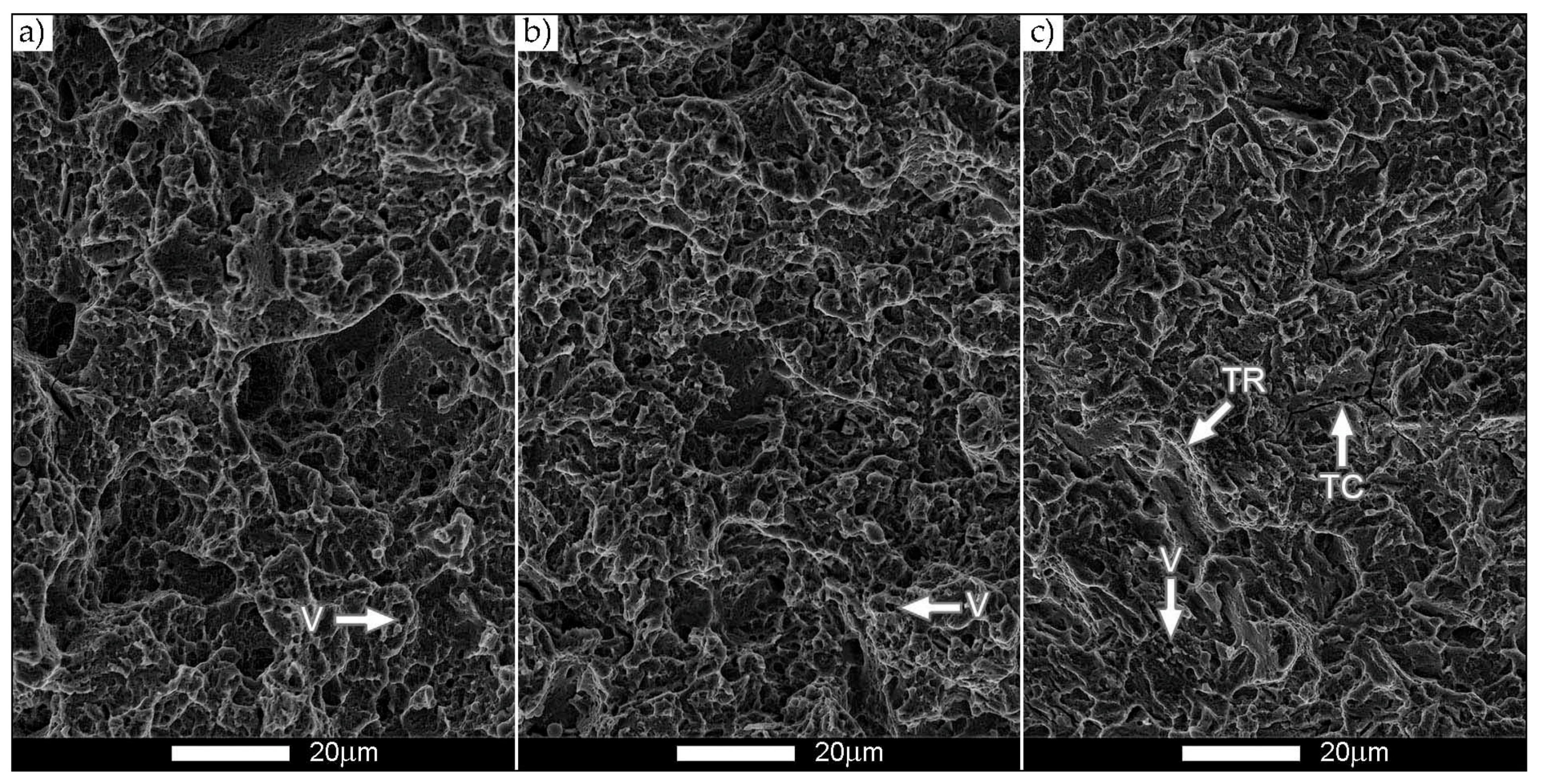

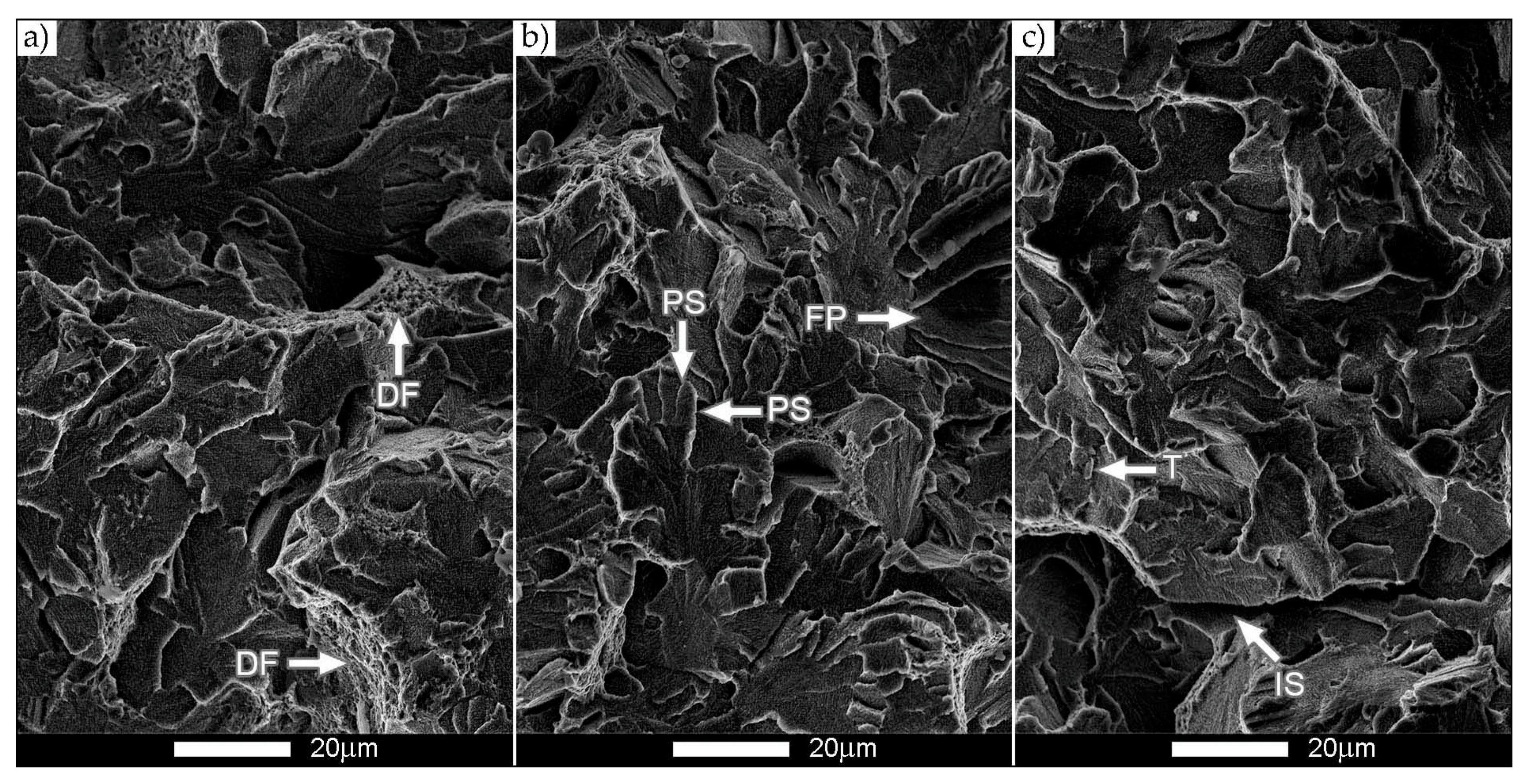

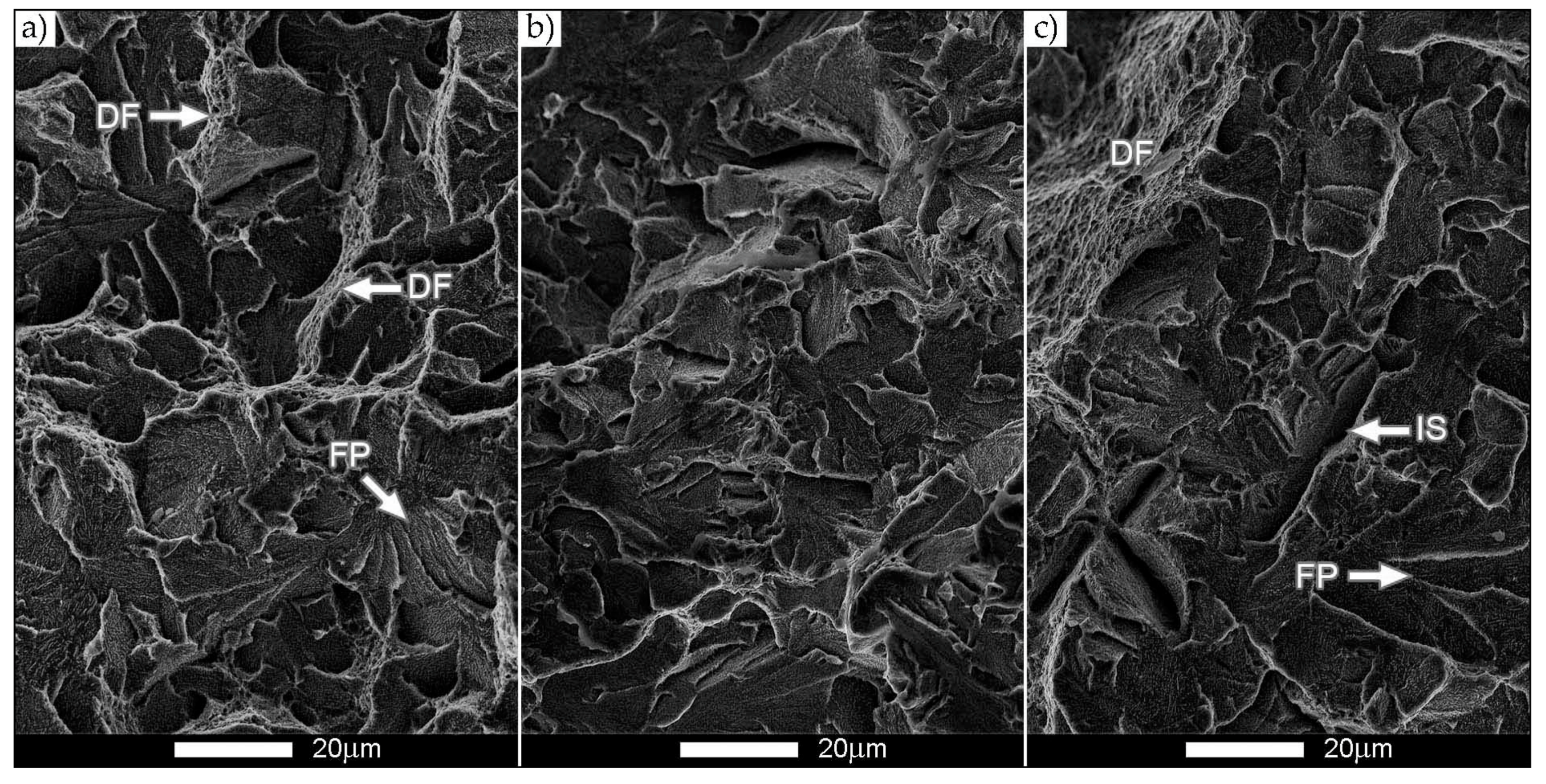

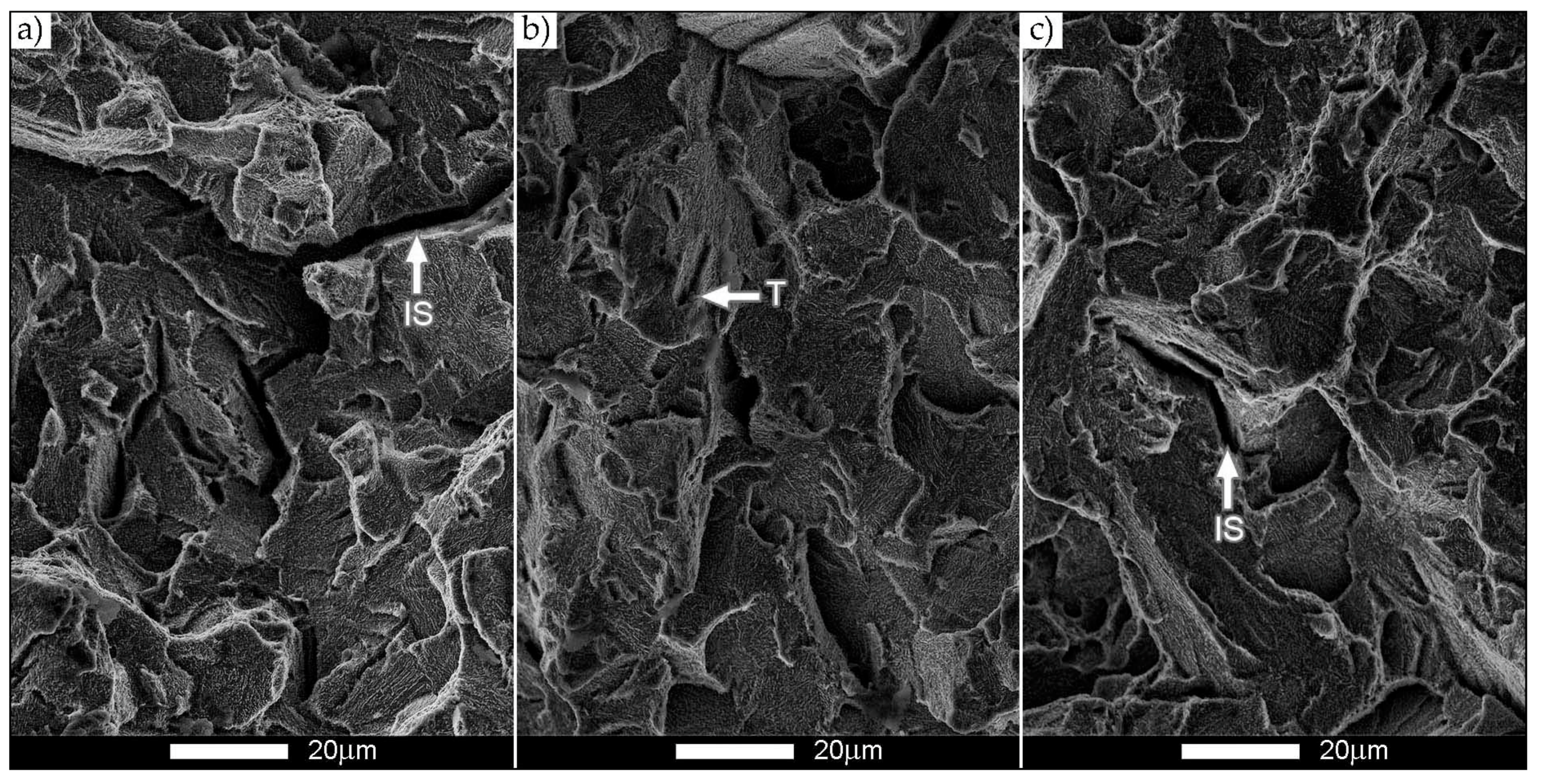

3.5. Fractographic Analysis

3.6. Analysis of Possible Hardox Extreme Steel Applications

- In the mining industry:

- Feeder system linings;

- Linings for vibration baskets and basket drawers;

- Excavator bucket cladding and sheathing;

- Highly loaded areas of fixed buckets wheel chute with a block crusher.

- In the transport industry:

- Walls and floors in semitrailers, trailers and containers;

- Floors and boards of tipper kippers and haul trucks;

- Concrete mixer drums.

- In construction industry:

- Cladding and sheathing for excavator buckets, loaders, crushers, and scissors;

- In agriculture;

- Ploughshares;

- Blades;

- Coulters.

4. Conclusions

- The structure of the Hardox Extreme steel in the delivery state constitutes medium carbon, fine-lath martensite with hardness of 60 HRC (longitudinal orientation) and 61 HRC (transverse orientation). In the normalized state, its structure with a hardness of 38 HRC (longitudinal and transverse orientation) is mainly composed of quenched sorbite and martensite.

- The analyzed material belongs to medium carbon steel group (0.44%C). Attention is directed to the alloy content of such elements as: chromium (0.83%), nickel (2.01%), molybdenum (0.14%) and boron (0.0021%).

- In the delivery state the Hardox Extreme steel is characterized by the following mechanical parameters: Rm—2411 MPa, Rp0.2—1549 MPa, Rp0.05—1150 MPa, E—210 GPa, A5—3.5%, Z—10.1% (longitudinal direction); Rm—2116 MPa, Rp0.2—1574 MPa, Rp0.05—1252 MPa, E—206 GPa, A5—1.5%, Z—8.0% (transverse direction).

- In the normalized state, the Hardox Extreme steel has the following mechanical indices: Rm—1255 MPa, Rp0.2—871 MPa, Rp0.05—660 MPa, E—203 GPa, A5—10.5%, Z—33.1% (longitudinal direction); Rm—1129 MPa, Rp0.2—862 MPa, Rp0.05—687 MPa, E—212 GPa, A5—11.3%, Z—36.8% (transverse direction).

- Fractures in the delivery state and after normalization show the lack of macroscopic plastic deformation in each case, and practically no participation, or very small participation, of ductile side zones and the area below the notch.

- The fractographic analysis showed that after normalization, the fracture exhibits the structure typical of transcrystalline brittle fracture, made of brittle facets, while in the delivery state the obtained fracture is classified as quasi-brittle in which facets are plastically deformed.

- The extremely high strength indices obtained in the research, despite the not completely satisfactory plastic indices, offer the Hardox Extreme steel extensive application opportunities. The use of this type of steel will allow one to significantly reduce fuel consumption and CO2 emissions due to the reduction of vehicle mass, which, especially in the transport industry, will allow one to comply with the regulations introducing CO2 emission quotas for high capacity, heavy goods vehicles.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MEPs Approve New CO2 Emissions Limits for Trucks. Available online: https://www.europarl.europa.eu/news/en/press-room/20190412IPR39009/meps-approve-new-co2-emissions-limits-for-trucks (accessed on 10 August 2020).

- Paris Agreement. Agreement between 197 Nations after Negotiations in Paris within the United Nations Framework Convention on Climate Change; COP21: Le Bourget, France, 2015. [Google Scholar]

- The Circular Economy: A powerful Force for Climate Migration. Available online: https://www.climate-kic.org/insights/the-circular-economy-a-powerful-force-for-climate-mitigation-2/ (accessed on 20 August 2020).

- Pei, M.; Petäjäniemi, M.; Regnell, A.; Wijk, O. Toward a fossil free future with HYBRIT: Development of iron and steelmaking technology in Sweden and Finland. Metals 2020, 10, 972. [Google Scholar] [CrossRef]

- Pelczar, M. The Influence of Micro-Additives on the Hardenability of Steel with Boron; AGH: Krakow, Poland, 2010. [Google Scholar]

- Walter, R. British Patent 160792; Intellectual Property Office: London, UK, 1921.

- Choi, Y.S.; Kim, S.J.; Park, I.M.; Kwon, K.W.; Yoo, I.S. Boron distribution in a low-alloy steel. Metal. Mater. 1997, 3, 118–124. [Google Scholar] [CrossRef]

- EcoUpgraded Tipping Trailer. Available online: https://www.ssab.com/products/brands/hardox/customer-case-ecoupgraded-tipping-trailer (accessed on 10 October 2020).

- EcoUpgraded Dumper Body. Available online: https://www.ssab.com/products/brands/hardox/customer-case-ecoupgraded-dumper-body (accessed on 10 October 2020).

- Hardox Extreme Steel for Extreme Abrasion Resistance. Available online: https://www.ssab.com/products/brands/hardox/products/hardox-extreme (accessed on 10 October 2020).

- Maitrepierre, P.; Thivellier, D.; Rofes-Vernis, J.; Rousseau, D.; Tricot, R. Hardenability Concepts with Application to Steels; Doane, D.V., Kirkaldy, J.S., Eds.; Metallurgical Society AIME: New York, NY, USA, 1978; pp. 421–447. [Google Scholar]

- Llewellyn, W.T.; Cook, W.T. Heat treatment distortion in case carburising steels. Metal. Tech. 1977, 4, 265–278. [Google Scholar] [CrossRef]

- Kapadia, B.M.; Brown, R.M.; Murphy, W.J. The influence of nitrogen, titanium and zirconium on the boron hardenability effect in constructional steel. AIME 1968, 242, 1689–1694. [Google Scholar]

- Melloy, G.F.; Slimmon, P.R.; Podgursky, P. Segregation and the strength of grain boundaries. Metal Trans. 1973, 4, 2279–2289. [Google Scholar] [CrossRef]

- Opiela, M. Structure and mechanical Properties of forged microalloyed steel products manufactured with the thermo-mechanical Treatment. Hutnik 2013, 80, 579–583. [Google Scholar]

- Davis, J.R. (Ed.) Metals Handbook Desk Edition, 2nd ed.; ASM International: Almere, The Netherlands, 1998. [Google Scholar]

- Wyrzykowski, J.W.; Pleszakow, E.; Sieniawski, J. Odkształcenie i Pękanie mEtali; Wydawnictwo Naukowe WNT: Warsaw, Poland, 1999. [Google Scholar]

- Dudziński, W.; Konat, Ł.; Pękalska, L.; Pękalski, G. Structures and properties of hardox 400 and hardox 500 steels. Inżynieria Materiałowa 2006, 27, 139–142. [Google Scholar]

- Maciejny, A. Kruchość Metali; Wydawnictwo Śląsk: Katowice, Poland, 1973. [Google Scholar]

- Białobrzeska, B.; Konat, Ł.; Jasiński, R. The influence of austenite grain size on the mechanical properties of low-alloy steel with boron. Metals 2017, 7, 26. [Google Scholar] [CrossRef] [Green Version]

- Białobrzeska, B.; Konat, Ł.; Jasiński, R. Fractographic analysis of brinar 400 and brinar 500 steels in impact testing. Scanning 2018, 2018, 2524735. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Crussard, C.; Tamhankar, R. High temperature deformation of steels: A study of equicohesion, activation energies and structural modifications. Min. Eng. 1958, 212, 718–730. [Google Scholar]

- Rosenfield, A.R.; Hahn, G.T.; Embury, J.D. Fracture of steels containing pearlite. Metall. Trans. 1971, 3, 2797–2804. [Google Scholar]

- Konat, Ł. Structures and Properties of Hardox Steels and Their Application Possibilities in Conditions of Abrasive Wear and Dynamic Loads; Wrocław University of Science and Technology: Wrocław, Poland, 2007. [Google Scholar]

| C | Mn | Si | P | S | Cr | Ni | Mo |

| 0.44 | 0.49 | 0.16 | 0.006 | 0.002 | 0.83 | 2.01 | 0.14 |

| V | Cu | Al | Ti | Nb | Co | B | Zr |

| 0.008 | 0.018 | 0.043 | 0.008 | 0.001 | 0.024 | 0.0021 | - |

| Sample | E | Rp0.05 | Rp0.2 | Rm | A5 | Z | Rp0.2/Rm | HRC |

|---|---|---|---|---|---|---|---|---|

| GPa | MPa | MPa | MPa | % | % | - | ||

| D(L) | 210 ± 8 | 1150 ± 60 | 1549 ± 28 | 2413 ± 116 | 3.5 ± 0.9 | 10.1 ± 2.2 | 0.64 | 60 ± 0.1 |

| D(T) | 206 ± 6 | 1252 ± 33 | 1574 ± 22 | 2117 ± 85 | 1.5 ± 0.9 | 8.0 ± 1.1 | 0.74 | 61 ± 0.1 |

| N(L) | 203 ± 12 | 660 ± 51 | 871 ± 86 | 1256 ± 132 | 10.5 ± 0.7 | 33.1 ± 3.5 | 0.69 | 38 ± 0.6 |

| N(T) | 212 ± 1 | 687 ± 161 | 863 ± 118 | 1130 ± 16 | 11.3 ± 0.8 | 36.8 ± 2.7 | 0.76 | 38 ± 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Białobrzeska, B.; Jasiński, R.; Konat, Ł.; Szczepański, Ł. Analysis of the Properties of Hardox Extreme Steel and Possibilities of Its Applications in Machinery. Metals 2021, 11, 162. https://doi.org/10.3390/met11010162

Białobrzeska B, Jasiński R, Konat Ł, Szczepański Ł. Analysis of the Properties of Hardox Extreme Steel and Possibilities of Its Applications in Machinery. Metals. 2021; 11(1):162. https://doi.org/10.3390/met11010162

Chicago/Turabian StyleBiałobrzeska, Beata, Robert Jasiński, Łukasz Konat, and Łukasz Szczepański. 2021. "Analysis of the Properties of Hardox Extreme Steel and Possibilities of Its Applications in Machinery" Metals 11, no. 1: 162. https://doi.org/10.3390/met11010162

APA StyleBiałobrzeska, B., Jasiński, R., Konat, Ł., & Szczepański, Ł. (2021). Analysis of the Properties of Hardox Extreme Steel and Possibilities of Its Applications in Machinery. Metals, 11(1), 162. https://doi.org/10.3390/met11010162