Experimental Review on Friction Stir Welding of Aluminium Alloys with Nanoparticles

Abstract

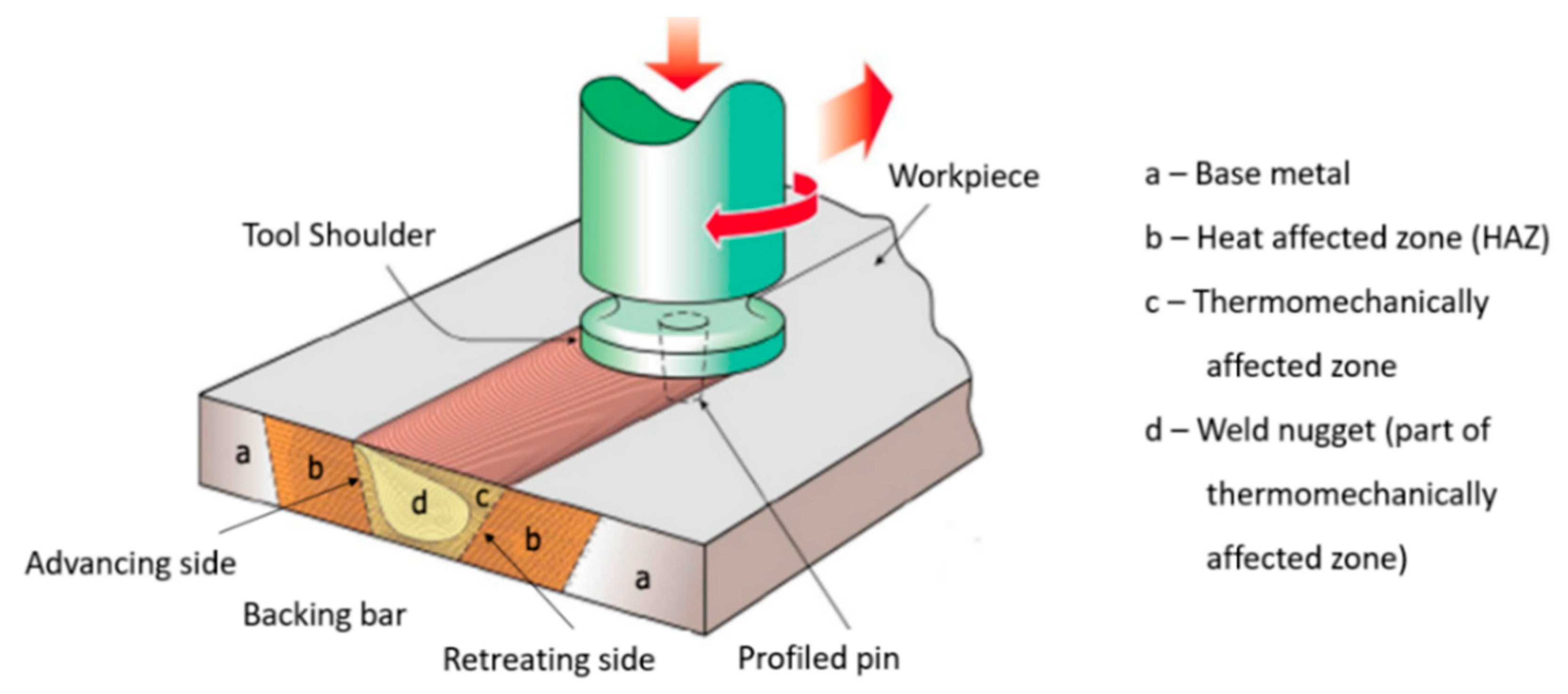

:1. Introduction

2. Friction Stir Welding of Al Alloys Using Nanoparticles

2.1. Friction Stir Welding of 5x Series Al Alloy

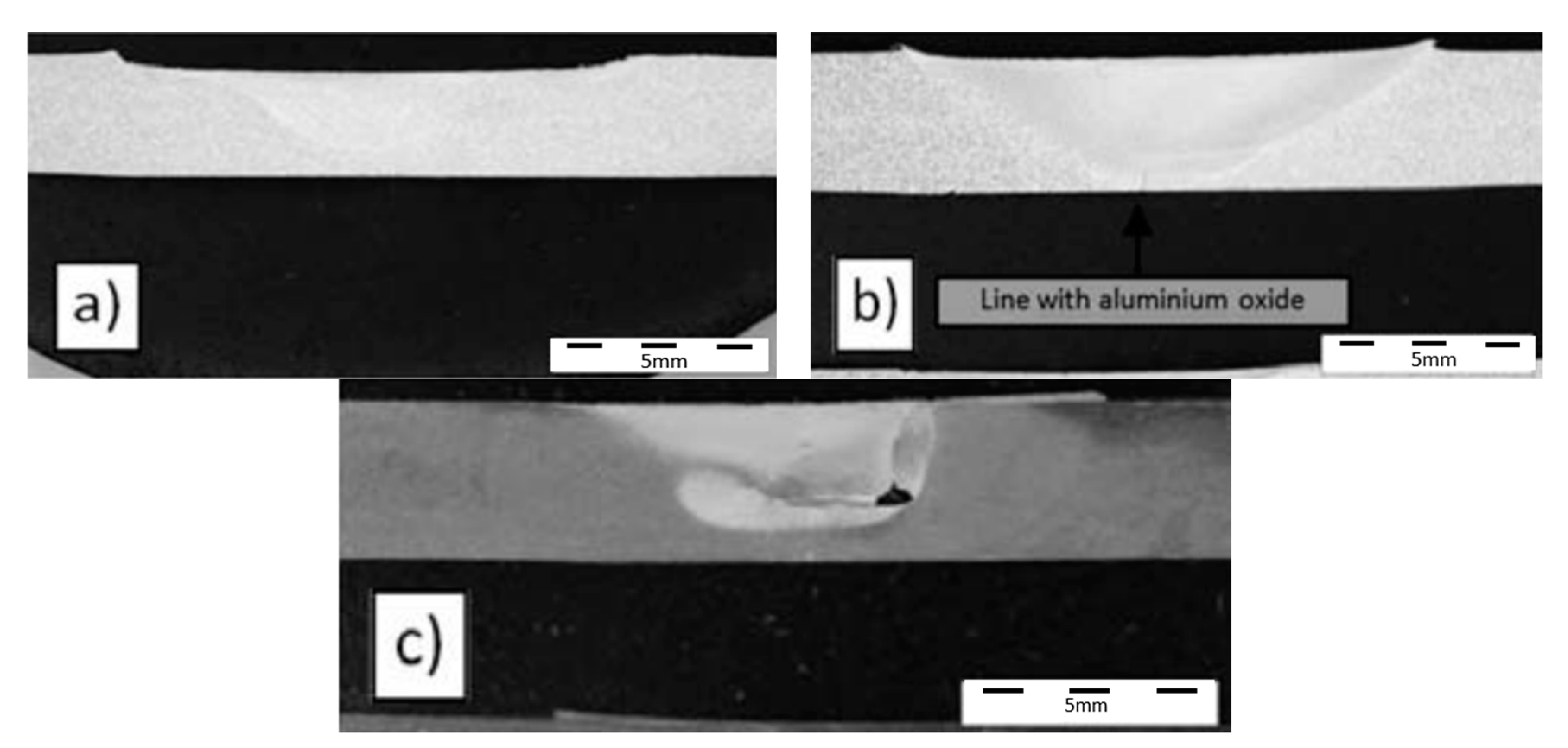

2.1.1. Effect of Welding Parameters on Joint Integrity of FSW Welds with Carbide and Oxide Nanoparticle Reinforcement

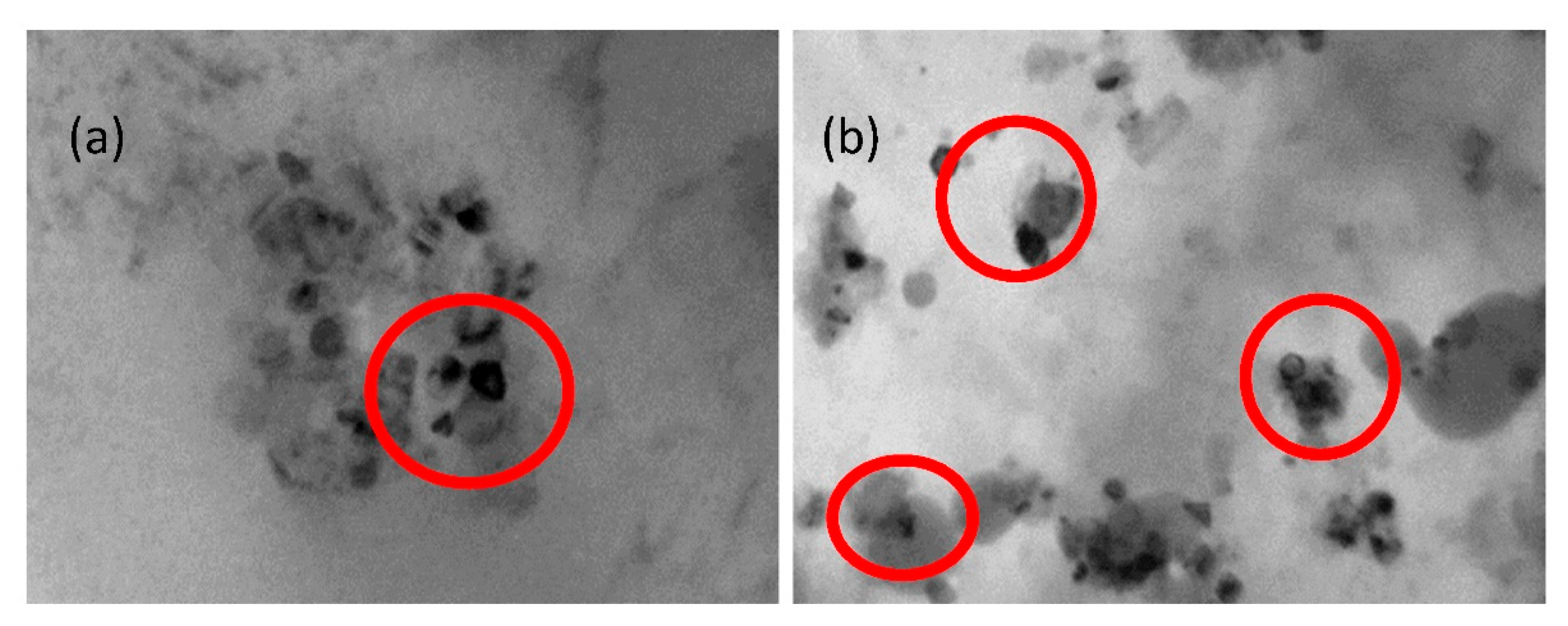

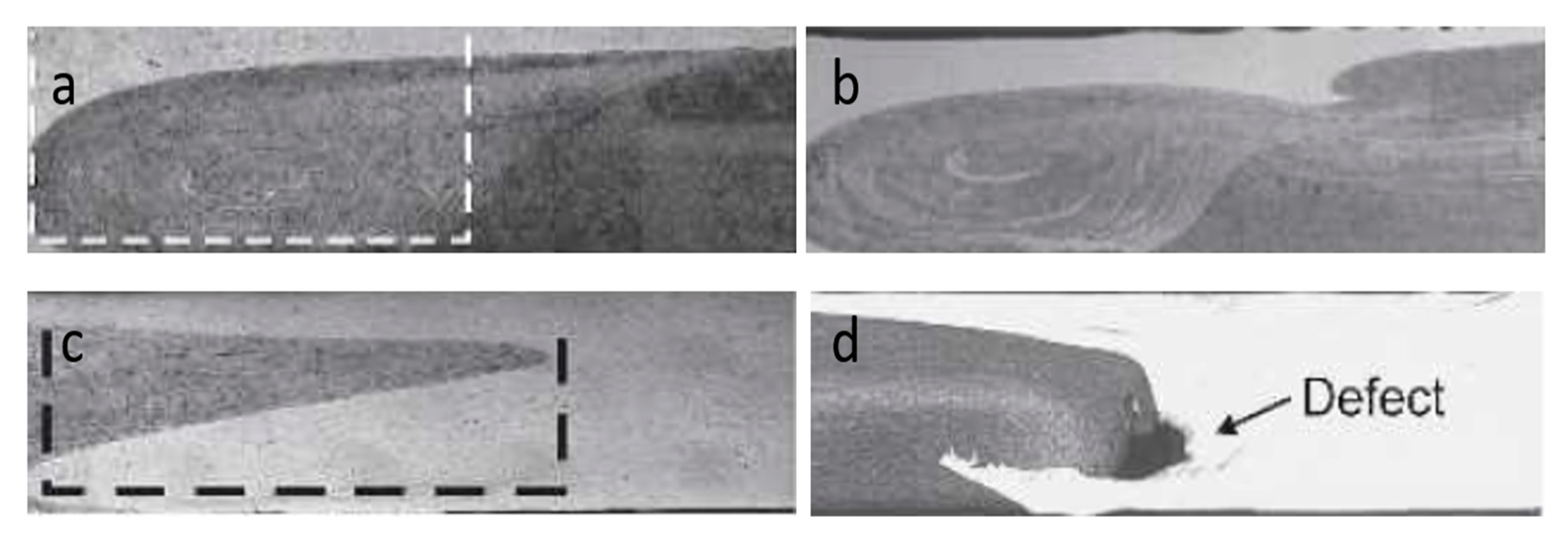

2.1.2. Effect of Carbide and Oxide Nanoparticles on Microstructural Formation

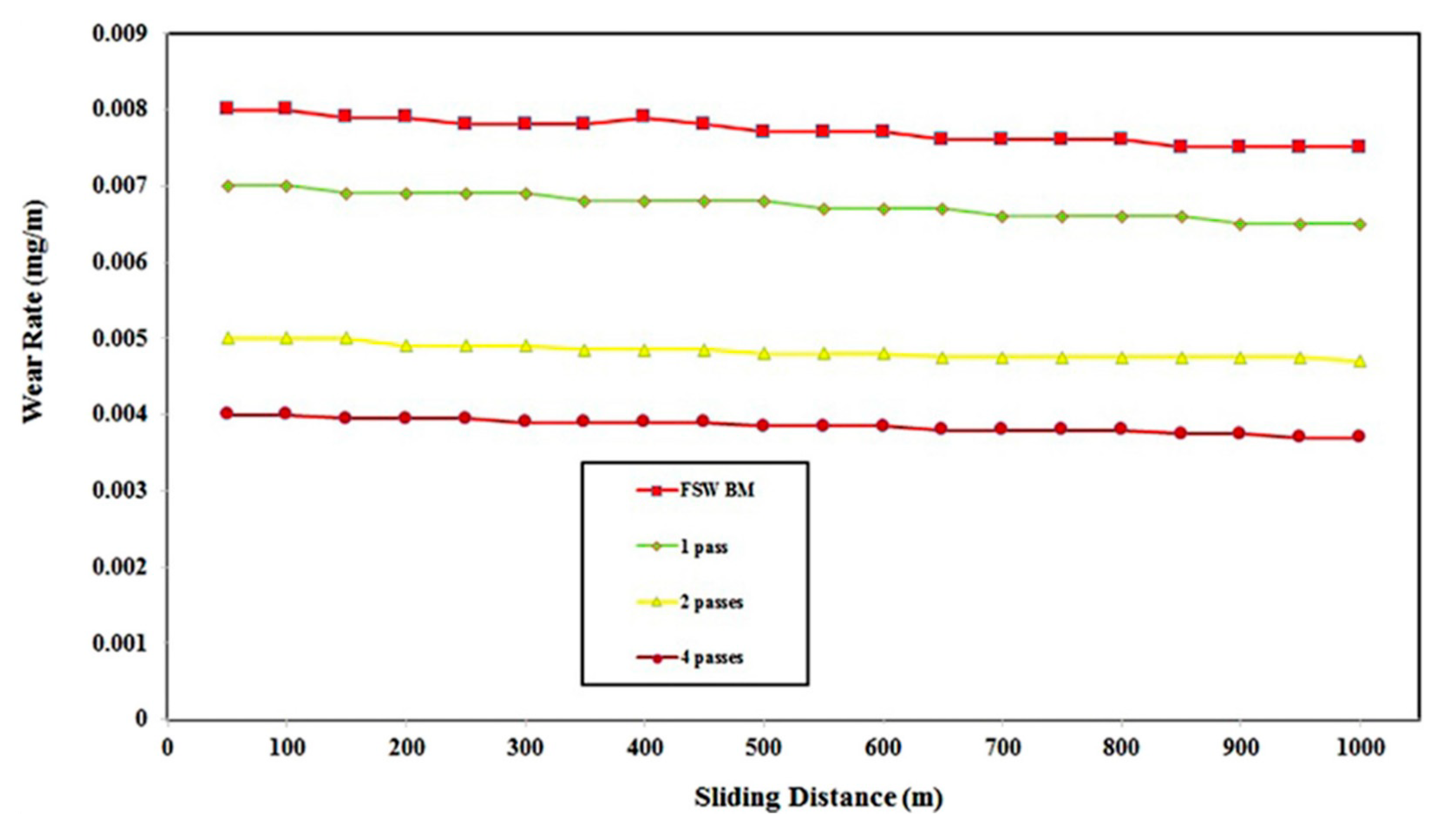

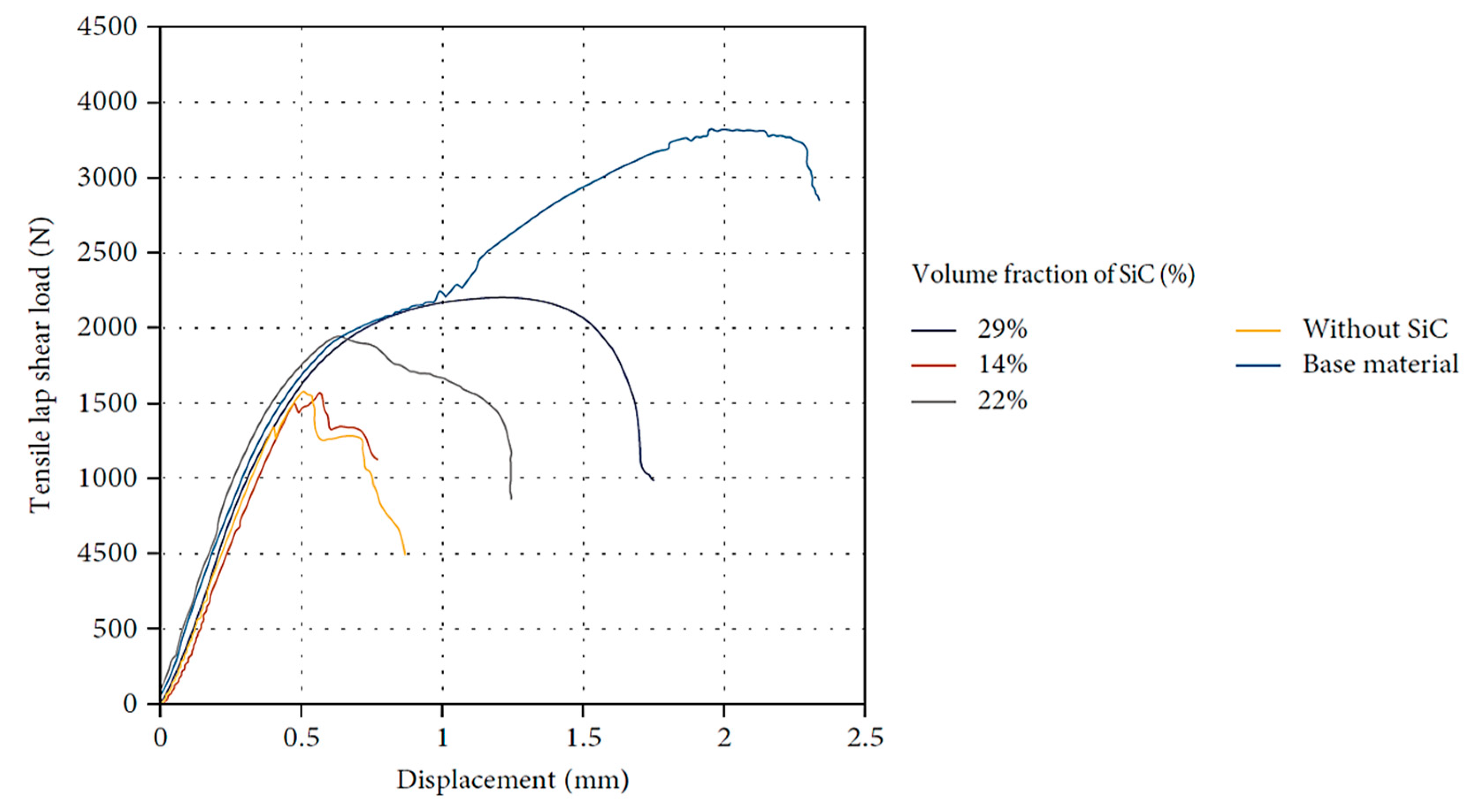

2.1.3. Effect of Carbide and Oxide Nanoparticles on Mechanical Properties

2.2. Friction Stir Welding of 6x Series Al Alloy

2.2.1. Effect of Welding Parameters on Joint Integrity of FSW Welds with Carbide Nanoparticle Reinforcement

2.2.2. Effect of Carbide Nanoparticles on Microstructural Formation

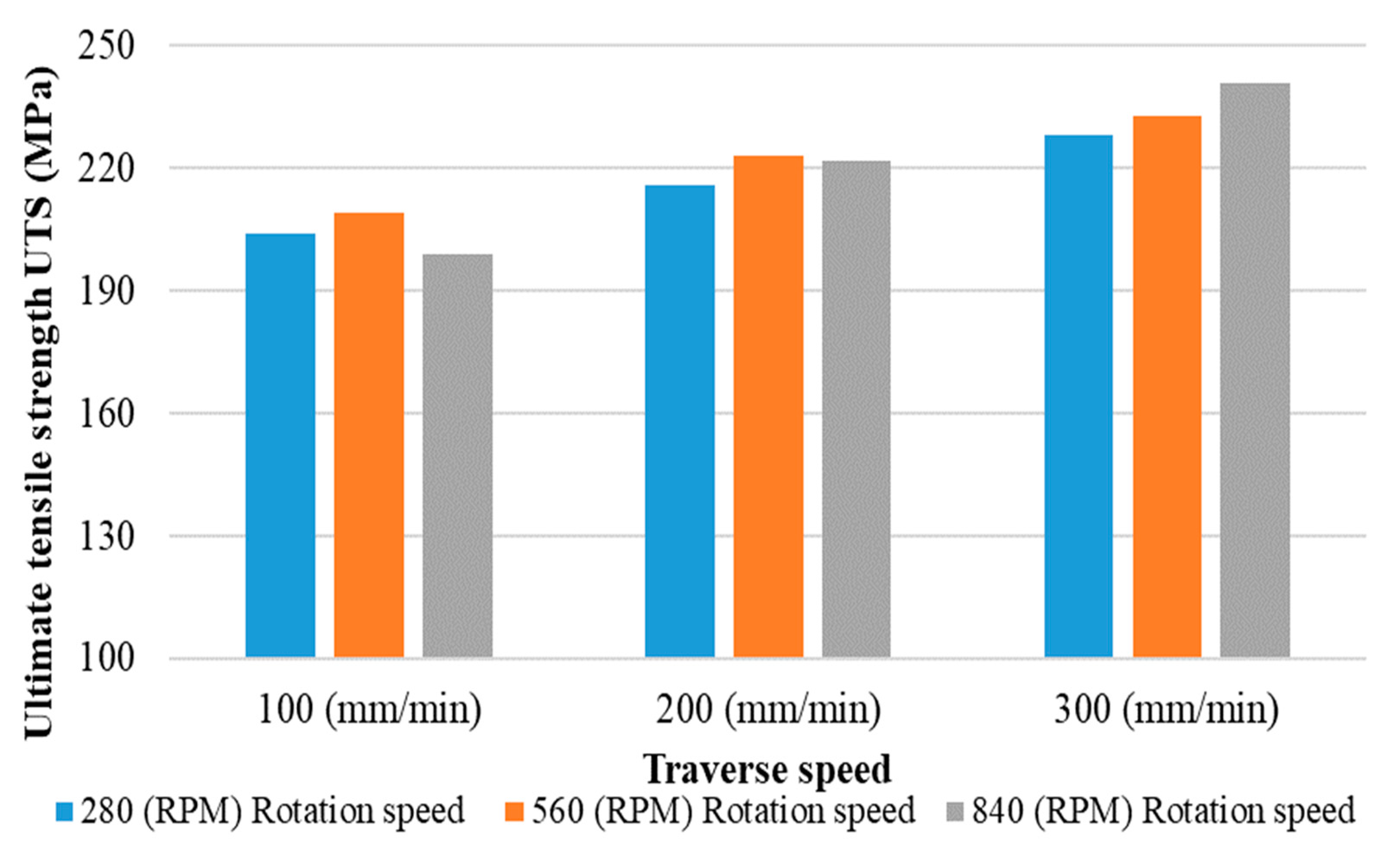

2.2.3. Effect of Carbide Nanoparticles on Mechanical Properties

3. Friction Stir Welding of Dissimilar 5x Series and 6x Series Al Alloys Using Nanoparticles

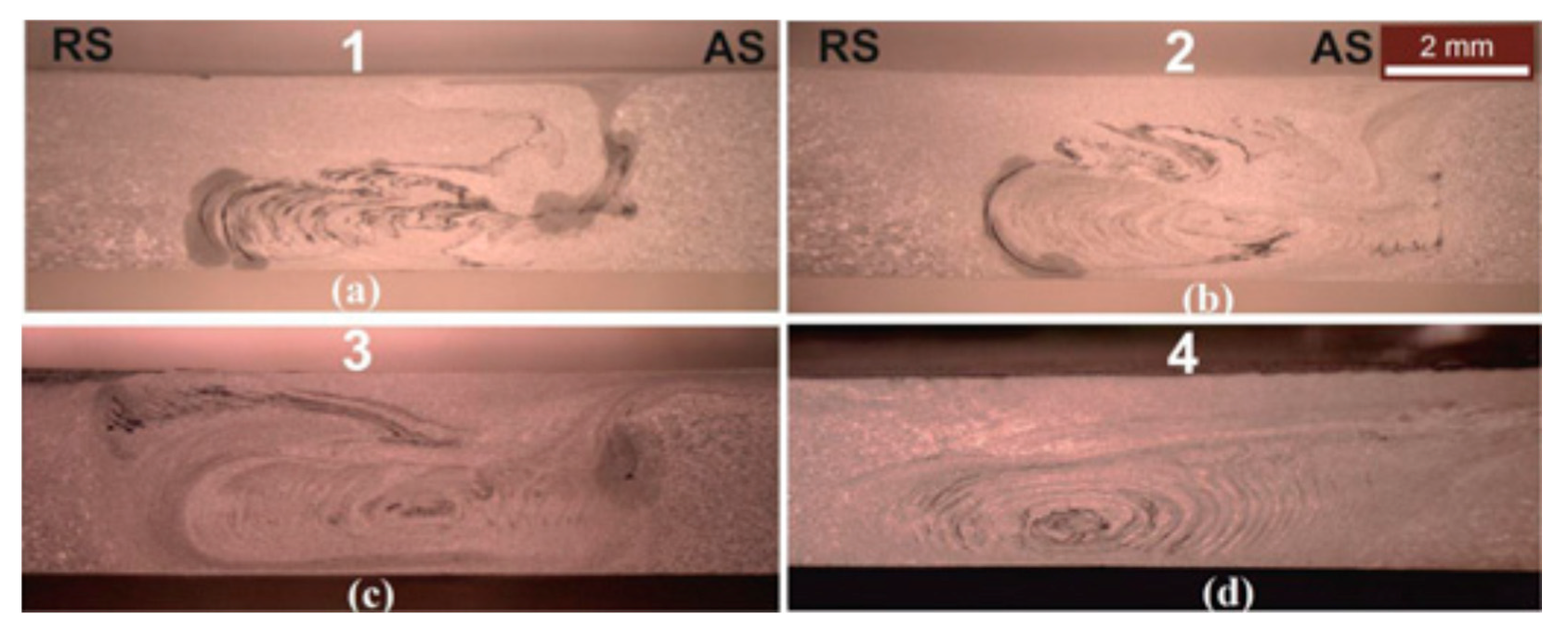

3.1. Effect of Welding Parameters on Joint Integrity of FSW Welds with Carbide Nanoparticle Reinforcement

3.2. Effect of Carbide Nanoparticles on Microstructural Formation

3.3. Effect of Carbide Nanoparticles on Mechanical Properties

4. Critical Analysis and Trends

- Even more research is required in FSW welding parameters, for corelating the type of nanoparticle reinforcement usage in the weld joint as well as base metal.

- As carbide and oxide nanoparticles possess high hardness properties, the selection of tool material is of paramount importance as it results in tool wear.

- Further research is needed on the reinforcement particles causing agglomeration in microstructural formation, which could be attained through FSW welding parameters (i.e., number of passes, high rotation and traverse speed).

- Studies are yet required on FSW of wide range of steel using nanoparticle reinforcement.

5. Discussion and Conclusions

- Homogeneous distribution of carbide nanoparticles (i.e., SiC and TiC) in joints requires slow traverse speed and high rotation speed; however, in the case of oxide nanoparticles (TiO2), an increase in number of passes is required.

- The same intermetallic compounds were found in joints with and without nanoparticle reinforcement; however, the grain size was reduced compared to the joints without reinforcement particles.

- Hardness and ultimate tensile strengths have been improved compared to the joint without reinforcement; however, reductions in elongation and yield strengths have been noted. This could be due to the type of nanoparticle added.

- Carbide nanoparticles (i.e., SiC and TiC) had variations in friction stir welding parameters for uniform distribution, because of the physical properties of particles.

- Dilution of base metal intermetallic particles and new precipitation formation as well as same intermetallic particles were observed in joints with and without reinforcement. Amount of nanoparticle reinforcement has an influence on grain size formations.

- Improved mechanical properties of joints were achieved by increasing content of nanoparticle addition and the softening effect along the HAZ was reduced with nanoparticle reinforcement.

- Rotational speed of the tool, number of passes and directional change greatly influenced dispersion of nanoparticles.

- Grain formation was equiaxed and the joint reinforced with TiC had small grain size compared to that with SiC. Dilution of strengthening precipitate occurred in AA6082.

- SiC nanoparticles improved joints’ hardness, ultimate tensile strengths and elongation compared to joints with TiC and without reinforcement. Moreover, SiC reduced the softening effect on the HAZ region of AA6082. However, the joints with TiC had improved yield strengths.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Al | Aluminum |

| Ce | Cerium |

| Cl | Chloride |

| Cr | Chromium |

| Cu | Copper |

| Fe | Iron |

| FSW | Friction Stir Welding |

| GMAW | Gas Metal Arc Welding |

| GTAW | Gas Tungsten Arc Welding |

| GPa | Giga Pascal |

| HAZ | Heat-Affected Zone |

| Mo | Molybdenum |

| Mg | Magnesium |

| MIG | Metal Inert Gas Welding |

| Mn | Manganese |

| MPa | Mega Pascal |

| MWCNT | Multiwall Carbon Nano Tube |

| Na | Sodium |

| RPM | Rotation per minute |

| SiC | Silicon Carbide |

| SZ | Stir Zone |

| TMAZ | Thermo-mechanically Affected Zone |

| TiC | Titanium Carbide |

| TIG | Tungsten Inert Gas Welding |

| TiO | Titanium Oxide |

| UTS | Ultimate Tensile Strength |

| WN | Weld nugget |

| Zn | Zinc |

| Zr | Zirconium |

References

- DuPont, J.N. Welding of Nickel-based alloys for energy applications. Weld. J. 2014, 93, 31–45. [Google Scholar]

- Purslow, M.A. Reducing the ecological impact of arc welding: Practical strategies are offered for reducing energy consumption when using various arc welding processes. Weld. J. 2012, 91, 24–27. [Google Scholar]

- Praveen, P.; Yarlagadda, P.K.D.V.; Kang, M.J. Advancements in pulse gas metal arc welding. J. Mater. Process. Technol. 2005, 164–165, 1113–1119. [Google Scholar] [CrossRef]

- Soysal, T.; Kou, S. Effect of filler metals on solidification cracking susceptibility of Al alloys 2024 and 6061. J. Mater. Process. Technol. 2019, 66, 421–428. [Google Scholar] [CrossRef]

- Lezzi, F.; Costa, L. The development of conventional welding processes in naval construction. Weld. Int. 2013, 27, 786–797. [Google Scholar] [CrossRef]

- Liu, Z.; Ji, S.; Meng, X. Joining of magnesium and aluminum alloys via ultrasonic assisted friction stir welding at low temperature. Int. J. Adv. Manuf. Technol. 2018, 97, 4127–4136. [Google Scholar] [CrossRef]

- Da Silva, C.L.M.; Scotti, A. The influence of double pulse on porosity formation in aluminum GMAW. J. Mater. Process. Technol. 2006, 171, 366–372. [Google Scholar] [CrossRef]

- Jannet, S.; Mathews, K.; Raja, R. Comparative investigation of friction stir welding and fusion welding of 6061 T6-5083 O aluminum alloy based on mechanical properties and microstructure. Bull. Pol. Acad. Sci. Tech. Sci. 2014, 62, 791–795. [Google Scholar] [CrossRef] [Green Version]

- Khaled, T. An Outsider Looks at Friction Stir Welding; Federal Aviation Administration: Washington, DC, USA, 2005; pp. 1–71. Available online: https://www.faa.gov/aircraft/air_cert/design_approvals/csta/publications/media/friction_stir_welding.pdf (accessed on 12 March 2019).

- Mahoney, M.W.; Rhodes, C.G.; Flintoff, J.G.; Bingel, W.H.; Spurling, R.A. Properties of friction-stir-welded 7075 T651 aluminum. Metall. Mater. Trans. A 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Storjohann, D.; Barabash, O.M.; David, S.A.; Sklad, P.S.; Bloom, E.E.; Babu, S.S. Fusion and friction stir welding of aluminum-metal-matrix composites. Metall. Mater. Trans. A 2005, 36, 3237–3247. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W.; Lienert, T.J.; Jata, K.V. Friction Stir Welding and Processing IV: Preface. In Proceedings of the TMS Annual Meet, Orlando, FL, USA, 25 February 2007. [Google Scholar]

- Shi, L.; Wu, C.S.H.; Liu, J. The effect of the welding parameters and tool size on the thermal process and tool torque in reverse dual-rotation friction stir welding. Int. J. Mach. Tools Manuf. 2015, 91, 1–11. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Aluminium Alloys in the Automotive Industry: A Handy Guide. Available online: https://aluminiuminsider.com/aluminium-alloys-automotive-industry-handy-guide/ (accessed on 4 May 2019).

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Aluminium in Shipbuilding. Available online: http://www.aluminiumindustry.org/en/aluminium-shipbuilding.html (accessed on 11 February 2009).

- Mathers, G. The Welding of Aluminium and Its Alloys, 1st ed.; Woodhead Publishing: New York, NY, USA, 2002. [Google Scholar]

- Tanaka, H.; Minoda, T. Mechanical properties of 7475 aluminum alloy sheets with fine subgrain structure by warm rolling. Trans. Nonferrous Met. Soc. China 2014, 24, 2187–2195. [Google Scholar] [CrossRef]

- Calogero, V.; Costanza, G.; Missori, S.; Sili, A.; Tata, M.E. A Weldability Study of Al–Cu–Li 2198 Alloy. Metallurgist 2014, 57, 1134–1141. [Google Scholar] [CrossRef]

- Koilraj, M.; Sundareswaran, V.; Vijayan, S.; Koteswara Rao, S.R. Friction stir welding of dissimilar aluminum alloys AA2219 to AA5083—Optimization of process parameters using Taguchi technique. Mater. Des. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Dolatkhah, A.; Golbabaei, P.; Besharati Givi, M.K.; Molaiekiya, F. Investigating effects of process parameters on microstructural and mechanical properties of Al5052/SiC metal matrix composite fabricated via friction stir processing. Mater. Des. 2012, 37, 458–464. [Google Scholar] [CrossRef]

- Bahrami, M.; Dehghani, K.; Givi, M.K.B. A novel approach to develop aluminum matrix nano-composite employing friction stir welding technique. Mater. Des. 2014, 53, 217–225. [Google Scholar] [CrossRef]

- Kianezhad, M.; Raouf, A.H. Effect of nano-Al2O3 particles and friction stir processing on 5083 TIG welding properties. J. Mater. Process. Technol. 2019, 263, 356–365. [Google Scholar] [CrossRef]

- Kumar, N.; Yuan, W.; Mishra, R.S. Chapter 1—Introduction. In Friction Stir Welding of Dissimilar Alloys and Materials; Butterworth-Heinemann: Oxford, UK, 2015; pp. 1–13. [Google Scholar] [CrossRef]

- Dimopoulos, A.; Vairis, A.; Vidakis, N.; Petousis, M. On the Friction Stir Welding of Al 7075 Thin Sheets. Metals 2021, 11, 57. [Google Scholar] [CrossRef]

- Givi, M.K.B.; Asadi, P. Advances in Friction-Stir Welding; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Heidarzadeh, A.; Khodaverdizadeh, H.; Mahmoudi, A.; Nazari, E. Tensile behavior of friction stir welded AA 6061-T4 aluminum alloy joints. Mater. Eng. 2012, 37, 166–173. [Google Scholar] [CrossRef]

- Ceschini, L.; Boromei, I.; Minak, G.; Morri, A.; Tarterini, F. Effect of friction stir welding on microstructure, tensile and fatigue properties of the AA7005/10vol.%Al2O3p composite. Compos. Sci. Technol. 2007, 67, 605–615. [Google Scholar] [CrossRef]

- Saeidi, M.; Barmouz, M.; Givi, M.K.B. Investigation on AA5083/AA7075+Al2O3 joint fabricated by friction stir welding: Characterizing microstructure, corrosion and toughness behavior. Mater. Res. 2015, 18, 1156–1162. [Google Scholar] [CrossRef] [Green Version]

- Vimalraj, C.; Kah, P.; Mvola, B.; Martikainen, J. Effect of nanomaterial addition using gmaw and gtaw processes. Rev. Adv. Mater. Sci. 2016, 44, 370–382. [Google Scholar]

- Pantelis, D.I.; Karakizis, P.N.; Daniolos, N.M.; Charitidis, C.A.; Koumoulos, E.P.; Dragatogiannis, D.A. Microstructural study and mechanical properties of dissimilar friction stir welded AA5083-H111 and AA6082-T6 reinforced with SiC nanoparticles. Mater. Manuf. Process. 2016, 31, 264–274. [Google Scholar] [CrossRef]

- Dragatogiannis, D.A.; Koumoulos, E.P.; Kartsonakis, I.A.; Pantelis, D.I.; Karakizis, P.N.; Charitidis, C.A. Dissimilar Friction Stir Welding Between 5083 and 6082 Al Alloys Reinforced With TiC Nanoparticles. Mater. Manuf. Process. 2016, 31, 2101–2114. [Google Scholar] [CrossRef]

- Scudino, S.; Liu, G.; Prashanth, K.G.; Bartusch, B.; Surreddi, K.B.; Murty, B.S.; Eckert, J. Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Mater. 2009, 57, 2029–2039. [Google Scholar] [CrossRef]

- El Rayes, M.M.; Soliman, M.S.; Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Abdel-mawla, M. Effect of Feed Rate in FSW on the Mechanical and Microstructural Properties of AA5754 Joints. Adv. Mater. Sci. Eng. 2019, 2019, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Bodaghi, M.; Dehghani, K. Friction stir welding of AA5052: The effects of SiC nano-particles addition. Int. J. Adv. Manuf. Technol. 2017, 88, 2651–2660. [Google Scholar] [CrossRef]

- Tjong, S. Novel Nanoparticle-Reinforced Metal Matrix Composites with Enhanced Mechanical Properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Paidar, M.; Asgari, A.; Ojo, O.O.; Saberi, A. Mechanical Properties and Wear Behavior of AA5182/WC Nanocomposite Fabricated by Friction Stir Welding at Different Tool Traverse Speeds. J. Mater. Eng. Perform. 2018, 27, 1714–1724. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Liu, B.L.; Xiao, W.G.; Wang, Z.Y. Tensile Strength and Electrical Conductivity of Carbon Nanotube Reinforced Aluminum Matrix Composites Fabricated by Powder Metallurgy Combined with Friction Stir Processing. J. Mater. Sci. Technol. 2014, 30, 649–655. [Google Scholar] [CrossRef]

- Karakizis, P.N.; Pantelis, D.I.; Fourlaris, G.; Tsakiridis, P. Effect of SiC and TiC nanoparticle reinforcement on the microstructure, microhardness, and tensile performance of AA6082-T6 friction stir welds. Int. J. Adv. Manuf. Technol. 2018, 95, 3823–3837. [Google Scholar] [CrossRef]

- Low, I.M. Nanoceramic Matrix Composites: Types, Processing, and Applications. In Advances in Ceramic Matrix Composites, Australia, 2nd ed.; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Bahrami, M.; Nikoo, M.F.; Givi, M.K.B. Microstructural and mechanical behaviors of nano-SiC-reinforced AA7075-O FSW joints prepared through two passes. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 626, 220–228. [Google Scholar] [CrossRef]

- Hamdollahzadeh, A.; Bahrami, M.; Farahmand Nikoo, M.; Yusefi, A.; Besharati Givi, M.K.; Parvin, N. Microstructure evolutions and mechanical properties of nano-SiC-fortified AA7075 friction stir weldment: The role of second pass processing. J. Manuf. Process. 2015, 20, 367–373. [Google Scholar] [CrossRef]

- Singh, T.; Tiwari, S.K.; Shukla, D.K. Mechanical and microstructural characterization of friction stir welded AA6061-T6 joints reinforced with nano-sized particles. Mater. Charact. 2020, 159, 110047. [Google Scholar] [CrossRef]

- Sielski, R.A. Review of structural design of aluminum ships and craft. Trans. Soc. Nav. Archit. Mar. Eng. 2007, 115, 1–30. [Google Scholar]

- Hakem, M.; Lebaili, S.; Miroud, J.; Bentaleb, A.; Toukali, S. Welding and characterization of 5083 aluminum alloy. In METAL 2012—Conference Proceedings, 21st International Conference on Metallurgy and Materials; Tanger Ltd.: Ostrava, Czech Republic, 2012. [Google Scholar]

- Paik, J.K. Mechanical properties of friction stir welded aluminum alloys 5083 and 5383. Int. J. Nav. Archit. Ocean Eng. 2009, 1, 39–49. [Google Scholar] [CrossRef] [Green Version]

- Klobcar, D.; Kosec, L.; Pietras, A.; Smolej, A. Friction-stir welding of aluminium alloy 5083. Mater. Technol. 2012, 46, 483–488. [Google Scholar]

- Aval, H.J.; Loureiro, A. Effect of welding parameters on microstructure, mechanical properties and residual stress fields of friction stirwelds on AA5086. Met. Mater. 2016, 53, 51–58. [Google Scholar] [CrossRef] [Green Version]

- Kartsonakis, I.A.; Dragatogiannis, D.A.; Koumoulos, E.P.; Karantonis, A.; Charitidis, C.A. Corrosion behaviour of dissimilar friction stir welded aluminium alloys reinforced with nanoadditives. Mater. Des. 2016, 102, 56–67. [Google Scholar] [CrossRef]

- Jamalian, H.M.; Ramezani, H.; Ghobadi, H.; Ansari, M.; Yari, S.; Besharati Givi, M.K. Processing-structure-property correlation in nano-SiC-reinforced friction stir welded aluminum joints. J. Manuf. Process. 2016, 21, 180–189. [Google Scholar] [CrossRef]

- Mirjavadi, S.S.; Alipour, M.; Emamian, S.; Kord, S.; Hamouda, A.M.S.; Koppad, P.G.; Keshavamurthy, R. Influence of TiO2 nanoparticles incorporation to friction stir welded 5083 aluminum alloy on the microstructure, mechanical properties and wear resistance. J. Alloys Compd. 2017, 712, 795–803. [Google Scholar] [CrossRef]

- Karakizis, P.N.; Pantelis, D.I.; Fourlaris, G.; Tsakiridis, P. The role of SiC and TiC nanoparticle reinforcement on AA5083-H111 friction stir welds studied by electron microscopy and mechanical testing. Int. J. Adv. Manuf. Technol. 2018, 94, 4159–4176. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Palani, K.; Elanchezhian, C.; Saiprakash, K.H.V.; Sreekanth, K.; Dayanand, D.; Kumar, K.; Kumar, D. Effect of welding parameters on mechanical properties of dissimilar friction stir processed AA 8011 and AA 5083-H321 aluminium alloys. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Tamilnadu, India, 2018. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V.; Valliappan, M. Effect of tool pin profile and tool rotational speed on mechanical properties of friction stir welded AA6061 aluminium alloy. Mater. Manuf. Process. 2008, 23, 251–260. [Google Scholar] [CrossRef]

- Mirjavadi, S.S.; Alipour, M.; Hamouda, A.M.S.; Matin, A.; Kord, S.; Afshari, B.M.; Koppad, P.G. Effect of multi-pass friction stir processing on the microstructure, mechanical and wear properties of AA5083/ZrO2 nanocomposites. J. Alloys Compd. 2017, 726, 1262–1273. [Google Scholar] [CrossRef]

- Jata, K.V.; Sankaran, K.K.; Ruschau, J.J. Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2000, 31, 2181–2192. [Google Scholar] [CrossRef]

- Shahraki, S.; Khorasani, S.; Abdi Behnagh, R.; Fotouhi, Y.; Bisadi, H. Producing of AA5083/ZrO2 nanocomposite by friction stir processing (FSP). Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 2013, 44, 1546–1553. [Google Scholar] [CrossRef]

- Hoseinlaghab, S.; Mirjavadi, S.S.; Sadeghian, N.; Jalili, I.; Azarbarmas, M.; Besharati Givi, M.K. Influences of welding parameters on the quality and creep properties of friction stir welded polyethylene plates. Mater. Des. 2015, 67, 369–378. [Google Scholar] [CrossRef]

- Avettand-Fènoël, M.; Simar, A.; Shabadi, R.; Tailard, R.; De Meester, B. Characterization of oxide dispersion strengthened copper based materials developed by friction stir processing. Mater. Des. 2014, 60, 343–357. [Google Scholar] [CrossRef]

- Scialpi, A.; De Filippis, L.A.C.; Cavaliere, P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminium alloy. Mater. Des. 2007, 28, 1124–1129. [Google Scholar] [CrossRef]

- Hoyingchareon, K.; Muangjunburee, P. Welding repair of aluminium alloy 6082 T6 by TIG welding process. Mater. Sci. Forum. 2016, 872. [Google Scholar] [CrossRef]

- Thimmaraju, P.; Arkanti, K.; Reddy, G.C.; Tilak, K.B.G. Comparison of microstructure and mechanical properties of friction stir welding of al 6082 aluminum alloy with different tool profiles. Mater. Today Proc. 2016, 3, 4173–4181. [Google Scholar] [CrossRef]

- Muthukrishnan, M.; Marimuthu, M. Some studies on mechanical properties of friction stir butt welded al-6082-T6 plates. In Proceedings of the International Conference on Frontiers in Automobile and Mechanical Engineering (FAME), Material today, Chennai, India, 25–27 November 2010. [Google Scholar] [CrossRef]

- Cavaliere, P.; Squillace, A.; Panella, F. Effect of welding parameters on mechanical and microstructural properties of AA6082 joints produced by friction stir welding. J. Mater. Process. Technol. 2008, 200, 364–372. [Google Scholar] [CrossRef]

- El-Rayes, M.M.; El-Danaf, E.A. The influence of multi-pass friction stir processing on the microstructural and mechanical properties of Aluminum Alloy 6082. J. Mater. Process. Technol. 2012, 212, 1157–1168. [Google Scholar] [CrossRef]

- Pantelis, D.I.; Karkizis, P.N.; Dragatogiannis, D.A.; Charitidis, C.A. Dissimilar Friction Stir Welding of Aluminum Alloys Reinforced with Carbon Nanotubes. In Nanomaterials in Joining. 2016. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84979178149&doi=10.1515%2f9783110339727-004&partnerID=40&md5=b1da077aafbc2afa4f2a4f5ff4016c5f (accessed on 7 May 2019). [CrossRef]

- Sing, S.K.; Rashid, M.; Kumar, D.; Kumar, S. Micro Structural and Mechanical Behaviours of Nano-TiC-Reinforced AA6082 FSW Joints. Int. J. Trend Res. Dev. (IJTRD) 2016, 3, 179–182. [Google Scholar]

- Pityana, S. Microstructures of alloyed and dispersed hard particles in the aluminium surface. In Proceedings of the 4th Pacific International Conference on Applications of Lasers and Optics (PICALO), Wuhan, China, 23 March 2010. [Google Scholar]

- Sun, Y.F.; Fujii, H. The effect of SiC particles on the microstructure and mechanical properties of friction stir welded pure copper joints. Mater. Sci. Eng. A 2011, 528, 5470–5475. [Google Scholar] [CrossRef]

- Suresh, S.; Venkatesan, K.; Natarajan, E. Influence of SiC nanoparticle reinforcement on FSS welded 6061-T6 aluminum alloy. J. Nanomater. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Tebyani, S.F.; Dehghani, K. Effects of SiC nanopowders on the mechanical properties and microstructure of interstitial free steel joined via friction stir spot welding. Mater. Des. 2016, 90, 660–668. [Google Scholar] [CrossRef]

- Moradi, M.M.; Jamshidi Aval, H.; Jamaati, R.; Amirkhanlou, S.; Ji, S. Effect of SiC nanoparticles on the microstructure and texture of friction stir welded AA2024/AA6061. Mater. Charact. 2019, 152, 169–179. [Google Scholar] [CrossRef]

- Luijendijk, T. Welding of dissimilar aluminium alloys. J. Mater. Process. Technol. 2000, 103, 29–35. [Google Scholar] [CrossRef]

- Peel, M.J.; Steuwer, A.; Withers, P.J.; Dickerson, T.; Shi, Q.; Shercliff, H. Dissimilar friction stir welds in AA5083-AA6082. Part I: Process parameter effects on thermal history and weld properties. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2006, 37, 2183–2193. [Google Scholar] [CrossRef]

- Karlsson, L.; Larsson, H.; Berggvist, E.L.; Stoltz, S. Friction stir welding of dissimilar al-alloys. In Proceedings of the 2nd Friction Stir Welding Symposium; TWI Ltd.: Cambridge, UK, 2000; pp. 281–290. [Google Scholar]

- Reynolds, A.P.; Lockwood, W.D.; Seidel, T.U. Processing-property correlation in friction stir welds. Mater. Sci. Forum. 2000, 331, II. [Google Scholar] [CrossRef]

- Jafari, H.; Mansouri, H.; Honarpisheh, M. Investigation of residual stress distribution of dissimilar Al-7075-T6 and Al-6061-T6 in the friction stir welding process strengthened with SiO2 nanoparticles. J. Manuf. Process. 2019, 43, 145–153. [Google Scholar] [CrossRef]

- Lee, S.; Shin, S.E.; Sun, Y.; Fujii, H.; Park, Y. Friction stir welding of multi-walled carbon nanotubes reinforced Al matrix composites. Mater. Charact. 2018, 145, 653–663. [Google Scholar] [CrossRef]

- Peel, M.J.; Steuwer, A.; Withers, P.J. Dissimilar friction stir welds in AA5083-AA6082. Part II: Process parameter effects on microstructure. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2006, 37, 2195–2206. [Google Scholar] [CrossRef]

- Donatus, U.; Thompson, G.E.; Zhou, X.; Wang, J.; Cassell, A.; Beamish, K. Corrosion susceptibility of dissimilar friction stir welds of AA5083 and AA6082 alloys. Mater. Charact. 2015, 107, 85–97. [Google Scholar] [CrossRef]

- Ji, S.D.; Shi, q.y.; Zhang, L.G.; Zou, A.L.; Gao, S.S.; Zan, L.V. Numerical simulation of material flow behavior of friction stir welding influenced by rotational tool geometry. Comput. Mater. Sci. 2012, 63, 218–226. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; Santos, T.; Tavares, S.M.O.; Richter-Trummer, V.; Vilaca, P.; De Castro, P.M.S.T. Mechanical and metallurgical characterization of friction stir welding joints of AA6061-T6 with AA6082-T6. Mater. Des. 2009, 30, 180–187. [Google Scholar] [CrossRef]

- Montemor, M.F. Corrosion Issues in Joining Lightweight Materials: A Review of the Latest Achievements. In Nanomaterials in Joining. 2016. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84979176724&doi=10.1515%2f9783110339727-005&partnerID=40&md5=4f572286bbfa2e77eb7e76998f241c8f (accessed on 4 May 2019). [CrossRef]

| Specimen | Effect | |

|---|---|---|

| SiC nanoparticle | 750 rpm, 85 mm/min and 2 passes | Porosity and agglomeration of nanoparticles |

| 1180 rpm, 85 mm/min and 3 passes (+++) | Porosity with agglomeration of particles. | |

| 1500 rpm, 85 mm/min and 3 passes (+−+) | No porosity with agglomeration of particles. | |

| 1500 rpm, 19 mm/min and 3 passes (+−+) | Uniform nanoparticle distribution and nil defect with better properties | |

| TiC nanoparticle | 750 rpm, 85 mm/min and 2 passes | Porosity and agglomeration of nanoparticles |

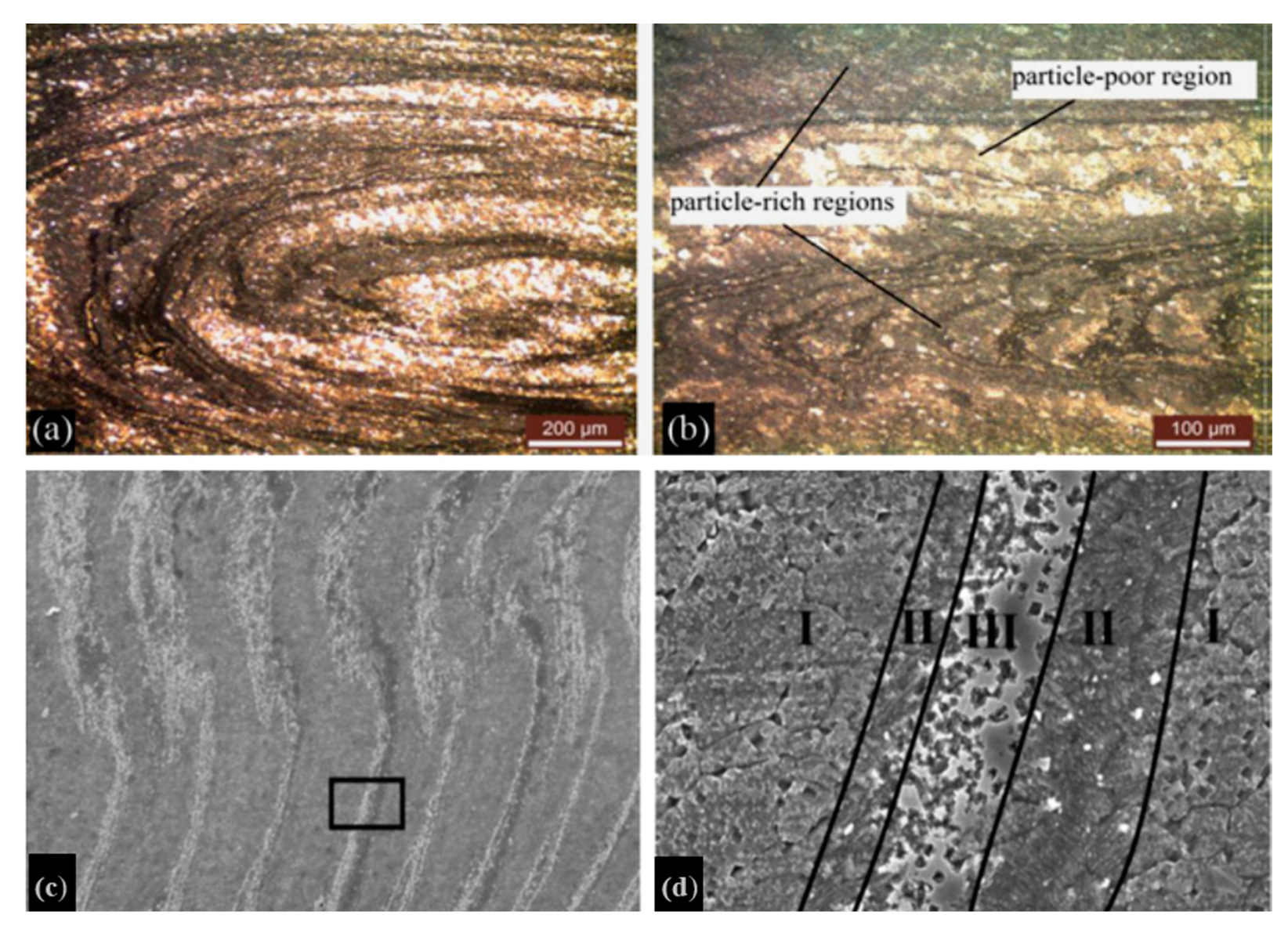

| 1180 rpm, 85 mm/min and 3 passes (+++) | Inhomogeneous distribution of nanoparticles with rich and poor region of particles | |

| 1500 rpm, 85 mm/min and 3 passes (+−+) | Uniform nanoparticle distribution and nil defect with better properties | |

| 1500 rpm, 19 mm/min and 3 passes (+−+) | No onion ring structure with inhomogeneous distribution forming poor and rich regions. | |

| Specimen | Grain Size (µm) |

|---|---|

| Base metal | 40 |

| WN of reinforcement | 5.5 |

| WN with reinforcement of TiC nanoparticles | 4.2 |

| WN with reinforcement of SiC nanoparticles | 5.1 |

| Joint Specimen | Young’s Modulus (GPa) | Yield Strength (MPa) | UTS (MPa) | Elongation (%) | Toughness (J/m3) |

|---|---|---|---|---|---|

| Without nanoparticles | 68.13 ± 2.71 | 146 ± 4.04 | 199.17 ± 5.8 | 3.79 ± 0.17 | 706.12 ± 13.28 |

| With SiC nanoparticle | 74.63 ± 4.94 | 106 ± 2.65 | 167.5 ± 7.49 | 5.97 ± 0.58 | 913.15 ± 22.35 |

| With TiC nanoparticle | 67.62 ± 3.6 | 139 ± 5.69 | 190.5 ± 4.82 | 3.95 ± 0.37 | 703.43 ± 9.39 |

| Specimen | Young’s Modulus (GPa) | Yield Stress (MPa) | UTS (MPa) | Elongation (%) |

|---|---|---|---|---|

| Without nanoparticles | 65.5 | 140 ± 3 | 193 ± 3 | 3 ± 0.4 |

| With SiC nanoparticles | 78 | 138 | 217 | 5 |

| With TiC nanoparticles | 76.8 | 145 ± 2 | 199 ± 3 | 3.7 ± 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vimalraj, C.; Kah, P. Experimental Review on Friction Stir Welding of Aluminium Alloys with Nanoparticles. Metals 2021, 11, 390. https://doi.org/10.3390/met11030390

Vimalraj C, Kah P. Experimental Review on Friction Stir Welding of Aluminium Alloys with Nanoparticles. Metals. 2021; 11(3):390. https://doi.org/10.3390/met11030390

Chicago/Turabian StyleVimalraj, Cyril, and Paul Kah. 2021. "Experimental Review on Friction Stir Welding of Aluminium Alloys with Nanoparticles" Metals 11, no. 3: 390. https://doi.org/10.3390/met11030390

APA StyleVimalraj, C., & Kah, P. (2021). Experimental Review on Friction Stir Welding of Aluminium Alloys with Nanoparticles. Metals, 11(3), 390. https://doi.org/10.3390/met11030390