Abstract

The phase and microstructure formation as well as mechanical properties of the rapidly solidified Mg67Ag33 (at. %) alloy were investigated. Owing to kinetic constraints effective during rapid cooling, the formation of equilibrium phases is suppressed. Instead, the microstructure is mainly composed of oversaturated hexagonal closest packed Mg-based dendrites surrounded by a mixture of phases, as probed by X-ray diffraction, electron microscopy and energy dispersive X-ray spectroscopy. A possible non-equilibrium phase diagram is suggested. Mainly because of the fine-grained dendritic and interdendritic microstructure, the material shows appreciable mechanical properties, such as a compressive yield strength and Young’s modulus of 245 ± 5 MPa and 63 ± 2 GPa, respectively. Due to this low Young’s modulus, the Mg67Ag33 alloy has potential for usage as biomaterial and challenges ahead, such as biomechanical compatibility, biodegradability and antibacterial properties are outlined.

1. Introduction

Mg and its alloys are known to be employed as structural materials for light-weight applications, due to their low density [1,2]. In general, Mg-based alloys show poor strength and plastic deformation, particularly at low temperatures [3]. The reason behind this is the limited number of slip systems. Twinning is a further deformation mode extensively investigated and which entails low temperature anisotropy and strain hardening in Mg-based alloys, too [2,3,4]. Effective measures for improving their strength and, hence, modulating their microstructure are diverse and encompass, for instance, processing at higher cooling rates to obtain finer grained microstructures or just by replacing rather adding further alloying elements [1,3,4,5]. Latter strategy can be described as alloy-design resulting in altered phase formation involving evolution of desired precipitations [6] and led to the development of a series of commercially employed alloys [7].

Nowadays, Mg-based alloys also attract attention as implant material [8]. Aside the low density, required mechanical properties of load-bearing implant materials are low elastic modulus, high yield strength in compression as well as tension and ultimate strength for load-bearing applications. Further required properties are wear resistance and osseointegration, which is defined as connection between the cell-bones and the surface of the implant. More recently also biodegradability is more in the focus of research, since it is required to achieve tissue regeneration [8]. Compared to for instance polymers, metallic materials have been widely used in orthopedic applications, due to their higher mechanical strength. Most prominent alloys are stainless steel or are based on cobalt–chromium as well as titanium and they are commercially available as implants [8]. All three material classes have one common big drawback, namely the low biomechanical compatibility, which requires the match to the Young’s moduli of the bone (about 30 GPa) [9,10,11,12,13,14]. If the implant has a distinctly higher Young’s modulus, E, it considerably takes over the loading, so that the bone is shielded from the necessary stress required to maintain its strength, density, and healthy structure. This phenomenon is known as “stress-shielding” and can lead to resorption of the bone which is in direct vicinity with the implant material [11]. Finally, stress-shielding can lead to premature failure or loosening of the implant [11,12,15,16]. Commercially used metallic implant materials, like cobalt–chromium (200–230 GPa), titanium alloys (66–110 GPa) and stainless steel (200 GPa) show high Young’s modulus [17] and density when compared to the human cortical bone. Another major drawback of the commercially available implant material is their non-degradability in the body environment, so that surgical procedure is necessary for their removal after the bone is healed. Therefore, at present, a great amount of research is focused on developing biodegradable, low density and bioactive implants without compromising the strength [8]. Mg and its alloys fulfill these requirements, since they show similar density (about 2 g/cm3) and Young’s modulus (45 GPa) as the bone [8]. Moreover, Mg is also one of the most abundant elements present in the human body with proven biocompatibility [18,19,20,21].

However, Mg has not prevailed as a load-bearing implant material due to its low strength. The main strategies for enhancing it can be borrowed from the already well investigated Mg-based alloys used for structural applications, namely grain refinement and alloy design including solid solution as well as precipitation strengthening [8]. Hereby, the selection of alloying elements to Mg must be not only based on improving mechanical properties, but also biocompatibility. Therefore, elements known from Mg-based alloys typically used for lightweight such as Al are not always suitable and other alloying elements must be identified. Works indicate Al to be possibly allergic [22]. By contrast, Ag is an element known to be biocompatible and Ag-additions to Mg increase the hardness and strength of the resulting solid solution [23]. A further measure to increase the strength is casting at high cooling rates, which can lead to the formation of fine-grained microstructures which also consist of oversaturated Mg-based solid solution [24,25]. Another positive property of Ag is its antibacterial effect [8]. The resulting Mg–Ag-based alloys could yield implant material with antibacterial surfaces which are generally categorized either as being antibiofouling or bactericidal. Antibiofouling surfaces may repel the initial attachment of bacteria, whereas bactericidal surfaces as imparted by Ag-additions inactivate bacteria by causing their death [26,27,28,29]. There are multiple differing approaches in designing antibacterial surfaces which have one common aim: to prevent the initial attachment of the bacteria and, hence, prevent the subsequent formation of a biofilm [26]. Therefore, Ag-based coatings are widely employed as antibacterial measures [27,30,31]. Nevertheless, the use of surface antibacterial coatings has also demonstrated several shortcomings. They are often not uniform, mechanically weak and they lack long-term durability, so they may be insufficient to maintain their antibacterial behavior for long periods [32,33,34,35]. Another solution for designing long-term durable antibacterial metallic implant materials would be alloying with a substantial volume fraction of bactericidal metallic element(s), such as Ag.

So far, only small additions of Ag to Mg have been investigated [36], so that only solid solution hardening of hexagonal closest packed (hcp) Mg was utilized. In order to further enhance the strength of Mg-Ag-based material, increasing the Ag-content would be a strategy, since it entails the formation of further binary phases possibly imparting precipitation strengthening. In order to fulfill the biomechanical compatibility-requirement, the resulting Mg–Ag composite should not feature a much high Young’s modulus than pure Mg. However, the first step in designing such a binary Mg–Ag-based composite is to select a binary composition and investigate the phase formation and microstructure. Mg67Ag33 appears to be a promising candidate, since according to the corresponding phase diagram, next to the ductile β′MgAg phase, the intermetallic Mg54Ag17 phase should form under solidification at near-equilibrium conditions. The latter phase could impart precipitation hardening. In order to extend the region of the also desired ductile β′MgAg phase, solidification at high cooling rates or rephrased non-equilibrium is a reasonable approach. Due to evolving kinetic constraints, the phase formation will be affected [37,38]. Therefore, in the present work, the binary Mg67Ag33 alloy is processed by copper mold casting at non-equilibrium conditions and the imparted phase formation as well as microstructure are studied. Here, we want to investigate whether the β′MgAg phase region is widened when the binary alloy is rapidly solidified. A further goal is to synthesize Mg–Ag-based material with high strength and, hence, exploit the mechanism of grain refinement caused by solidification at higher cooling rates. From additional uniaxial compression tests, the strength and Young’s modulus of the Mg–Ag-based alloy are determined to evaluate whether the obtained material fulfills the required biomechanical compatibility and outline the challenges with respect to antibacterial properties and biodegradability ahead.

2. Materials and Methods

The Mg67Ag33 prealloyed ingots were prepared from high-purity elements (purity ≥ 99.99%) by induction-melting in an Ar-atmosphere. Ingots with an approximate weight of 5–6 g were used to fabricate 50 mm long rods with a diameter of 3 mm via induction casting into a copper mold, whereby the recipient pressure was set to 1bar (Induret, Feinwerktechnik GmbH, Bad Essen, Germany). The specimens were investigated by X-ray diffraction (XRD) using a D3290 PANalytical X′pert PRO with Cu-Kα radiation (λ = 0.17889 nm) in Bragg–Brentano configuration (Malvern Panalytical, Malvern, UK). Microstructural investigations were carried out with a Zeiss Gemini 1530 electron microscope (Carl ZeissAG, Oberkochen, Germany) equipped with a Bruker Xflash 4010 spectrometer (Bruker Corporation, Billerica, MA, USA) enabling energy-dispersive x-ray spectroscopy (EDX). Specimens with an aspect ratio of 2:1 (6 mm length and 3 mm diameter) were subjected to uniaxial compression using an Instron 5869 at a constant displacement rate of 6 × 10−4 mm/s (Instron, Norwood, MA, USA). Both cross-sectional areas which are in contact with the testing device were lubricated (MOLYKOTE paste) prior to testing. The strain was directly monitored at the lateral surface of the samples using a laser-extensometer (Fiedler Optoelektronik GmbH, Lützen, Germany). The yield strength was determined at 0.2%-offset.

3. Results and Discussion

3.1. Phase and Microstructure Formation

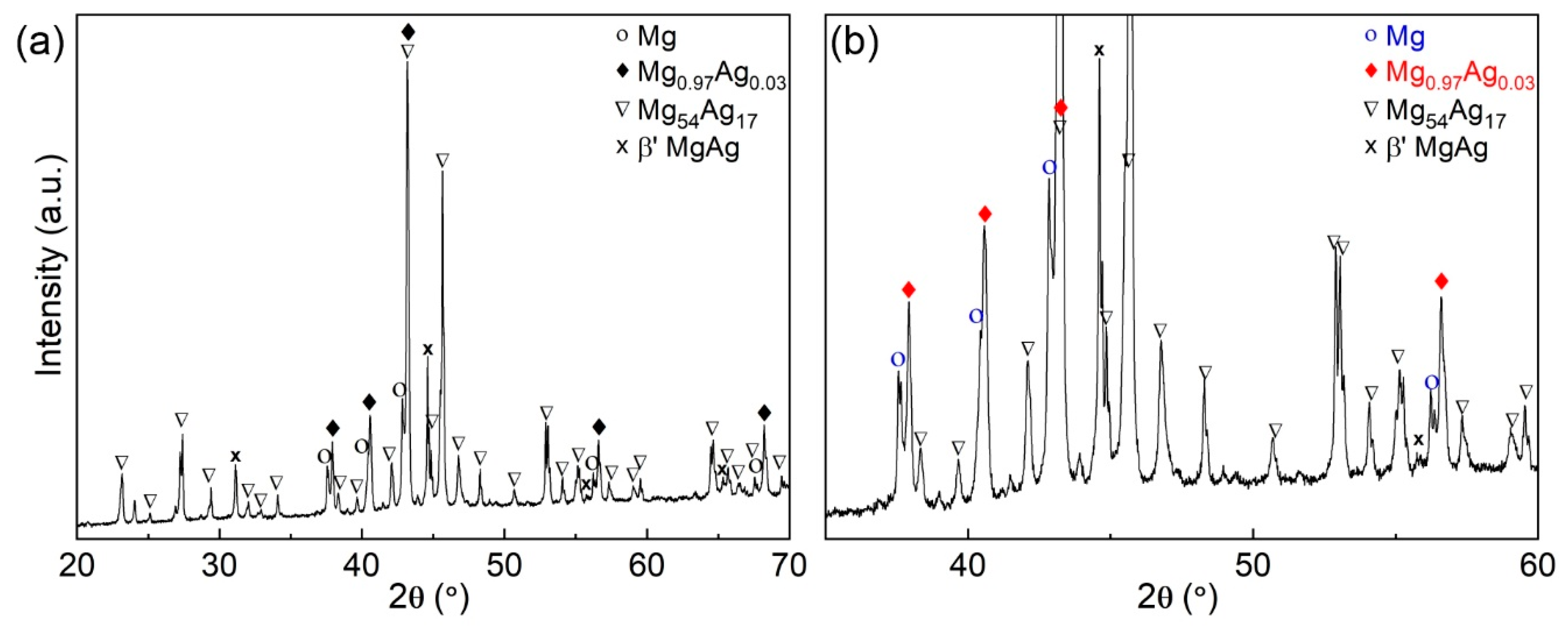

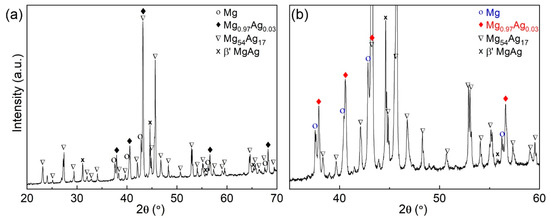

Figure 1 shows a representative XRD pattern of the binary Mg67Ag33 alloy solidified at conditions far from equilibrium by suction casting. Sharp reflections corresponding to the hcp Mg and Mg0.97Ag0.03 phases as well as the binary phases β′MgAg () and orthorhombic Mg54Ag17 phases can be observed. Reflections with highest intensity originate from the Mg0.97Ag0.03 and Mg54Ag17 phases, so that the microstructure appears to be mainly composed of them.

Figure 1.

X-ray diffraction pattern of a Mg67Ag33 specimen solidified at high cooling rates by suction casting. The microstructure is composed of the Mg, Mg0.97Ag0.03, β′MgAg and Mg54Ag17 phases and their reflections are indicated. (a) Overview over whole measured 2θ-range and (b) the magnified section highlights both hcp Mg phases.

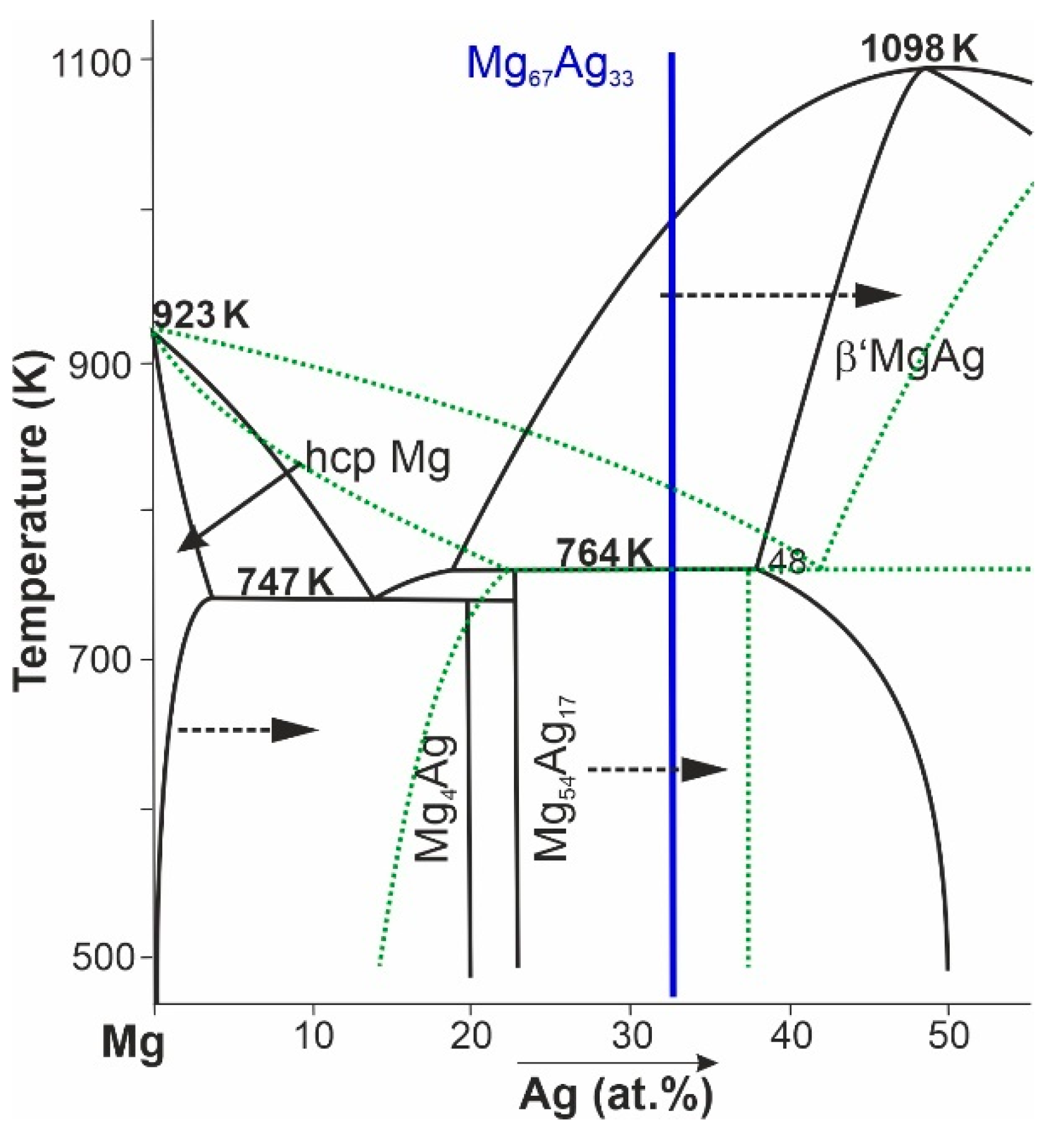

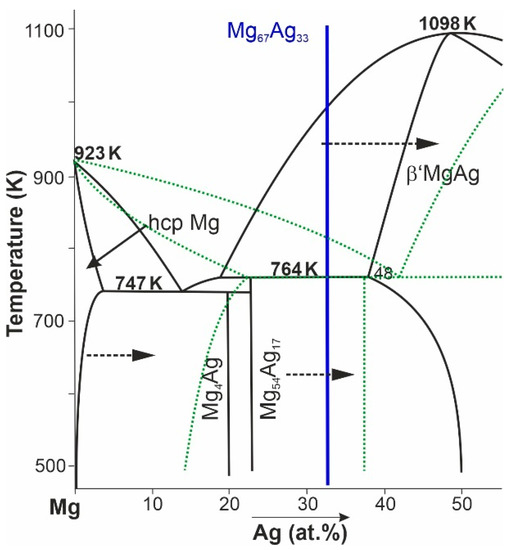

Based on the binary equilibrium phase diagram (Figure 2), one would expect the supercooled liquid to firstly crystallize into the β′MgAg phase during cooling. The residual liquid should subsequently crystallize into the Mg54Ag17, γ-Mg4Ag and hcp Mg phases [39,40]. Consequently, a substantial fraction of the β′MgAg phase should form.

Figure 2.

Schematic illustration of shifting phase boundaries during the solidification of Mg67Ag33 (blue line) at about 50 K/s superposed on a segment of the binary Mg–Ag equilibrium phase diagram. The shifted phase boundaries characterize the non-equilibrium solidification, and they are depicted as dashed green lines. The equilibrium phase diagram was created on data reported in [39].

No further phases were identified by XRD, although the thermodynamically-stable γ-Mg4Ag [41] phase should be also present according to the near-equilibrium phase diagram (Figure 2). However, the Mg67Ag33 specimens were prepared via melt-quenching at fast cooling rates. In this casting technique, heat is extracted via water-cooled copper-mold, which guarantees rapid cooling conditions, far from equilibrium. In the present case, specimens 3 mm in diameter were cast, which corresponds to cooling rates of at least 50 K/s [42], as has been experimentally determined from interlamellar spacing of the eutectic Al-33 wt. % alloy and later successfully employed for estimating the cooling rates inherent to quenching in a water bath [43] or laser powder bed fusion, an additive manufacturing technique [44]. High cooling rates impose kinetic constraints, which can lead to the precipitation of metastable phases whose formation can be favored over the corresponding thermodynamically stable phases [45,46,47]. In the present case, the formation of the γ-Mg4Ag phase must have been suppressed, due to rapid cooling. Such a phenomenon is also present in Cu50Zr50-based alloys, where the formation of low-temperature equilibrium phases can be completely suppressed during rapid solidification [48,49]. The effect of kinetic constraints on the phase formation can be illustrated using a non-equilibrium phase diagram. Figure 2 displays a possible shift of the phase boundaries during melt-quenching at 50 K/s that leads to the phase formation observed.

Once the liquidus temperature is crossed during rapid cooling of the Mg67Ag33 melt (blue line in Figure 2), the hcp Mg phases crystallize at first. At such fast quenching, the solubility of this phase is greatly enlarged towards higher Ag-contents resulting in supersaturated hcp Mg and, here, additionally the formation of the binary hcp Mg0.97Ag0.03 phase. Both phases have the same crystal structure, as can be seen from the XRD pattern (Figure 1). A splitting of all reflections characteristic for hcp Mg could be observed. Such a splitting can indicate the presence of two phases with the same structure, but slightly different lattice parameters due to slightly varying chemical composition. Another reason could be the XRD-measurements with two wavelengths like Cu(Kα,1) and Cu(Kα,2), which is not the case here, since a monochromator leading to only Cu(Kα,1) radiation was used. Furthermore, cooling the residual supercooled liquid crystallizes into the Mg54Ag17 phase followed by the formation of a eutectic which further consists of the β′MgAg phase.

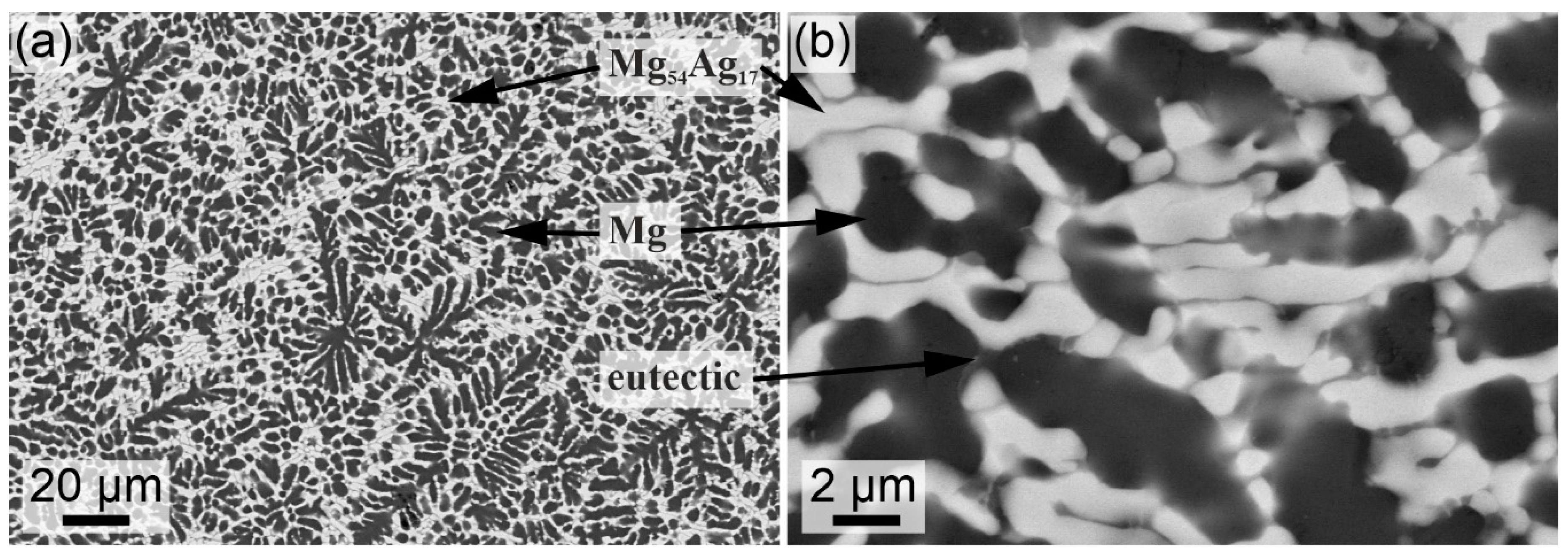

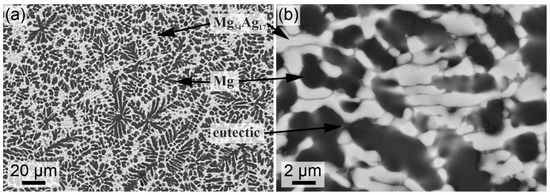

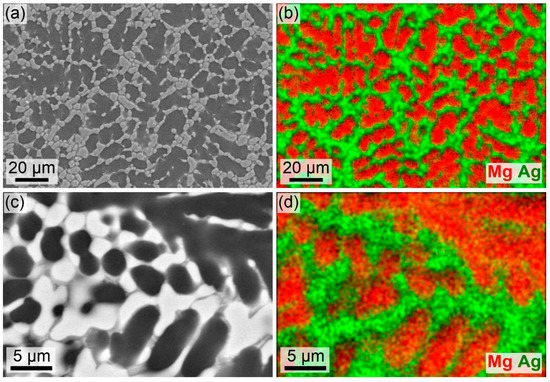

The prevailing cooling rates not only govern the phase formation, but also the microstructural evolution during solidification. Under consideration of the specific alloy composition, the cooling rates can dictate the occurrence and degree of segregation, supersaturation and the grain size as well as morphology in alloys [45,46,48,49,50,51,52,53]. Figure 3 displays the typical microstructure of the rapidly solidified Mg67Ag33 alloy. The microstructure consists of a dendritic phase (dark contrast in Figure 3a) surrounded by an interdendritic phase.

Figure 3.

Microstructure of the rapidly solidified Mg67Ag33 alloy: (a) a secondary electron micrograph depicts hcp Mg dendrites surrounded by a phase mixture. (b) The secondary electron micrograph at higher magnification highlights the structure of the interdendritic phase.

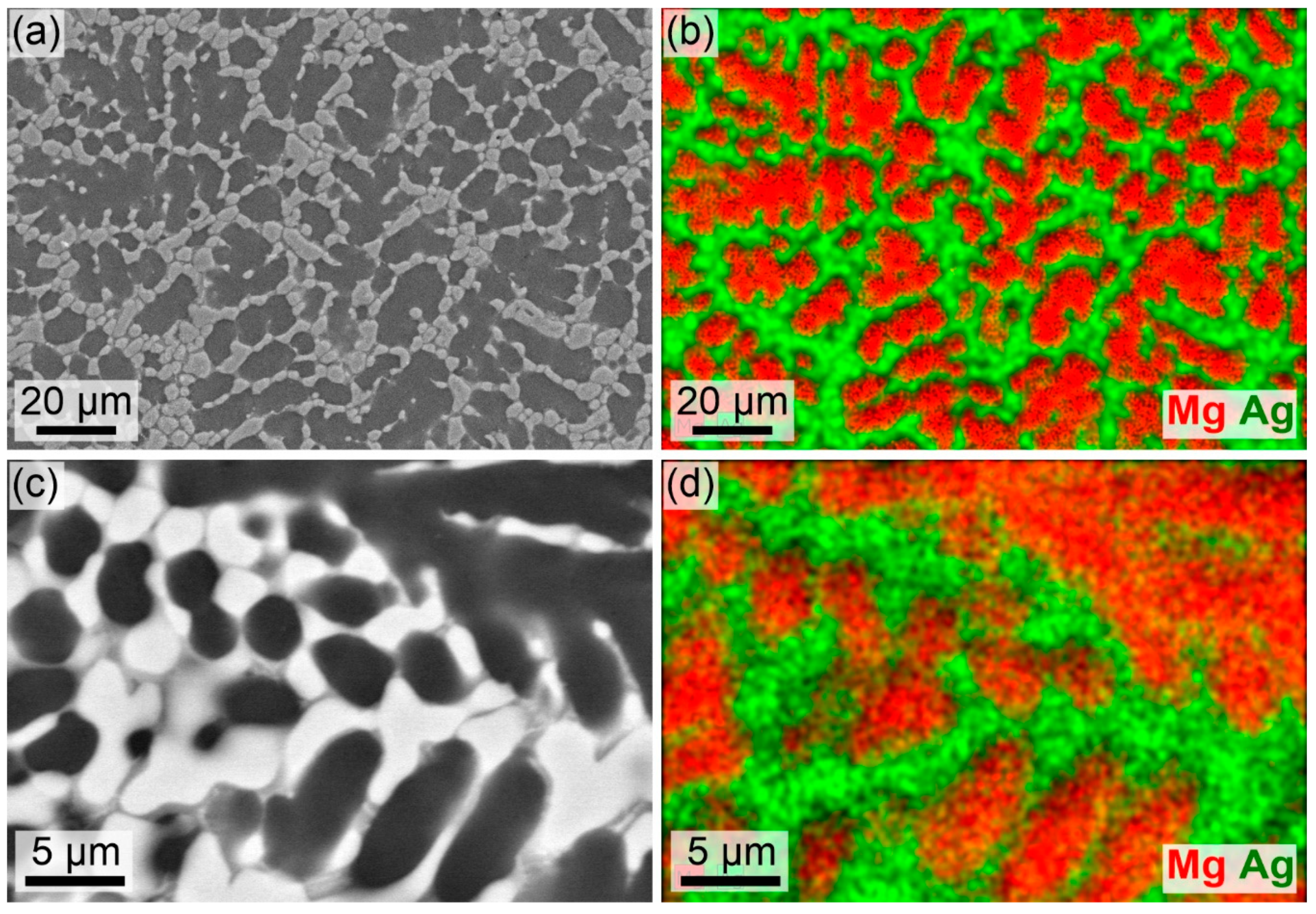

The SEM image at higher magnification (Figure 3b) permits description of the interdendritic structure with differing contrast. It consists of elongated crystals, which seem to be connected by a eutectic phase. Energy X-ray dispersive mapping allows allocation of the phases to the microstructural features. The hcp Mg and Mg0.97Ag0.03 phases crystallize as darker dendrites, and they are surrounded by an interdendritic phase enriched in Ag (Figure 4a,b).

Figure 4.

Secondary electron microscopic (SEM) images and energy X-ray dispersive (EDX) maps of the Mg67Ag33 microstructure: (a) SEM image and (b) corresponding EDX map illustrate the overall microstructure. (c) SEM image at higher magnification and (d) respective EDX map of the interdendritic phases.

According to the XRD results, the microstructure also includes the Mg54Ag17 phase and this is in line with the EDX results (Figure 4). The interdendritic phase consists of crystals, which are enriched in Ag when compared to the hcp Mg phases (Figure 4b,d). By contrast, the interconnecting eutectic phase seems to be more depleted in Ag (Figure 4c,d: less intense green coloring) and according to the XRD results (Figure 1) must then also consist of the equiatomic β′MgAg phase. The presence of such interdendritic structures is quite effective for strengthening the material, as will be discussed next.

3.2. Mechanical Properties

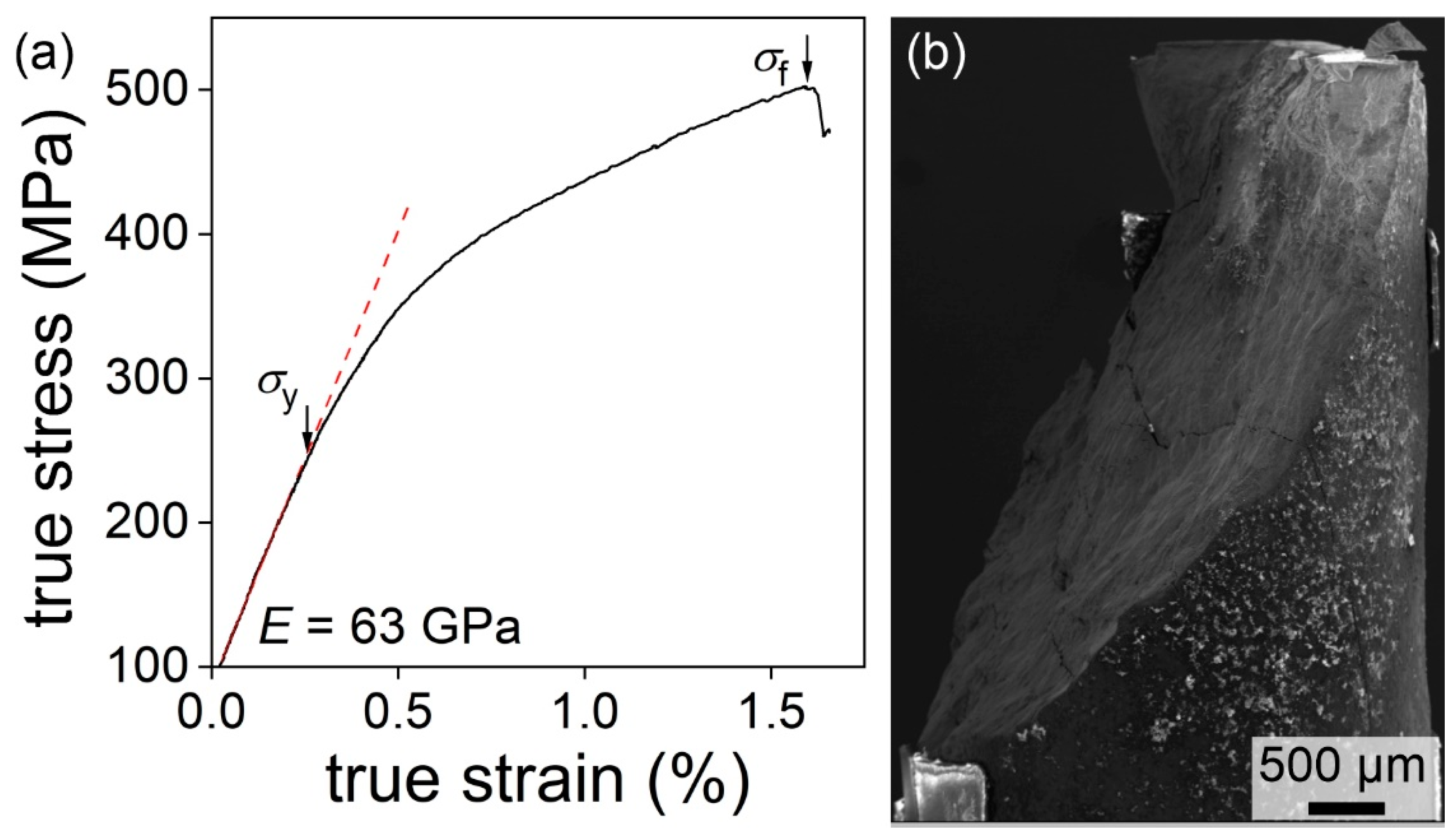

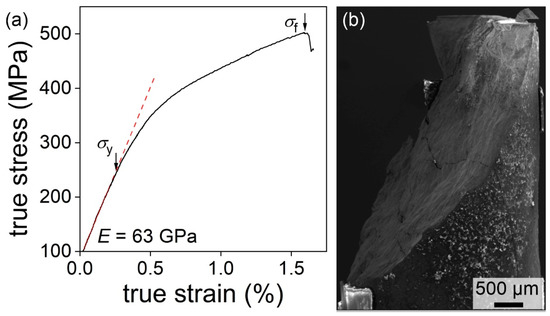

The mechanical properties, particularly the Young’s modulus, E, yield strength, σy, and fracture strength, σf, are of interest for load-bearing implant materials [8]. Therefore, Mg67Ag33 samples were subjected to uniaxial compression at room temperature and Figure 5a depicts representative true stress–strain curves. At first elastic deformation with a Young’s modulus of 63 ± 2 GPa can be observed up to yielding which sets in at 245 ± 5 MPa. Afterwards, the stress augments with increasing strain leading to pronounced work hardening up to 503 ± 15 MPa, where fracture occurs at about 1.6 ± 0.11% strain. By contrast, unalloyed samples with a microstructure only consisting of hcp Mg dendrites (average size of about 30 µm) show a yield and fracture strength of 60 MPa and 315 MPa, respectively [36]. Due to arising friction at the cross-sectional areas which are in contact with the testing machine, barreling could occur during uniaxial compressive loading. This was not the case in the present work since a lubricating paste was used and the SEM image of a fractured specimen demonstrates no barreling (Figure 5b). Two deformation mechanisms prevail for hcp Mg, which are the “{0001} < >” basal dislocation slip and the “{} < >” extension twinning, whereby the twinning is only active when positive stress is applied along the c-axis of the unit cell [36].

Figure 5.

Characteristics of rapidly solidified Mg67Ag33 subjected to uniaxial compression. (a) True stress–strain curve with indicated Young’s modulus, E, yield strength, σy, and fracture strength, σf. (b) SEM image of a fractured specimen. No barreling was observed.

The Mg67Ag33 samples show distinctly higher yield and fracture strengths and the reasons behind will be addressed next. First of all, the present specimens were cast at much higher cooling rates entailing larger supercooling and, hence, the growth of more supercritical nuclei which led to the evolution of a very fine-grained microstructure [54]. The higher volume fraction of grain boundaries hinders dislocation movement. Besides grain-refinement, the hcp Mg crystals are oversaturated in Ag, so that solid solution strengthening is also effective [54]. Next to the additional Mg0.97Ag0.03 crystals, the interdendritic phase, consisting of the Mg54Ag17 and β′MgAg phases is present. Both phases completely different in composition and crystallographic symmetry seemed to form a eutectic within this compound phase. The involved phase boundaries with different morphologies may lead to effective pinning of the dislocations [55]. Owing to these three mechanisms, a much stronger material (σy = 245 ± 5 MPa) than pure hcp Mg (σy = 60 MPa [36]) results, which is desirable for the application as a load-bearing implant. Although this alloy exhibits a substantial fraction of Ag, its Young’s modulus did only slightly increase up to 63 ± 2 GPa when compared to hcp Mg (60 GPa [36]), which is many times lower than implant materials currently in service, such as steel (200 GPa), cobalt–chromium (200–230 GPa) or Ti6Al4V (112 GPa). A relatively good biomechanical match with the bone can be expected and the occurrence of the stress-shielding phenomenon is then less likely. Thus, the original goal of strengthening the material, while not perceptibly increasing the Young’s modulus was fulfilled. Aside the biomechanical performance of the present Mg67Ag33 material, its bactericidal properties and effect on cell viability is another aspect which should be studied next. Based on the relatively high Ag-content, one could expect positive antibacterial properties leading to decreasing survival rates of pathogenic bacteria. The effect is based on the release of Ag-ions causing damage to the bacterial membrane, which in turn disrupts the function of the bacterial enzymes and/or nucleic acids [3,24,25]. The higher Ag-content also led to the formation of a significant volume fraction of interdendritic compound phase and, hence, to the formation of a heterogeneous microstructure. Therefore, increased and more heterogeneous rates should be effective during corrosion [23,56]. This is a critical aspect, since rather low corrosion rates are especially desirable for biodegradable implant material in physiological environment. Further investigations on determining the corrosion rate for the present Mg67Ag33 material are indispensable, since one aims at controlling the degradation of the implant. The controlled degradation of this metastable Mg67Ag33 material poses, hence, a challenge, which must be overcome in the future. Eventually a reduction in the Ag-content leading to the formation of less interdendritic compound phase might be necessary, so that a less heterogeneous microstructure, which is still strong, is produced.

4. Conclusions

Mg-based alloys show low Young’s modulus close to that of bone and are therefore potential candidates as load-bearing implant materials. Such biomaterials suffer from the formation of biofilms on their surface, due to colonialization of bacteria. In the current work, a substantial fraction of Ag was alloyed to hcp Mg, since Ag has a distinct antibacterial effect entailing the significant reduction in biofilm-formation. From the resulting Mg67Ag33 alloy, specimens were prepared via melt-quenching. Rapid cooling rates of more than 50 K/s are inherent to this casting technology, which led to a metastable phase and microstructure formation. Owing to these effective kinetic constraints, phases, which one would expect to form at near-equilibrium conditions, are being suppressed, while others emerge. Such phenomena could be observed for the Mg67Ag33 alloy. The formation of the thermodynamically stable γ-Mg4Ag phase is suppressed, while oversaturation of hcp Mg occurred even leading to the formation of the structurally similar Mg0.97Ag0.03 phase, as XRD results confirmed. The Mg54Ag17 and β′MgAg phases formed, though to a different volume fraction as one would expect under equilibrium conditions. We visualized the phase formation under such kinetic constraints in a possible non-equilibrium phase diagram. The high cooling rates naturally affected the morphology of the microstructure, too. It is very fine-grained and is composed of hcp Mg and Mg0.97Ag0.03 as dendritic phases enshrouded by a compound phase consisting of Mg54Ag17 and β′MgAg. The finely grained oversaturated Mg crystals and the presence of the interdendritic phase boundaries pose effective measures for dislocation movement and, hence, strengthen. Thus, the cast Mg67Ag33 materials exceeds the yield strength of pure Mg-based materials by far and this is attractive as potential biomaterial. Although binary phases are present, the Young’s modulus is still low and close to that of the bone. Next, the antibacterial performance and properties concerning cell viability and, particularly, corrosion rates of the Mg67Ag33 material in body fluid should be studied to elucidate the biodegradable behavior and to ultimately clarify whether the synthesized binary MgAg-based material can be applied as biomaterial.

Author Contributions

Conceptualization, K.K.; methodology, K.K., K.G.P. and S.S.; validation, K.K., K.G.P. and S.S.; formal analysis, K.K., K.G.P. and S.S.; investigation, K.G.P.; data curation, K.K. and K.G.P.; writing—original draft preparation, K.K.; writing—review and editing, K.K., K.G.P. and S.S.; visualization, K.K., K.G.P. and S.S.; supervision, K.K., K.G.P. and S.S.; funding acquisition, K.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Research Foundation (DFG), grant number KO 5771/1-1.

Data Availability Statement

The data presented in this study are available on reasonable request from the corresponding author.

Acknowledgments

We thank Sven Donath, Romy Keller and Nicole Geißler for experimental support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mordike, B.L.; Ebert, T. Magnesium: Properties–applications–potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Kulekci, M.K. Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851–865. [Google Scholar] [CrossRef]

- Bettles, C.; Gibson, M. Current wrought magnesium alloys: Strengths and weaknesses. JOM 2005, 57, 46–49. [Google Scholar] [CrossRef]

- Yang, Z.; Li, J.; Zhang, J.; Lorimer, G.; Robson, J. Review on Research and Development of Magnesium Alloys. Acta Met. Sin. (Engl. Lett.) 2008, 21, 313–328. [Google Scholar] [CrossRef]

- Papenberg, N.P.; Gneiger, S.; Weißensteiner, I.; Uggowitzer, P.J.; Pogatscher, S. Mg-alloys for forging applications—A Review. Materials 2020, 13, 985. [Google Scholar] [CrossRef]

- Nie, J.-F. Precipitation and Hardening in Magnesium Alloys. Met. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

- Zinszer, W.K. Magnesium, Its Manufacture and Alloys. Trans. Kans. Acad. Sci. 1943, 46, 161. [Google Scholar] [CrossRef]

- Radha, R.; Sreekanth, D. Insight of magnesium alloys and composites for orthopedic implant applications—A review. J. Magnes. Alloys 2017, 5, 286–312. [Google Scholar] [CrossRef]

- Calin, M.; Helth, A.; Gutierrez Moreno, J.J.; Bönisch, M.; Brackmann, V.; Giebeler, L.; Gemming, T.; Lekka, C.E.; Gebert, A.; Schnettler, R.; et al. Elastic softening of β-type Ti–Nb alloys by indium (In) additions. J. Mech. Behav. Biomed. Mater. 2014, 39, 162–174. [Google Scholar] [CrossRef] [PubMed]

- Helth, A.; Pilz, S.; Kirsten, T.; Giebeler, L.; Freudenberger, J.; Calin, M.; Eckert, J.; Gebert, A. Effect of thermomechanical processing on the mechanical biofunctionality of a low modulus Ti-40Nb alloy. J. Mech. Behav. Biomed. Mater. 2017, 65, 137–150. [Google Scholar] [CrossRef]

- Geetha, R.M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Gepreel, M.A.-H.; Niinomi, M. Biocompatibility of Ti-alloys for long-term implantation. J. Mech. Behav. Biomed. Mater. 2013, 20, 407–415. [Google Scholar] [CrossRef] [PubMed]

- He, G.; Hagiwara, M. Ti alloy design strategy for biomedical applications. Mater. Sci. Eng. C 2006, 26, 14–19. [Google Scholar] [CrossRef]

- Deng, L.; Wang, S.; Wang, P.; Kühn, U.; Pauly, S. Selective laser melting of a Ti-based bulk metallic glass. Mater. Lett. 2018, 212, 346–349. [Google Scholar] [CrossRef]

- Huiskes, R.; Weinans, H.; Van Rietbergen, B. The relationship between stress shielding and bone resorption around total hip stems and the effects of flexible materials. Clin. Orthop. Relat. Res. 1992, 274, 124–134. [Google Scholar] [CrossRef]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R Rep. 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Semlitsch, M.; Willert, H.G. Properties of implant alloys for artificial hip joints. Med. Biol. Eng. Comput. 1980, 18, 511–520. [Google Scholar] [CrossRef]

- Yun, Y.; Dong, Z.; Yang, D.; Schulz, M.J.; Shanov, V.N.; Yarmolenko, S.; Xu, Z.; Kumta, P.; Sfeir, C. Biodegradable Mg corrosion and osteoblast cell culture studies. Mater. Sci. Eng. C 2009, 29, 1814–1821. [Google Scholar] [CrossRef]

- Brar, H.S.; Platt, M.O.; Sarntinoranont, M.; Martin, P.I.; Manuel, M.V. Magnesium as a biodegradable and bioabsorbable material for medical implants. JOM 2009, 61, 31–34. [Google Scholar] [CrossRef]

- Chiu, K.; Wong, M.; Cheng, F.; Man, H. Characterization and corrosion studies of fluoride conversion coating on degradable Mg implants. Surf. Coat. Technol. 2007, 202, 590–598. [Google Scholar] [CrossRef]

- Ng, W.; Chiu, K.; Cheng, F. Effect of pH on the in vitro corrosion rate of magnesium degradable implant material. Mater. Sci. Eng. C 2010, 30, 898–903. [Google Scholar] [CrossRef]

- Gu, X.; Zheng, Y.; Cheng, Y.; Zhong, S.; Xi, T. In vitro corrosion and biocompatibility of binary magnesium alloys. Biomaterials 2009, 30, 484–498. [Google Scholar] [CrossRef] [PubMed]

- Tie, D.; Feyerabend, F.; Hort, N.; Hoeche, D.; Kainer, K.U.; Willumeit, R.; Mueller, W.D. In vitro mechanical and corrosion properties of biodegradable Mg-Ag alloys. Mater. Corros. 2013, 65, 569–576. [Google Scholar] [CrossRef]

- Scudino, S.; Sakaliyska, M.; Surreddi, K.B.; Ali, F.; Eckert, J. Structure and mechanical properties of Al–Mg alloys produced by copper mold casting. J. Alloys Compd. 2010, 504, S483–S486. [Google Scholar] [CrossRef]

- Chaubey, A.; Scudino, S.; Prashanth, K.; Eckert, J. Microstructure and mechanical properties of Mg–Al-based alloy modified with cerium. Mater. Sci. Eng. A 2015, 625, 46–49. [Google Scholar] [CrossRef]

- Hasan, J.; Crawford, R.J.; Ivanova, E.P. Antibacterial surfaces: The quest for a new generation of biomaterials. Trends Biotechnol. 2013, 31, 295–304. [Google Scholar] [CrossRef] [PubMed]

- Tiller, J.C.; Liao, C.-J.; Lewis, K.; Klibanov, A.M. Designing surfaces that kill bacteria on contact. Proc. Natl. Acad. Sci. USA 2001, 98, 5981–5985. [Google Scholar] [CrossRef]

- Chung, K.K.; Schumacher, J.F.; Sampson, E.M.; Burne, R.A.; Antonelli, P.J.; Brennan, A.B. Impact of engineered surface microtopography on biofilm formation of Staphylococcus aureus. Biointerphases 2007, 2, 89–94. [Google Scholar] [CrossRef] [PubMed]

- Ivanova, E.P.; Hasan, J.; Webb, H.K.; Truong, V.K.; Watson, G.S.; Watson, J.A.; Baulin, V.A.; Pogodin, S.; Wang, J.Y.; Tobin, M.J.; et al. Natural Bactericidal Surfaces: Mechanical Rupture of Pseudomonas aeruginosa Cells by Cicada Wings. Small 2012, 8, 2489–2494. [Google Scholar] [CrossRef]

- Gordon, O.; Slenters, T.V.; Brunetto, P.S.; Villaruz, A.E.; Sturdevant, D.E.; Otto, M.; Landmann, R.; Fromm, K.M. Silver Coordination Polymers for Prevention of Implant Infection: Thiol Interaction, Impact on Respiratory Chain Enzymes, and Hydroxyl Radical Induction. Antimicrob. Agents Chemother. 2010, 54, 4208–4218. [Google Scholar] [CrossRef]

- Schierholz, J.M.; Lucas, L.J.; Rump, A.; Pulverer, G. Efficacy of silver-coated medical devices. J. Hosp. Infect. 1998, 40, 257–262. [Google Scholar] [CrossRef]

- Zhao, L.; Chu, P.K.; Zhang, Y.; Wu, Z. Antibacterial coatings on titanium implants. J. Biomed. Mater. Res. Part B Appl. Biomater. 2009, 91, 470–480. [Google Scholar] [CrossRef]

- Hume, E.; Baveja, J.; Muir, B.; Schubert, T.; Kumar, N.; Kjelleberg, S.; Griesser, H.; Thissen, H.; Read, R.; Poole-Warren, L.; et al. The control of Staphylococcus epidermidis biofilm formation and in vivo infection rates by covalently bound furanones. Biomaterials 2004, 25, 5023–5030. [Google Scholar] [CrossRef] [PubMed]

- Price, J.S.; Tencer, A.F.; Arm, D.M.; Bohach, G.A. Controlled release of antibiotics from coated orthopedic implants. J. Biomed. Mater. Res. 1996, 30, 281–286. [Google Scholar] [CrossRef]

- Ding, S.-J.; Lee, T.-L.; Chu, Y.-H. Environmental effect on bond strength of magnetron-sputtered hydroxyapatite/titanium coatings. J. Mater. Sci. Lett. 2003, 22, 479–482. [Google Scholar] [CrossRef]

- Wiese, B.; Willumeit-Römer, R.; Letzig, D.; Bohlen, J. Alloying effect of silver in magnesium on the development of microstructure and mechanical properties by indirect extrusion. J. Magnes. Alloys 2020, 9. [Google Scholar] [CrossRef]

- Kosiba, K.; Song, K.; Kühn, U.; Wang, G.; Pauly, S. Glass-forming ability, phase formation and mechanical properties of glass-forming Cu-Hf-Zr alloys. Prog. Nat. Sci. 2019, 29, 576–581. [Google Scholar] [CrossRef]

- Kosiba, K.; Rothkirch, A.; Han, J.; Deng, L.; Escher, B.; Wang, G.; Kühn, U.; Bednarcik, J. Phase formation of a biocompatible Ti-based alloy under kinetic constraints studied via in-situ high-energy X-ray diffraction. Prog. Nat. Sci. 2020, 30. [Google Scholar] [CrossRef]

- Okamoto, H. Ag-Mg (silver-magnesium). J. Phase Equilibria Diffus. 1998, 19, 487. [Google Scholar] [CrossRef]

- Lim, M.; Tibballs, J.E.; Rossiter, P.L. Thermodynamic assessment of the Ag-Mg binary system. Metall. J. 1997, 88, 162–169. [Google Scholar]

- Kudla, C.; Prots, Y.; Leineweber, A.; Kreiner, G. On the crystal structure of γ-AgMg4. Z. Kristallogr. 2005, 220, 102–114. [Google Scholar] [CrossRef]

- Srivastava, R.M.; Eckert, J.; Löser, W.; Dhindaw, B.K.; Schultz, L. Cooling Rate Evaluation for Bulk Amorphous Alloys from Eutectic Microstructures in Casting Processes. Mater. Trans. 2002, 43, 1670–1675. [Google Scholar] [CrossRef]

- Kosiba, K.; Pauly, S. Inductive flash-annealing of bulk metallic glasses. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef]

- Pauly, S.; Wang, P.; Kühn, U.; Kosiba, K. Experimental determination of cooling rates in selectively laser-melted eutectic Al-33Cu. Addit. Manuf. 2018, 22, 753–757. [Google Scholar] [CrossRef]

- Snopiński, P.; Król, M.; Tański, T.; Krupińska, B. Effect of cooling rate on microstructural development in alloy ALMG9. J. Therm. Anal. Calorim. 2018, 133, 379–390. [Google Scholar] [CrossRef]

- Tian, L.; Guo, Y.; Li, J.; Xia, F.; Liang, M.; Bai, Y. Effects of Solidification Cooling Rate on the Microstructure and Mechanical Properties of a Cast Al-Si-Cu-Mg-Ni Piston Alloy. Materials 2018, 11, 1230. [Google Scholar] [CrossRef] [PubMed]

- Kosiba, K.; Scudino, S.; Kobold, R.; Kühn, U.; Greer, A.; Eckert, J.; Pauly, S. Transient nucleation and microstructural design in flash-annealed bulk metallic glasses. Acta Mater. 2017, 127, 416–425. [Google Scholar] [CrossRef]

- Pauly, S.; Kosiba, K.; Gargarella, P.; Escher, B.; Song, K.; Wang, G.; Kühn, U.; Eckert, J. Microstructural Evolution and Mechanical Behaviour of Metastable Cu–Zr–Co Alloys. J. Mater. Sci. Technol. 2014, 30, 584–589. [Google Scholar] [CrossRef]

- Kosiba, K.; Gargarella, P.; Pauly, S.; Kühn, U.; Eckert, J. Predicted glass-forming ability of Cu-Zr-Co alloys and their crystallization behavior. J. Appl. Phys. 2013, 113, 123505. [Google Scholar] [CrossRef]

- Scudino, S.; Unterdörfer, C.; Prashanth, K.G.; Attar, H.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J. Additive manufacturing of Cu–10Sn bronze. Mater. Lett. 2015, 156, 202–204. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Liu, Y.; Li, S.; Wang, H.; Hou, W.; Hao, Y.; Yang, R.; Sercombe, T.; Zhang, L. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting. Acta Mater. 2016, 113, 56–67. [Google Scholar] [CrossRef]

- Prashanth, K.; Scudino, S.; Klauss, H.; Surreddi, K.; Löber, L.; Wang, Z.; Chaubey, A.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Caillard, D. Dislocations and mechanical properties. In Alloy Physics: A Comprehensive Reference, 1st ed.; Pfeiler, W., Ed.; John Wiley and Sons (Wiley)-VCH: Weinheim, Germany, 2007. [Google Scholar]

- Chaubey, A.; Scudino, S.; Khoshkhoo, M.S.; Prashanth, K.; Mukhopadhyay, N.; Mishra, B.; Eckert, J. High-strength ultrafine grain Mg–7.4%Al alloy synthesized by consolidation of mechanically alloyed powders. J. Alloys Compd. 2014, 610, 456–461. [Google Scholar] [CrossRef]

- Liu, Z.; Feyerabend, F.; Bohlen, J.; Willumeit-Römer, R.; Letzig, D. Mechanical properties and degradation behavior of binary magnesium-silver alloy sheets. J. Phys. Chem. Solids 2019, 133, 142–150. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).