Development of Hydrometallurgical Process for Recovery of Rare Earth Metals (Nd, Pr, and Dy) from Nd-Fe-B Magnets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Pre-Treatment of Nd-Fe-B Magnets

2.2. Leaching Procedure

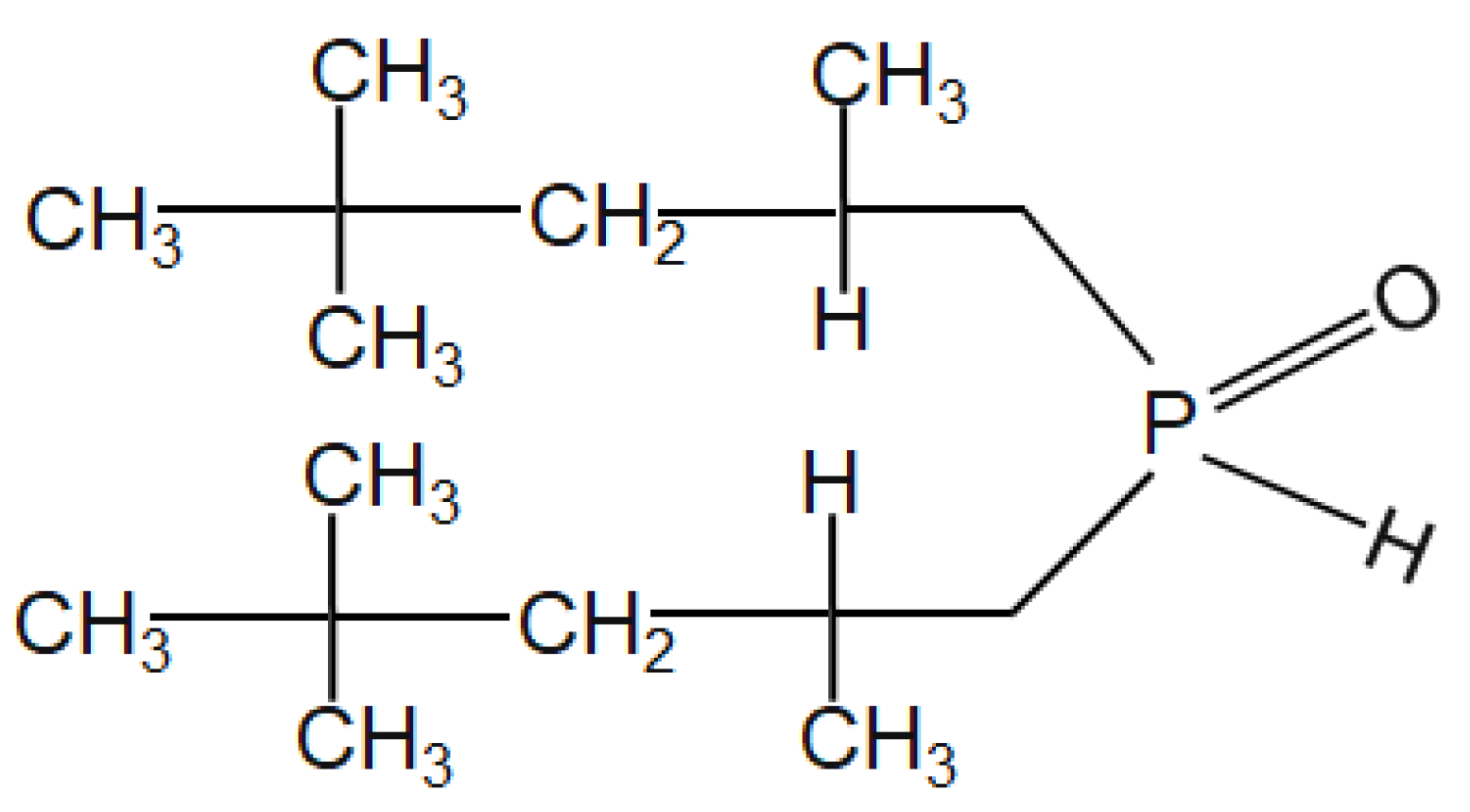

2.3. Solvent Extraction Procedure

2.4. Precipitation Procedure

2.5. Characterization and Analysis of Samples

3. Results and Discussion

3.1. Leaching Study

3.1.1. Effect of Acid Concentration

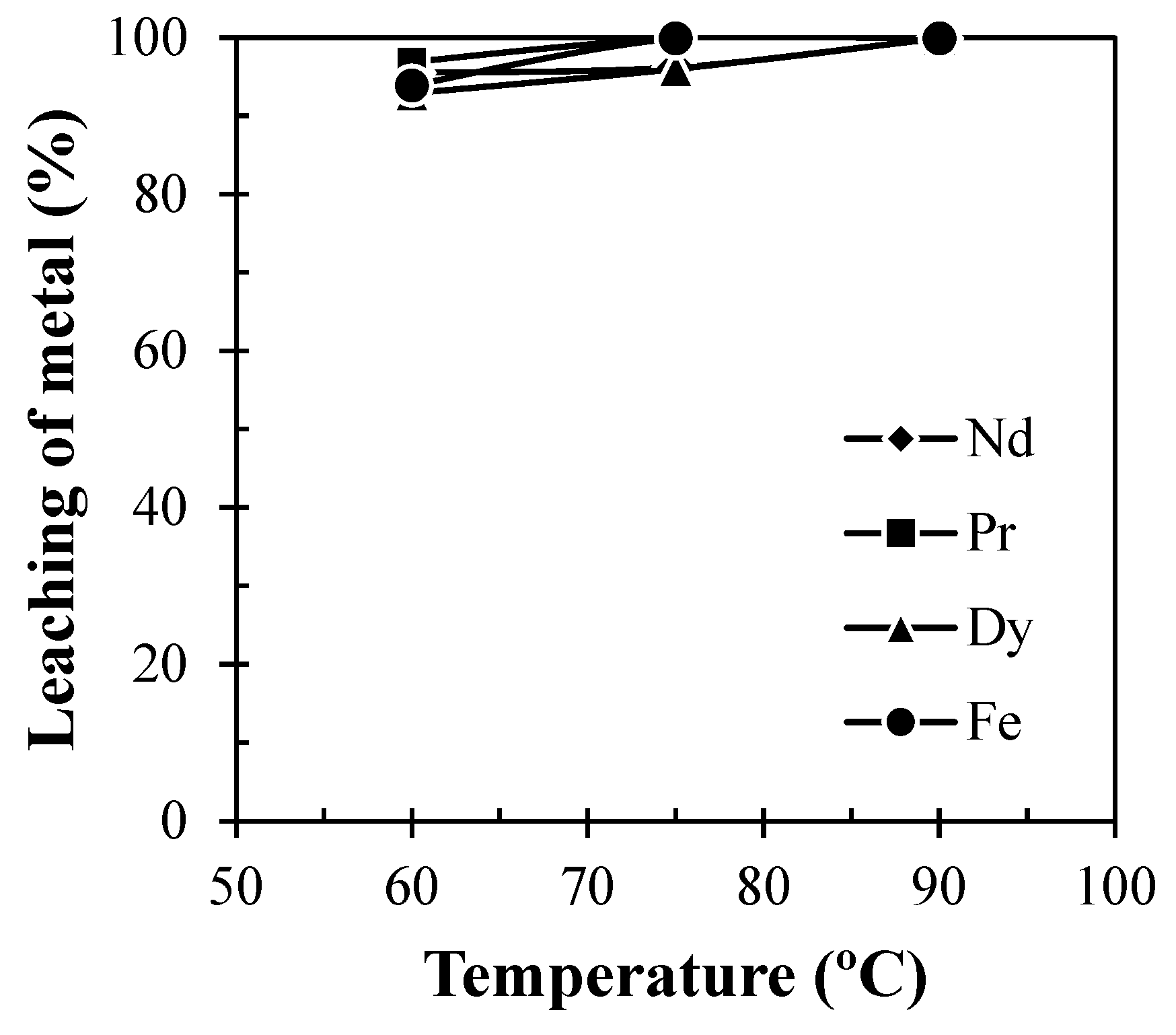

3.1.2. Effect of Temperature

3.1.3. Effect of Pulp Density

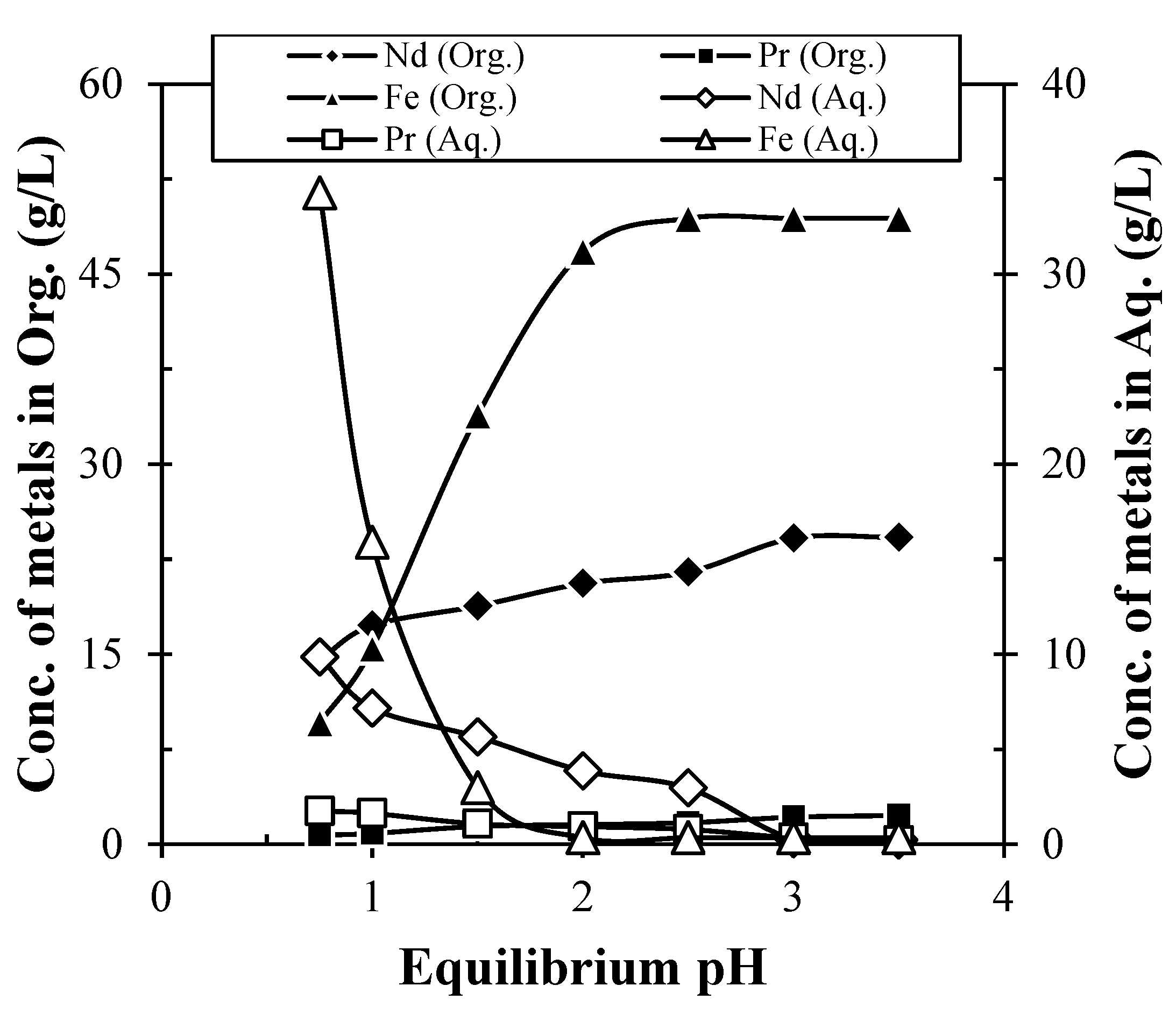

3.2. Solvent Extraction of Nd and Pr

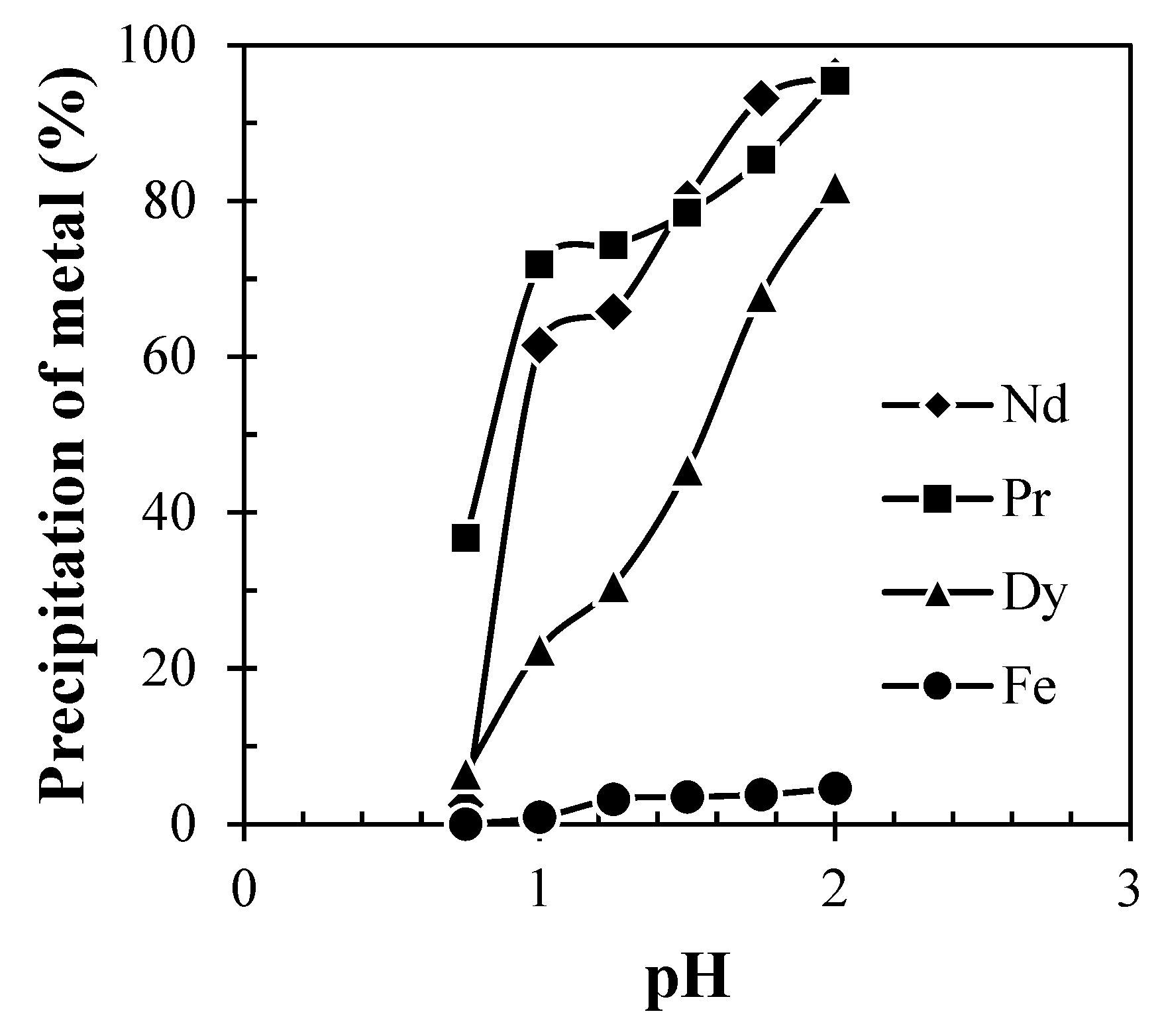

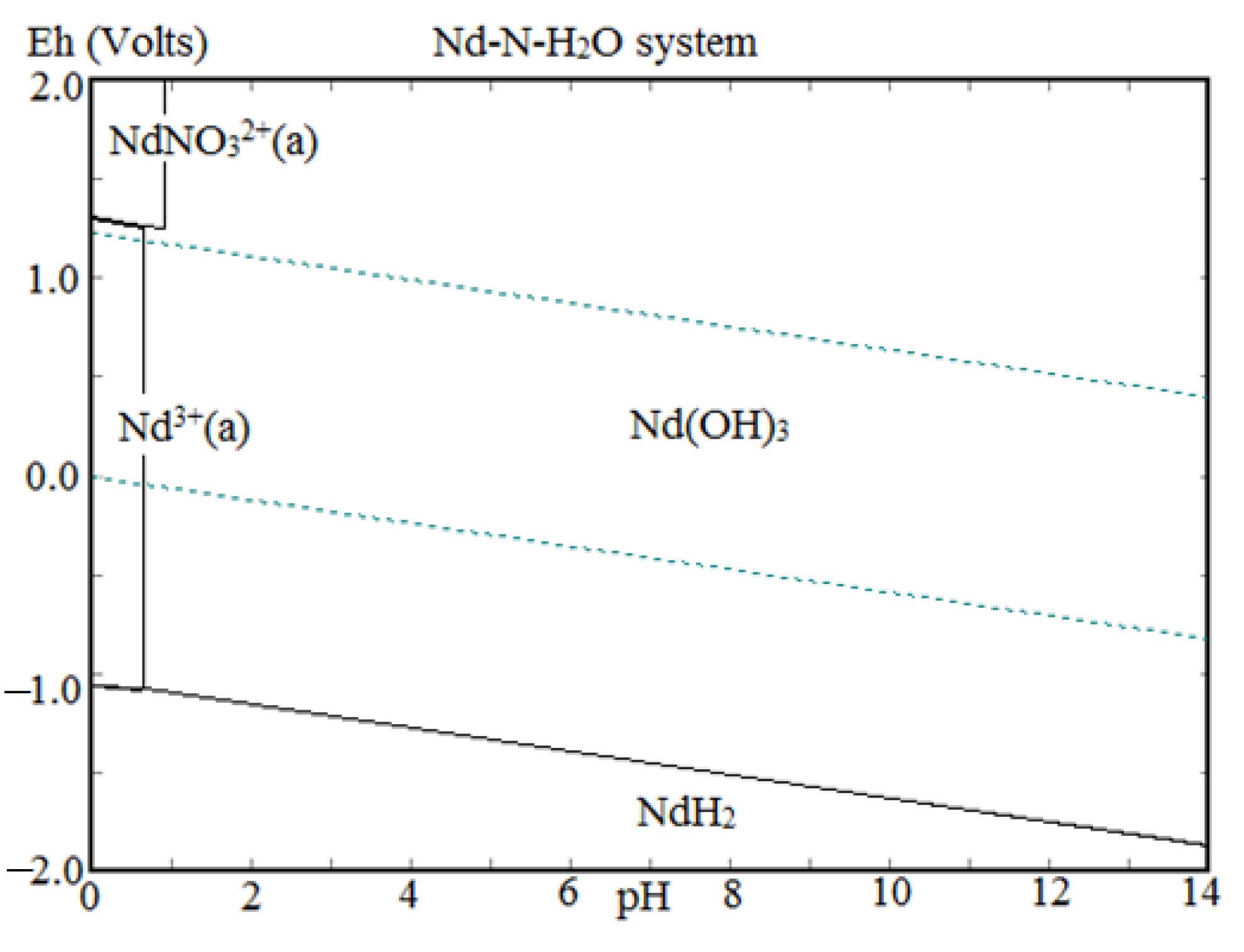

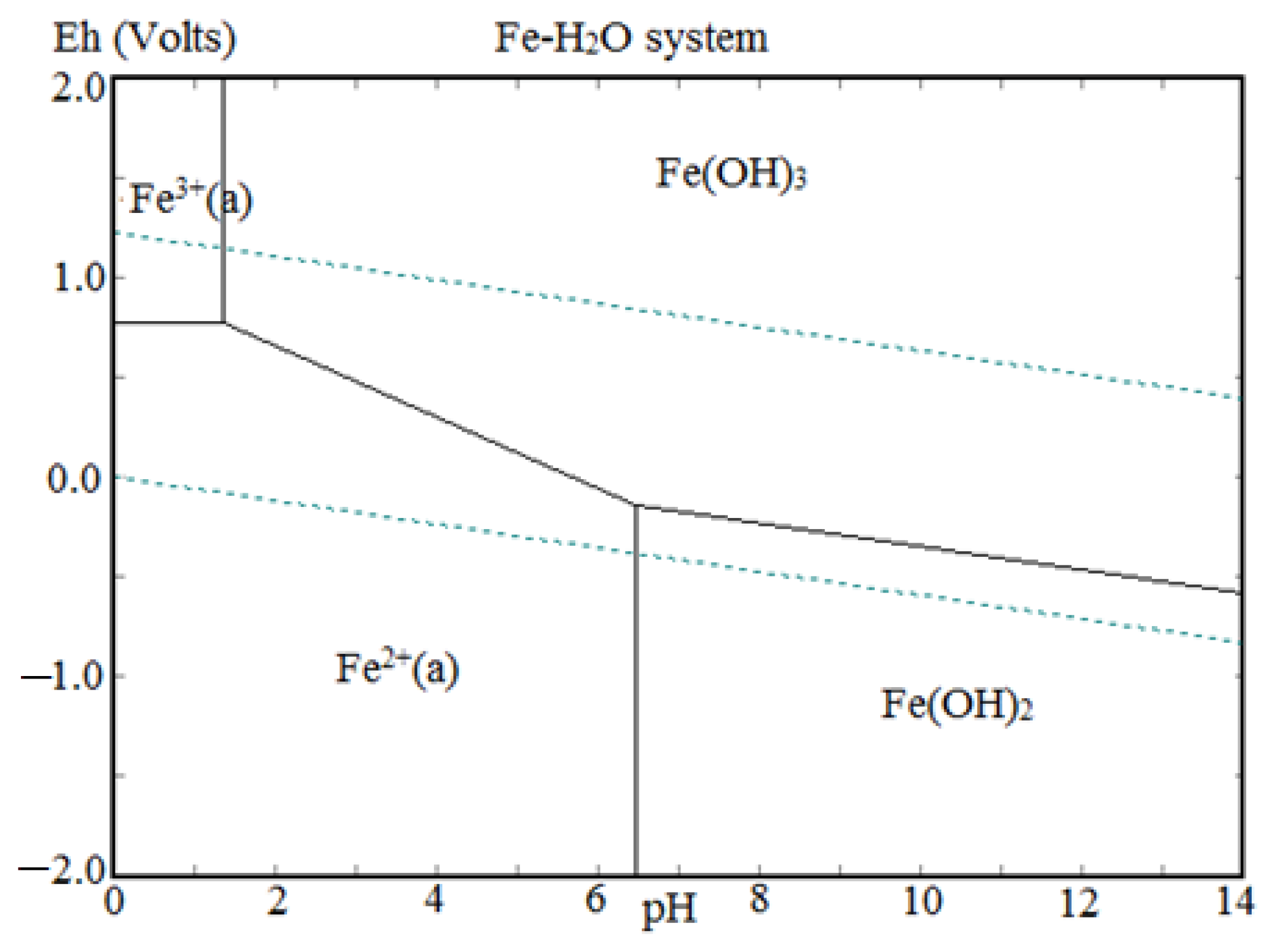

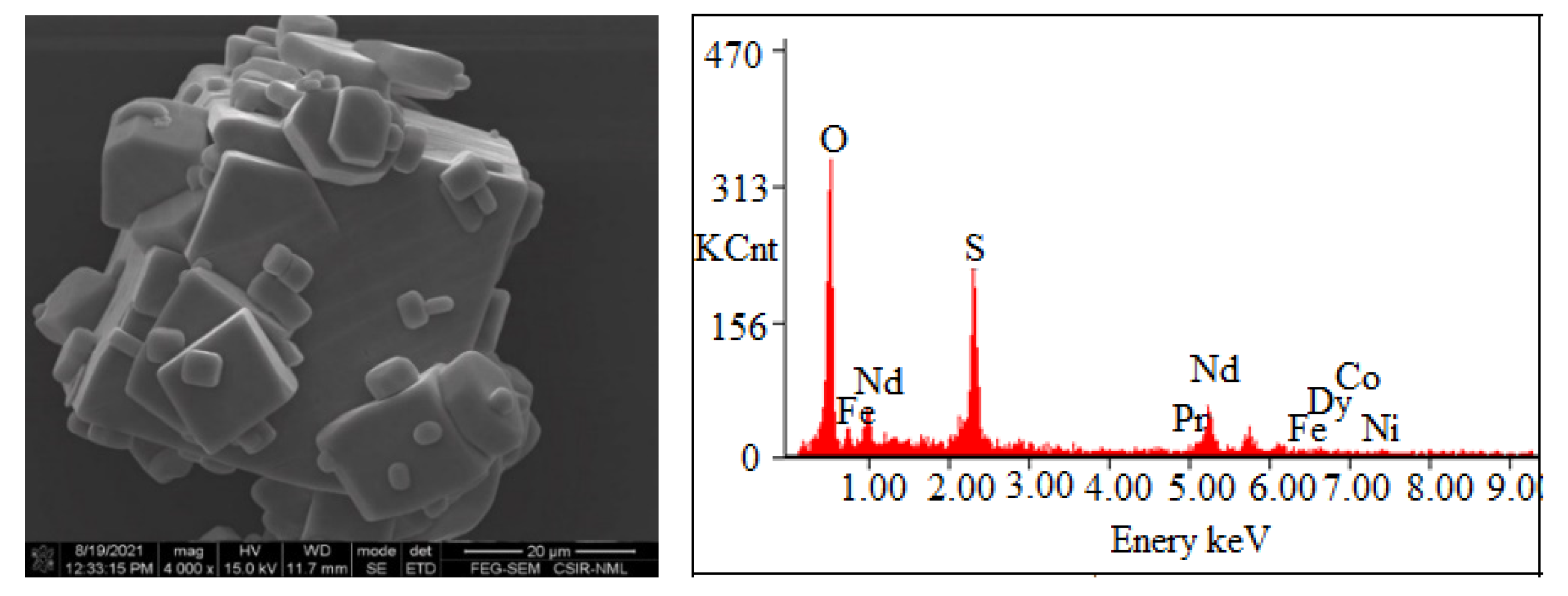

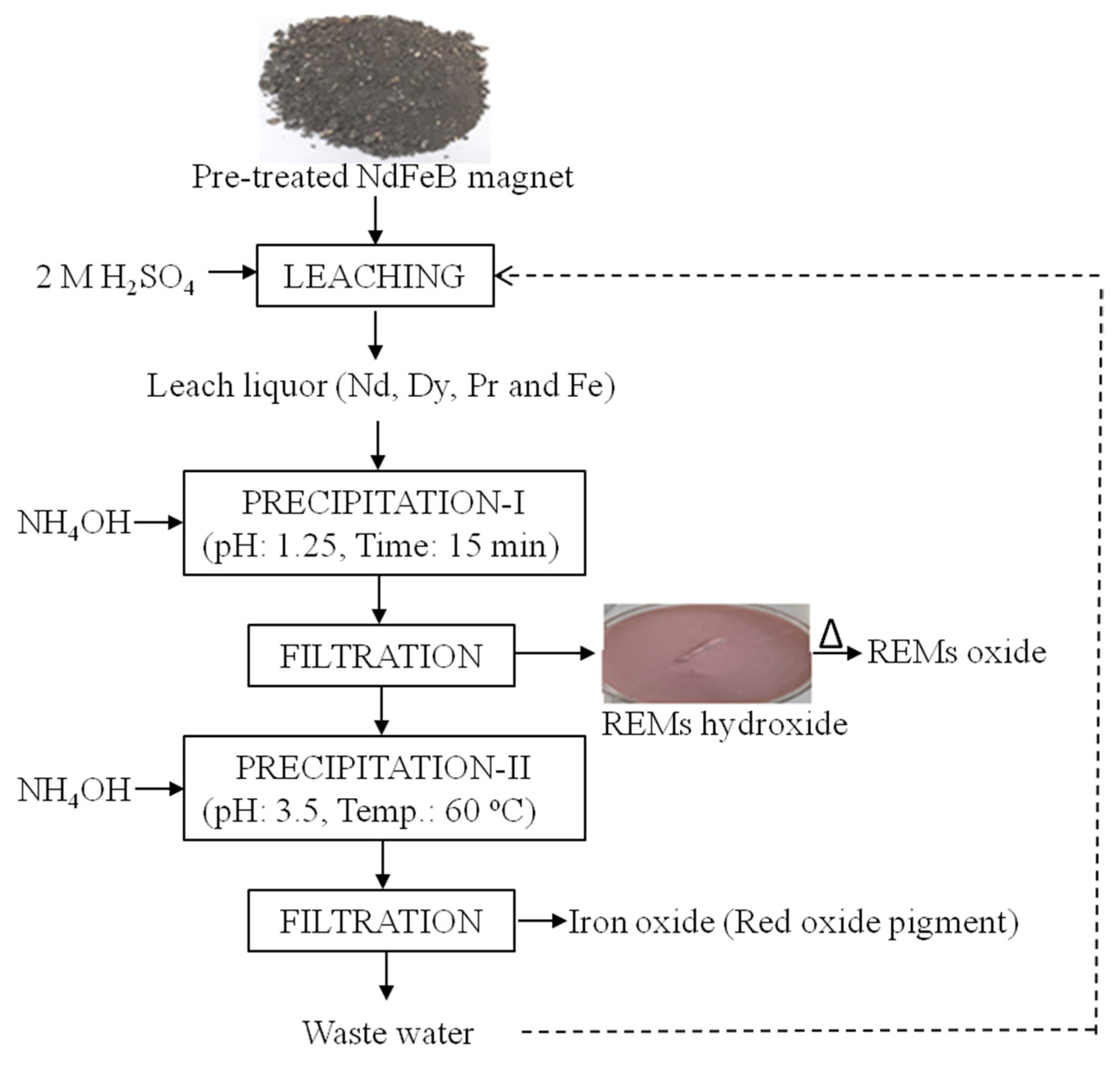

3.3. Recovery of REMs from Leach Liquor by Precipitation

4. Conclusions

- It was found that the magnetic strength of Nd-Fe-B hard disk magnet was lost by heat treatment at 300 °C in 2 h.

- The complete leaching of Nd, Pr, Dy, and Fe occurred from the demagnetized magnet using 2 M H2SO4 at 75 °C in 60 min and pulp density 100 g/L.

- It was found that 99.1% Nd, 94% Pr, and 99.9% Fe got extracted from leach liquor using 35% Cyanex 272 at O/A ratio 1/1 in 10 min. The selective extraction of REMs can only be achieved by using multistage solvent extraction. Thus, direct precipitation studies were carried out at different eq. pH for the selective extraction of REMs and Fe.

- Further, ~93.15% Nd, ~85% Pr, and ~68% Dy were precipitated from the leach liquor of discarded magnet at pH 1.75 at room temperature in 15 min. The precipitated hydroxide of REMs was converted to their oxides by heating at 120 °C for 2 h.

- Finally, 96.5% Fe was precipitated as ferric ion through the air sparging between eq. pH 3.5 to 4 at 60 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumari, A.; Jha, M.K.; Pathak, D.D. An innovative environmental process for the treatment of scrap Nd-Fe-B magnets. J. Environ. Manag. 2020, 273, 111063. [Google Scholar] [CrossRef] [PubMed]

- Dhir, A.; Malodia, S.; Awan, U.; Sakashita, M.; Kaur, P. Extended valence theory perspective on consumers’ e-waste recycling intentions in Japan. J. Clean. Prod. 2021, 312, 127443. [Google Scholar] [CrossRef]

- Onal, M.A.R.; Aktan, E.; Borra, C.R.; Blanpain, B.; Gerven, T.V.; Guo, M. Recycling of NdFeB magnets using nitration, calcination and water leaching for REE recovery. Hydrometallurgy 2017, 167, 115–123. [Google Scholar] [CrossRef]

- Liu, F.; Porvali, A.; Wang, J.; Wang, H.; Peng, C.; Wilson, B.P.; Lundstrom, M. Recovery and separation of rare earths and boron from spent Nd-Fe-B Magnets. Miner. Eng. 2020, 145, 106097. [Google Scholar] [CrossRef]

- Loy, S.V.; Onal, M.A.R.; Binnemans, K.; Gerven, T.V. Recovery of valuable metals from NdFeB magnets by mechanochemically assisted ferric sulfate leaching. Hydrometallurgy 2020, 191, 105154. [Google Scholar]

- Reisdorfer, G.; Bertuol, D.; Tanabe, E.H. Recovery of neodymium from the magnets of hard disk drives using organic acids. Miner. Eng. 2019, 143, 105938. [Google Scholar] [CrossRef]

- Makarova, I.; Soboleva, E.; Osipenko, M.; Kurilo, I.; Laatikainen, M. Electrochemical leaching of rare-earth elements from spent NdFeB magnets. Hydrometallurgy 2020, 192, 105264. [Google Scholar] [CrossRef]

- Pavon, S.; Fortunya, A.; Collb, M.T.; Sastrec, A.M. Neodymium recovery from NdFeB magnet wastes using Primene 81R·Cyanex 572 IL by solvent extraction. J. Environ. Manag. 2018, 222, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Niam, A.C.; Wang, Y.; Chen, S.; Chang, G.; You, S. Simultaneous recovery of rare earth elements from waste permanent magnet (WPMs) leach liquor by solvent extraction and hollow fiber supported liquid membrane. Chem. Eng. Process. 2020, 148, 107831. [Google Scholar] [CrossRef]

- Lee, C.H.; Chen, Y.J.; Liao, C.H.; Popuri, R.S.; Tsai, S.L.; Hung, C.E. Selective leaching process for Neodymium recovery from scrap Nd-Fe-B magnet. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2013, 44, 5825–5833. [Google Scholar] [CrossRef]

- Rabatho, J.P.; Tongamp, W.; Takasaki, Y.; Haga, K.; Shibayama, A. Recovery of Nd and Dy from rare earth magnetic waste sludge by hydrometallurgical process. J. Mater. Cycles Waste Manag. 2013, 15, 171–178. [Google Scholar] [CrossRef]

- Yingnakorn, T.; Laokhen, P.; Sriklang, L.; Patcharawit, T.; Khumkoa, S. Study on Recovery of Rare Earth Elements from NdFeB Magnet Scrap by Using Selective Leaching. Mater. Sci. Forum 2020, 1009, 149–154. [Google Scholar] [CrossRef]

- Feng, L.Y.; Zhu, M.G.; Wei, L.; Dong, Z.; Feng, L.; Lang, C.; Wu, J.Y.; Yan, Q.; An, D. The Impact Induced Demagnetization Mechanism in NdFeB Permanent Magnets. Chin. Phys. Lett. 2013, 30, 097501. [Google Scholar]

- Hoogerstraete, T.V.; Blanpain, B.; Gerven, T.V.; Binnemans, K. From NdFeB magnets towards the rare-earth oxides: A recycling process consuming only oxalic acid. RSC Adv. 2014, 4, 64099–64111. [Google Scholar] [CrossRef] [Green Version]

- Riano, S.; Binnemans, K. Extraction and separation of neodymium and dysprosium from used NdFeB magnets: An application of ionic liquids in solvent extraction towards the recycling of magnets. Green Chem. 2015, 17, 2931–2942. [Google Scholar] [CrossRef]

- Onal, M.A.R.; Borra, C.R.; Guo, M.; Blanpain, B.; Van Gerven, T. Recycling of NdFeB magnets using sulfation, selective roasting, and water leaching. J. Sustain. Metall. 2015, 1, 199–215. [Google Scholar] [CrossRef]

| REMs | Contents (wt %) | Non-REMs | Contents (wt %) |

|---|---|---|---|

| Nd | 29.5 | Fe | 59.5 |

| Dy | 2.5 | Ni | 4.1 |

| Pr | 1.3 | Co | 3.1 |

| Element | Wt % | At % |

|---|---|---|

| O K | 26.1 | 62.9 |

| S K | 16.8 | 20.2 |

| Pr L | 6.10 | 1.67 |

| Nd L | 41.6 | 11.1 |

| Fe K | 1.02 | 0.70 |

| Dy L | 5.03 | 1.20 |

| Co K | 0.91 | 0.65 |

| Ni K | 0.47 | 0.23 |

| Demagnetization and Roasting Conditions | Experimental Conditions (Leaching and Precipitation/Evaporation) | Salient Results | References |

|---|---|---|---|

| Demagnetization and roasting not done | Leachant: 2 M H2SO4, Temp.: 25 °C, Time: 24 h, Evaporation: Temp.: 110 °C | ~95% REEs were extracted | Yingnakorn et al. [12] |

| Demagnetization: 500 °C, Time: 60 min | Not done | Demagnetized | Lee et al. [10] |

| Demagnetization: 400 °C, Time: 120 min | Not done | Demagnetized | Feng et al. [13] |

| Demagnetization: 350, Time: 60 min, Roasting: 800 °C, Time: 120 min | Temp.: 180 °C, Time: 120 min; Acid concentration: 0.6 M HCl, Pulp density: 100 g/L Precipitation: Temp.: 50 °C, Initial pH: 2.2, Time: 30 min | 99% of REEs were extracted | Liu et al. [4] |

| Demagnetization: 350 °C, Roasting: 900 °C | Leachant: 1 M Citric/Maleic Acid, Temp.: 90 °C, Pulp density: 50 g/L | 99% recovery of Nd occurred | Reisdorfer et al. [6] |

| Roasting: 950 °C | Leachant: 1.8 M HCl + 3.5 M NH4Cl, Pulp density: 100 g/ L, Temp.: 100 °C, Time: 5 days Precipitant: Oxalic acid | 90% REMs were dissolved | Hoogerstraete et al. [14] |

| Roasting: 950 °C | Leachant: 5 M HNO3, Pulp density: 1000 g/L, Temp.: 80 °C, Time: 72 h Precipitant: Ammonium nitrate, Eq. pH: 2, Time: 60 min, Temp.: 70 °C | Nd and Dy recovered as Nd2O3 and Dy2O3 with purity 99.6% and 99.8%, respectively | Riano and Binnemans [15] |

| Roasting: 750 °C | Leachant: Water, Pulp density: 20 g/L, Time:1 h, Temp.: 25 °C | 95–100% REMs were extracted | Onal et al. [16] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choubey, P.K.; Singh, N.; Panda, R.; Jyothi, R.K.; Yoo, K.; Park, I.; Jha, M.K. Development of Hydrometallurgical Process for Recovery of Rare Earth Metals (Nd, Pr, and Dy) from Nd-Fe-B Magnets. Metals 2021, 11, 1987. https://doi.org/10.3390/met11121987

Choubey PK, Singh N, Panda R, Jyothi RK, Yoo K, Park I, Jha MK. Development of Hydrometallurgical Process for Recovery of Rare Earth Metals (Nd, Pr, and Dy) from Nd-Fe-B Magnets. Metals. 2021; 11(12):1987. https://doi.org/10.3390/met11121987

Chicago/Turabian StyleChoubey, Pankaj Kumar, Nityanand Singh, Rekha Panda, Rajesh Kumar Jyothi, Kyoungkeun Yoo, Ilhwan Park, and Manis Kumar Jha. 2021. "Development of Hydrometallurgical Process for Recovery of Rare Earth Metals (Nd, Pr, and Dy) from Nd-Fe-B Magnets" Metals 11, no. 12: 1987. https://doi.org/10.3390/met11121987

APA StyleChoubey, P. K., Singh, N., Panda, R., Jyothi, R. K., Yoo, K., Park, I., & Jha, M. K. (2021). Development of Hydrometallurgical Process for Recovery of Rare Earth Metals (Nd, Pr, and Dy) from Nd-Fe-B Magnets. Metals, 11(12), 1987. https://doi.org/10.3390/met11121987