The Development of WC-Based Composite Tools for Friction Stir Welding of High-Softening-Temperature Materials

Abstract

:1. Introduction

2. Experimental Work

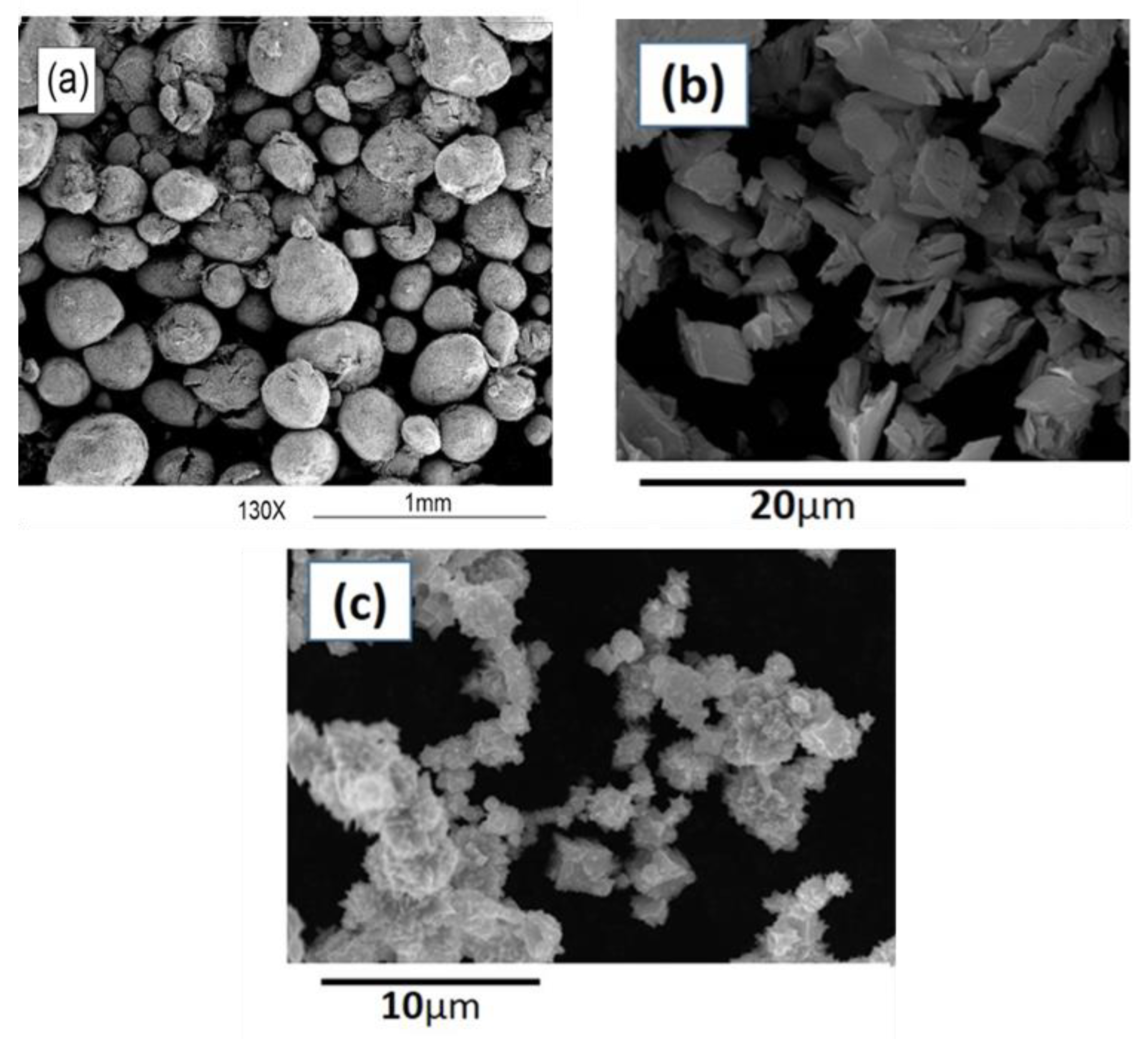

2.1. Materials

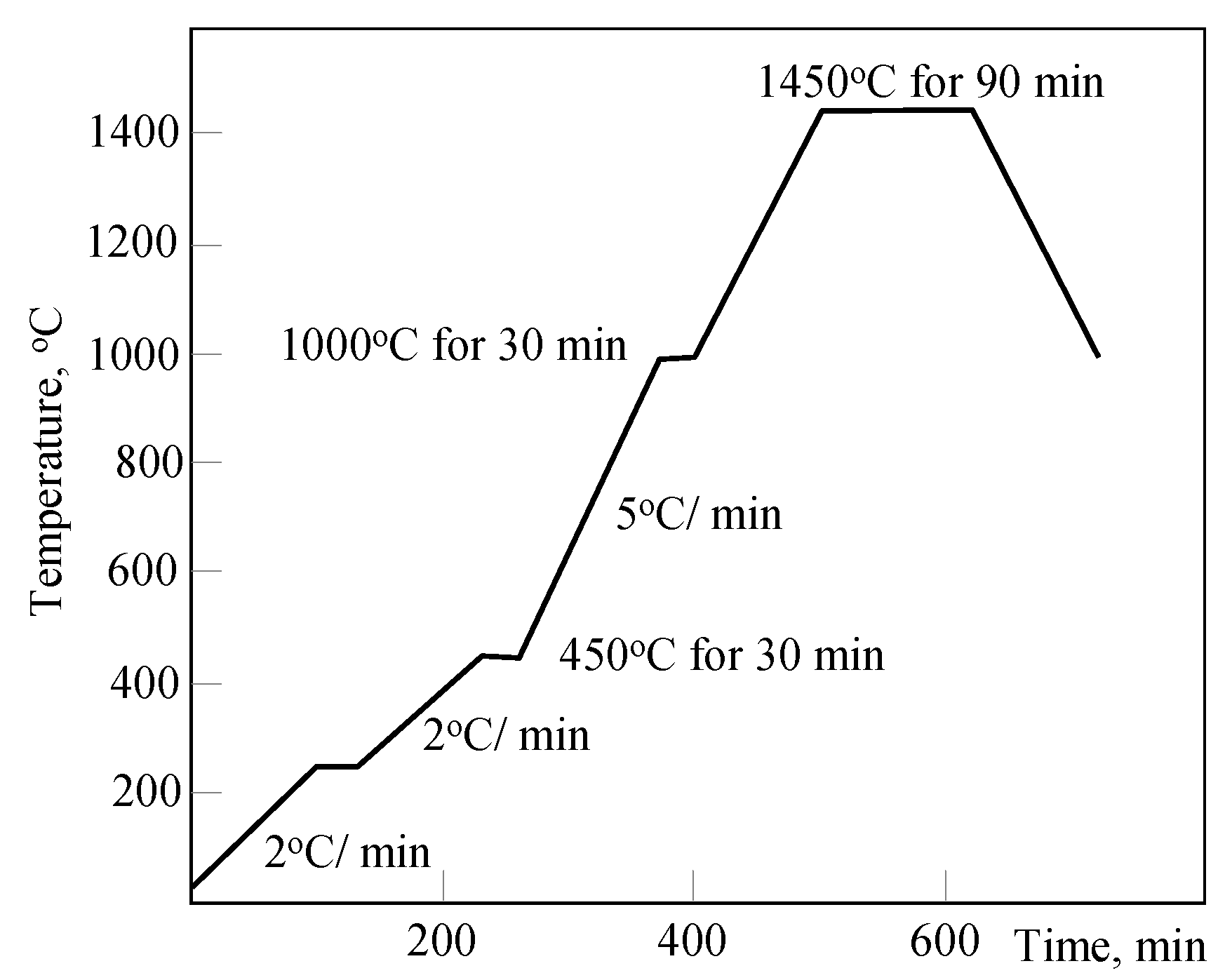

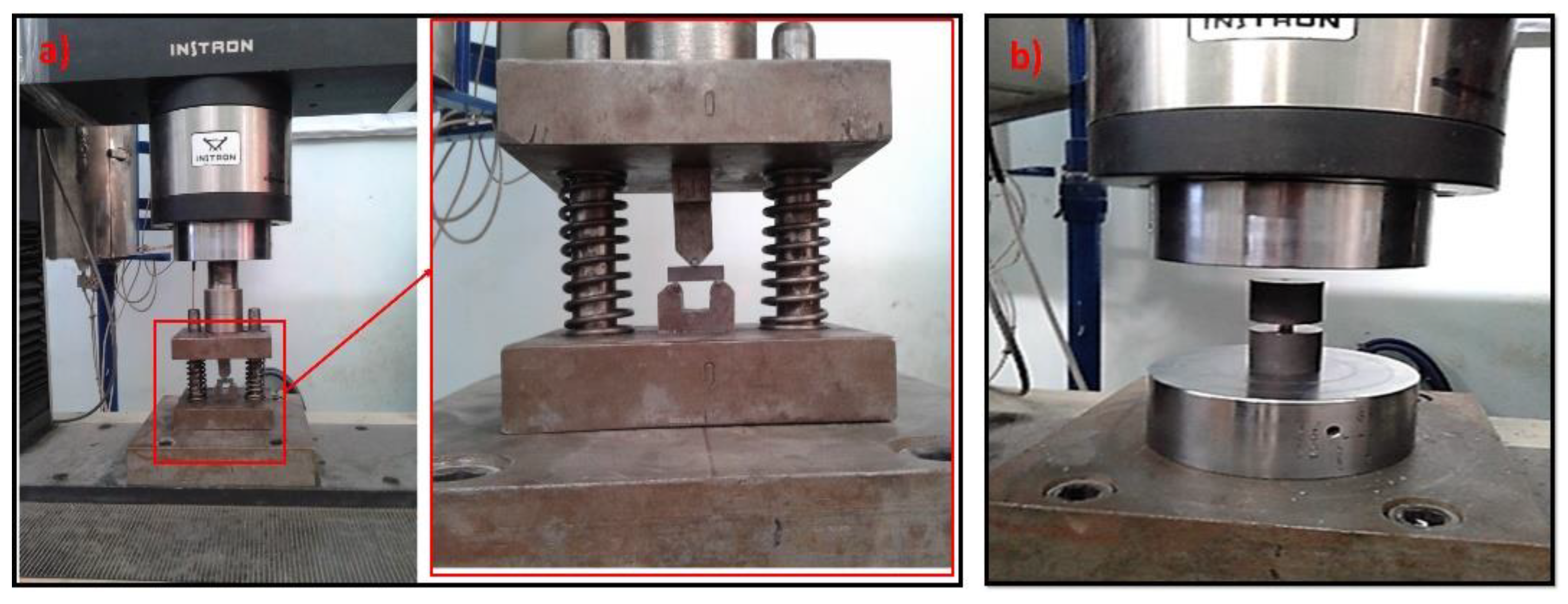

2.2. Powder Compaction and Sintering

2.3. Characteriztion of the Consolidated Composites

3. Results and Discussion

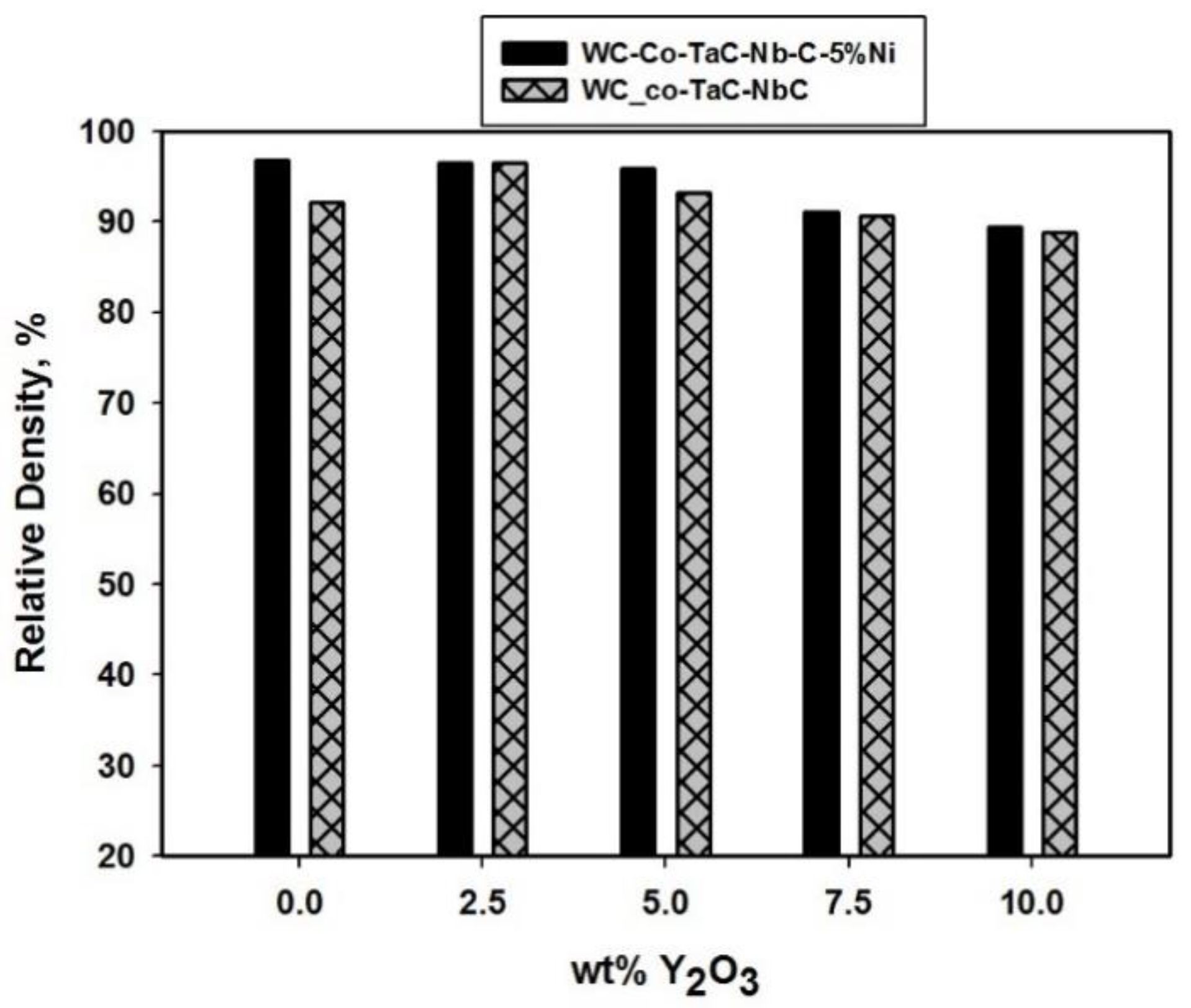

3.1. Densification

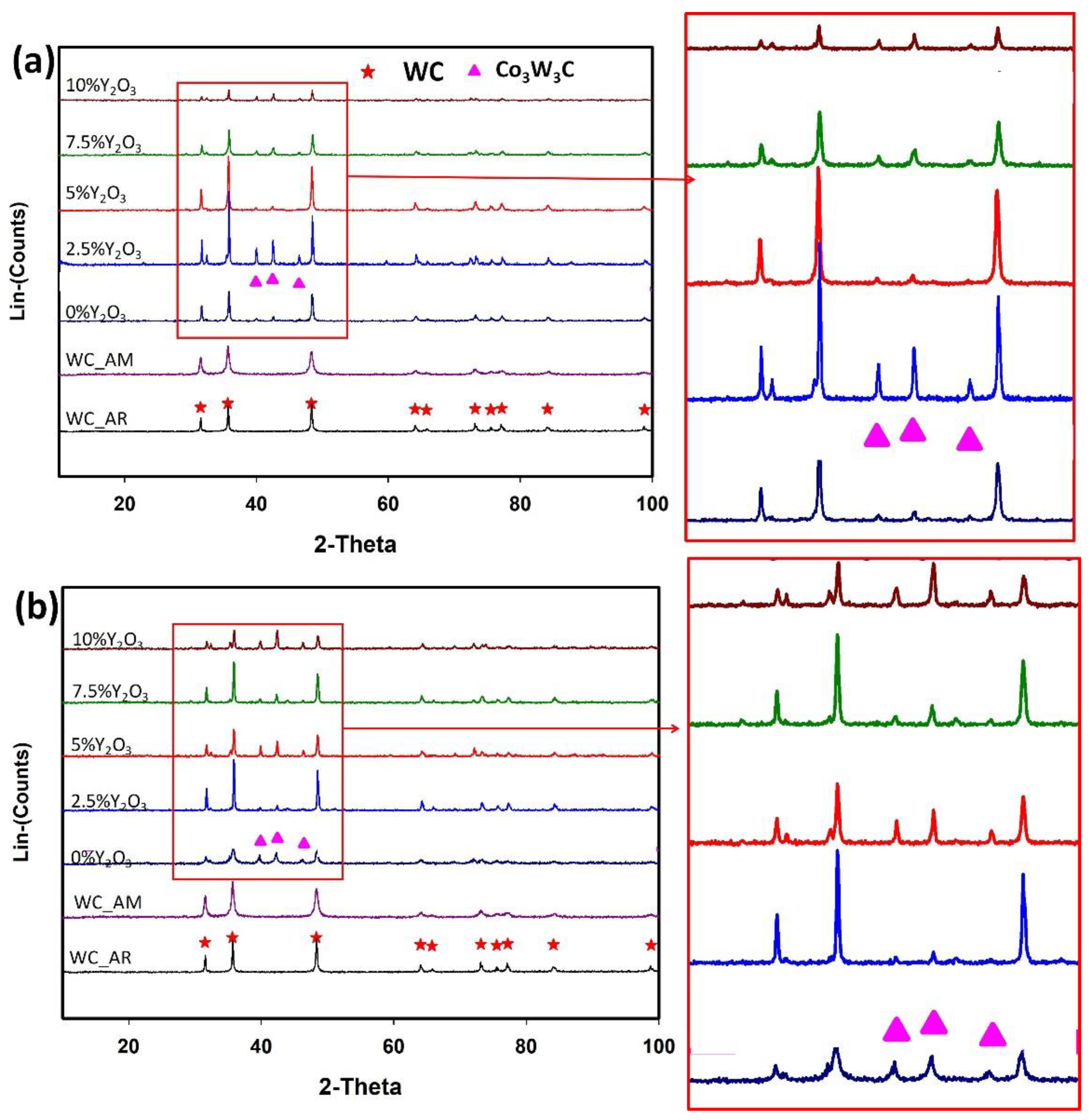

3.2. XRD Analysis

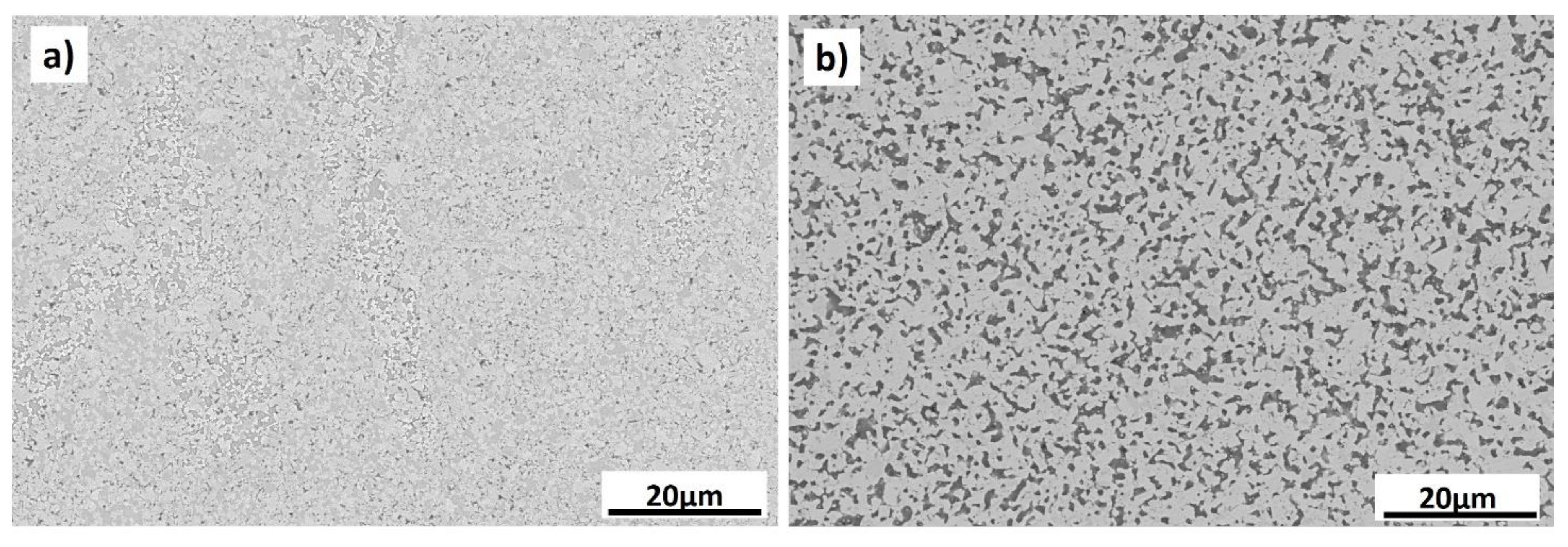

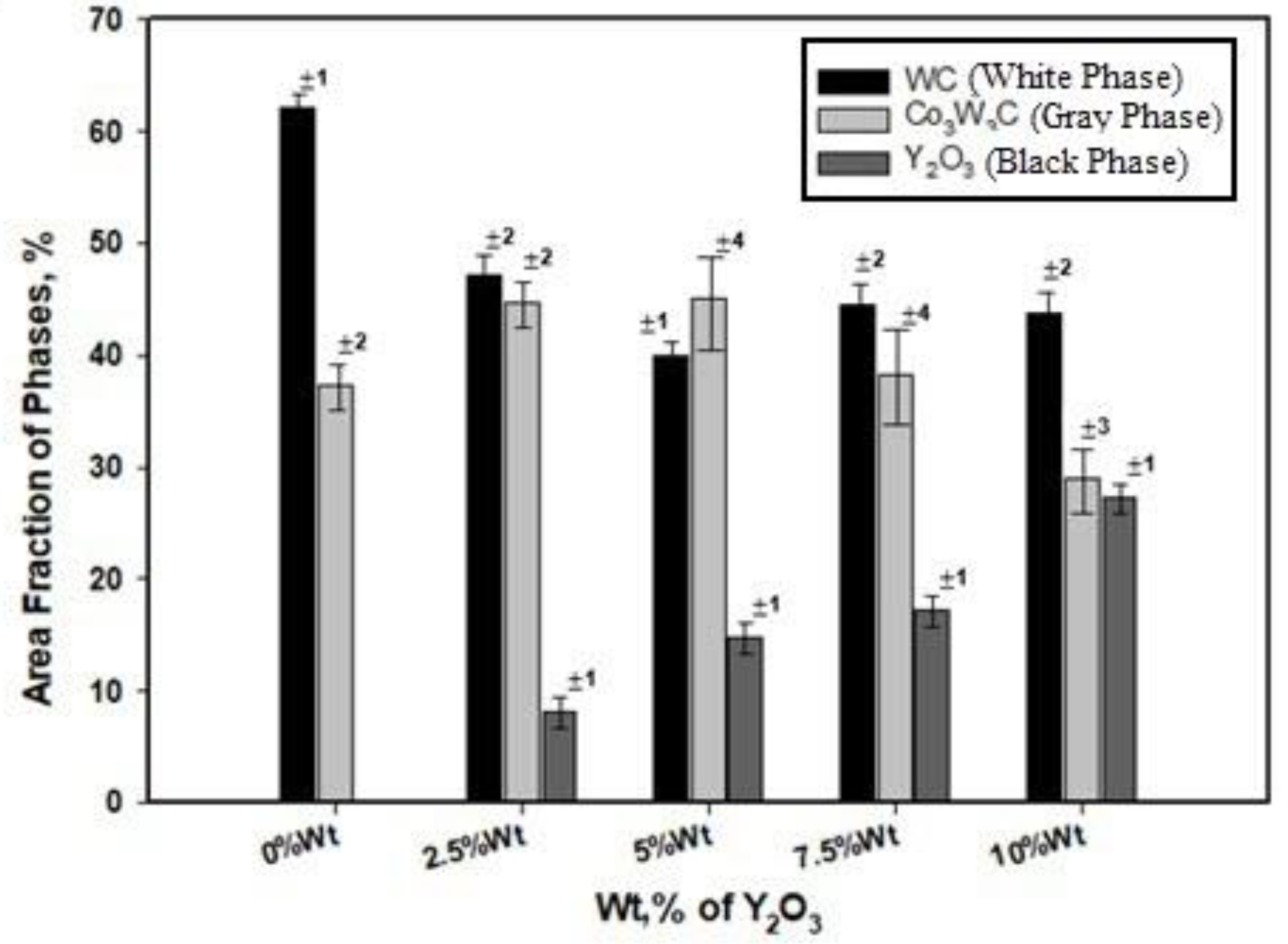

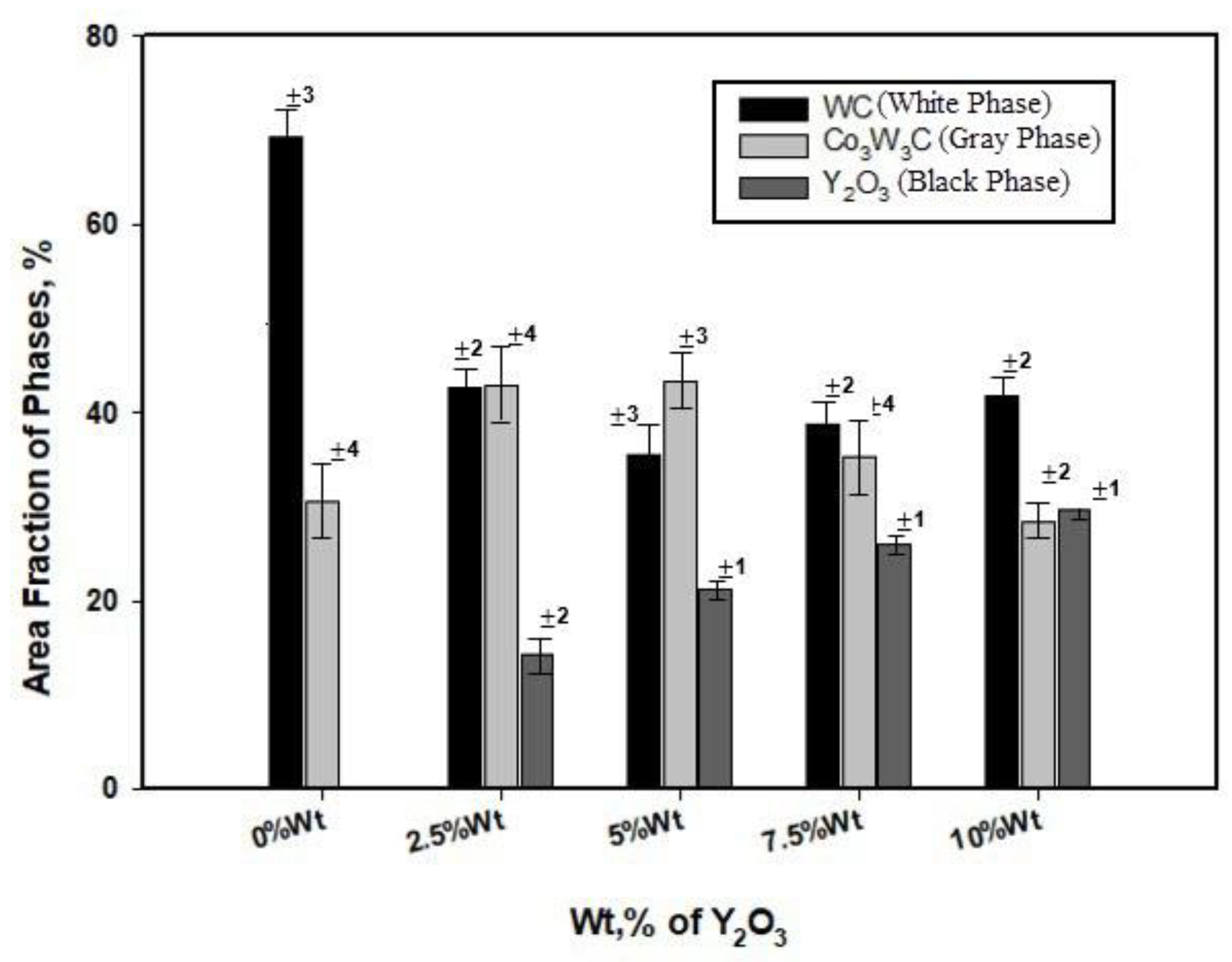

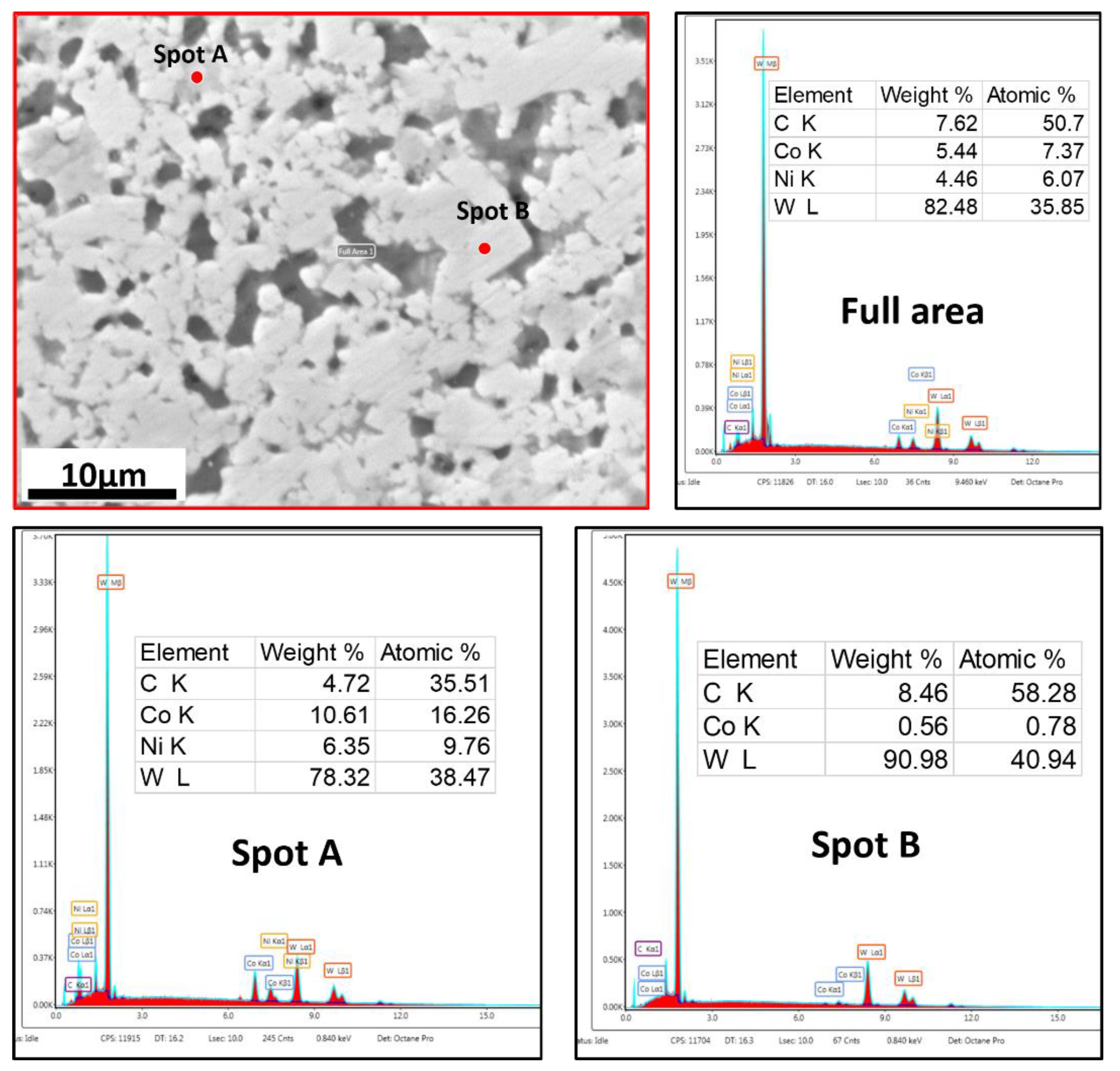

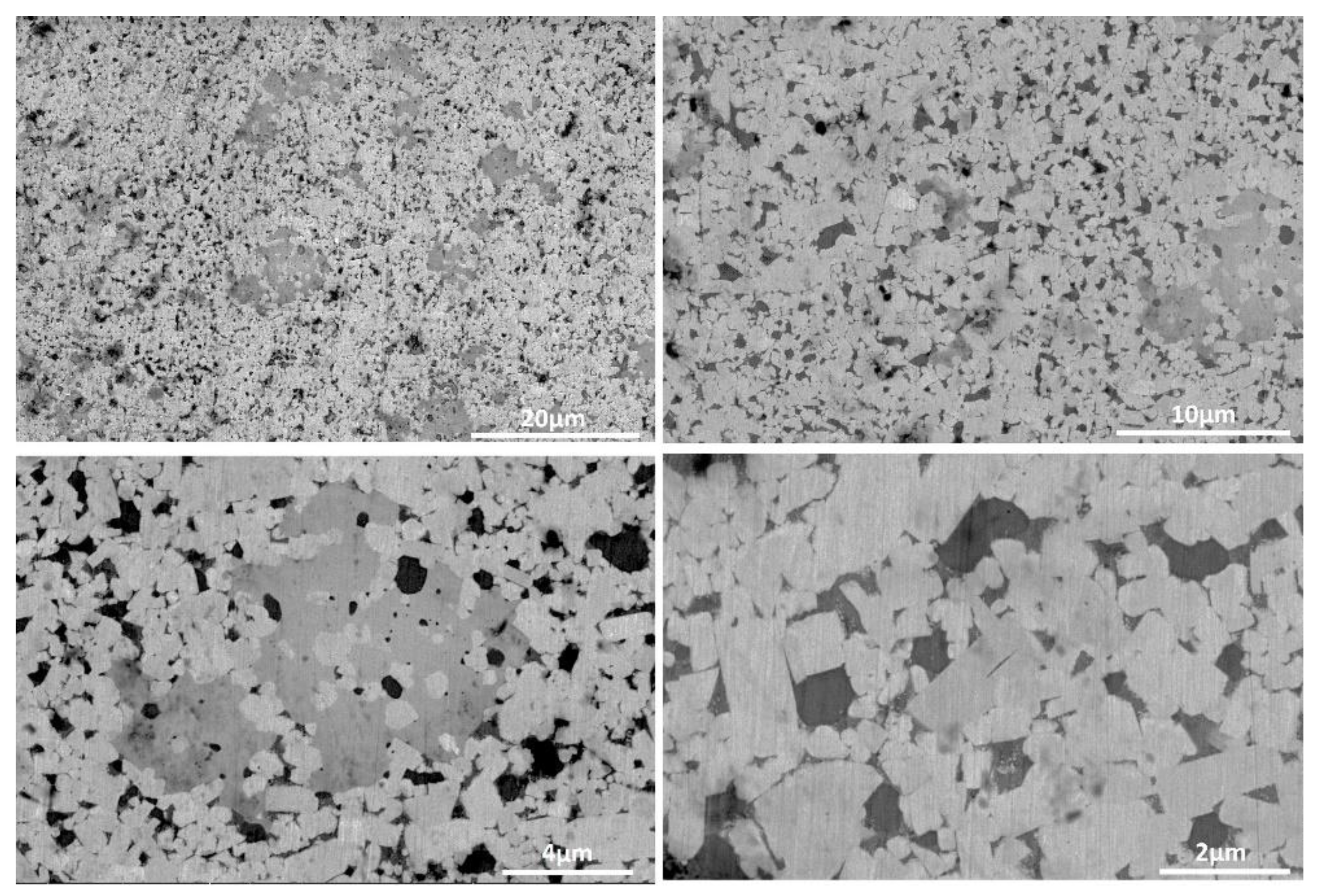

3.3. Microstructure of the Consolidated Composites

3.4. Mechanical Properties

4. FSW Tool for High-Softening-Temperature Materials

5. Conclusions

- The consolidation process applied to the WC-based composites resulted in a relative density of up to 97%, which was enhanced by the 5 wt% Ni addition.

- Upon the sintering process, the Co3W3C η-phase was formed, and its formation was slightly reduced by the addition of 5 wt% Ni and 2.5 wt% Y2O3.

- The microstructure of the consolidated composites consisted of a very well-connected WC matrix, with homogenous dispersion of the Y2O3 particles at the lower Y2O3 content (up to 5 wt%) which retarded the grain growth during sintering.

- The addition of 5 wt% Ni significantly enhanced the fracture toughness (max. of 10.4 MPa ), the transverse rupture strength (max. of 758 Mpa) and the compressive strength (max. of 3013 MPa). On the other hand, only the hardness was slightly reduced for all Y2O3 contents; for example, at 0 w% Y2O3, the hardness was reduced from 1425 MPa to 1398 MPa.

- The WC-Co-TaC-NbC with 2.5 wt% Y2O3 and 5 wt% Ni was selected to manufacture friction stir welding tools, which were successfully used for the FSW of Ni base alloy and carbon steel, with more than 25 plunges and more than 500 cm of butt joints. This can be a cost-effective tool material for the FSW of high-softening-temperature materials such as steel and nickel-based alloys.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, J.; Zhu, S.; Ouyang, C. Two-Step Hot-Pressing Sintering of Nanocomposite WC-MgO Compacts. J. Eur. Ceram. Soc. 2011, 31, 1927–1935. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Chakravarty, D.; Basu, B. Spark Plasma-Sintered WC-ZrO2-Co Nanocomposites with High Fracture Toughness and Strength. J. Am. Ceram. Soc. 2010, 93, 1754–1763. [Google Scholar] [CrossRef]

- Kim, H.C.; Shon, I.J.; Yoon, J.K.; Doh, J.M. Consolidation of Ultra Fine WC and WC-Co Hard Materials by Pulsed Current Activated Sintering and Its Mechanical Properties. Int. J. Refract. Met. Hard Mater. 2007, 25, 46–52. [Google Scholar] [CrossRef]

- Sivaprahasam, D.; Chandrasekar, S.B.; Sundaresan, R. Microstructure and Mechanical Properties of Nanocrystalline WC-12Co Consolidated by Spark Plasma Sintering. Int. J. Refract. Met. Hard Mater. 2007, 25, 144–152. [Google Scholar] [CrossRef]

- Kim, C.S.; Massa, T.R.; Rohrer, G.S. Modeling the Relationship between Microstructural Features and the Strength of WC-Co Composites. Int. J. Refract. Met. Hard Mater. 2006, 24, 89–100. [Google Scholar] [CrossRef]

- Schreiber, J. Springer Series in Materials Science 11; Springer Nature Switzerland AG: Cham, Switzerland, 2010; Volume 190, ISBN 9783319005232. [Google Scholar]

- Xiao, D.H.; He, Y.H.; Song, M.; Lin, N.; Zhang, R.F. Y2O3- and NbC-Doped Ultrafine WC-10Co Alloys by Low Pressure Sintering. Int. J. Refract. Met. Hard Mater. 2010, 28, 407–411. [Google Scholar] [CrossRef]

- Agrawal, D.; Cheng, J.; Seegopaul, P.; Gao, L. Grain Growth Control in Microwave Sintering of Ultrafine WC-Co Composite Powder Compacts. Powder Metall. 2000, 43, 15–16. [Google Scholar]

- Azcona, I.; Ordóñez, A.; Sánchez, J.M.; Castro, F. Hot Isostatic Pressing of Ultrafine Tungsten Carbide-Cobalt Hardmetals. J. Mater. Sci. 2002, 37, 4189–4195. [Google Scholar] [CrossRef]

- Chen, J.; Liu, W.; Deng, X.; Wu, S. Tool Life and Wear Mechanism of WC-5TiC-0.5VC-8Co Cemented Carbides Inserts When Machining HT250 Gray Cast Iron. Ceram. Int. 2016, 42, 10037–10044. [Google Scholar] [CrossRef]

- Seleman, M.M.E.; Ahmed, M.M.Z.; Ataya, S.; Mohamed, M.; El-Sayed, S.; Mohamed, M.Z.; Ahmed, S.A. Microstructure and Mechanical Properties of Hot Extruded 6016 Aluminum Alloy/Graphite Composites. J. Mater. Sci. Technol. 2018, 34, 1580–1591. [Google Scholar] [CrossRef]

- Duman, D.; Gökçe, H.; Çimenoĝlu, H. Synthesis, Microstructure, and Mechanical Properties of WC-TiC-Co Ceramic Composites. J. Eur. Ceram. Soc. 2012, 32, 1427–1433. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Wang, X.; Ryu, T.; Hwang, K.S.; Sohn, H.Y. Synthesis, Sintering, and Mechanical Properties of Nanocrystalline Cemented Tungsten Carbide—A Review. Int. J. Refract. Met. Hard Mater. 2009, 27, 288–299. [Google Scholar] [CrossRef]

- Yu, H.; Li, W.N.; Jiang, X.Q.; Jiao, P.H. Effect of VC, TaC and NbC Additions on Microstructure and Properties of Ultrafine WC-10%Co Cemented Carbides. Appl. Mech. Mater. 2013, 320, 281–286. [Google Scholar] [CrossRef]

- Xiao, D.H.; He, Y.H.; Luo, W.H.; Song, M. Effect of VC and NbC Additions on Microstructure and Properties of Ultrafine WC-10Co Cemented Carbides. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2009, 19, 1520–1525. [Google Scholar] [CrossRef]

- Liu, S.; Huang, Z.L.; Liu, G.; Yang, G. Bin Preparing Nano-Crystalline Rare Earth Doped WC/Co Powder by High Energy Ball Milling. Int. J. Refract. Met. Hard Mater. 2006, 24, 461–464. [Google Scholar] [CrossRef]

- Lin, N.; Jiang, Y.; Zhang, D.F.; Wu, C.H.; He, Y.H.; Xiao, D.H. Effect of Cu, Ni on the Property and Microstructure of Ultrafine WC-10Co Alloys by Sinter-Hipping. Int. J. Refract. Met. Hard Mater. 2011, 29, 509–515. [Google Scholar] [CrossRef]

- Yajiang, L.; Zengda, Z.; Xiao, H.; Tao, F.; Xinghong, W. A Study on Microstructure in the Brazing Interface of WC–TiC–Co Hard Alloys. Int. J. Refract. Met. Hard Mater. 2002, 20, 169–173. [Google Scholar] [CrossRef]

- Huang, S.G.; Liu, R.L.; Li, L.; Van der Biest, O.; Vleugels, J. NbC as Grain Growth Inhibitor and Carbide in WC-Co Hardmetals. Int. J. Refract. Met. Hard Mater. 2008, 26, 389–395. [Google Scholar] [CrossRef]

- Zhou, W.; Xiong, J.; Wan, W.; Guo, Z.; Lin, Z.; Huang, S.; Tang, L.; Zhong, H. The Effect of NbC on Mechanical Properties and Fracture Behavior of WC-10Co Cemented Carbides. Int. J. Refract. Met. Hard Mater. 2015, 50, 72–78. [Google Scholar] [CrossRef]

- Venkateswaran, T.; Sarkar, D.; Basu, B. Tribological Properties of WC-ZrO2 Nanocomposites. J. Am. Ceram. Soc. 2005, 88, 691–697. [Google Scholar] [CrossRef]

- Su, W.; Sun, Y.; Liu, J.; Feng, J.; Ruan, J. Effects of Ni on the Microstructures and Properties of WC-6Co Cemented Carbides Fabricated by WC-6(Co, Ni) Composite Powders. Ceram. Int. 2015, 41, 3169–3177. [Google Scholar] [CrossRef]

- Tarragó, J.M.; Roa, J.J.; Valle, V.; Marshall, J.M.; Llanes, L. Fracture and Fatigue Behavior of WC-Co and WC-CoNi Cemented Carbides. Int. J. Refract. Met. Hard Mater. 2015, 49, 184–191. [Google Scholar] [CrossRef] [Green Version]

- Shi, K.H.; Zhou, K.C.; Li, Z.Y.; Zhang, D.; Zan, X.Q. Microstructure and Formation Process of Ni-Pool Defect in WC-8Ni Cemented Carbides. Trans. Nonferrous Met. Soc. China 2015, 25, 873–878. [Google Scholar] [CrossRef]

- Sha, L. Study on Rare-Earth Doped Cemented Carbides in China. Int. J. Refract. Met. Hard Mater. 2009, 27, 528–534. [Google Scholar] [CrossRef]

- Pan, Q. Effects of Rare Earth Oxides on the Properties of WC– Co Cemented Carbide. Rare Met. Mater. Eng. 1993, 41, 22–35. [Google Scholar]

- El-kady, O.A.M. Effect of Nano-Yttria Addition on the Properties of WC/Co Composites. Mater. Des. 2013, 52, 481–486. [Google Scholar] [CrossRef]

- Qin, Y.; Peng, Y.; Tian, Y.; Luo, L.; Ma, Y.; Zan, X. Effect of Y2O3 on Microstructure and Mechanical Properties of WC-Co- Cemented Carbides Prepared via Solid-Liquid Doping Method and Spark Plasma Sintering. Mater. Today Commun. 2020, 24, 101096. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, L.; Zan, X.; Zhu, X.; Zhu, L.; Wu, Y. International Journal of Refractory Metals Synthesis of Y2O3 -Doped WC-Co Powders by Wet Chemical Method and Its Effect on the Properties of WC-Co Cemented Carbide Alloy. Int. J. Refract. Metals Hard Mater. 2020, 92, 105324. [Google Scholar] [CrossRef]

- Li, J.; Cheng, J.; Wei, B.; Chen, P. Preparation and Performance of Ultra Fi Ne Grained WC-10Co Alloys With. Ceram. Int. 2019, 45, 3969–3976. [Google Scholar] [CrossRef]

- Shetty, D.K.; Wright, I.G.; Mincer, P.N.; Clauer, A.H. Indentation fracture of WC-Co Cermets. J. Mater. Sci. 1985, 20, 1873–1882. [Google Scholar] [CrossRef]

- Ewais, E.M.M.; Besisa, D.H.A.; Zaki, Z.I.; Kandil, A.E.H.T. Tailoring of Functionally Graded Zirconia-Mullite/Alumina Ceramics. J. Eur. Ceram. Soc. 2012, 32, 1561–1573. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S. Mechanical Alloying Energy Storage, Protective Coatings, and Medical Applications, 3rd ed.; William Andrew: Norvich, NY, USA, 2020; ISBN 9780128181805. [Google Scholar]

- El-eskandarany, M.S.; Mahday, A.A.; Ahmed, H.A.; Amer, A.H. Synthesis and Characterizations of Ball-Milled Nanocrystalline WC and Nanocomposite WC–Co Powders and Subsequent Consolidations. J. Alloys Compd. 2000, 312, 315–325. [Google Scholar] [CrossRef]

- Riedel, R.; Chen, I.W. Ceramics Science and Technology; Wiley: Hoboken, NJ, USA, 2008; ISBN 9783527313204. [Google Scholar]

- Fang, Z.Z.; Eso, O.O. Liquid Phase Sintering of Functionally Graded WC—Co Composites. Scr. Mater. 2005, 52, 785–791. [Google Scholar] [CrossRef]

- Silva, A.G.P.; Schubert, W.D.; Lux, B. The Role of the Binder Phase in the WC-Co Sintering. Mater. Res. 2001, 4, 59–62. [Google Scholar]

- Anderson, T.L. Fracture Mechanics Fundamentals and Applications, 3rd ed.; Taylor & Francis Group: Abingdon, UK, 2005; ISBN 9781420058215. [Google Scholar]

- Bouaouadja, N.; Hamidouche, M.; Osmani, H.; Fantozzi, G. Fracture Toughness of WC-Co Cemented Carbides at Room Temperature. J. Mater. Sci. Lett. 1994, 13, 17–19. [Google Scholar] [CrossRef]

- Spiegler, R.; Schmauder, S.; Sigl, L.S. Fracture Toughness Evaluation of WC–Co Alloys by Indentation Testing. J. Hard Mater. 1990, 1147–1158. [Google Scholar]

- Quinn, G.D.; Morrell, R. Design Data for Engineering Ceramics: A Review of the Flexure Test. J. Am. Ceram. Soc. 1991. [Google Scholar] [CrossRef]

- Hewitt, S.A. Consolidation of WC-Co Nanocomposites Synthesised By Mechanical Alloying. Ph.D. Thesis, University of Wolverhampton, Wolverhampton, UK, 2009. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction Stir Welding and Processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction Stir Welding of Aluminium Alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; El-Sayed Seleman, M.M.; Rainforth, W.M. A comparison of crystallographic texture and grain structure development in aluminum generated by friction stir welding and high strain torsion. Mater. Des. 2016, 103, 259–267. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.; Zidan, Z.A.; Ramadan, R.M.; Ataya, S.; Alsaleh, N.A. Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded AA2024-T4/AA7075-T6 T-Butt Joints. Metals 2021, 11, 128. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; Seleman, M.M.E.; Allam, T. Grain Structure, Crystallographic Texture, and Hardening Behavior of Dissimilar Friction Stir Welded AA5083-O And AA5754-H14. Metals 2021, 11, 181. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; Seleman, M.M.E.; Mahdy, A.M.A.; Alsaleh, N.A.; Ahmed, E. Heat Input and Mechanical Properties Investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA. Metals 2021, 11, 68. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Martin, J.P. Effect of Friction Stir Welding Speed on Mechanical Properties and Microstructure of Nickel Based Super Alloy Inconel 718. Sci. Technol. Weld. Join. 2013, 18, 680–687. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.S.; Shazly, M.; Attallah, M.M.; Ahmed, E. Microstructural Development and Mechanical Propertiesof Friction Stir Welded Ferritic Stainless Steel AISI. J. Mater. Eng. Perform. 2019, 28, 6391–6406. [Google Scholar] [CrossRef]

- Refat, M.; Elashery, A.; Toschi, S.; Ahmed, M.M.Z.; Morri, A.; El-Mahallawi, I.; Ceschini, L. Microstructure, Hardness and Impact Toughness of Heat-Treated Nanodispersed Surface and Friction Stir-Processed Aluminum Alloy AA. J. Mater. Eng. Perform. 2016, 25, 5087–5101. [Google Scholar] [CrossRef]

- Meilinger, A.; Torok, I. The Importance of Friction Stir Welding Tool. Prod. Process. Syst. 2013, 6, 25–34. [Google Scholar]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Ammar, H.R.; Ahmed, E. Friction Stir Welding of Similar and Dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 2017, 242, 77–91. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Addison, A.; Martin, J.P.; Threadgill, P.L. Effect of Tool Geometry and Heat Input on the Hardness, Grain Structure, and Crystallographic Texture of Thick-Section Friction Stir-Welded Aluminium. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 271–284. [Google Scholar] [CrossRef]

- Tiwari, A. Tool Performance Evaluation of Friction Stir Welded Shipbuilding Grade DH36 Steel Butt Joints. Int. J. Adv. Manuf. Technol. 2019, 103, 1989–2005. [Google Scholar] [CrossRef]

- Kangazian, J.; Shamanian, M. Microstructure and Mechanical Characterization of Incoloy 825 Ni-Based Alloy Welded to 2507 Super Duplex Stainless Steel through Dissimilar Friction Stir Welding. Trans. Nonferrous Met. Soc. China 2019, 29, 1677–1688. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ahmed, E.; Hamada, A.S.; Khodir, S.A.; El-Sayed Seleman, M.M.; Wynne, B.P. Microstructure and Mechanical Properties Evolution of Friction Stir Spot Welded High-Mn Twinning-Induced Plasticity Steel. Mater. Des. 2016, 91. [Google Scholar] [CrossRef]

- Haneklaus, N.; Cionea, C.; Reuven, R.; Frazer, D.; Hosemann, P.; Peterson, P.F. Hybrid Friction Diffusion Bonding of 316L Stainless Steel Tube-to-Tube Sheet Joints for Coil-Wound Heat Exchangers. J. Mech. Sci. Technol. 2016, 30, 4925–4930. [Google Scholar] [CrossRef]

- Zayed, E.M.; El-Tayeb, N.S.M.; Ahmed, M.M.Z.; Rashad, R.M. Development and Characterization of AA5083 Reinforced with SiC and Al2O3 Particles by Friction Stir Processing. In Engineering Design Applications; Springer: Cham, Switzerland, 2019; Volume 92. [Google Scholar]

| Powder | Purity % | Particle Size | Density g/cm3 |

|---|---|---|---|

| WC-Co-NbC-TaC | 99.99 | 100–290 μm | 15.223 |

| Y2O3 | 99.995 | 2–3 μm | 5.01 |

| Ni | 99.96 | 3–5 μm | 8.9 |

| Batch No. | Y2O3 | Ni | (WC/Co/NbC/TaC) | Theoretical Density, gm/cm3 |

|---|---|---|---|---|

| 1 | 0.0 | - | 100 | 15.223 |

| 2 | 2.5 | - | 97.5 | 14.96768 |

| 3 | 5.0 | - | 95 | 14.71235 |

| 4 | 7.5 | - | 92.5 | 14.45703 |

| 5 | 10 | - | 90 | 14.2017 |

| 6 | 0.0 | 5 | 95 | 14.90685 |

| 7 | 2.5 | 5 | 92.5 | 14.65153 |

| 8 | 5.0 | 5 | 90 | 14.3962 |

| 9 | 7.5 | 5 | 87.5 | 14.14088 |

| 10 | 10 | 5 | 85 | 13.88555 |

| Composite/ Y2O3.wt% | (WC-Co-TaC-NbC) | WC-Co-TaC-NbC-5wt%Ni |

|---|---|---|

| 0 | Halfpenny | Palmqvist |

| 2.5 | Halfpenny | Palmqvist |

| 5 | Halfpenny | Palmqvist |

| 7.5 | Palmqvist | Palmqvist |

| 10 | Palmqvist | Palmqvist |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.M.Z.; Barakat, W.S.; Y. A. Mohamed, A.; A. Alsaleh, N.; Elkady, O.A. The Development of WC-Based Composite Tools for Friction Stir Welding of High-Softening-Temperature Materials. Metals 2021, 11, 285. https://doi.org/10.3390/met11020285

Ahmed MMZ, Barakat WS, Y. A. Mohamed A, A. Alsaleh N, Elkady OA. The Development of WC-Based Composite Tools for Friction Stir Welding of High-Softening-Temperature Materials. Metals. 2021; 11(2):285. https://doi.org/10.3390/met11020285

Chicago/Turabian StyleAhmed, Mohamed M. Z., Waheed S. Barakat, Abdelkarim Y. A. Mohamed, Naser A. Alsaleh, and Omayma A. Elkady. 2021. "The Development of WC-Based Composite Tools for Friction Stir Welding of High-Softening-Temperature Materials" Metals 11, no. 2: 285. https://doi.org/10.3390/met11020285