Recent Advancements in AI-Enabled Smart Electronics Packaging for Structural Health Monitoring

Abstract

:1. Introduction

- A comprehensive overview of ML applications in smart SHM electronics is elaborated.

- The state of the art of data-driven SHM is thoroughly studied and organized systematically.

- Separate tables are provided to illustrate diverse SHM methods chronologically for the reader’s convenience.

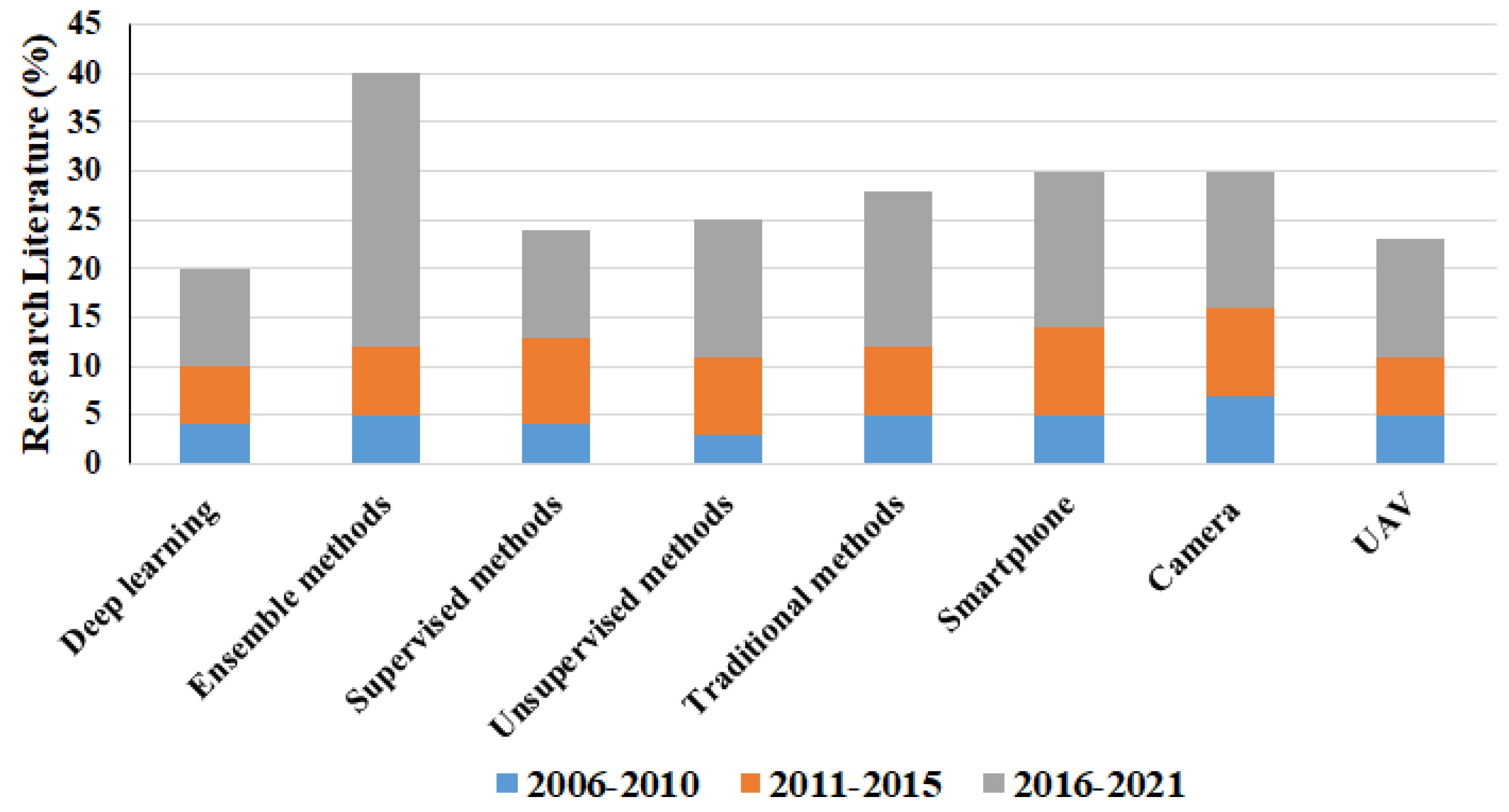

- Research trends of the past fifteen years are thoroughly studied and illustrated to identify the popularity of ML models for structural damage detection and localization.

- The implementation of smart sensing technologies for SHM is discussed in detail with the Internet of Things and smart city implications.

- The pros and cons of conventional and advanced SHM techniques are provided in tables that also highlight their important features.

- Current technological challenges and future research perspectives of AI algorithms in SHM are also discussed.

1.1. Research Methodology

- A comprehensive review was performed on advanced smart data acquisition methods for SHM.

- AI applications in SHM were studied to deliver a broad review of the existing technologies and advancements.

- We provide a brief description of diverse challenges prevailing in the SHM domain.

- We offer insights about future research directions and challenges in the application of ML for SHM.

- We provide a chronological arrangement of recently published works for diverse sensor-based techniques for reader ease.

- Efforts were made to illustrate various methodologies pictorially.

Data Diversity and Databases Utilized for SHM

2. Overview of Structural Health Monitoring

2.1. Overview of Artificial Intelligence

2.1.1. Deep Learning in SHM

2.1.2. Machine Learning-Based Damage Detection for SHM

2.1.3. Data-Driven Pipeline Leakage Detection

3. Next-Generation Smart Electronic Packaging Solutions

3.1. Camera Method

3.2. Smartphone-Based Electronic Packaging Approach

3.3. Unmanned Aerial Vehicle Method

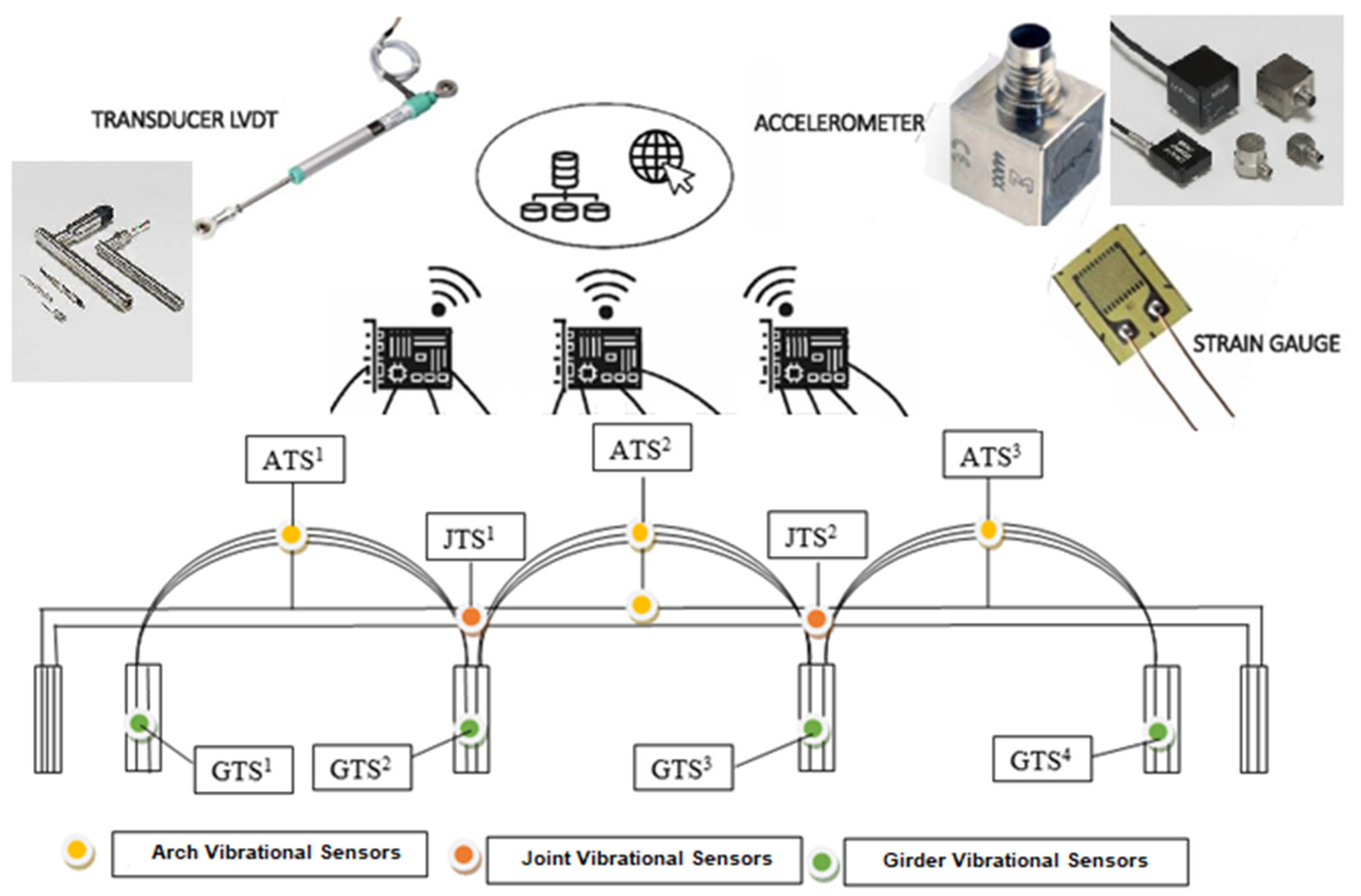

3.4. Internet of Thing (IoT) for SHM

4. Recent Concept of Smart Cities

5. Current Challenges and Future Perspective of SHM Domain

6. Conclusions

- Contact sensors are often utilized for SHM due to their smaller size, lower economic cost, and less power consumption. However, the discrimination of signals from background environment noise is a difficult task due to its weak strength. These contact sensors are embedded types that cannot be utilized for other purposes after installation. Reliability is also a major concern if any sensor becomes faulty.

- Several non-contact sensors are preferred over contact sensors for SHM due to their technological advantages. Camera position, the number of cameras, blind spots, database complexity, weather conditions, etc., are few limitations faced by camera-based SHM methods.

- Smartphones are low-cost cell phones that are utilized for SHM due to their versatility and enormous stockpiling limits, noteworthy computational force, and effectively modifiable programming. However, they require particular preparation in programming and PC programming alongside broad stockpiling instrumentation to process large volumes of information productively.

- UAVs equipped with a lightweight camera are primarily used for imaging and, consequently, measuring an area with the overall prosperity of a structure. Certain limitations are also reported for UAV-based SHM methods, such as difficulties in finding an appropriate UAV position, environment conditions, the stability of the UAV, design challenges, motor faults and failure, limited control range, etc.

- Other non-contact sensors, such as laser vibrometers, LIDAR, and radar interferometry, have been reported to give excellent estimation results for SHM. These instruments are reported to be costly and adversely affected by rough climate conditions.

- Machine learning models are found unsuitable for vision-based systems. However, deep learning models have been widely applied to vision-based SHM systems, allowing them to deal with large real-time datasets.

- Unmanned aerial vehicle and non-contact sensors are found to be the most promising smart data acquisition technology, whereas convolution neural networks comprise the most impressive data-driven models reported for SHM.

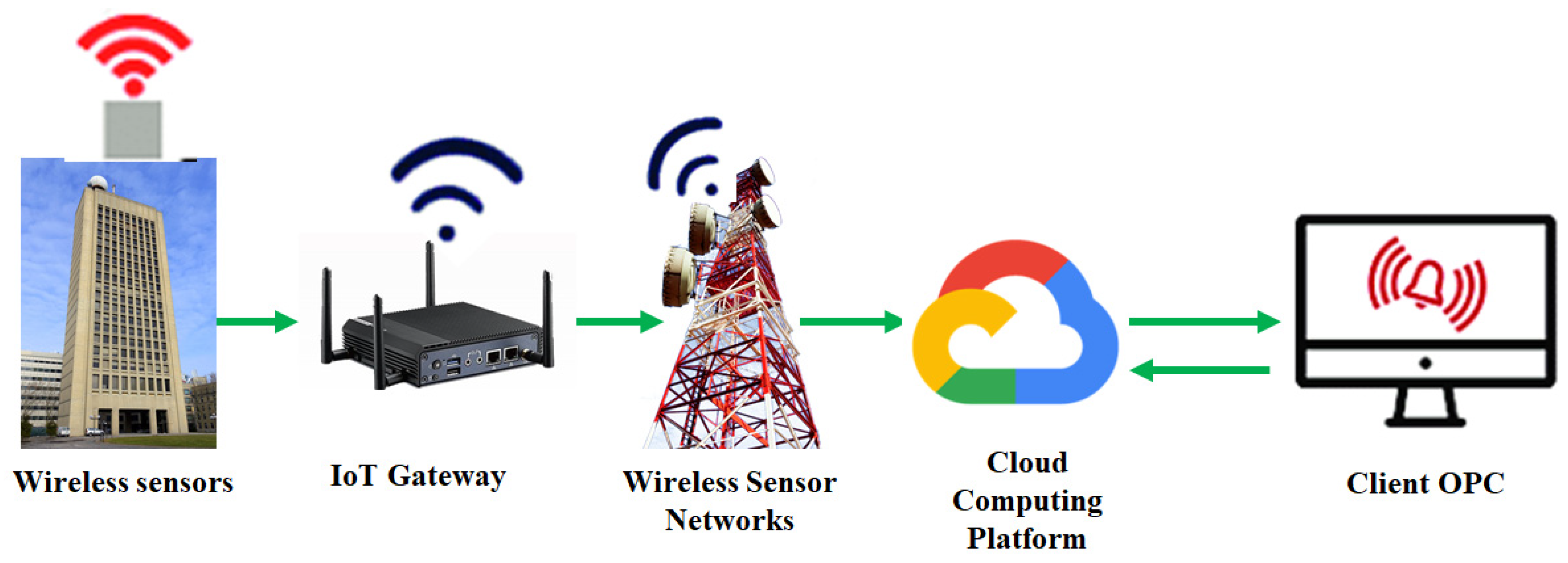

- With the progress of IoT integrated with AI algorithms, health monitoring of civil structures has become a much easier task compared to traditional SHM systems. Algorithms such as CNNs are continuously monitoring civil structural integrity and may schedule maintenance to minimize any damage in the structure.

- IoT-based structural health inspections may provide a promising solution for SHM systems that are fast, accurate, and low cost. The integration of SHM, IoT, and cloud-based computing can lead to sophisticated data diagnosis. Cloud platforms can act as storage, and use intelligent monitoring devices on an SHM system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| S. No. | Source | Data Types | Dataset Description |

|---|---|---|---|

| 1 | Los Alamos National Laboratory | Diverse experimental data types | Alamosa Canyon Bridge Data, I-40 Bridge Data, UC-Irvine Bridge Column Data, Sheraton Hotel (Universal City, CA) Ambient Vibration Data, 8-DOF System Data, Bookshelf Frame Structure—DSS 2000, Bookshelf Frame Structure and 4-DOF Nonlinearity data set |

| 2. | Laboratory of Infrastructure Science and Sustainability | Diverse data types | Camera-based motion magnification, vibrational data of building, etc. |

| 3. | IASC-ASCE Task Group on Structural Health Monitoring | Simulated data | SHM of civil structure using simulated vibration data |

| 4 | National Center for Research on Earthquake Engineering | Diverse vibrational and images data related to earthquakes | Structural vibrational frame test data in diverse earthquake scenarios, 5000 data images, etc. |

| 5 | IEEE Dataport | Vibrational data and LIDAR data | Multiple LIDAR datasets such as aerial warehouse data, indoor experimental data collected from two 3D sensors, etc. |

| 6 | Maguire et al. [231] | SDNET2018 | 56,000 2D images of deck, wall, and pavement of a bridge |

| 7 | Hoskere et al. [232] | 2D image data | Pictures of building, walls, etc.; laboratory experimental results |

| 8 | Avci et al. [65] | Vibrational data | 330 signals each containing 245,760 samples |

| 9 | Beckman et al. [233] | Vision-based data | 444 concrete spalling images (853 × 1440 pixels) |

| 10 | Bao et al. [234] | Vision data | 333,792 acceleration signals |

| 11 | Dung and Anh [235] | 2D image data | An open database with 40,000 data samples of concrete fractures with 227 × 227 pixel pictures |

| 12 | Lin et al. [236] | Vibrational data | 459 datasets captured from nine nodes present in 1024 × 9 matrices |

| 13 | Gulgec et al. [68] | 2D image data | 30,000 unhealthy and 30,000 undamaged tension distribution matrices in 28 × 56 measurement |

| 14 | Tung et al. [237] | Vibrational data | 10,014 responses of a long hanging bridge cable having two output channels with 100 × 100 resolution |

| 15 | Nahata et al. [238] | 2D image data | 224 × 224 × 3 pixels containing 1200 RGB image data |

| 16 | Ni et al. [239] | Deep learning image repository | Images (RGB 224 × 224 pixels) for GoogLeNet with 60,000 pictures |

| 17 | Duarte et al. [240] | 2D image data | 12,973 pictures of the satellite and an airborne vehicle (224 × 224 resolution) |

| 18 | Kim et al. [186] | 2D image data | 3186 pictures of cracks and intact surfaces (227 × 227 pixels) |

| 19 | Chen [241] | Vision data | 147,344 cracks and 149,460 non-cracks (120 × 120 patches) |

| 20 | Sharma et al. [242] | 2D image data | 15,600 factures and non-factures (28 × 28 RGB patches) |

| 21 | Pathirage [243] | Vibrational data | Modal information of 10,300 fractures (7 arrays) |

| 22 | Wang et al. [244] | 2D image data | 500 pictures (500 × 500 pixels) |

| 23 | Dorafshan et al. [245] | 2D image data | 9011 (227 × 227 pixel) images of lab-made bridge decks |

| 25 | Jang et al. [246] | 2D image data with vision data | 20,000 hybrid images by merging vision and infrared thermography of concrete factures (224 × 224 pixel) |

| 27 | Yu et al. [247] | Vibrational data | 1900 clusters of 5 × 2832 matrices |

| 28 | Ye et al. [248] | 2D image data | 14,000 fracture pictures (80 × 80 resolution) |

| 29 | Modarres et al. [249] | 2D image data | Data of 2400 concrete fractures, sandwich panels with a resolution of 96 × 96 pixels |

| 30 | Zhang et al. [250] | Vibrational data | 8595, 14,465, and 4800 vibrational signal (9 Ch. × 10,000) |

| 31 | Xu et al. [251] | 2D image data | 2400 pictures (640 × 640 resolution), concrete fractures, spalling, rebar exposure, and buckling |

| 32 | Yang et al. [118] | 2D image data | 800 images of cracks (224 × 224-pixel resolution) |

| 33 | Abdeljaber et al. [65] | Vibrational data | 749 × 12 vectors of vibration signals (128 × 1 dimension) |

| 34 | Atha and Jahanshahi [252] | 2D image data | 67,187 images of corrosion (128 × 128 resolution) |

| 35 | Zhang et al. [253] | 2D image data | 300 images with 224 × 224 pixels |

| 36 | Silva et al. [254] | 2D image data | 3500 sample images of 256 × 256 pixels |

| 37 | Kumar et al. [255] | 2D image data | 12,000 pictures of fractures, extreme cracks, intrusions, scaling, deposits, corrosion in pipelines (256 × 256 dimension) |

| S. No | Method Name | Description | Applicability | Results | Use for Water-Based or Oil-Based Conduit | Comments for Future Prediction of Damages |

|---|---|---|---|---|---|---|

| 1 | Corrosion Coupon | Coupon is placed within the working material, thus invasive | Can be applicable for pipe/reactor of any shape or size | No precision position and time of leak/corrosion | Water-based system | Difficult to predict any future damage location |

| 2 | Electrical Resistance Probe | Invasive probe works as a real-time corrosion coupon | Can be applicable for pipe/reactor of any shape or size | No precise positioning but time and extent of corrosion or mass loss can be determined | Suitable for oil and water-based system | Real-time data may be utilized to detect the future damage or probable future leaks |

| 3 | Electrochemical Sensors | In situ electrochemical corrosion rate determination | Can be applicable for pipe/reactor of any shape or size | No precise positioning but time and extent of corrosion can be determined | Works better for ion conducting electrolytes | Difficult to predict any future damage location |

| 4 | Ultrasonic (Acoustic) Testing Sensor | Ultrasonic probes are placed inside the pipe to detect pipe thickness, flow change or loss | Can be applicable for pipe/reactor of any shape or size | Good precision; real-time positioning is possible; not suitable for very small leaks or structural damages | Suitable for oil and water-based system | Real-time data can be utilized to detect the future damage or fault location |

| 5 | Magnetic Flux Leakage Method | Invasive technique for detection of damage in structure by comparing magnetic flux lines | Can be applicable for pipe of any shape or size | Cannot precisely locate the position of structural damage | Oil/water-based system | Difficult to predict damage location |

| 6 | Point OFS for Corrosion | Optical corrosion coupon using optical spectrum from its position inside the pipe | Can be applicable for pipe of any shape or size | No precise positioning but incidence and extent of corrosion can be determined | Suitable for oil/water-based system | Difficult to predict damage location |

| 7 | Quasi-Distributed OFS for Corrosion | It uses FBG based external point sensors to determine change in temperature and strain; the pressure wave generated transmits in both the directions from point of leakage, where the pressure sensors detect the leakage point my analyzing pressure wave | Very useful to determine the corrosion in pipeline and wellbore in real time | Precise point and time of leakage can be determined using this technique of negative pressure wave (NPW) | Suitable for oil or water-based system, it can detect gas leaks | Can be useful for predicting future leak or damage |

| 8 | Distributed OFS for Physical Sensing | Parameters of corrosion and leaks are determined by monitoring pressure and temperature change due to leak; optical fibers are winded over the pipe to detect the leak | The technique is also useful for determination of efficient flow of crude in pipes and impacts in flow due to corrosion; estimates corrosion and structural changes | The leak can be determined precisely and in real time | Can work for conduits carrying oil, waters, and gas | The technology can be extended to determine corrosion or damages in pipe |

| 9 | Distributed OFS for Chemical Sensing | Optical fibers with chemical coating and air holes is activated over pipe core or cladding, can be applied to check the external or internal health of piping structure | Multi-sensor OFS are designed and utilized to determine leaks of gases of different types and nature of environments the conduits are exposed to | Precise determination of leaks and damages are possible in real time | Can work for conduits carrying oil, waters, and gas for leak detection | It gives early signs of corrosion; it is the best method to predict the damage or leak |

| 10 | SCADA and CMS | Acoustic emission, optic fiber, thermographic, photogrammetric techniques and other are used to remotely collect and monitor the surface of structure | These can be used to detect damages in pipelines and other civil infrastructures | Cracks can be easily monitored; very fine cracks may not be detected through real-time data | Can work for conduits carrying oil, waters, and gas | Monitoring external conditions may not hint always any impending danger |

| 11 | UAV-Based Technique | Multi-sensor (thermal, laser, sonic, spectroscopic, photogrammetric) remote sensing of crack, and structural deformations using UAV platform | Determine the surface damages to any infrastructure of oil and gas industry | Laser UAV can detect fine damages if scanning is performed from close proximity; data are required to be analyzed to determine the leaks | Can work over oil, water, gas conduits or any other infrastructure | The damages existing in pipelines or infrastructure may be extrapolated to determine the future source of leak or gas emissions |

| Authors | Year | Type of SHM | Techniques | Reference |

|---|---|---|---|---|

| Mosalam et al. | 2019 | Civil infrastructure | Deep learning | [54] |

| An et al. | 2019 | Bridge and truss structure | Deep learning | [55] |

| Baroudi et al. | 2019 | Oil and gas infrastructure and pipelines | Data fusion techniques | [90] |

| Aalsalem et al. | 2018 | Oil and gas pipelines | ANNs | [57] |

| Abdeljaber et al. | 2018 | Large framed structure | 1D CNNs | [66] |

| Vitola et al. | 2017 | Large civil structure | SVM and K-NN | [49] |

| Abdeljaber et al. | 2017 | Steel framed structures | 1D CNN | [65] |

| Goyal et al. | 2017 | Water pipelines | ANN | [82] |

| Shi et al. | 2017 | Pipeline structures | ML, SVM | [85] |

| Santos et al. | 2016 | Bridge and cable structure | ANN and Clustering techniques | [47] |

| Vitola et al. | 2016 | Large civil structure | PCA, K-NN, SVM, Boosted tree, Bagged tree, Subspace K-NN, Subspace Discriminant, and RUSBoosted Trees | [208] |

| Santos et al. | 2015 | Bridge structure | Unsupervised detection | [47] |

| Fagiani et al. | 2015 | Gas pipelines and water grid structure | SFSA, GMM, HMM, and OCSVM | [32] |

| Nasir et al. | 2014 | Oil and gas pipelines | ANN and SVM techniques | [80] |

| Khaleghi et al. | 2013 | Building structures | Multi-sensors data fusion | [56] |

| Wan et al. | 2012 | Natural gas pipeline | SVM | [79] |

| Jayawardhana et al. | 2011 | R.C.C. Slab | Autocorrelation Function-Cross Correlation Function and Auto-Regressive (AR) time series model | [48] |

| Laurentys et al. | 2011 | Pipeline structures | ANN | [76] |

| Glaser et al. | 2008 | Tall structures | Microsensors wireless network technology | [52] |

| González et al. | 2008 | Earthquake-resistant building | ANN | [59] |

| Farrar et al. | 2007 | Civil and mechanical structures | Statistical pattern recognition | [51] |

| Yuen et al. | 2006 | Symmetrical large civil structure | ANN along with feature extraction | [58] |

| Chen et al. | 2004 | Water pipelines | SVM | [77] |

| Authors | Year | Camera Types | Numerical Strategy | Main Topics Researched | Reference |

|---|---|---|---|---|---|

| Chang et al. | 2020 | High-speed camera | Scattered wavefield reconstruction | Damage that has been hidden from view | [257] |

| Bao et al. | 2020 | Video camera | Image processing | Stay cable condition assessment | [234] |

| Bao et al. | 2020 | Digital camera | Machine learning | Symmetrical structure | [258] |

| Xu et al. | 2018 | Action camera | Encoding, software design | Stiffness of cable bridge | [92] |

| Javh et al. | 2018 | DSLR D850 | ANN, CNN technique | Displacement measurement | [138] |

| Khuc et al. | 2018 | DSLR D5600 | C and C++ Techniques | Deflection identification | [140] |

| Javh et al. | 2018 | High-speed camera | Software design | Nonlinear building frames | [139] |

| Xu et al. | 2017 | DSLR D7000 | ANN technique | Crack detection | [100] |

| Chen et al. | 2016 | Digital video camera | Dynamic techniques | Earth retaining and tall structure | [126] |

| Santos | 2016 | Digital camera | Kalman filter | Stiffness of tall building | [47] |

| Yang et al. | 2015 | DSLR L18 | Head segment interest | Present time crack detection | [93] |

| Oh et al. | 2015 | DSLR D5300. | Vision-based identification | Health assessment of building frames | [113] |

| Chen et al. | 2015 | Digital video camera | Motion magnification | Symmetrical linear structures | [127] |

| Trebuna et al. | 2014 | 3D high-speed camera | Typical mode and complexmode marker work | Modular investigation | [259] |

| Im et al. | 2013 | Digital camera | GPS technology | Symmetrical structures | [196] |

| Olsen et al. | 2010 | Terrestrial laser scanner camera | Feature extraction by software | Damage assessment of the structure | [260] |

| Helfrick et al. | 2009 | Computer vision camera | Computerized picture connection | Shape strategy for crack recognition | [95] |

| Authors | Year | Phone Types | Numerical Strategy | Researched Topics | References |

|---|---|---|---|---|---|

| Wang et al. | 2021 | Android | CNNs | Steel beam analysis | [162] |

| Dong et al. | 2020 | Android | Computer vision-based | Local and global stiffness analysis | [115] |

| Zhang et al. | 2020 | Android | Vibration monitoring | Seismic structure analysis | [155] |

| Wang et al. | 2018 | Apple 6s | Stiffness detection | High-speed camera | [150] |

| Khuc and Catbas | 2018 | Apple 5s | Damage identification | Health monitoring of bridge | [140] |

| Yu et al. | 2017 | Apple 4S | Crack detection | Seismic wave measurement | [134] |

| Zeng et al. | 2017 | Tablets with Android | Android utilization | Pavement cracks detection | [151] |

| Feng et al. | 2017 | Apple 4S | Hybrid motion sensing | High rise structure | [128] |

| Zhao et al. | 2016 | A5 Android | Android utilization | Stiffness detection by laser technique | [153] |

| Ozer and Feng | 2016 | Android Apple 4S | Displacement measurement | Assessment of bridge health monitoring | [261] |

| Matarazzo and Pakzad | 2016 | Apple 4s | Crack identification | For multi-story frame structure | [262] |

| Marulanda et al. | 2016 | Android | Ambient excitation | For seismic structure | [263] |

| Dashti et al. | 2014 | Apple 3G | Earthquakes checking | Seismic measurement | [264] |

| Höpfner et al. | 2013 | Android | Smartphone sensors | Measuring mechanical oscillation | [265] |

| Tang et al. | 2002 | Android | Mobile manipulator | Bridge crack inspection | [266] |

| Authors | Year | Type | Methods | Main Topics Researched | References |

|---|---|---|---|---|---|

| Liu et al. | 2021 | Drone | ML | Confrontation of multi-UAV assault and defensive | [195] |

| Saleem et al. | 2020 | UAV | CNN | Bridge visual inspection | [194] |

| Mozaffari et al. | 2019 | UAV | ML | Channel modeling, resource management, positioning, and security | [193] |

| Germanese et al. | 2018 | Drone | Compact system camera | Damage design in an old building | [187] |

| Duque et al. | 2018 | UAV | Digital image processing | Detection for bridge deterioration | [191] |

| Lei et al. | 2018 | UAV | A digital camera with acoustic sensors | Crack detection and bridge inspection | [267] |

| Omar et al. | 2017 | Inspire T600 | Infrared imaging camera | Detecting of extension deck | [186] |

| Chiu et al. | 2017 | UAV | Digital camera | Tall structure monitoring | [181] |

| Qidwai et al. | 2017 | N/A | Quadcopters | Health monitoring of civil infrastructure | [178] |

| Radopoulou and Brilakis | 2016 | Drone | Quadcopters | Detection of multiple pavements | [102,103] |

| Na and Baek | 2016 | Camera drone | NDT testing | Large civil infrastructure | [176] |

| Ellenberg | 2015 | Camera drone | Action camera | Crack measurement | [169] |

| Sankarasrinivasan et al. | 2015 | N/A | Quadcopters | Damage measurement in a tall structure | [172] |

| Hallermann et al. | 2015 | Ascending Technologies | Mirrorless camera | Assessing spans | [171] |

| Franke et al. | 2014 | Drone | Small aerial vehicle | Geotechnical site investigation | [177] |

| Dobson et al. | 2013 | UAV | Quadcopters | Unpaved road evaluation | [157] |

| Roca et al. | 2013 | Skyjack | Small aerial vehicle | Outdoor assessment of building frames | [156] |

| Ortiz et al. | 2012 | Drone | Quadcopters | Civil structure surveillance | [168] |

| Rathinam et al. | 2008 | N/A | Aerial vehicle | Linear structure assessment | [164] |

| Metni and Hamel | 2007 | N/A | Small aerial vehicle | Bridge damage assessment | [163] |

References

- Doebling, S.; Farrar, C.; Prime, M.; Shevitz, D. Damage Identification and Health Monitoring of Structural and Mechanical Systems from Changes in their Vibration Characteristics: A Literature Review; U.S. Department of Energy Office of Scientific and Technical Information: Los Alamos, NM, USA, 1996. [CrossRef] [Green Version]

- Maia, N.M.M.; Silva, J.M.M. Modal analysis identification techniques. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2001, 359, 29–40. [Google Scholar] [CrossRef]

- Doebling, S.W.; Farrar, C.R.; Prime, M. A Summary review of vibration-based damage identification methods. Shock. Vib. Dig. 1998, 30, 91–105. [Google Scholar] [CrossRef] [Green Version]

- Carpinteri, A.; Lacidogna, G.; Niccolini, G. Acoustic emission monitoring of medieval towers considered as sensitive earthquake receptors. Nat. Hazards Earth Syst. Sci. 2007, 7, 251–261. [Google Scholar] [CrossRef] [Green Version]

- Melbourne, C.; Tomor, A.K. Application of acoustic emission for masonry arch bridges. Strain 2006, 42, 165–172. [Google Scholar] [CrossRef]

- Carden, E.P.; Fanning, P. Vibration based condition monitoring: A review. Struct. Health Monit. 2004, 3, 355–377. [Google Scholar] [CrossRef]

- Guo, T.; Sause, R.; Frangopol, D.M.; Li, A. Time-dependent reliability of PSC box-girder bridge considering creep, shrinkage, and corrosion. J. Bridg. Eng. 2011, 16, 29–43. [Google Scholar] [CrossRef]

- Sony, S.; LaVenture, S.; Sadhu, A. A literature review of next-generation smart sensing technology in structural health monitoring. Struct. Control Health Monit. 2019, 26, e2321. [Google Scholar] [CrossRef]

- Kuang, K.S.C.; Quek, S.T.; Koh, C.G.; Cantwell, W.J.; Scully, P.J. Plastic optical fiber sensors for structural health monitoring: A review of recent progress. J. Sens. 2009, 3, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Lynch, J.P. A Summary review of wireless sensors and sensor networks for structural health monitoring. Shock. Vib. Dig. 2006, 38, 91–128. [Google Scholar] [CrossRef] [Green Version]

- Mascarenas, D.L.; Todd, M.D.; Park, G.; Farrar, C. Development of an impedance-based wireless sensor node for structural health monitoring. Smart Mater. Struct. 2007, 16, 2137–2145. [Google Scholar] [CrossRef] [Green Version]

- Park, G.; Sohn, H.; Farrar, C.R.; Inman, D.J. Overview of piezoelectric impedance-based health monitoring and path forward. Shock. Vib. Dig. 2003, 35, 451–463. [Google Scholar] [CrossRef] [Green Version]

- Raghavan, A.; Cesnik, C.E.S. Review of guided-wave structural health monitoring. Shock. Vib. Dig. 2007, 39, 91–114. [Google Scholar] [CrossRef]

- Liu, C.; Park, J.-W.; Spencer, B.F., Jr.; Moon, D.-S.; Fan, J. Sensor fusion for structural tilt estimation using an acceleration-based tilt sensor and a gyroscope. Smart Mater. Struct. 2017, 26, 105005. [Google Scholar] [CrossRef]

- Spencer, B.F.; Ruiz-Sandoval, M.E.; Kurata, N. Smart sensing technology: Opportunities and challenges. Struct. Control Health Monit. 2004, 11, 349–368. [Google Scholar] [CrossRef]

- Lynch, J.P. An overview of wireless structural health monitoring for civil structures. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 365, 345–372. [Google Scholar] [CrossRef]

- Cho, S.; Yun, C.; Lynch, J.P.; Zimmerman, A.T.; Spencer, B.F.; Nagayama, T. Smart wireless sensor technology for structural health monitoring of civil structures. Steel Struct. 2008, 8, 267–275. [Google Scholar]

- Farrar, C.R.; Park, G.; Allen, D.W.; Todd, M.D. Sensor network paradigms for structural health monitoring. Struct. Control Health Monit. 2005, 13, 210–225. [Google Scholar] [CrossRef]

- Rice, J.A.; Mechitov, K.A.; Sim, S.-H.; Spencer, B.F.; Agha, G.A. Enabling framework for structural health monitoring using smart sensors. Struct. Control Health Monit. 2010, 18, 574–587. [Google Scholar] [CrossRef]

- Santos, A.D.; Silva, M.F.; Sales, C.S.; Costa, J.C.; Figueiredo, E. Applicability of linear and nonlinear principal component analysis for damage detection. In Proceedings of the 2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Pisa, Italy, 11–14 May 2015; pp. 869–874. [Google Scholar]

- Faniel, I.; Zimmerman, A. Beyond the data deluge: A research agenda for large-scale data sharing and reuse. Int. J. Digit. Curation 2011, 6, 58–69. [Google Scholar] [CrossRef]

- Cremona, C.; Santos, J. Structural health monitoring as a big-data problem. Struct. Eng. Int. 2018, 28, 243–254. [Google Scholar] [CrossRef]

- Wu, L.; Casciati, F. Local positioning systems versus structural monitoring: A review. Struct. Control Health Monit. 2014, 21, 1209–1221. [Google Scholar] [CrossRef]

- Maksymowicz, M.; Cruz, P.; Bien, J. Load capacity of damaged RC slab spans of railway-bridges. Arch. Civ. Mech. Eng. 2011, 11, 963–978. [Google Scholar] [CrossRef]

- Pieraccini, M.; Fratini, M.; Parrini, F.; Atzeni, C.; Bartoli, G. Interferometric radar vs. accelerometer for dynamic monitoring of large structures: An experimental comparison. NDT E Int. 2008, 41, 258–264. [Google Scholar] [CrossRef]

- Oraczewski, T.; Staszewski, W.J.; Uhl, T. Nonlinear acoustics for structural health monitoring using mobile, wireless and smartphone-based transducer platform. J. Intell. Mater. Syst. Struct. 2015, 27, 786–796. [Google Scholar] [CrossRef]

- Beskhyroun, S.; Wegner, L.D.; Sparling, B.F. New methodology for the application of vibration-based damage detection tech-niques. Struct. Cont. Health Monit. 2011, 19, 88–106. [Google Scholar]

- Ribeiro, D.; Calçada, R.; Ferreira, J.; Martins, T. Non-contact measurement of the dynamic displacement of railway bridges using an advanced video-based system. Eng. Struct. 2014, 75, 164–180. [Google Scholar] [CrossRef]

- Zhou, G.-D.; Yi, T.-H. Thermal load in large-scale bridges: A state-of-the-art review. Int. J. Distrib. Sens. Netw. 2013, 9. [Google Scholar] [CrossRef]

- Lang, X.; Li, P.; Cao, J.T.; Li, Y.; Ren, H. A small leak localization method for oil pipelines based on information fusion. IEEE Sens. J. 2018, 18, 6115–6122. [Google Scholar] [CrossRef]

- Water Sense. LeakFacts. Available online: http://www3.epa.gov/watersense/pubs/fixleak.html (accessed on 30 October 2015).

- Fagiani, M.; Squartini, S.; Gabrielli, L.; Spinsante, S.; Piazza, F. A review of datasets and load forecasting techniques for smart natural gas and water grids: Analysis and experiments. Neurocomputing 2015, 170, 448–465. [Google Scholar] [CrossRef]

- Spinsante, S.; Pizzichini, M.; Mencarelli, M.; Squartini, S.; Gambi, E. Evaluation of the Wireless M-Bus Standard for Future Smart Water Grids. In Proceedings of the Wireless Communications and Mobile Computing Conference, 9th International, Cagliari, Sardinia, Italy, 1–5 July 2013; pp. 1382–1387. [Google Scholar]

- Spinsante, S.; Squartini, S.; Gabrielli, L.; Pizzichini, M.; Gambi, E.; Piazza, F. Wireless m-bus sensor networks for smart water grids: Analysis and results. Int. J. Distrib. Sens. Netw. 2014, 10. [Google Scholar] [CrossRef] [Green Version]

- Ying, Y.; Garrett, J.H.; Oppenheim, I.J.; Soibelman, L.; Harley, J.B.; Shi, J.; Jin, Y. Toward data-driven structural health moni-toring: Application of machine learning and signal processing to damage detection. J. Comp. Civil Eng. 2013, 27, 667–680. [Google Scholar] [CrossRef]

- Chan, T.K.; Chin, C.S.; Zhong, X. Review of current technologies and proposed intelligent methodologies for water distributed network leakage detection. IEEE Access 2018, 6, 78846–78867. [Google Scholar] [CrossRef]

- Markou, M.; Singh, S. Novelty detection: A review—part 1: Statistical approaches. Signal Process. 2003, 83, 2481–2497. [Google Scholar] [CrossRef]

- Markou, M.; Singh, S. Novelty detection: A review-part 2: Neural network-based approaches. Signal Process. 2003, 83, 2499–2521. [Google Scholar] [CrossRef]

- Chis, T. Pipeline Leak Detection Techniques. arXiv 2009, arXiv:0903.4283. [Google Scholar]

- Murvay, P.-S.; Silea, I. A survey on gas leak detection and localization techniques. J. Loss Prev. Process. Ind. 2012, 25, 966–973. [Google Scholar] [CrossRef]

- Amer. API 1130 Computational Pipeline Monitoring; Petroleum Inst.: Washington, DC, USA, 2002. [Google Scholar]

- Abdel-Aleem, M.; Chibelushi, C.; Moniri, M. Multisensory data fusion for the simultaneous location and condition assessment of underground water pipelines. In Proceedings of the 2011 International Conference on Networking, Sensing and Control, ICNSC 2011, Delft, The Netherlands, 11–13 April 2011; pp. 416–421. [Google Scholar]

- Khatir, S.; Dekemele, K.; Loccufier, M.; Khatir, T.; Wahab, M.A. Crack identification method in beam-like structures using changes in experimentally measured frequencies and Particle Swarm Optimization. Comptes Rendus Méc. 2018, 346, 110–120. [Google Scholar] [CrossRef]

- Gillich, G.R.; Abdel Wahab, M.; Yan, R.; Araújo dos Santos, J.V. Damage models, and assessment methods. Shock Vib. 2016, 2016, 1748712. [Google Scholar] [CrossRef]

- Remennikov, A.; Kaewunruen, S. A review of loading conditions for railway track structures due to train and track vertical interaction. Struct. Control Health Monit. 2008, 15, 207–234. [Google Scholar] [CrossRef]

- Santos, J.P.; Crémona, C.; Calado, L.; Silveira, P.; Orcesi, A.D. On-line unsupervised detection of early damage. Struct. Control Health Monit. 2015, 23, 1047–1069. [Google Scholar] [CrossRef]

- Santos, J.P.; Cremona, C.; Silveira, P.; Calado, L. Real-time damage detection based on pattern recognition. Struct. Concr. 2016, 17, 338–354. [Google Scholar]

- Jayawardhana, M.; Zhu, X.; Liyanapathirana, R. An experimental study on distributed damage detection algorithms for structural health monitoring. J. Phys. Conf. Ser. 2011, 305, 012068. [Google Scholar] [CrossRef] [Green Version]

- Vitola, J.; Tibaduiza, D.; Anaya, M.; Pozo, F. Structural damage detection and classification based on machine learning algo-rithms. In Proceedings of the 8th European Workshop on Structural Health Monitoring (EWSHM 2016), Bilbao, Spain, 5–8 July 2016; pp. 5–8. [Google Scholar]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Heidarrezaei, M.; Koloor, S.S.R.; Petru, M. Application of the subspace-based methods in health monitoring of civil structures: A systematic review and meta-analysis. Appl. Sci. 2020, 10, 3607. [Google Scholar] [CrossRef]

- Farrar, C.; Worden, K. An introduction to structural health monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 365, 303–315. [Google Scholar] [CrossRef] [PubMed]

- Glaser, S.D.; Tolman, A. Sense of sensing: From data to informed decisions for the built environment. J. Infrastruct. Syst. 2008, 14, 4–14. [Google Scholar] [CrossRef] [Green Version]

- Posenato, D.; Lanata, F.; Inaudi, D.; Smith, I.F. Model-free data interpretation for continuous monitoring of complex structures. Adv. Eng. Inform. 2008, 22, 135–144. [Google Scholar] [CrossRef]

- Mosalam, K.; Muin, S.; Gao, Y. New directions in structural health monitoring. NED Univ. J. Res. 2019, 2, 77–112. [Google Scholar] [CrossRef]

- An, Y.; Chatzi, E.; Sim, S.; Laflamme, S.; Blachowski, B.; Ou, J. Recent progress and future trends on damage identification methods for bridge structures. Struct. Control Health Monit. 2019, 26, e2416. [Google Scholar] [CrossRef]

- Khaleghi, B.; Khamis, A.; Karray, F.O.; Razavi, S.N. Multisensor data fusion: A review of the state-of-the-art. Inf. Fusion 2013, 14, 28–44. [Google Scholar] [CrossRef]

- Aalsalem, Y.M.; Khan, W.Z.; Gharibi, W.; Khan, M.K.; Arshad, Q. Wireless sensor networks in the oil and gas industry: Recent advances, taxonomy, requirements, and open challenges. J. Netw. Comput. Appl. 2018, 113, 87–97. [Google Scholar] [CrossRef]

- Yuen, K.-V.; Lam, H.F. On the complexity of artificial neural networks for smart structures monitoring. Eng. Struct. 2006, 28, 977–984. [Google Scholar] [CrossRef]

- González, M.P.; Zapico, J.L. Seismic damage identification in buildings using neural networks and modal data. Comput. Struct. 2008, 86, 416–426. [Google Scholar] [CrossRef]

- Lam, H.F.; Ng, C.T. The selection of pattern features for structural damage detection using an extended Bayesian ANN algo-rithm. Eng. Struct. 2008, 30, 2762–2770. [Google Scholar] [CrossRef] [Green Version]

- Rucka, M.; Wilde, K. Neuro-wavelet damage detection technique in beam, plate and shell structures with experimental vali-dation. J. Theor. Appl. Mech. 2010, 48, 579–604. [Google Scholar]

- Betti, M.; Facchini, L.; Biagini, P. Damage detection on a three-story steel frame using artificial neural networks and genetic algorithms. Meccanica 2015, 50, 875–886. [Google Scholar] [CrossRef]

- Chappell’s, D. Introduction for Technical Professionals White Paper. Available online: http://download.microsoft.com/down-load/3/B/9/3B9FBA69-8AAD-4707-830F6C70A545C389/ntroducing_Azure_Machine_Learning.pdf (accessed on 1 March 2021).

- Sarkar, S.; Reddy, K.K.; Giering, M.; Gurvich, M.R. Deep learning for structural health monitoring: A damage characterization application. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Denver, CO, USA, 3–6 October 2016. [Google Scholar]

- Abdeljaber, O.; Avci, O.; Kiranyaz, S.; Gabbouj, M.; Inman, D.J. Real-time vibration-based structural damage detection using one-dimensional convolutional neural networks. J. Sound Vib. 2017, 388, 154–170. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Avci, O.; Kiranyaz, M.S.; Boashash, B.; Sodano, H.; Inman, D.J. 1-D CNNs for structural damage detection: Verification on a structural health monitoring benchmark data. Neurocomputing 2018, 275, 1308–1317. [Google Scholar] [CrossRef]

- Cha, Y.; Choi, W.; Büyüköztürk, O. Deep learning-based crack damage detection using convolutional neural networks. Comput. Civ. Infrastr. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Gulgec, N.S.; Takáč, M.; Pakzad, S.N. Structural damage detection using convolutional neural networks. Model Valid. Uncertain. Quantif. 2017, 3, 331–337. [Google Scholar] [CrossRef]

- Lee, S.; Ha, J.; Zokhirova, M.; Moon, H.; Lee, J. Background information of deep learning for structural engineering. Arch. Comput. Methods Eng. 2017, 25, 121–129. [Google Scholar] [CrossRef]

- Na, Y.; El-Tawil, S.; Ibrahim, A.; Eltawil, A.; Soules, J.G. The feasibility of using smart devices for quantifying seismic damage to buildings. Struct. Congr. 2017, 145–154. [Google Scholar] [CrossRef]

- Alzughaibi, A.A.; Ibrahim, A.; Eltawil, A.M.; Na, Y.; El-Tawil, S. Post-disaster structural health monitoring system using personal mobile-phones. In Proceedings of the 2019 IEEE Topical Conference on Wireless Sensors and Sensor Networks (WiSNet), Orlando, FL, USA, 20–23 January 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Na, Y.; El-Tawil, S.; Ibrahim, A.; Eltawil, A. Dynamic behavior of a smart device on a surface subjected to earthquake motion. Earthq. Eng. Struct. Dyn. 2018, 47, 1905–1920. [Google Scholar] [CrossRef]

- Kong, Q.; Allen, R.M.; Kohler, M.D.; Heaton, T.H.; Bunn, J. Structural health monitoring of buildings using smartphone sen-sors. Seismol. Res. Lett. 2018, 89, 594–602. [Google Scholar] [CrossRef]

- Moughty, J.J.; Casas, J.R. A state-of-the-art review of modal-based damage detection in bridges: Development, challenges, and solutions. Appl. Sci. 2017, 7, 510. [Google Scholar] [CrossRef] [Green Version]

- Billman, L.; Isermann, R. Leak detection methods for pipelines. Automatica 1987, 23, 381–385. [Google Scholar] [CrossRef]

- Laurentys, C.; Bomfim, C.; Menezes, B.; Caminhas, W. Design of a pipeline leakage detection using expert system: A novel approach. Appl. Soft Comput. 2011, 11, 1057–1066. [Google Scholar] [CrossRef]

- Chen, H.; Ye, H.; Lv, C.; Su, H. Application of support vector machine learning to leak detection and location in pipelines. In Proceedings of the 21st IEEE Instrumentation and Measurement Technology Conference, Como, Italy, 18–20 May 2004. [Google Scholar] [CrossRef]

- Qu, Z.; Feng, H.; Zeng, Z.; Zhuge, J.; Jin, S. A SVM-based pipeline leakage detection and pre-warning system. Measurement 2010, 43, 513–519. [Google Scholar] [CrossRef]

- Wan, J.; Yu, Y.; Wu, Y.; Feng, R.; Yu, N. Hierarchical leak detection and localization method in natural gas pipeline monitoring sensor networks. Sensors 2011, 12, 189–214. [Google Scholar] [CrossRef] [Green Version]

- Nasir, M.T.; Mysorewala, M.; Cheded, L.; Siddiqui, B.; Sabih, M. Measurement error sensitivity analysis for detecting and locating leak in pipeline using ANN and SVM. In Proceedings of the 2014 IEEE 11th International Multi-Conference on Systems, Signals & Devices (SSD14), Barcelona, Spain, 11–14 February 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Fagiani, M.; Squartini, S.; Severini, M.; Piazza, F. A novelty detection approach to identify the occurrence of leakage in smart gas and water grids. In Proceedings of the 2015 International Joint Conference on Neural Networks (IJCNN), Killarney, Ireland, 12–16 July 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Goyal, M.K.; Ojha, C.S.P.; Burn, D.H. Machine learning algorithm and their application in water resources management. In Sustainable Water Resources Management; Springer: Gewerbestr, Switzerland, 2017; pp. 165–178. [Google Scholar] [CrossRef]

- Gupta, K.; Kishore, K.; Jain, S.C. Modeling and simulation of CEERI’s water distribution network to detect leakage using HLR approach. In Proceedings of the 2017 6th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 20–22 September 2017; pp. 289–294. [Google Scholar] [CrossRef]

- Gupta, G. Monitoring Water Distribution Network using Machine Learning; KTH Royal Institute of Sweden: Stockholm, Sweden, 2017. [Google Scholar]

- Shi, F.; Liu, Z.; Li, E. Prediction of pipe performance with ensemble machine learning based approaches. In Proceedings of the 2017 International Conference on Sensing, Diagnostics, Prognostics, and Control (SDPC), Shanghai, China, 16–18 August 2017; pp. 408–414. [Google Scholar] [CrossRef]

- Adedeji, K.B.; Hamam, Y.; Abe, B.T.; Abu-Mahfouz, A.M. Towards achieving a reliable leakage detection and localization algorithm for application in water piping networks: An overview. IEEE Access 2017, 5, 20272–20285. [Google Scholar] [CrossRef]

- Kang, J.; Park, Y.-J.; Lee, J.; Wang, S.-H.; Eom, D.-S. Novel leakage detection by ensemble CNN-SVM and graph-based localization in water distribution systems. IEEE Trans. Ind. Electron. 2017, 65, 4279–4289. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, X.; Yuting, L.; Yong, T.; Yinghui, Z.; Jing, G. Water pipeline leakage detection based on machine learning and wireless sensor networks. Sensors 2019, 19, 5086. [Google Scholar] [CrossRef] [Green Version]

- Fuentes, V.C., Jr.; Pedrasa, J.R.I. Leak detection in water distribution networks via pressure analysis using a machine learning ensemble. In Proceedings of the International Conference on Society with Future: Smart and Liveable Cities, Braga, Portugal, 4–6 December 2019; pp. 1–44. [Google Scholar]

- Baroudi, U.; Al-Roubaiey, A.A.; Devendiran, A. Pipeline leak detection systems and data fusion: A survey. IEEE Access 2019, 7, 97426–97439. [Google Scholar] [CrossRef]

- Azimi, M.; Pekcan, G. Structural health monitoring using extremely compressed data through deep learning. Comput. Civ. Infrastruct. Eng. 2019, 35, 597–614. [Google Scholar] [CrossRef]

- Xu, Y.; Brownjohn, J.; Kong, D. A non-contact vision-based system for multipoint displacement monitoring in a cable-stayed footbridge. Struct. Control Health Monit. 2018, 25, e2155. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Nagarajaiah, S. Dynamic imaging: Real-time detection of local structural damage with blind separation of low-rank background and sparse innovation. J. Struct. Eng. 2016, 142, 04015144. [Google Scholar] [CrossRef]

- Huňady, R.; Hagara, M.; Schrotter, M. Using high-speed digital image correlation to determine the damping ratio. Procedia Eng. 2012, 48, 242–249. [Google Scholar] [CrossRef] [Green Version]

- Helfrick, M.; Niezrecki, C.; Avitabile, P. Curvature methods of damage detection using digital image correlation. Health Monit. Struct. Biol. Syst. 2009, 7295, 72950D. [Google Scholar]

- Feng, M.Q.; Fukuda, Y.; Feng, D.; Mizuta, M. Nontarget vision sensor for remote measurement of bridge dynamic response. J. Bridg. Eng. 2015, 20, 04015023. [Google Scholar] [CrossRef]

- Luo, L.; Feng, M.Q.; Wu, Z.Y. Robust vision sensor for multi-point displacement monitoring of bridges in the field. Eng. Struct. 2018, 163, 255–266. [Google Scholar] [CrossRef]

- Xu, Y.; Li, S.; Zhang, D.; Jin, Y.; Zhang, F.; Li, N.; Li, H. Identification framework for cracks on a steel structure surface by a restricted Boltzmann machines algorithm based on consumer-grade camera images. Struct. Control Health Monit. 2017, 25, e2075. [Google Scholar] [CrossRef]

- Zhou, M.; Pan, Z.; Liu, Y.; Zhang, Q.; Cai, Y.; Pan, H. Leak Detection and Location Based on ISLMD and CNN in a Pipeline. IEEE Access 2019, 7, 30457–30464. [Google Scholar] [CrossRef]

- Xu, Y.; Brownjohn, J.M.W. Review of machine-vision based methodologies for displacement measurement in civil structures. J. Civ. Struct. Health Monit. 2017, 8, 91–110. [Google Scholar] [CrossRef] [Green Version]

- Bell, S.E.; Gaylord, S.; Goudreau, A.; White, D. Instrumentation, Digital Image Correlation, and Modelling to Monitor Bridge Behavior and Condition Assessment; FHWA-NH-RD-15680L; U.S. Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2015.

- Radopoulou, S.C.; Brilakis, I. Automated detection of multiple pavement defects. J. Comp. Civ. Eng. 2016, 31, 4016057. [Google Scholar] [CrossRef] [Green Version]

- Radopoulou, S.C.; Brilakis, I. Parking camera calibration for assisting automated road defect detection. In Proceedings of the 16th International Conference on Computing in Civil and Building Engineering, Osaka, Japan, 6–8 July 2016. [Google Scholar]

- Park, C.Y.; Kim, J.H.; Jun, S.-M. A structural health monitoring project for a composite unmanned aerial vehicle wing: Overview and evaluation tests. Struct. Control Health Monit. 2012, 19, 567–579. [Google Scholar] [CrossRef]

- Oh, W.-B.; Kim, I.-S.; Yun, T.-J.; Lee, B.-R.; Lee, C.-W.; Park, K.-Y.; Jin, B.-J.; Lee, Y.-C. A Study on the prediction of real-time bead width using a DNN algorithm in GTA welding. J. Weld. Join. 2020, 38, 593–601. [Google Scholar] [CrossRef]

- Kim, M.S.; Shin, S.M.; Kim, D.H.; Rhee, S. A study on the algorithm for determining back bead generation in GMA welding using deep learning. J. Weld. Join. 2018, 36, 74–81. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.; Kim, J.-W. Review on mitigation of welding-induced distortion based on FEM analysis. J. Weld. Join. 2020, 38, 56–66. [Google Scholar] [CrossRef] [Green Version]

- Go, B.-S.; You, H.; Bang, H.-S.; Kim, C. Penetration depth modeling and process parameter maps for laser welds using machine learning. J. Weld. Join. 2021, 39, 392–401. [Google Scholar] [CrossRef]

- Lee, K.; Yi, S.; Hyun, S.; Kim, C. Review on the recent welding research with application of CNN-based deep learning part II: Model evaluation and visualizations. J. Weld. Join. 2021, 39, 20–26. [Google Scholar] [CrossRef]

- Lee, K.; Kang, S.; Kang, M.; Yi, S.; Hyun, S.; Kim, C. Modeling of laser welds using machine learning algorithm Part I: Penetration depth for laser overlap Al/Cu dissimilar metal welds. J. Weld. Join. 2021, 39, 27–35. [Google Scholar] [CrossRef]

- You, H.; Kang, M.; Yi, S.; Hyun, S.; Kim, C. Modeling of laser welds using machine learning algorithm Part II: Geometry and mechanical behaviors of laser overlap welded high strength steel sheets. J. Weld. Join. 2021, 39, 36–44. [Google Scholar] [CrossRef]

- Koo, C.-D.; Yang, H.-S.; Kim, M.-N. Bead visualization using spline algorithm. J. Weld. Join. 2016, 34, 54–58. [Google Scholar] [CrossRef] [Green Version]

- Oh, B.K.; Hwang, J.W.; Kim, Y.; Cho, T.; Park, H.S. Vision-based system identification technique for building structures using a motion capture system. J. Sound Vib. 2015, 356, 72–85. [Google Scholar] [CrossRef]

- Dworakowski, Z.; Kohut, P.; Gallina, A.; Holak, K.; Uhl, T. Vision-based algorithms for damage detection and localization in structural health monitoring. Struct. Control Health Monit. 2015, 23, 35–50. [Google Scholar] [CrossRef]

- Ye, X.; Yi, T.; Dong, C.; Liu, T. Vision-based structural displacement measurement: System performance evaluation and in-fluence factor analysis. Measurement 2016, 88, 372–384. [Google Scholar] [CrossRef] [Green Version]

- Santos, C.A.; Costa, C.O.; Batista, J. A vision-based system for measuring the displacements of large structures: Simultaneous adaptive calibration and full motion estimation. Mech. Syst. Signal. Process. 2016, 72–73, 678–694. [Google Scholar] [CrossRef]

- Yang, Y.; Dorn, C.; Mancini, T.; Talken, Z.; Kenyon, G.; Farrar, C.; Mascareñas, D. Blind identification of full-field vibration modes from video measurements with phase-based video motion magnification. Mech. Syst. Signal. Process. 2017, 85, 567–590. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, X.B. Image analyses for video-based remote structure vibration monitoring system. Front. Struct. Civ. Eng. 2016, 10, 12–21. [Google Scholar] [CrossRef]

- Fukuda, Y.; Feng, M.Q.; Shinozuka, M. Cost-effective vision-based system for monitoring dynamic response of civil engineering structures. Struct. Control Health Monit. 2010, 17, 918–936. [Google Scholar] [CrossRef]

- Wu, L.-J.; Casciati, F.; Casciati, S. Dynamic testing of a laboratory model via vision-based sensing. Eng. Struct. 2014, 60, 113–125. [Google Scholar] [CrossRef]

- Yoon, H.; Elanwar, H.; Choi, H.; Golparvar, F.M.; Spencer, B.F. Target free approach for vision based structural system iden-tification using consumer grade cameras. Struct. Control Health Monit. 2016, 23, 1405–1416. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Identification of structural stiffness and excitation forces in time domain using noncontact vision-based displacement measurement. J. Sound Vib. 2017, 406, 15–28. [Google Scholar] [CrossRef]

- Seventekidis, P.; Giagopoulos, D.; Arailopoulos, A.; Markogiannaki, O. Structural Health Monitoring using deep learning with optimal finite element model generated data. Mech. Syst. Signal Process. 2020, 145, 106972. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Yu, Y.; Luo, X.; Huang, T.; Yang, X. Automatic pixel-level crack detection and measurement using fully convolutional network. Comput. Civ. Infrastruct. Eng. 2018, 33, 1090–1109. [Google Scholar] [CrossRef]

- Chen, J.G.; Wadhwa, N.; Cha, Y.-J.; Durand, F.; Freeman, W.T.; Buyukozturk, O. Modal identification of simple structures with high-speed video using motion magnification. J. Sound Vib. 2015, 345, 58–71. [Google Scholar] [CrossRef]

- Chen, J.G.; Davis, A.; Wadhwa, N.; Durand, F.; Freeman, W.T.; Büyüköztürk, O. Video camera-based vibration measurement for civil infrastructure applications. J. Infrast. Syst. 2016, 23, 1–11. [Google Scholar] [CrossRef]

- Chen, Y.L.; Abdelbarr, M.; Jahanshahi, M.R.; Masri, S.F. Color and depth data fusion using an RGB-D sensor for inexpensive and contactless dynamic displacement-field measurement. Struct. Control Health Monit. 2017, 24, 1–14. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Vision-based multipoint displacement measurement for structural health monitoring. Struct. Control Health Monit. 2015, 23, 876–890. [Google Scholar] [CrossRef]

- Kromanis, R.; Al-Habaibeh, A. Low-cost vision-based systems using smartphones for measuring deformation in structures for condition monitoring and asset management. In Proceedings of the 8th International Conference on Structural Health Mon-itoring of Intelligent Infrastructure, Brisbane, Australia, 5–8 December 2017. [Google Scholar]

- Poozesh, P.; Sarrafi, A.; Mao, Z.; Niezrecki, C. Modal parameter estimation from optically-measured data using a hybrid output-only system identification method. Measurement 2017, 110, 134–145. [Google Scholar] [CrossRef]

- Molina, V.A.; Felipe Sesé, L.; López, A.E.; Díaz, F. High frequency mode shapes characterisation using digital image correlation and phase-based motion magnification. Mech. Syst. Sign. Proc. 2018, 102, 245–261. [Google Scholar] [CrossRef]

- Kim, S.; Jeon, B.-G.; Cheung, J.-H.; Kim, S.-D.; Park, J.-B. Stay cable tension estimation using a vision-based monitoring system under various weather conditions. J. Civ. Struct. Health Monit. 2017, 7, 343–357. [Google Scholar] [CrossRef]

- Zhou, H.; Zheng, J.; Xie, Z.; Lu, L.; Ni, Y.-Q.; Ko, J. Temperature effects on vision measurement system in long-term continuous monitoring of displacement. Renew. Energy 2017, 114, 968–983. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. Single-camera high-speed stereo-digital image correlation for full-field vibration measurement. Mech. Syst. Signal. Process. 2017, 94, 374–383. [Google Scholar] [CrossRef]

- Yeum, C.M.; Choi, J.; Dyke, S.J. Autonomous image localization for visual inspection of civil infrastructure. Smart Mater. Struct. 2017, 26, 035051. [Google Scholar] [CrossRef]

- Yongchao, Y.; Charles, D.; Tyler, M.; Zachary, T.; Satish, N.; Garrett, K.; Charles, F.; David, M. Blind identification of full field vibration modes of output only structures from uniformly sampled, possibly temporally aliased (sub-Nyquist), video measurements. J. Sound Vib. 2017, 390, 232–256. [Google Scholar]

- Oh, B.K.; Kim, D.; Park, H.S. modal response-based visual system identification and model updating methods for building structures. Comput. Civ. Infrastruct. Eng. 2016, 32, 34–56. [Google Scholar] [CrossRef]

- Javh, J.; Slavič, J.; Boltežar, M. High frequency modal identification on noisy high-speed camera data. Mech. Syst. Signal. Process. 2018, 98, 344–351. [Google Scholar] [CrossRef]

- Javh, J.; Slavič, J.; Boltežar, M. Measuring full-field displacement spectral components using photographs taken with a DSLR camera via an analogue Fourier integral. Mech. Syst. Signal. Process. 2018, 100, 17–27. [Google Scholar] [CrossRef]

- Khuc, T.; Catbas, F.N. Structural identification using computer vision–based bridge health monitoring. J. Struct. Eng. 2018, 144, 04017202. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Computer vision for SHM of civil infrastructure: From dynamic response measurement to damage de-tection—A review. Eng. Struct. 2018, 156, 105–117. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, H.; Yu, Y.; Zhu, Q.; Hu, W.; Li, M.; Ou, J. Displacement monitoring technique using a smartphone based on the laser projection-sensing method. Sens. Actuators A Phys. 2016, 246, 35–47. [Google Scholar] [CrossRef]

- Kumar, S.; Mallik, S.; Ekere, N.; Jung, J.P. Stencil printing behavior of lead-free Sn-3Ag-0.5Cu solder paste for wafer level bumping for sub-100 µm size solder bumps. Met. Mater. Int. 2013, 19, 1083–1090. [Google Scholar] [CrossRef]

- Nishida, H. Committee of system integration packaging. Prospects of system integration technologies for evolving AI and IoT. J. Jpn. Inst. Electron. Packag. 2019, 22, 43–47. [Google Scholar]

- Lie, S. Wafer scale deep learning. In Proceedings of the IEEE Hot Chips 31 Symposium (HCS), Cupertino, CA, USA, 18–20 August 2019; ISBN 978-1-7281-2089. [Google Scholar]

- Nishida, H. Packaging technologies for HPC/AI applications in new intelligence era. J. Jpn. Inst. Electron. Packag. 2020, 23, 562–572. [Google Scholar] [CrossRef]

- Imam, N.l.; Cleland, T.A. Rapid online learning and robust recall in a neuromorphic olfactory circuit. Nat. Mach. Intel. 2020, 2, 181–191. [Google Scholar] [CrossRef]

- Dunbar, G.E.; Shen, B.Y.; Aref, A.A. The Sensimed Triggerfish contact lens sensor: Efficacy, safety, and patient perspectives. Clin. Ophthalmol. 2017, ume 11, 875–882. [Google Scholar] [CrossRef] [Green Version]

- Hayashi, K.; Arata, S.; Murakami, S.; Nishio, Y.; Kobayashi, A.; Niitsu, K. A 6.1-nA Fully integrated CMOS supply modulated OOK transmitter in 55-nm DDC CMOS for glasses-free, self-powered, and fuel-cell-embedded continuous glucose monitoring contact lens. IEEE Trans. Circuits Syst. II Express Briefs 2018, 65, 1360–1364. [Google Scholar] [CrossRef]

- Wang, N.; Ri, K.; Liu, H.; Zhao, X. Structural displacement monitoring using smartphone camera and digital image correlation. IEEE Sens. J. 2018, 18, 4664–4672. [Google Scholar] [CrossRef]

- Zeng, H.; Park, H.; Smith, B.L.; Parkany, E. Feasibility assessment of a smartphone-based application to estimate road roughness. KSCE J. Civ. Eng. 2017, 22, 3120–3129. [Google Scholar] [CrossRef]

- Zhao, X.; Han, R.; Ding, Y.; Yu, Y.; Guan, Q.; Hu, W.; Li, M.; Ou, J. Portable and convenient cable force measurement using smartphone. J. Civ. Struct. Health Monit. 2015, 5, 481–491. [Google Scholar] [CrossRef]

- Zhao, X.; Ri, K.; Han, R.; Yu, Y.; Li, M.; Ou, J. Experimental research on quick structural health monitoring technique for bridges using smartphone. Adv. Mater. Sci. Eng. 2016, 2016, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Han, R.; Yu, Y.; Hu, W.; Jiao, D.; Mao, X.; Li, M.; Ou, J. Smartphone-based mobile testing technique for quick bridge cable–force measurement. J. Bridge Eng. 2017, 22, 06016012. [Google Scholar] [CrossRef]

- Zhang, D.; Tian, J.; Li, H. Design and validation of android smartphone based wireless structural vibration monitoring system. Sensors 2020, 20, 4799. [Google Scholar] [CrossRef]

- Roca, D.; Lagüela, S.; Díaz-Vilariño, L.; Armesto, J.; Arias, P. Low-cost aerial unit for outdoor inspection of building façades. Autom. Constr. 2013, 36, 128–135. [Google Scholar] [CrossRef]

- Dobson, R.J.; Brooks, C.; Roussi, C.; Colling, T.; Brooks, C.L. Developing an unpaved road assessment system for practical deployment with high-resolution optical data collection using a helicopter UAV. In Proceedings of the 2013 International Conference on Unmanned Aircraft Systems (ICUAS), Atlanta, GA, USA, 28–31 May 2013; pp. 235–243. [Google Scholar] [CrossRef]

- Yu, Y.; Zhao, X.; Ou, J. A new idea: Mobile structural health monitoring using smartphones. In Proceedings of the Third International Conference on Intelligent Control and Information Processing, Dalian, China, 15–17 July 2012. [Google Scholar]

- Zhao, X.; Yu, Y.; Li, M.; Ou, J. Research on Cloud-SHM and its applications. In Proceedings of the 7th International Conference on Structural Health Monitoring of Intelligent Infrastructure (SHMII-7), Torino, Italy, 1–3 July 2015. [Google Scholar]

- Yu, Y.; Han, R.; Zhao, X.; Mao, X.; Hu, W.; Jiao, D.; Li, M.; Ou, J. Initial validation of mobile-structural health monitoring method using smartphones. Int. J. Distrib. Sens. Netw. 2015, 11, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Dong, C.-Z.; Catbas, F.N. A review of computer vision–based structural health monitoring at local and global levels. Struct. Health Monit. 2020, 20, 692–743. [Google Scholar] [CrossRef]

- Wang, L.; Dang, J.; Wang, X.; Shrestha, A. Waveform-based fracture identification of steel beam ends using convolutional neural networks. Struct. Control Health Monit. 2021, 28, 9. [Google Scholar] [CrossRef]

- Metni, N.; Hamel, T. A UAV for bridge inspection: Visual servoing control law with orientation limits. Autom. Constr. 2007, 17, 3–10. [Google Scholar] [CrossRef]

- Rathinam, S.; Kim, Z.W.; Sengupta, R. Vision-Based Monitoring of Locally Linear Structures Using an Unmanned Aerial Vehicle. J. Infrastruct. Syst. 2008, 14, 52–63. [Google Scholar] [CrossRef]

- Zhang, C.; Elaksher, A. An unmanned aerial vehicle-based imaging system for 3d measurement of unpaved road surface distresses. Comput. Civ. Infrastruct. Eng. 2011, 27, 118–129. [Google Scholar] [CrossRef]

- Sreenath, S.; Malik, H.; Husnu, N.; Kalaichelavan, K. Assessment and Use of Unmanned Aerial Vehicle for Civil Structural Health Monitoring. Proc. Comp. Sci. 2020, 170, 656–663. [Google Scholar] [CrossRef]

- Eschmann, C.; Kuo, C.M.; Kuo, C.H.; Boller, C. Unmanned aircraft systems for remote building inspection and monitoring. In Proceedings of the 6th European Workshop on Structural Health Monitoring, Dresden, Germany, 3–6 July 2013; pp. 1–8. [Google Scholar]

- Ortiz, P.; Vazquez, M.A.; Martin, J.M.; Aparicio, P.; Ferruz, J.; Ollero, A. The diagnosis of the royal tobacco factory of seville assisted by quad rotor helicopter. In Proceedings of the RICH 2012 1st Conference on Robotics Innovation for Cultural Heritage, Venice, Italy, 3–4 December 2012. [Google Scholar]

- Ellenberg, A.; Branco, L.; Krick, A.; Bartoli, I.; Kontsos, A. Use of unmanned aerial vehicle for quantitative infrastructure evaluation. J. Infrastruct. Syst. 2015, 21, 04014054. [Google Scholar] [CrossRef]

- Galarreta, J.F.; Kerle, N.; Gerke, M. UAV-based urban structural damage assessment using object-based image analysis and semantic reasoning. Nat. Hazards Earth Syst. Sci. 2015, 15, 1087–1101. [Google Scholar] [CrossRef] [Green Version]

- Hallermann, N.; Morgenthal, G.; Rodehorst, V. Unmanned aerial systems (UAS)—Case studies of vision-based monitoring of ageing structures. In Proceedings of the International Symposium Non-Destructive Testing in Civil Engineering, Berlin, Germany, 15–17 September 2015. [Google Scholar]

- Sankarasrinivasan, S.; Balasubramanian, E.; Karthik, K.; Chandrasekar, U.; Gupta, R. Health monitoring of civil structures with integrated UAV and image processing system. Procedia Comput. Sci. 2015, 54, 508–515. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Kong, H.; Wei, L.; Creighton, D.; Nahavandi, S. Efficient road detection and tracking for unmanned aerial vehicle. IEEE Trans. Intell. Transp. Syst. 2014, 16, 297–309. [Google Scholar] [CrossRef]

- Cho, O.H.; Kim, J.C.; Kim, E.K. Context-aware high-rise structure cracks image monitoring system using unmanned aerial vehicles. Int. J. Control. Autom. 2016, 9, 11–18. [Google Scholar] [CrossRef]

- Ham, Y.; Han, K.K.; Lin, J.J.; Golparvar Fard, M. Visual monitoring of civil infrastructure systems via camera equipped un-manned aerial vehicles (UAVs): A review of related works. Vis. Eng. 2016, 4, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Na, W.S.; Baek, J. Impedance-based non-destructive testing method combined with unmanned aerial vehicle for structural health monitoring of civil infrastructures. Appl. Sci. 2016, 7, 15. [Google Scholar] [CrossRef] [Green Version]

- Franke, K.; Rollins, K.M.; Ledezma, C.; Hedengren, J.D.; Wolfe, D.; Ruggles, S.; Bender, C.; Reimschiissel, B. Reconnaissance of two liquefaction sites using small unmanned aerial vehicles and structure from motion computer vision following the April 1, 2014 Chile earthquake. J. Geotech. Geoenviron. Eng. 2017, 143, 04016125. [Google Scholar] [CrossRef]

- Qidwai, U.; Akbar, M.A. Coordinated robotic system for civil structural health monitoring. MATEC Web Conf. 2017, 120, 01003. [Google Scholar] [CrossRef] [Green Version]

- Reagan, D.; Sabato, A.; Niezrecki, C. Unmanned aerial vehicle acquisition of three-dimensional digital image correlation measurements for structural health monitoring of bridges. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Portland, OR, USA, 25–29 March 2017; p. 1016909. [Google Scholar] [CrossRef]

- Reagan, D.; Sabato, A.; Niezrecki, C. Feasibility of using digital image correlation for unmanned aerial vehicle structural health monitoring of bridges. Struct. Health Monit. 2017, 17, 1056–1072. [Google Scholar] [CrossRef]

- Chiu, W.; Ong, W.; Kuen, T.; Courtney, F. Large structures monitoring using unmanned aerial vehicles. Procedia Eng. 2017, 188, 415–423. [Google Scholar] [CrossRef]

- Yoon, H.; Shin, J.; Spencer, B.F. Structural displacement measurement using an unmanned aerial system. Comput. Civ. Infrastruct. Eng. 2017, 33, 183–192. [Google Scholar] [CrossRef]

- Morgenthal, G.; Hallermann, N. Quality assessment of unmanned aerial vehicle (UAV) based visual inspection of structures. Adv. Struct. Eng. 2014, 17, 289–302. [Google Scholar] [CrossRef]

- Ellenberg, A.; Kontsos, A.; Moon, F.; Bartoli, I. Bridge related damage quantification using unmanned aerial vehicle imagery. Struct. Control Health Monit. 2016, 23, 1168–1179. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.; Ahn, E.; Cho, S.; Shin, M.; Sim, S.-H. Concrete crack identification using a UAV incorporating hybrid image processing. Sensors 2017, 17, 2052. [Google Scholar] [CrossRef] [Green Version]

- Omar, T.; Nehdi, M.L. Remote sensing of concrete bridge decks using unmanned aerial vehicle infrared thermography. Autom. Constr. 2017, 83, 360–371. [Google Scholar] [CrossRef]

- Germanese, D.; Leone, G.R.; Moroni, D.; Pascali, M.A.; Tampucci, M. Long-term monitoring of crack patterns in historic structures using UAVs and planar markers: A preliminary study. J. Imaging 2018, 4, 99. [Google Scholar] [CrossRef] [Green Version]

- Walker, K. Use of Virtual Visual Sensors in the Determination of Natural Frequencies of Timber Structures for Structural Health Monitoring. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 2015. [Google Scholar]

- Hallermann, N.; Morgenthal, G. Unmanned aerial vehicles (UAV) for the assessment of existing structures. In Proceedings of the 36th International Association for Bridge and Structural Engineering Kolkata Symposium, Zurich, Switzerland, 24–27 September 2013; p. 101. [Google Scholar]

- Sławomir, K.; Krzysztof, S.; Sergiusz, S. Small UAV SHM System Functional Hazard Analysis. J. KONBiN 2021, 51, 33–41. [Google Scholar] [CrossRef]

- Duque, L.; Seo, J.; Wacker, J. Bridge deterioration quantification protocol using UAV. J. Bridg. Eng. 2018, 23, 04018080. [Google Scholar] [CrossRef]

- Bithas, P.S.; Michailidis, E.T.; Nomikos, N.; Vouyioukas, D.; Kanatas, A.G. A Survey on machine-learning techniques for UAV-based communications. Sensors 2019, 19, 5170. [Google Scholar] [CrossRef] [Green Version]

- Mozaffari, M.; Saad, W.; Bennis, M.; Nam, Y.-H.; Debbah, M. A Tutorial on UAVs for wireless networks: Applications, challenges, and open problems. IEEE Commun. Surv. Tutor. 2019, 21, 2334–2360. [Google Scholar] [CrossRef] [Green Version]

- Saleem, M.R.; Park, J.-W.; Lee, J.-H.; Jung, H.-J.; Sarwar, M.Z. Instant bridge visual inspection using an unmanned aerial vehicle by image capturing and geo-tagging system and deep convolutional neural network. Struct. Health Monit. 2020, 20, 1760–1777. [Google Scholar] [CrossRef]

- Bo, L.; Li, X.; Zheng, T.; Gao, W.; Zhang, X.; Wang, X. Research on multi-UAV attack defense confrontation algorithm based on machine learning. Acad. J. Comp. Inf. Sci. 2021, 4, 52–59. [Google Scholar]

- Im, S.B.; Hurlebaus, S.; Kang, Y.J. Summary review of GPS technology for structural health monitoring. J. Struct. Eng. 2013, 139, 1653–1664. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The internet of things: A survey. Comp. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Abdelgawad, A.; Yelamarthi, K. Structural health monitoring: Internet of things application. In Proceedings of the 2016 IEEE 59th International Midwest Symposium on Circuits and Systems (MWSCAS), Abu Dhabi, United Arab Emirates, 16–19 October 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Abdelgawad, A.; Yelamarthi, K. Internet of things (IoT) platform for structure health monitoring. Wirel. Commun. Mob. Comput. 2017, 2017, 1–10. [Google Scholar] [CrossRef]

- Tokognon, C.A.; Gao, B.; Tian, G.Y.; Yan, Y. Structural health monitoring framework based on internet of things: A survey. IEEE Internet Things J. 2017, 4, 619–635. [Google Scholar] [CrossRef]

- Lamonaca, F.; Sciammarella, P.; Scuro, C.; Carni, D.; Olivito, R. Internet of things for structural health monitoring. In Proceedings of the 2018 IEEE International Workshop on Metrology for Industry 4.0 and IoT, Brescia, Italy, 16–18 April 2018; pp. 95–100. [Google Scholar] [CrossRef]

- Mohanty, S.; Choppali, U.; Kougianos, E. Everything you wanted to know about smart cities: The Internet of things is the backbone. IEEE Consum. Electron. Mag. 2016, 5, 60–70. [Google Scholar] [CrossRef]

- Wang, L.; Sng, D. Deep learning algorithms with applications to video analytics for a smart city: A survey. arXiv 2015, arXiv:151203131. [Google Scholar]

- Chin, J.; Callaghan, V.; Lam, I. Understanding and personalizing smart city services using machine learning, the internet of things and big data. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, Scotland, 19–21 June 2017; pp. 2050–2055. [Google Scholar]

- Han, B.; Yu, X.; Ou, J. Self-Sensing Concrete in Smart Structures; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Aza, C.A. Self sensing carbon nanotube (CNT) and nanofiber (CNF) cementitious composites for real time damage assessment in smart structures. Cem. Concr. Compos. 2014, 53, 162–169. [Google Scholar] [CrossRef]

- Gupta, S.; Gonzalez, J.G.; Loh, K.J. Self-sensing concrete enabled by nano-engineered cement-aggregate interfaces. Struct. Health Monit. 2016, 16, 309–323. [Google Scholar] [CrossRef]

- Vitola, J.; Pozo, F.; Tibaduiza, D.A.; Anaya, M. A sensor data fusion system based on k-nearest neighbor pattern classification for structural health monitoring applications. Sensors 2017, 17, 417. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.W.; Choi, H.W. Study on laser welding of Al-Cu dissimilar material by green laser and weld quality evaluation by deep learning. J. Weld. Join. 2021, 39, 67–73. [Google Scholar] [CrossRef]

- Seo, B.W.; Jeong, Y.C.; Cho, Y.T. Machine learning for prediction of arc length for seam tracking in tandem welding. J. Weld. Join. 2020, 38, 241–247. [Google Scholar] [CrossRef]

- Lee, K.; Yi, S.; Hyun, S.; Kim, C. Review on the recent welding research with application of CNN-based deep learning part I: Models and applications. J. Weld. Join. 2021, 39, 10–19. [Google Scholar] [CrossRef]

- Sharma, A.; Lee, S.H.; Ban, H.O.; Shin, Y.S.; Jung, J.-P. Effect of various factors on the brazed joint properties in al brazing technology. J. Weld. Join. 2016, 34, 30–35. [Google Scholar] [CrossRef]

- Kim, M.-S.; Hong, W.S.; Kim, S.Y.; Jeon, S.M.; Moon, J.T. Ultrasonic bonding interface degradation characteristics of gold-coated silver wire for semiconductor packaging. J. Weld. Join. 2021, 39, 343–348. [Google Scholar] [CrossRef]

- Sharma, A.; Jung, D.H.; Cheon, J.S.; Jung, J.P. Epoxy polymer solder pastes for micro-electronic packaging applications. J. Weld. Join. 2019, 37, 7–14. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.S.; Hong, W.S.; Kim, M. Flip chip—Chip scale package bonding technology with type 7 solder paste printing. J. Weld. Join. 2021, 39, 359–367. [Google Scholar] [CrossRef]

- Oh, W.-B.; Kim, I.-S.; Yun, T.-J.; Lee, B.-R.; Lee, C.-W.; Kang, B.-Y.; Shim, J.-Y. A study on the optimization of welding conditions for titanium drums using GPS. J. Weld. Join. 2021, 39, 419–426. [Google Scholar] [CrossRef]

- Wu, C.; Wang, C.; Kim, J.-W. Welding distortion prediction for multi-seam welded pipe structures using equivalent thermal strain method. J. Weld. Join. 2021, 39, 435–444. [Google Scholar] [CrossRef]

- Yoon, J.-W.; Lee, D.-H.; Lee, B.-S. A study of transient liquid phase bonding using an Ag-Sn3. 0Ag0.5Cu hybrid solder paste. J. Weld. Join. 2021, 39, 376–383. [Google Scholar] [CrossRef]

- Hong, W.S.; KIm, M.S.; Kim, M. MLCC Solder joint property with vacuum and hot air reflow soldering processes. J. Weld. Join. 2021, 39, 349–358. [Google Scholar] [CrossRef]

- Terner, M. Innovative 3D-manufacturing of complex ceramic parts by means of commercial digital light processing apparatus. J. Weld. Join. 2019, 37, 369–377. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Qi, H. Numerical simulation of transport phenomena for laser full penetration welding. J. Weld. Join. 2017, 35, 13–22. [Google Scholar] [CrossRef]

- Baghel, P.K.; Nagesh, D.S. Pulse TIG welding: Process, automation and control. J. Weld. Join. 2017, 35, 43–48. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Cheon, J.; Kim, C. Global market analysis for welding power source and welding robot (I). J. Weld. Join. 2020, 38, 300–304. [Google Scholar] [CrossRef]

- Bang, J.-H.; Yu, D.-Y.; Ko, Y.-H.; Yoon, J.-W.; Lee, C.-W. Lead-free solder for automotive electronics and reliability evaluation of solder joint. J. Weld. Join. 2016, 34, 26–34. [Google Scholar] [CrossRef]

- Lee, T.H.; Oh, J.H.; Kam, D.-H. High speed photography for arc welding phenomenon using 808 nm diode laser illumination and optical filter. J. Weld. Join. 2020, 38, 429–434. [Google Scholar] [CrossRef]

- Yun, T.-J.; Park, M.-H.; Oh, W.-B.; Lee, B.-R.; Kim, I.-S. A study on spatter tracking algorithm for a vertical GMA welding process. J. Weld. Join. 2019, 37, 347–356. [Google Scholar] [CrossRef] [Green Version]

- Jin, B.-J.; Park, M.-H.; Yun, T.-J.; Kim, I.-S.; Park, K.-Y.; Kim, Y.; Yang, H.-J. Optimization of disk laser welding parameters in pure ti using taguchi method. J. Weld. Join. 2018, 36, 34–40. [Google Scholar] [CrossRef] [Green Version]

- Jin, B.-J.; Park, M.-H.; Yun, T.-J.; Kim, I.-S.; Park, K.-Y.; Kim, Y.; Yang, H.-J. Optimization of laser welding parameters in titanium sheet using grey-fuzzy logic. J. Weld. Join. 2017, 35, 59–66. [Google Scholar] [CrossRef] [Green Version]

- Kang, M.; Lee, K. Influence of welding variables on indentation depth in ultrasonically welded Al/Cu dissimilar joints and theoretical fracture load estimation. J. Weld. Join. 2020, 38, 289–294. [Google Scholar] [CrossRef]

- Yoo, J.; Ha, Y.; Rajesh, S.R. A Numerical study of the residual hydrogen concentration in the weld Metal. J. Weld. Join. 2016, 34, 42–46. [Google Scholar] [CrossRef] [Green Version]

- SDNET2018: A Concrete Crack Image Dataset for Machine Learning Applications. Available online: https://digitalcommons.usu.edu/all_datasets/48/ (accessed on 9 May 2020).

- Hoskere, V.; Narazaki, Y.; Hoang, T.A.; Spencer, B.F., Jr. Vision-based structural inspection using multiscale deep convolutional neural networks. In Proceedings of the 3rd Huixian International Forum on Earthquake Engineering for Young Researchers, Urbana-Champaign, IL, USA, 11–12 August 2012. [Google Scholar]

- Beckman, G.H.; Polyzois, D.; Cha, Y.-J. Deep learning-based automatic volumetric damage quantification using depth camera. Autom. Constr. 2019, 99, 114–124. [Google Scholar] [CrossRef]

- Bao, Y.; Li, J.; Nagayama, T.; Xu, Y.; Spencer, B.F., Jr.; Li, H. The 1st international project competition for structural health monitoring (IPC-SHM, 2020): A summary and benchmark problem. Struct. Health Monit. 2020, 20, 2229–2239. [Google Scholar] [CrossRef]

- Dung, C.V.; Anh, L.D. Autonomous concrete crack detection using deep fully convolutional neural network. Autom. Constr. 2018, 99, 52–58. [Google Scholar] [CrossRef]

- Lin, Y.; Nie, Z.-H.; Ma, H. Structural damage detection with automatic feature-extraction through deep learning. Comput. Civ. Infrastruct. Eng. 2017, 32, 1025–1046. [Google Scholar] [CrossRef]

- Tung, P.-C.; Hwang, Y.-R.; Wu, M.-C. The development of a mobile manipulator imaging system for bridge crack inspection. Autom. Constr. 2002, 11, 717–729. [Google Scholar] [CrossRef]

- Nahata, D.; Mulchandani, H.; Bansal, S.; Muthukumar, G. Post-earthquake. Assessment. Buildings using deep learning. J. Comput. Civ. Eng. 2019, 8, 330–345. [Google Scholar]

- Ni, F.; Zhang, J.; Chen, Z. Zernike-moment measurement of thin-crack width in images enabled by dual-scale deep learning. Comput.-Aided Civ. Infrastruct. Eng. 2018, 32, 67–69. [Google Scholar] [CrossRef]

- Duarte, D.; Nex, F.; Kerle, N.; Vosselman, G. Multi-resolution feature fusion for image classification of building damages with convolutional neural networks. Remote. Sens. 2018, 10, 1636. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.-C.; Jahanshahi, M.R. NB-CNN: Deep learning-based crack detection using convolutional neural network and naïve bayes data fusion. IEEE Trans. Ind. Electron. 2017, 65, 4392–4400. [Google Scholar] [CrossRef]

- Sharma, M.; Anotaipaiboon, W.; Chaiyasarn, K. Crack Detection in Masonry Structures using Convolutional Neural Networks and Support Vector Machines. In Proceedings of the 35th International Symposium on Automation and Robotics in Construction (ISARC 2018), Berlin, Germany, 20–25 July 2018. [Google Scholar]

- Pathirage, C.S.N.; Li, J.; Li, L.; Hao, H.; Liu, W.; Wang, R. Development and application of a deep learning–based sparse autoencoder framework for structural damage identification. Struct. Health Monit. 2018, 18, 103–122. [Google Scholar] [CrossRef] [Green Version]

- Cha, Y.-J.; Wang, Z. Automated damage-sensitive feature extraction using unsupervised convolutional neural networks. Sens. Smart Struct. Technol. Civ. Mech. Aerosp. Syst. 2018, 10598, 105981J. [Google Scholar] [CrossRef]

- Dorafshan, S.; Maguire, M.; Hoffer, N.V.; Coopmans, C. Fatigue crack detection using unmanned aerial systems in under-bridge inspection. Ida. Transp. Dep. 2017, 2, 1–120. [Google Scholar]

- Jang, K.; Kim, N.; An, Y.-K. Deep learning–based autonomous concrete crack evaluation through hybrid image scanning. Struct. Health Monit. 2018, 18, 1722–1737. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, C.; Gu, X.; Li, J. A novel deep learning-based method for damage identification of smart building structures. Struct. Health Monit. 2018, 18, 143–163. [Google Scholar] [CrossRef] [Green Version]

- Ye, X.-W.; Jin, T.; Chen, P.-Y. Structural crack detection using deep learning–based fully convolutional networks. Adv. Struct. Eng. 2019, 22, 3412–3419. [Google Scholar] [CrossRef]

- Modarres, C.; Astorga, N.; Droguett, E.L.; Meruane, V. Convolutional neural networks for automated damage recognition and damage type identification. Struct. Control Health Monit. 2018, 25, e2230. [Google Scholar] [CrossRef]

- Zhang, T.; Biswal, S.; Wang, Y. SHMnet: Condition assessment of bolted connection with beyond human-level performance. Struct. Health Monit. 2019, 19, 1188–1201. [Google Scholar] [CrossRef]

- Xu, J.; Fu, Z.; Han, Q.; Lacidogna, G.; Carpinteri, A. Micro-cracking monitoring and fracture evaluation for crumb rubber concrete based on acoustic emission techniques. Struct. Health Monit. 2017, 17, 946–958. [Google Scholar] [CrossRef]

- Atha, D.J.; Jahanshahi, M.R. Evaluation of deep learning approaches based on convolutional neural networks for corrosion detection. Struct. Health Monit. 2017, 17, 1110–1128. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, K.C.P.; Fei, Y.; Liu, Y.; Chen, C.; Yang, G.; Li, J.Q.; Yang, E.; Qiu, S. Automated pixel-level pavement crack detection on 3D asphalt surfaces with a recurrent neural network. Comput. Civ. Infrastruct. Eng. 2018, 34, 213–229. [Google Scholar] [CrossRef]

- Silva, W.R.L.d.; Lucena, D.S.d. Concrete cracks detection based on deep learning image classification. In Proceedings of the 18th International Conference on Experimental Mechanics, Brussels, Belgium, 1–5 July 2018; 2001; p. 489. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.S.; Abraham, D.M.; Jahanshahi, M.R.; Iseley, T.; Starr, J. Automated defect classification in sewer closed circuit television inspections using deep convolutional neural networks. Autom. Constr. 2018, 91, 273–283. [Google Scholar] [CrossRef]

- Sharma, V.B.; Singh, K.; Gupta, R.; Joshi, A.; Dubey, R.; Gupta, V.; Bharadwaj, S.; Zafar, M.; Bajpai, S.; Khan, M.A.; et al. Review of structural health monitoring techniques in pipeline and wind turbine industries. Appl. Syst. Innov. 2021, 4, 59. [Google Scholar] [CrossRef]