The Corrosion Resistance of Al Film on AZ31 Magnesium Alloys by Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating Preparation

2.3. Test Method

3. Results

3.1. Al Film Structure

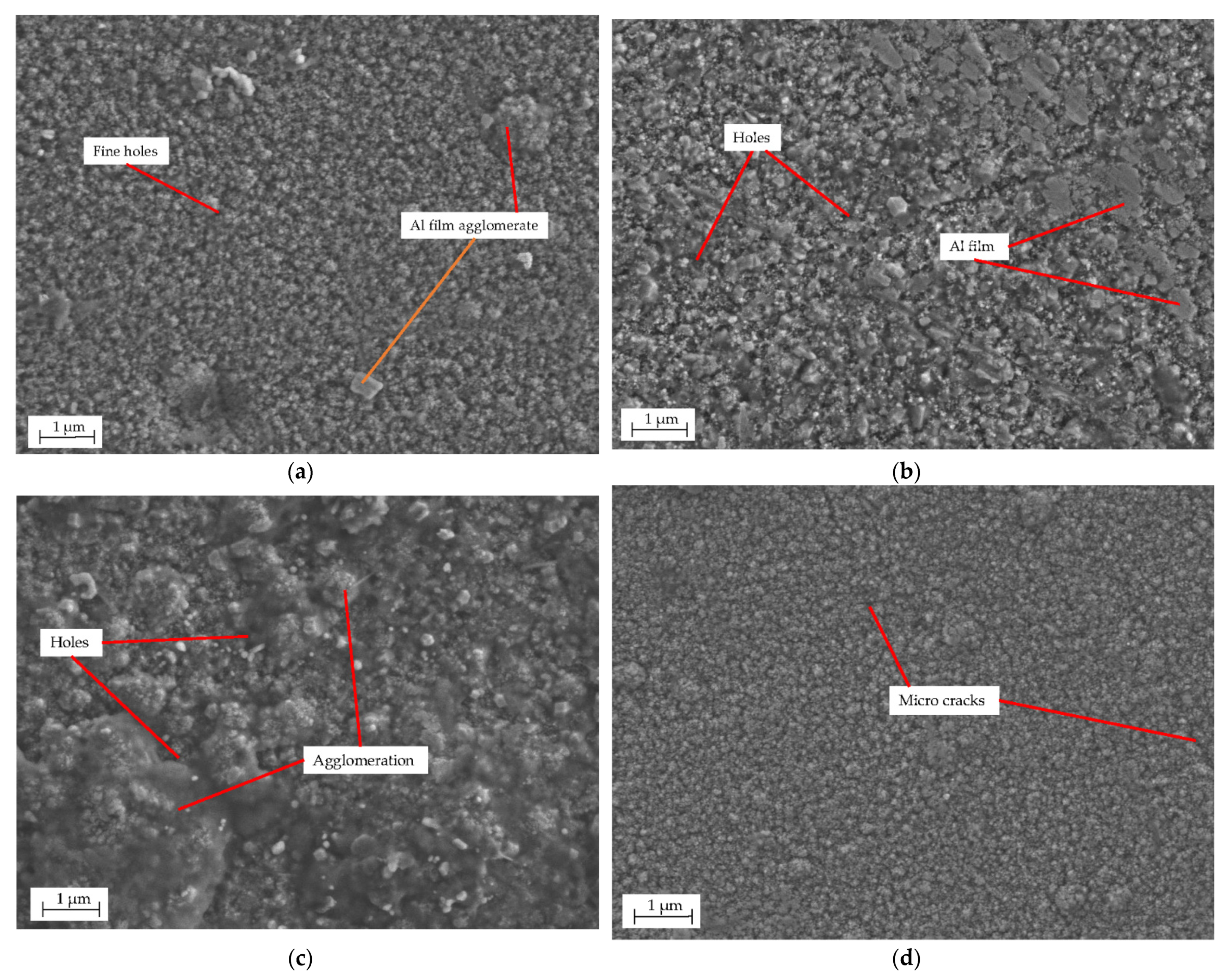

3.2. Surface Morphology and Crystal Orientation of Al Films

3.3. Corrosion Resistance of Al Films

4. Discussion

4.1. Analysis of Al Film Structure

4.2. Analysis of Surface Morphology and Crystal Orientation under Different Sputtering Powers

4.3. Analysis of Corrosion Resistance under Different Sputtering Powers

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Powell, B.R.; Krajewski, P.E.; Luo, A.A. Magnesium alloys for lightweight powertrains and automotive bodies. In Materials Design and Manufacturing for Lightweight Vehicles; Mallick, P.K., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2010; pp. 114–168. [Google Scholar]

- Czerwinski, F. Controlling the ignition and flammability of magnesium for aerospace applications. Corros. Sci. 2014, 86, 1–16. [Google Scholar] [CrossRef]

- Kumar, D.; Phanden, R.K.; Thakur, L. A review on environment friendly and lightweight Magnesium-Based metal matrix composites and alloys. Mater. Today Proc. 2020, 38, 359–364. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, H.; Hu, X.; Ju, D. A novel processing for CNT-Reinforced Mg-Matrix laminated composites to enhance the electromagnetic shielding property. Coatings 2021, 11, 1030. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, N. Novel Magnesium alloys developed for biomedical application: A review. J. Mater. Sci. Technol. 2013, 29, 489–502. [Google Scholar]

- Liu, S.; Li, G.; Qi, Y.; Peng, Z.; Liang, J. Corrosion and tribocorrosion resistance of MAO-based composite coating on AZ31 magnesium alloy. J. Magnes. Alloy. 2021. In Press. [Google Scholar] [CrossRef]

- Lin, R.; Liu, C.; Wang, F.; Jia, Y.; Ding, Y.; Ban, G.; Li, Z. Development of corrosion surface modification technology for magnesium alloys. Surf. Technol. 2016, 45, 124–131. [Google Scholar]

- Song, G.L.; Atrens, A. Corrosion mechanisms of magnesium alloys. Adv. Eng. Mater. 1999, 1, 11–33. [Google Scholar]

- Esmaily, M.; Svensson, J.E.; Fajardo, S.; Birbilis, N.; Frankel, G.S.; Virtanen, S.; Arrabal, R.; Thomas, S.; Johanssonet, L.G. Fundamentals and advances in magnesium alloy corrosion. Prog. Mater. Sci. 2017, 89, 92–193. [Google Scholar] [CrossRef]

- Gusieva, K.; Davies, C.; Scully, J.; Birbilis, N. Corrosion of magnesium alloys: The role of alloying. Int. Mater. Rev. 2015, 60, 169–194. [Google Scholar] [CrossRef]

- Saji, V.S. Review of rare-earth-based conversion coatings for magnesium and its alloys. J. Mater. Res. Technol. 2019, 8, 5012–5035. [Google Scholar] [CrossRef]

- Tu, X.; Miao, C.; Yang, Z.; Xu, Y.; Li, J. Plasma Electrolytic Oxidation of Magnesium alloy AZ31B in electrolyte containing Al2O3 sol as additives. Materials 2018, 11, 1618. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.; Zhao, J.; Xie, Y.; Yang, Z. Progress of electroplating and electroless plating on magnesium alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 630–637. [Google Scholar] [CrossRef]

- Rolink, G.; Weisheitb, A.; Biermann, T.; Bobzin, K.; Öte, M.; Linke, T.F.; Schulz, C.; Kelbassa, I. Investigations of laser clad, thermal sprayed and laser remelted AlSi20-coatings on magnesium alloy AZ31B under constant and cycling thermal load. Surf. Coat. Technol. 2014, 259, 751–758. [Google Scholar] [CrossRef]

- Xin, Y.; Liu, C.; Zhang, W.; Jiang, J.; Tang, G.; Tian, X.; Chu, P. Electrochemical behavior. Al2O3/Al coated surgical az91 magnesium alloy in simulated body fluids. J. Electrochem. Soc. 2008, 155, C178–C182. [Google Scholar] [CrossRef]

- Xin, Y.; Liu, C.; Huo, K.; Tang, G.; Tian, X.; Chu, P.K. Corrosion behavior of ZrN/Zr coated biomedical AZ91 magnesium alloy. Surf. Coat. Technol. 2009, 203, 2554–2557. [Google Scholar] [CrossRef]

- Singh, A.; Harimkar, S.P. Laser surface engineering of magnesium alloys: A review. JOM 2012, 64, 716–733. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, K.; Shimada, Y.; Miyashita, T. Effect of vapor pressure during the steam coating treatment on structure and corrosion resistance of the Mg(oh)2/Mg-Al LDH composite film formed on mg alloy az61. Materials 2018, 11, 1659. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Yang, D.; Ou, X. Microstructures and properties of aluminum film and its effect on corrosion resistance of AZ31B substrate. Trans. Nonferrous Met. Soc. China 2008, 18, s312–s317. [Google Scholar] [CrossRef]

- Wu, G.; Wang, A.; Ding, K.; Xu, C.; Dai, W.; Xu, A. Fabrication of Cr coating on AZ31 magnesium alloy by magnetron sputtering. Trans. Nonferrous Met. Soc. China 2008, 18, s329–s333. [Google Scholar] [CrossRef]

- McCafferty, E. Validation of corrosion rates measured by the Tafel extrapolation method. Corros. Sci. 2005, 47, 3202–3215. [Google Scholar] [CrossRef]

- Chen, E.; Peng, K.; Yang, W.; Zhu, J.; Li, D.; Zhou, L. Effects of Al coating on corrosion resistance of sintered NdFeB magnet. Trans. Nonferrous Met. Soc. China 2014, 24, 2864–2869. [Google Scholar] [CrossRef]

- Tang, J.; Niu, D.; Tai, Z.; Hu, X. Deposition of highly c-axis-oriented ScAlN thin films at different sputtering power. J. Mater. Sci. 2017, 28, 5512–5517. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, K. Dependence of strain-energy density on the grain orientation in fcc-polycrystalline films. Acta Phys. Sin. 2002, 51, 2562–2565. [Google Scholar]

- Hua, Y.; Zhu, A.; Chen, R.; Guo, L. Microstructure and electrical properties of Al nano-particle films by DC magnetron sputtering. J. Funct. Mater. 2015, 46, 4071–4075. [Google Scholar]

| Sputtering Power/W | Film Thickness/nm |

|---|---|

| 50 | 320 |

| 75 | 372 |

| 100 | 670 |

| 150 | 1243 |

| Sputtering Power/W | Grain Size/nm |

|---|---|

| 50 | 161 |

| 75 | 220 |

| 100 | 285 |

| 150 | 192 |

| Sputtering Power/W | Eocp (V) | Ecorr (V/SCE) | Icorr (A/cm2) |

|---|---|---|---|

| Uncoated (AZ31 Substrate) | −1.554 | −1.538 | 1.538 × 10−5 |

| 50 | −1.548 | −1.602 | 1.269 × 10−6 |

| 75 | −1.559 | −1.519 | 2.534 × 10−6 |

| 100 | −1.555 | −1.506 | 4.801 × 10−6 |

| 150 | −1.561 | −1.357 | 7.033 × 10−7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Yang, D.; Sun, C.; Du, L.; Zhang, X.; An, Z. The Corrosion Resistance of Al Film on AZ31 Magnesium Alloys by Magnetron Sputtering. Metals 2021, 11, 1522. https://doi.org/10.3390/met11101522

Gao Z, Yang D, Sun C, Du L, Zhang X, An Z. The Corrosion Resistance of Al Film on AZ31 Magnesium Alloys by Magnetron Sputtering. Metals. 2021; 11(10):1522. https://doi.org/10.3390/met11101522

Chicago/Turabian StyleGao, Zhengyuan, Dong Yang, Chengjin Sun, Lianteng Du, Xiang Zhang, and Zhiguo An. 2021. "The Corrosion Resistance of Al Film on AZ31 Magnesium Alloys by Magnetron Sputtering" Metals 11, no. 10: 1522. https://doi.org/10.3390/met11101522