Towards Manufacturing of Ultrafine-Laminated Structures in Metallic Tubes by Accumulative Extrusion Bonding

Abstract

:1. Introduction

2. Methods

2.1. Theory of Bonding

- A very thin brittle surface must exist on both metallic faces to be bonded.

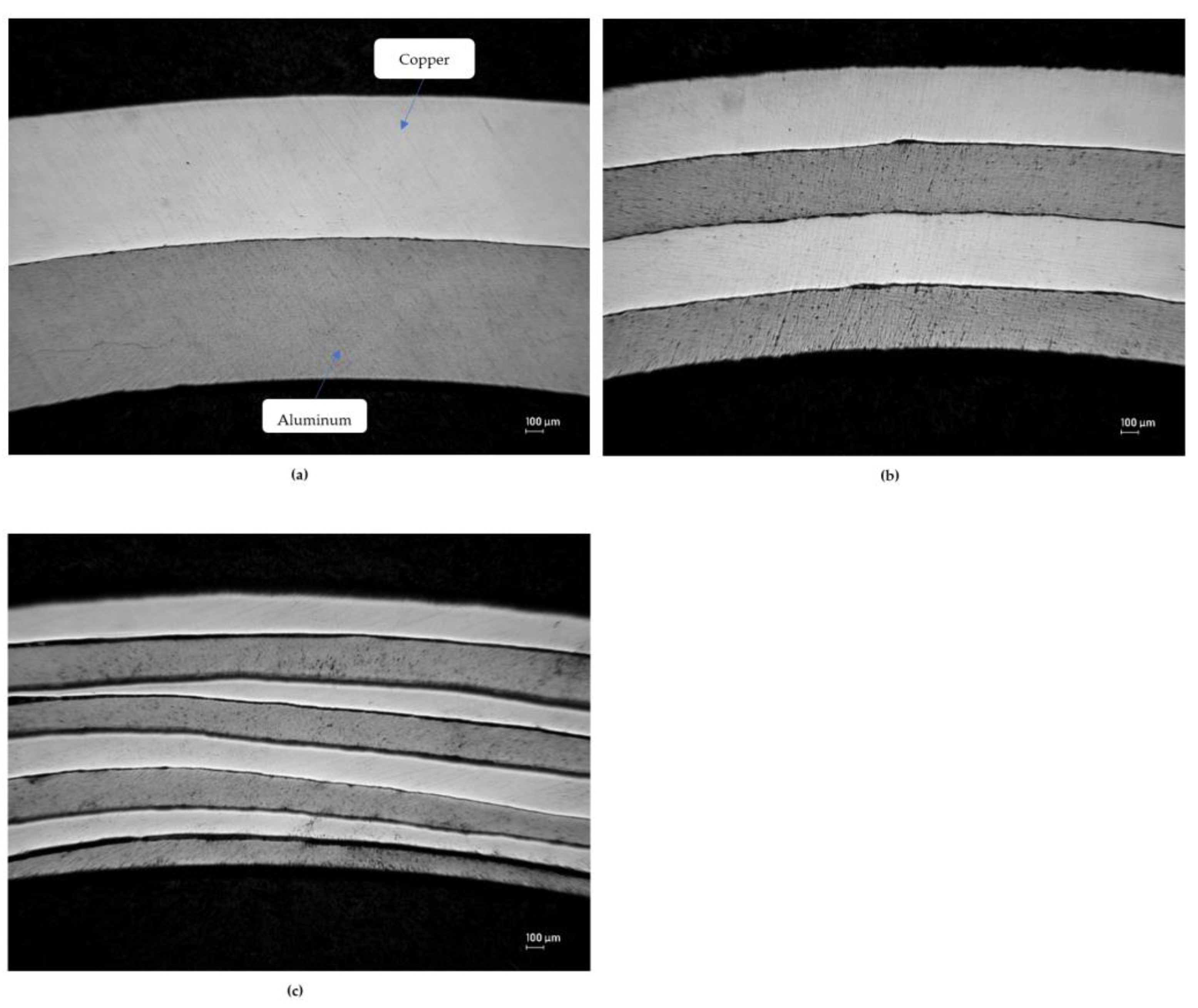

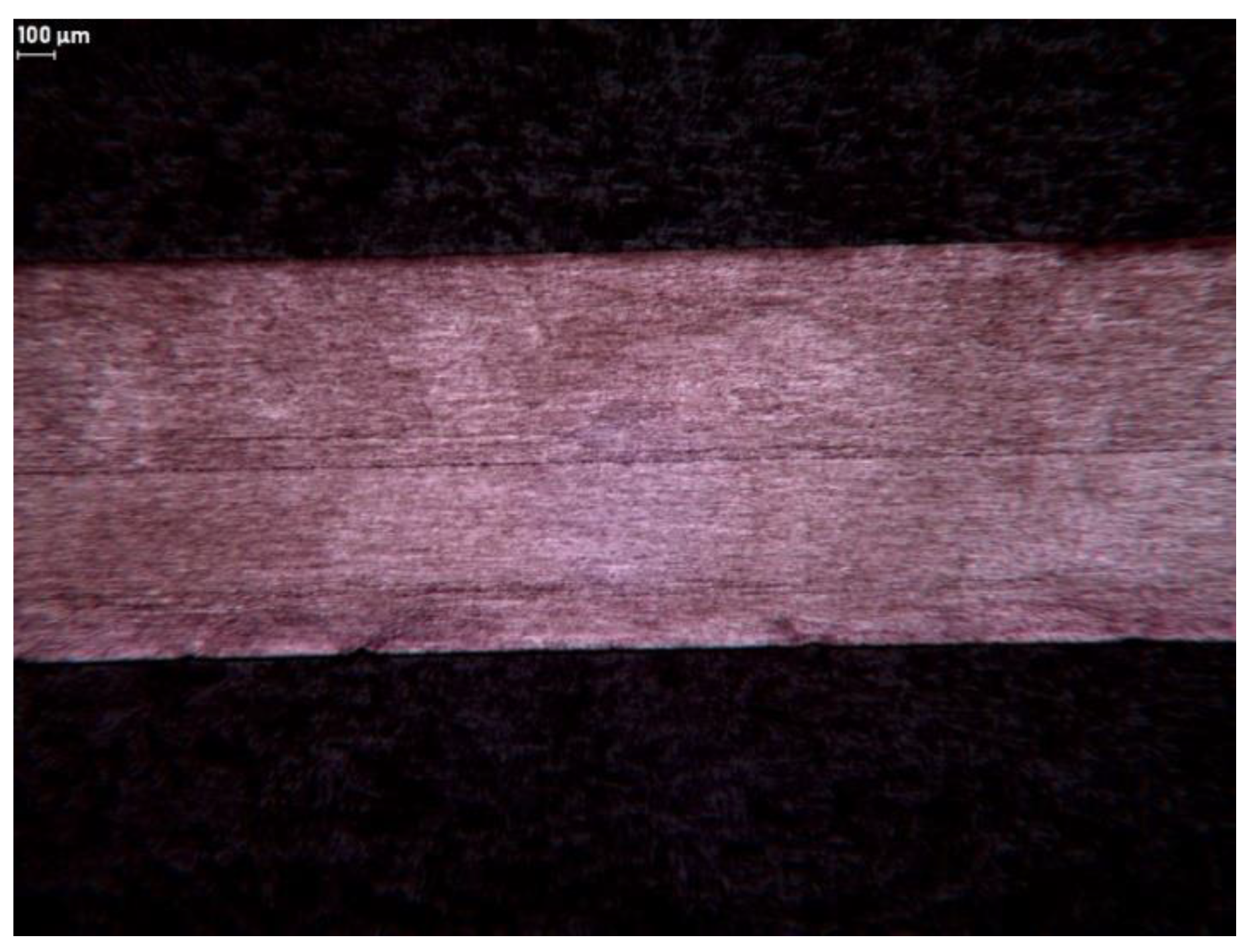

- Under high pressure, the metallic faces are forced into one interface where the thin brittle surfaces on both metals begin to crack under a significant amount of imposed strain.

- Through the small cracks fresh virgin material extrudes which interact with the opposing virgin material to form a metallic bond.

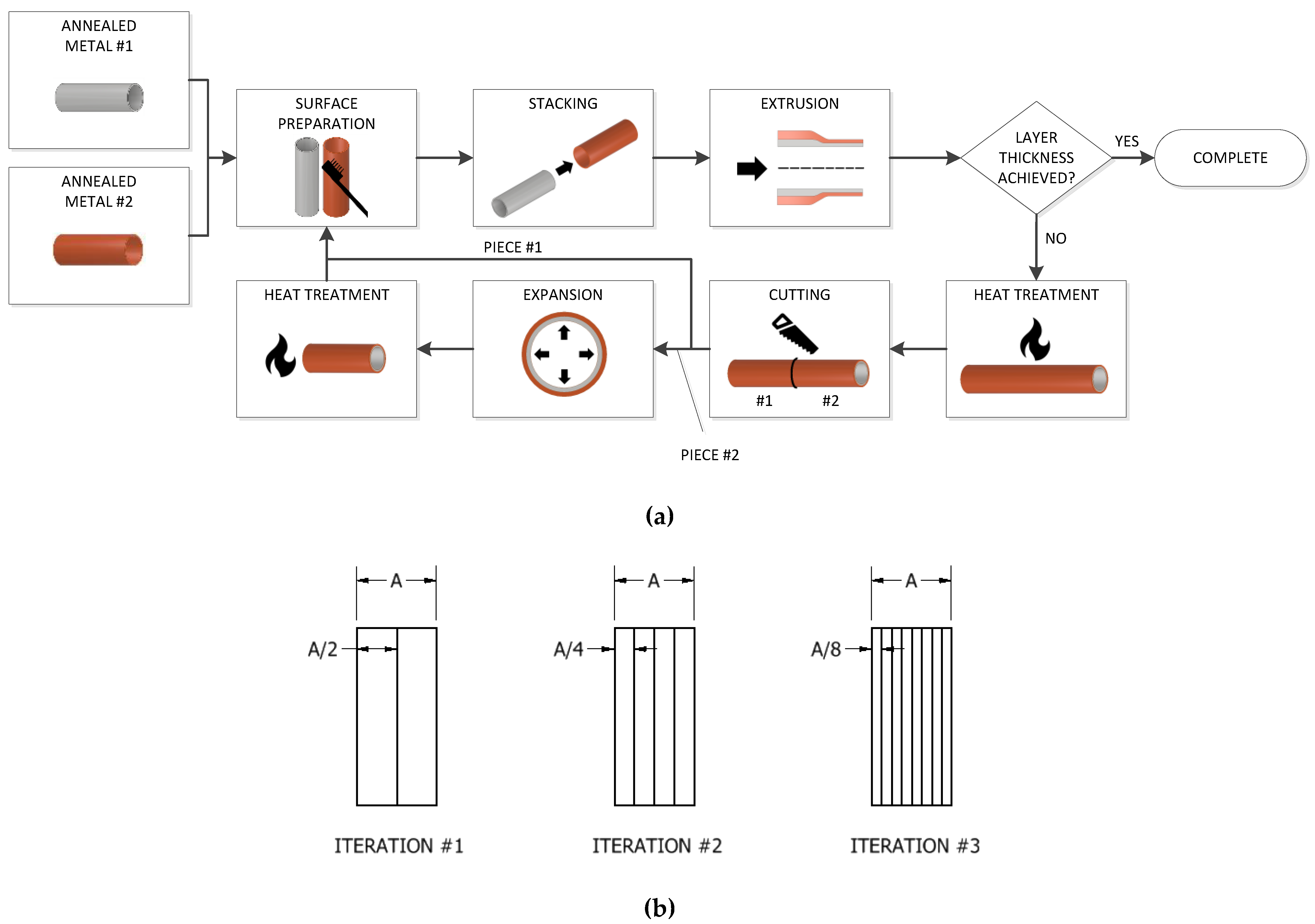

2.2. Manufacturing

2.2.1. Surface Preparation

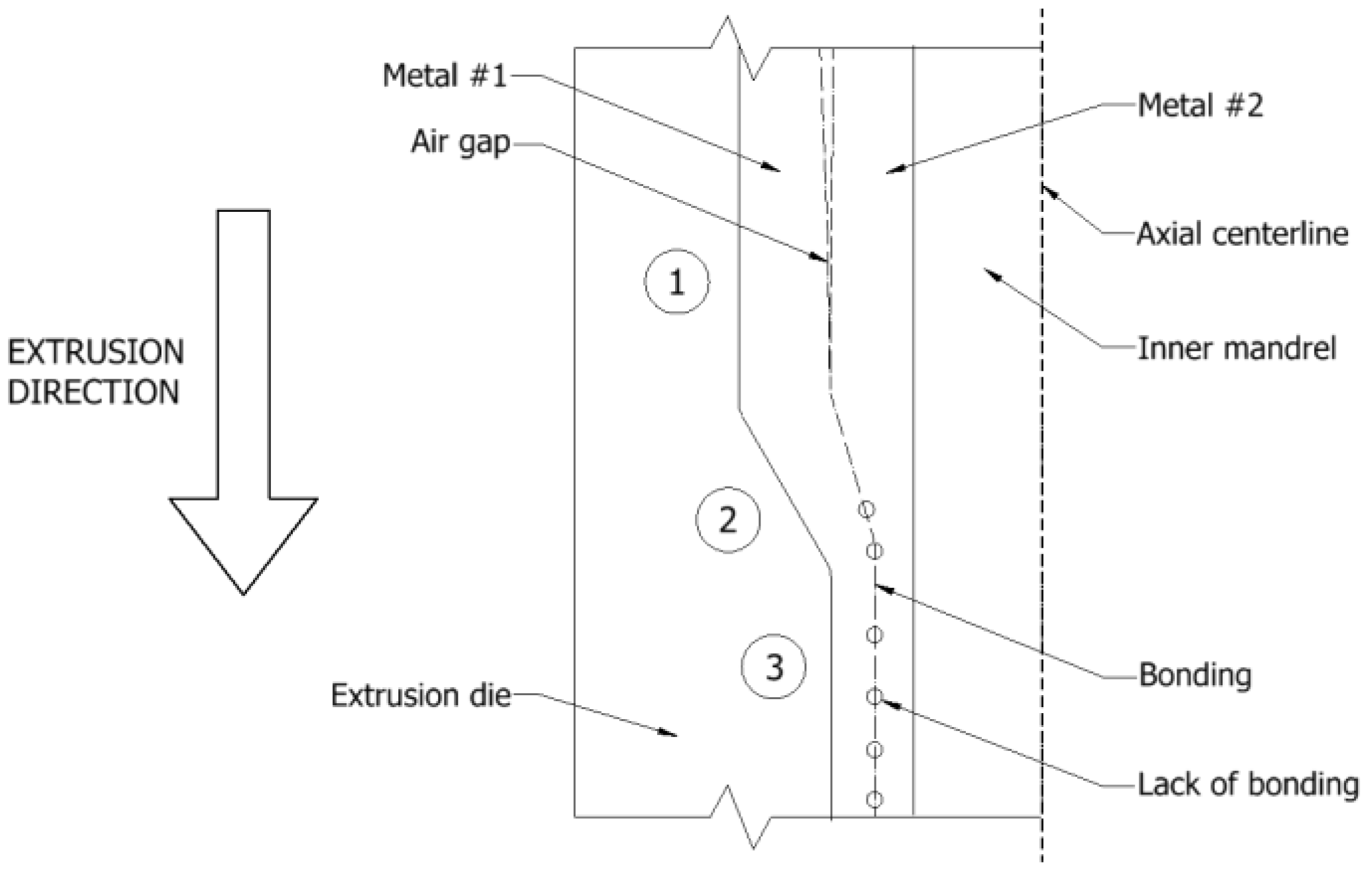

2.2.2. Extrusion

2.2.3. Cutting

2.2.4. Expansion

2.2.5. Heat treatment

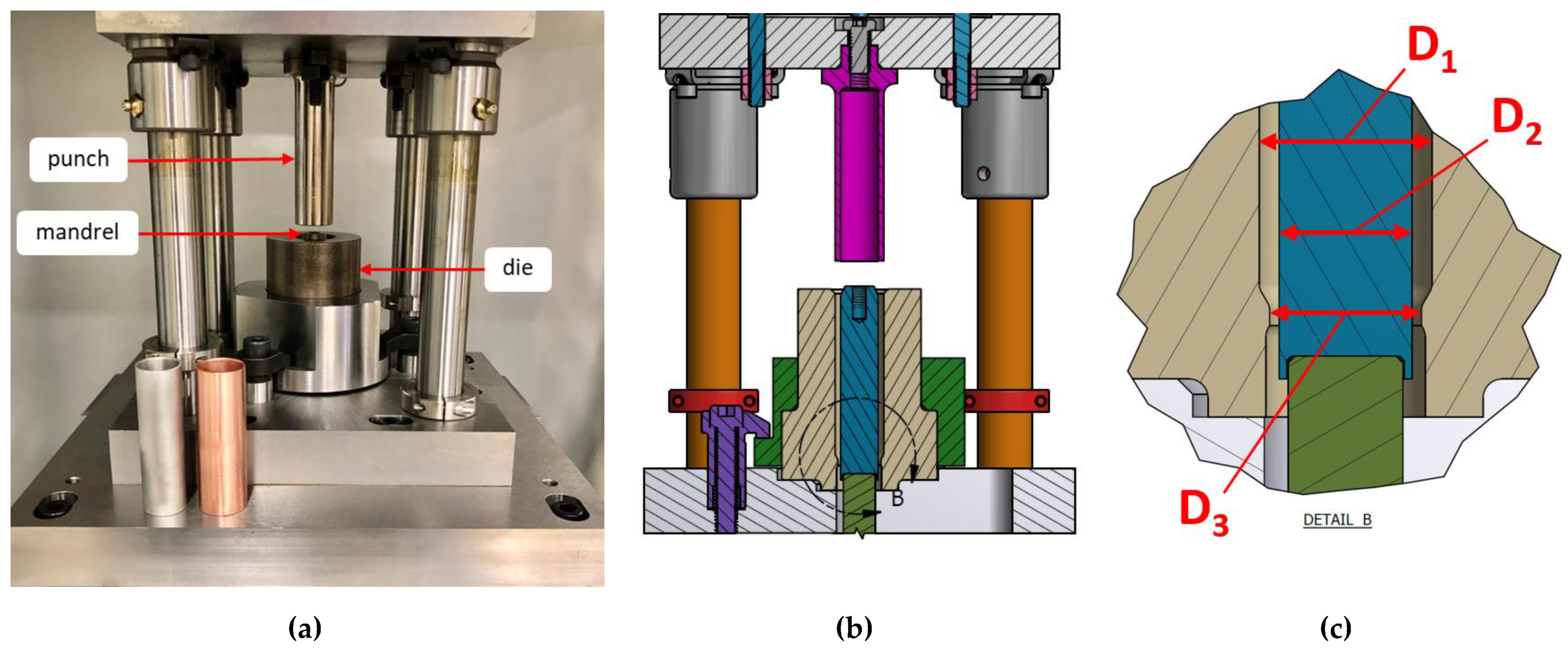

3. Die and Expansion Designs

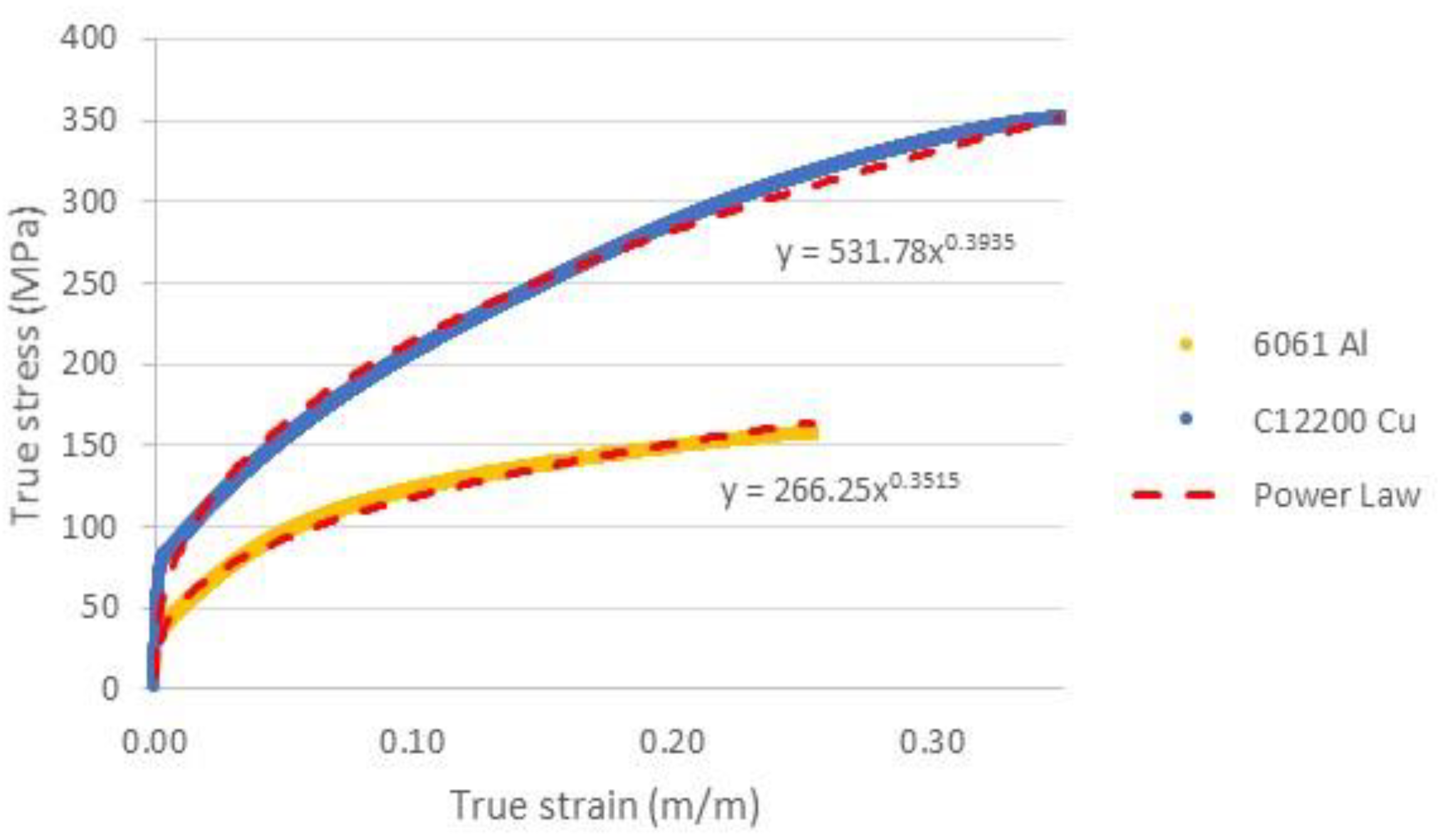

4. Materials

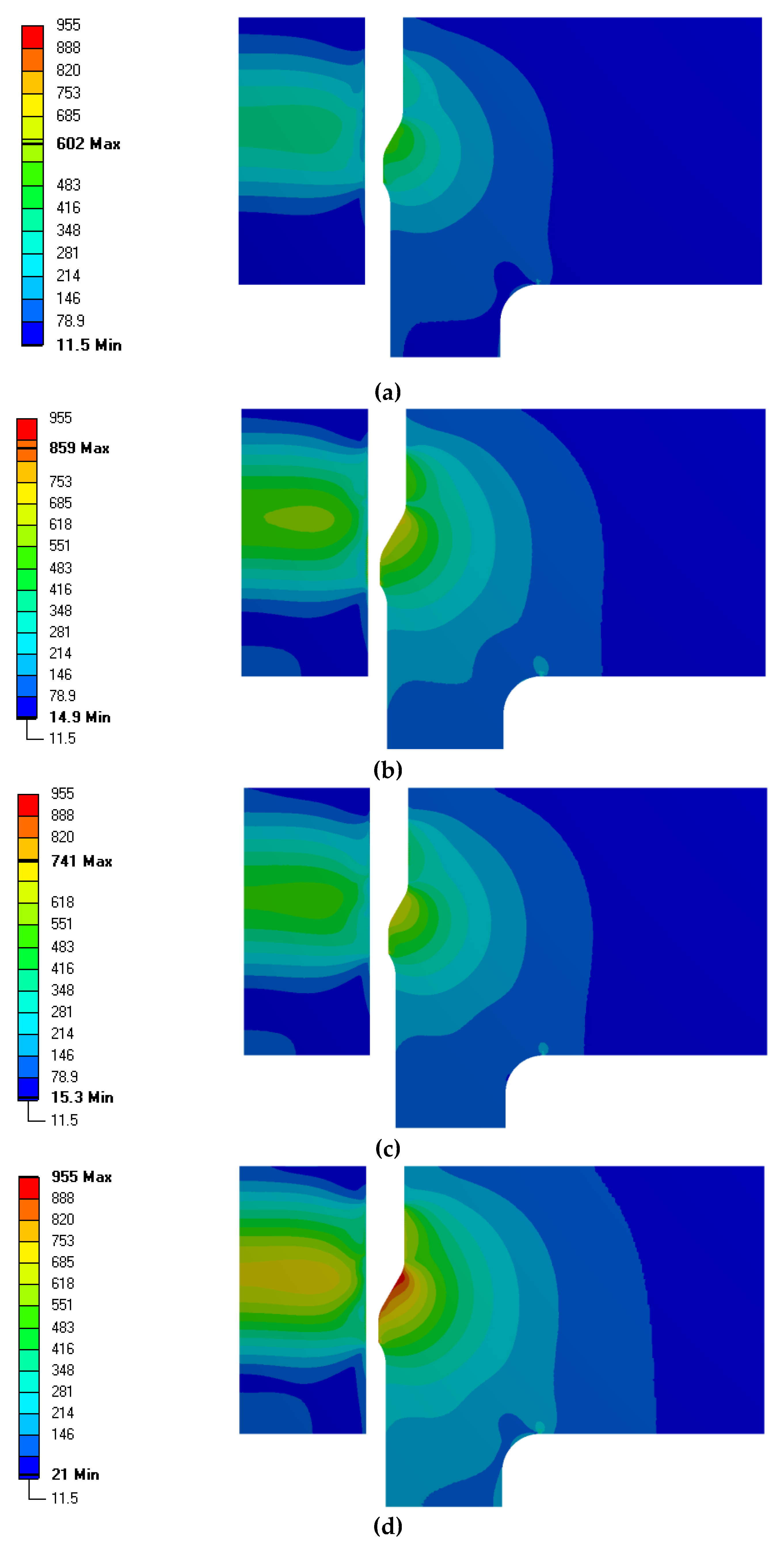

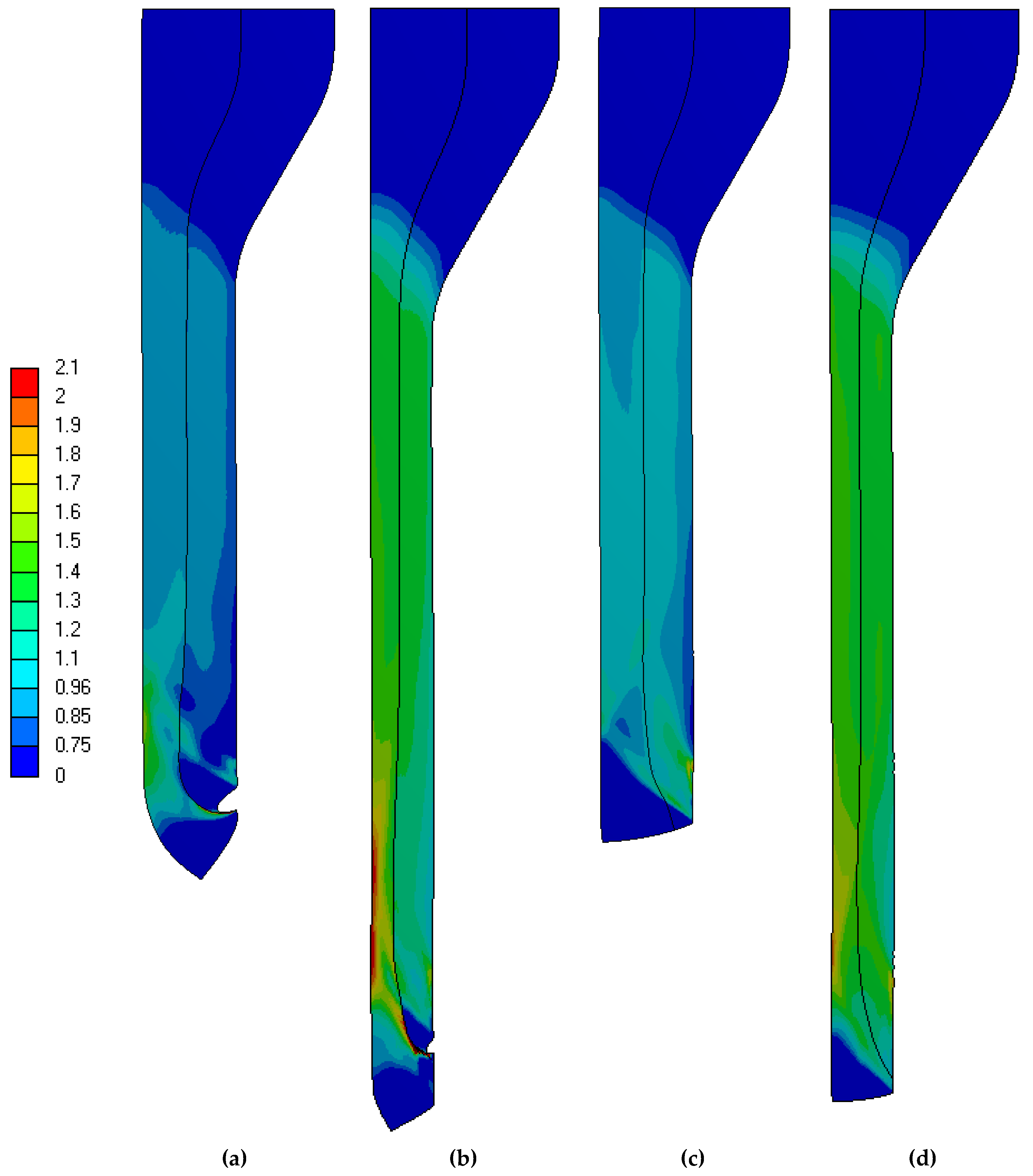

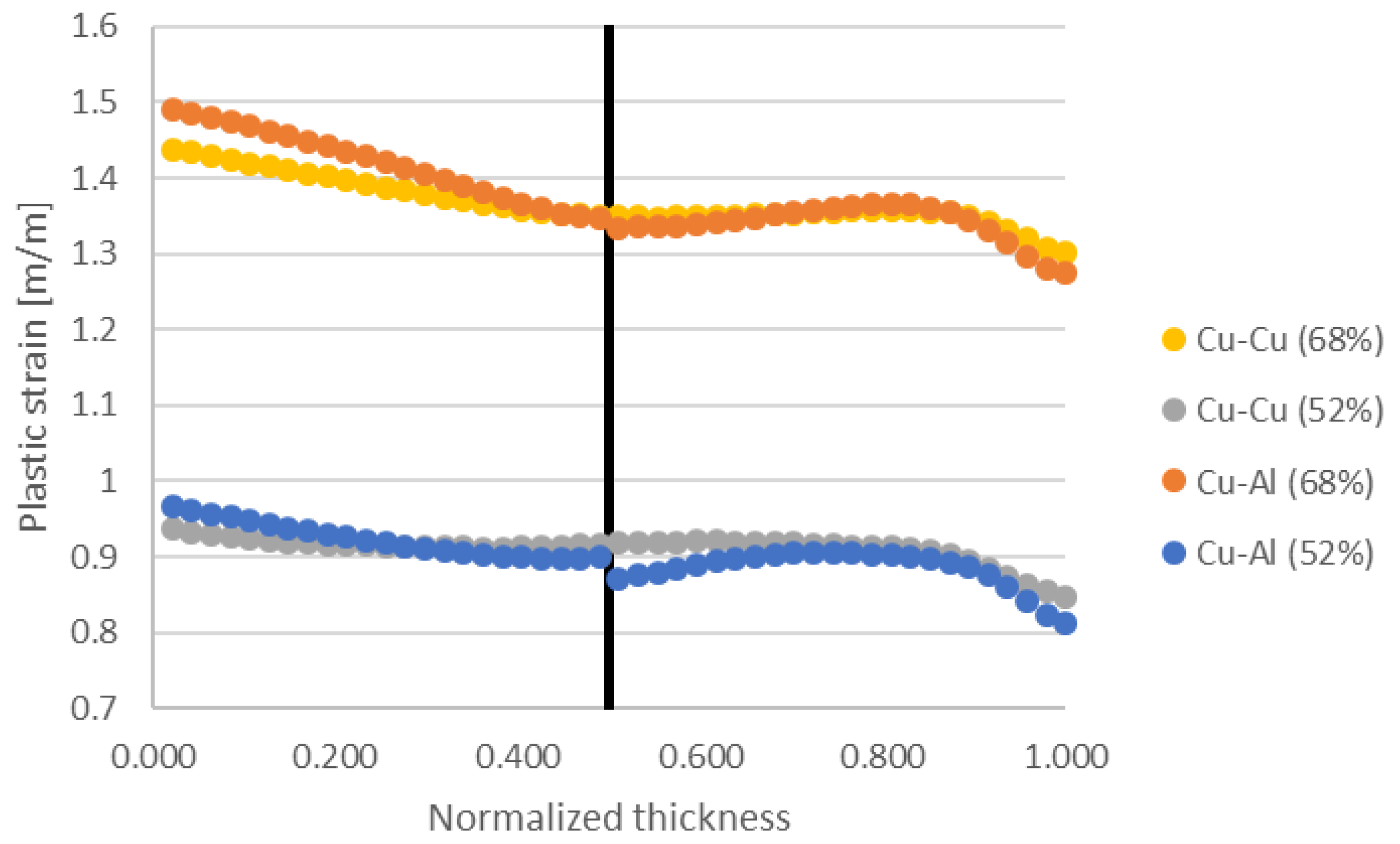

5. Finite Element Method-Based Simulations of Extrusion

6. Results and Discussion

7. Summary and Conclusions

- Bonding using AEB does not occur at 50% deformation revealing the significant role of more complex geometry of tubes relative to sheets in solid-state bonding. Mechanical fields in the tube during AEB are different from those in the sheet during ARB making the required strain levels for bonding greater in AEB process than those in ARB process.

- It is necessary to achieve bonding on the first extrusion pass/iteration as future extrusion passes would not promote bonding. Since bonding does not occur on the first extrusion pass at 52% deformation, the material layers act independently for each future extrusion. Moreover, the layers begin to lose their integrity with plastic strain.

- Surface preparation before forming the interface is very important to facilitate bonding using AEB. Any imperfection left on the interfacial layer will become an inclusion at the interface. During processing it is therefore critical to minimize inadvertent mishandling or extraneous debris. Further processing will thin and stretch areas of contamination but will not remove the inclusions. Moreover, oxidation layer minimization is necessary to aid in bonding. Scratch brushing is used as the process to promote surface hardening while also aiding in the removal of any oxide layer. This method also does not produce any noticeable debris from the bristles which helps promote cleanliness. It is found that over-brushing does not improve the amount of bonding. Beyond scratch brushing, which is a key application to remove oxides and encourage surface hardness, minimizing contact with the atmosphere is also essential.

- Annealing during each iteration is necessary to remove strain hardening caused during extrusion. Samples extruded with the annealing step omitted failed during extrusion due to wrinkling and tearing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bimetallic Tubes. Available online: http://www.beca-engineering.com/product/bimetallictubes.php (accessed on 12 January 2021).

- Bimetallic Tubes. Available online: https://www.dmitubes.com/bimetallic-tubes.html (accessed on 12 January 2021).

- New Generation Bimetallic Tubes. Available online: https://www.energetictubes.com/ (accessed on 12 January 2021).

- Bimetallic Tubes. Available online: https://www.materials.sandvik/en-us/products/tube-pipe-fittings-and-flanges/tubular-products/bimetallic-tubes/ (accessed on 12 January 2021).

- Hosseini, M.; Pardis, N.; Manesh, H.D.; Abbasi, M.; Kim, D.-I. Structural characteristics of cu/ti bimetal composite produced by accumulative roll-bonding (arb). Mater. Des. 2017, 113, 128–136. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R. Manufacturing of high-strength aluminum/alumina composite by accumulative roll bonding. Mater. Sci. Eng. A 2010, 527, 4146–4151. [Google Scholar] [CrossRef]

- Dehsorkhi, R.N.; Qods, F.; Tajally, M. Investigation on microstructure and mechanical properties of al–zn composite during accumulative roll bonding (arb) process. Mater. Sci. Eng. A 2011, 530, 63–72. [Google Scholar] [CrossRef]

- Chang, H.; Zheng, M.; Xu, C.; Fan, G.; Brokmeier, H.; Wu, K. Microstructure and mechanical properties of the mg/al multilayer fabricated by accumulative roll bonding (arb) at ambient temperature. Mater. Sci. Eng. A 2012, 543, 249–256. [Google Scholar] [CrossRef]

- Mahdavian, M.; Ghalandari, L.; Reihanian, M. Accumulative roll bonding of multilayered cu/zn/al: An evaluation of microstructure and mechanical properties. Mater. Sci. Eng. A 2013, 579, 99–107. [Google Scholar] [CrossRef]

- Ghalandari, L.; Mahdavian, M.; Reihanian, M. Microstructure evolution and mechanical properties of cu/zn multilayer processed by accumulative roll bonding (arb). Mater. Sci. Eng. A 2014, 593, 145–152. [Google Scholar] [CrossRef]

- Knezevic, M.; Nizolek, T.; Ardeljan, M.; Beyerlein, I.J.; Mara, N.A.; Pollock, T.M. Texture evolution in two-phase zr/nb lamellar composites during accumulative roll bonding. Int. J. Plast. 2014, 57, 16–28. [Google Scholar] [CrossRef]

- Ardeljan, M.; Beyerlein, I.J.; Knezevic, M. A dislocation density based crystal plasticity finite element model: Application to a two-phase polycrystalline hcp/bcc composites. J. Mech. Phys. Solids 2014, 66, 16–31. [Google Scholar] [CrossRef]

- Savage, D.J.; Beyerlein, I.J.; Mara, N.A.; Vogel, S.C.; McCabe, R.J.; Knezevic, M. Microstructure and texture evolution in mg/nb layered materials made by accumulative roll bonding. Int. J. Plast. 2020, 125, 1–26. [Google Scholar] [CrossRef]

- Leu, B.; Savage, D.J.; Wang, J.; Alam, M.E.; Mara, N.A.; Kumar, M.A.; Carpenter, J.S.; Vogel, S.C.; Knezevic, M.; Decker, R.; et al. Processing of dilute mg–zn–mn–ca alloy/nb multilayers by accumulative roll bonding. Adv. Eng. Mater. 2020, 22, 1900673. [Google Scholar] [CrossRef]

- Mashhadi, A.; Atrian, A.; Ghalandari, L. Mechanical and microstructural investigation of zn/sn multilayered composites fabricated by accumulative roll bonding (arb) process. J. Alloys Compd. 2017, 727, 1314–1323. [Google Scholar] [CrossRef]

- Clemens, B.; Kung, H.; Barnett, S. Structure and strength of multilayers. MRS Bull. 1999, 24, 20–26. [Google Scholar] [CrossRef]

- Mara, N.; Bhattacharyya, D.; Dickerson, P.; Hoagland, R.; Misra, A. Deformability of ultrahigh strength 5 nm cu∕ nb nanolayered composites. Appl. Phys. Lett. 2008, 92, 231901. [Google Scholar] [CrossRef]

- Zhang, X.; Misra, A.; Wang, H.; Shen, T.; Nastasi, M.; Mitchell, T.; Hirth, J.; Hoagland, R.; Embury, J. Enhanced hardening in cu/330 stainless steel multilayers by nanoscale twinning. Acta Mater. 2004, 52, 995–1002. [Google Scholar] [CrossRef]

- Ardeljan, M.; Knezevic, M.; Jain, M.; Pathak, S.; Kumar, A.; Li, N.; Mara, N.A.; Baldwin, J.K.; Beyerlein, I.J. Room temperature deformation mechanisms of mg/nb nanolayered composites. J. Mater. Res. 2018, 33, 1311–1332. [Google Scholar] [CrossRef] [Green Version]

- Ardeljan, M.; Savage, D.J.; Kumar, A.; Beyerlein, I.J.; Knezevic, M. The plasticity of highly oriented nano-layered zr/nb composites. Acta. Mater. 2016, 115, 189–203. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.; Ardeljan, M.; Knezevic, M.; Jain, M.; Pathak, S.; Beyerlein, I.J. Elastic constants of pure body-centered cubic mg in nanolaminates. Comput. Mater. Sci. 2020, 174, 109501. [Google Scholar] [CrossRef]

- Knezevic, M.; Zecevic, M.; Beyerlein, I.J.; Lebensohn, R.A. A numerical procedure enabling accurate descriptions of strain rate-sensitive flow of polycrystals within crystal visco-plasticity theory. Comput. Methods Appl. Mech. Eng. 2016, 308, 468–482. [Google Scholar] [CrossRef] [Green Version]

- Knezevic, M.; Kalidindi, S.R. Fast computation of first-order elastic-plastic closures for polycrystalline cubic-orthorhombic microstructures. Comput. Mater. Sci. 2007, 39, 643–648. [Google Scholar] [CrossRef]

- Jahedi, M.; Ardjmand, E.; Knezevic, M. Microstructure metrics for quantitative assessment of particle size and dispersion: Application to metal-matrix composites. Powder Technol. 2017, 311, 226–238. [Google Scholar] [CrossRef] [Green Version]

- Misra, A.; Hoagland, R. Effects of elevated temperature annealing on the structure and hardness of copper/niobium nanolayered films. J. Mater. Res. 2005, 20, 2046–2054. [Google Scholar] [CrossRef]

- Bellou, A.; Scudiero, L.; Bahr, D. Thermal stability and strength of mo/pt multilayered films. J. Mater. Sci. 2010, 45, 354–362. [Google Scholar] [CrossRef]

- Han, W.; Misra, A.; Mara, N.; Germann, T.; Baldwin, J.; Shimada, T.; Luo, S. Role of interfaces in shock-induced plasticity in cu/nb nanolaminates. Philos. Mag. 2011, 91, 4172–4185. [Google Scholar] [CrossRef]

- Wei, Q.; Li, N.; Mara, N.; Nastasi, M.; Misra, A. Suppression of irradiation hardening in nanoscale v/ag multilayers. Acta Mater. 2011, 59, 6331–6340. [Google Scholar] [CrossRef]

- Zhernenkov, M.; Jablin, M.S.; Misra, A.; Nastasi, M.; Wang, Y.; Demkowicz, M.J.; Baldwin, J.K.; Majewski, J. Trapping of implanted he at cu/nb interfaces measured by neutron reflectometry. Appl. Phys. Lett. 2011, 98, 241913. [Google Scholar] [CrossRef]

- Lesuer, D.; Syn, C.; Sherby, O.; Wadsworth, J.; Lewandowski, J.; Hunt, W. Mechanical behaviour of laminated metal composites. Int. Mater. Rev. 1996, 41, 169–197. [Google Scholar] [CrossRef]

- Knezevic, M.; Jahedi, M.; Korkolis, Y.P.; Beyerlein, I.J. Material-based design of the extrusion of bimetallic tubes. Comput. Mater. Sci. 2014, 95, 63–73. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zechetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Knezevic, M.; Bhattacharyya, A. Characterization of microstructure in nb rods processed by rolling: Effect of grooved rolling die geometry on texture uniformity. Int. J. Refract. Met. Hard Mater. 2017, 66, 44–51. [Google Scholar] [CrossRef]

- Kalidindi, S.R.; Duvvuru, H.K.; Knezevic, M. Spectral calibration of crystal plasticity models. Acta Mater. 2006, 54, 1795–1804. [Google Scholar] [CrossRef]

- Jahedi, M.; Knezevic, M.; Paydar, M. High-pressure double torsion as a severe plastic deformation process: Experimental procedure and finite element modeling. J. Mater. Eng. Perform. 2015, 24, 1471–1482. [Google Scholar] [CrossRef]

- Jahedi, M.; Beyerlein, I.J.; Paydar, M.H.; Knezevic, M. Effect of grain shape on texture formation during severe plastic deformation of pure copper. Adv. Eng. Mater. 2018, 20, 1600829. [Google Scholar]

- Jahedi, M.; Beyerlein, I.J.; Paydar, M.H.; Zheng, S.; Xiong, T.; Knezevic, M. Effects of pressure and number of turns on microstructural homogeneity developed in high-pressure double torsion. Metall. Mater. Trans. A 2017, 48, 1249–1263. [Google Scholar] [CrossRef]

- Jahedi, M.; Paydar, M.H.; Knezevic, M. Enhanced microstructural homogeneity in metal-matrix composites developed under high-pressure-double-torsion. Mater. Charact. 2015, 104, 92–100. [Google Scholar] [CrossRef]

- Jahedi, M.; Paydar, M.H.; Zheng, S.; Beyerlein, I.J.; Knezevic, M. Texture evolution and enhanced grain refinement under high-pressure-double-torsion. Mater. Sci. Eng. A 2014, 611, 29–36. [Google Scholar] [CrossRef]

- Qiao, X.G.; Gao, N.; Starink, M.J. A model of grain refinement and strengthening of al alloys due to cold severe plastic deformation. Philos. Mag. 2012, 92, 446–470. [Google Scholar] [CrossRef]

- Bachmaier, A.; Pippan, R. Generation of metallic nanocomposites by severe plastic deformation. Int. Mater. Rev. 2013, 58, 41–62. [Google Scholar] [CrossRef]

- Xu, C.; Xia, K.; Langdon, T.G. The role of back pressure in the processing of pure aluminum by equal-channel angular pressing. Acta Mater. 2007, 55, 2351–2360. [Google Scholar] [CrossRef]

- Harsha, R.; Kulkarni, V.M.; Babu, B.S. Severe plastic deformation-a review. Mater. Today Proc. 2018, 5, 22340–22349. [Google Scholar] [CrossRef]

- Valiev, R.; Korznikov, A.; Mulyukov, R. Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater. Sci. Eng. A 1993, 168, 141–148. [Google Scholar] [CrossRef]

- Sadasivan, N.; Balasubramanian, M. Severe plastic deformation of tubular materials–process methodology and its influence on mechanical properties–a review. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Zare, H.; Jahedi, M.; Toroghinejad, M.R.; Meratian, M.; Knezevic, M. Microstructure and mechanical properties of carbon nanotubes reinforced aluminum matrix composites synthesized via equal-channel angular pressing. Mater. Sci. Eng. A 2016, 670, 205–216. [Google Scholar] [CrossRef] [Green Version]

- Zare, H.; Jahedi, M.; Toroghinejad, M.R.; Meratian, M.; Knezevic, M. Compressive, shear, and fracture behavior of cnt reinforced al matrix composites manufactured by severe plastic deformation. Mater. Des. 2016, 106, 112–119. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Huang, G.; Liu, S.; Han, T.; Jiang, B.; Tang, A.; PAN, F.; ZHU, Y. Grain refinement and mechanical properties of pure aluminum processed by accumulative extrusion bonding. Trans. Nonferrous Met. Soc. China 2019, 29, 437–447. [Google Scholar] [CrossRef]

- Chen, X.; Xia, D.; Zhang, J.; Huang, G.; Liu, K.; Tang, A.; Jiang, B.; Pan, F. Ultrafine-grained al–zn–mg–cu alloy processed via cross accumulative extrusion bonding and subsequent aging: Microstructure and mechanical properties. J. Alloys Compd. 2020, 846, 156306. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, J.; Xia, D.; Huang, G.; Liu, K.; Jiang, B.; Tang, A.; Pan, F. Microstructure and mechanical properties of 1060/7050 laminated composite produced via cross accumulative extrusion bonding and subsequent aging. J. Alloys Compd. 2020, 826, 154094. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, J.; Chen, X.; Huang, G.; Xia, D.; Tang, A.; Zhu, Y.; Jiang, B.; Pan, F. Improving mechanical properties of heterogeneous mg-gd alloy laminate via accumulated extrusion bonding. Mater. Sci. Eng. A 2020, 785, 139324. [Google Scholar] [CrossRef]

- Mehr, V.Y.; Toroghinejad, M.R.; Rezaeian, A. The effects of oxide film and annealing treatment on the bond strength of al–cu strips in cold roll bonding process. Mater. Des. 2014, 53, 174–181. [Google Scholar] [CrossRef]

- Ana, S.A.; Reihanian, M.; Lotfi, B. Accumulative roll bonding (arb) of the composite coated strips to fabricate multi-component al-based metal matrix composites. Mater. Sci. Eng. A 2015, 647, 303–312. [Google Scholar] [CrossRef]

- Mozaffari, A.; Hosseini, M.; Manesh, H.D. Al/ni metal intermetallic composite produced by accumulative roll bonding and reaction annealing. J. Alloys Compd. 2011, 509, 9938–9945. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R. Effect of friction, annealing conditions and hardness on the bond strength of al/al strips produced by cold roll bonding process. Mater. Des. 2010, 31, 4508–4513. [Google Scholar] [CrossRef]

- Chitkara, N.; Aleem, A. Extrusion of axi-symmetric bi-metallic tubes from solid circular billets: Application of a generalised upper bound analysis and some experiments. Int. J. Mech. Sci. 2001, 43, 2833–2856. [Google Scholar] [CrossRef]

- Chaudhari, G.; Andhale, S.; Patil, N. Experimental evaluation of effect of die angle on hardness and surface finish of cold forward extrusion of aluminum. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 334–338. [Google Scholar]

- Vaidyanath, L.; Nicholas, M.; Milner, D. Pressure welding by rolling. Br. Weld. J. 1959, 6, 13–28. [Google Scholar]

- Hua, F.; Yang, Y.; Zhang, Y.; Guo, M.; Guo, D.; Tong, W.; Hu, Z. Three-dimensional finite element analysis of tube spinning. J. Mater. Process. Technol. 2005, 168, 68–74. [Google Scholar] [CrossRef]

- Xia, Q.; Xie, S.W.; Huo, Y.; Ruan, F. Numerical simulation and experimental research on the multi-pass neck-spinning of non-axisymmetric offset tube. J. Mater. Process. Technol. 2008, 206, 500–508. [Google Scholar] [CrossRef]

- Ardeljan, M.; Knezevic, M.; Nizolek, T.; Beyerlein, I.J.; Mara, N.A.; Pollock, T.M. A study of microstructure-driven strain localizations in two-phase polycrystalline hcp/bcc composites using a multi-scale model. Int. J. Plast. 2015, 74, 35–57. [Google Scholar] [CrossRef]

- Dallas, D.B. Tool and Manufacturing Engineers Handbook, 3rd ed.; McGraw Hill Inc.: New York, NY, USA, 1976. [Google Scholar]

- McCauley, E.O.A.C.J. Tool Steels, 28th ed.; Industrial Press Inc.: New York, NY, USA, 2008. [Google Scholar]

- Thermal Diffusion (VCTDH) Coatings. Available online: https://www.ibccoatings.com/thermal-diffusion-td-coatings (accessed on 12 January 2021).

- de Moraes Costa, A.L.; da Silva, U.S.; Valberg, H.S. On the friction conditions in fem simulations of cold extrusion. Procedia Manuf. 2020, 47, 231–236. [Google Scholar] [CrossRef]

- Zecevic, M.; McCabe, R.J.; Knezevic, M. A new implementation of the spectral crystal plasticity framework in implicit finite elements. Mech. Mater. 2015, 84, 114–126. [Google Scholar] [CrossRef] [Green Version]

- Knezevic, M.; Beyerlein, I.J. Multiscale modeling of microstructure-property relationships of polycrystalline metals during thermo-mechanical deformation. Adv. Eng. Mater. 2018, 20, 1700956. [Google Scholar] [CrossRef]

- Knezevic, M.; Kalidindi, S.R. Crystal plasticity modeling of microstructure evolution and mechanical fields during processing of metals using spectral databases. JOM 2017, 69, 830–838. [Google Scholar] [CrossRef]

- Madaah-Hosseini, H.; Kokabi, A. Cold roll bonding of 5754-aluminum strips. Mater. Sci. Eng. A 2002, 335, 186–190. [Google Scholar] [CrossRef]

- Fattah-Alhosseini, A.; Imantalab, O.; Mazaheri, Y.; Keshavarz, M. Microstructural evolution, mechanical properties, and strain hardening behavior of ultrafine grained commercial pure copper during the accumulative roll bonding process. Mater. Sci. Eng. A 2016, 650, 8–14. [Google Scholar] [CrossRef]

- Babaei, A.; Mashhadi, M. Tubular pure copper grain refining by tube cyclic extrusion–compression (tcec) as a severe plastic deformation technique. Prog. Nat. Sci. Mater. Int. 2014, 24, 623–630. [Google Scholar] [CrossRef] [Green Version]

- Alvandi, H.; Farmanesh, K. Microstructural and mechanical properties of nano/ultra-fine structured 7075 aluminum alloy by accumulative roll-bonding process. Procedia Mater. Sci. 2015, 11, 17–23. [Google Scholar] [CrossRef] [Green Version]

| Process | Surface | Material | Before μm RA√ | After μm RA√ | % Increase |

|---|---|---|---|---|---|

| Rotary brush | Inner diameter | Copper | 1.15 | 1.49 | 29.6 |

| Handheld brush | Outer diameter | Aluminum | 0.32 | 0.47 | 46.8 |

| Deformation | D1 mm | D2 mm | D3 mm |

|---|---|---|---|

| 52% | 28.70 | 22.07 | 25.25 |

| 68% | 28.70 | 22.07 | 24.18 |

| Characteristic | AISI A2 Tool Steel |

|---|---|

| Safety in hardening | A |

| Depth of hardening | A |

| Resistance to decarburization | B |

| Stability of shape in heat treatment | A |

| Machinability | E |

| Hot hardness | C |

| Wear resistance | B/C |

| Toughness | E |

| Coating Information | Result |

|---|---|

| Thickness (µm) | 5.08–7.62 |

| Micro hardness (HV) | 3500–3800 |

| Coefficient of friction | 0.08 |

| Composition | Vanadium carbide |

| Material | Mill | Annealed |

|---|---|---|

| Copper | 141.1 | 56.1 |

| Aluminum | 126.4 | 40.7 |

| Material | Strength Coefficient K, MPa | Strain Hardening Exponent n |

|---|---|---|

| Copper | 531.78 | 0.3935 |

| Aluminum | 266.25 | 0.3515 |

| 52% Deformation | |||

| Material | 2-layer | 4-layer | 8-layer |

| copper-aluminum | Yes * | Yes * | Yes * |

| copper-copper | Yes * | ||

| 68% Deformation | |||

| Material | 2-layer | 4-layer | 8-layer |

| copper-copper | Yes | ||

| Layers | 2 | 4 | 8 | |||

|---|---|---|---|---|---|---|

| Material | Cu | Al | Cu | Al | Cu | Al |

| Expected | 794 | 794 | 396 | 396 | 198 | 198 |

| Average | 819 | 775 | 414 | 375 | 212 | 200 |

| Minimum | 802 | 743 | 385 | 349 | 0 | 0 |

| Maximum | 847 | 798 | 462 | 402 | 440 | 504 |

| Deformation | Annealed | 2-Layer | Increase (%) |

|---|---|---|---|

| 52% | 56.1 | 148.8 | 165.1 |

| 68% | 56.1 | 150.7 | 168.5 |

| Material | Annealed | 2-Layer | Increase (%) | 4-Layer | Increase (%) |

|---|---|---|---|---|---|

| Copper | 56.1 | 144.0 | 156.6 | 146.9 | 161.9 |

| Aluminum | 40.7 | 72.8 | 78.9 | 71.8 | 76.4 |

| Process | Iteration | Ultimate Tensile Strength (MPa) | Percent Difference to Annealed (%) |

|---|---|---|---|

| 68% AEB | 1 | 683 | 172% |

| ARB [70] | 1 | 350 | 39% |

| ARB [70] | 2 | 370 | 47% |

| ARB [70] | 3 | 395 | 57% |

| ARB [70] | 4 | 395 | 57% |

| TCEC [71] | 1 | 275 | 10% |

| TCEC [71] | 2 | 300 | 20% |

| TCEC [71] | 3 | 310 | 24% |

| TCEC [71] | 4 | 325 | 29% |

| Annealed | - | 251 | 0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Standley, M.R.; Knezevic, M. Towards Manufacturing of Ultrafine-Laminated Structures in Metallic Tubes by Accumulative Extrusion Bonding. Metals 2021, 11, 389. https://doi.org/10.3390/met11030389

Standley MR, Knezevic M. Towards Manufacturing of Ultrafine-Laminated Structures in Metallic Tubes by Accumulative Extrusion Bonding. Metals. 2021; 11(3):389. https://doi.org/10.3390/met11030389

Chicago/Turabian StyleStandley, Matthew R., and Marko Knezevic. 2021. "Towards Manufacturing of Ultrafine-Laminated Structures in Metallic Tubes by Accumulative Extrusion Bonding" Metals 11, no. 3: 389. https://doi.org/10.3390/met11030389

APA StyleStandley, M. R., & Knezevic, M. (2021). Towards Manufacturing of Ultrafine-Laminated Structures in Metallic Tubes by Accumulative Extrusion Bonding. Metals, 11(3), 389. https://doi.org/10.3390/met11030389