Enhancing Properties of Soft Magnetic Materials: A Study into Hot Isostatic Pressing and Sintering Atmosphere Influences

Abstract

:1. Introduction

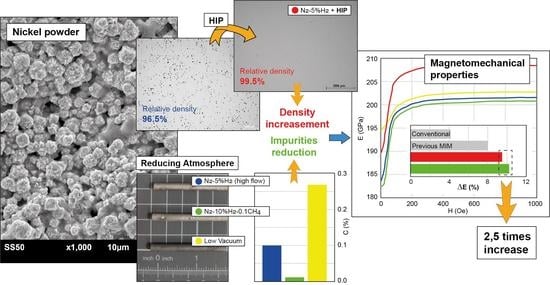

- Execution of a HIP treatment after sintering to minimize the residual porosity of the pieces.

- Selection of an adequate sintering atmosphere (N-5%H, N-10%H-0.1%CH or low vacuum) which decreases impurities.

2. Experimental Procedure

3. Results and Discussion

3.1. Effect of Thermal Treatment (HIP)

3.1.1. Density

3.1.2. Microstructure

3.1.3. Mechanical Properties

3.1.4. Magnetoelastic Properties

3.1.5. Final Pieces

3.2. Effect of Sintering Atmosphere

3.2.1. Density Effects

3.2.2. Microstructure

3.2.3. Carbon Content and Mechanical Properties

3.2.4. Magnetoelastic Properties

3.2.5. Final Pieces

4. Conclusions

- HIP treatment causes almost complete densification and enormous grain growth. Closing of porosity leads to a slight increase of hardness and facilitates magnetic domain motion. The best magnetic performance (E∼9.6% and 208.32 GPa of the saturated elastic modulus) has been obtained after HIP treatment on the sintered sample for 12 h of the plateau at the maximum temperature.

- An optimal sintering cycle consisting of a temperature of 1325 C and 12 h of plateau time has been selected for the sintering process under all the atmospheres. Higher temperatures result in melted zones, and longer times do not improve density values. Under these conditions, the relative density values are between 95.7% and 96.5%, depending on the atmosphere used.

- Microstructure of the sintered components consists of large coaxial grains with twinning. Pores that appear in the microstructure are spherical in shape and are isolated.

- A large variation in the final carbon content is obtained depending on the sintering atmosphere. The higher the carbon content, the higher the microhardness values obtained.

- E-effect increases for longer sintering times in the most reducing atmospheres due to lower carbon content. Values around 10% are achieved when an atmosphere of N-10%H-0.1%CH or a high flow of N-5%H are used. These values are remarkable because the obtained E-effect not only is 2.5 times higher than those measured in conventionally processed nickel, but also slightly higher than those obtained after applying a secondary HIP heat treatment.

- Sintered parts suffer very close shrinkages. However, a better surface appearance, with higher brightness and metallic aspect, is obtained using the more reducing atmospheres.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MIM | Metal Injection Moulding |

| HIP | Hot Isostatic Pressing |

| SEM | Scanning Electron Micrograph |

| PW | Paraffin Wax |

| HDPE | High Density Polyethylene |

| HV | Vickers microhardness |

References

- ASM Specialty Handbook. In Nickel, Cobalt, and Their Alloys; Chapter Powder Metallurgy Processing of Nickel Alloys; ASM International: Almere, The Netherlands, 2000.

- Lall, C. Effects of sintering temperature and atmosphere on soft magnetic properties of PM materials. Met. Powder Rep. 1992, 47, N58. [Google Scholar] [CrossRef]

- Herranz, G. Control of carbon content in metal injection moulding. In Handbook of Metal Injection Molding; Woodhead Publishing: Cambridge, UK, 2019; Chapter 14. [Google Scholar]

- Banerjee, S.; Joens, C. Debinding and sintering of metal injection molding (MIM) components. In Handbook of Metal Injection Molding; Woodhead Publishing: Cambridge, UK, 2019; Chapter 7. [Google Scholar]

- Heckel, R. Effects of gas composition on gas-solid equilibrium during sintering of ferrous powders. Prog. Powder Metall. 1978, 34, 419–430. [Google Scholar]

- German, R. Metallurgy of Iron and Steel; John Wiley & Sons: Hoboken, NJ, USA, 1998. [Google Scholar]

- Blais, C. Atmosphere sintering. In Sintering of Advanced Materials; Metals and Surface Engineering; Woodhead Publishing: Cambridge, UK, 2010; Chapter 7. [Google Scholar]

- Romero, A.; Herranz, G.; Morales, A. Study of magnetoelastic properties of pure nickel parts produced by metal injection moulding. Mater. Des. 2015, 88, 438–445. [Google Scholar] [CrossRef]

- Ma, J.; Qin, M.; Zhang, L.; Tian, L.; Ding, X.; Qu, X. Improvements in magnetic performance and sintered density of metal injection-molded soft magnetic alloy by hot isostatic pressing. Mater. Lett. 2014, 125, 227–230. [Google Scholar] [CrossRef]

- Qiu, C.; Attallah, M.; Wu, X.; Andrews, P. Influence of hot isostatic pressing temperature on microstructure and tensile properties of a nickel-based superalloy powder. Mater. Sci. Eng. A 2013, 564, 176–185. [Google Scholar] [CrossRef]

- Martínez, C.; Briones, F.; Aguilar, C.; Araya, N.; Iturriza, I.; Machado, I.; Rojas, P. Effect of hot pressing and hot isostatic pressing on the microstructure, hardness, and wear behavior of nickel. Mater. Lett. 2020, 273, N127944. [Google Scholar] [CrossRef]

- Horke, K.; Meyer, A.; Singer, R. Metal Injection Molding (MIM) of Nickel-Base Superalloys. In Handbook of Metal Injection Molding; Woodhead Publishing: Cambridge, UK, 2019; Chapter 24. [Google Scholar]

- Sreenu, B.; Sarkar, R.; Satheesh-Kumar, S.; Chatterjee, S.; Appa-Rao, G. Microstructure and mechanical behaviour of an advanced powder metallurgy nickel base superalloy processed through hot isostatic pressing route for aerospace applications. Mater. Sci. Eng. A 2020, 797, 140254. [Google Scholar] [CrossRef]

- El-Rakayby, H.; Kim, H.; Hong, S.; Kim, K. An investigation of densification behavior of nickel alloy powder during hot isostatic pressing. Adv. Powder Technol. 2015, 26, 1314–1318. [Google Scholar] [CrossRef]

- Sentyurina, Z.; Baskov, F.; Loginov, P.; Kaplanskii, Y.; Mishukov, A.; Logachev, I.; Bychkova, M.; Levashov, E.; Logacheva, A. The effect of hot isostatic pressing and heat treatment on the microstructure and properties of EP741NP nickel alloy manufactured by laser powder bed fusion. Addit. Manuf. 2021, 37, 101629. [Google Scholar] [CrossRef]

- Lan, J.; Xuan, W.; Han, Y.; Li, Y.; Wu, H.; Shao, W.; Li, C.; Wang, J.; Ren, Z. Enhanced high temperature elongation of nickel based single crystal superalloys by hot isostatic pressing. J. Alloys Compd. 2019, 805, 78–83. [Google Scholar] [CrossRef]

- Cai, C.; Pan, K.; Teng, Q.; Gao, X.; Song, B.; Liu, J.; Wei, Q.; Zhou, K.; Shi, Y. Simultaneously enhanced strength and ductility of FGH4097 nickel-based alloy via a novel hot isostatic pressing strategy. Mater. Sci. Eng. A 2019, 760, 19–25. [Google Scholar] [CrossRef]

- Herranz, G.; Romero, A.; Pérez, J.; Rodríguez, G. Optimisation of feedstock based on pure nickel to produce parts with magnetomechanical properties. In Proceedings of the EUROPM2013, Gothenburg, Sweden, 15–18 September 2013; pp. 277–282. [Google Scholar]

- ISO 2738:1999. Sintered Metal Materials, Excluding Hardmetals. Permeable Sintered Metal Materials. Determination of Density, Oil Content and Open Porosity; ISO/TC 119: Geneva, Switzerland, 1999. [Google Scholar]

- ISO 4498:2010. Sintered Metal Materials, Excluding Hardmetals. Determination of Apparent Hardness and Microhardness; ISO/TC 119: Geneva, Switzerland, 2010. [Google Scholar]

- Morales, A.; Nieto, A.; Chicharro, J.; Pintado, P. Automatic measurement of field-dependent elastic modulus and damping by laser Doppler vibrometry. Meas. Sci. Technol. 2008, 19, N125702. [Google Scholar] [CrossRef] [Green Version]

- Horton, D.; Thomson, C.; Randle, V. Aspects of twinning and grain growth in high purity and commercially pure nickel. Mater. Sci. Eng. A 1995, 203, 408–414. [Google Scholar] [CrossRef]

- Randle, V.; Rios, P.; Hu, Y. Grain growth and twinning in nickel. Scr. Mater. 2008, 58, 130–133. [Google Scholar] [CrossRef]

- Pasebani, S.; Dutt, A.; Burns, J.; Charit, I.; Mishra, R. Oxide dispersion strengthened nickel based alloys via spark plasma sintering. Mater. Sci. Eng. A 2015, 630, 155–169. [Google Scholar] [CrossRef] [Green Version]

- Morales, A.; Nieto, A.; Chicharro, J.; Pintado, P.; Rodriguez, G.; Herranz, G. Influence of internal stresses on field-dependent elastic modulus and damping in pure nickel. J. Magn. Magn. Mater. 2010, 322, 3584–3594. [Google Scholar] [CrossRef]

- Morales, A.; Nieto, A.; Chicharro, J.; Pintado, P. Field-dependent elastic modulus and damping in pure iron, nickel and cobalt. J. Magn. Magn. Mater. 2010, 322, 1952–1961. [Google Scholar] [CrossRef]

- ASM Handbook. ASM International Vol. 3, Alloy Phase Diagrams; ASM International: Almere, The Netherlands, 2016. [Google Scholar]

- German, R. Powder Injection Molding. Mater. Res. 1998, 7, 355–364. [Google Scholar]

- Johnson, J.; Westcot, E. Metal injection molding of commercially pure nickel for the chemical processing industry. Int. J. Powder Metall. 2003, 39, 37–45. [Google Scholar]

- Özgün, Ö.; Özkan-Gülsoy, H.; Yilmaz, R.; Findik, F. Injection molding of nickel based 625 superalloy: Sintering, heat treatment, microstructure and mechanical properties. J. Alloys Compd. 2013, 546, 192–207. [Google Scholar] [CrossRef]

- Bidulskýa, R.; Actis, M.; Ferrarisa, L.; Ferrarisa, P.; Bidulskáb, J. The effects of chemical composition on soft magnetic materials behaviour. Acta Phys. Pol. A 2010, 118, 802–803. [Google Scholar] [CrossRef]

- Ma, J.; Qin, M.; Wang, X.; Zhang, L.; Tian, L.; Zhang, X.; Li, X.; Qu, X. Microstructure and magnetic properties of Fe–79fabricated by metal injection moulding. Powder Technol. 2014, 253, 158–162. [Google Scholar] [CrossRef]

- Palermo, T.; Malas, A. Carbon potential control in MIM sintering furnace atmospheres. Met. Powder Rep. 2014, 69, 16–21. [Google Scholar] [CrossRef]

- German, R. Carbon Control: An important discriminant in Metal Injection Moulding. PIM Int. 2015, 9, 31–41. [Google Scholar]

| Microhardness (HV) | ||

|---|---|---|

| Sintering Plateau | 4 h | 12 h |

| Pre-HIP | 125 ± 7 | 131 ± 2 |

| Post-HIP | 143 ± 6 | 138 ± 8 |

| Sintering | Magnetic Field | E | E |

|---|---|---|---|

| Conditions | (Oe) | (GPa) | (GPa) |

| 4 h | 0 | 182.63 | 7.04 |

| 2000 | 195.49 | ||

| 4 h + HIP | 0 | 191.01 | 8.73 |

| 2000 | 207.68 | ||

| 12 h | 0 | 189.91 | 8.11 |

| 2000 | 205.32 | ||

| 12 h + HIP | 0 | 190.02 | 9.60 |

| 2000 | 208.32 |

| Sintering Time | Carbon Content | Microhardness |

|---|---|---|

| (h) | (%) | (HV) |

| 1 | 0.1554 ± 0.0036 | 88 ± 5 |

| 4 | 0.0973 ± 0.0018 | 102 ± 7 |

| 8 | 0.0289 ± 0.0009 | 98 ± 6 |

| 12 | 0.0071 ± 0.0012 | 89 ± 2 |

| Atmosphere | C (%) | HV |

|---|---|---|

| N-5%H | 0.0992 ± 0.0020 | 129 ± 2 |

| N-10%H-0.1%CH | 0.0071 ± 0.0012 | 89 ± 2 |

| Low Vacuum | 0.2696 ± 0.0100 | 140 ± 4 |

| Atmosphere | Sintering Time (h) | E (%) |

|---|---|---|

| N-5%H | 1 | 6.39 |

| 4 | 7.00 | |

| 8 | 8.80 | |

| 12 | 10.03 | |

| N-10%H-0.1%CH | 1 | 8.89 |

| 4 | 10.61 | |

| 8 | 9.57 | |

| 12 | 10.15 | |

| Low Vacuum | 1 | 4.46 |

| 4 | 4.76 | |

| 8 | 4.17 | |

| 12 | 4.34 |

| Atmosphere | Field (Oe) | E (GPa) | E (%) |

|---|---|---|---|

| N-5%H | 0 | 183.27 | 10.03 |

| 2000 | 201.66 | ||

| N-10%H-0.1%CH | 0 | 182.29 | 10.15 |

| 2000 | 200.78 | ||

| Low Vacuum | 0 | 194.41 | 4.34 |

| 2000 | 202.96 |

| Atmosphere | Length | Shrinkage | Diameter | Shrinkage |

|---|---|---|---|---|

| (mm) | (%) | (mm) | (%) | |

| N-5%H | 47.88 ± 0.01 | 19.68 | 4.75 ± 0.01 | 20.83 |

| N-10%H-0.1%CH | 48.28 ± 0.04 | 19.00 | 4.79 ± 0.02 | 20.17 |

| Low Vacuum | 48.05 ± 0.06 | 19.39 | 4.77 ± 0.04 | 20.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero, A.; Morales, A.L.; Herranz, G. Enhancing Properties of Soft Magnetic Materials: A Study into Hot Isostatic Pressing and Sintering Atmosphere Influences. Metals 2021, 11, 643. https://doi.org/10.3390/met11040643

Romero A, Morales AL, Herranz G. Enhancing Properties of Soft Magnetic Materials: A Study into Hot Isostatic Pressing and Sintering Atmosphere Influences. Metals. 2021; 11(4):643. https://doi.org/10.3390/met11040643

Chicago/Turabian StyleRomero, Ana, Angel L. Morales, and Gemma Herranz. 2021. "Enhancing Properties of Soft Magnetic Materials: A Study into Hot Isostatic Pressing and Sintering Atmosphere Influences" Metals 11, no. 4: 643. https://doi.org/10.3390/met11040643

APA StyleRomero, A., Morales, A. L., & Herranz, G. (2021). Enhancing Properties of Soft Magnetic Materials: A Study into Hot Isostatic Pressing and Sintering Atmosphere Influences. Metals, 11(4), 643. https://doi.org/10.3390/met11040643