Effect of Welding Sequence and the Transverse Geometry of the Weld Overlay on the Distribution of Residual Stress in the Weld Overlay Repair of T23 Tubes

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

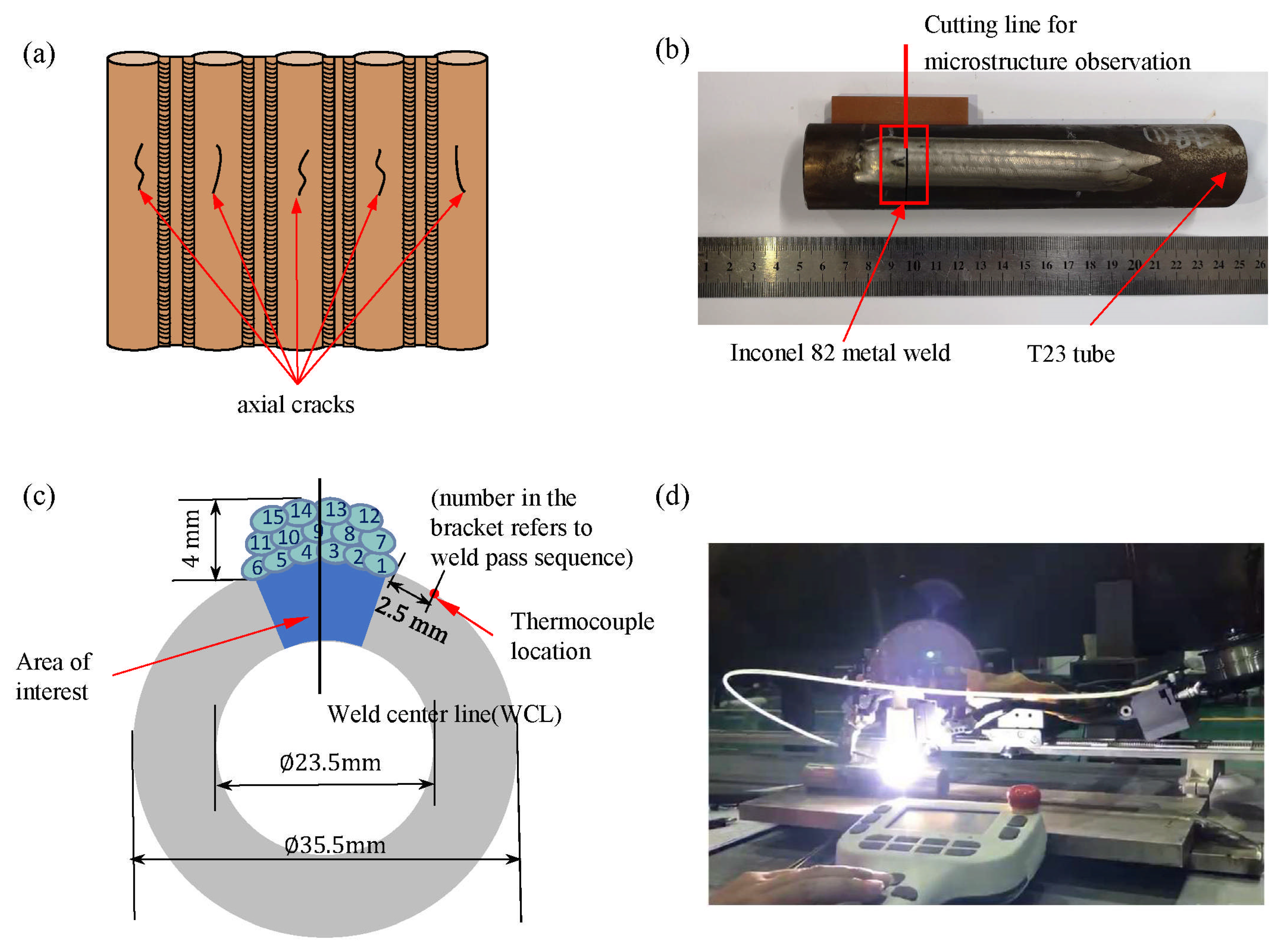

2.2. Fabrication of the Overlaying Sample and Thermal Measurement Experiment

2.3. Stress Measurement with Hole Drilling Method

2.4. Stress Measurement with XRD Method

3. Finite Element Analysis

3.1. Three-Dimensional Finite Element Model

3.2. Thermal Analysis

3.3. Phase Transformation

3.4. Mechanical Analysis

3.5. Simulation Cases

4. Results and Discussion

4.1. Temperature Field

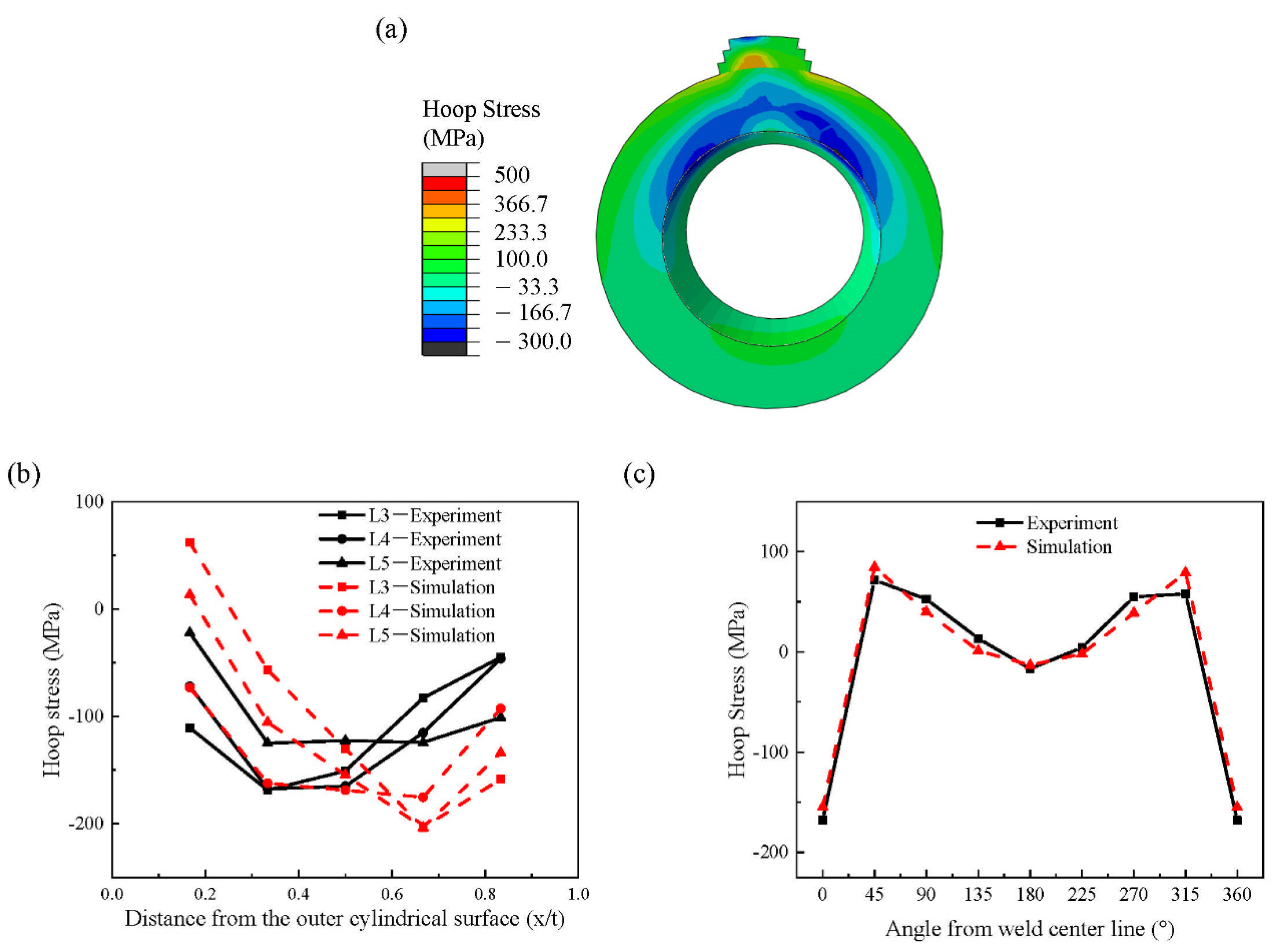

4.2. Residual Stress Distribution on the Outer Surface of the Weld Overlay

4.3. Residual Stress Distribution on the Cross Section of the Overlaying Sample

4.4. Effects of Welding Sequence on the Residual Stress Distribution

4.5. Effects of the Number of the Weld Layers on the Residual Stress Distribution

4.6. Effects of the Number of Weld Passes on the Residual Stress Distribution

5. Conclusions

- The simulated model with right-to-left sequence has acceptable consistency with the experimental overlaying model, which proves the validity of the finite element model.

- Under the weld repair influence, the repaired area below the weld overlay is mainly in −200 to 0 MPa compression, balanced by 0–400 MPa tensile stress in the weld overlay and around the outer surface area of the tube.

- The residual stress induced by overlaying welding along the pipeline axis in this paper has similar residual stress distribution and residual stress magnitude as girth welding in the repaired area; however, the former requires simpler equipment and operation.

- Under the condition of overlaying one layer, the of center-to-outside is −70 MPa, close to right-to-left’s −73 MPa, and higher than outside’s −37 MPa. The of center-to-outside is 96 MPa, lower than right-to-left’s 127 MPa and outside-to-center’s 213 MPa. Hence the order of the weld overlay effect is as follows: center-to-outside > right-to-left > outside-to-center.

- As the number of weld layers increases, the compressive stress area of the repaired area is expanded, the of the WCL of the repaired area is increased from −70 MPa to −110 MPa, and the of the WCL of the repaired area is decreased from 96 MPa to 3 MPa.

- When overlaying one layer with the center-to-outside welding sequence, the number of the weld passes should be no less than four layers.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Senthur, P.S.; Choudhary, A.; Mittal, N.; Gupta, S.; Ramkumar, D.; Natarajan, A. Failure evaluation of SA 210C riffle water wall tubes in 70 MW CFBC boiler. Eng. Fail. Anal. 2019, 95, 239–247. [Google Scholar] [CrossRef]

- Rahman, M.M.; Purbolaksono, J.; Ahmad, J. Root cause failure analysis of a division wall superheater tube of a coal-fired power station. Eng. Fail. Anal. 2010, 17, 1490–1494. [Google Scholar] [CrossRef]

- Aloraier, A.; Al-Mazrouee, A.; Price, J.W.H.; Shehata, T. Weld repair practices without post weld heat treatment for ferritic alloys and their consequences on residual stresses: A review. Int. J. Press. Vessel. Pip. 2010, 87, 127–133. [Google Scholar] [CrossRef]

- Dong, P. On repair weld residual stresses and significance to structural integrity. Weld. World 2018, 62, 351–362. [Google Scholar] [CrossRef]

- Liu, R.-F.; Wang, J.-C. Finite element analyses of the effect of weld overlay sizing on residual stresses of the dissimilar metal weld in PWRs. Nucl. Eng. Des. 2021, 372, 110959. [Google Scholar] [CrossRef]

- Jiang, W.; Luo, Y.; Wang, B.Y.; Tu, S.T.; Gong, J.M. Residual stress reduction in the penetration nozzle weld joint by overlay welding. Mater. Des. 2014, 60, 443–450. [Google Scholar] [CrossRef]

- American Society of Mechanical Engineers, P.V.; Piping Division Staff Corporate, A. Weld-Overlay Analyses-An Investigation of the Effect of Weld Sequencing. In Proceedings of the ASME Pressure Vessels and Piping Conference—2008, Chicago, IL, USA, 27–31 July 2008; pp. 565–574. [Google Scholar]

- Iwamatsu, F.; Yanagida, N.; Miyazaki, K. Effect of Weld Overlay Repair on Residual Stress and Crack Propagation in a Welding Pipe. In Proceedings of the ASME Pressure Vessels and Piping Conference, San Antonio, TX, USA, 22–26 July 2007; pp. 645–651. [Google Scholar]

- Jiang, W.C.; Wang, B.Y.; Gong, J.M.; Tu, S.T. Finite element analysis of the effect of welding heat input and layer number on residual stress in repair welds for a stainless steel clad plate. Mater. Des. 2011, 32, 2851–2857. [Google Scholar] [CrossRef]

- Schaupp, T.; Schroepfer, D.; Kromm, A.; Kannengiesser, T. Welding residual stresses in 960MPa grade QT and TMCP high-strength steels. J. Manuf. Process. 2017, 27, 226–232. [Google Scholar] [CrossRef]

- Dong, P.; Hong, J.K.; Bouchard, P.J. Analysis of residual stresses at weld repairs. Int. J. Press. Vessel. Pip. 2005, 82, 258–269. [Google Scholar] [CrossRef]

- Hu, M.; Li, K.; Li, S.; Cai, Z.; Pan, J. Numerical investigation on stress distribution and evolution in 9Cr/2.25Cr dissimilar welded rotor undergoing welding and heat treatment. Weld. World 2020, 64, 1981–1995. [Google Scholar] [CrossRef]

- Mičian, M.; Winczek, J.; Gucwa, M.; Koňár, R.; Málek, M.; Postawa, P. Investigation of Welds and Heat Affected Zones in Weld Surfacing Steel Plates Taking into Account the Bead Sequence. Materials 2020, 13, 5666. [Google Scholar] [CrossRef] [PubMed]

- Tomków, J.; Fydrych, D.; Rogalski, G. Role of Bead Sequence in Underwater Welding. Materials 2019, 12, 3372. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, P. On the Mechanics of Residual Stresses in Girth Welds. J. Press. Vessel Technol. 2006, 129, 345–354. [Google Scholar] [CrossRef]

- Dai, P.; Wang, Y.; Li, S.; Lu, S.; Feng, G.; Deng, D. FEM analysis of residual stress induced by repair welding in SUS304 stainless steel pipe butt-welded joint. J. Manuf. Process. 2020, 58, 975–983. [Google Scholar] [CrossRef]

- Deng, D. Influence of deposition sequence on welding residual stress and deformation in an austenitic stainless steel J-groove welded joint. Mater. Des. 2013, 49, 1022–1033. [Google Scholar] [CrossRef]

- Zhao, L.; Liang, J.; Zhong, Q.; Yang, C.; Sun, B.; Du, J. Numerical simulation on the effect of welding parameters on welding residual stresses in T92/S30432 dissimilar welded pipe. Adv. Eng. Softw. 2014, 68, 70–79. [Google Scholar] [CrossRef]

- Song, S.; Dong, P. Residual stresses at weld repairs and effects of repair geometry. Sci. Technol. Weld. Join. 2017, 22, 265–277. [Google Scholar] [CrossRef]

- Guo, Q.; Du, B.; Xu, G.; Chen, D.; Ma, L.; Wang, D.; Zhang, Y. Influence of filler metal on residual stress in multi-pass repair welding of thick P91 steel pipe. Int. J. Adv. Manuf. Technol. 2020, 110, 2977–2989. [Google Scholar] [CrossRef]

- Li, S.; Ren, S.; Zhang, Y.; Deng, D.; Murakawa, H. Numerical investigation of formation mechanism of welding residual stress in P92 steel multi-pass joints. J. Mater. Process. Technol. 2017, 244, 240–252. [Google Scholar] [CrossRef]

- Lant, T.; Robinson, D.L.; Spafford, B.; Storesund, J. Review of weld repair procedures for low alloy steels designed to minimise the risk of future cracking. Int. J. Press. Vessel. Pip. 2001, 78, 813–818. [Google Scholar] [CrossRef]

- Odanovic, Z.; Arsic, M.; Grabulov, V.; Djurdjevic, M. Investigation of the Repair Welding Technology Using Ni Base Electrode. Struct. Integr. Welded Struct. 2013, 814, 25–32. [Google Scholar] [CrossRef]

- Marques, E.S.V.; Silva, F.J.G.; Pereira, A.B. Comparison of Finite Element Methods in Fusion Welding Processes—A Review. Metals 2020, 10, 75. [Google Scholar] [CrossRef] [Green Version]

- Holman, J.P. Heat Transfer, 10th ed.; McGraw-Hill: New York, NY, USA, 2002; pp. 4–19. [Google Scholar]

- V&M T23. High-Temperature Ferritic Steel. Alloy Dig. 2001, 50, 1. [Google Scholar]

- RIMA 82. Nickle-Base Welding Wire. Alloy Dig. 2002, 51, 6. [Google Scholar]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Xu, G.; Guo, Q.; Hu, Q.; Pan, H.; Qian, H.; Du, B. Numerical and Experimental Analysis of Dissimilar Repair Welding Residual Stress in P91 Steel Considering Solid-State Phase Transformation. J. Mater. Eng. Perform 2019, 28, 5734–5748. [Google Scholar] [CrossRef]

- Song, S.; Dong, P.; Kim, M.H. Residual stresses in narrow-groove girth welds and applications for fitness-for-service assessment. Int. J. Press. Vessel. Pip. 2020, 188, 104238. [Google Scholar] [CrossRef]

- Dong, P. Length scale of secondary stresses in fracture and fatigue. Int. J. Press. Vessel. Pip. 2008, 85, 128–143. [Google Scholar] [CrossRef]

| Fe | Cr | Ni | Mn | Mo | V | Nb | C | Si | |

|---|---|---|---|---|---|---|---|---|---|

| T23 | Bal.- | 2.33 | 0.06 | 0.22 | 0.08 | 0.24 | 0.05 | 0.06 | 0.21 |

| 82 | Bal.- | 19.02 | 75.98 | 2.46 | - | - | 2.22 | 0.36 | 0.08 |

| Layer Number | Voltage (V) | Peak/Base Current Value (A) | Peak/Base Heat Input (J/mm) | Time for Peak/Base Current (s) | Peak/Base Wire Feeding Speed (mm/min) | Peak/Base Welding Speed (mm/min) | Current Decay Time (s) |

|---|---|---|---|---|---|---|---|

| 1 | 9.5 | 160/120 | 1382/622 | 0.20/0.30 | 1000/550 | 66/110 | 8 |

| 2 | 10.0 | 180/120 | 1636/655 | ||||

| 3 | 10.0 | 180/120 | 1636/655 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, X.; Liu, Q.; Hu, M.; Li, K.; Cai, Z. Effect of Welding Sequence and the Transverse Geometry of the Weld Overlay on the Distribution of Residual Stress in the Weld Overlay Repair of T23 Tubes. Metals 2021, 11, 568. https://doi.org/10.3390/met11040568

Xiao X, Liu Q, Hu M, Li K, Cai Z. Effect of Welding Sequence and the Transverse Geometry of the Weld Overlay on the Distribution of Residual Stress in the Weld Overlay Repair of T23 Tubes. Metals. 2021; 11(4):568. https://doi.org/10.3390/met11040568

Chicago/Turabian StyleXiao, Xin, Qu Liu, Mengjia Hu, Kejian Li, and Zhipeng Cai. 2021. "Effect of Welding Sequence and the Transverse Geometry of the Weld Overlay on the Distribution of Residual Stress in the Weld Overlay Repair of T23 Tubes" Metals 11, no. 4: 568. https://doi.org/10.3390/met11040568

APA StyleXiao, X., Liu, Q., Hu, M., Li, K., & Cai, Z. (2021). Effect of Welding Sequence and the Transverse Geometry of the Weld Overlay on the Distribution of Residual Stress in the Weld Overlay Repair of T23 Tubes. Metals, 11(4), 568. https://doi.org/10.3390/met11040568