Abstract

Twinning-induced plasticity (TWIP) steels have higher strength and ductility than conventional steels. Deformation mechanisms producing twins that prevent gliding and stacking of dislocations cause a higher ductility than that of steel grades with the same strength. TWIP steels are considered to be within the new generation of advanced high-strength steels (AHSS). However, some aspects, such as the corrosion resistance and performance in service of TWIP steel materials, need more research. Application of TWIP steels in the automotive industry requires a proper investigation of corrosion behavior and corrosion mechanisms, which would indicate the optimum degree of protection and the possible decrease in costs. In general, Fe−Mn-based TWIP steel alloys can passivate in oxidizing acid, neutral, and basic solutions, however they cannot passivate in reducing acid or active chloride solutions. TWIP steels have become as a potential material of interest for automotive applications due to their effectiveness, impact resistance, and negligible harm to the environment. The mechanical and corrosion performance of TWIP steels is subjected to the manufacturing and processing steps, like forging and casting, elemental composition, and thermo-mechanical treatment. Corrosion of TWIP steels caused by both intrinsic and extrinsic factors has posed a serious problem for their use. Passivity breakdown caused by pitting, and galvanic corrosion due to phase segregation are widely described and their critical mechanisms examined. Numerous studies have been performed to study corrosion behavior and passivation of TWIP steel. Despite the large number of articles on corrosion, few comprehensive reports have been published on this topic. The current trend for development of corrosion resistance TWIP steel is thoroughly studied and represented, showing the key mechanisms and factors influencing corrosion processes, and its consequences on TWIP steel. In addition, suggestions for future works and gaps in the literature are considered.

1. Introduction

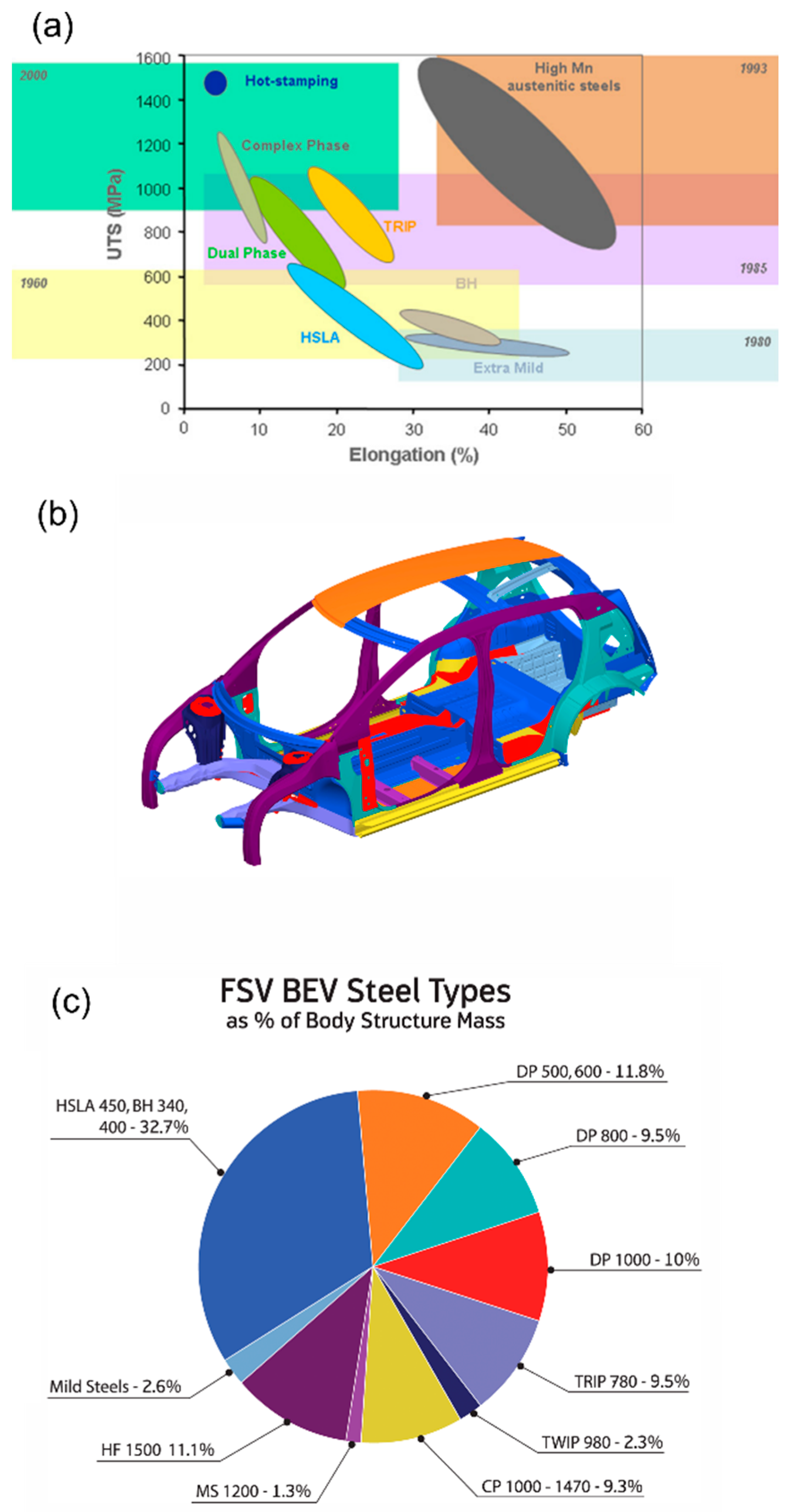

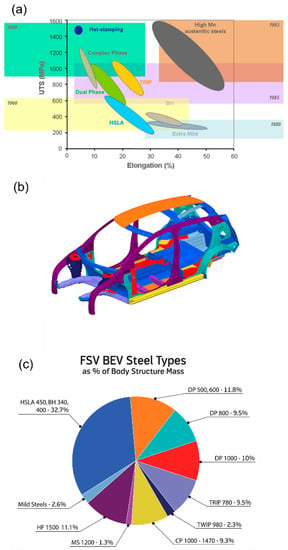

Steel used in the automotive industry can be classified into three categories determined by their tensile strength: Mild steels have a tensile strength less than 300 MPa, high strength steels (HSS) show a tensile strength between 300 MPa and 700 MPa, and ultra-high strength steels (UHSS) boast a tensile strength above 700 MPa [1]. Recently, advances in HSS led to the development of advanced high-strength steels (AHSS) designed for lighter weight and cost effectiveness. The evolution has been constant, and nowadays it is possible to speak of a third generation of AHSS. The major difference between conventional HSS and AHSS is the microstructure. HSS exhibit a single ferrite phase, whereas AHSS presents ferrite, martensite, bainite, and/or retained austenite in sufficient amounts to affect mechanical properties. Some AHSS have increased hardenability and greater strength-ductility compared to conventional steels. The manufacturing of AHSS is more complex than conventional steel and require greater manufacturing control due to the required percentages of different phases. Within the group of AHSS, there are several groups: Dual-phase (DP), transformation-induced plasticity (TRIP), complex phase (CP), high-strength low alloy (HSLA) steel, ferritic-bainitic (FB), twinning-induced plasticity (TWIP), and hot formed (HF) post-forming heat-treatable (PFHT) [1].

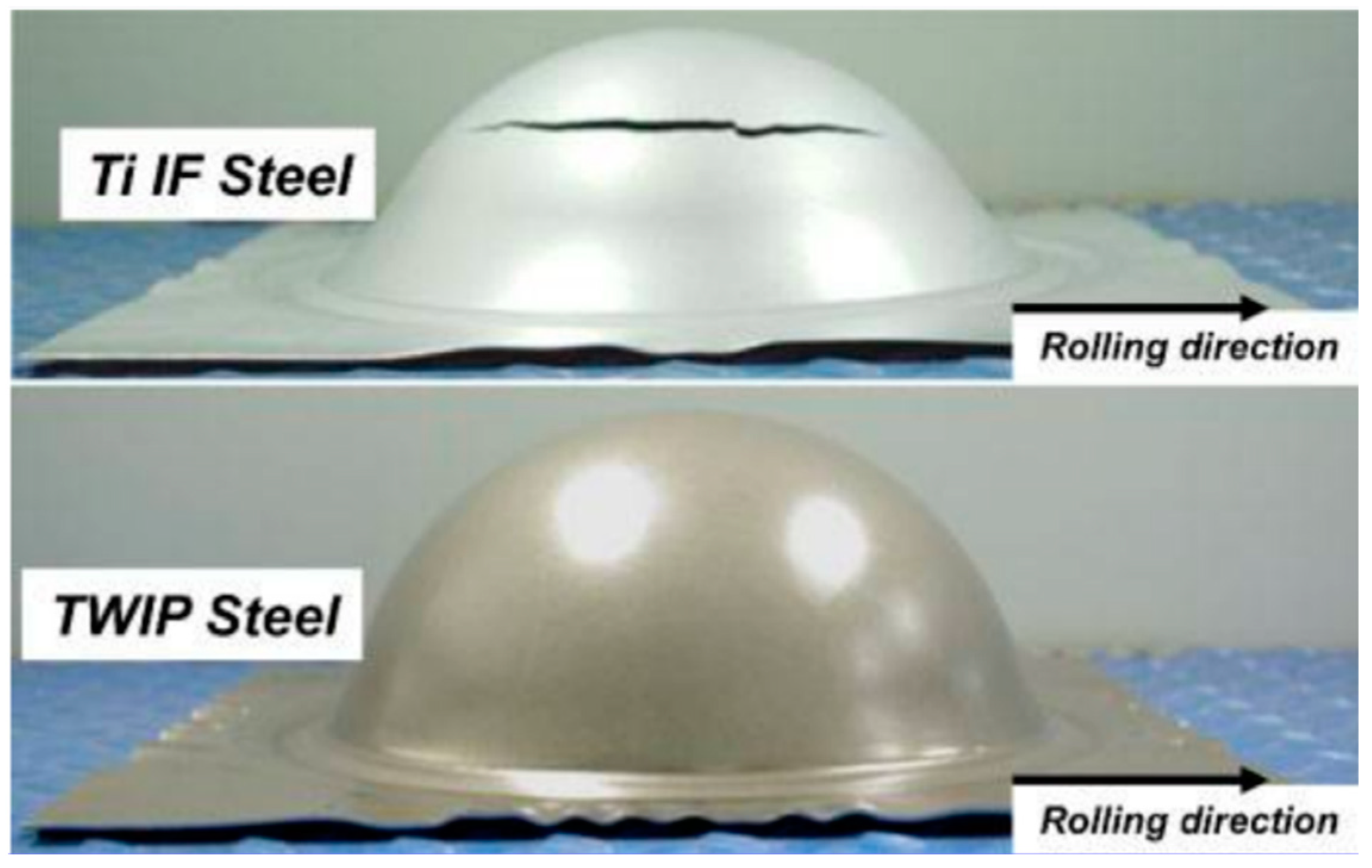

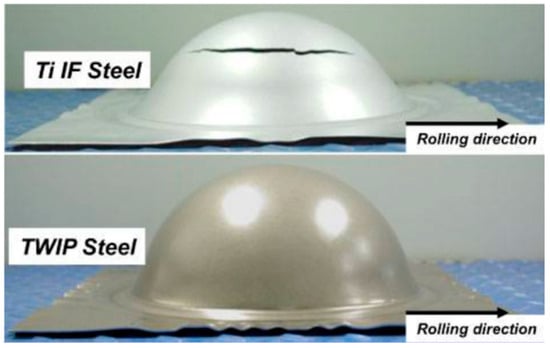

TWIP steel is defined by a single austenite phase, which is stable at room temperature and can be deformed by dislocation gliding in specific slip planes induced by mechanical or deformation twinning [2,3,4,5,6,7,8,9,10,11]. Furthermore, high-Mn TWIP steel is a high-strength, structural steel with superior formability. TWIP steel offers enhanced mechanical properties by strain hardening modification. Therefore, the use of TWIP steel may decrease the weight of steel components and improve press forming behavior. These key advantages coincide with current trends in the automotive industry, which emphasize reduced greenhouse gas emissions and lower fuel consumption [12,13,14]. The high-Mn TWIP steels have greater strength and ductility compared to all other classes of steels for automotive application, as shown in Figure 1a,b [15]. The high strain hardening leads to enhanced press forming performance, as illustrated in Figure 2 [14,16,17,18,19,20,21,22].

Figure 1.

Advanced high strength steels (for example, dual-phase (DP), complex phase (CP), transformation-induced plasticity (TRIP), twinning-induced plasticity (TWIP)) in automotive industry, (a) mechanical properties, (b,c) different applications on the car body or on the chassis [23,24]. (Reproduced with permission from refs. [23,24]. Copyright (2011, 2017), Elsevier).

Figure 2.

Comparison of Nakashima test samples for interstitial-free (IF) and TWIP steels [14]. (Reproduced with permission from refs. [14]. Copyright (2012), Taylor & Francis).

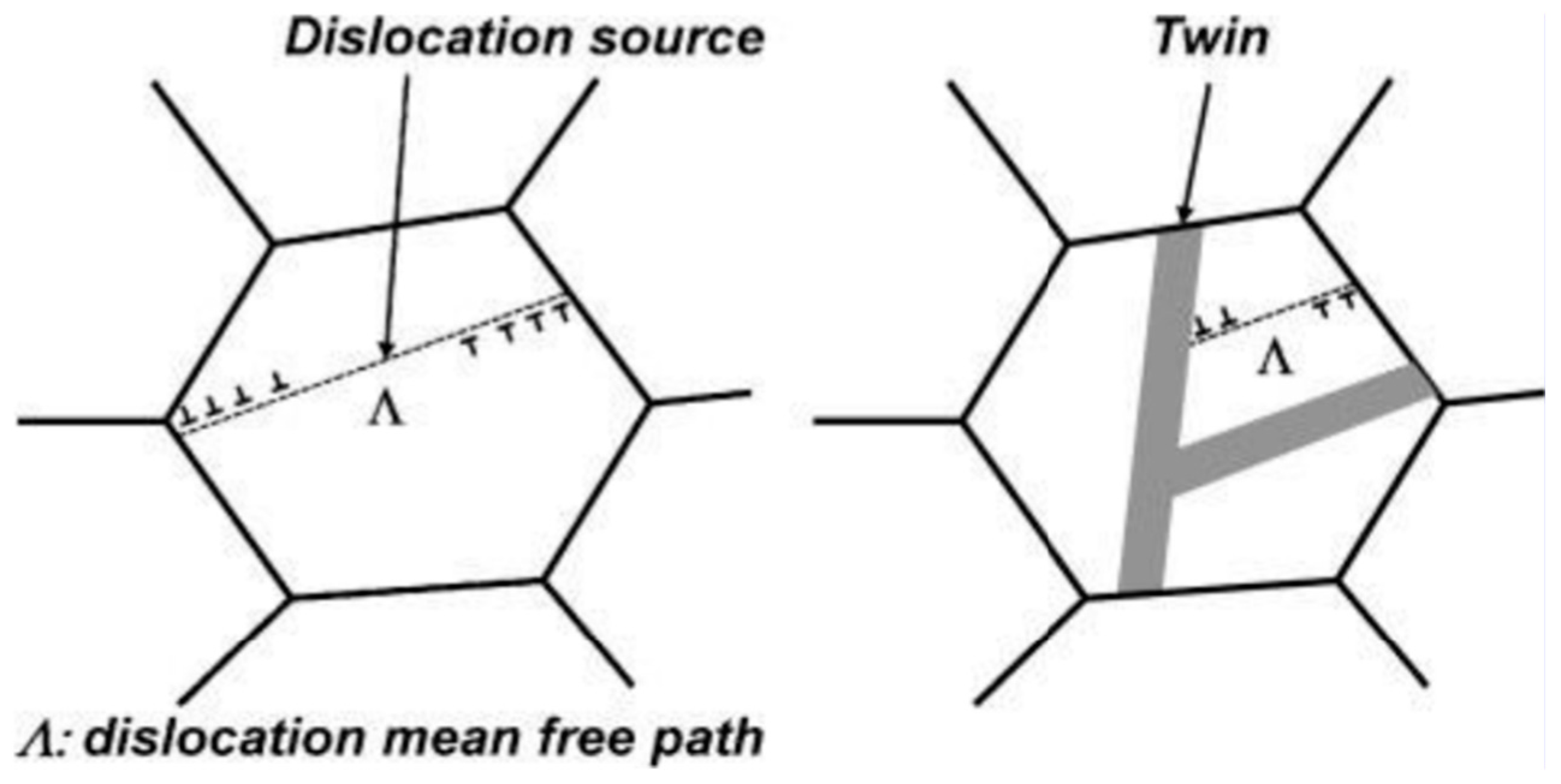

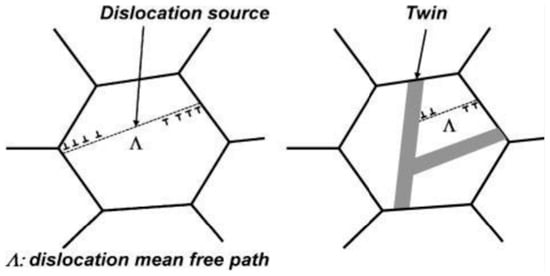

TWIP steel shows dislocation glide as the major deformation mechanism, however due to the Hall-Petch effect, mechanical twins are continuously forming during strain. The mechanical twins involve new crystal orientations, thus reducing the ‘mean free path’ or effective glide distance of dislocations and increase the flow stress. The increase in twin density causes in high strain hardening observed in TWIP steel. Precisely, controlling stacking fault energy (SFE) governs twin formation; values below 20 mJ m–2 are more likely to induce strain transformation, whereas SFE values greater than 50 mJ m–2 suppresses twin formation [14]. The mechanism for strain hardening in TWIP steel is described as the Hall-Petch effect, illustrated in Figure 3.

Figure 3.

Schematic of strain hardening mechanism in TWIP steels [14]. (Reproduced with permission from refs. [14]. Copyright (2012), Taylor & Francis).

The formation of mechanical twins has been studied in the literature using the method of observing textures in the microstructure. Transmission electron microscopy (TEM) and electron backscattered diffraction (EBSD) indicated an increase in the volume fraction of twinning with plastic deformation [25,26,27,28,29]. During cold rolling of the high-Mn TWIP steel, the development of pronounced brass-type evolution at low strain levels is produced due to the high Mn content [30].

High-Mn steel have grown in popularity owing to their relationship between cost, strength, ductility, and density [31]. The effect of work hardening on TWIP steels shows a greater benefit than any other austenitic steels. The deformation twins, it is believed, act as pinning centers for gliding dislocation, thus increasing the work-hardening rate. Moreover, TWIP steels simultaneously display high strength and high ductility, it is found that nanometer scale twinning (nano-twinning) is significant for improvement of ductility according to recent works regarding metals and alloys [23]. The two prominent plastic deformation mechanisms are dislocation slip and deformation twinning. The superior dislocation storage capacity favors deformation twinning and benefits work hardening and ductility improvement [32,33,34,35,36,37].

The main alloying element in TWIP steels, Mn, is a key factor in preserving the austenitic structure and maintaining a low SFE value to allow for mechanical twinning, yet high enough to avoid martensitic transformation [31,38,39]. Both Mn and Ni are gammagenous elements that favor the formation of austenite phase.

Al is a ferrite stabilizer and does not stabilize the austenite, however it increases the SFE and accordingly favors the formation of twins (TWIP effect) over martensitic transformation (TRIP effect) during deformation [28,40,41,42,43]. Additionally, Al offers increased strength imparted through solid-solution hardening. Moreover, Al improves the corrosion resistance of TWIP steels by formation of a thin, stable surface oxide layer [44]. The addition of Al has been shown to be successful in the delay of fracture in press-formed parts [45]. Nevertheless, Al additions cause a lower strain hardening rate, consequently exhibiting a decreased tensile strength [46].

Contrary to Al, Si additions decrease the austenite phase formation and aids the transformation of γ-austenite to ε-martensite throughout the cooling and deformation process [47]. Silicon provides benefits for passivating intermetallic materials, such as Fe3Al-Si and Fe3Al-Ge, and additions increase the breakdown pitting potential (Epit) and the extent of passivation [48].

Additions of Cr to ferrous alloys stimulates the passive layer formation, therefore improving corrosion resistance [49]. A ferrite stabilizing agent, Cr increases N stability in the melt during the casting process [50]. Yet, adding Cr to the Fe−Mn-based alloy causes an increase in the SFE [51].

Carbon can be used as an alloying element to stabilize austenite and strengthen the matrix due to solid solution hardening [2,28]. For instance, in order to produce stable austenite in alloys with Mn less than 25 wt.% and at room temperature, α’- and ε-martensite formation must be suppressed. The addition of C (~0.6 wt.%) allows the formation of carbide-free austenitic structures while avoiding the formation of ε-martensite. However, higher amounts of C results in carbide (M3C) formation. Carbon and N are used to produce stable austenite structure and N also improves the pitting corrosion resistance [50].

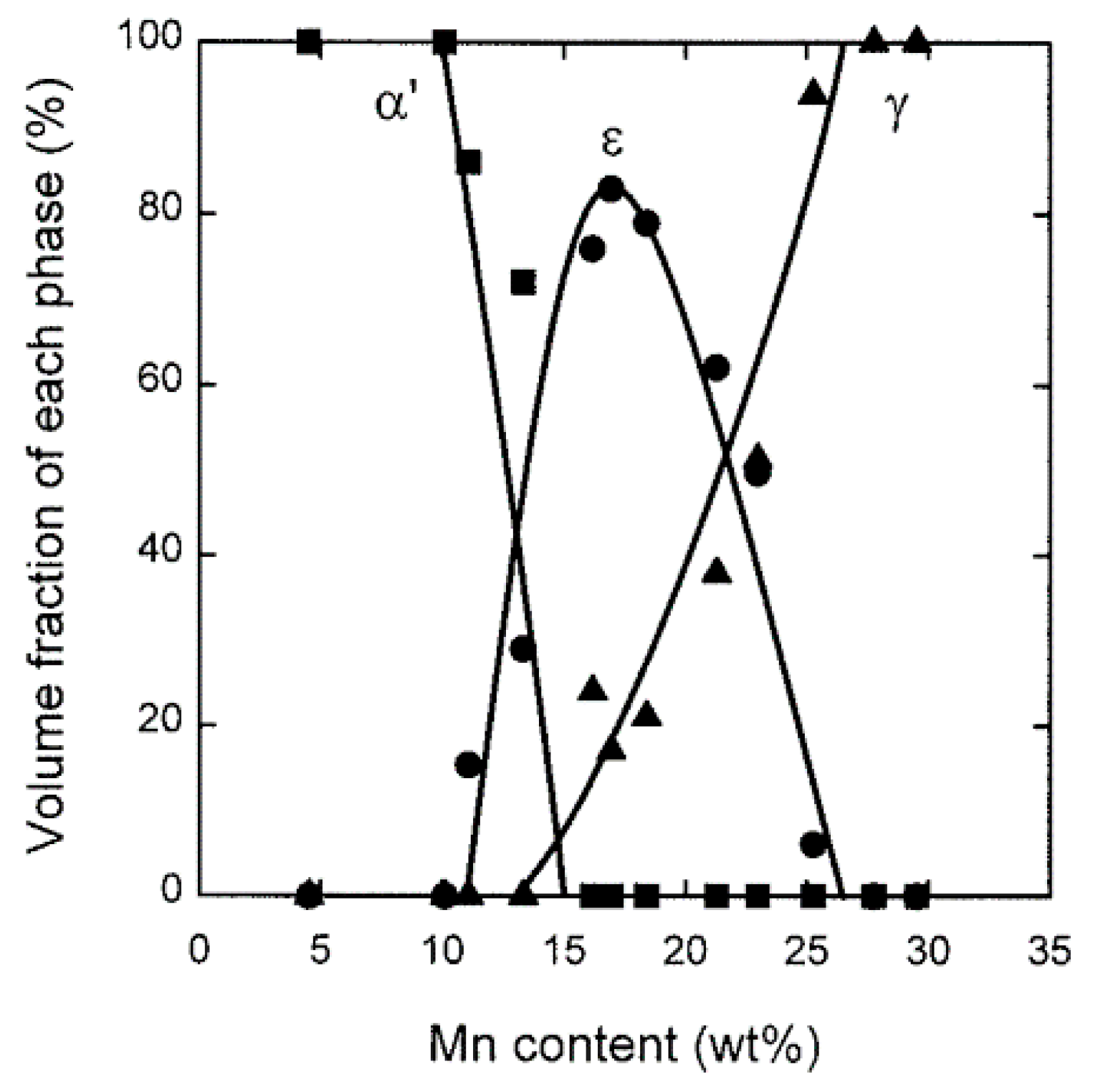

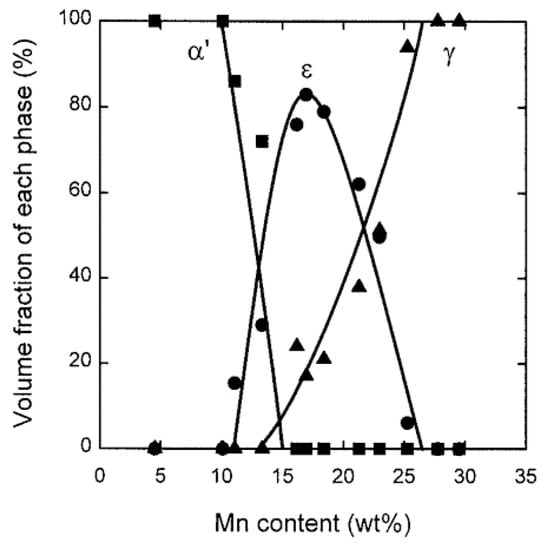

The constituent phase found in cast Fe−Mn binary alloys can be seen in Figure 4 [52]. As released recently by the authors, the stability of the austenite phase in high-Mn steels is increased, showing a single γ-austenite phase in the temperature range of 800−1200 °C [53].

Figure 4.

Volume fraction of each constituent phase in cast Fe−Mn alloys versus concentration of Mn in the alloy [52]. (Reproduced with permission from refs. [52]. Copyright (1997), ISIJ international).

The excellent tensile strength and ductility, along with the significant energy absorption capacity during high impact events highlight the potential for high-Mn TWIP steel (15‒30 wt.% Mn) in the automotive industry. These characteristics provide increased safety to automobile passengers, greater than twice that of conventional HSS, i.e., TRIP steel and DP steel, such as TRIP700 and DP600, respectively [54,55,56].

The development of highly deformable TWIP steels in the automotive industry has been actively pursued for weight reduction, thus decreasing CO2 emissions, and increasing the fuel efficiency [2,3]. The quaternary system of Fe−Mn−Al−C steel achieves higher density reduction ~18% (6.5 g cm−3) than conventional steels, increased strength, an ultimate tensile strength (UTS) ~1 GPa, and excellent ductility >80%.

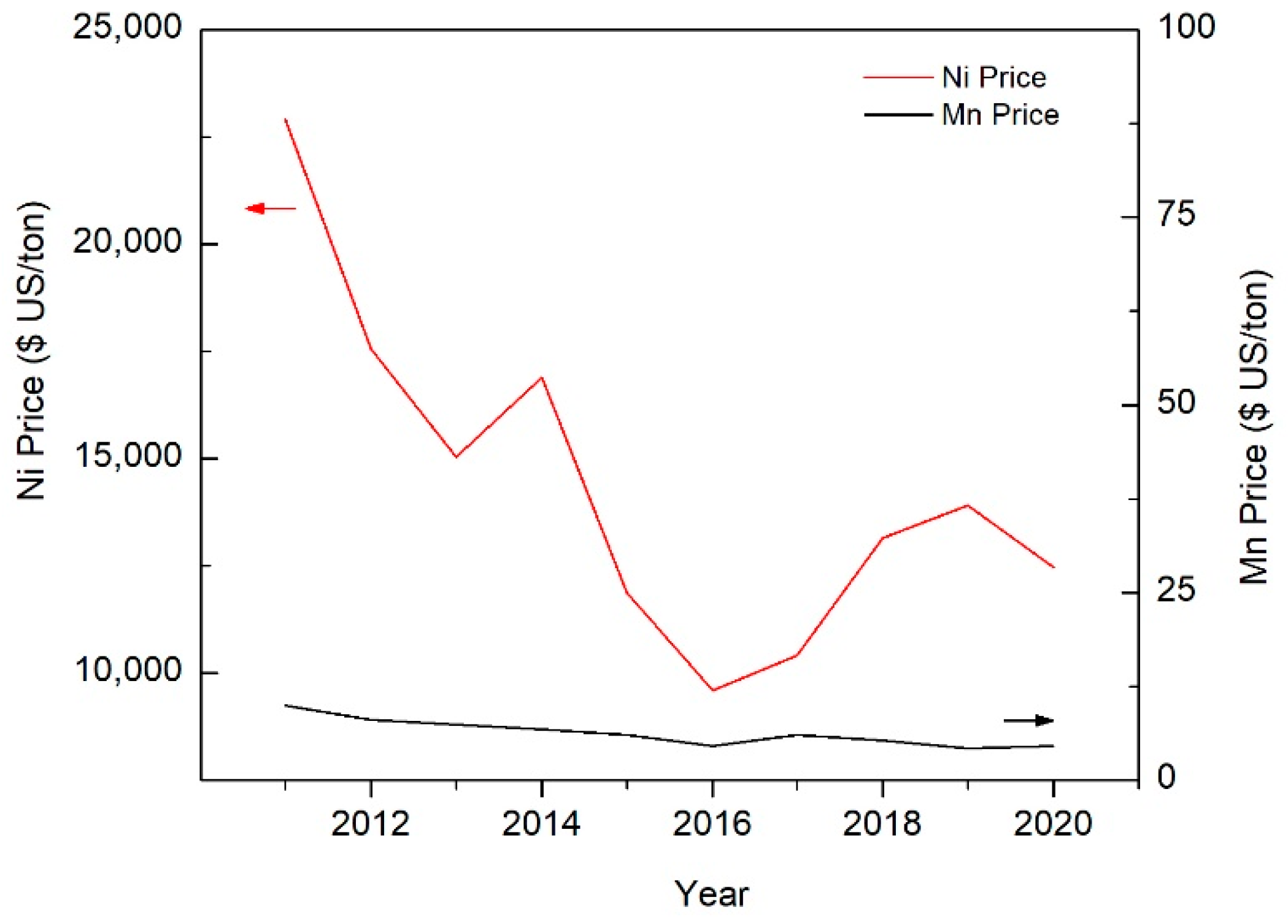

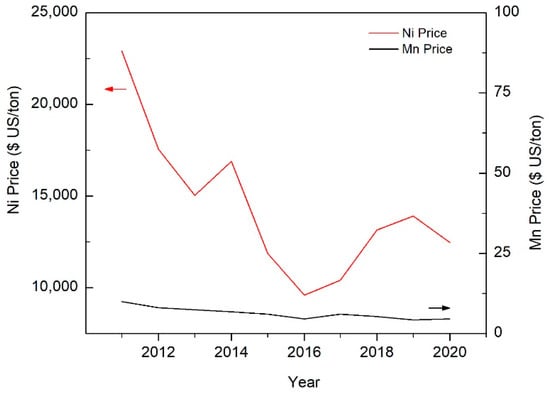

The Fe−Mn−C system began with the work of Hadfield in 1988. During deformation, the austenite remains stable and elongation is enhanced by twinning induced plastic deformation [57]. Fe−(11−14)Mn−(1.1−1.4)C, also known as Hadfield steels, contain a high amount of Mn and are described in ASTM standard for their development standards and use in industry [58]. In the 1980s, Fe−Mn−Al alloys were developed to decrease cost and replace 300 series austenitic stainless steels (SS) [59]. The development of TWIP steel is driven by the need for low-cost stainless steel by replacing Ni with Mn and Cr with Al to achieve austenite stability and decrease material cost while simultaneously imparting corrosion protection. The stock prices for Ni and Mn are shown in Figure 5, the increasing trend evidences the economic incentive to replace Ni with Mn. Table 1 summarizes current production grades of TWIP steels for automotive applications [24,60].

Figure 5.

Average price ($US/ton) for Ni and Mn metals over the last decade (2011−2020).

Table 1.

Current production grades of TWIP steels for automotive applications [24,60].

The aim of this review is to perform a holistic examination of current literature on high-Mn TWIP steels for identification of a number of critical factors that need to be considered to study the corrosion mechanism of high-Mn TWIP steels, and will affect the electrochemical corrosion behavior, material performance and lifetime in service, such as chemical composition, impurity phase-segregation, grain-size, crystal-phases and environment. For that reason, this work would help in developing a better approach to mitigate corrosion phenomena, making TWIP steels more suitable for even more applications.

2. Effect of Alloying Elements on Aqueous Corrosion Behavior of High-Mn TWIP Steels

Current corrosion studies focused on high-Mn TWIP steel focus on the effects of alloying elements added to the base Fe−Mn TWIP alloy, such as Al, Cr, Si, Cu, P, N, and others. Generally, alloying elements provide passive film formation and galvanic-coupling effects of TWIP steel due to the formation of different phases. These mechanisms are discussed in detail in the following sections.

2.1. Effect of Al Alloying on High-Mn TWIP Steel Corrosion

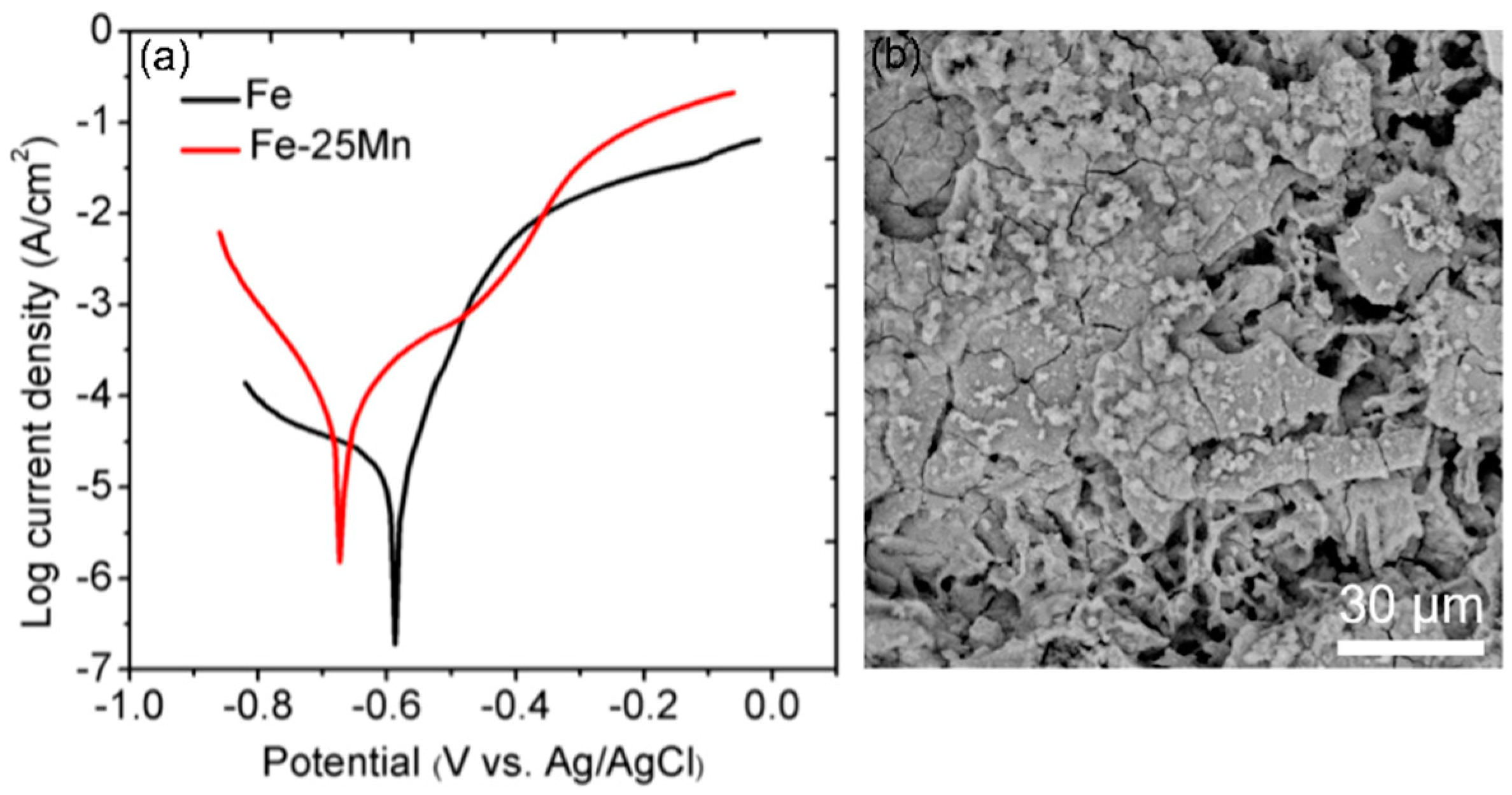

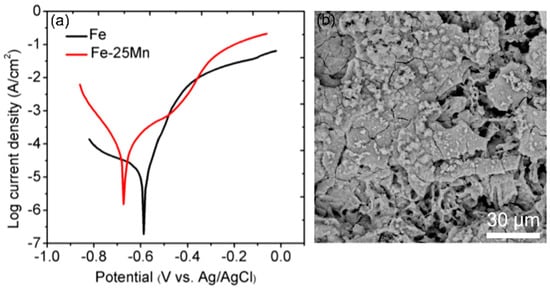

Additions of 25 wt.% Mn to steel in Fe−Mn binary alloys was discovered to be disadvantageous to the corrosion resistance, as the significant amount of Mn causes the alloy to become reactive in acid and chloride environments [61]. Fe−25Mn alloy showed difficulty towards passivation, even in neutral 1M Na2SO4 solution. With increasing Al content to 5 wt.%, the anodic polarization curve of Fe−25Mn−5Al alloy showed a stable passivation region in 1M Na2SO4 solution; contrarily, no passivation in 3.5 wt.% NaCl solution was observed.

The corrosion behavior of Fe−25Mn−5Al−0.15C alloy and the effects of Al alloying were studied in 10–15% NaOH, 1M Na2SO4, 3.5 wt.% NaCl, 10–15% HNO3, and 10% HCl solutions by Zhang and Zhu [61]. The Al content increase yielded an increase of corrosion potential (Ecorr) and a decrease of corrosion current density (icorr), whereas the increase in Mn reduced the corrosion resistance. The changes in corrosion behavior were ascribed to the standard electrode potential of Al (−1.66 V vs. SHE, standard hydrogen electrode) though it is more negative than Mn (Mn2+: −1.18 V vs. SHE; Mn3+: −0.283 V vs. SHE), thus improving the formation of a stable and compact Al2O3 layer. Furthermore, the results showed that aging the samples for 15 min to 5 h (pre-passivating at a constant passive potential in a 50% HNO3) had a beneficial effect on the stability of the passive film, confirmed by Auger electron spectroscopy (AES) and X-ray photoelectron spectroscopy (XPS) results. It was reported that the passive film is likely made up of bounded water, Fe2O3 and FeO (or Fe3O4), Mn2O3 and MnO (or Mn3O4), Al2O3, and metallic state Fe, Mn, and Al.

The effect of Mn additions on the corrosion properties of Hadfield steel with Al, Fe−(19.8−32.5)Mn−(7.1−10.2)Al−(0.76−0.99)C, in 1N NaOH, 1N H2SO4, and borate buffer (pH 8.4) solutions were analyzed by Cavallini et al. [62]. An increase in icorr and decrease in Ecorr was observed compared to conventional AISI 316 SS. Aluminum acts as a reactive, amphoteric alloying element, which generates a protective oxide layer in the pH range 4–9 [63]. However, the oxide layer is unstable in acidic or alkaline solutions, therefore corrosion occurs with hydrogen gas evolution [64].

Tjong et al. studied the corrosion properties of Fe−29.7Mn−8.7Al−1.04C alloy in 1N H2SO4, 1M Na2SO4 (pH 5.55), 1M NaCl, and borate buffer solution (pH 8.4) and the anodic polarization response was inferior compared to AISI 316 SS [65]. AES was used to investigate the composition of the anodic film. Passivation in 1N H2SO4 acid solution was difficult, however passive film was formed in the pH range of 5.55−6.10.

The electrochemical behavior of several Fe−Mn−Al−Si−C TWIP steels in synthetic mine drainage water, 1N H2SO4, and 3.5 wt.% NaCl had been analyzed by Alstetter et al., finding that the studied alloys exhibited lower corrosion resistance than conventional AISI 304 SS [66].

Gau et al. studied the galvanic corrosion of austenitic Fe−24.8Mn−7.3Al−0.12Si−0.90C steel and DP Fe−24.4Mn−9.2Al−0.14Si−0.40C steel alloys in seawater [67]. The measured corrosion rate for AISI 304 SS, austenitic alloy, DP alloy, and mild steel were 0.2, 2.1, 3.0, and 7.3 mm year−1, respectively. The austenitic alloy exhibited a corrosion rate 10 times larger than AISI 304 SS, while the DP alloy showed a corrosion rate 5 times less than AISI 304 SS. The galvanic series of DP alloys coupled to mild steel and AISI 304 SS was more active than austenitic alloy.

The pitting corrosion behavior studied by Park et al. for DP, TRIP, and TWIP steel in 3.5 wt.% NaCl solution examined the high density of single MnS inclusions generated on DP steel, consequently displaying the lowest resistance to pitting corrosion. Complex MnS on TRIP and complex Mn oxy-sulfide inclusions on TWIP act as galvanic anodes [68].

The study by Ruscak and Perng examined the corrosion behavior of five Fe−Mn−Al−Cr−C TWIP steels with ferrite contents 0.5−98% in 3.5 wt.% NaCl solution at room temperature [69]. The passive layer thickness decreased with increasing amounts of ferrite; thus, the ferritic alloy passivation was correlated with the addition of 6.23 wt.% Cr. The ferrite phase produced pitting at the austenite/ferrite interface. Steel containing ferrite fractions from 46 to 61% on Fe−24Mn−9Al, Fe−30Mn−13Al, Fe−27Mn−9Al−3Cr, and Fe−27Mn−13Al−6Cr steel alloys were analyzed by Shih et al. in 3.5 wt.% NaCl solution [70]. Pitting corrosion was observed in the ferritic grains and the austenite/ferrite interface. Over a 10-day immersion period, the order of weight loss was 24Mn > 30Mn > 3Cr > 6Cr.

Fe−30.5Mn−18.68Al−1.85C alloy was studied in 3.5 wt.% NaCl solution and showed a passive region, the Epit was determined to depend on the potential scan rate (ν) [71]. Therefore, the results corroborated findings for AISI 304L and 316L SSs in 3.5 wt.% NaCl solution and defined a linear relationship between Epit and the square root of the ν (Epit α ν½) [72].

The passive film formation on Fe−30Mn−9Al alloy in neutral 1M Na2SO4 solution was analyzed by Zhu and Zhang, the duplex structure contained an outer hydrous passive layer and a low valence oxide, internal transition layer between the passive film and alloy matrix [73].

Fe−26Mn−0.14C alloy in 3.5 wt.% NaCl solution and of Fe−24Mn−3Al−0.1C alloy in 0.1M H2SO4 solution was studied by Hamada and Karjalainen by applying electroless Ni−P coatings [74]. For the 26Mn alloy, an icorr of 28 μA cm−2 (324.8 µm year−1) and 6 µA cm−2 (69.6 µm year−1) for the uncoated and coated specimens, respectively. The Fe−24Mn−3Al−0.1C specimen displayed icorr values of 3217 μA cm−2 (37.3 × 103 µm year−1) and 20 µA cm−2 (232 µm year−1) for the uncoated and coated specimens, respectively. An increase in corrosion resistance by a factor of 4 was observed by the specimens with Ni−P coatings. The high icorr values were attributed to the Mn oxide (MnO) formation, thus reducing the corrosion resistance imparted by its fragile and unstable structure. The MnO is a basic oxide and reacts with aqueous acids to produce Mn2+ cations and hydrogen evolution; additionally, Al oxide is unstable below pH 4 [63,75].

The corrosion properties of the Fe−25Mn−(1−8)Al−0.2C TWIP steels in 3.5 wt.% NaCl was investigated by Hamada et al., uniform corrosion and low corrosion resistance were reported. Steels containing up to 6 wt.% Al and a homogenous austenite structure displayed scarce pitting, however DP structure (Fe−25Mn−8Al−0.2C), which includes both ferrite and austenite, showed pitting corrosion occurring preferentially in the α-ferrite grains. Moreover, the corrosion resistance of the surface was improved by aging through an anodic passivation treatment in HNO3 acid, due to the Al incorporated on the surface [76].

The electrochemical behavior of the austenitic Fe−29.95Mn−8.25Al−0.85C and Fe−25.94Mn−9.33Al−1.45C TWIP alloys, solution-annealed and/or age-treated, was investigated in 3.5 wt.% NaCl solution [77]. The tested alloys showed a decreased ability to passivate and a higher anodic passive current density (ipass) compared to 316 SS. Uniform and pitting corrosion were observed in a 6% FeCl3 solution under open circuit potential conditions. The observed corrosion rates for the alloys were one order of magnitude higher than conventional 316 SS.

Austenitic Fe−17Mn−3Al−0.24C, Fe−21Mn−3.5Al−0.29C, and Fe−27Mn−5Al−0.57C steels were studied by Jablonska and Michalik in 3.5 wt.% NaCl solution, and in acid rain solution (molar ratio H2SO4:HNO3:HCl as 1:0.3:0.17) (pH 3.5) [78]. The three steel grades displayed increased corrosion resistance in chloride solution compared to the acid rain solution. The corrosion rate of the Fe−27Mn−9Al alloys in 50 wt.% acetic acid, 5 wt.% H2SO4, boiling HNO3, 10 and 40 wt.% FeCl3, and 3.0 wt.% NaCl solution was higher than that of AISI 304 SS [79,80]. The corrosion resistance of TWIP steel was enhanced by hot-dipping Al and subsequent thermal diffusion treatment [81], showing the increased ability to repassivate promoted by aluminum. According to the Pourbaix diagram, Al generates a protective and stable Al2O3 film in the 4−9 pH range [63]. The passive layer of TWIP steels is stable due to the spontaneous passivation caused by Al2O3 film, which are higher than Cr, Mn, and Fe [61,82].

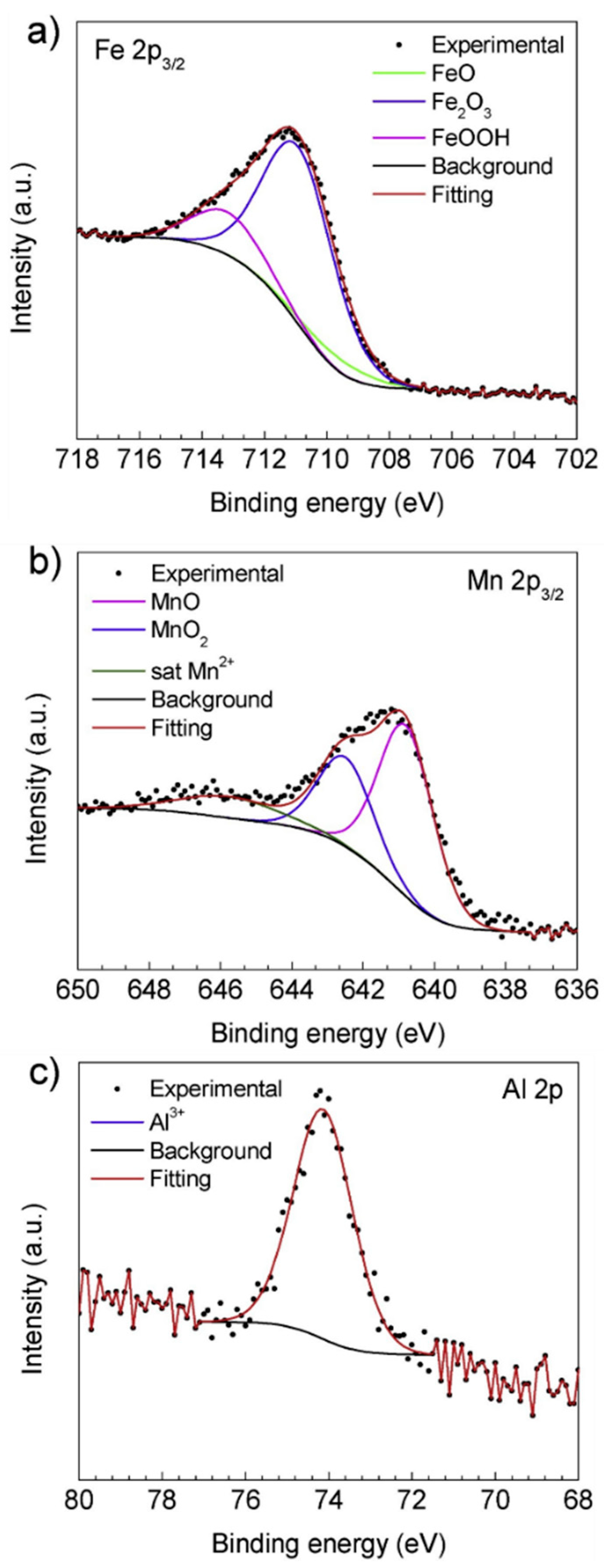

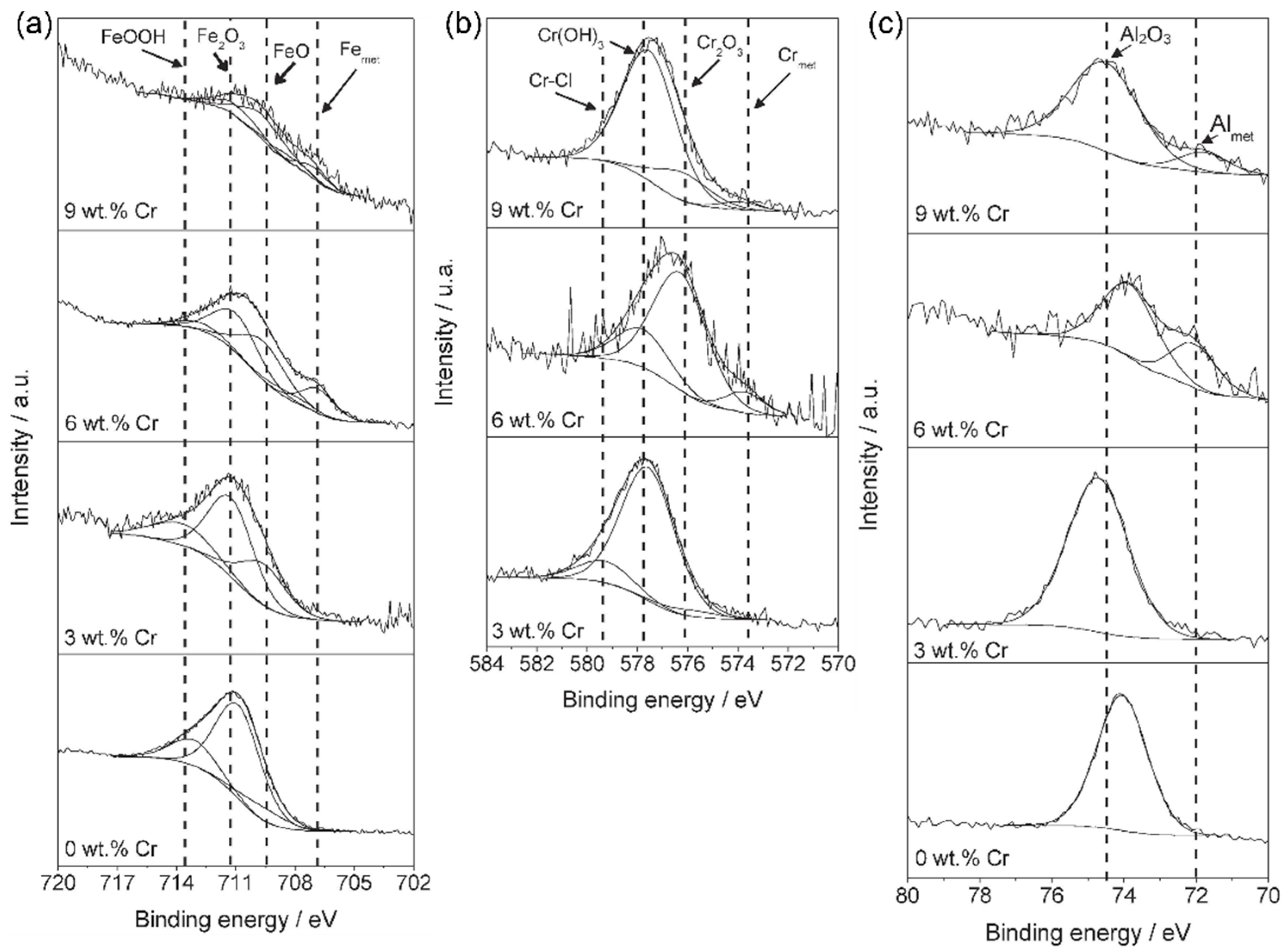

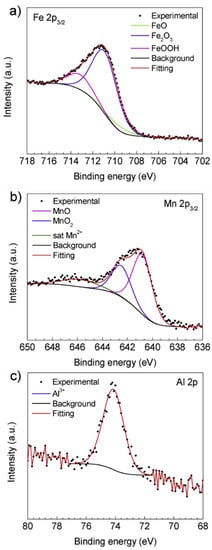

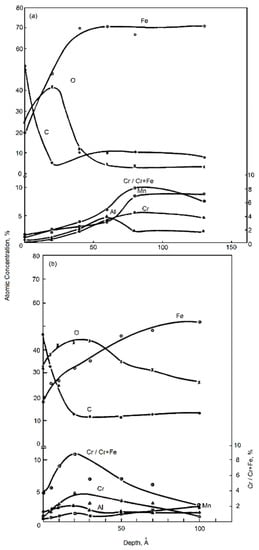

Recently, the authors have studied the effect of Mn additions on the corrosion behavior of Fe−(21,25,28)Mn−3Al−5Si steels in a 0.1M NaCl solution [83]. The high-resolution XPS spectra in Figure 6 shows the steady Mn enrichment in the outermost oxide scale layer along with a decrease in oxidized Fe species. The absence of Al enrichment in the oxide explained the detrimental effects of Mn addition on the corrosion resistance of the high-Mn TWIP steels. The XPS results were consistent with the cyclic potentiodynamic polarization (CPP) curves and electrochemical impedance spectroscopy (EIS) results, and the increase of Mn in the alloy caused lower polarization resistance (Rp) values [83].

Figure 6.

High-resolution XPS spectra for Fe−(21,25,28)Mn−3Al−5Si TWIP steels in 0.1M NaCl solution. (a) Fe 2p3/2, (b) Cr 2p3/2, and (c) Al 2p [83]. (Reproduced with permission from refs. [83]. Copyright (2019), Elsevier).

2.2. Effect of Al and Cr Alloying on High-Mn TWIP Steel Corrosion

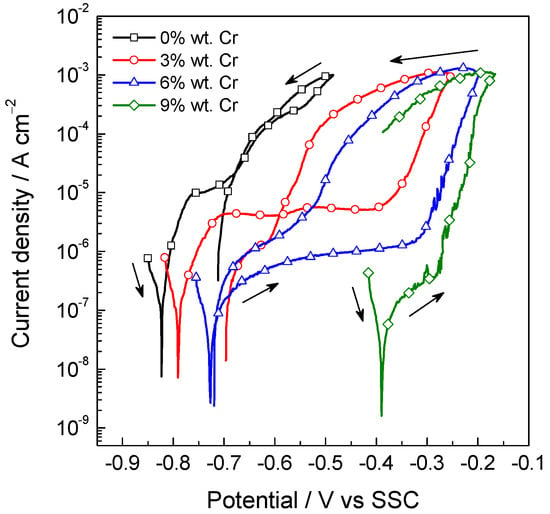

Alloying with higher amounts of Cr and decreased C content has been a significant attempt to improve the corrosion resistance of Fe−Mn−Al−C steel [83], due to the ability of Cr and C to act as ferrite and austenite forming elements, respectively. In this respect, high amounts of Cr and low C content leads to a DP microstructure in austenite and ferrite. The DP Fe−Mn−Al−Cr−C exhibits inferior mechanical properties compared to austenitic alloy. Furthermore, the DP alloy displays issues in hot forming processes for alloys including Fe−(21.5−27.7)Mn−(8.9−9.9)Al−(3.1−6.2)Cr−(0.33−0.42)C [83]. Tuan et al. studied the corrosion behavior of as-quenched austenitic Fe−30Mn−7Al−(0,3,6,9)Cr−1C alloys in a 3.5 wt.% NaCl solution [84]. The Cr addition showed an enhancement of Epit up to 6 wt.% Cr, 9 wt.% Cr showed a decreased Epit attributed to the formation of the intermetallic κ-carbide (Fe,Mn,Cr)7C3.

The effect of Cr additions on the passivity of Fe−30Mn−5Al−(0,3,6,9)Cr−0.5C high-Mn TWIP steels under thermo-mechanical processing (TMP) and in deaerated 0.1M NaCl solution was studied by the authors [85]. Chromium addition showed a beneficial effect, however high Cr content was shown to cause phase-segregation, thus reducing the corrosion resistance [86]. The results indicate that TMP diminishes corrosion resistance.

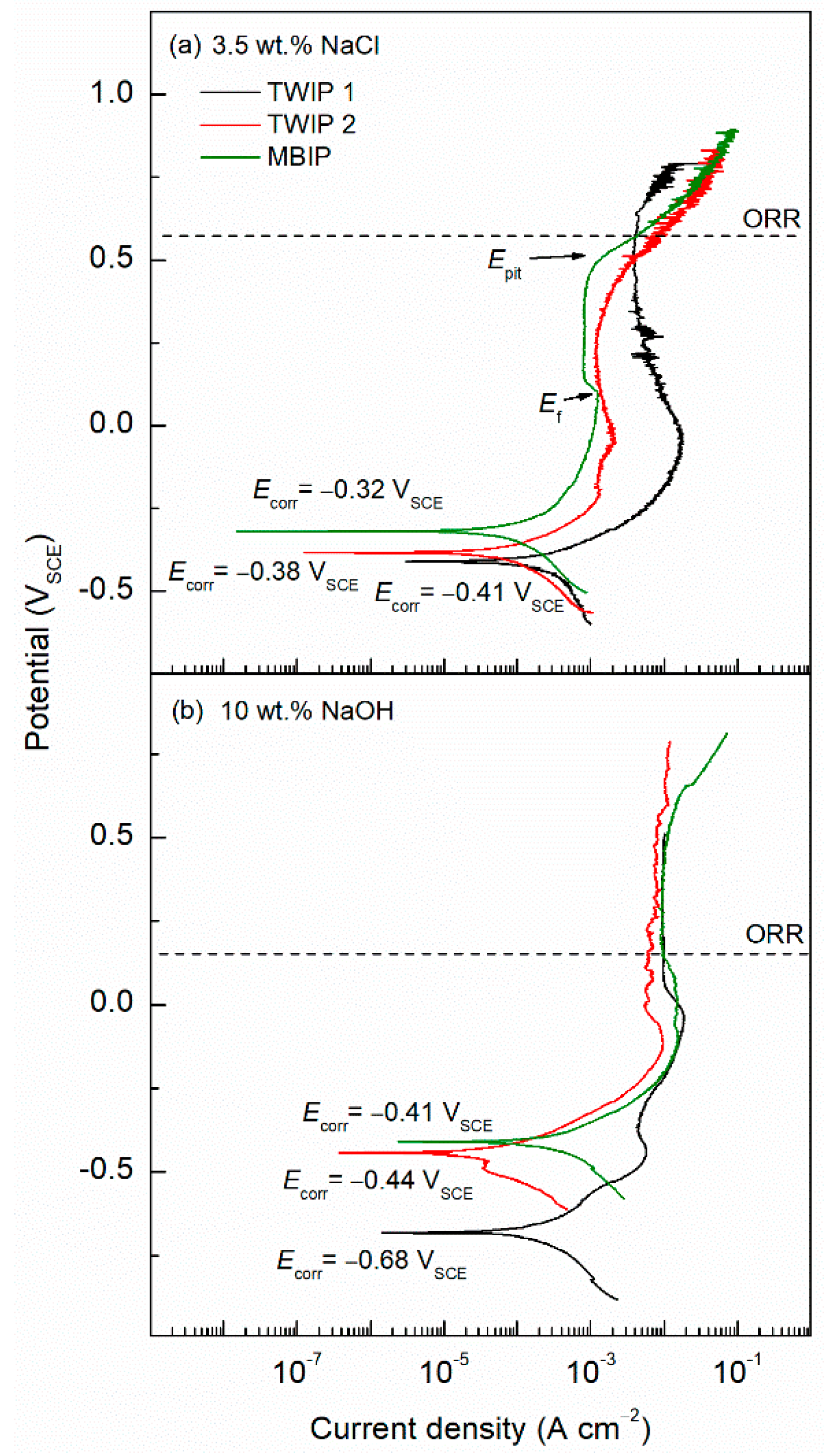

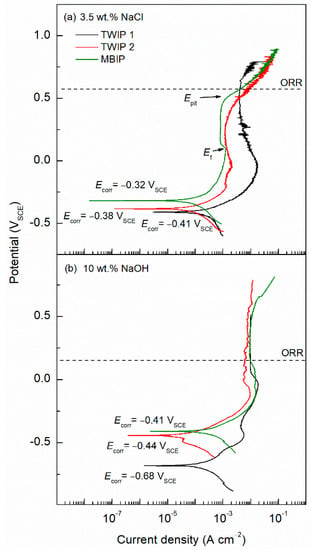

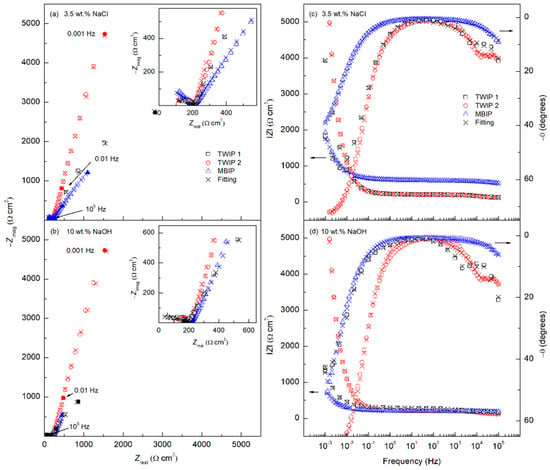

Hamada et al. reported that Al and Cr additions in Fe−30Mn−4Al−4Cr−0.26C or Fe−30Mn−8Al−6Cr−0.25C TWIP alloys increased the corrosion resistance significantly, particularly after anodic passivation ageing in an oxidizing solution (HNO3). Steels containing Cr have been shown to passivate with enrichment of Al and Cr and a depletion of Fe and Mn [76]. Hamada et al. have reported that high-Al TWIP steels exhibited salt-film precipitation as a passivation mechanism [82]. A comparison of corrosion properties of Fe−25Mn−(5−8)Al−0.2C, Fe−30Mn−(4−8)Al−(14−16)Cr−0.2C, and AISI 304 SS alloys in 5−50% HNO3 acid solution was presented [82]. The anodic polarization curves depict an active-to-passive peak, followed by a stable passivation region. In the transpassive region, a breakdown Epit, a secondary passivation region, and the evolution of oxygen are observed. At the beginning of the transpassive region peak, formation of Fe, Al, and Cr oxyhydroxides may take place. The passivation current of Fe−30Mn−8Al−6Cr is lower than that of AISI 304 SS, thus the passive film of Fe−30Mn−8Al−6Cr steel is more stable, attributed to the high passivity properties of Al, which are higher than Cr and considerably higher than those of Mn and Fe [82]. High current density oscillations for the Fe−25Mn−8Al alloy can be observed in the beginning of passive region and after the Flade potential (Ef), the potential at active-passive transition, i.e., the active-passive region. Two oscillation-type regimens were determined by Hamada et al., the first high-frequency oscillations were associated with the mass transfer-controlled plateau connected with the formation-disappearance of a porous salt film. The low-frequency-type oscillations, which consisted of periods of seconds to minutes, were associated with the relaxation processes, according to previous results in the literature [87]. Therefore, the passivation of Fe−25Mn−8Al steel was ascribed to salt film precipitation, contrary to the spontaneous oxide film formation in a Cr-bearing steel, as previously stated. In another study, the corrosion behavior of austenitic Fe−Mn−Al−Cr−C twinning-induced plasticity (TWIP) and microband-induced plasticity (MBIP) steels exposed to 3.5 wt.% NaCl and 10 wt.% NaOH solutions was studied [88]. Figure 7 presents the potentiodynamic polarization curves for two TWIP steels with a composition of Fe−22.6Mn−6.3Al−3.1Cr−0.68C and Fe−28Mn−5.2Al−5.1Cr−2.8Si−0.95C and a MBIP steel with a composition of Fe−30Mn−8.5Al−3.2Cr−1.1Mo−1.0C in both media, 3.5 wt.% NaCl and 10 wt.% NaOH solutions [88]. Figure 7 shows a decreasing trend in the cathodic kinetics as the content of Mn increases. This was related to the catalytic properties of the TWIP alloys towards the oxygen reduction reaction (ORR). In the alkaline media, the anodic branch was found to be stable showing a lack of current density oscillations related to the spontaneous formation of Al2O3 film that imparted passivity. Contrarily, in the neutral area, these oscillations were observed, confirming the salt-film precipitation passivation mechanism [88].

Figure 7.

Polarization curves for two TWIP steels (Fe−22.6Mn−6.3Al−3.1Cr−0.68C and Fe−28Mn−5.2Al−5.1Cr−2.8Si−0.95C) and a microband-induced plasticity (MBIP) steel (Fe−30Mn−8.5Al−3.2Cr−1.1Mo−1.0C) in: (a) 3.5 wt.% NaCl solution, and (b) 10 wt.% NaOH solution [88].

Mujica et al. examined the effect of Cr in the formation of passive layers on Fe−25Mn−12Cr−0.3C−0.4N alloy in 0.5M H2SO4 solution [50,89]. The Cr, C, and N enriched steel displays passivity and icorr values five orders of magnitude lower than the Fe−22Mn−0.6C steel.

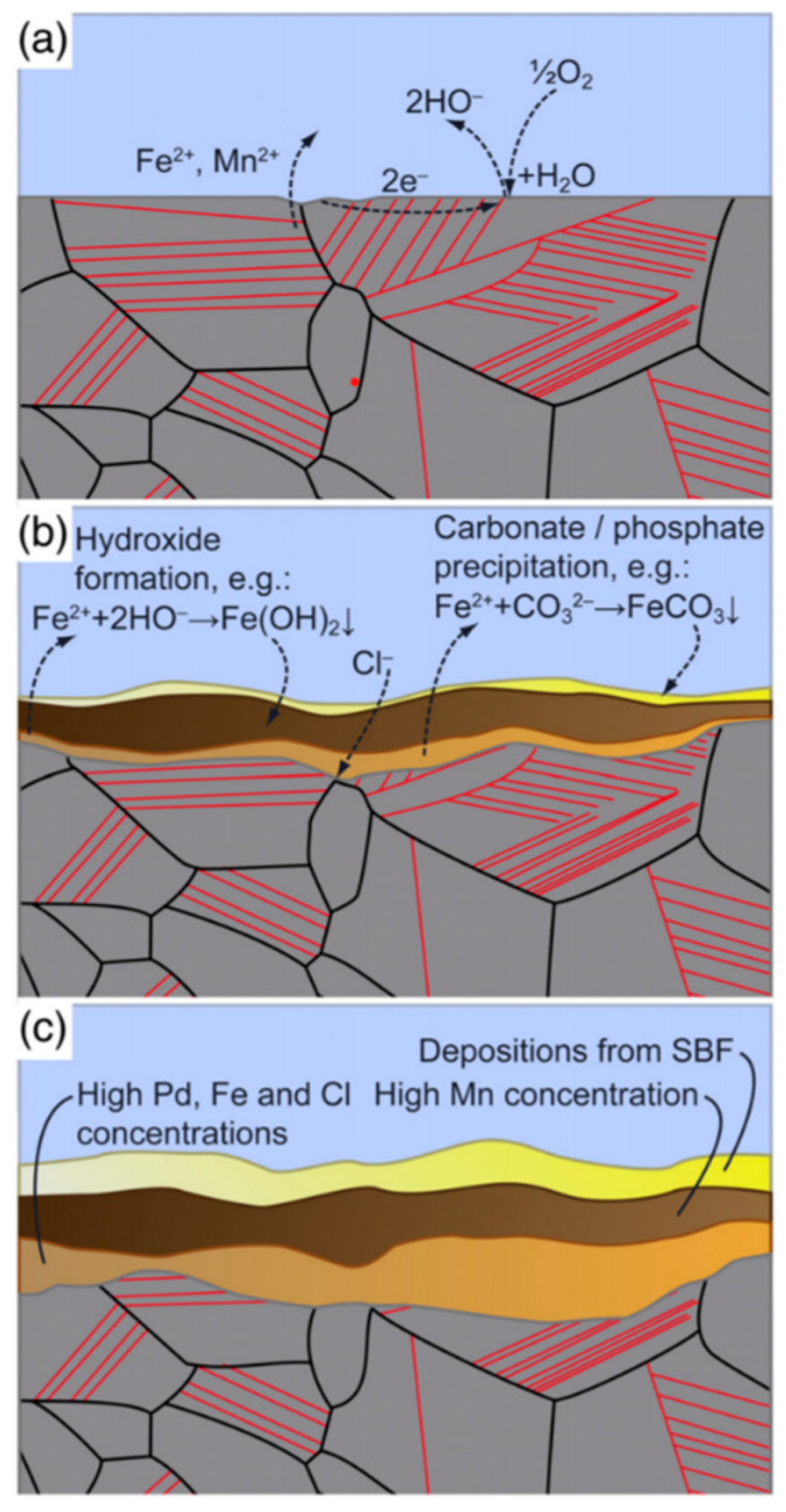

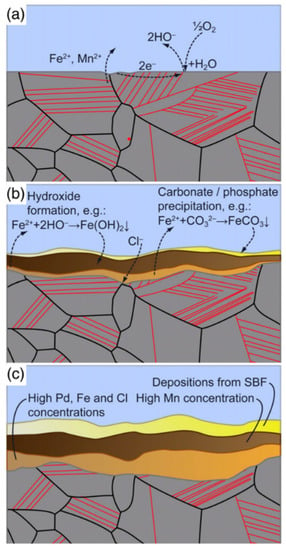

The corrosion behavior and passivation of Fe−(17−31)Mn−(1−9)Al−(1−7)Cr alloys in 1M Na2SO4, 3.5 wt.% NaCl and rainwater solutions were investigated by Zhu and Zhang [90]. The increased content of Al produced increased Ecorr values and decreased icorr values, however increased Mn counteracted the Al and no passivation was observed [90]. The passive film formed on the Fe−24Mn−4Al−5Cr alloy in 1M Na2SO4 solution was comprised of three parts: bounded water and hydroxides present at the surface; the outer portion of film made up of a mixture of Fe, Mn, Cr, and Al oxides; and a transition region consisting of low valence oxides and metallic Fe, Mn, Cr, and Al between the passive film and the matrix, see Figure 8. The corrosion resistance was imparted by the barrier film of bounded water, hydroxides, and oxides of Cr, Al, and Fe [91].

Figure 8.

Schematic illustration of the degradation process and the formation of degradation products for TWIP-1Pd alloys: (a) Initiation of the corrosion reaction: The anodic partial reactions are the metal oxidation, whereas the cathodic partial reaction is oxygen reduction, (b) formation of hydroxides/oxides, and precipitation of carbonates and phosphates that comprise the degradation products. Cl− ions diffuse to the surface, causing localized attacks, and (c) further build-up of degradation products. The Pd remains in the layer close to the sample surface and acts as a macrogalvanic element to increase degradation [92]. (Reproduced with permission from refs. [92]. Copyright (2013), Elsevier).

Several corrosion protection strategies have been used including alloying, thermal treatments, and coatings to improve corrosion resistance of the Fe−Mn−Al−C TWIP steels [82,93,94,95,96,97,98,99,100]. As-quenched, austenitic Fe−30Mn−9Al−(3,5,6.5,8)Cr−1C alloys in 3.5 wt.% NaCl solution showed passivation and lower Ecorr and Epit values as Cr content increased above 5 wt.%, yet the Ecorr and Epit decrease for Cr concentration up to 6.5 wt.% and 8 wt.% due to κ-carbide (Fe,Mn,Cr)7C3 [101]. The alloy was aged using an anodic passivation current to promote a thick, protective passive film [74].

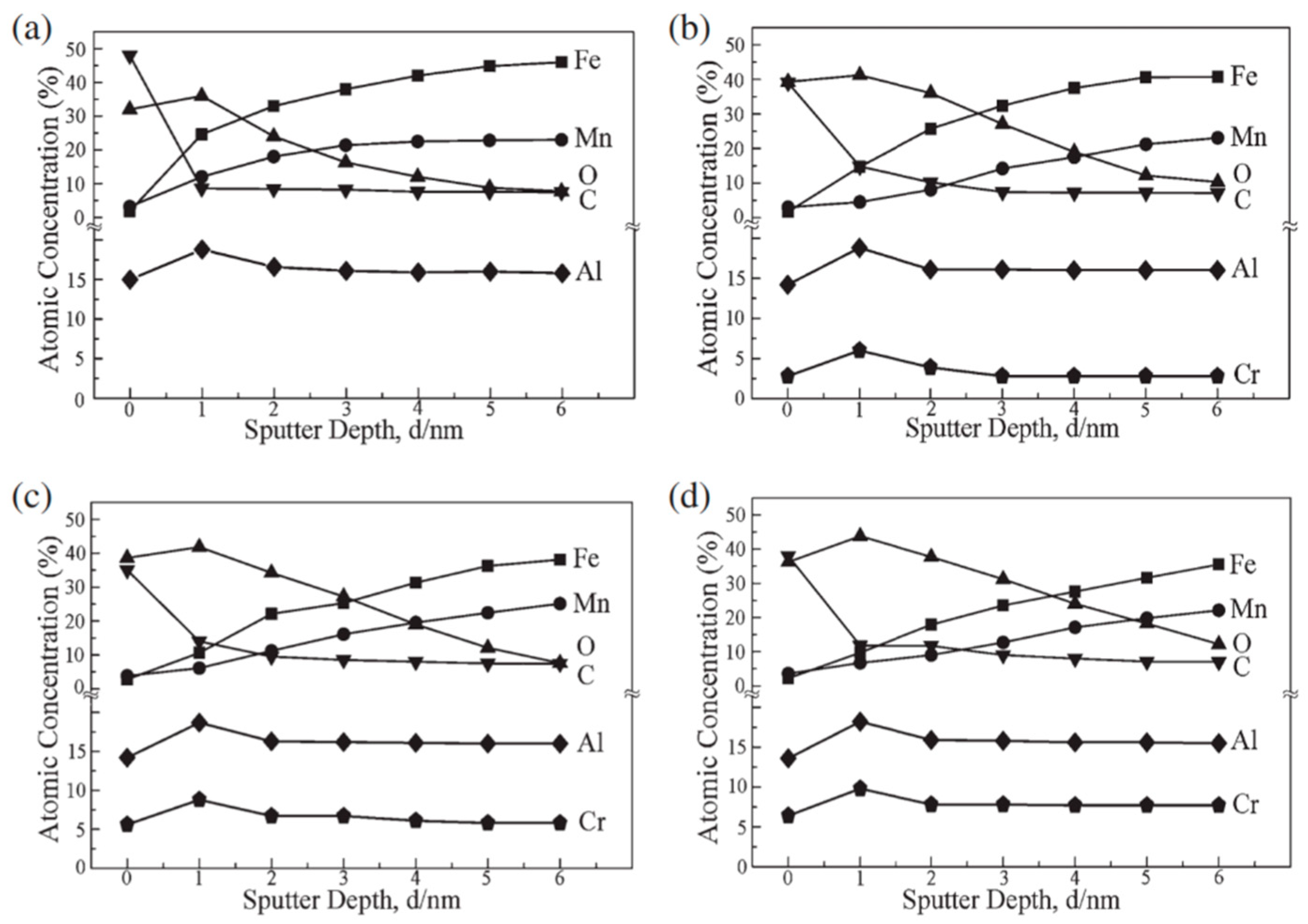

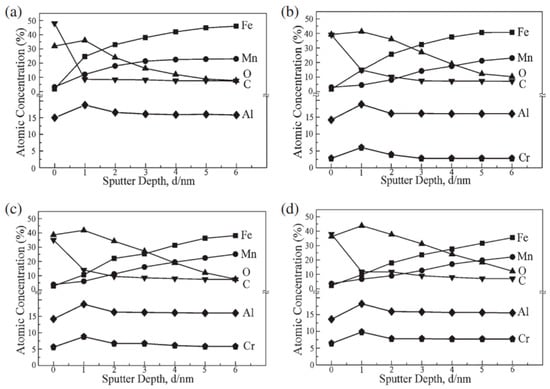

Tsay et al. studied the corrosion behavior of Fe−28Mn−9Al−6Cr−1.8C alloy in 3.5 wt.% NaCl [102]. Due to Cr and Al oxide formation, the Ecorr and Epit were −538 mV and −25 mV, respectively, significantly higher than −920 mV (∼−789 mV) and −500 mV (∼−240 mV) for Ecorr and Epit, respectively, of Fe−28Mn−9Al−6Cr−1.8C alloy. The Auger depth profiles of the passive film are shown in Figure 9a−d for the alloys containing (a) 0Cr, (b) 3Cr, (c) 6Cr and (d) 8Cr. For the alloys with (b) 3Cr, (c) 6Cr, and (d) 8Cr, broad Al, Cr, and O peaks are observed at a depth of 0–2 mm. Thus, the presence of Al and Cr oxides in samples (b) and (c) may explain the high corrosion resistance, however sample (d) with the highest concentration of Cr showed coarse, Cr-rich, (Fe,Mn,Cr)7C3 κ-carbides which caused a significant decrease in Ecorr and Epit values. The presence of a layer of Cr and Al oxides in the passive film may play an important role in improving the corrosion resistance characteristics of alloys (b) 3Cr through (c) 6Cr. However, the formation of the coarse Cr-rich (Fe,Mn,Cr)7C3 κ-carbides resulted in a drastic decrease in the Ecorr and Epit values of alloy (d) 8Cr.

Figure 9.

Auger depth profiles of the passive film present on Fe‒28Mn‒9Al‒6Cr‒1.8C alloy (a) 0Cr, (b) 3Cr, (c) 6Cr, and (d) 8Cr [102]. (Reproduced with permission from refs. [102]. Copyright (2010), Materials transactions).

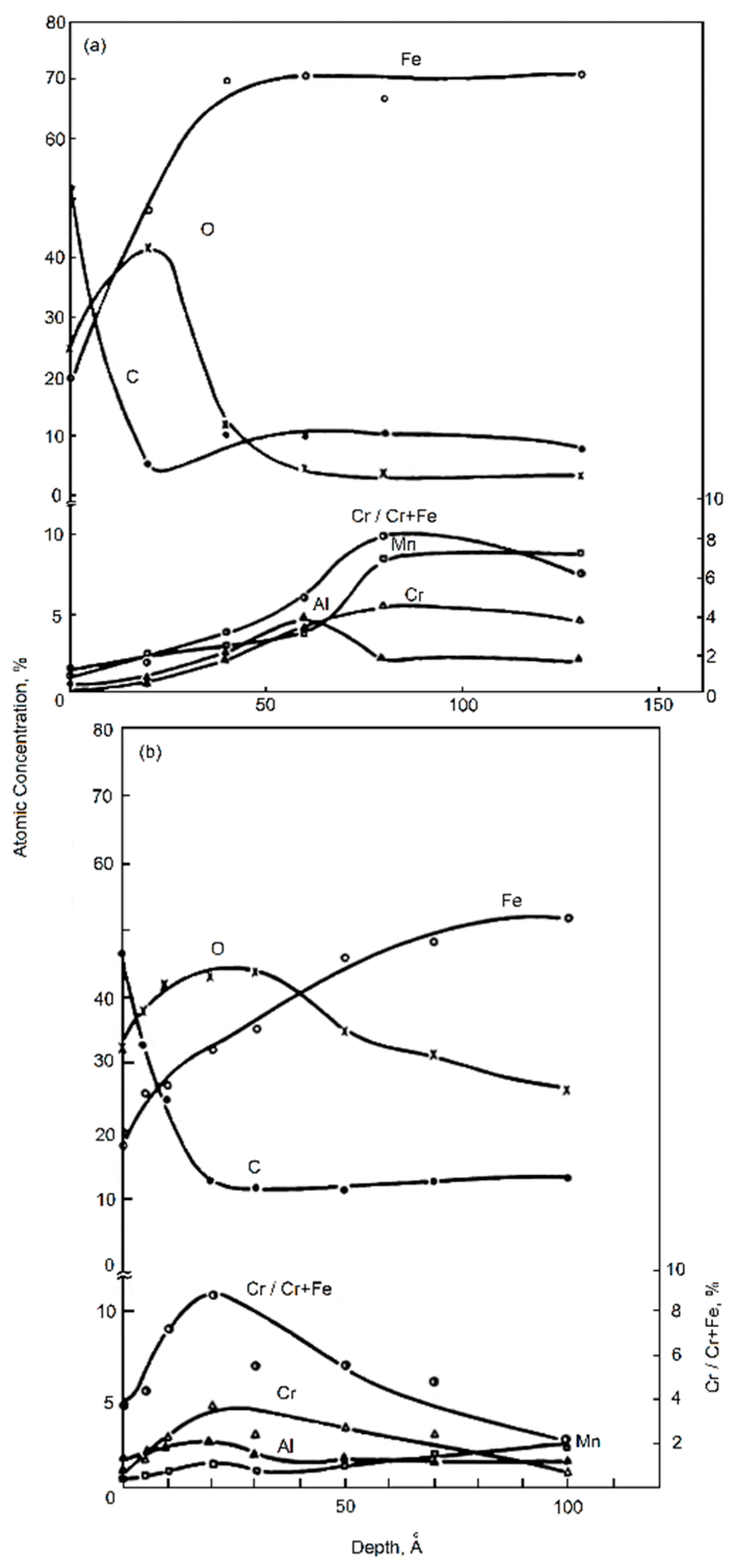

Fe−Mn−Al alloys, which contain significant amounts of Mn (>30 wt.%) and Al (>8 wt.%) demonstrate difficult workability, forming, and welding. Due to the requirement to combine Al with Cr to enhance the passive layer, it is cost efficient to reduce Cr additions to Fe−Mn−Al alloys [103]. The outer layer of the passive film for Fe−24Mn−3Al−7Cr in 1M Na2SO4 solution was found to be enriched in Fe oxides, while the inner portion was enriched in Cr and Al. Figure 10 shows the different distributions of Cr and Al in the passive film in strong oxidizing 50% HNO3 solution compared to neutral Na2SO4 solution. The maximum O concentration is determined by the amounts of Cr and Al. XPS results showed the majority oxide constituents in the passive film to be Cr2O3, Al2O3, and Fe2O3, which display good corrosion resistance, while Mn oxides in the film (primarily MnO2) reduces the corrosion resistance due to their fragile and unstable structure [103], as indicated above in Figure 8.

Figure 10.

Auger depth profiles for passive film of Fe‒24Mn‒3Al‒7Cr: (a) Formed in 1M Na2SO4 at 500 mVSCE, and (b) formed in 50% HNO3 at 1050 mVSCE [103]. (Reproduced with permission from refs. [103]. Copyright (1997), Taylor & Francis).

The corrosion properties of austenitic Fe−(23−30)Mn, Fe−(23−30)Mn−(2.8−8.2)Al, Fe−(23−30)Mn−(4.9−6.9)Cr, and Fe−(23−30)Mn−(2.8−8.2)Al−(4.9−6.9)Cr alloys have been studied in various aqueous solutions pH from −0.8 to 15.3 using electrochemical, AES, and XPS results [97]. Fe−Mn binary alloys were passivated in 10−50% NaOH solutions; additions of Al and Cr, however, showed no significant corrosion resistance increase in HNO3 or Na2SO4 solutions. All of the Fe−Mn-based alloys showed no passivation in neither 10% HCl nor 3.5 wt.% NaCl solutions. The Fe−Mn alloys containing Al, Cr, or a combination of the two showed passivation in 10−50% HNO3, 1M Na2SO4, and rainwater solutions. Bound water and hydroxides were present on the outermost portion of the passive film, while the oxides of Fe, Al, Cr, and Mn were found on the inner surface of the film. Overall, Fe−Mn-based alloys showed passivation in oxidizing acid, neutral, and basic solutions, however it did not passivate in reducing acid or active chloride solutions [97]. Table 2 and Table 3 summarize corrosion rate (vcorr) (µm year−1) values for high-Mn TWIP steel containing Al, and Al and Cr, respectively.

Table 2.

Corrosion rate (vcorr) (µm year−1) values for high-Mn TWIP steels with aluminum alloying.

Table 3.

Corrosion rate (vcorr) (µm year−1) values for high-Mn TWIP steels with aluminum and chromium elements.

2.3. Effect of Al and Si Alloying on High-Mn TWIP Steel Corrosion

The corrosion resistance of Fe−Mn−Al−Si−C TWIP steel alloys in tap water, synthetic mine, 3.5 wt.% NaCl, and H2SO4 solutions and the effects with Si additions have been investigated in literature [66,104]. It has been reported that Si can increase corrosion resistance of the alloy. The role of Si in Fe−Mn−Al alloys was suggested to act as a solid solution strengthener [105,106]. The principal restriction in industrial applications of Fe−Mn−Al−Si−C alloys is their poor corrosion resistance in severely aggressive media [66,88]. However, Wang and Beck reported that the Fe−30.5Mn−10.4Al−1.3Si−1.01C alloy presented a higher corrosion resistance than the Fe−18.59Cr−0.63Ni−1.07Ti−0.08C steel in a marine environment [107].

Kannan et al., in a comparative study, examined the corrosion properties of austenitic Fe−29Mn−3.1Al−1.4Si−0.05C and interstitial-free (IF)-type steel using immersion and polarization tests in 3.5 wt.% NaCl and 0.1M H2SO4 solutions [108]. High-Mn TWIP steel demonstrated lower corrosion resistance than IF steel in chloride and acid solutions, however the corrosion resistance of austenitic high-Mn steel in 3.5 wt.% NaCl was higher than in 0.1M H2SO4.

The corrosion behavior of Fe−32.7Mn−6.59Al−1.26Si−0.25C, and Fe−32.5Mn−8.54Al−1.31Si−0.54C alloys was studied by Lins et al. in 1N H2SO4, 3.0 wt.% NaCl, lactic acid, gasoline, fuel alcohol, and boiler water. Manganese exhibits poor passivity properties; however, it forms an unstable MnO film, increase icorr and decreased Ecorr values [109,110,111]. Abuzriba and Musa examined the electrochemical response of three austenitic Fe−33Mn−9Al−1.4Si−0.9C, Fe−29Mn−8.6Al−2.7Si−0.7C, and Fe−24Mn−7.3Al−2Si−1C alloys in 3.5 wt.% NaCl solution [112]. The alloys were determined to be unsuitable as substitutes for conventional SS.

Lean Mn TWIP steels Fe−18Mn−1.5Al−0.6C, Fe−15Mn−0.5Al−1.5Si−0.7C, and Fe−12Mn−2.0Si−0.9C in seawater with a flowing condition of 3.0 cm s−1 were studied by Moon et al. [113]. The most noble value of Ecorr was the 18Mn alloy, and 12Mn showed the least noble Ecorr, thus indicating that 18Mn presented the highest corrosion resistance. The polarization results indicate a passivity plateau width of 500, 380, and 250 mV for 18Mn, 15Mn, and 12 Mn, respectively.

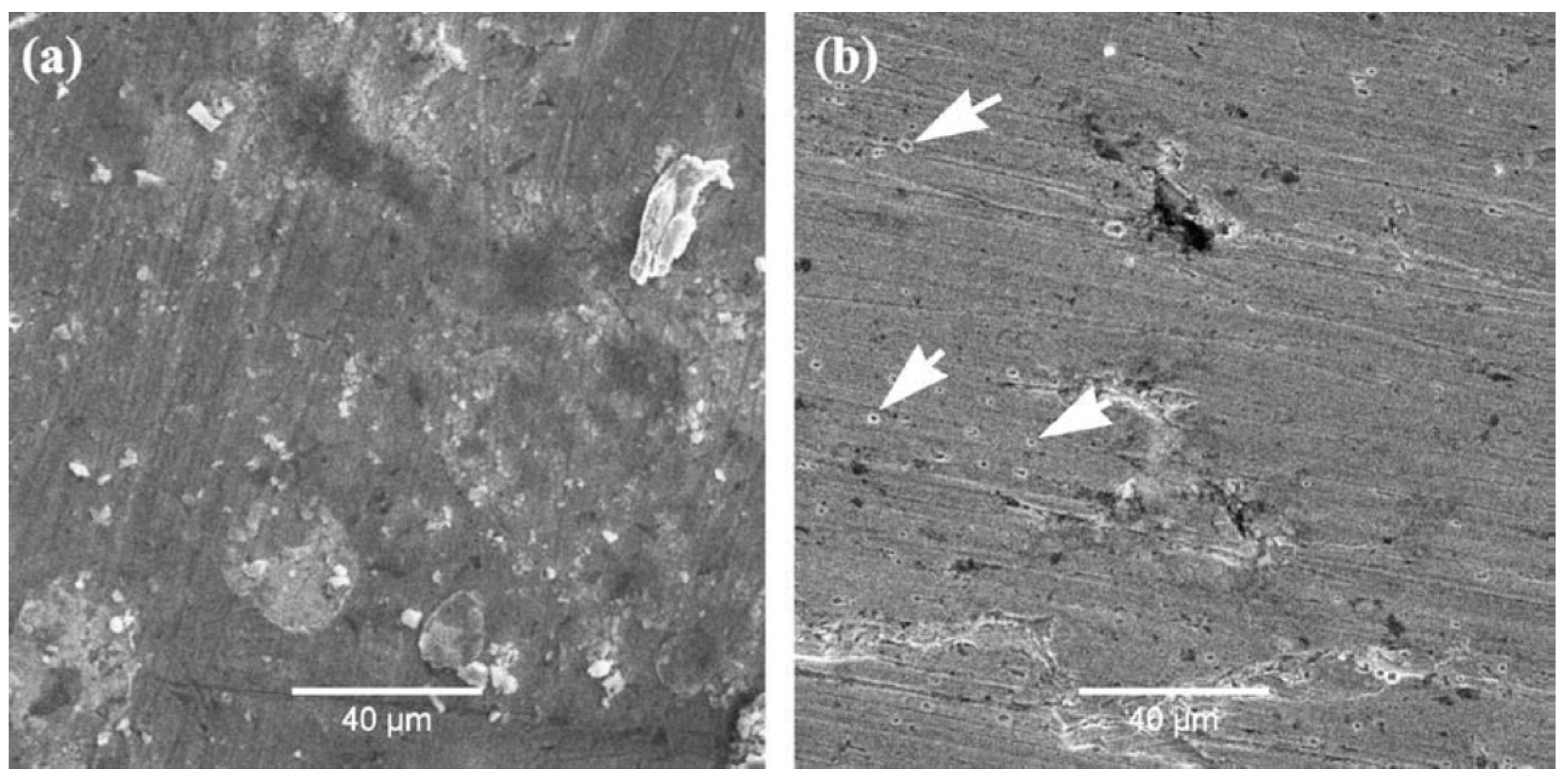

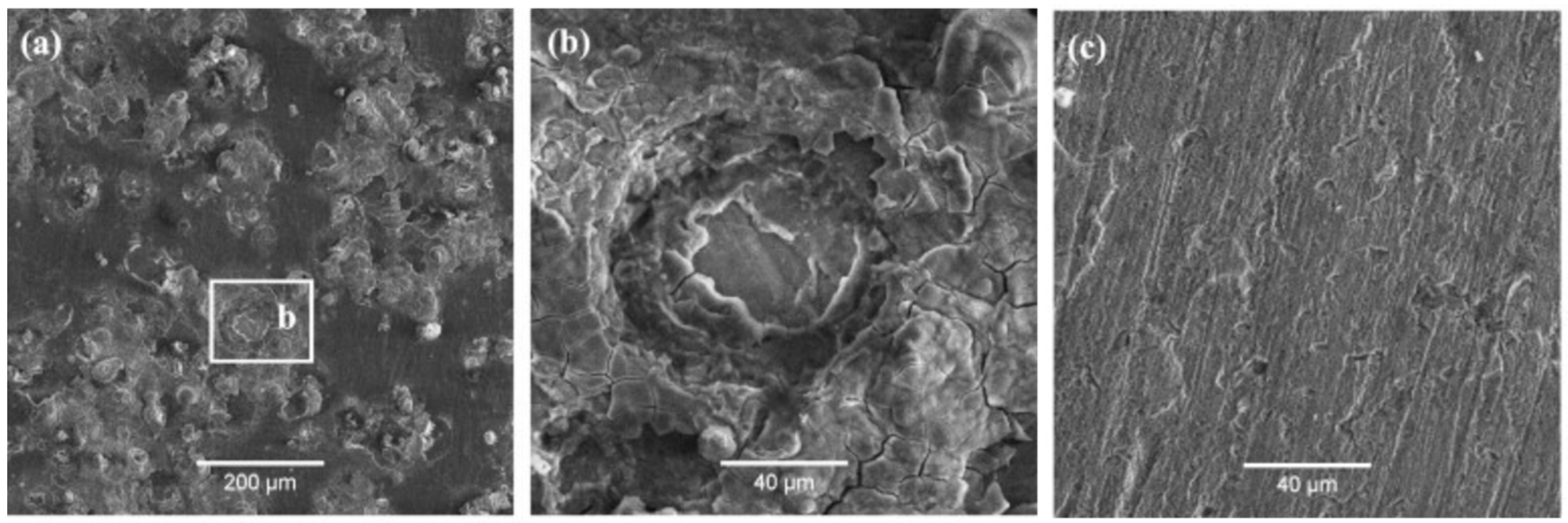

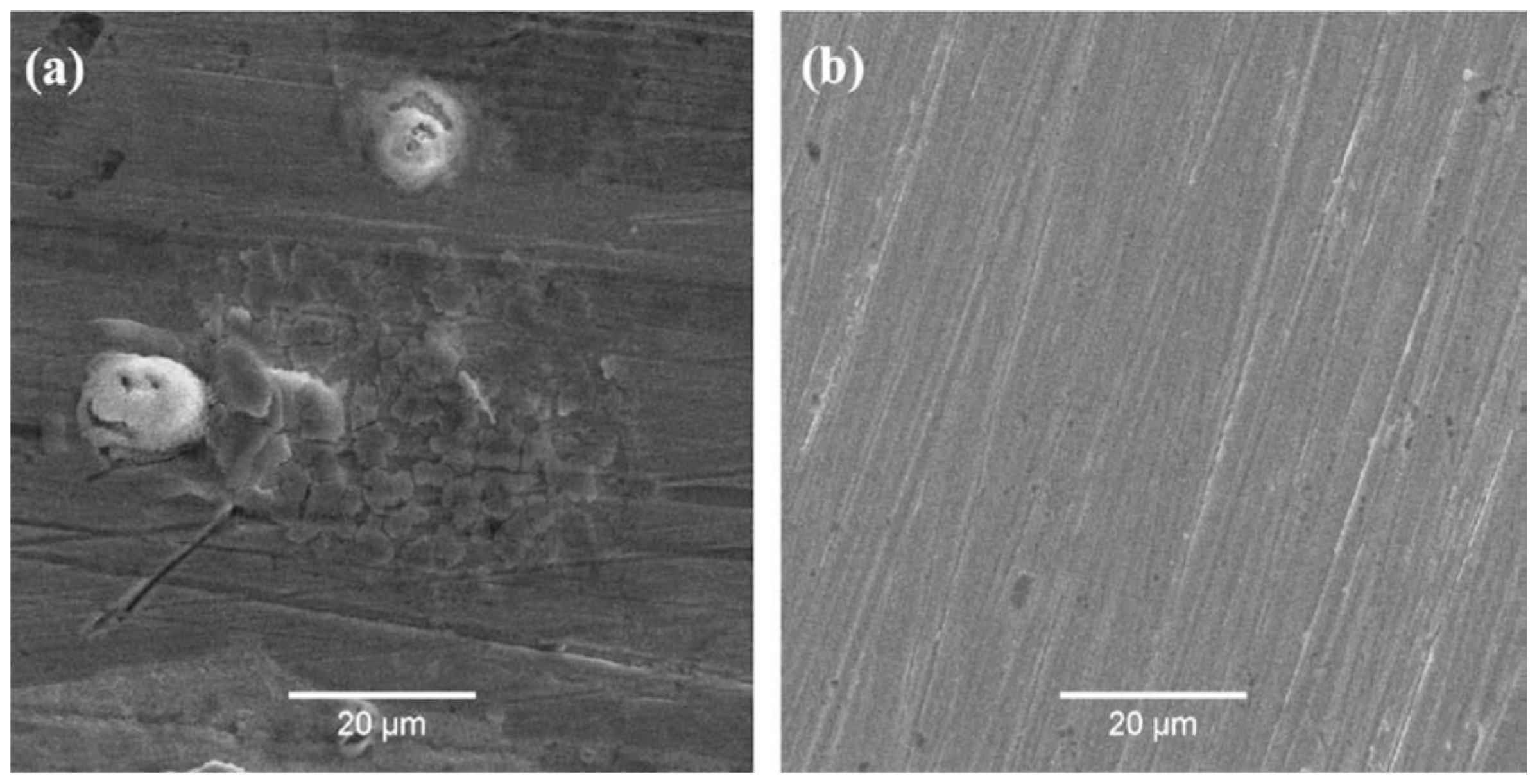

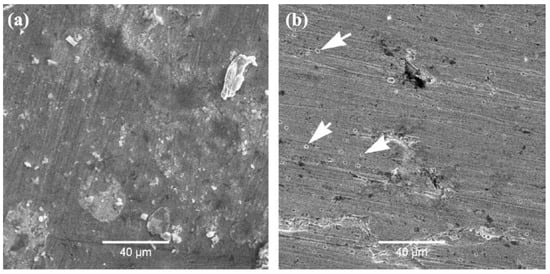

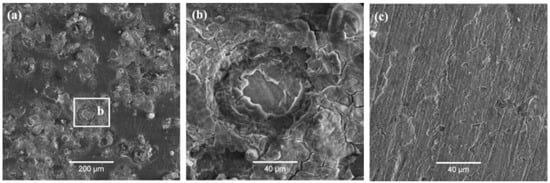

The corrosion properties of Fe−29Mn−3.1Al−1.4Si−0.05C steel compared to IF steel in acidic (0.1M H2SO4), alkaline (0.1M NaOH), and chloride-containing (3.5 wt.% NaCl) environments were studied by Kannan et al. using immersion and polarization experiments [107]. The alloy exhibited considerably lower corrosion resistance in acidic solution compared to IF steel. Despite the lower corrosion resistance of Fe−Mn−Al−Si−C steel compared to IF steel, the difference was not substantial. The Fe−Mn−Al−Si−C steel, however, showed no significant difference in the corrosion resistance compared with that of IF steel; furthermore, it exhibited substantially high corrosion resistance than in acidic and chloride solution. High corrosion attack of Fe−Mn−Al−Si−C steel exposed to acidic solution was observed compared to the alkaline and chloride solutions, which is consistent with the corrosion measurement data. The scanning electron microscopy (SEM) micrographs of the Fe−Mn−Al−Si−C and IF steels, after the polarization experiments in three different environments, are shown in Figure 11, Figure 12, Figure 13 [107]. In chloride solution, the Fe−Mn−Al−Si−C steel showed no localized corrosion (see Figure 11a), however uniform corrosion was observed. Contrarily, IF steel showed pitting corrosion in addition to the uniform corrosion (see Figure 11b). Both the steels showed extensive localized corrosion in acidic solution (see Figure 12). Fe−Mn−Al−Si−C steel was found to have increased corrosion compared to IF steel. A pit like morphology and some mud cracking adjacent to the region of localized attack region can be seen in the higher magnification micrograph of Fe−Mn−Al−Si−C steel tested in acidic solution, see Figure 12b. Pitting corrosion, however, was limited to a few small pits in the case of IF steel (see Figure 12c). Fe−Mn−Al−Si−C steel showed only a few sites of localized attack (see Figure 13a) in alkaline solution, however IF steel showed no noticeable corrosion attack (see Figure 13b).

Figure 11.

SEM micrographs for (a) Fe-Mn-Al-Si, and (b) interstitial-free (IF) steel after polarization experiments in 3.5 wt.% NaCl [108]. (Reproduced with permission from refs. [108]. Copyright (2008), Elsevier).

Figure 12.

SEM micrographs for (a) and (b) Fe-Mn-Al-Si, and (c) interstitial-free (IF) steel after polarization experiments in 0.1 M NaOH [108]. (Reproduced with permission from refs. [108]. Copyright (2008), Elsevier).

Figure 13.

SEM micrographs for (a) Fe-Mn-Al-Si, and (b) interstitial-free (IF) steel after polarization experiments in 0.1 M H2SO4 [108]. (Reproduced with permission from refs. [108]. Copyright (2008), Elsevier).

2.4. Effect of Al, Cu and P Alloying on high-Mn TWIP Steel Corrosion

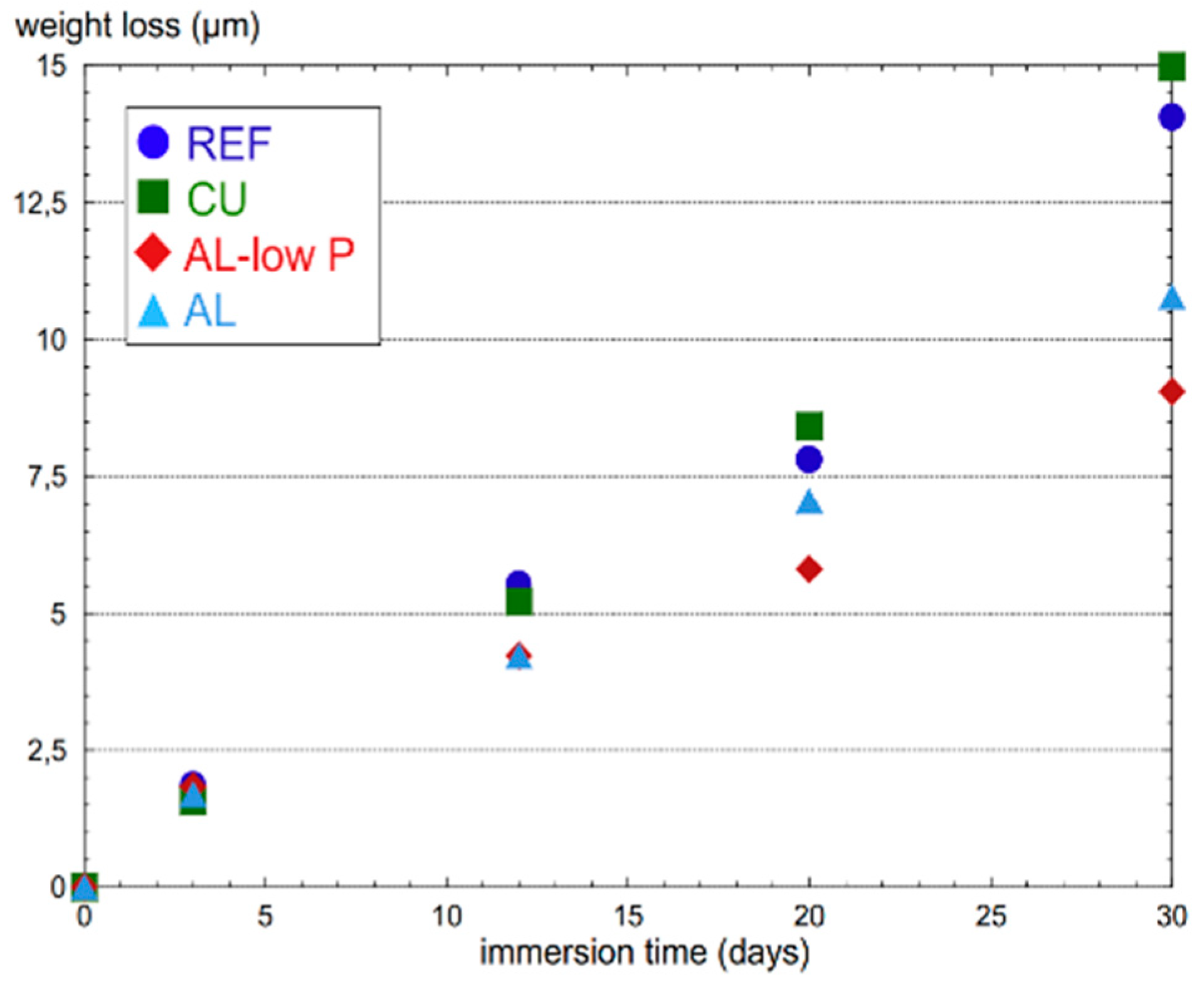

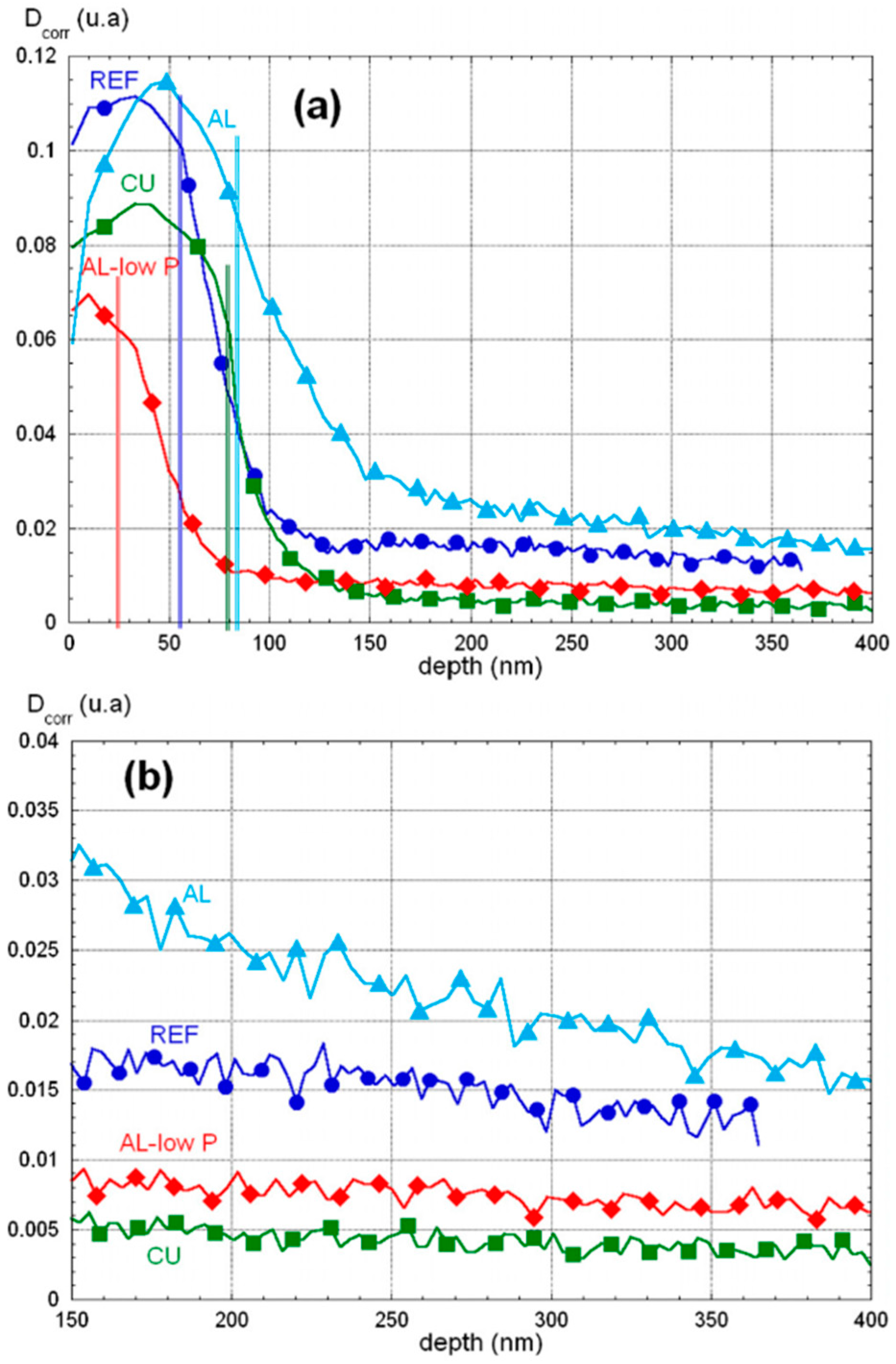

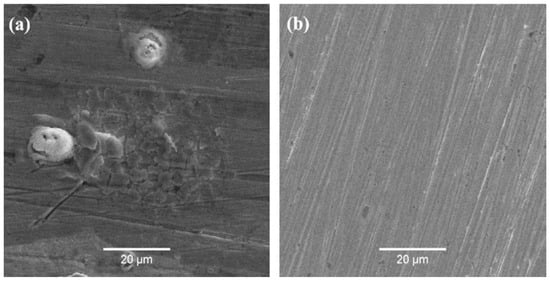

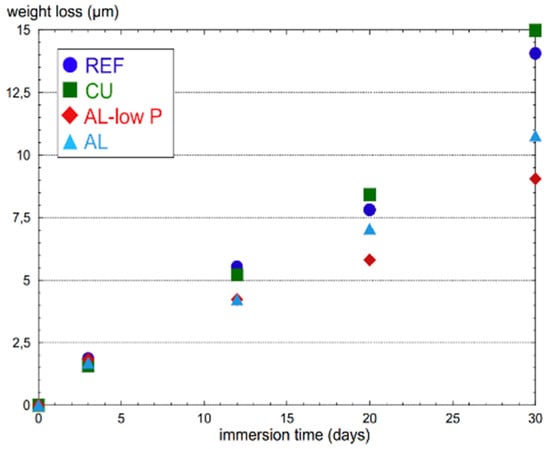

Dieudonné et al. studied the corrosion behavior of four TWIP steel alloys Fe−18Mn−0.6C−0.2Si−0.2V−0.032P (REF); Fe−18Mn−0.6C−0.2Si−0.2V−1.7Cu−0.031P (CU); Fe−17Mn−1.5Al−0.6C−0.2Si−0.2V−0.005P (AL-low P); and also Fe−17Mn−1.5Al−0.6C−0.2Si−0.2V−0.037P (AL) in a 5 wt.% NaCl (neutral pH) using weight loss measurements, in a 5% Na2SO4 solution (pH 1, 4 and 6) using polarization experiments [98,114]. Weight loss for REF, CU, AL, and AL-low P specimens can be seen in Figure 14, the average corrosion rate was ~0.2 mm year−1 for the REF and CU specimens and ~0.1 mm year−1 for both the AL and AL-low P specimens [98]. Therefore, Cu alloying has no significant effect on the overall corrosion resistance, however the addition of Al produces a lower corrosion rate. This increased corrosion resistance is attributed to the formation of an Al rich passive layer. Using Faraday’s law, the corrosion rates (vcorr) of the four TWIP steel alloys were recorded in 5% Na2SO4 at pH 6, the obtained vcorr values were 0.5 mm year−1 for the REF and AL-low P, and 0.4 mm year−1 for CU and AL. Thus, the addition of alloying elements did not produce a significant difference on the initial vcorr. Furthermore, the addition of P in the AL specimen produced a lower vcorr, possibly due to a drop in surface reactivity during the initial stage of passivation, thus making the oxide layer less passive. The link between corrosion rates and hydrogen absorption by secondary ion mass spectrometry (SIMS) results in 5% Na2SO4 solution at pH 4, as shown in Figure 15. Therefore, the P impurities in the AL sample increase the hydrogen adsorption. Cu does not affect the corrosion rates of the specimen; however, Cu enrichment of the oxide layer promote hydrogen recombination and decreases hydrogen adsorption. An improved corrosion resistance has been reported when alloying with Al, due to decreased hydrogen absorption, therefore minimizing hydrogen embrittlement (HE) [98]. Consequently, the addition of minor alloying elements such as Al and Cu may help improve resistance of Fe−Mn−C steels to HE and stress corrosion cracking (SCC).

Figure 14.

Weight loss versus time for Fe-18Mn-0.6C-0.032P exposed to 5 wt.% NaCl [98]. (Reproduced with permission from refs. [98]. Copyright (2014), Elsevier).

Figure 15.

Secondary ion mass spectrometry (SIMS) profiling of deuterium (Dcorr) in austenitic Fe–Mn–C TWIP steels exposed for 24 h at 25 °C to a 5 wt.% Na2SO4 deuterated solution at a pH of 4. (a) Influence of alloying elements on the deuterium profile (vertical lines represent the oxide/metal interface), and (b) zoom of the deuterium profiles in the matrix [98]. (Reproduced with permission from refs. [98]. Copyright (2014), Elsevier).

2.5. Effect of Cr, Cu, Si and N Alloying on High-Mn TWIP Steel Corrosion

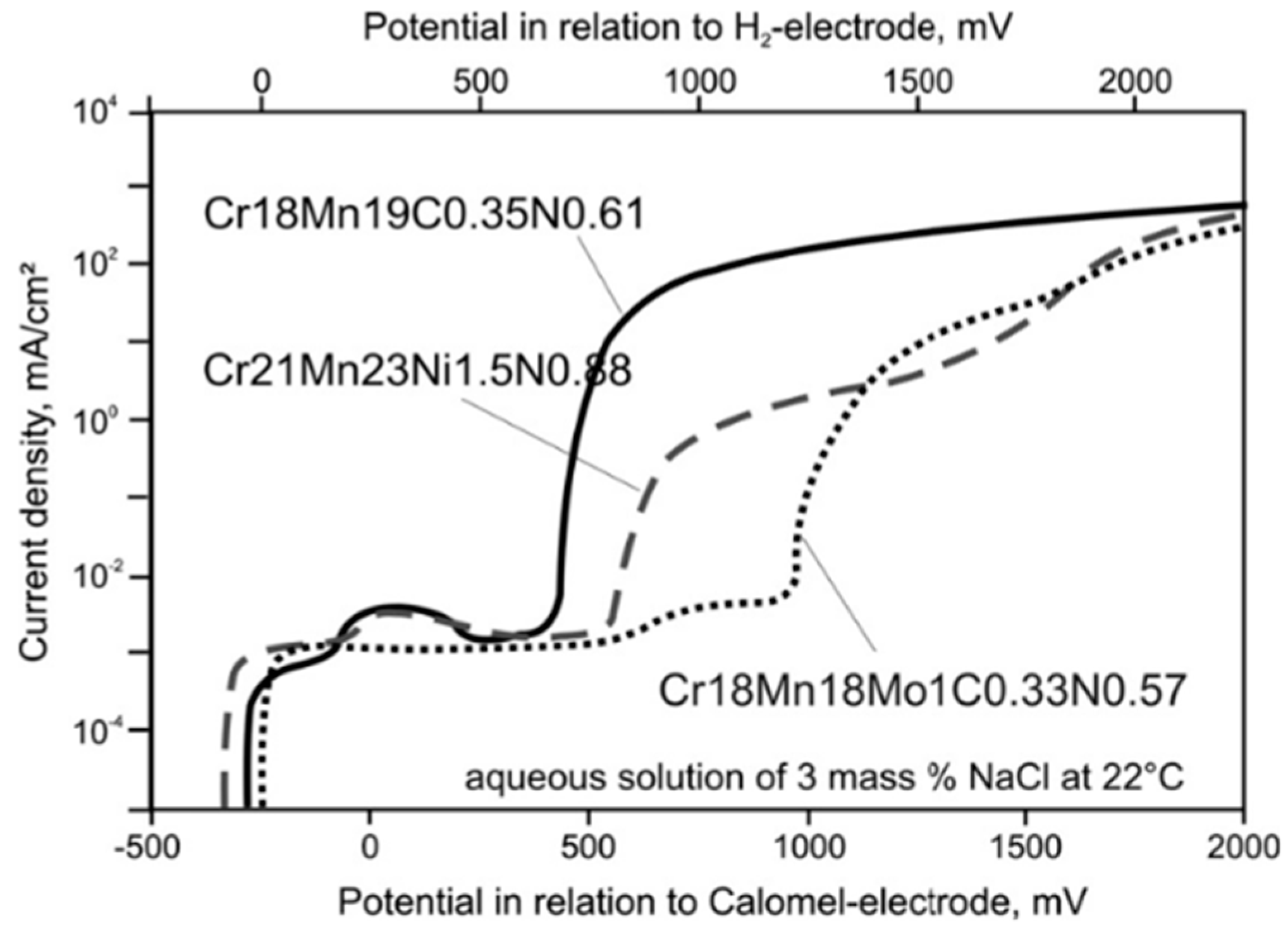

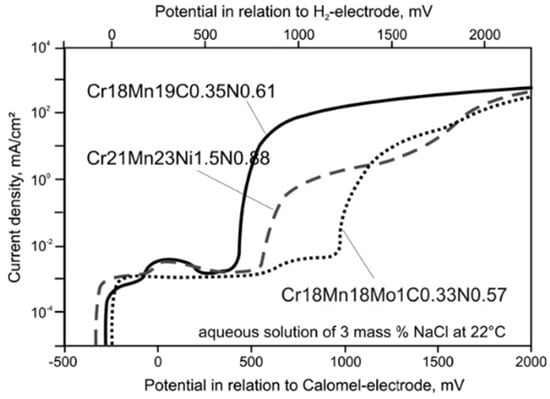

Múgica-Roncery et al. reported results on the corrosion resistance of the Fe−22Mn−0.6C and Fe−25Mn−3Al−3Si alloys in 0.5M H2SO4. Manganese was incorporated to provide the plasticity effect. Various works regarding Fe−Mn−Al and Fe−Mn−Al−Si systems in several environments show that the steel exhibits poor corrosion performance in saline and acidic environments compared to Fe−Cr−Ni SSs and IF-type steels [50]. Fe−18Mn−18Cr−C−N steel shows improved corrosion resistance compared to high-Mn Hadfield steel in a saline solution as shown in Figure 16 [115]. All the studied alloys, the reference Fe−24Mn−0.003Al−0.3Si−0.5C and the developed Fe−(20−30)Mn−12Cr−(0.24−0.3)C−(0.32−0.4)N steels showed a C/N ratio of 0.75 in 0.5M H2SO4 solution at room temperature. The active region of the steels was defined in the range of −300 mV to 0 mV vs. SCE, followed by a passive region with icorr between 1–20 μA cm−2 associated with the Cr-rich layers, and lastly, a transpassive region was defined. Compared to the reference steel, the developed samples exhibited more passive icorr values and smaller active areas.

Figure 16.

Potentiodynamic curves of steels Cr18Mn19C0.35N0.61, Cr18Mn18Mo1C0.33N0.57, and Cr21Mn23Ni1.5N0.88 [115]. (Reproduced with permission from refs. [115]. Copyright (2008), Elsevier).

The corrosion resistance of Fe−25Mn−12Cr−0.3C−0.4N in 0.5 M H2SO4 was compared to conventional TWIP steels, including Fe−25Mn−3Al−3Si and Fe−22Mn−0.6C [89]. It should be said that previous studies have been performed on Fe−Mn−Al−Si [108], showing poor corrosion resistance in acidic 0.1M H2SO4 solution due to the inability of Al to passivate, according to the Pourbaix diagram [116]. The Fe−25Mn−12Cr−0.3C−0.4N steel showed superior corrosion behavior compared to the Fe−Mn−C reference steel in 0.5M H2SO4 solution. The significant difference between the reference steel and the Fe−25Mn−12Cr−0.3C−0.4N steel is the ability for Cr to build passive layers. Fe−25Mn−12Cr−0.3C−0.4N steel shows an active region from −250 mV to +125 mV vs. SCE and has a critical icorr of 72 × 103 μA cm−2 and the passive region reaches 1250 mV vs. SCE, in which the ipass is 5 μA cm−2 and the first breakdown potential can be observed. Subsequently, a second passive region can be observed between 1125 to 1375 mV vs. SCE. In contrast, the reference TWIP steel exhibits a significantly larger active region with higher current density values compared to the Fe−25Mn−12Cr−0.3C−0.4N steel.

As a brief summary of the corrosion effect of the different elements, Al promotes passivity via the formation of a passive layer of Al2O3 film. This passivity ability is higher than the one promoted by Cr, Mn, or Fe [61,82]. Similarly, lower contents of Cr enhance passivity. However, higher contents (i.e., 6−9 wt.%) are detrimental [117]. This is due to the Cr causing phase-segregations, generating nucleation points for pitting corrosion [85]. Regarding Si, the formation of intermetallics such as Fe3Al-Si impart passivity. Furthermore, an increase in the Epit and an extension of the passive region is observed [84,118]. Molybdenum affects the polarity of the passive film via formation of molybdates as well as a creation a bipolar interface that promotes repassivation via deactivation of pits growth [119]. Furthermore, Mo enhances the corrosion resistance forming a MoO3 oxide layer that converts to MoO42– in the interface. This limits the flux of OH– and Cl– ions into the surface [119].

3. Effect of Mechanical Deformation on Corrosion of High-Mn TWIP Steels

The corrosion behavior of steels may be altered by cold-working due to the increase in internal energy, thus increasing the corrosion rate [120]. As well, the passivation of conventional SS has also shown to be affected by cold-working [121], high-N SS display a high defect density in the alloy matrix, thus decreasing passivity in 3.5 wt.% NaCl solution [122]. Moreover, 20% cold-working has been shown to enhance the pitting resistance of austenitic SS containing N, however further deformation is detrimental to the passivity of the alloy, this behavior is attributed to the structural changes and deformations caused by cold-working [123].

Grajcar studied the corrosion behavior of Fe−26Mn−3Al−3Si−Nb and Fe−25Mn−1.5Al−3Si−Nb−Ti alloy sheets after a thermo-mechanical rolling process: (a) Heating at 1100 °C and austenitizing for 15 min, (b) rolling from 1050 °C to 850 °C in 3 passes (20, 15 and 15% reduction), (c) holding of the rolled sheet at the temperature of finishing for 15 s, and (d) solution heat treatment of the specimens in water [124]. Immersion tests in 0.5 M H2SO4 solution for 100 h revealed 38% and 41% weight loss for 3Al and 1.5Al alloys, respectively, while in 3.5 wt.% NaCl solution, lower weight loss was observed of 0.4% and 0.5%, for 3Al and 1.5Al alloys, respectively. The observed differences in weight loss were attributed to the presence of a small fraction of ε-martensite that has little effect on the corrosion process. Pitting was observed for both alloys, greater amounts of pitting was found in areas containing non-metallic inclusions. Hydrogen failures were observed to a depth of 0.3 mm. The icorr in 0.5M H2SO4 was measured to be ~3400 μA cm−2, over 2 orders of magnitude higher than the icorr measured in 3.5 wt.% NaCl solution (~8 μA cm−2). A similar corrosion rate was observed for Fe−29Mn−3.1Al−1.4Si−0.05C steel [108]. The difference in the corrosion performance may be caused by the cathodic reaction, hydrogen ions are reduced to hydrogen gas in acidic 0.5M H2SO4, while in the neutral 3.5 wt.% NaCl environment, the cathodic reaction is the reduction of oxygen to hydroxide ions. The corrosion products formed were related to the chemical composition of the alloy rather than the phase structure, confirmed by the increased corrosion in the 1.5Al specimen due to its low Al concentration.

The study of corrosion properties of TMP TWIP steel in 3.5 wt.% NaCl was examined by Wang et al. [125], the TMP was found to enhance the corrosion properties by measurements of Ecorr, which increased from −0.92 V to −0.69 V, and icorr, which decreased from 8.76 × 10−5 A cm−2 to 1.92 × 10−5 A cm−2.

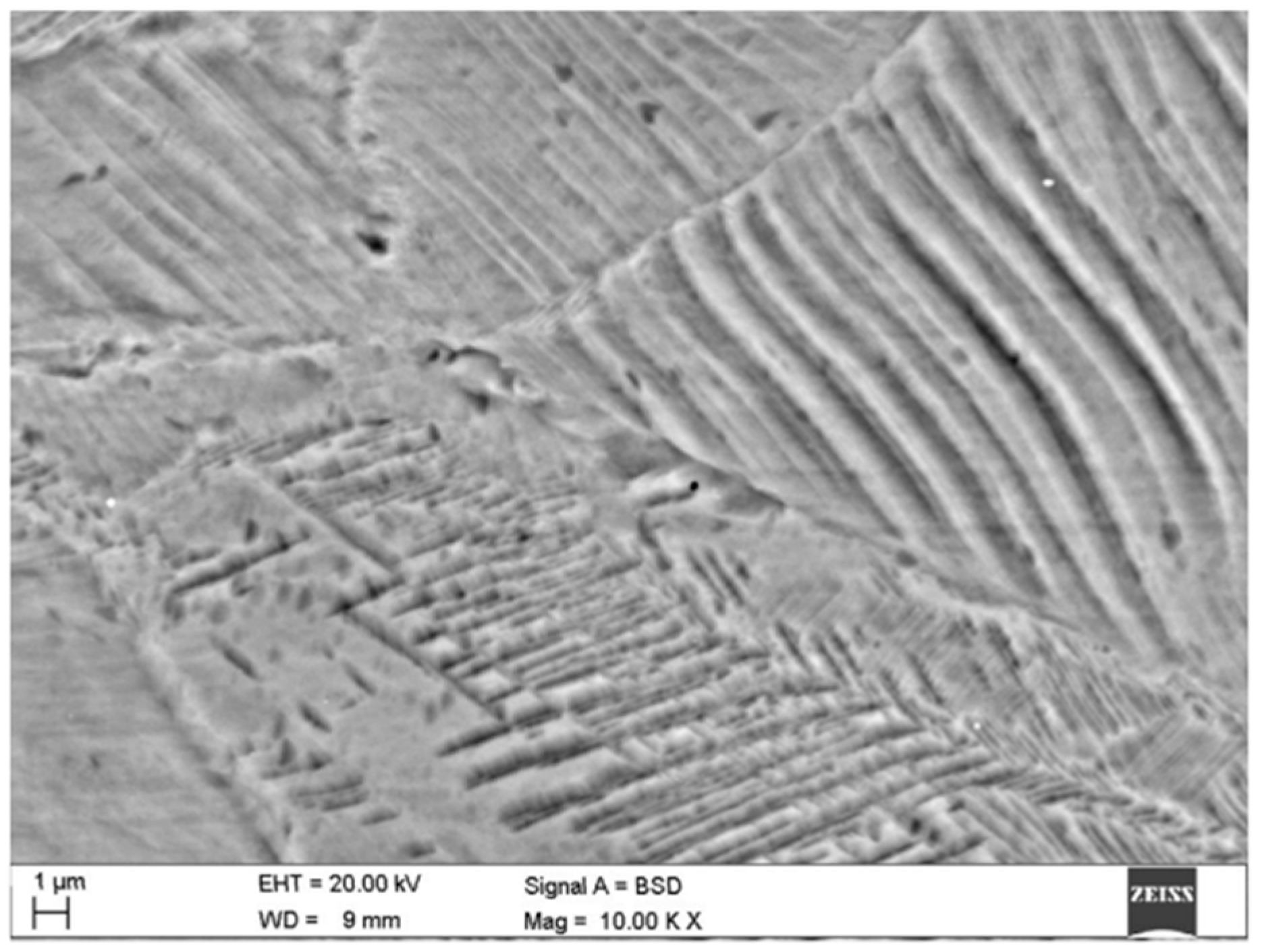

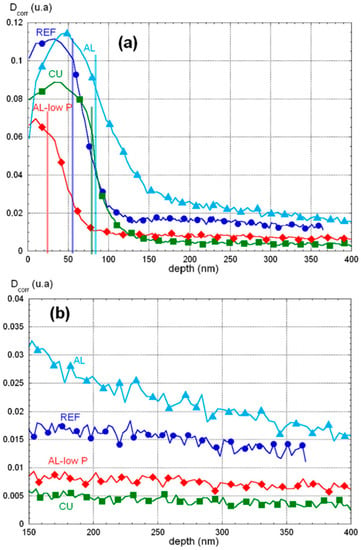

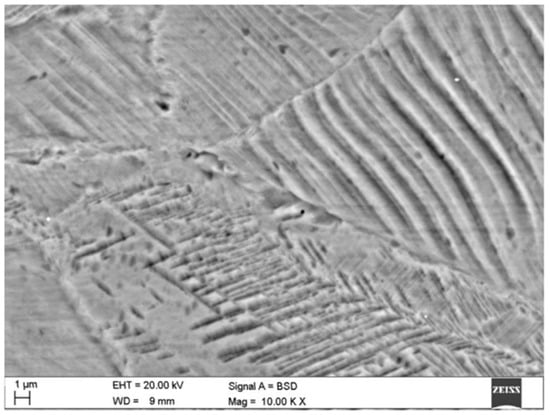

The existence of the second phases after heat treatment (ferrite, α′- and ε-martensite) or as a result of plastic deformation during cold-straining (strain induced α′- or ε-martensite) increases the icorr [126]. A galvanic couple is formed by the different phases with an austenite matrix; therefore, the corrosion rate increases. The results suggest that cold deformation of steel (Fe−26Mn−3Al−3Si) has a significant effect on the icorr (3.7 mA cm−2) in 0.1M H2SO4. Compared to TMP specimens (1.7 mA cm−2), cold-deformed Fe−26Mn−3Al−3Si steel specimens show lower corrosion resistance. Cold-deformed steel showed greater amounts of corrosion pits than the TMP steel. This can be attributed to the increased dislocation density and twins after cold-working, see Figure 17. The grain boundaries show a particular susceptibility to pit nucleation [126]. The current density values measured for cold-strained 26Mn−2.9Al−3Si steel were notably less than that of hot-rolled steel containing a lower Al content (Fe−27Mn−1.7Al−4Si). Consequently, the effect of cold working is less significant than the combined effects offered by the decreased Al addition and the increased Si content in the Fe−27Mn−1.7Al−4Si steel. Therefore, the corrosion resistance of high-Mn steels shows greater dependency on chemical composition than the effects of cold-work deformation. Increasing Al additions from 1.7% to approximately 2.9% produces a noticeable advantage in corrosion behavior.

Figure 17.

SEM image of the austenitic microstructure of 16Mn–3Si–3Al cold-worked TWIP steel showing slip bands and deformation twins [126].

The corrosion behavior changes of Fe−29Mn−3.5Al−0.5Si−0.5C steel in 3.5 wt.% NaCl solution induced by cold-plastic deformation was studied by Ghayad et al. [127]. Using potentiodynamic testing, no tendency for passivation was detected, thus it is independent of the steel structure after heat treatment (supersaturated aged or strain-aged). Annealing causes faster steel dissolution, thus the deformed specimens exhibit a higher corrosion rate than the supersaturated specimens and have a different potential than the matrix. The strain-aged samples display the highest corrosion rate due to the galvanic cell created by the coupling of ferrite with the austenite matrix [124].

The corrosion properties of Fe−29Mn−3Al−1.6Si−0.06C TWIP steel cold-worked to 0%, 20%, and 35% were studied in 0.1M H2SO4, 0.1M NaOH, and 3.5 wt.% NaCl [120]. The Ecorr values for the 20% cold-worked specimen in 3.5 wt.% NaCl presented more noble values compared to the non-deformed steel. Nevertheless, cold-work deformation of 35% shifted the Ecorr closer to the non-deformed specimen. The icorr measured for 20% cold-work deformation (18 μA cm−2) was lower and less active than the icorr measured for the non-deformed specimen (23 μA cm−2), howeve when cold-work is increased to 35%, icorr increased to 21 μA cm−2. For the 0.1M NaOH environment, the Ecorr of 20% cold-worked specimen showed a similar value to that of the non-deformed specimen, although 35% cold-work showed a shift towards more noble values. The 20% specimen icorr was 2 μA cm−2 as well as the non-deformed steel, however the 35% cold-worked specimen had an icorr of 3 μA cm−2. The Ecorr and icorr values for 0.1M H2SO4 solution were similar to those observed in 3.5 wt.% NaCl solution. For the 20% cold-worked, non-deformed, and 35% cold-worked specimens, the icorr was 1513 μA cm−2, 2237 μA cm−2 and 1729 μA cm−2, respectively. The difference in corrosion performance was attributed to the Si, which forms a silica film in acidic solution, therefore the passive film formation is impeded by high dissolution of Fe and Mn [69,90]. In chloride solutions near neutral pH, Al forms a protective Al oxide passive film, while alkaline pH experiences high corrosion resistance due to the passivating properties of Fe and Mn.

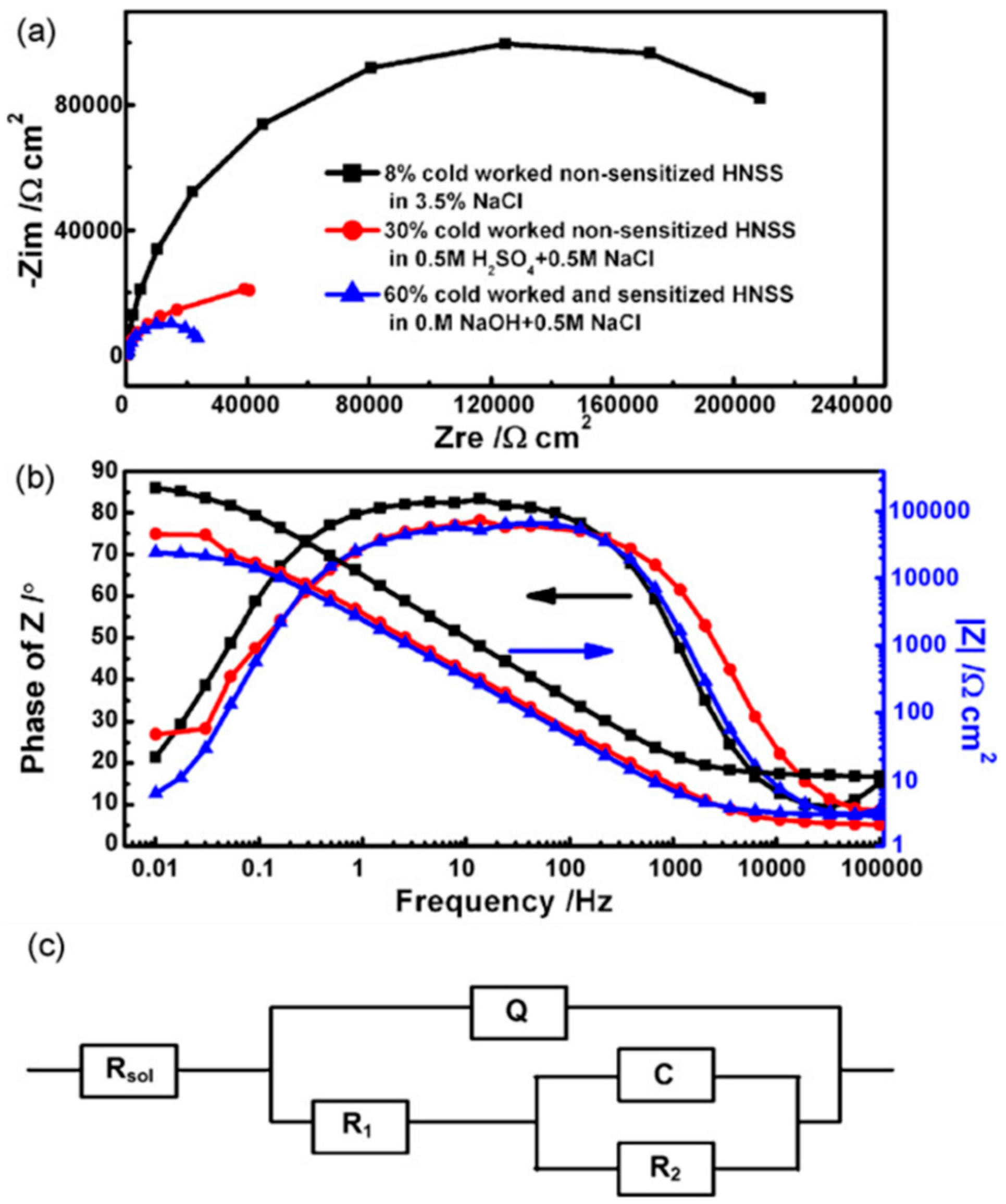

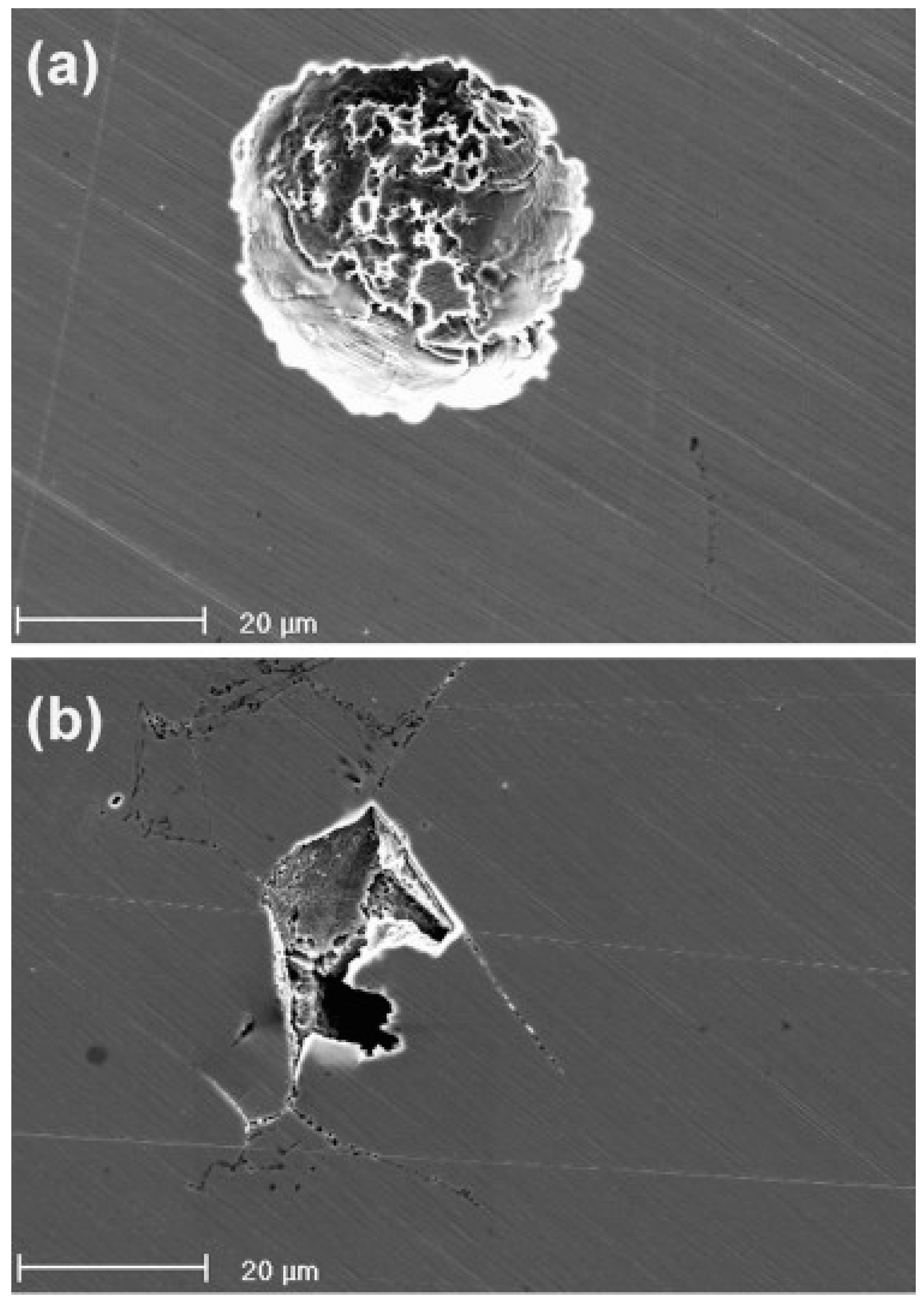

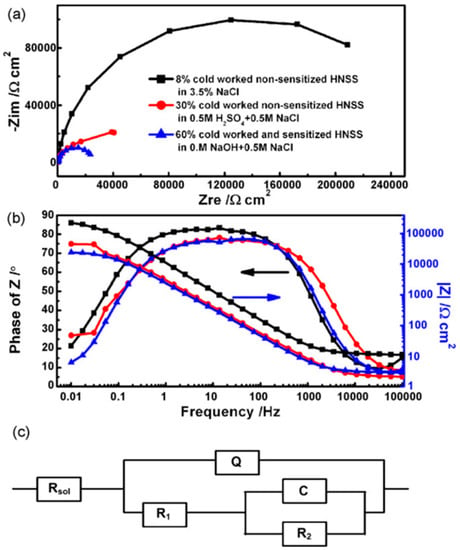

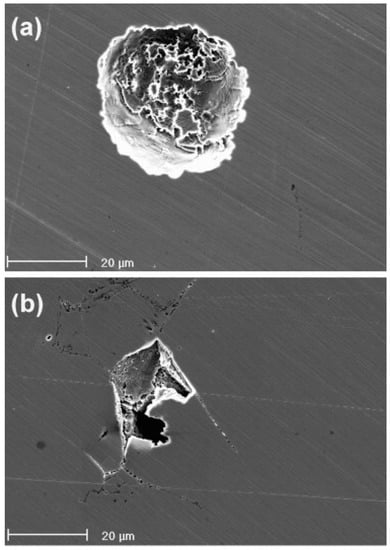

Fu et al. studied the effect cold-rolling and/or sensitization on the corrosion properties of nickel-free high-N SS (HNSS), Fe−15.8Mn−18.4Cr−2.19Mo−0.66N−0.24Si−0.04C, in 3.5 wt.% NaCl (pH ~5.8), 0.5M H2SO4 + 0.5M NaCl (pH ~0.4), and 0.5M NaOH + 0.5M NaCl (pH ~13.1) using polarization, EIS, XPS, SEM, and TEM results [122]. The cold rolling was conducted with thickness reductions of 8, 30, 49, or 60% and the sensitization was performed at 650 °C for 2 h. The Nyquist plots with fitting to an equivalent circuit are shown in Figure 18 [122,128,129]. Cold-working creates an increase defect density into the matrix, thus producing a less protective passive film and reduced corrosion resistance for HNSS with heavy cold-working (30 and 60%) in a 3.5 wt.% NaCl solution. The highly cold-worked HNSS developed a passive film with fewer oxides and greater amounts of hydroxides. Unsensitized HNSS displayed no decrease in corrosion resistance. The poor corrosion resistance properties were attributed to the loss of anti-corrosion elements in the passive film, such as Cr and Mo, supported by the XPS results. SEM images showed the precipitation of χ–phase in the grain and at the grain boundaries; see Figure 19 [122,130].

Figure 18.

Fe-15Mn-18Cr-2Mo-0.7N-0.04C in 3.5 wt.% NaCl: (a) Nyquist plot, (b) bode plot, and (c) electrical equivalent circuit used to fit impedance data [122]. (Reproduced with permission from refs. [122]. Copyright (2009), Elsevier).

Figure 19.

SEM micrographs showing surface pit in: (a) 49% cold worked non-sensitized specimen, and (b) 49% cold worked and sensitized specimen after potentiodynamic polarization in a 3.5% NaCl solution [122]. (Reproduced with permission from refs. [122]. Copyright (2009), Elsevier).

Studies of pitting corrosion were examined on cold-worked (thickness reduction of 5, 10, 15, 20, 30, or 60%) N-bearing (0.05, 0.1, and 0.22%) type austenitic AISI 316L SS, in neutral chloride solution (3.5 wt.% NaCl) [123]. A decrease in pitting corrosion was observed at up to 20% cold-working, while increasing to 30% and 40% cold-working caused a sudden decrease in pitting resistance. N promotes passivity, increasing the pitting corrosion resistance and improves stress corrosion cracking resistance [131]. For instance, the study performed by Kamachi Mudali et al. showed that increasing the content of N from 0.05% to 0.22% significantly increased the pitting corrosion resistance [123]. Regarding cold work, a relationship between pitting and cold work was identified. Setting the optimal cold work to 20% as higher values drastically affect pitting corrosion resistance [123].

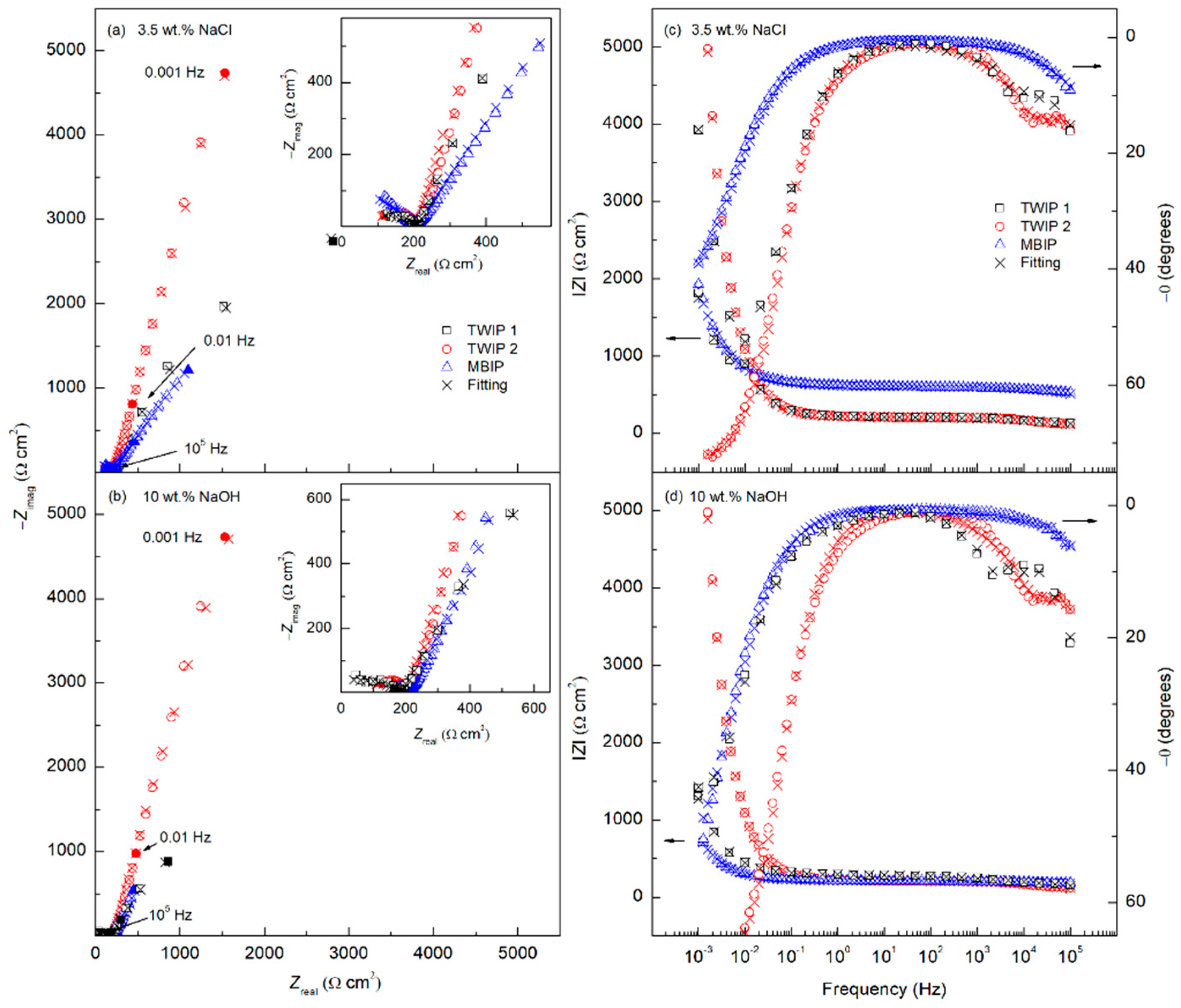

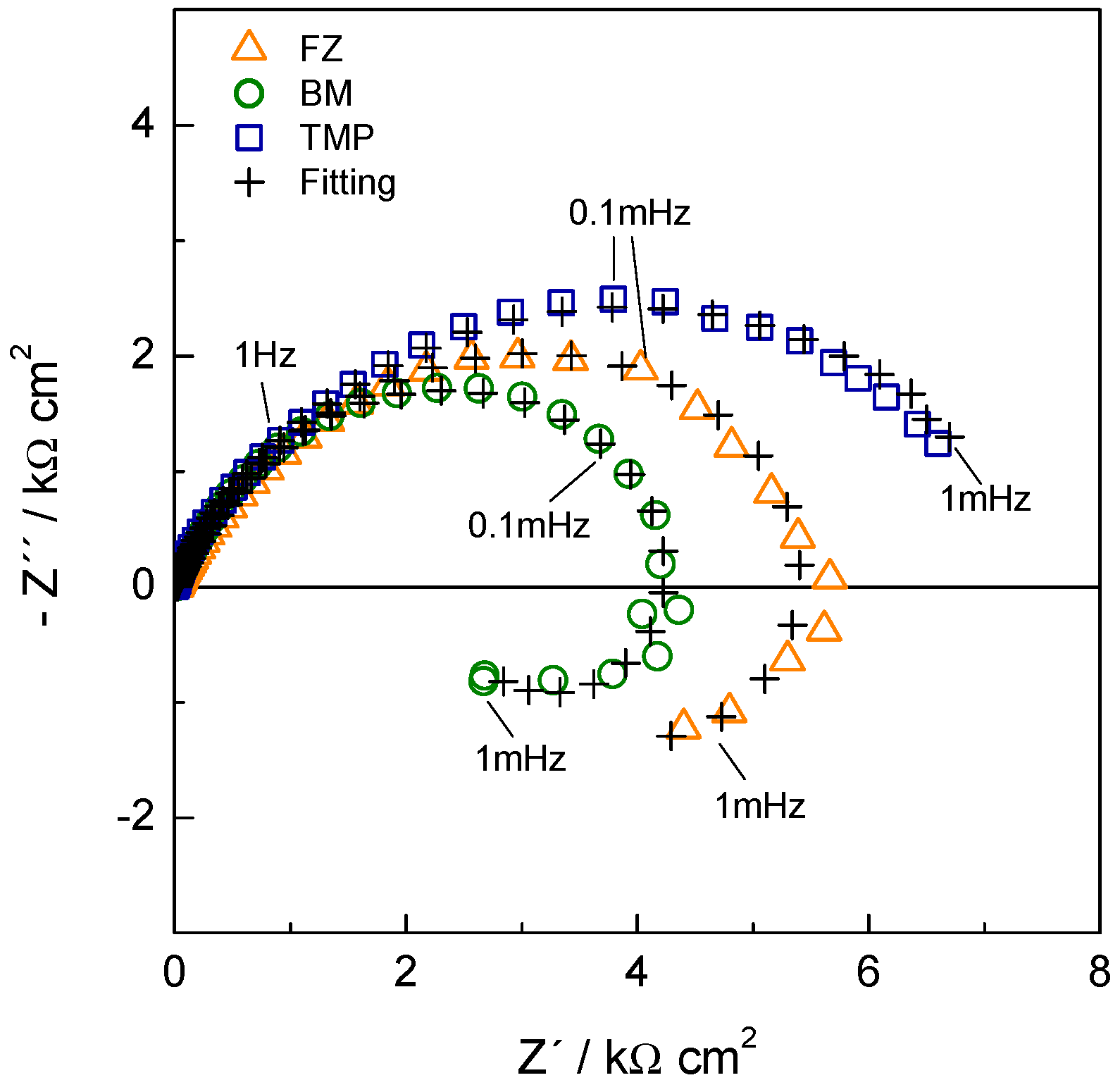

Austenitic steels have been shown to improve the mechanical properties with the formation of nano/fine-grained structures [132,133]. The effect of TMP on the corrosion behavior of Fe−18Mn−2Al−2Si−0.07C steel in 3.5 wt.% NaCl solution was studied by Yeganeh et al. [134]. The Bode plots showed higher Z-module (|Z|) and phase-angle (θ) values for the fine-grained (FG) specimen compared to the coarse-grained (CG) specimen, corresponding to the higher resistance of the oxide or passive film. These findings were attributed to the lowest energy grain boundaries evaluated on the microstructure of FG specimen [135]. The Mott–Schottky plots for the FG and CG specimens showed a higher donor density (ND) for FG specimen (11 × 1021 cm−3) than for CG specimen (9 × 1021 cm−3), which was attributed to higher quantities of grain boundary defects of the FG specimen, favoring the diffusion of oxygen atoms through the surface [134]. Similarly, a study performed by Bosch et al. showed a capacitive behavior consisting of two-time constants at high frequencies, attributed to the passive layer, and one at the low frequencies attributed to the corrosion phenomena, as shown in Figure 20 [88]. These results also showed how the high Mn content (30 wt.%) severely affected the corrosion performance [88].

Figure 20.

Nyquist plots of two TWIP steels (Fe−22.6Mn−6.3Al−3.1Cr−0.68C and Fe−28Mn−5.2Al−5.1Cr−2.8Si−0.95C) and a MBIP steel (Fe−30Mn−8.5Al−3.2Cr−1.1Mo−1.0C) in: (a) 3.5 wt.% NaCl solution, and (b) 10 wt.% NaOH solution. Corresponding bode plots in: (c) 3.5 wt.% NaCl solution, and (d) 10 wt.% NaOH solution [88].

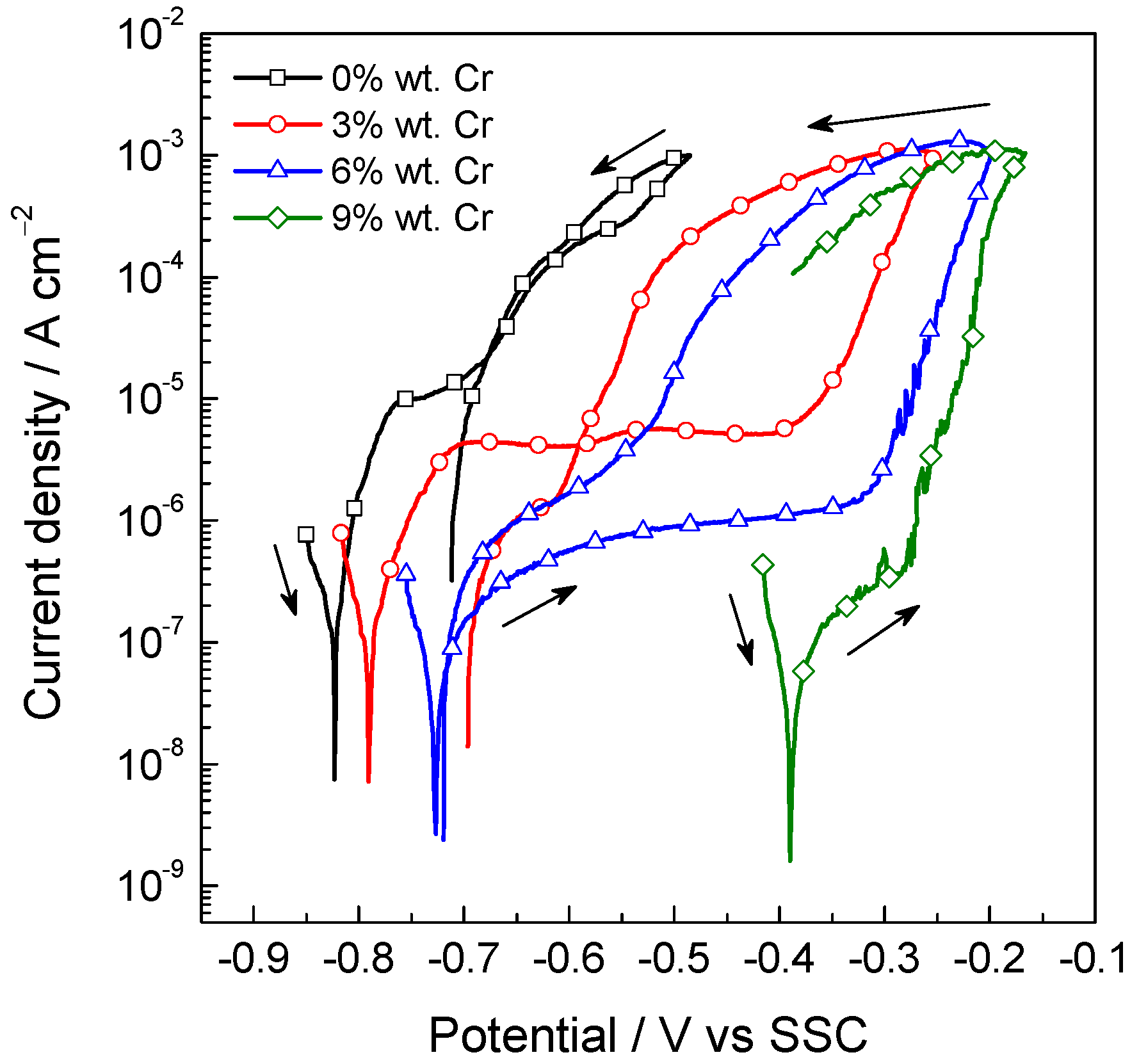

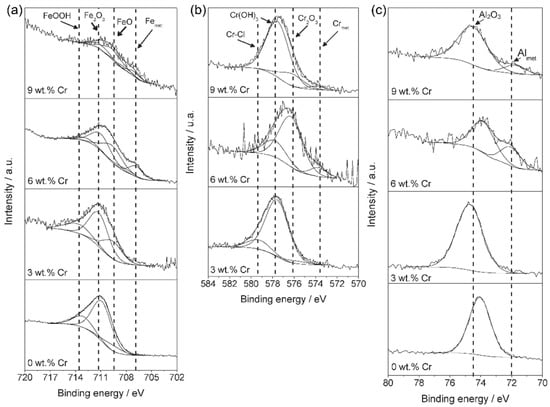

As indicated above, recently the authors have studied the influence of Cr on the passivity of TMP Fe−30Mn−5Al−(0,3,6,9)Cr−0.5C TWIP steel in 0.1M NaCl solution [85]. XPS results for Fe−30Mn−5Al−0.5C TWIP steel can be seen in Figure 21. The outer layer of the passive film experienced a gradual enrichment of Cr. The TWIP steel (Fe−30Mn−5Al−0.5C) passive film was determined to be composed primarily of Fe and Al oxides. Increased concentrations of oxidized Cr species were detected for all four TWIP steels tested, corroborating the electrochemical results. The CPP curves for the four TMP Fe−30Mn−5Al−(0,3,6,9)Cr−0.5C TWIP steels are shown in Figure 22 for the reference TWIP steel specimen (0 wt.% Cr) and the three developed steels (3, 6, and 9 wt.% Cr), immersed in the deaerated 0.1M NaCl solution at room temperature. Both the reference and developed TWIP alloy showed peaks corresponding to the oxidized Mn species [85].

Figure 21.

High-resolution XPS spectra for thermo-mechanical processed (TMP) Fe-30Mn-5Al-(0,3,6,9)Cr-0.5C TWIP steels with 0, 3, 6, and 9 wt.% Cr. (a) Fe 2p3/2, (b) Cr 2p3/2, and (c) Al 2p after exposure to deaerated 0.1 M NaCl solution [85]. (Reproduced with permission from refs. [85]. Copyright (2020), Elsevier).

Figure 22.

Cyclic polarization curves for thermo-mechanical processed (TMP) Fe-30Mn-5Al-(0,3,6,9)Cr-0.5C TWIP steels with 0, 3, 6, and 9 wt.% Cr exposed to 0.1 M NaCl solution [85]. (Reproduced with permission from refs. [85]. Copyright (2020), Elsevier).

High-entropy DP Fe−30Mn−10Co−10Cr alloy (DP-HEA) was studied in 3.5 wt.% NaCl solution by Lu et al. [136], and a decreased Epit and narrower passive region than equiatomic Co−Cr−Fe−Mn−Ni (HEA) was observed. Higher Mn content and lower Cr and Fe content was detected for DP-HEA compared to HEA. Table 4 summarizes corrosion rate (vcorr) (µm year−1) values for high-Mn TWIP steel containing Al and Si elements.

Table 4.

Corrosion rate (vcorr) (µm year−1) values for high-Mn TWIP steels with aluminum and silicon elements.

4. Stress Corrosion Cracking of High-Mn TWIP Steels

High-Mn TWIP steels, while they provide high strength, ductility, and good corrosion properties, suffer from the combined effect of the tensile stress and corrosion, a phenomenon known as stress corrosion cracking (SCC), degrading the steel and leading to a premature failure. The SCC mechanism in high-Mn TWIP steels depends on several factors including: Outer surface microstructure, type of environment and applied potential and, elemental composition of the steel [137,138].

The outermost surface of the TWIP steel plays an important role on the SCC behavior, the higher the grain refinement the higher the grain boundary density, increasing the sites for SCC initiation, as the grain boundaries behave as hydrogen trapping sites [139,140]. The percentage of strain-induced martensite and deformation twins also influence the SCC initiation, due to the higher susceptibility of martensite and deformation twins to suffer SCC than the austenitic microstructure. This difference can be seen in literature, where martensitic stainless steels subjected to SCC in 3.5 wt.% NaCl at room temperature (25 °C) experience intergranular fracture with the formation of secondary cracks [141,142]; while austenitic stainless steels needed higher temperatures to develop SCC (>100 °C) [137,143], lower pH (pH < 3) [144,145], or higher chloride content (24.2 wt.% NaCl) in the case of exposure to alkaline solutions (sat. CaCl2) [143,146].

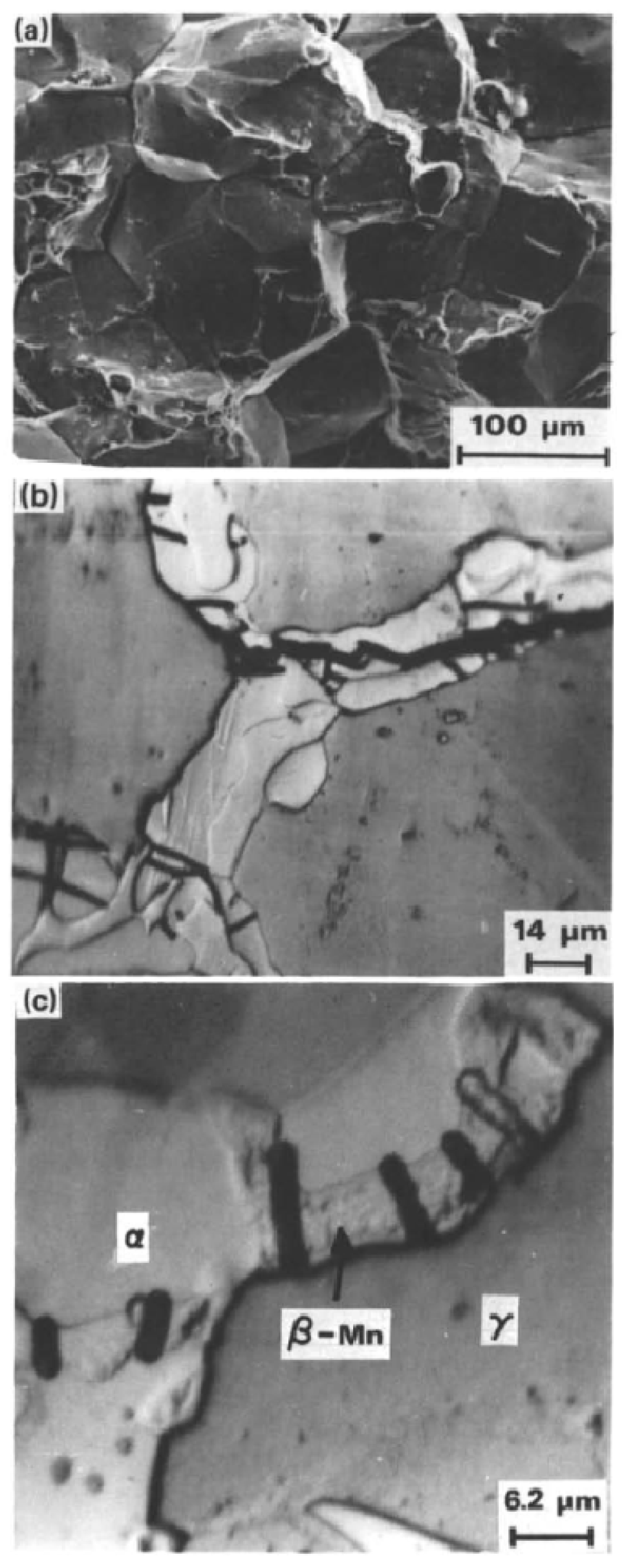

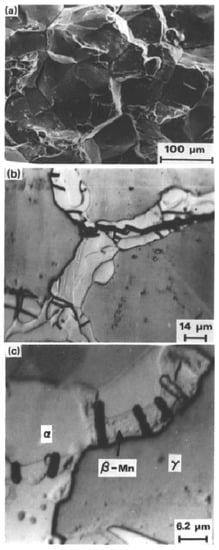

The environment will also influence the SCC susceptibility as higher chloride contents will promote a faster crack initiation, and lower pH will promote faster hydrogen evolution reactions kinetics increasing the HE susceptibility. In addition to the environment, the applied potential may cause a premature hydrogen evolution for cathodic potentials, while more anodic dissolution is seen for anodic potentials [146]. Cathodic potentials have shown to increase the SCC susceptibility, where the dominant mechanism is the HE promoting a brittle fracture by transgranular SCC [137,138,147,148]. SCC mechanism of high-Mn austenitic Fe−29.7Mn−8.7Al−1.04C steel was studied by Tjong in 20 wt.% NaCl solution at 100 °C using slow strain rates [142]. HE occurred at cathodic potentials induced by hydrogen adsorption and diffusion into the alloy during the slow strain rate test. Moreover, aging treatments lead to the decomposition of austenite into ferrite and β-Mn phases at the austenite grain boundaries [147]. The fracture surface of the alloy strained at 2.8 × l0–7 s–1 is shown in Figure 23. The intergranular fracture can be observed. Furthermore, the crack propagation occurred through the β−Mn phase and subsequently along the ferrite−β−Mn and austenite grain boundaries. However, the initiation was observed on the β−Mn phase [147].

Figure 23.

(a) SEM fractography of the Fe−8.7A1−29.7Mn−1.04C alloy (aged at 550 °C for 396 ks) after slow-rate straining in a 20% NaCl solution (100 °C) at the applied cathodic potential of −0.800 V(Ag/AgCl); (b) optical micrograph of the longitudinal cross section of this aged alloy, which failed at −0.800 V(Ag/AgCl); (c) a higher magnification of the SEM micrograph showing that the cracks originated from the β−Mn phase [147]. (Reproduced with permission from refs. [147]. Copyright (1986), Elsevier).

The elemental composition of high-Mn TWIP steels can induce a higher SCC susceptibility or a protection against it depending on the alloy elements and their ratios. Additions of Cr to Fe-Mn-Cr-N steel decreased the SCC susceptibility when subjected to artificial sea water environment [149]. From the study of Chang et al., the addition of Mo did not increase the SCC susceptibility, but it moved the HE potential towards more negative potential. However, the addition of Si did increase the SCC susceptibility even if it lowered the HE potential like in the Mo addition [146]. In addition, on the regard of element addition to high-Mn TWIP steels, Al has been of great interest for the scientific community. Al additions have shown to increase the stacking fault energy (SFE), accordingly reducing the deformation twinning and decreasing the probability of forming ε-martensite [150,151]. Other studies regarded the Al additions to reduce the effect of the HE in TWIP steels, which is very detrimental [152,153]. Increasing the Al content of TWIP steels decrease the HE effect by reducing the dynamic strain aging [154]; similarly, the Al addition to TWIP steels showed the decrease in shear modulus hence, decreasing the hydrogen charging and promoting less HE [151,155].

5. Hydrogen Embrittlement of High-Mn TWIP Steels

The phenomenon known as HE is a destructive process of hydrogen damage to the mechanical properties of a metal, which has been extensively studied in high-Mn TWIP steels [156,157,158,159,160,161,162,163,164,165,166,167,168]. The introduction of hydrogen into the steel depends on variables such as hydrogen concentration, temperature, applied or residual stress, microstructure, and surface finishing [152,169,170,171,172], and may be introduced into the steel from finishing processes including electroplating, forging, welding, corrosion, and cathodic protection system [173,174].

Fe−Mn−C TWIP steels show superior elongation and strength due to deformation twinning [164], therefore they are highly suitable for automobile applications [159,160]. Various Fe−Mn−C austenitic steels, however, have reported HE in recent works [154,156,157,158,159,160,161,162,163,164,165]. Koyama et al. have reported an excellent overview of HE susceptibility of high-Mn steels, however the mechanistic effect of adding Al to TWIP steels has not been sufficiently investigated [167,168,169,170,171,172,173,174,175].

TWIP steel have been reported to be susceptible to hydrogen-delayed fracture (HDF) caused by HE after forming [176,177]. However, some grades of TWIP steels have shown immunity to HDF [137,165]. Additionally, addition of Al decreased the susceptibility to HDF or even imparted immunity [178,179]. The study by Noh et al. investigated the effect of grain size on HE, concluding that grain refinement suppressed HE in the Fe−18Mn−1.5Al−0.6C TWIP steel [180,181].

Negligible mechanical degradation has been observed using tensile tests with specimens pre-charged with hydrogen [148,178,182,183]. Little difference was observed by So et al. between the mechanical properties of Fe−18Mn−1.5Al−0.6C TWIP steel charged with different amounts of hydrogen contents and those without hydrogen charging [137]. The work of Ronevich et al. examined the different hydrogen contents on TWIP steels introduced by cathodic charging. Ultimately, the tensile properties, including yield stress, UTS, strain to failure, and strain hardening behavior, were nearly identical [182].

Hydrogen-induced fracture in TWIP steels was studied by Suh, who determined hydrogen experienced limited penetration, thus little change in mechanical properties was observed [183]. Contrarily, Koyama et al. discovered that mechanical properties of Fe−18Mn−0.6C and Fe−18Mn−1.2C TWIP steel decrease significantly in the presence of hydrogen [171]. Similarly, reductions were observed in elongation from 80% to 42%, and UTS by 20% caused by hydrogen [156,162,165].

The HE susceptibility is generally increased by strength increases in steels, presenting a significant challenge for AHSS [184,185]. Once a critical value is reached, hydrogen can induce a strength and ductility reduction. This critical hydrogen concentration differs depending on the steel grade [186]. HE is commonly studied by slow strain rate tensile testing on hydro-generated specimens [187]. Austenitic alloys are considered to be immune to this type of corrosion damage; however, stress or strain-induced martensite transformation of austenite, which takes place in TRIP-aided austenitic alloys, can be a reason for embrittlement. This may be attributed to the significant differences in solubility and diffusion rate of hydrogen in the body-centered cubic (bcc) and face-centered cubic (fcc) lattices, thus acting as hydrogen sinks, lowering hydrogen mobility, and increasing the concentration. It is difficult to reach hydrogen concentrations high enough to cause embrittlement in austenite due to its slow diffusion rate. It has been observed that the hydrogen concentration in the surface regions of high-Mn steel, however, is much higher than in the center zone [186].

Sheng et al. studied the cutting method on HE of Fe−20Mn−1Al−1.6Cr−0.35C TWIP steel, determining that high HE susceptibility of specimens prepared by the blanking method was attributed to high local dislocation density aided by the hydrogen-enhanced localized plasticity mechanism [188]. The effects of hydrogen on the nanomechanical properties of Fe−22Mn−0.6C TWIP steel was studied by Wang et al., and the change in nanohardness was attributed to hydrogen-enhanced lattice friction and the hydrogen-reduced plastic zone size [189].

Delayed fracture may occur when the newly formed automotive elements are exposed to air. Cup forming tests are used to investigate the technological formability [190,191]. Fe−22Mn−0.6C steel cup was shown to undergo delayed fracture when exposed to air for seven days, despite the specimen showing no cracking during formation [191]. This is due to strain-induced martensite transformation during the cupping test in areas of high stress concentration. With 1.2 wt.% addition of Al, the steel cup forms with increased amounts of mechanical twinning in place of γ → α′ transformation.

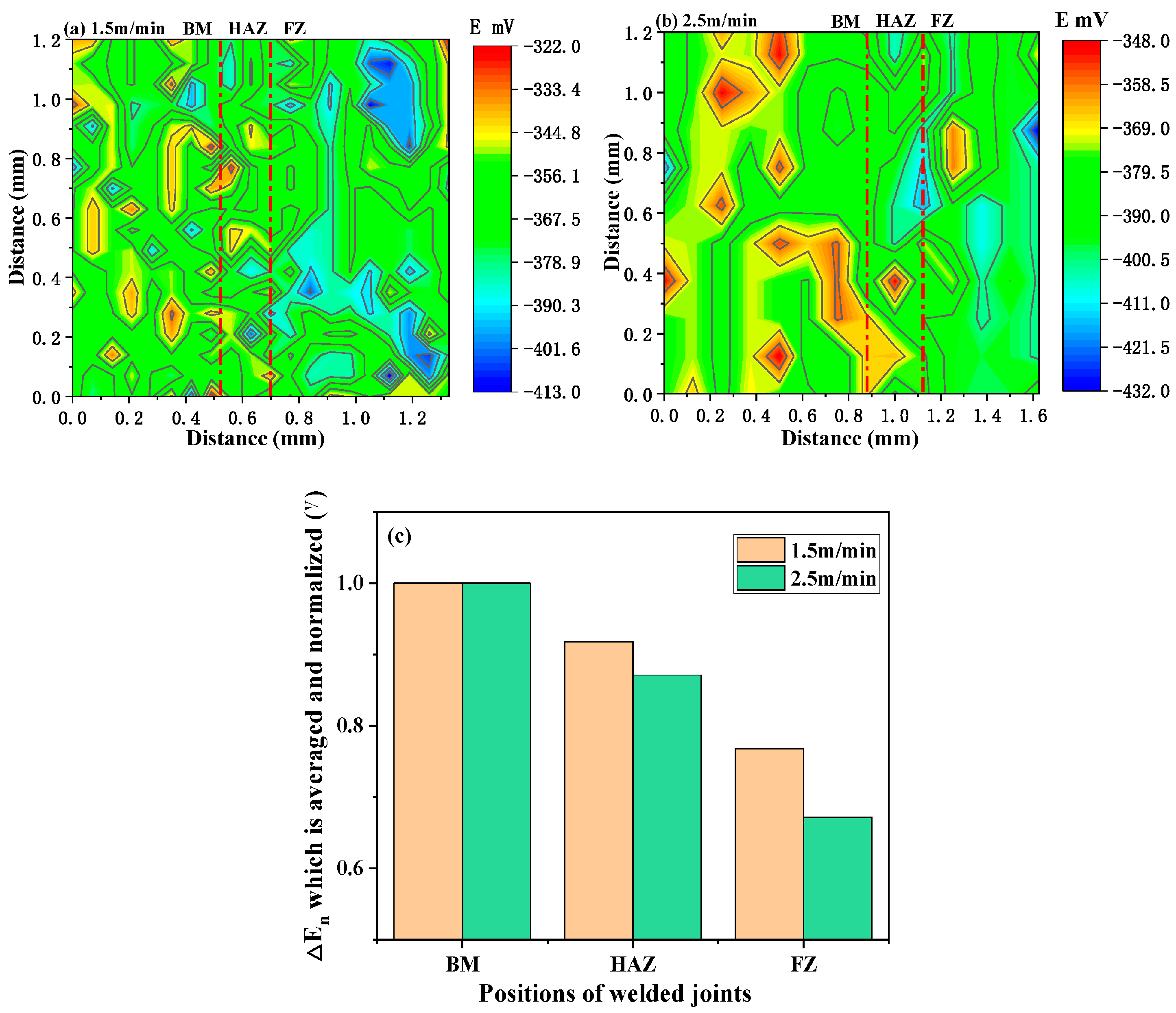

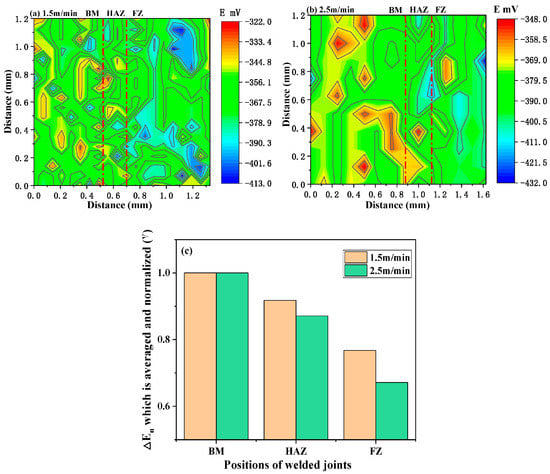

The novel scanning Kelvin probe force microscopy (SKPFM) approach was successfully used for hydrogen detection in deformation twin plates of Fe−Mn−C austenitic TWIP steels [169]. Hydrogen stored in deformation twins persists in the material for a longer period than diffusible hydrogen in interstitial sites, vacancies, and dislocations, but displays significant mobility at room temperature. The difference in potential between the twins and the matrix is highest after an exposure time of 67 h and decreases with further exposure time. The potential difference between the twins and the matric shows the potential increase over the exposure time until 67 h and decrease between 67 h and 300 h, relating to the evolution and disappearance of dark contrast as a function of the exposure time to the dry nitrogen atmosphere [169]. In another study, the SKP was used to characterize the potential distribution on the welded metal surface relating the microstructure with corrosion behavior [192]. A relationship between the different zones of the weld was observed in the potential as can be seen in Figure 24. Furthermore, the fusion zone (FZ) acted as the anode due to the lower surface potential, whereas the heat affected zone (HAZ) and bulk material (BM) constituted the cathode zone [192]. The preferential active area was found to be the FZ, this is in agreement with previous literature [193].

Figure 24.

Volta potential distribution of welded joints under the welding speed of (a) 1.5 m/min and (b) 2.5 m/min; and (c) the average surface potential of welded joint of Fe−18Mn−1.5Al−0.6C TWIP steel obtained via micro-area SKP [192].

The HE of Fe−(15−16)Mn−0.6C, Fe−22M−0.6C [194], Fe−15Mn−3Al−0.7C [195], and Fe−18Mn−0.6C [167] TWIP steels was triggered by the cup-forming tests and the consequent exposure in air. Similarly, tensile tests following electrochemical hydrogen charging showed HE in austenite as well, the mode of fracture was intergranular [196,197]. Tensile tests during charging was shown to produce considerable amounts of diffusible hydrogen, as shown by Koyama, a clear intergranular fracture in the Fe−18Mn−0.6C TWIP steel was observed [167]. Hydrogen was effectively introduced to the specimens during the tensile tests by simple diffusion as well as dislocation motions [158,198], resulting in a clear embrittlement phenomenon. Mobility of slip dislocations [150], the behavior of martensitic transformation [195,196], the deformation twinning [160,161], and the cohesive energy of the grain boundary are affected by hydrogen in austenitic steels [199,200].

6. Elevated Temperature Oxidation of High-Mn TWIP Steels

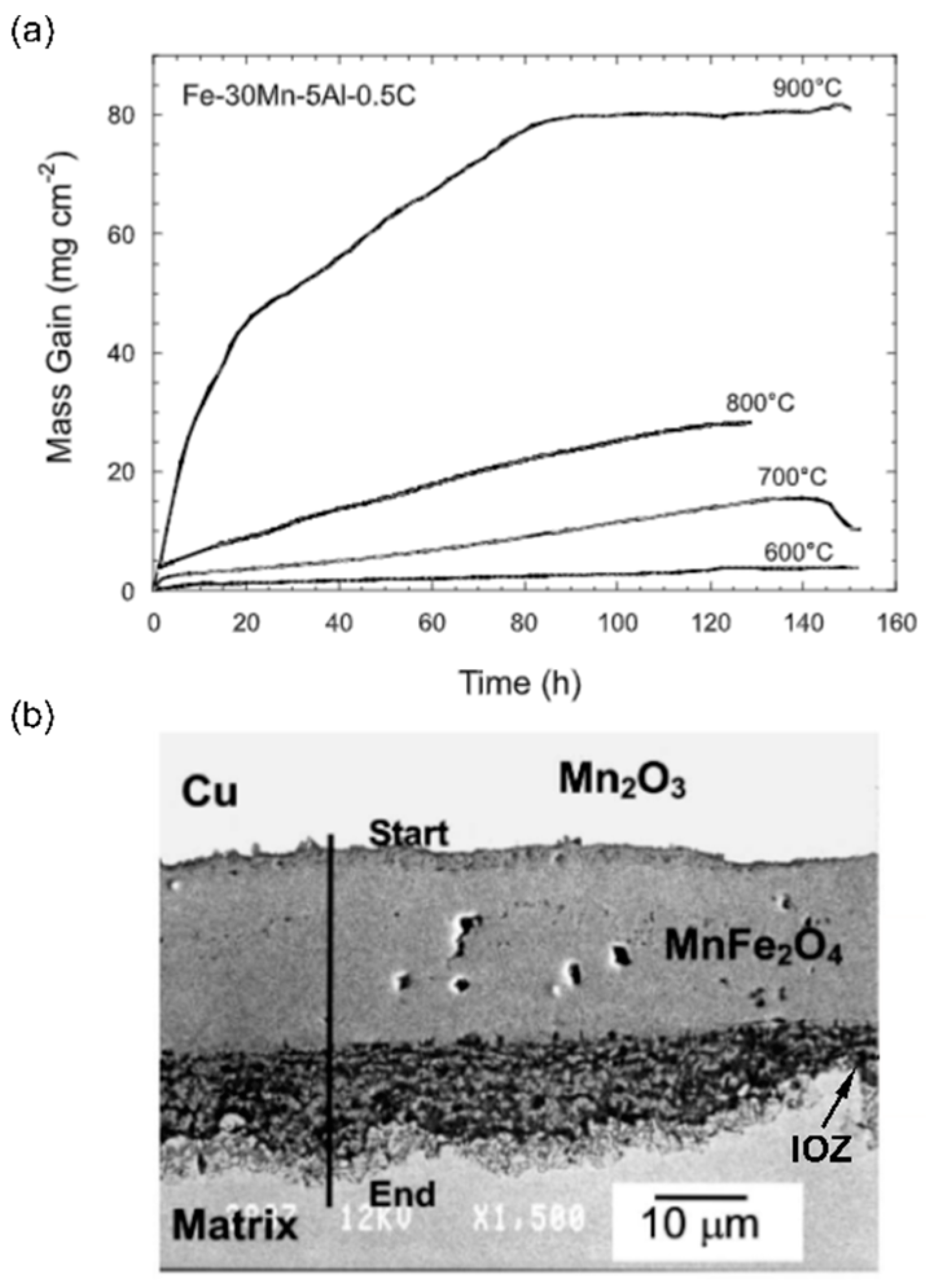

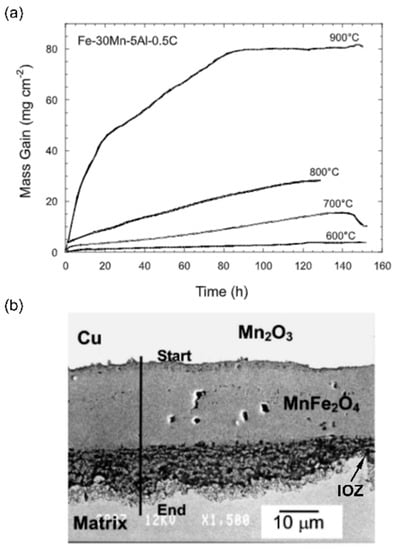

The oxidation behavior of austenitic Fe−30Mn−5Al−0.5C alloy was studied in air in the 600–900 °C temperature range by Pérez et al. [200], the alloy exhibited good oxidation resistance below 700 °C. The low oxidation resistance above 700 °C was attributed to the occurrence of internal oxidation. High-Mn alloys form complex oxide scale comprising stratified, Mn-rich oxides. Decreasing the amount of Mn increases the oxidation resistance, and in addition, increasing the temperature, causes the limit of Al to form a protective scale decrease [200]. Different mechanisms have been proposed to explain these alloys oxidation mechanisms, Sato et al. proposed that oxidation is governed by the supply of Al, Mn, Fe, and O2 to the alloy surface to form protective scales [38].

Analysis of the cross-section of the oxide layer developed after high temperature oxidation of austenitic Fe−Mn−Al−C TWIP steel exhibited four distinct layers in the scale with 32 ± 5 μm thickness. Figure 25 shows the cross section and the depth profile of the oxide scale containing a 2 μm thick outer layer of Mn oxide. The presence of Fe in solid solutions was determined via X-ray diffraction (XRD) analysis in the formation of Mn2O3, a homogeneous (Mn,Fe)-rich oxide layer developed underneath the Mn2O3 [200].

Figure 25.

Gravimetric corrosion study (a) mass gain versus time for Fe−30Mn−5Al alloy oxidized in air between 600 °C and 900 °C, and (b) cross-section and the corresponding depth profile of the oxide scale after 100 h at 600 °C [200]. (Reproduced with permission from refs. [200]. Copyright (2002), Elsevier).

The focus on high-temperature oxidation has been on Fe−Mn−Al−C alloys, due to their potential to replace Fe−Cr−Ni SS alloy [104], cryogenic and nonmagnetic steels [105,201]. The oxidation of the new austenitic Fe−15Mn−1.5Al−0.5C alloy was studied at extremely high temperature up to 1250 °C and was found that the oxide can be divided into two zones, the external and internal oxide zones. The external zone composition was ascertained to consist of Mn2O3, Mn3O4, (Fe,Mn)O and MnAl2O4 phases, while the internal zone was found to consist of MnAl2O4 formed by selective oxidation of Mn and Al. The γ-austenite matrix was transformed to α-ferrite and ε-martensite phases by the selective oxidation of Mn [202]. Fe−(5−10)Mn−(6−10)Al alloy developed continuous protective alumina scales and are totally ferritic [202].

The oxidation of Fe−30Mn−10Al−1.0Si alloy at high O2 pressure of 10.13 Pa immediately leads to formation of oxide nodules, and surface exposure to air at 800−1100 °C showed the formation of a dense and protective Al2O3 scale [203]. The oxidation kinetics of Fe−5.5Al−0.55C alloy after 24 h oxidation at 600, 800, and 1000 °C presented simple, three- and two-stage parabolic laws, respectively. Carbides were observed on the alloy at all temperatures except 600 °C; moreover, a carbide-free zone was observed on oxidized specimens at 800 and 1000 °C, resulting from carbide stability at different oxidation temperatures [204]. Fe−7.5Al−0.65C alloy was oxidized at 600–900 °C for 24 h, and was also classified into two groups, and the change in the oxidation behavior observed between 600 and 700–900 °C was related to the effect of the temperature on the diffusion of Al in the alloy [205]. Internal oxidation occurred beneath the nodules formed on Fe−7.5Al−0.65C alloy after oxidation at 600 °C, but no internal oxidation was observed in the specimens of this alloy after 24 h oxidation at 700−900 °C.

The oxidation behavior of the austenitic Fe−30Mn−5Al−(3−9)Cr alloy was studied in air between 600 and 900 °C. The alloy with the highest Cr content showed the best oxidation resistance. Chromium addition delayed the beginning of internal oxidation for longer times and/or higher temperatures [206]. Lins et al. studied the oxidation at high temperature from 600 to 900 °C of Fe−31.8Mn−6.09Al−1.6Si−0.40C, and concluded that the alloy showed good oxidation resistance at 600 and 700 °C [207].

7. Corrosion Behavior of Welded High-Mn TWIP Steels

The joining of sheet metal components is a critical issue regarding automotive applications and car body parts. Specifically, fusion-welding causes major changes to the material in the fusion zone (FZ) and heat-affected-zone (HAZ). Furthermore, regarding the production of TWIP steel sheets, the effects of grain size ought to be considered. The mechanical properties of welded TWIP steels have been examined in literature [208,209,210,211,212,213]. Despite the significance of the corrosion behavior of TWIP steel welded joints, it has scarcely been studied in literature [83,214].

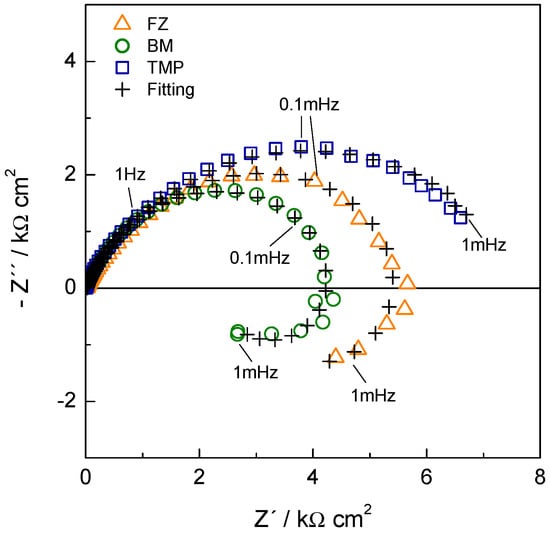

Recently, the authors have studied the corrosion behavior of resistance-spot-welded (RSW) high-Mn austenitic Fe−30Mn−5Al−6Cr−0.5C TWIP steel in a 3.5 wt.% NaCl solution [193]. The Nyquist plots indicate a capacitive behavior for the TMP specimen and the FZ and base-material (BM) specimens at high-frequencies; additionally, an inductive behavior was observed for the BM specimen at low-frequencies, see Figure 26. Micro-segregation can lead to Cr-depleted zones, increasing pitting corrosion susceptibility, which frequently influences the presence of an inductive loop on the Nyquist plot, attributed to the presence of corrosion reaction intermediates or the relaxation of surface adsorbed species such as chlorides [193].

Figure 26.

Nyquist plots for the fusion zone (FZ), base metal (BM), and thermo-mechanically processed (TMP) Fe-30Mn-5Al-6Cr-0.5C TWIP specimen in 3.5 wt.% NaCl solution at room temperature [193]. (Reproduced with permission from refs. [193]. Copyright (2020), Taylor & Francis).

8. Tribocorrosion of High-Mn TWIP Steels

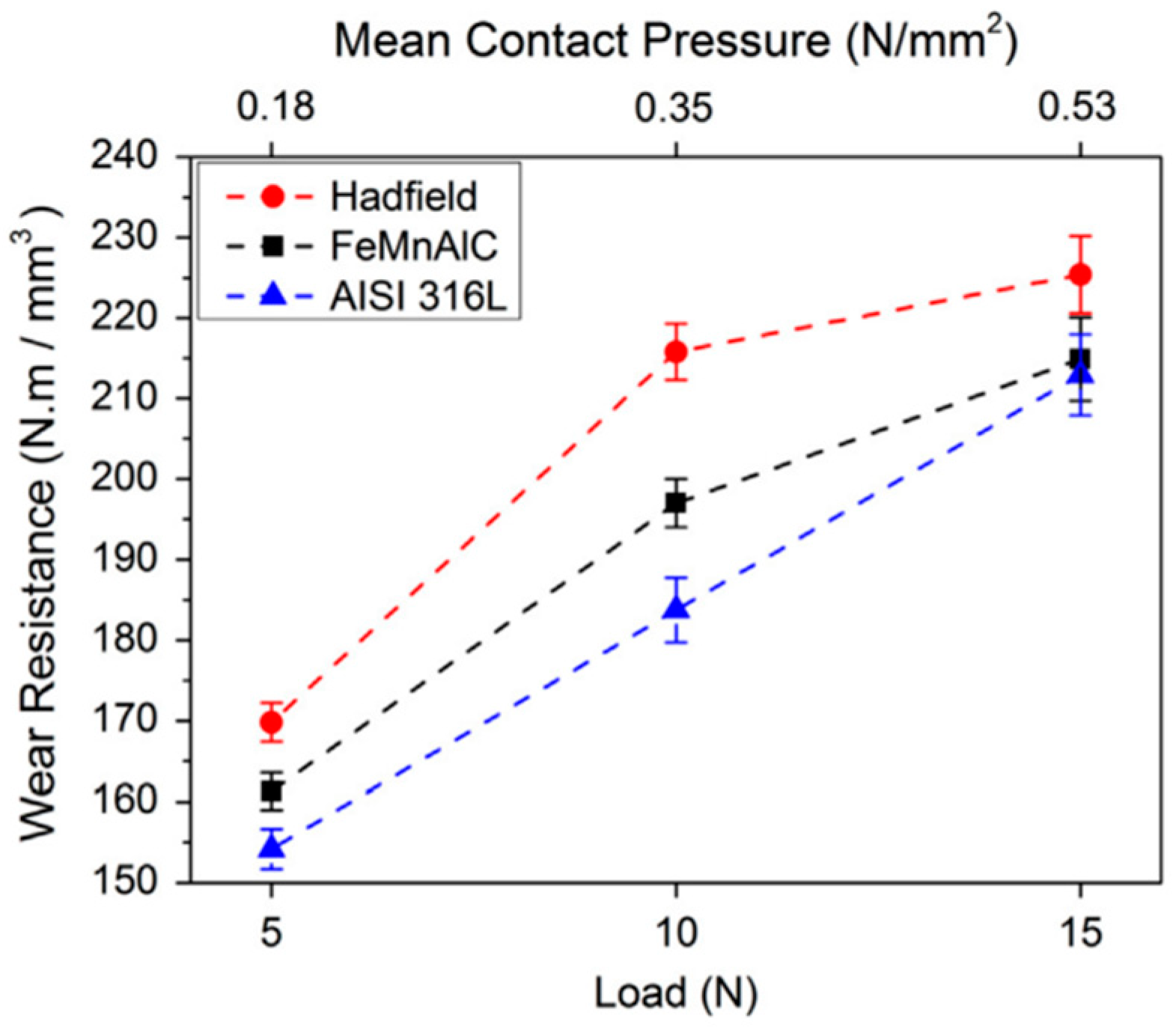

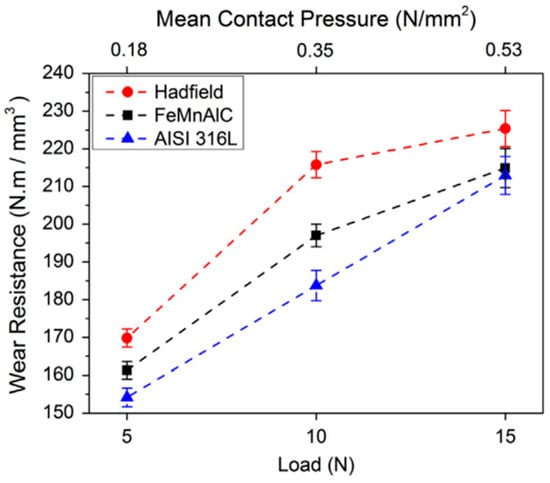

The role of SFE in two-body abrasive wear of austenitic steels was studied by Zambrano et al. applying a pin-abrasion test with 220 grit garnet paper as the counter body and three austenitic steels, Fe−Mn−Al−C (medium SFE), Hadfield steel (lowest SFE), and AISI 316L SS (highest SFE). Ultimately, the study showed Fe−Mn−Al−C steel exhibited higher wear resistance compared to AISI 316L SS, yet lower than Hadfield steel [214]. When tested at the highest load, however, all three steel types showed similar wear resistance. The steel with the lowest SFE had the highest abrasive wear resistance and the steel with the highest SFE had the lowest abrasive wear resistance, as shown in Figure 27 [214]. The main wear mechanisms were described as microcutting and microploughing, and a transition from microploughing to microcutting occurred as the normal load was increased. The SFE could be a more general parameter to characterize the wear resistance in austenitic steels [215,216,217].

Figure 27.

The effect of normal load on the wear resistance of the Fe-Mn-Al-C steel, Hadfield steel, and AISI 316L stainless steel (the bars correspond to the interval of confidence at 95%) [214]. (Reproduced with permission from refs. [214]. Copyright (2016), Elsevier).

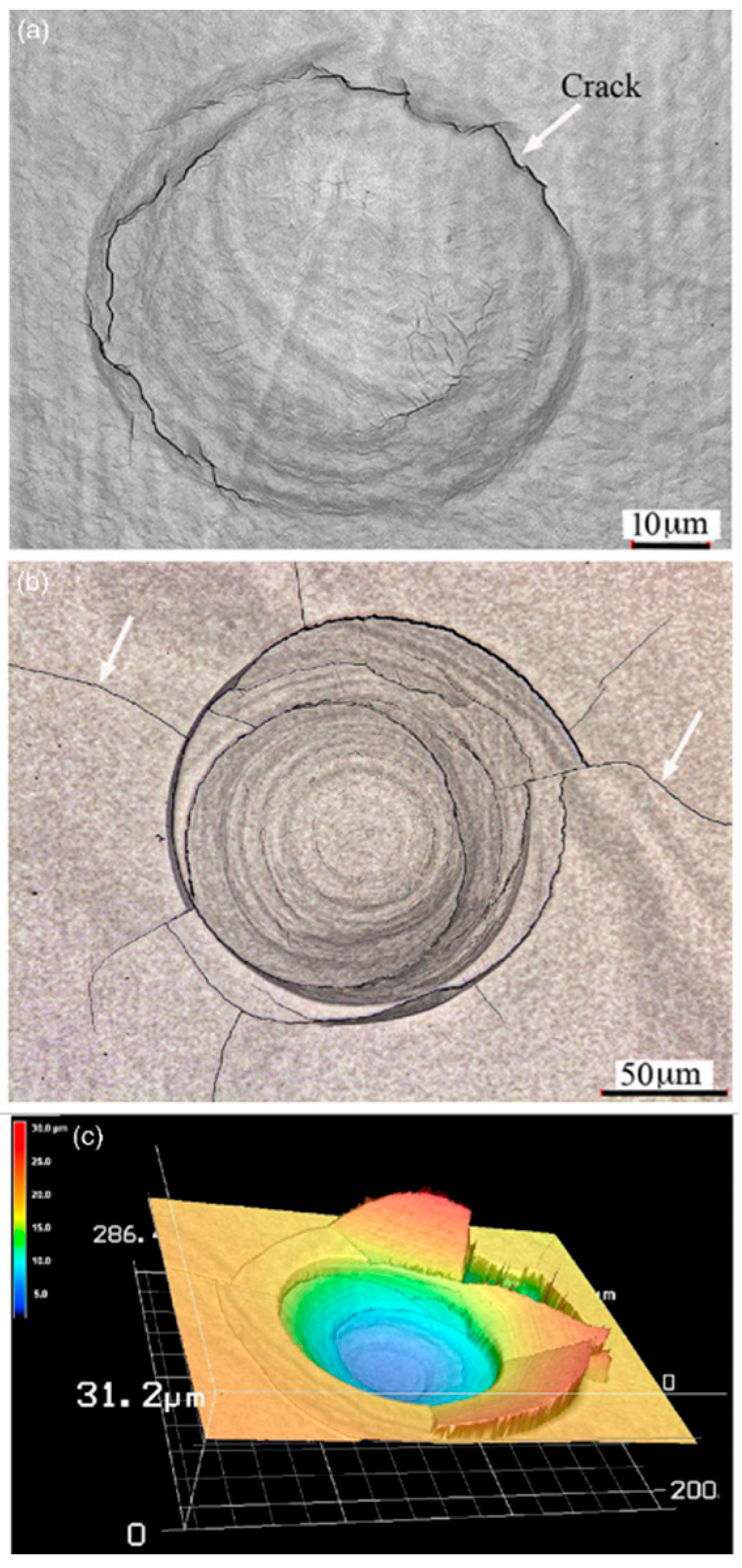

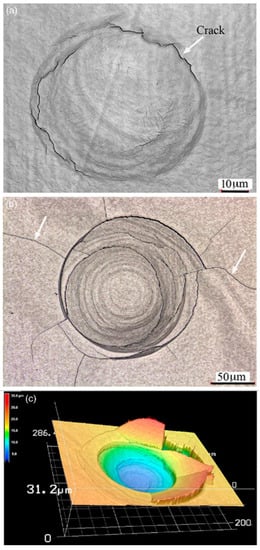

The study by Hamada et al. discovered that Ni–P coatings could substantially improve the corrosion performance and surface hardness of Fe–25Mn–3Al TWIP steel [218]. Improvements in the corrosion resistance in sulfuric acid solution for the Ni–P coated steel was observed compared to uncoated TWIP steel. The lowest icorr was found for the as-plated Ni−P TWIP steel samples (20 μA cm−2) compared to Ni–P coated TWIP samples annealed at 350 °C and 700 °C, with icorr values of 81 μA cm−2 and 33 μA cm−2, respectively. Additionally, the Berkovich indentation tests showed a plastic material devoid of cracks and with a hardness and elastic modulus significantly higher than that of substrate TWIP steel, see Figure 28 [218]. The formation of deleterious Ni3P particles was found to decrease performance and enhance diffusion of Mn towards the surface, thus forming Mn oxides and increasing the corrosion rate of the substrate.

Figure 28.

Laser-optical micrograph of the PT coating at 350 °C showing crack formation under a ball indentation after different applied loads: (a) 6 N, (b) 20 N; and (c) 3-dimensional profile after loading 20 N [218]. (Reproduced with permission from refs. [218]. Copyright (2015), Elsevier).

9. Corrosion of High-Mn TWIP Steels in Harsh Environments

Fe−Mn−Al−C steel was first developed in late 1950s for the use of cryogenic or highly corrosive environments by replacing the high Fe−Ni−Cr SS cryogenic [219], and recently reappraised as a promising candidate for austenitic SS by adding some content of Cr [102].

The first research reported on Fe−Mn−Al−C alloys for cryogenic applications that were intended to substitute Fe−Cr−Ni SSs was carried out in the 80′s [66]. More recent studies have reported on the development of new TWIP steel alloys for cryogenic devices [219]. Manganese is added to replace Ni and obtain an austenitic microstructure, and Al has a similar role as Cr. Improvement of corrosion resistance by Al results from the formation of thin, stable oxide layers. It was found that Fe−Mn−Al−C alloys show inferior corrosion resistance compared to Fe−Cr−Ni SSs and can be used as a substitute in specific applications [220].

10. Corrosion of Additively Manufactured High-Mn TWIP Steels