Overview of the Mechanical Properties of Tungsten/Steel Brazed Joints for the DEMO Fusion Reactor

Abstract

:1. Introduction

- No deformation of the materials being joined, while during diffusion bonding the steel creeps up to 8% [16];

- Full integrity of the seam if the brazing alloy and brazing mode are chosen correctly, which is important for good heat transportation;

- The possibility of simultaneous heat treatment of the base materials and the brazing procedure;

- The possible replacement of defective elements after manufacturing and during production [17];

- Low cost, i.e., no expensive equipment is required to carry out the process. There is a wide range of brazing methods available, from vacuum brazing to ohmic or induction brazing, even in air under flux, or blowing with an inert gas.

- Section 2 is a review of the working conditions of a tungsten/steel joint, including heat loads (Section 2.1), understanding the mechanical property requirements using Finite Element Analysis (FEM) (Section 2.2), and other requirements aside from the mechanical properties (Section 2.3);

- Section 3 gives an overview of the recent progress made in tungsten/steel brazing (attention is mainly paid to mechanical properties);

2. Working Conditions and Requirements

2.1. Heat Loads

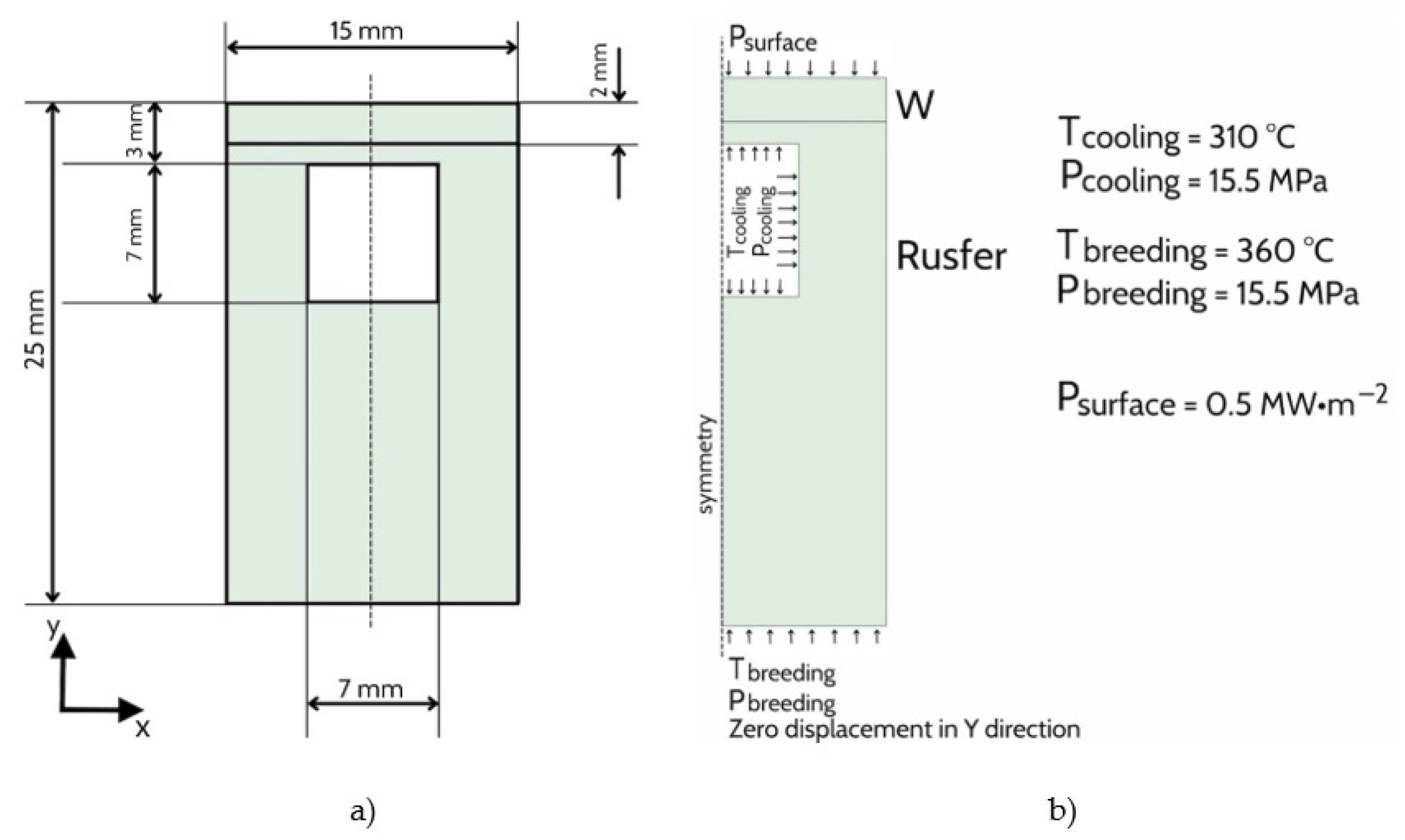

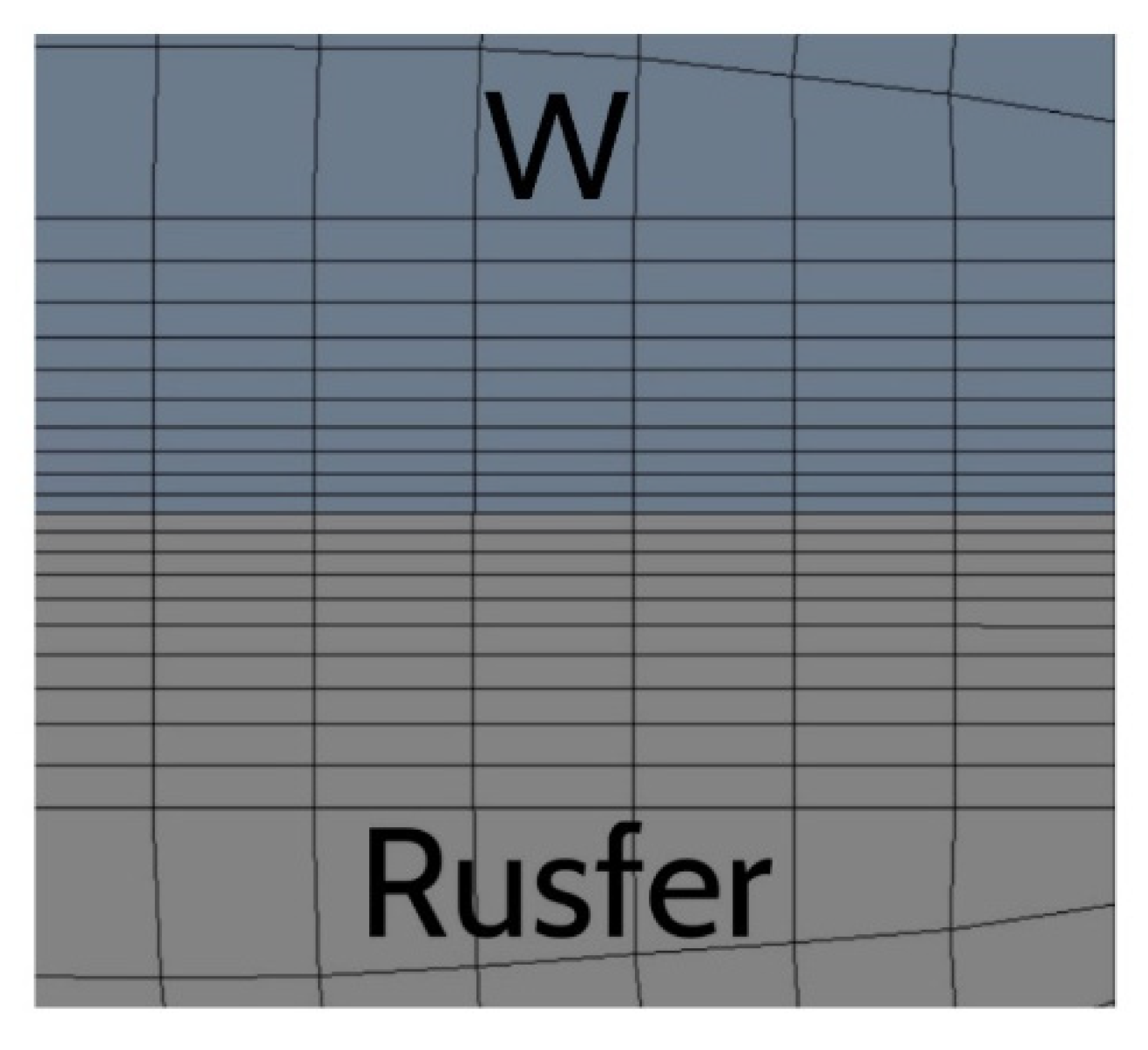

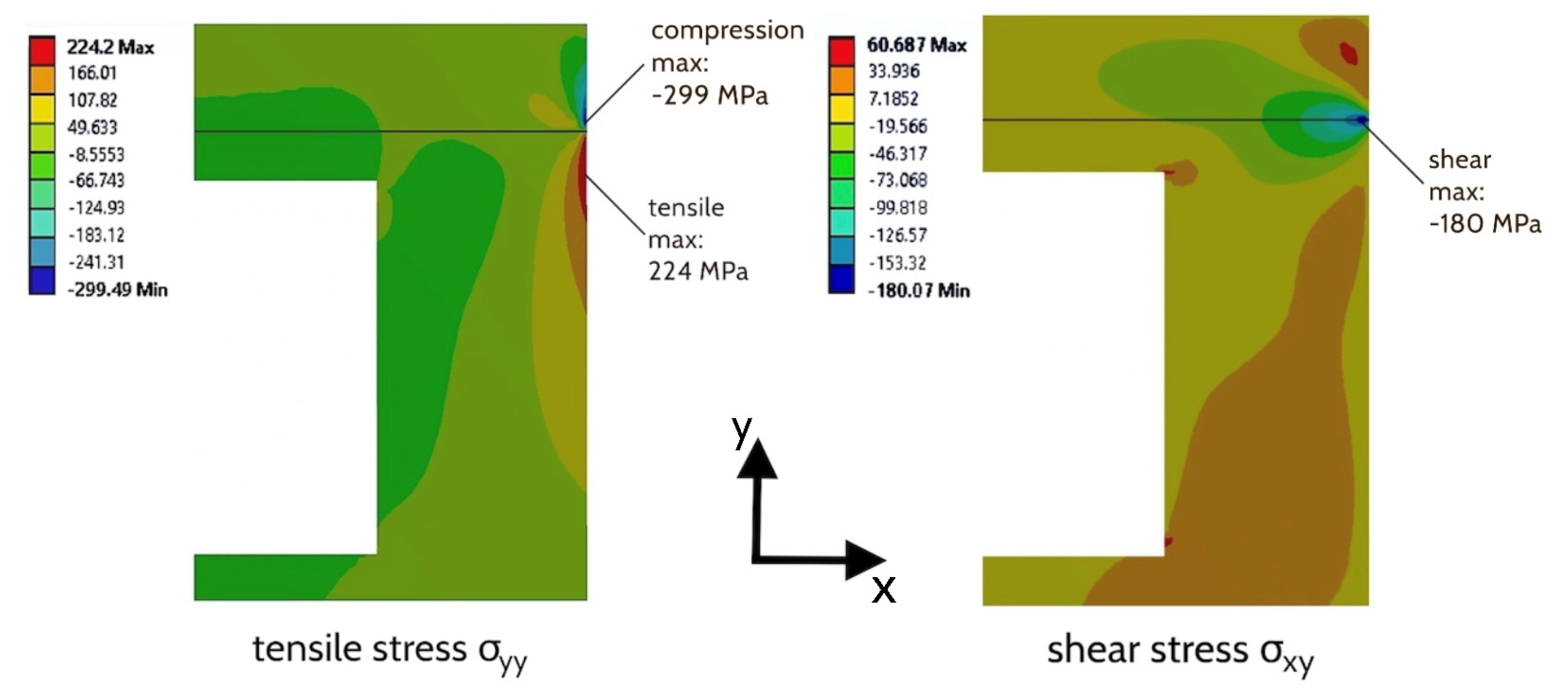

2.2. FEM Calculations

- Cooling, from a joining temperature of 1100 °C to room temperature within 100 s;

- Increasing the temperature and pressure of the breeder and coolant within 1 h;

- Power ignition—with a heat load of 0.5 MW/m2 on the tungsten surface within 100 s.

2.3. Additional Requirements

3. The Latest Progress Made in Tungsten/Steel Brazing

| Ref. | Brazed Joint, wt.% | Brazing Mode, °C/min | Mechanical Properties As-Received, MPa | Thermo-Mechanical Properties, MPa | |||

|---|---|---|---|---|---|---|---|

| [18] | W/brazing foil Ni–7Cr–5Si–3B/Ta 0.5 mm/brazing foil Ni–7Cr–5Si–3B/steel Fe–17Cr–0.1C | 1050/60 | σu = 240–275 | - | |||

| W/brazing foil Ni–7Cr–5Si–3B/Cu 0.5 mm/brazing foil Ni–7Cr–5Si–3B/steel Fe–17Cr–0.1C | σu = 255–295 | - | |||||

| [13] | W/brazing foil Ni–7Cr–5Si–3B–3Fe/V 0.3 mm/brazing foil Ni–7Cr–5Si–3B–3Fe/steel Fe–17Cr | 1150/30 | σu = 143 | - | |||

| [27] | W/Ti/Ni/Ti foils of liquid forming interlayer/steel Fe-17Cr-0.1C | 1050/60 cooling to 650/120 | σu = 185 (RT) σu = 175 (500 °C) σu = 150 (650 °C) | - | |||

| [24] | W/Ni/Cu/Ni electro-chemical plated liquid forming interlayer/steel | 1100/10 | τ = 100 | - | |||

| [26] | W/brazing foil Cu-50Ti/Rusfer | 1100/20 | - | Thermocycling: 700 °C—water quenching 50 cycles | Cracks after 30 cycles | ||

| [33] | W/brazing foil Cu-50Ti/V 0.2 mm/brazing foil Cu-12Ge/Rusfer | 1100/20 | τ = 106 | τ = 60 | |||

| W/brazing foil Cu-50Ti/V 0.2 mm/brazing foil Cu-25Ge/Rusfer | 1100/20 | τ = 126 | τ = 47 | ||||

| [12] | W/brazing foil Cu-50Ti/V 0.2 mm/brazing foil Cu-12Sn/Rusfer | 1100/20 | τ = 140 | τ = 35 | |||

| W/brazing foil Cu-50Ti/V 0.2 mm/brazing foil Cu-12Sn-0.4P/Rusfer | 1100/20 | τ = 84 | τ = 28 | ||||

| W/brazing foil Cu-50Ti/V 0.2 mm/brazing foil Cu-20Sn/Rusfer | 1100/20 1100/60 cooling to RT + 720/180 | τ = 160 τ = 93 | τ = 46 | ||||

| [38] | W/brazing foil Cu-50Ti/V 0.2 mm/brazing foil Cu-28Ti/Rusfer | 1100/20 1100/60 cooling to RT + 720/180 | τ = 205 τ = 173 | τ = 126 τ = 50 | |||

| W/brazing foil Cu-50Ti/V 0.2 mm/brazing foil Cu-20Ti/Rusfer | 1100/20 | τ = 98 | τ = 30 | ||||

| [39,40] | W/Cu-20Ti pure powders with binder/Eurofer | 960/10 | τ = 145 | High Heat Flux Tests 1000 cycles | 400 °C 500 °C 600 °C | τ = 135 τ = 75 failure after 79 cycles | |

| [14,41] | W/Cu-20Ti mechanically alloyed powders with binder/Eurofer | 960/10 960/5 960/5 cooling to RT + 780/30 | τ = 93 τ = 100 τ = 60 | - | |||

| [19] | W/Ti/Cu/Ti foils of liquid formings interlayer/steel Fe–17Cr–0.1C | 100 MPa hot isostatic pressure 1050/60 | τ = 248 | - | |||

| [44] | W/Cu-22TiH2 powder paste/SS301 | 700/30 to decompose TiH2 + 900/10 | τ = 98 | - | |||

| [33] | W/brazing foil of pure Cu 0.1 mm/Rusfer | 1100/20 | τ = 260 | Thermocycling: 700 °C—water quenching 50 cycles | τ = 102 | ||

| [46] | W/brazing foil of pure Cu 0.25 mm/Eurofer | 1135/10 1135/10 cooling to RT + 760/90 1110/10 | τ = 309 τ = 180 τ = 204 | - | |||

| W/brazing foil of pure Cu 0.05 mm/Eurofer | 1135/10 1135/10 cooling to RT + 760/90 1110/10 | τ = 225 τ = 150 τ = 193 | - | ||||

| [15] | W/electrodeposited Sn and Fe on Ti foil: Sn/Fe/Ti/Fe/Sn/CLF-1 | Sn thickness, mg/cm2 | 1090/5 cooling to 900/30 | τ = 220 | Thermocycling: 700 °C—water quenching 30 cycles | Failure after 2–3 cycles | |

| 0 | |||||||

| 0.57 | - | - | |||||

| 1.12 | - | - | |||||

| 1.55 | τ = 250 | No failure | |||||

| 2.12 | - | No failure | |||||

| 2.7 | - | No failure | |||||

| [47] | W/brazing foil Fe-3B-5Si/ODS K1 | 1200/30–240 | - | - | |||

| [25] | Monocrystalline W/powder Ti-22.5Cr-7.5 V-(2–3)Be/Ta 0.1 mm/powder Fe-18Ta-(6–10)Ge-(0–4)Si-(0–2)Pd-(2–3)B/ODS Eurofer97 | 1150/20–60 | - | Thermocycling: 750 °C/20 min and air cooling/3–5 min No failure | |||

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ihli, T.; Raffray, A.; Abdel-Khalik, S.; Shin, S. Design and performance study of the helium-cooled T-tube divertor concept. Fusion Eng. Des. 2007, 82, 249–264. [Google Scholar] [CrossRef]

- Raffray, A.R.; Malang, S.; Wang, X. Optimizing the overall configuration of a He-cooled W-alloy divertor for a power plant. Fusion Eng. Des. 2009, 84, 1553–1557. [Google Scholar] [CrossRef]

- Wang, X.; Malang, S.; Raffray, A.R. Design Optimization of High-Performance Helium-Cooled Divertor Plate Concept. Fusion Sci. Technol. 2009, 56, 1023–1027. [Google Scholar] [CrossRef]

- Tillack, M.S.; Raffray, A.R.; Wang, X.R.; Malang, S.; Abdel-Khalik, S.; Yoda, M.; Youchison, D. Recent US activities on advanced He-cooled W-alloy divertor concepts for fusion power plants. Fusion Eng. Des. 2011, 86, 71–98. [Google Scholar] [CrossRef]

- Martelli, E.; Giannetti, F.; Caruso, G.; Tarallo, A.; Polidori, M.; Barucca, L.; Del Nevo, A. Study of EU DEMO WCLL breeding blanket and primary heat transfer system integration. Fusion Eng. Des. 2018, 136, 828–833. [Google Scholar] [CrossRef]

- Aiello, G.; Aubert, J.; Jonquères, N.; Li Puma, A.; Morin, A.; Rampal, G. Development of the Helium Cooled Lithium Lead blanket for DEMO. Fusion Eng. Des. 2014, 89, 1444–1450. [Google Scholar] [CrossRef]

- Kessel, C.E.; Blanchard, J.P.; Davis, A.; El-Guebaly, L.; Garrison, L.M.; Ghoniem, N.M.; Humrickhouse, P.W.; Huang, Y.; Katoh, Y.; Khodak, A.; et al. Overview of the fusion nuclear science facility, a credible break-in step on the path to fusion energy. Fusion Eng. Des. 2018, 135, 236–270. [Google Scholar] [CrossRef]

- Cai, Q.; Liu, W.; Ma, Y.; Zhu, W.; Pang, X. Effect of joining temperature on the microstructure and strength of W–steel HIP joints with Ti/Cu composite interlayer. J. Nucl. Mater. 2018, 507, 198–207. [Google Scholar] [CrossRef]

- Wang, J.C.; Huang, J.; Sun, H.; Gao, X.; Wang, W.; Li, Q.; Xie, C.; Wang, X.; Chen, Z.; Gao, Q.; et al. Effect of deuterium on bonding quality of W/Ti/Steel HIP joints in first wall application. Fusion Eng. Des. 2019, 138, 313–320. [Google Scholar] [CrossRef]

- Chen, H.Y.; Luo, L.M.; Zhang, J.; Zan, X.; Zhu, X.Y.; Luo, G.N.; Wu, Y.C. Investigation on W/Fe diffusion bonding using Ti foil and Ti powder interlayer by SPS. J. Nucl. Mater. 2015, 467, 566–571. [Google Scholar] [CrossRef]

- Tan, C.; Wang, C.; Wang, S.; Wang, G.; Ji, L.; Tong, Y.; Duan, X.M. Investigation on 316 L/316 L-50 W/W plate functionally graded materials fabricated by spark plasma sintering. Fusion Eng. Des. 2017, 125, 171–177. [Google Scholar] [CrossRef]

- Bachurina, D.; Suchkov, A.; Gurova, Y.; Sevryukov, O. Investigation of a brazed joint EK-181/V/W obtained by Cu-Sn and Cu-Ti amorphous foils. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1005, 012010. [Google Scholar] [CrossRef]

- Ma, Y.Z.; Cai, Q.S.; Liu, W.S.; Liu, S.H. Microstructure and Mechanical Properties of Brazed Tungsten/Steel Joint for Divertor Applications. Mater. Sci. Forum 2014, 789, 384–390. [Google Scholar] [CrossRef]

- De Prado, J.; Sánchez, M.; Ureña, A. Improvements in W-Eurofer first wall brazed joint using alloyed powders fillers. Fusion Eng. Des. 2017, 124, 1082–1085. [Google Scholar] [CrossRef]

- Zhu, W.; Qiang, J.; Wang, Y.; Sun, J.; Wang, J.; Lian, Y.; Feng, F.; Liu, X. A Ti-Fe-Sn thin film assembly for joining tungsten and reduced activation ferritic-martensitic steels. Mater. Des. 2017, 125, 55–61. [Google Scholar] [CrossRef]

- Basuki, W.W.; Aktaa, J. Investigation of tungsten/EUROFER97 diffusion bonding using Nb interlayer. Fusion Eng. Des. 2011, 86, 2585–2588. [Google Scholar] [CrossRef]

- Litunovsky, N.; Alekseenko, E.; Makhankov, A.; Mazul, I. Development of the armoring technique for ITER Divertor Dome. Fusion Eng. Des. 2011, 86, 1749–1752. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Z.; Ma, Y.; Cai, Q. Investigation of tungsten/steel brazing using Ta and Cu interlayer. Fusion Eng. Des. 2016, 113, 102–108. [Google Scholar] [CrossRef]

- Liu, W.; Pang, X.; Cai, Q.; Ma, Y.; Zhu, W. Fabrication of W/steel joint using hot isostatic pressing with Ti/Cu/Ti liquid forming interlayer. Fusion Eng. Des. 2018, 135, 59–64. [Google Scholar] [CrossRef]

- Bolt, H.; Barabash, V.; Krauss, W.; Linke, J.; Neu, R.; Suzuki, S.; Yoshida, N. Materials for the plasma-facing components of fusion reactors. J. Nucl. Mater. 2004, 329–333, 66–73. [Google Scholar] [CrossRef] [Green Version]

- Norajitra, P.; Antusch, S.; Giniyatulin, R.; Kuznetsov, V.; Mazul, I.; Ritzhaupt-Kleissl, H.J.; Spatafora, L. Progress of He-cooled divertor development for DEMO. Fusion Eng. Des. 2011, 86, 1656–1659. [Google Scholar] [CrossRef]

- Reiser, J.; Rieth, M. Optimization and limitations of known DEMO divertor concepts. Fusion Eng. Des. 2012, 87, 718–721. [Google Scholar] [CrossRef] [Green Version]

- Diegele, E.; Pintsuk, G.; Reiser, J. Divertor Materials for DEMO: How did we progress during the last decade? In Proceedings of the 17th International Conference on Fusion Reactor Materials, Aachen, Germany, 12–16 October 2018; p. 1. [Google Scholar]

- Krauss, W.; Lorenz, J.; Konys, J. Performance of electro-plated and joined components for divertor application. Fusion Eng. Des. 2013, 88, 1704–1708. [Google Scholar] [CrossRef]

- Kalin, B.A.; Fedotov, V.T.; Sevrjukov, O.N.; Kalashnikov, A.N.; Suchkov, A.N.; Moeslang, A.; Rohde, M. Development of brazing foils to join monocrystalline tungsten alloys with ODS-EUROFER steel. J. Nucl. Mater. 2007, 367, 1218–1222. [Google Scholar] [CrossRef]

- Bachurina, D.; Suchkov, A.; Kalin, B.; Sevriukov, O.; Fedotov, I.; Dzhumaev, P.; Ivannikov, A.; Leont’Eva-Smirnova, M.; Mozhanov, E. Joining of tungsten with low-activation ferritic–martensitic steel and vanadium alloys for demo reactor. Nucl. Mater. Energy 2018, 15, 135–142. [Google Scholar] [CrossRef]

- Cai, Q.; Liu, W.; Ma, Y.; Wang, Z. Diffusion brazing of tungsten and steel using Ti–Ni liquid phase forming interlayer. Fusion Eng. Des. 2015, 91, 67–72. [Google Scholar] [CrossRef]

- Federici, G.; Boccaccini, L.; Cismondi, F.; Gasparotto, M.; Poitevin, Y.; Ricapito, I. An overview of the EU breeding blanket design strategy as an integral part of the DEMO design effort. Fusion Eng. Des. 2019, 141, 30–42. [Google Scholar] [CrossRef]

- Wenninger, R.; Albanese, R.; Ambrosino, R.; Arbeiter, F.; Aubert, J.; Bachmann, C.; Barbato, L.; Barrett, T.; Beckers, M.; Biel, W.; et al. The DEMO wall load challenge. Nucl. Fusion 2017, 57, 046002. [Google Scholar] [CrossRef]

- Huang, Y.; Cismondi, F.; Diegele, E.; Federici, G.; Del Nevo, A.; Moro, F.; Ghoniem, N. Thermo-structural design of the European DEMO water-cooled blanket with a multiscale-multiphysics framework. Fusion Eng. Des. 2018, 135, 31–41. [Google Scholar] [CrossRef]

- Igitkhanov, Y.; Bazylev, B.; Fetzer, R. The Quantification of the Key Physics Parameters for the DEMO Fusion Power Reactor and Analysis of the Reactor Relevant Physics Issues; KIT Scientific Publishing: Karlsruhe, Germany, 2015; 147p. [Google Scholar]

- Heuer, S.; Coenen, J.W.; Pintsuk, G.; Matějíček, J.; Vilémová, M.; Linsmeier, C. Overview of challenges and developments in joining tungsten and steel for future fusion reactors. Phys. Scr. 2020, 171, 014028. [Google Scholar] [CrossRef]

- Bachurina, D.; Suchkov, A.; Filimonov, A.; Fedotov, I.; Savelyev, M.; Sevryukov, O.; Kalin, B. High-temperature brazing of tungsten with steel by Cu-based ribbon brazing alloys for DEMO. Fusion Eng. Des. 2019, 146, 1343–1346. [Google Scholar] [CrossRef]

- Gilbert, M.R.; Sublet, J.-C.; Forrest, R.A. Handbook of Activation, Transmutation, and Radiation Damage Properties of the Elements Simulated Using FISPACT-II & TENDL-2014; Magnetic Fusion Plants; CCFE-R(15)26; Culham Centre for Fusion Energy: Abingdon, UK, 2015; pp. 1–696. [Google Scholar]

- Tsuchida, K.; Miyazawa, T.; Hasegawa, A.; Nogami, S.; Fukuda, M. Recrystallization behavior of hot-rolled pure tungsten and its alloy plates during high-temperature annealing. Nucl. Mater. Energy 2018, 15, 158–163. [Google Scholar] [CrossRef]

- De Oliveira, V.B.; Padilha, A.F. Abnormal Grain Growth in Ferritic-Martensitic Eurofer-97 Steel. Mater. Sci. Forum 2013, 753, 333–336. [Google Scholar] [CrossRef]

- Stopher, M.A. The effects of neutron radiation on nickel-based alloys. Mater. Sci. Technol. 2017, 33, 518–536. [Google Scholar] [CrossRef]

- Bachurina, D.; Suchkov, A.; Gurova, J.; Savelyev, M.; Dzhumaev, P.; Kozlov, I.; Svetogorov, R.; Leont’Eva-Smirnova, M.; Sevryukov, O. Joining tungsten with steel for DEMO: Simultaneous brazing by Cu-Ti amorphous foils and heat treatment. Fusion Eng. Des. 2021, 162, 112099. [Google Scholar] [CrossRef]

- De Prado, J.; Sánchez, M.; Ureña, A. Development of brazing process for W–EUROFER joints using Cu-based fillers. Phys. Scr. 2016, 2016, 014022. [Google Scholar] [CrossRef]

- De Prado, J.; Sánchez, M.; Wirtz, M.; Pintsuk, G.; Du, J.; Linke, J.; Ureña, A. High heat flux performance of W-Eurofer brazed joints. J. Nucl. Mater. 2018, 499, 225–232. [Google Scholar] [CrossRef]

- De Prado, J.; Sánchez, M.; Ureña, A. Evaluation of mechanically alloyed Cu-based powders as filler alloy for brazing tungsten to a reduced activation ferritic-martensitic steel. J. Nucl. Mater. 2017, 490, 188–196. [Google Scholar] [CrossRef]

- De Prado, J.; Sánchez, M.; Ureña, A. Wettability study of a Cu-Ti alloy on tungsten and EUROFER substrates for brazing components of DEMO fusion reactor. Mater. Des. 2016, 99, 93–101. [Google Scholar] [CrossRef]

- De Prado, J.; Sánchez, M.; Arbizu, G.; Ureña, A. In-Situ SEM Fracture Analysis of W-Eurofer Brazed Joints Under Three-Point Bending Test Configuration. Met. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 3488–3496. [Google Scholar] [CrossRef]

- Peng, L.; Mao, Y.; Zhang, Y.; Xi, L.; Deng, Q.; Wang, G. Microstructural and mechanical characterizations of W/CuCrZr and W/steel joints brazed with Cu-22TiH2 filler. J. Mater. Process. Technol. 2018, 254, 346–352. [Google Scholar] [CrossRef]

- Cai, Q.; Zhu, W.; Ma, Y.; Liu, W.; Pang, X.; Liang, C. Rational design of composite interlayer for diffusion bonding of tungsten–steel joints. Int. J. Refract. Met. Hard Mater. 2018, 70, 155–161. [Google Scholar] [CrossRef]

- De Prado, J.; Sánchez, M.; Ruiz, A.; Ureña, A. Effect of brazing temperature, filler thickness and post brazing heat treatment on the microstructure and mechanical properties of W-Eurofer joints brazed with Cu interlayers. J. Nucl. Mater. 2020, 533, 152117. [Google Scholar] [CrossRef]

- Oono, N.; Noh, S.; Iwata, N.; Nagasaka, T.; Kasada, R.; Kimura, A. Microstructures of brazed and solid-state diffusion bonded joints of tungsten with oxide dispersion strengthened steel. J. Nucl. Mater. 2011, 417, 253–256. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bachurina, D.; Vorkel, V.; Suchkov, A.; Gurova, J.; Ivannikov, A.; Penyaz, M.; Fedotov, I.; Sevryukov, O.; Kalin, B. Overview of the Mechanical Properties of Tungsten/Steel Brazed Joints for the DEMO Fusion Reactor. Metals 2021, 11, 209. https://doi.org/10.3390/met11020209

Bachurina D, Vorkel V, Suchkov A, Gurova J, Ivannikov A, Penyaz M, Fedotov I, Sevryukov O, Kalin B. Overview of the Mechanical Properties of Tungsten/Steel Brazed Joints for the DEMO Fusion Reactor. Metals. 2021; 11(2):209. https://doi.org/10.3390/met11020209

Chicago/Turabian StyleBachurina, Diana, Vladimir Vorkel, Alexey Suchkov, Julia Gurova, Alexander Ivannikov, Milena Penyaz, Ivan Fedotov, Oleg Sevryukov, and Boris Kalin. 2021. "Overview of the Mechanical Properties of Tungsten/Steel Brazed Joints for the DEMO Fusion Reactor" Metals 11, no. 2: 209. https://doi.org/10.3390/met11020209

APA StyleBachurina, D., Vorkel, V., Suchkov, A., Gurova, J., Ivannikov, A., Penyaz, M., Fedotov, I., Sevryukov, O., & Kalin, B. (2021). Overview of the Mechanical Properties of Tungsten/Steel Brazed Joints for the DEMO Fusion Reactor. Metals, 11(2), 209. https://doi.org/10.3390/met11020209