Effects of Variable Punch Speed and Blank Holder Force in Warm Superplastic Deep Drawing Process

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

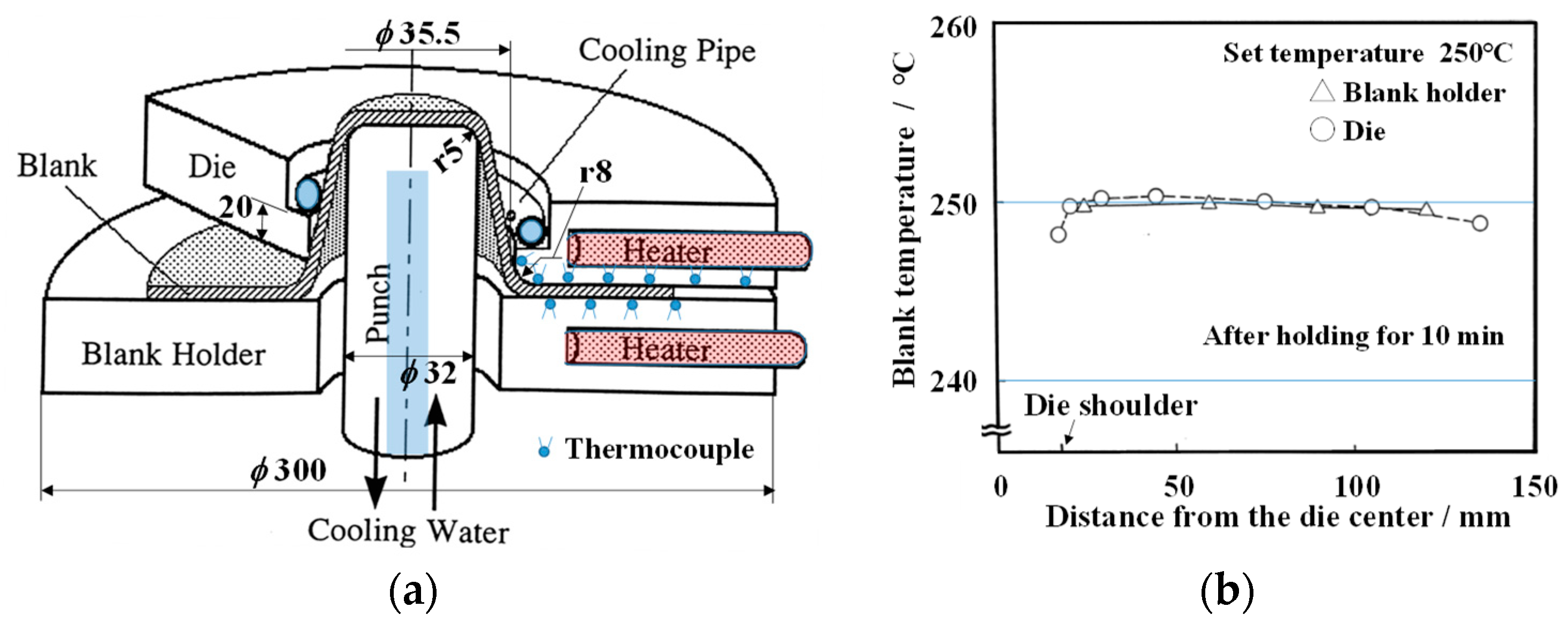

2.2. Experimental Equipment and Experimental Procedure

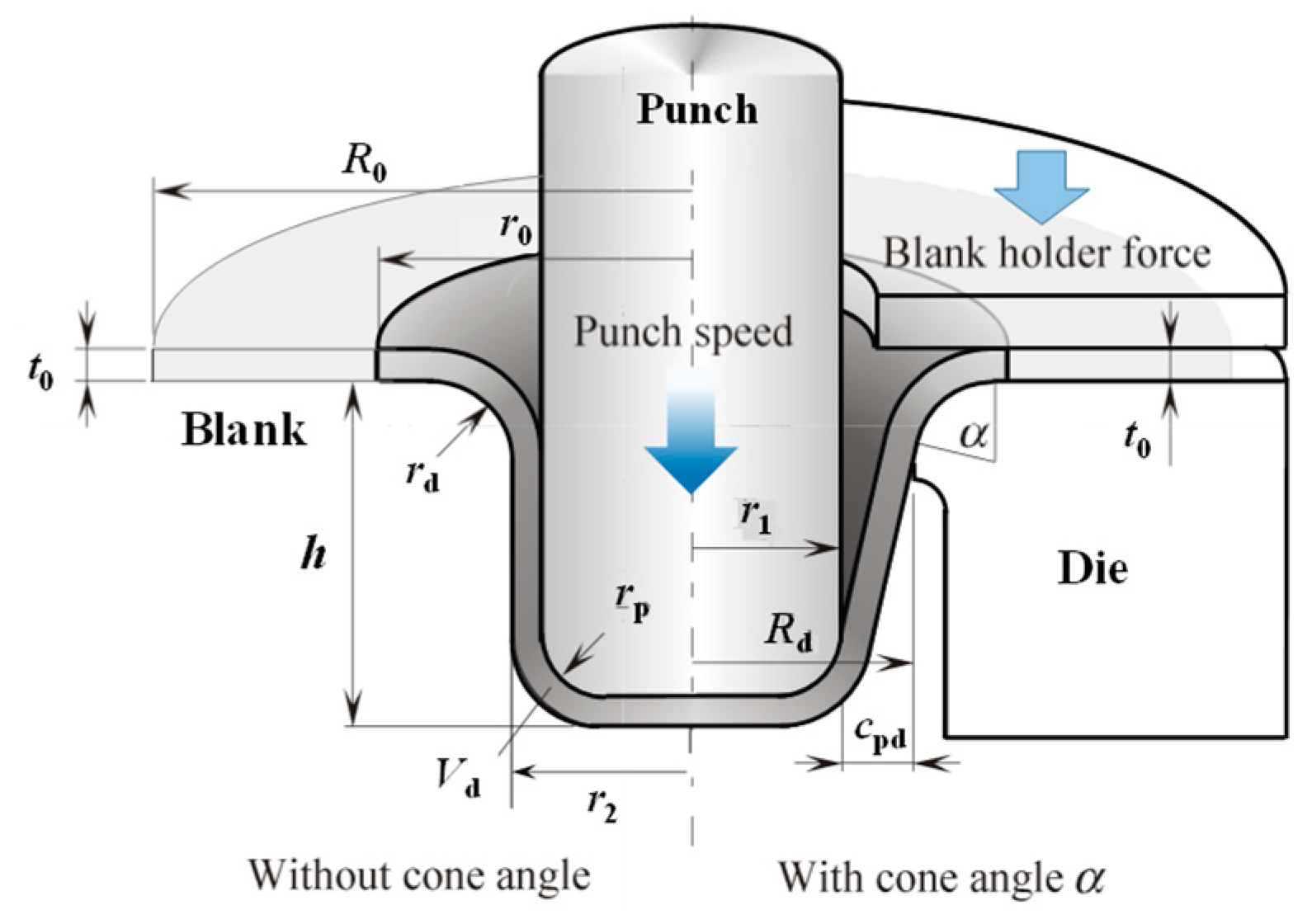

2.3. Analysis with Superplastic Deep Drawing Theory and Calculation Conditions

3. Results and Discussion

3.1. Wrinkle Formation and Growth Behavior on the Flange Part for Large Blank DR = 5

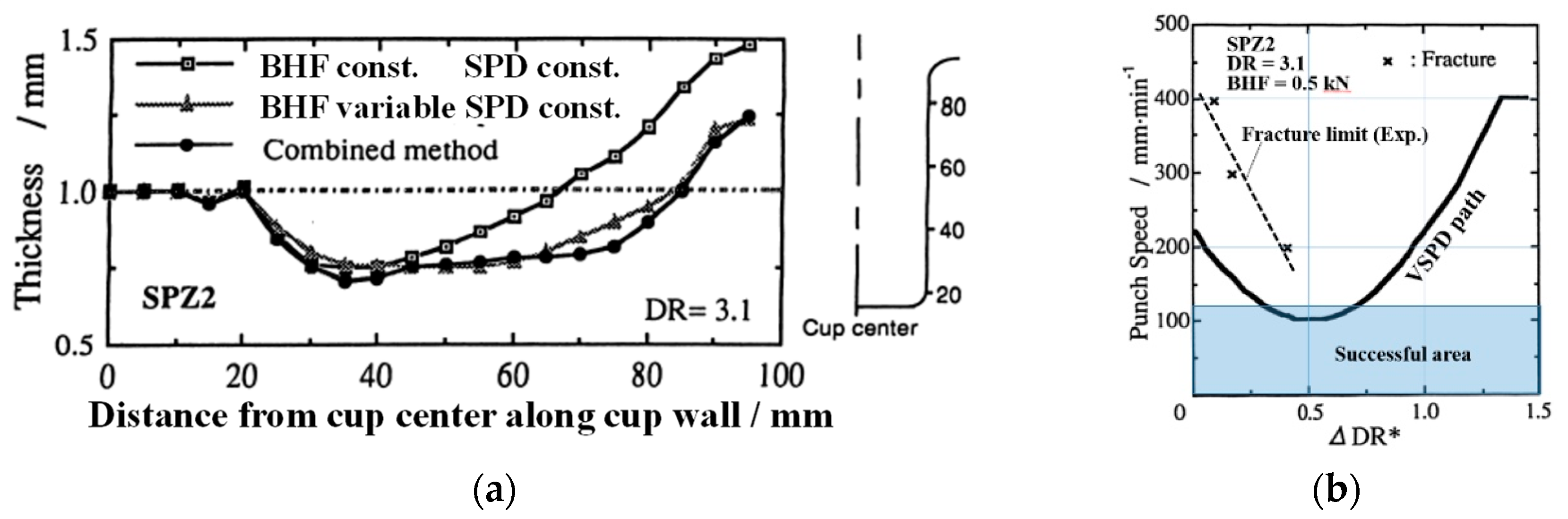

3.2. Experimental Fracture Limit and Wrinkle Limit of Warm Deep Drawing for Middle Size Blank DR = 3.1

3.3. Theoretical Fracture Limit and Wrinkle Limit of Warm Deep Drawing for Middle Size Blank

3.4. Verification of Effect of Variable BHF and SPD Methods in Warm Superplastic Deep Drawing

4. Conclusions

- Under constant forming conditions of the superplastic warm deep drawing experiment for SPZ2 with a larger blank, the flange wrinkle limit is affected by BHF and SPD. If the SPD is faster, the wrinkles with a large wavelength flange are likely to occur; the appropriate conditions of the BHF and SPD were low (BHF = 0.5 kN) and slow (SPD = 100 mm/min). When the BHF is larger, the wrinkles are likely to occur early, experimentally and theoretically. For the larger DR = 5, the wrinkle mode shifts to the streaky wrinkles near the die inlet with increasing BHF. In the case of lower punch speed with larger BHF conditions, the streaky wrinkles occur at the early stage.

- For the VBHF and VSPD processes in which the variable pattern of BHF and SPD increases in the late stage, it is confirmed experimentally that the VBHF process exerted a significant effect on making the drawn cup uniform for DR = 5 and 3.1. The VSPD process has a great effect on shortening the processing time, and for DR = 3.1, the processing time was reduced by 40%.

- The fracture limit and wrinkle limit based on the elementary theory are qualitatively consistent with the experimental results. It is important to understand the scope of the application of the theory and to use finite element analysis together for detailed deformation analysis.

- It was confirmed that the VBHF/VSPD processes have the potential to greatly contribute to the improvement of formability, product quality, and processing time reduction as a superplastic forming process. Precise process sensing and control of material deformation in a highly accurate experimental environment are expected to increase its practical use and expand its applications.

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

Appendix A. Nomenclature

| BHF | blank holder force |

| DR = R0/r2 | drawing ratio |

| DR* = r0/r2 | current drawing ratio |

| ΔDR* = DR − DR* = (R0 − r0)/r2 | flange reduction ratio |

| reduced modulus | |

| tangential modulus | |

| H | blank holder force |

| Hcrf | critical blank holder force for fracture |

| Hcrw | critical blank holder force for flange wrinkle |

| h | punch stroke (drawn cup height) |

| K | strength coefficient |

| m | strain rate sensitivity index |

| n | strain hardening exponent |

| SPD, v | punch speed |

| Vcr | critical punch speed at constant punch speed condition |

| VBHF | variable blank holder force |

| VSPD | variable punch speed |

| α | die contact angle (inclination angle of cup wall) |

| (see Figure 1) | |

| (see Figure 1) | |

| relative die diameter | |

| mean equivalent strain rate | |

| μ | coefficient of friction between blank and tool |

| ρd = rd/to | relative die shoulder radius |

| σal | allowable fracture stress of blank material |

| mean equivalent stress | |

| ideal drawing stress | |

| σd | drawing stress |

| ωcr | allowable specific wrinkle height |

Appendix B. Theory of Warm Deep Drawing

Appendix B.1. Basic Equations for Warm Deep Drawing

Appendix B.2. Critical Wrinkle Limit BHF, Hcrw

Appendix B.3. Critical Fracture Limit BHF, Hcrf

References

- Japanese Standards Association. Glossary of Terms Used in Metallic Superplastic Materials; JIS H7007:2002 No.1001; Japanese Standards Association: Tokyo, Japan.

- Ohsawa, H.; Saito, T.; Ikeda, H.; Nishimura, H.; Miyagawa, M. High speed deep drawing of Zn-Al alloy superplastic sheet (2nd report). In Proceedings of the 1977 Japanese Spring Conference on Technology of Plasticity, Tokyo, Japan, 31 May–2 June 1977; pp. 499–502. [Google Scholar]

- Yoshihara, S.; Nishimura, H.; Yamamoto, H.; Manabe, K. Formability enhancement in magnesium alloy stamping using a local heating and cooling technique: Circular cup deep drawing process. J. Mater. Process. Technol. 2003, 142, 609–613. [Google Scholar] [CrossRef]

- Manabe, K.; Nishimura, H.; Hamano, H. An Improvement in Deep Drawability of Steel/Plastic Laminate Sheets by Control of Blank Holding Force. Proceedings the Second International Conference on Technology of Plasticity, Stuttgart, Germany, 24 August 1987; pp. 1297–1304. [Google Scholar]

- Murata, A.; Ebine, Y.; Matsui, M. Effect of Blank Holding Force Control on Deep Drawability of Square Shell. J. Jpn. Soc. Tech. Plast. 1992, 33, 411–416. [Google Scholar]

- Ahmetoglu, M.; Coremans, G.L.; Kinzei, G.L.; Altan, T. Improving Drawability by Using Variable Blank Holder Force and Pressure in Deep Drawing of Round and Non-Symmetric Parts. Soc. Automot. Eng. Tech. 1993, 113–120. [Google Scholar]

- Hirose, Y.; Kojima, M.; Ujihara, S.; Hishida, Y. Development of Forming Technique with Real-Time Control of Blank Holding Force. In Proceedings of the 17th Biennial Congress of the IDDRG, Shenyang and Beijing, China, 11–13 June 1992; pp. 300–308. [Google Scholar]

- Manabe, K.; Koyama, H. Intelligent Control Scheme of Divided Blank Holder for Square–Cup Deep-Drawing Process. Int. J. Mater. Product Technol. 2008, 32, 476–490. [Google Scholar] [CrossRef]

- Koyama, H.; Wagoner, R.H.; Manabe, K. Blank Holding Force Control in Panel Stamping Process Using a Database and FEM Assisted Intelligent Press Control System. J. Mater. Process. Technol. 2004, 152, 190–196. [Google Scholar] [CrossRef]

- Yixiong, F.; Zhifeng, Z.; Guangdong, T.; Zhihan, L.; Shaoxu, T.; Hongfei, J. Data-driven accurate design of variable blank holder force in sheet forming under interval uncertainty using sequential approximate multi-objective optimization. Future Gener. Comput. Syst. 2018, 86, 1242–1250. [Google Scholar]

- Kitayama, S.; Natsume, S.; Yamazaki, K.; Han, J.; Uchida, H. Numerical investigation and optimization of pulsating and variable blankholder force for identification of formability window for deep drawing of cylindrical cup. Int. J. Adv. Manuf. Technol. 2016, 82, 583–593. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, W.; Chen, G. A new strategy to optimize variable blank holder force towards improving the forming limits of aluminum sheet metal forming. J. Mater. Process. Technol. 2007, 183, 339–346. [Google Scholar]

- Wang, L.; Lee, T.C. Controlled strain path forming process with space variant blank holder force using RSM method. J. Mater. Process. Technol. 2005, 167, 447–455. [Google Scholar] [CrossRef]

- Kergen, R.; Jodogne, P. Computerized Control of Blank Holder Pressure on Deep Drawing Presses. In Proceedings of the International Congress and Exposition, SAE Technical Papers Series, Detroit, MI, USA, 24–28 February 1992; pp. 51–56. [Google Scholar]

- Sim, H.B.; Boyce, M.C. FEM Anaysis of Real-Time Stability Control in Sheet Forming Process. Trans. ASME J. Eng. Mater. Technol. 1992, 114, 18–188. [Google Scholar] [CrossRef]

- Siegert, K.; Zielgler, M.; Wagner, S. Closed Loop Control of the Friction Force. Deep Drawing Process. J. Mater. Process. Technol. 1997, 71, 126–133. [Google Scholar] [CrossRef]

- Yagami, T.; Manabe, K.; Yang, M.; Koyama, H. Intelligent Sheet Stamping Process Using Segment Blank Holder Modules. J. Mater. Process. Technol. 2004, 155–156, 2099–2105. [Google Scholar] [CrossRef]

- Hongsheng, Z.; Siji, Q.; Liqin, C.; Linyuan, M.; Qianrong, Z.; Chuang, L. Research on Deep Drawing Process Using Radial Segmental Blank Holder based on Electro-permanent Magnet Technology. J. Manuf. Process. 2020, 59, 636–648. [Google Scholar]

- Benny, E.; Søren, T.; Joachim, D. A novel feedback control system—Controlling the material flow in deep drawing using distributed blank-holder force. J. Mater. Process. Technol. 2013, 213, 36–50. [Google Scholar]

- Koyama, H.; Manabe, K. Virtual Processing in Intelligent BHF Control Deep Drawing of Sheet Metal. J. Mater. Process. Technol. 2003, 143–144, 261–265. [Google Scholar] [CrossRef]

- Sheng, Z.Q.; Jirathearanat, S.; Altan, T. Adaptive FEM simulation for prediction of variable blank holder force in conical cup drawing. Int. J. Mach. Tools Manuf. 2004, 44, 487–494. [Google Scholar] [CrossRef]

- Marek, H.; Jakob, W.; Jens-Peter, M. Optimisation of deep drawn paperboard structures by adaptation of the blank holder force trajectory. J. Mater. Process. Technol. 2016, 232, 142–152. [Google Scholar]

- Manabe, K.; Yoshihara, S.; Nishimura, H.; Shibata, A. Theoretical analysis of punch speed and blank holding force control in deep drawing process of strain-rate-sensitive materials. In Proceedings of the ASME Dynamics Systems and Control Division ASME, Atlanta, GA, USA, 17–22 November; pp. 175–182.

- Yoshihara, S.; Koyama, H.; Manabe, K. Database-Oriented Adaptive Punch Speed Control of Sheet Stamping Process Using Fuzzy Logic. In Intelligence in a Materials World (Selected Papers from IPMM2001); CRC Press: Cleveland Heights, OH, USA, 2003; pp. 763–769. [Google Scholar]

- Manabe, K.; Koyama, H.; Yoshihara, S.; Yagami, T. Development of a Combination Punch-Speed and Blank-Holder Control System for the Deep Drawing Process. J. Mater. Process. Technol. 2002, 125–126, 440–445. [Google Scholar] [CrossRef]

- Manabe, K.; Yagami, T.; Yoshihara, S.; Koyama, H. An Intelligent Process Control of Punch Speed and Blank Holder Force in Deep Drawing. In Proceedings of the 22nd Biennial Congress of the IDDRG2002, Nagoya, Japan, 20–22 May 2002; pp. 185–192. [Google Scholar]

- Yagami, T.; Manabe, K. FE Analysis on Deformation Mechanism of Strain-Rate-Sensitive Materials in Cylindrical Deep-Drawing with Combination Punch Speed and Blank Holder Control. J. Solid Mech. Mater. Eng. 2007, 1, 1385–1396. [Google Scholar] [CrossRef] [Green Version]

- Manabe, K.; Yoshihara, S.; Yang, M.; Nishimura, H. Optimization of the Variable BHF Deep-Drawing Process by Fuzzy Model. J. JSTP 1995, 36, 1015–1022. [Google Scholar]

- Manabe, K.; Hamano, J.; Nishimura, H. A New Variable Blank Holding Force Method in Deep Drawing of Sheet Materials. J. JSTP 1988, 29, 740–747. [Google Scholar]

- Kawai, N. Critical Conditions of Wrinkling in Deep Drawing of Sheet Metals—Reports 1,2 and 3. Bull. JSME 1961, 4, 169–192. [Google Scholar] [CrossRef]

- Siebel, E. Der Niederhalterdrunk beim Tiefzien. Stahl Und Eisen 1954, 74, 155–158. [Google Scholar]

| Temperature/°C | K/MPa | m | n | Strain Range | Strain Rate Range |

|---|---|---|---|---|---|

| 250 | 7.65 | 0.32 | 0.005 | 10−2 < ε < 1 | 2 × 10−2 < < 3 × 10−1 |

| Process | Forming Time/s | Time Reduction Rate, % |

|---|---|---|

| Constant punch speed method (at successful limiting punch speed) | 48 | - |

| Variable punch speed method | 29 | Δ40 |

| Combined method | 29 | Δ40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manabe, K.-i.; Soeda, K.; Shibata, A. Effects of Variable Punch Speed and Blank Holder Force in Warm Superplastic Deep Drawing Process. Metals 2021, 11, 493. https://doi.org/10.3390/met11030493

Manabe K-i, Soeda K, Shibata A. Effects of Variable Punch Speed and Blank Holder Force in Warm Superplastic Deep Drawing Process. Metals. 2021; 11(3):493. https://doi.org/10.3390/met11030493

Chicago/Turabian StyleManabe, Ken-ichi, Kentaro Soeda, and Akinori Shibata. 2021. "Effects of Variable Punch Speed and Blank Holder Force in Warm Superplastic Deep Drawing Process" Metals 11, no. 3: 493. https://doi.org/10.3390/met11030493

APA StyleManabe, K.-i., Soeda, K., & Shibata, A. (2021). Effects of Variable Punch Speed and Blank Holder Force in Warm Superplastic Deep Drawing Process. Metals, 11(3), 493. https://doi.org/10.3390/met11030493