Correlation between Microstructures and Ductility Parameters of Cold Drawn Hyper-Eutectoid Steel Wires with Different Drawing Strains and Post-Deformation Annealing Conditions

Abstract

:1. Introduction

2. Materials and Methods

3. Results

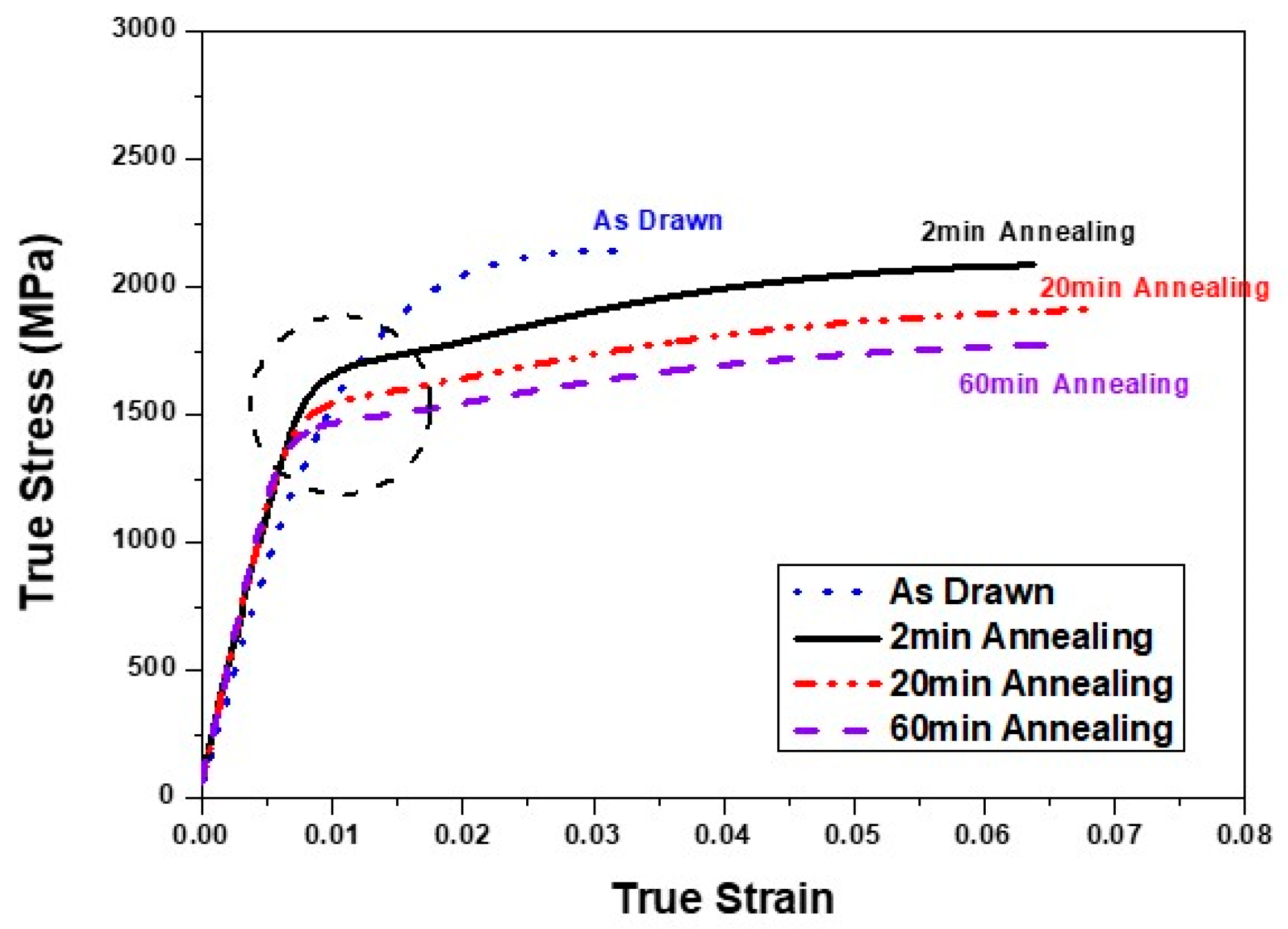

3.1. Tensile Strength

3.2. Elongation to Failure

3.3. Torsional Ductility

3.4. Reduction of Area

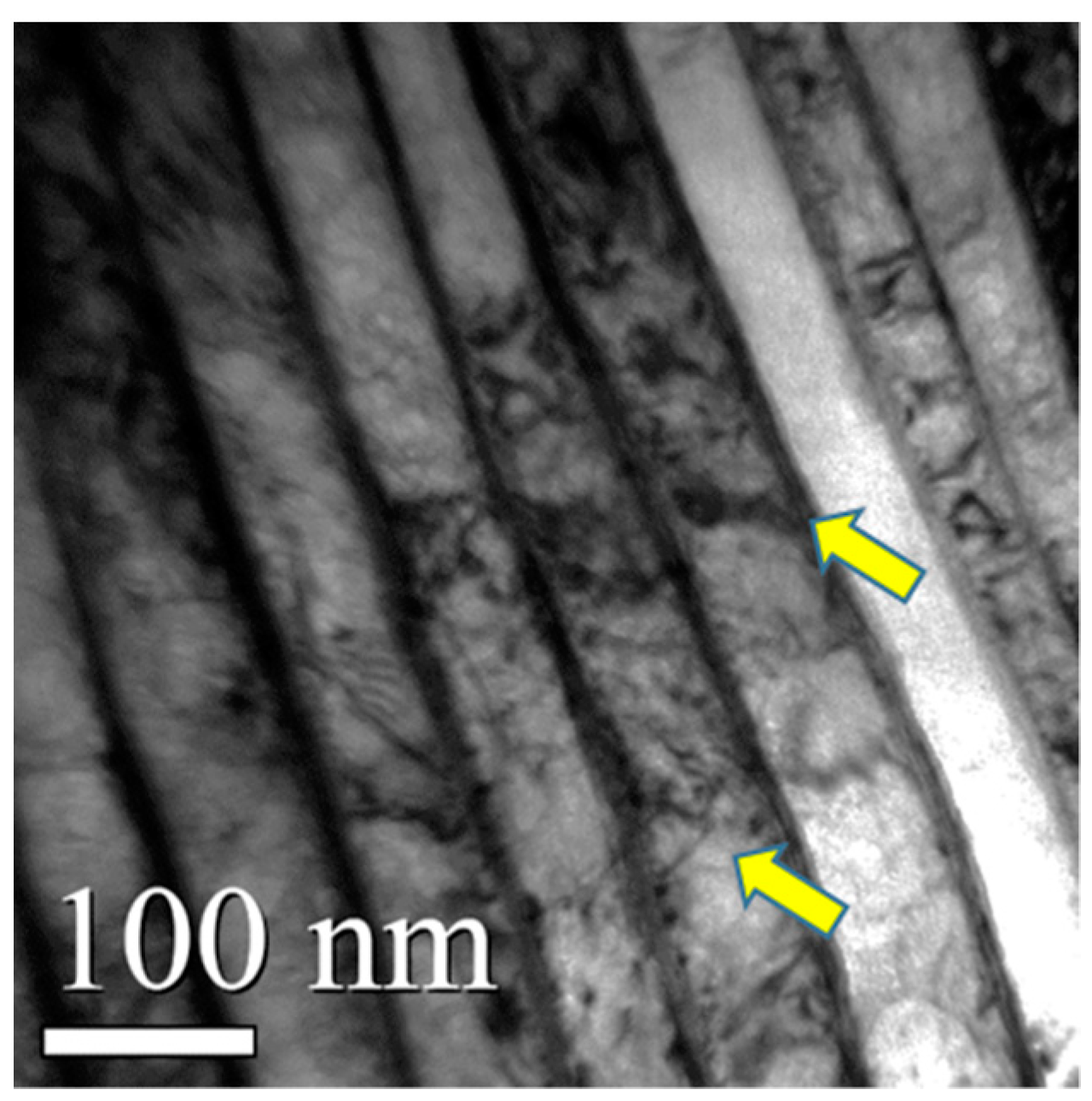

4. Discussion

4.1. Elongation to Failure

4.2. Torsional Ductility

4.3. Reduction of Area

5. Conclusions

- (1)

- The increase of tensile strength (TS) during wire drawing was attributed to work hardening of lamellar ferrite and solid solution hardening of dissolved carbon atoms by dynamic strain aging. During post-deformation annealing, TS of steel wires with high drawing strain decreased continuously with annealing time, since age softening became the major process to control TS. Meanwhile, steel wires with low drawing strain showed the sequential variation of TS; increasing, showing the peak, and decreasing with annealing time. The increment of TS for a short annealing time was due to the occurrence of age hardening.

- (2)

- The variation of elongation to failure (EL) in cold drawn and/or annealed steel wires depends on the formation of dislocation substructures in lamellar ferrite. The formation of dislocation tangles or cells would become one of main causes for the EL drop at low strain. The rapid increase of EL during annealing came from the transformation from dislocation cells to subgrains as a recovery process. The formation of dislocation substructures showed the stronger effect on the variation of EL than dislocation density in cold drawn and/or annealed steel wires.

- (3)

- Occurrence of delamination (DEL) caused a significant drop of number of turns to failure in torsion (NT). Since DEL depends on the amount of carbon atoms dissolved in ferrite, steel wires with the higher drawing strains showed the larger range of DEL region and the larger decrease of NT during annealing. The higher drawing strain induced the more damage in lamellar cementite and resulted in the increased amount of dissolved carbon atoms in ferrite during annealing. Thus, the higher drawing strain resulted in the larger drop of NT and more frequent DEL during annealing.

- (4)

- Number of turns to failure (NT) increased with the realignment of lamellar cementite and decreased with fracturing of lamellar cementite and dynamic strain aging in cold drawn steel wires. During post-deformation annealing, NT of steel wires decreased with annealing time, except for DEL. The orientation of lamellar cementite and the shape of cementite particles would become an effective factor controlling NT of cold drawn and annealed steel wires.

- (5)

- With drawing strain, reduction of area (RA) increased due to the realignment along the wire axis, showed the peak, and decreased gradually due to work hardening of ferrite and fragmenting lamellar cementite at high strain. During post-deformation annealing, RA of cold drawn wires significantly dropped and increased slowly with annealing time. The orientation and shape of lamellar cementite would become a dominant microstructural feature in controlling RA of cold drawn and annealed steel wires. The occurrence of recovery during annealing also contributed to RA to some extent.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Borchers, C.; Kirchheim, R. Cold-drawn Pearlitic Steel Wires. Prog. Mater. Sci. 2016, 82, 405–444. [Google Scholar] [CrossRef]

- Nam, W.J.; Bae, C.M.; Oh, S.J.; Kwon, S.J. Effect of Interlamellar Spacing on Cementite Dissolution during Wire Drawing of Pearlitic Steel Wires. Scr. Mater. 2000, 42, 457–463. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Effect of Cumulative Cold Drawing on the Pearlite Intrlamellar Spacing in Eutectoid Steel. Scr. Mater. 1998, 39, 323–328. [Google Scholar] [CrossRef]

- Li, Y.J.; Choi, P.; Goto, S.; Borchers, C.; Raabe, D.; Kirchheim, R. Evolution of Strength and Microstructure during Annealing of Heavily Cold-drawn 6.3 GPa Hypereutectoid Pearlitic Steel Wire. Acta Mater. 2012, 60, 4005–4016. [Google Scholar] [CrossRef]

- Lu, X. Correlation between Microstructural Evolution and Mechanical Properties of 2000 MPa Cold-Drawn Pearlitic Steel Wires during Galvanizing Simulated Annealing. Metals 2019, 9, 326. [Google Scholar] [CrossRef] [Green Version]

- Tashiro, H.; Tarui, T. State of the Art for High Tensile Strength Steel Cord. Nippon Steel Tech. Rep. 2003, 88, 87–91. [Google Scholar]

- Tarui, T.; Maruyama, N.; Takahashi, J.; Nishida, S.; Tashiro, H. Microstructure Control and Strengthening of High-carbon Steel Wires. Nippon Steel Tech. Rep. 2005, 91, 56–61. [Google Scholar]

- Sakamoto, M.; Teshima, T.; Nakamura, K. Wire Rod for High Tensile Strength Steel Cords. Nippon Steel Tech. Rep. 2019, 122, 129–136. [Google Scholar]

- Takahashi, J.; Kosaka, M.; Kawakami, K.; Tarui, T. Change in Carbon State by Low-temperature aging in Heavily Drawn Pearlitic Steel Wires. Acta Mater. 2012, 60, 387–395. [Google Scholar] [CrossRef]

- Song, H.R.; Kang, E.G.; Bae, C.M.; Lee, C.Y.; Lee, D.L.; Nam, W.J. The Effect of a Cr Addition and Transformation Temperature on the Mechanical Properties of Cold Drawn Hyper-Eutectoid Steel Wires. Met. Mater. Int. 2006, 12, 239–243. [Google Scholar] [CrossRef]

- Tarui, T.; Takahashi, T.; Ohashi, S.; Uemori, R. Effect of Silicon on the Age Softening of High Carbon Steel. Iron Steel Maker 1994, 21, 25–30. [Google Scholar]

- Joung, S.; Nam, W. Effects of Alloying Elements, Si and Cr, on Aging and Delamination Behaviors in Cold-Drawn and Subsequently Annealed Hyper-eutectoid Steel Wires. Met. Mater. Int. 2019, 25, 34–44. [Google Scholar] [CrossRef]

- Zhao, T.Z.; Zhang, S.H.; Zhang, G.L.; Song, H.W.; Cheng, M. Hardening and Softening Mechanisms of Pearlitic Steel Wire under Torsion. Mater. Des. 2014, 59, 397–405. [Google Scholar] [CrossRef]

- Zhou, L.; Fang, F.; Wang, L.; Hu, X.; Xie, Z.; Jiang, J. Torsion Performance of Pearlitic Steel Wires: Effects of Morphology and Crystallinity of Cementite. Mater. Sci. Eng. A 2019, 743, 425–435. [Google Scholar] [CrossRef]

- Toribio, J.; Ayaso, F.J.; González, B.; Matos, J.C.; Vergara, D.; Lorenzo, M. Tensile Fracture behavior of Progressively-Drawn Pearlitic Steels. Metals 2016, 6, 114. [Google Scholar] [CrossRef] [Green Version]

- Shiota, Y.; Tomota, Y.; Moriai, A.; Kamiyama, T. Structure and Mechanical Behavior of Heavily Drawn Pearlite and Martensite in a High Carbon Steel. Met. Mater. Int. 2005, 11, 371–376. [Google Scholar] [CrossRef]

- Zelin, M. Microstructure Evolution in Pearlitic Steels during Wire Drawing. Acta Mater. 2002, 50, 4431–4447. [Google Scholar] [CrossRef]

- Joung, S.W.; Kang, U.G.; Hong, S.P.; Kim, Y.W.; Nam, W.J. Aging Behavior and Delamination in Cold Drawn and Post-deformation Annealed Hyper-eutectoid Steel Wires. Mater. Sci. Eng. A 2013, 586, 171–177. [Google Scholar] [CrossRef]

- Nam, W.J.; Bae, C.M. Void Initiation and Microstructural Changes during Wire Drawing of Pearlitic Steels. Mater. Sci. Eng. A 1995, 203, 278–285. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Microstructure Orientation in a Pearlitic Steel Subjected to Progressive Plastic Deformation. J. Mater. Sci. Lett. 1998, 17, 1045–1048. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Microstructure Evolution in a Pearlitic Steel Subjected to Progressive Plastic Deformation. Mater. Sci. Eng. A 1997, 234–236, 579–582. [Google Scholar] [CrossRef]

- Read, H.G.; Reynolds, W.T., Jr.; Hono, K.; Tarui, T. AFPIM and TEM Studies of Drawn Pearlitic Wire. Scr. Mater. 1997, 37, 1221–1230. [Google Scholar] [CrossRef]

- Takahashi, J.; Tarui, T.; Kawakami, K. Three-dimensional Atom Probe Analysis of Heavily Drawn Steel Wires by Probing Perpendicular to the Pearlitic Lamellae. Ultramicroscopy 2009, 109, 193–199. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.J.; Choi, P.; Borchers, C.; Chen, Y.Z.; Goto, S.; Raabe, D.; Kirchheim, R. Atom probe tomography characterization of heavily cold drawn pearlitic steel wire. Ultramicroscopy 2011, 111, 628–632. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.J.; Choi, P.; Borchers, C.; Westerkamp, S.; Goto, S.; Raabe, D.; Kirchheim, R. Atomic-scale Mechanisms of Deformation-induced Cementite Decomposition in Pearlite. Acta Mater. 2011, 59, 3965–3977. [Google Scholar] [CrossRef]

- Maruyama, N.; Tarui, T.; Tashiro, H. Atom Probe Study on the Ductility of Drawn Pearlitic Steels. Scr. Mater. 2002, 46, 599–603. [Google Scholar] [CrossRef]

- Hammerle, J.R.; de Almeida, L.H.; Monteiro, S.N. Lower Temperatures Mechanism of Strain Aging in Carbon Steels for Drawn Wires. Scr. Mater. 2004, 50, 1289–1292. [Google Scholar] [CrossRef]

- Watte, P.; Humbeeck, J.V.; Aernoudt, E.; Lefever, I. Strain ageing in heavily drawn eutectoid steel wires. Scr. Mater. 1996, 34, 89–95. [Google Scholar] [CrossRef]

- Hinchliffe, C.E.; Smith, G.D.W. Strain Aging of Pearlitic Steel Wire during Post-drawing Heat Treatments. Mater. Sci. Technol. 2001, 17, 148–154. [Google Scholar] [CrossRef]

- Lee, J.W.; Lee, J.C.; Lee, Y.S.; Park, K.T.; Nam, W.J. Effects of Post-deformation Annealing Conditions on the Behavior of Lamellar Cementite and the Occurrence of Delamination in Cold-drawn Steel Wires. J. Mater. Process. Technol. 2009, 209, 5300–5304. [Google Scholar] [CrossRef]

- Fang, F.; Hu, J.; Chen, S.H.; Xie, Z.H.; Jiang, J.Q. Revealing Microstructural and Mechanical Characteristics of Cold-drawn Pearlitic Steel Wires undergoing Simulated Galvanization Treatment. Mater. Sci. Eng. A 2012, 547, 51–54. [Google Scholar] [CrossRef]

- Zhou, L.C.; Fang, F.; Wang, L.; Chen, H.Q.; Xie, Z.H.; Jiang, J.Q. Torsion Delamination and Recrystallized Cementite of Heavy Drawing Pearlitic Wires after Low Temperature Annealing. Mater. Sci. Eng. A 2018, 713, 52–60. [Google Scholar] [CrossRef]

- Xiang, L.; Liang, L.W.; Wang, Y.J.; Chen, Y.; Wang, H.Y.; Dai, L.H. One-step Annealing Optimizes Strength-ductility Tradeoff in Pearlitic Steel Wires. Mater. Sci. Eng. A 2019, 757, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Godfrey, A.; Huang, X.; Hansen, N.; Liu, Q. Microstructure and strengthening Mechanisms in cold-drawn pearlitic steel wire. Acta Mater. 2011, 59, 3422–3430. [Google Scholar] [CrossRef]

- Gondo, S.; Tanemura, R.; Suzuki, S.; Kajino, S.; Asakawa, M.; Takemoto, K.; Tashima, K. Microstructures and Mechanical Properties of Fiber Textures forming Mesoscale Structure of Drawn Fine High Carbon Steel Wire. Mater. Sci. Eng. A 2019, 747, 255–264. [Google Scholar] [CrossRef]

- Zhang, X.; Hansen, N.; Godfrey, A.; Huang, X. Dislocation-based Plasticity and Strengthening Mechanisms in sub-20 nm Lamellar Structures in Pearlitic Steel Wire. Acta Mater. 2016, 114, 176–183. [Google Scholar] [CrossRef] [Green Version]

- He, Y.; Xiang, S.; Shi, W.; Liu, J.; Ji, X.; Yu, W. Effect of Microstructure Evolution on Anisotropic Fracture Behavior of Cold Drawing Pearlitic Steels. Mater. Sci. Eng. A 2017, 683, 153–163. [Google Scholar] [CrossRef]

- Li, Y.J.; Kosta, A.; Choi, P.; Goto, S.; Ponge, D.; Kirchheim, R.; Raabe, D. Mechanisms of Subgrain Coarsening and Its Effect on the Mechanical Properties of Carbon-supersaturated Nanocrystalline Hypereutectoid Steel. Acta Mater. 2015, 84, 110–123. [Google Scholar] [CrossRef]

- Jung, J.Y.; An, K.S.; Park, P.Y.; Nam, W.J. Effects of Wire Drawing and Annealing Conditions on Torsional Ductility of Cold Drawn and Annealed Hyper-Eutectoid Steel Wires. Metals 2020, 10, 1043. [Google Scholar] [CrossRef]

| Drawing step | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Diameter (mm) | 4.9 | 4.44 | 4.02 | 3.64 | 3.29 | 2.98 | 2.70 | 2.45 | 2.21 | 2.01 | 1.82 | 1.65 | 1.49 |

| Total reduction (%) | - | 17.9 | 32.7 | 44.8 | 54.9 | 63.0 | 69.6 | 75.0 | 79.7 | 83.2 | 86.2 | 88.7 | 90.8 |

| Drawing strain (ε) | - | 0.20 | 0.40 | 0.59 | 0.80 | 0.99 | 1.19 | 1.39 | 1.59 | 1.78 | 1.98 | 2.18 | 2.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, J.Y.; An, K.S.; Park, P.Y.; Nam, W.J. Correlation between Microstructures and Ductility Parameters of Cold Drawn Hyper-Eutectoid Steel Wires with Different Drawing Strains and Post-Deformation Annealing Conditions. Metals 2021, 11, 178. https://doi.org/10.3390/met11020178

Jung JY, An KS, Park PY, Nam WJ. Correlation between Microstructures and Ductility Parameters of Cold Drawn Hyper-Eutectoid Steel Wires with Different Drawing Strains and Post-Deformation Annealing Conditions. Metals. 2021; 11(2):178. https://doi.org/10.3390/met11020178

Chicago/Turabian StyleJung, Jin Young, Kang Suk An, Pyeong Yeol Park, and Won Jong Nam. 2021. "Correlation between Microstructures and Ductility Parameters of Cold Drawn Hyper-Eutectoid Steel Wires with Different Drawing Strains and Post-Deformation Annealing Conditions" Metals 11, no. 2: 178. https://doi.org/10.3390/met11020178

APA StyleJung, J. Y., An, K. S., Park, P. Y., & Nam, W. J. (2021). Correlation between Microstructures and Ductility Parameters of Cold Drawn Hyper-Eutectoid Steel Wires with Different Drawing Strains and Post-Deformation Annealing Conditions. Metals, 11(2), 178. https://doi.org/10.3390/met11020178