Dissimilar Welding of Low Alloy Steels Welded Joints: Effect of Run-Off and Run-On Plates

Abstract

:1. Introduction

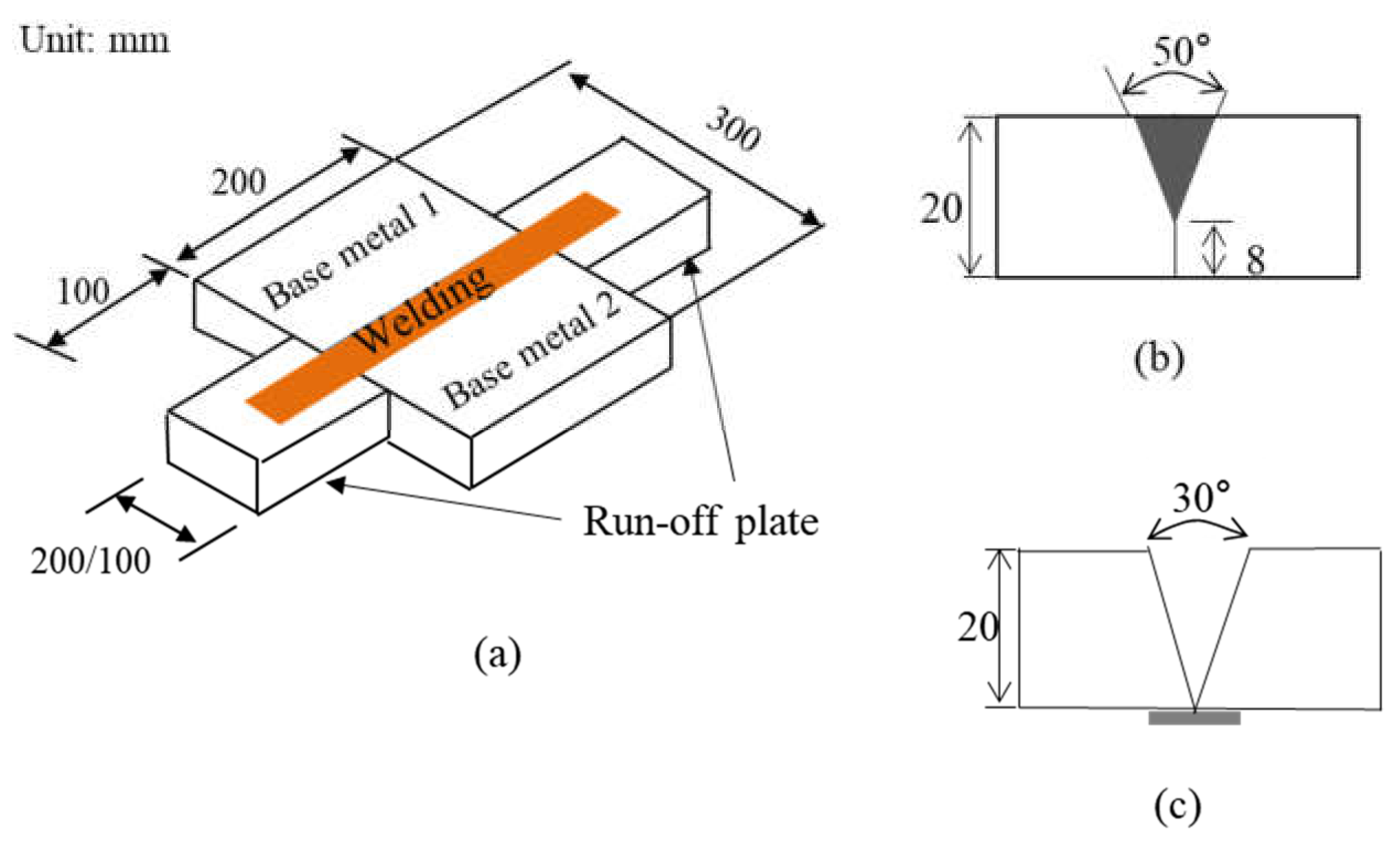

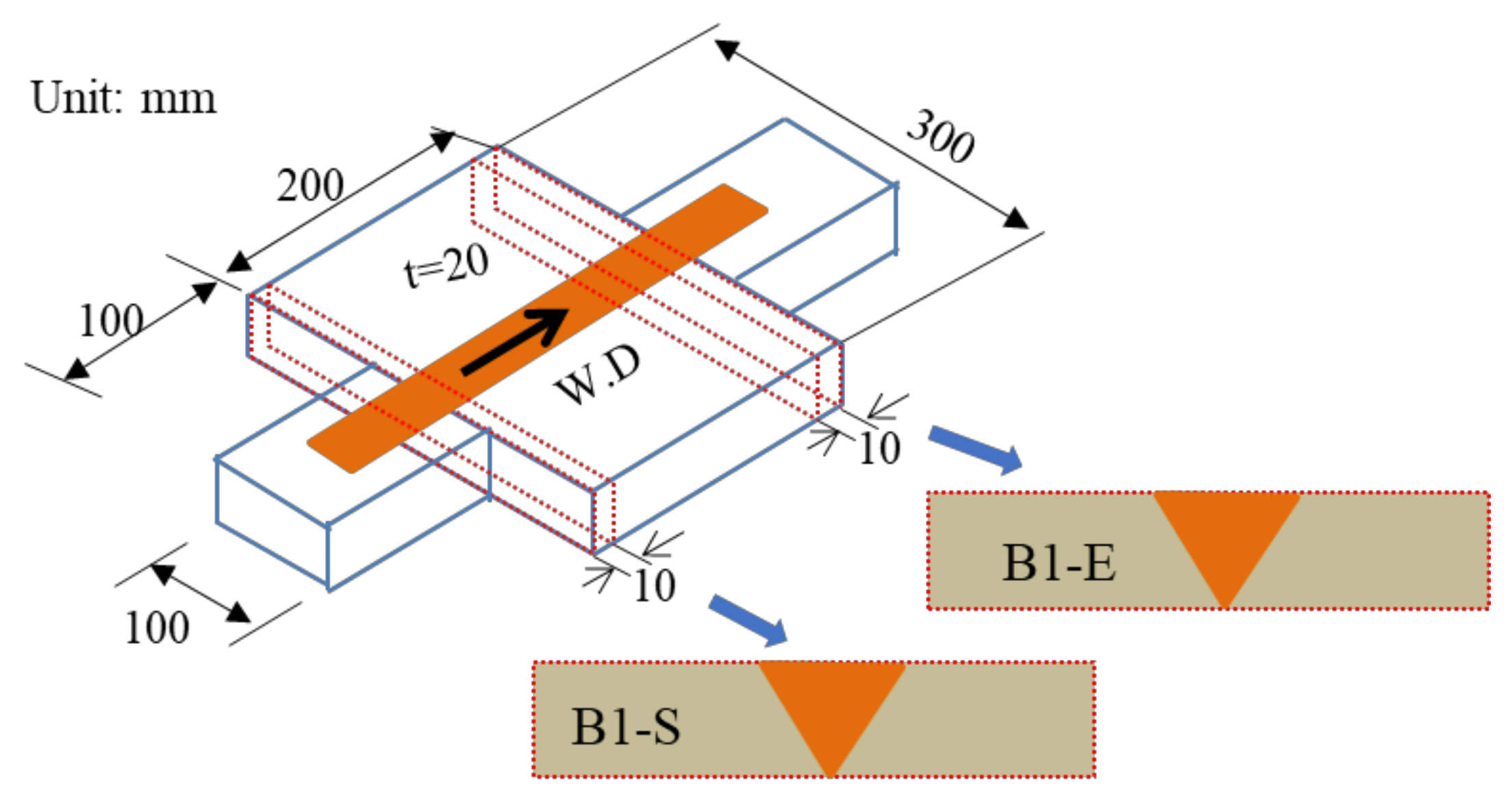

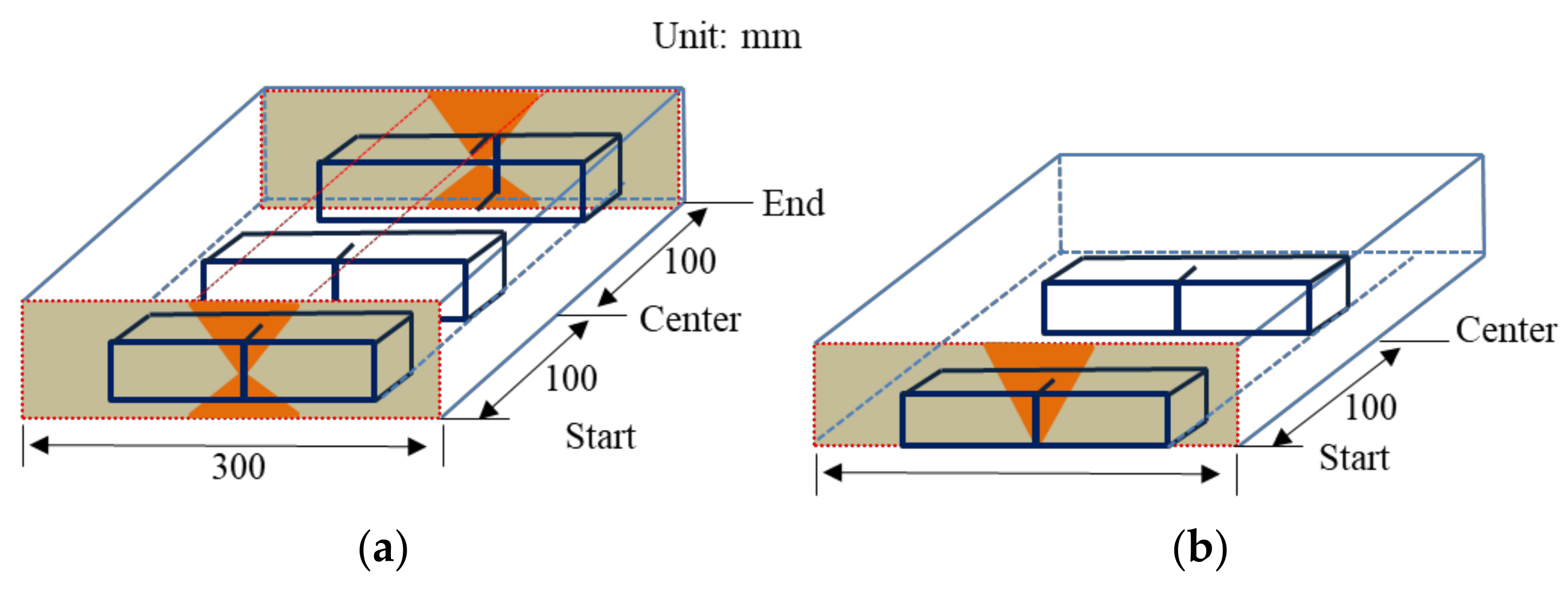

2. Materials and Test Methods

3. Results and Discussion

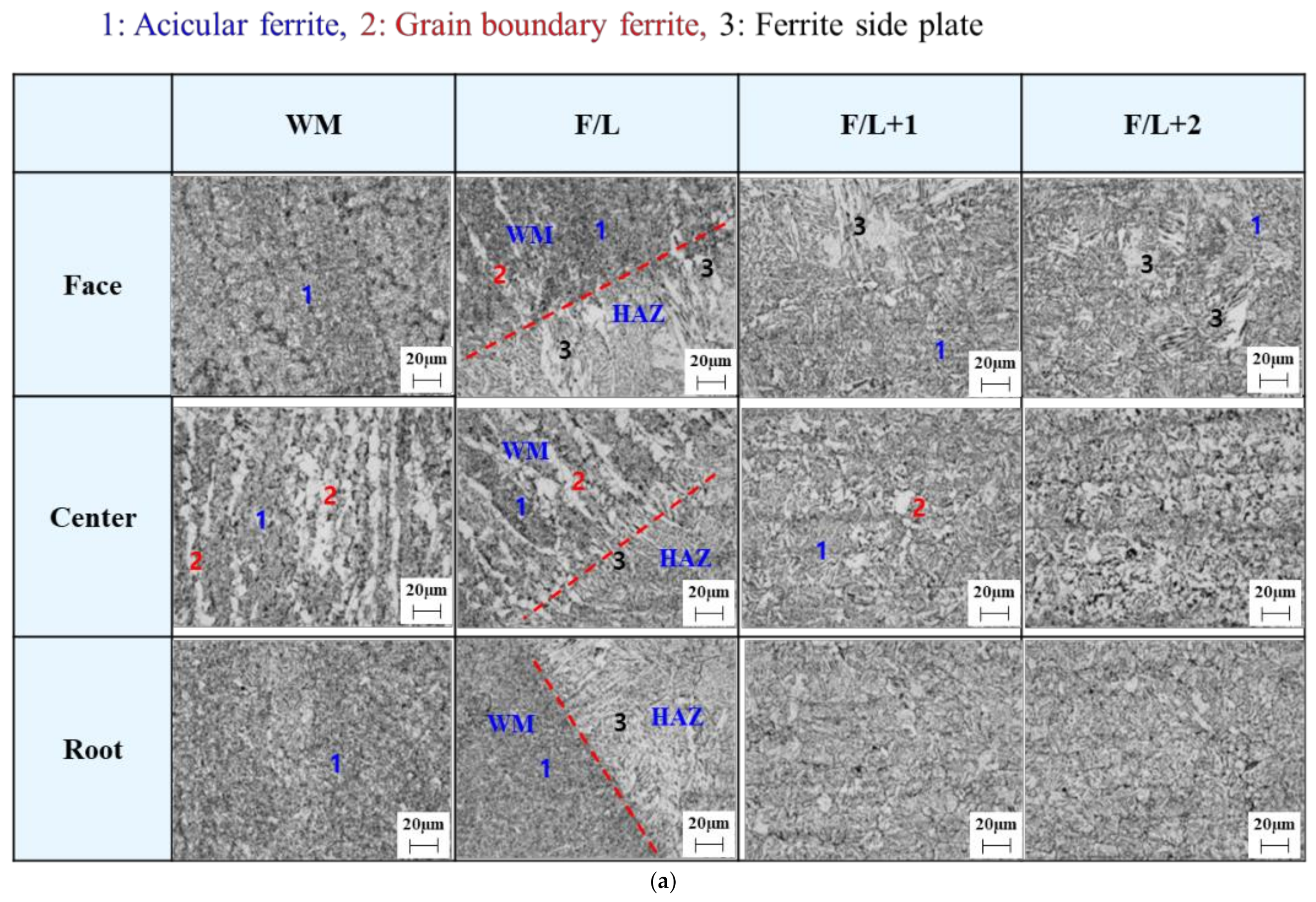

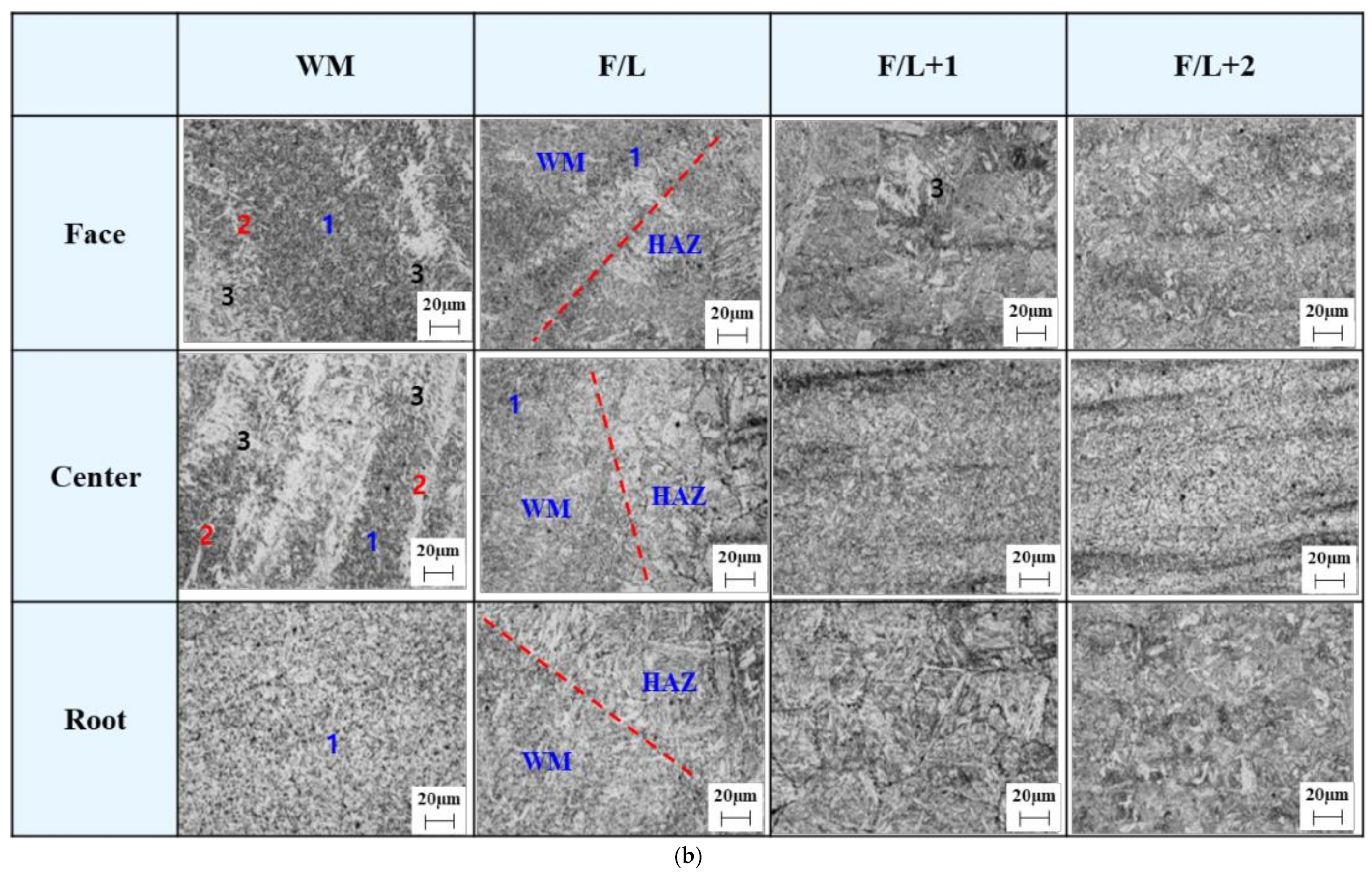

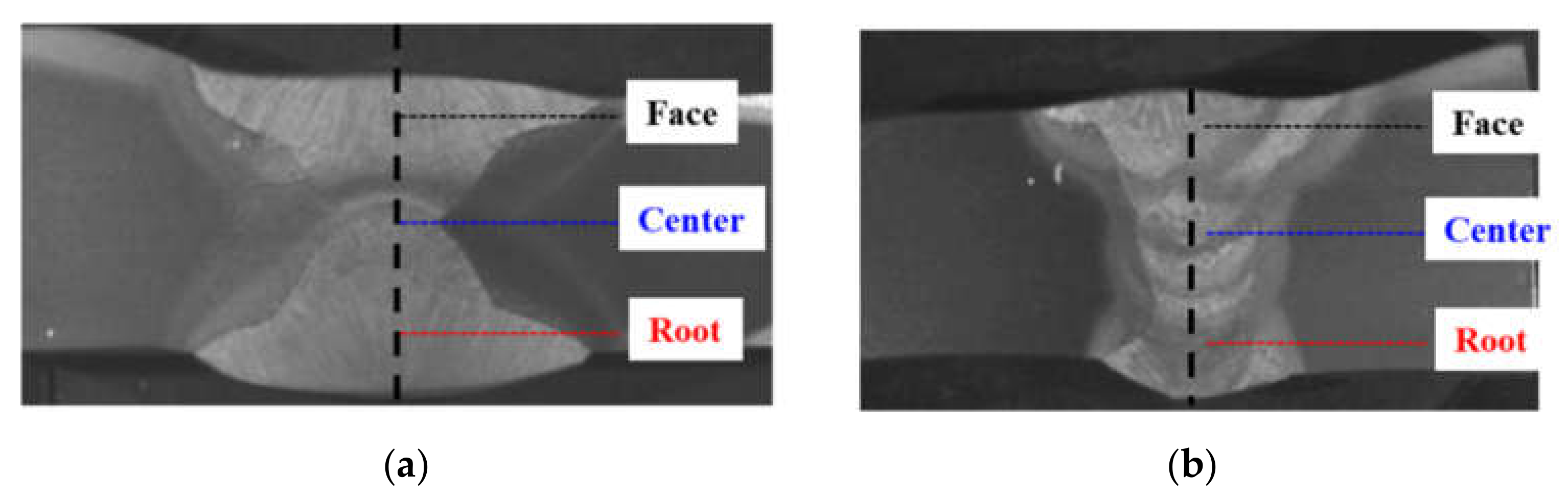

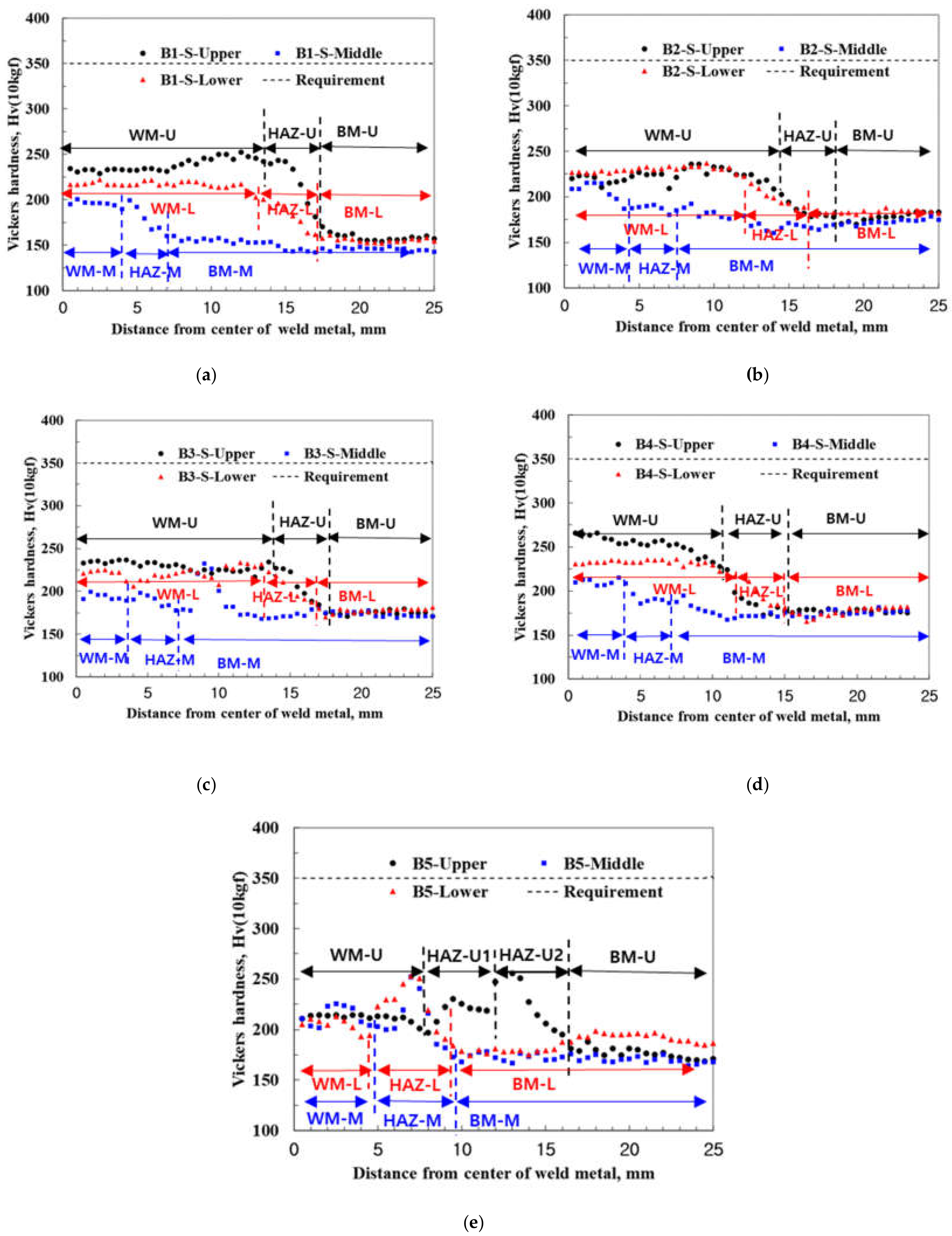

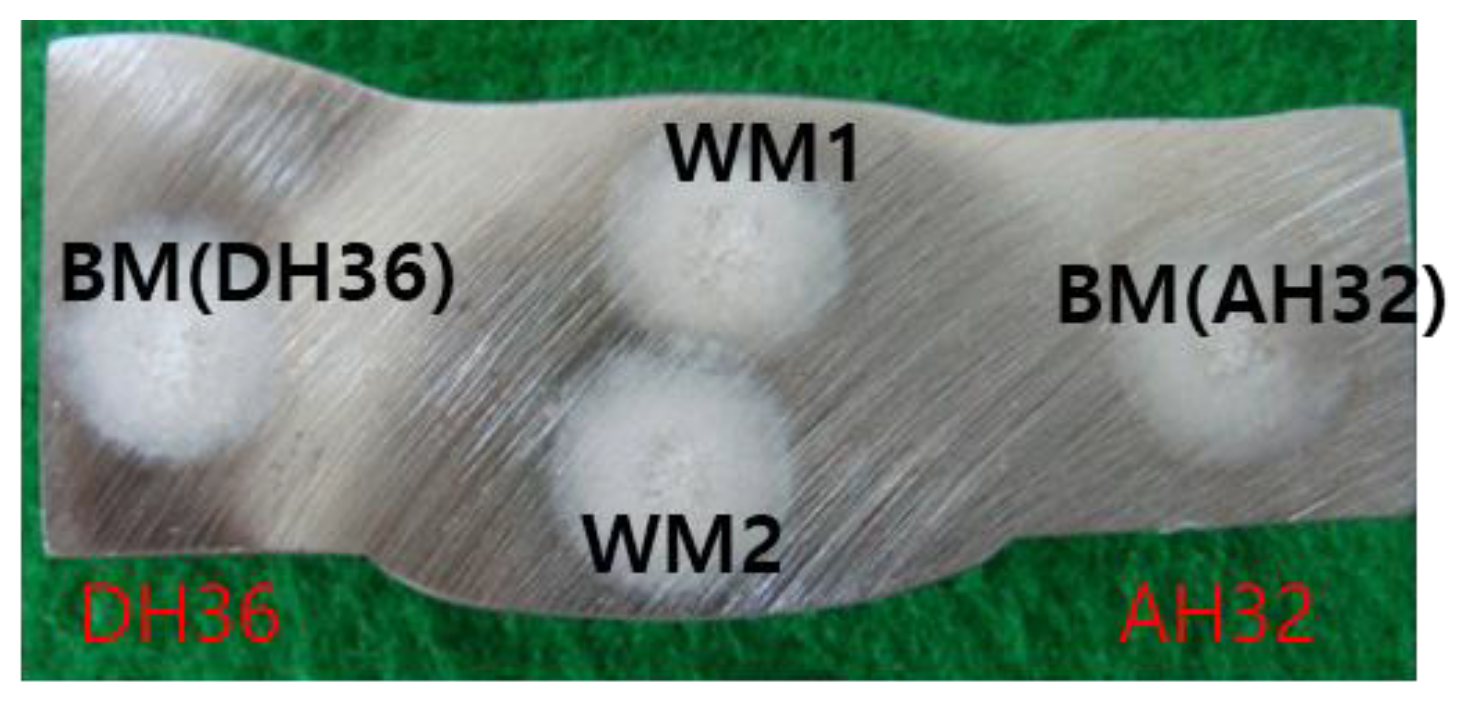

3.1. Microstructure and Hardness

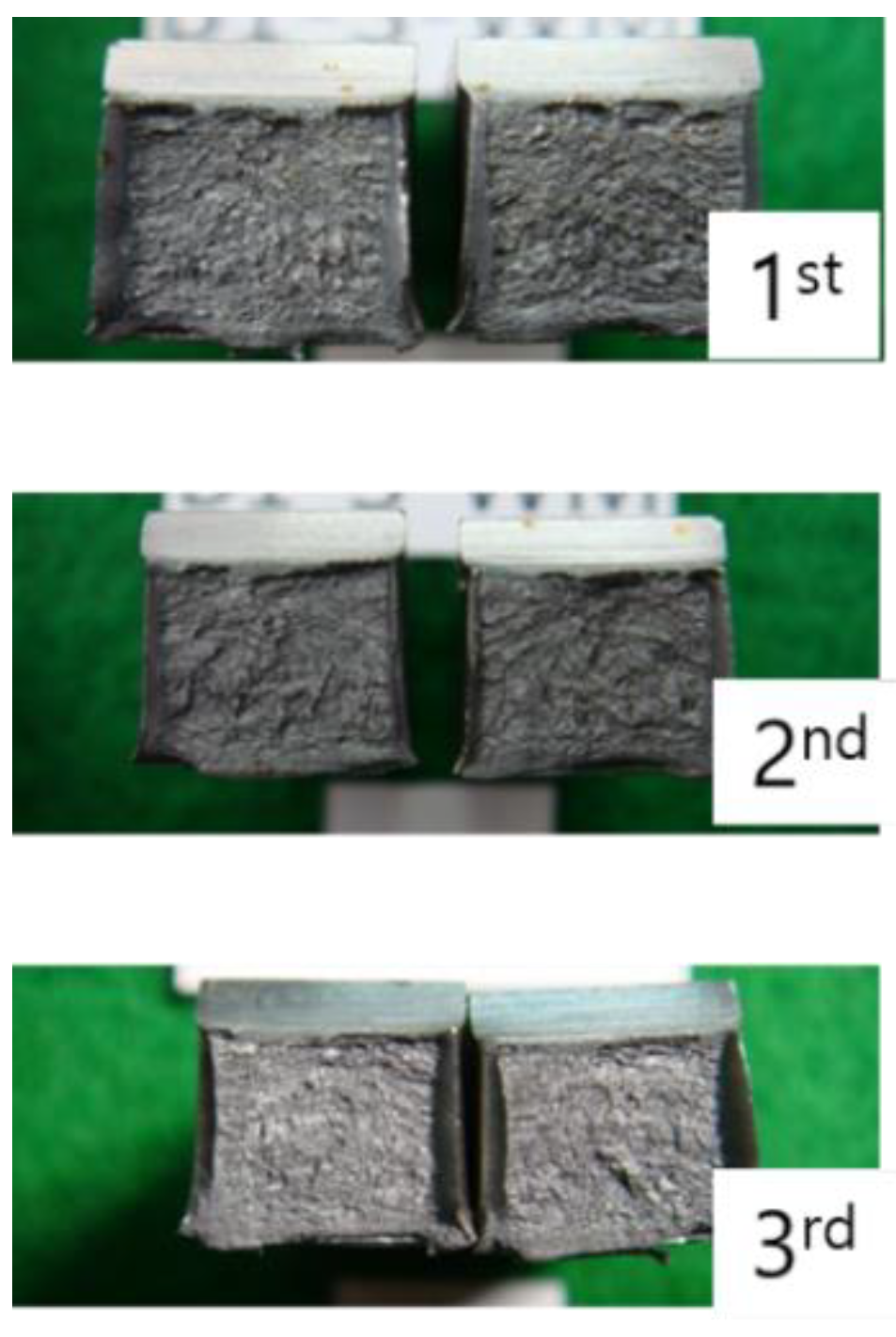

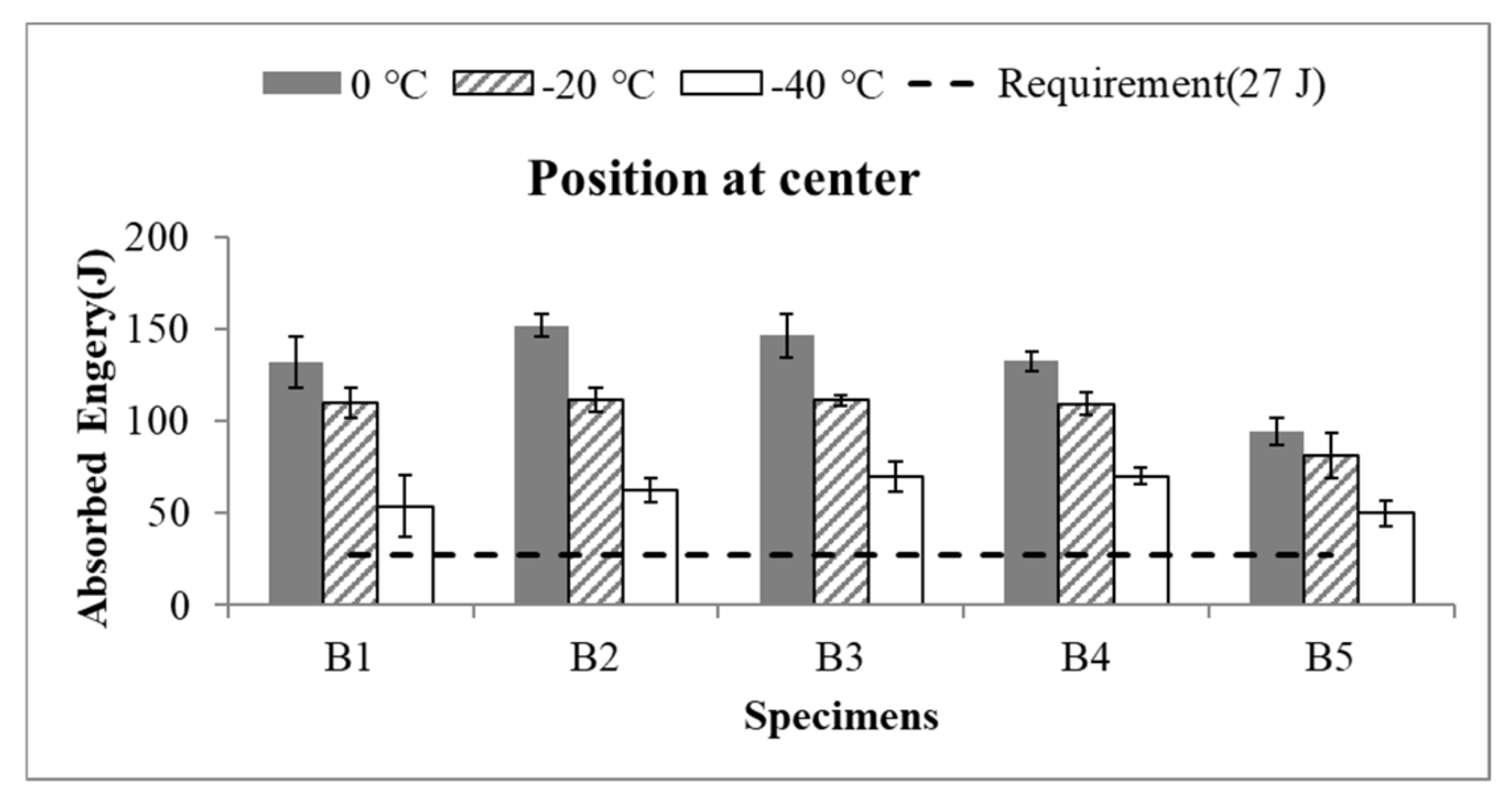

3.2. Toughness

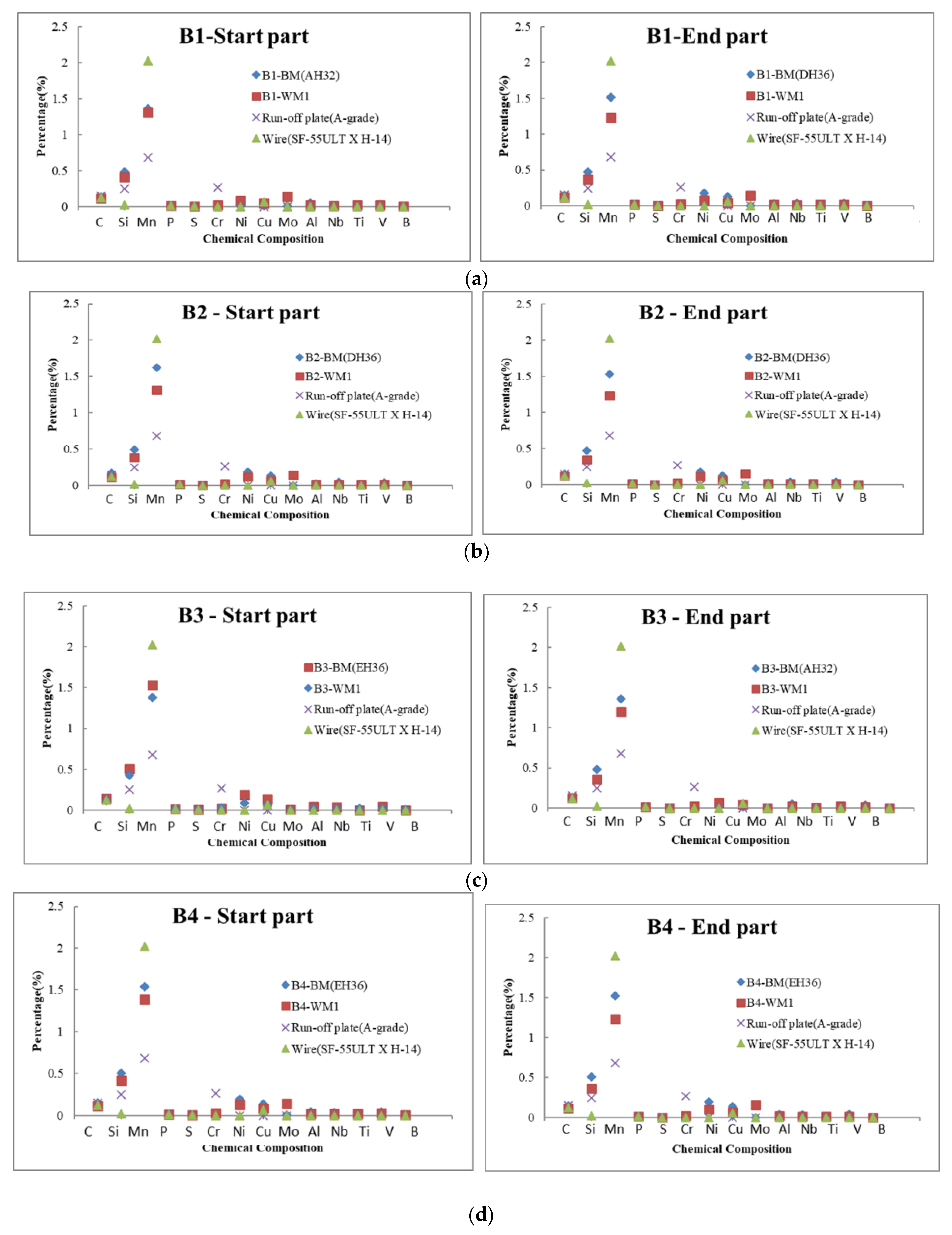

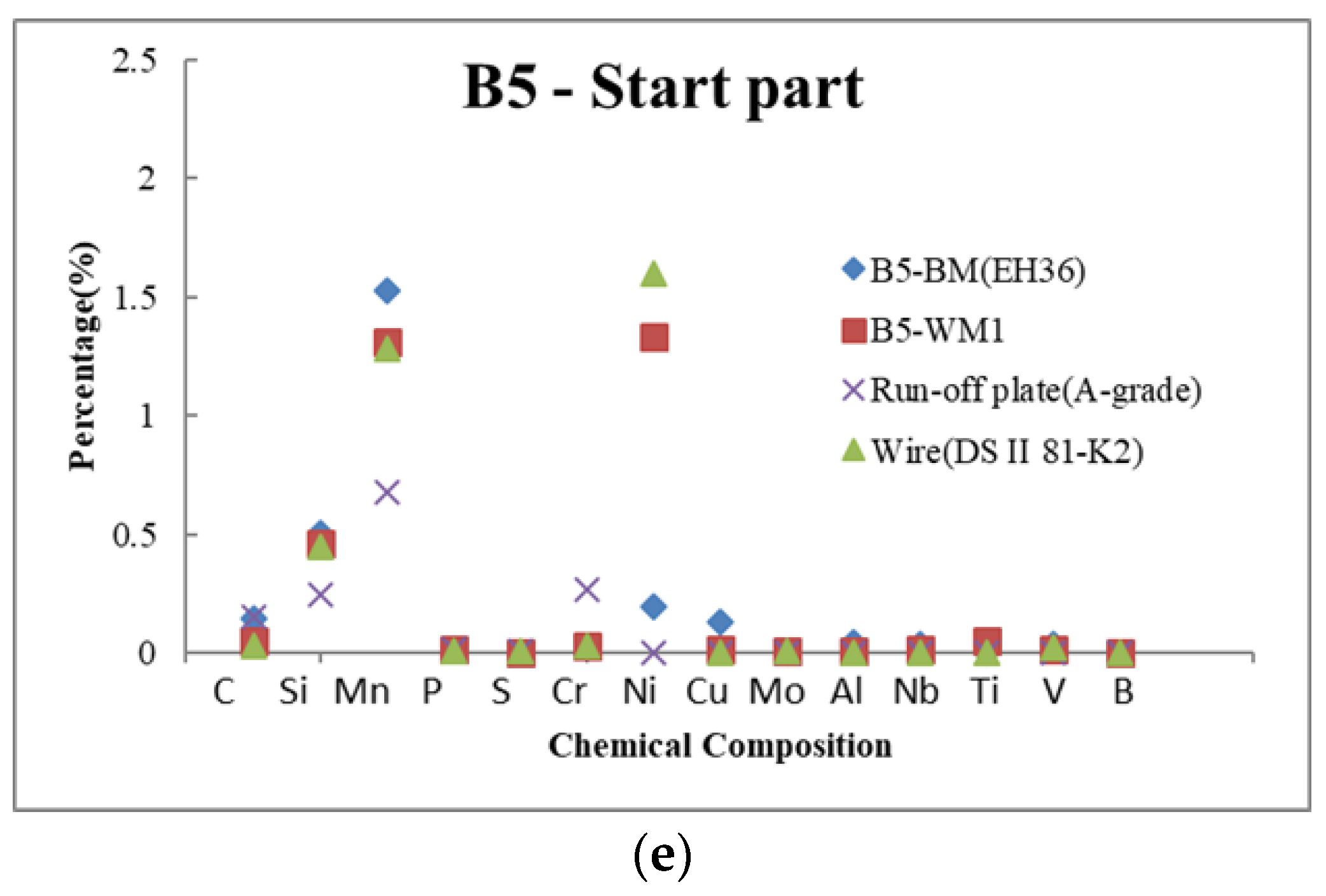

3.3. Component Analysis

4. Conclusions

- The metal microstructure of the cut surface was observed after the removal of the run-off plate. Only the metal microstructure of the welding wire could be observed in the weld metal, and changes in the metal microstructure caused by dissimilar welding between the base plate and run-off plate were not observed.

- Although the hardness value of the welded part was larger than that of the other parts, it was still less than 350 Hv10.

- The Charpy impact value at the end of the weld was slightly larger than the start of the weld, but it was almost the same when considering the deviation of the experiment. And it was confirmed that all of the impact results obtained were at a reference value of 27 J or higher.

- All of the components measured at the welded part coincided with the wire component. This demonstrates that components of the run-off metal are not transferred to the base metal during welding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, W.-F.; Duan, L. Bridge Engineering Handbook: Construction and Maintenance; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Satoh, K.; Mukai, Y.; Toyoda, M. Welding Engineering; Tokyo Rikogakusha Publishing Japan: Tokyo, Japan, 1979. [Google Scholar]

- Masubuchi, K. Analysis of Welded Structures; Pergammon Press: Oxford, UK, 1980; pp. 268–269. [Google Scholar]

- Okuda, N.; Tanaka, K. Mechanism and Prevention of the End Crack in One Side Submerged Arc Welding (Report 1): The Effect of Welding Conditions and the Occurrence Mechanism. Trans. Jpn. Weld. Soc. 1983, 14, 63–64. [Google Scholar]

- Okuda, N.; Tanaka, K. Mechanism and Prevention of the End Crack in One Side Submerged Arc Welding (Report 2): Observation of Rotative Distortion and Its Prevention with the Tab Plate. Trans. Jpn. Weld. Soc. 1983, 14, 66. [Google Scholar]

- Asai, S. Trends of Automatic Welding System and In-Process Quality Control System. J. Jpn. Weld. Soc. 2012, 81, 34–44. [Google Scholar] [CrossRef] [Green Version]

- Coniglio, N.; Cross, C.E.; Michael, T.; Lammers, M. Defining a critical weld dilution to avoid solidification cracking in aluminum. Weld. J. 2008, 87, 237s–247s. [Google Scholar]

- Park, H.-C.; Lee, C.-H.; Chang, K.-H. Strengthening a damaged steel girder bridge by the replacement repair welding. KSCE J. Civ. Eng. 2012, 16, 1243–1249. [Google Scholar] [CrossRef]

- Shin, H.S.; Park, K.T.; Lee, C.H.; Chang, K.H.; Van Do, V.N. Low temperature impact toughness of structural steel welds with different welding processes. KSCE J. Civ. Eng. 2015, 19, 1431–1437. [Google Scholar] [CrossRef]

- Lee, J.-S.; Kim, M.-S. Strength Assessment of T-type Lifting Lugs Considering Deformation of Blocks. J. Ocean Eng. Technol. 2015, 29, 309–316. [Google Scholar] [CrossRef] [Green Version]

- Nouri, M.; Abdollah-Zadeh, A.; Malek, F. Effect of welding parameters on dilution and weld bead geometry in cladding. J. Mater. Sci. Technol. 2007, 23, 817. [Google Scholar]

- Tomków, J.; Fydrych, D.; Rogalski, G. Role of Bead Sequence in Underwater Welding. Materials 2019, 12, 3372. [Google Scholar] [CrossRef] [Green Version]

- Tomków, J.; Janeczek, A.; Rogalski, G.; Wolski, A. Underwater Local Cavity Welding of S460N Steel. Materials 2020, 13, 5535. [Google Scholar] [CrossRef]

- Rogalski, G.; Świerczyńska, A.; Landowski, M.; Fydrych, D. Mechanical and Microstructural Characterization of TIG Welded Dissimilar Joints between 304L Austenitic Stainless Steel and Incoloy 800HT Nickel Alloy. Metals 2020, 10, 559. [Google Scholar] [CrossRef]

- Pańcikiewicz, K.; Świerczyńska, A.; Hućko, P.; Tumidajewicz, M. Laser Dissimilar Welding of AISI 430F and AISI 304 Stainless Steels. Materials 2020, 13, 4540. [Google Scholar] [CrossRef]

- Landowski, M.; Świerczyńska, A.; Rogalski, G.; Fydrych, D. Autogenous Fiber Laser Welding of 316L Austenitic and 2304 Lean Duplex Stainless Steels. Materials 2020, 13, 2930. [Google Scholar] [CrossRef]

- Świerczyńska, A.; Landowski, M. Plasticity of Bead-on-Plate Welds Made with the Use of Stored Flux-Cored Wires for Offshore Applications. Materials 2020, 13, 3888. [Google Scholar] [CrossRef] [PubMed]

- Om, H.; Pandey, S. Effect of heat input on dilution and heat affected zone in submerged arc welding process. Sadhana 2013, 38, 1369–1391. [Google Scholar] [CrossRef] [Green Version]

- Gunaraj, V.; Murugan, N. Prediction and comparison of the area of the heat-affected zone for the bead-on-plate and bead-on-joint in submerged arc welding of pipes. J. Mater. Process. Technol. 1999, 95, 246–261. [Google Scholar] [CrossRef]

- Adams, C.M., Jr. Cooling Rates and Peak Temperatures in Fusion Welding. Weld. J. 1958, 37, 210–215. [Google Scholar]

- Sun, Y.L.; Obasi, G.; Hamelin, C.J.; Vasileiou, A.N.; Flint, T.E.; Balakrishnan, J.; Smith, M.C.; Francis, J.A. Effects of dilution on alloy content and microstructure in multi-pass steel welds. J. Mater. Process. Technol. 2018, 265, 71–86. [Google Scholar] [CrossRef]

- American Bureau of Shipping. PART 2 Materials and Welding. In Regulations of the Classification and Registry of Ships; American Bureau of Shipping: Houston, TX, USA, 2019. [Google Scholar]

- Bird, J. Improving the toughness of high strength GMA welds. Mar. Struct. 1993, 6, 461–474. [Google Scholar] [CrossRef]

- Choi, D.; Lee, H.; Cho, S.-K.; Kim, H.C.; Hyun, S.-K.; Shin, S.Y. Microstructure and Charpy Impact Properties of FCAW and SAW Heat Affected Zones of 100 mm Thick Steel Plate for Offshore Platforms. Met. Mater. Int. 2020, 26, 867–881. [Google Scholar] [CrossRef]

- Park, J.; An, G.; Lee, H. Influence on Properties of Base Metal after Elimination of Lifting-Lug Member in a Dissimilar Welding between Steel Base and Steel Lifting Lug. Int. J. Nav. Archit. Ocean Eng. 2019, 11, 858–864. [Google Scholar] [CrossRef]

| Specimen | Chemical Composition (mass, %) | ||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | ||

| Base Metal | MA-A(SS400) | 0.150 | 0.068 | - | 0.028 | 0.0144 | 0.0060 |

| AH32 | 0.129 | 0.044 | 0.1286 | 0.0145 | 0.0021 | 0.0001 | |

| DH36 | 0.1551 | 0.441 | 0.1483 | 0.0170 | 0.0035 | 0.187 | |

| EH36 | 0.156 | 0.045 | 0.1501 | 0.0154 | 0.0031 | 0.0020 | |

| Welding Consumables | AWS A.5.17 F7A8 EH14 (Φ4.0 mm) for SAW (Hyundai Weld) | 0.120 | 0.020 | 2.02 | 0.0150 | 0.003 | - |

| AWS A5.29 E81T1-K2C (Φ1.2 mm) for FCAW(ESAB) | 0.030 | 0.450 | 1.28 | 0.010 | 0.008 | 1.60 | |

| Specimen | Mechanical Properties | ||||||

|---|---|---|---|---|---|---|---|

| Thickness (mm) | Yield Stress (MPa) | Tensile Strength (MPa) | Elongation (%) | V-Type Impact Test (ABS) * Mill Test Report | |||

| Temp. (°C) | J | ||||||

| Base Metals | MA-A(SS400) | 20 | 285 | 448 | 29 | - | - |

| AH32 | 20 | 379 | 515 | 28 | −40 | ≥27 | |

| DH36 | 20 | 394 | 552 | 30 | −40 | ≥27 | |

| EH36 | 20 | 415 | 576 | 28 | −40 | ≥27 | |

| Welding Consumables | AWS A.5.17 F7A8 EH14 (Φ4.0 mm) for SAW | - | 578 | 625 | 29 | −20 −62 * | ≥27 ≥27 * |

| AWS A5.29 E81T1-K2C (Φ1.2 mm) for FCAW | - | 526 | 602 | 29 | −20 −40 * | ≥27 93 * | |

| Specimens | Base Metal 1 | Base Metal 2 | Run-Off Plate Metal | Quantity (Set) | Welding Procedure, Wire |

|---|---|---|---|---|---|

| B1 | DH36 | AH32 | A (SS400) | 6 | -SAW -WIRE + FLUX: H-14 + SF-55ULT |

| B2 | DH36 | DH36 | A (SS400) | 6 | |

| B3 | EH36 | AH32 | A (SS400) | 6 | |

| B4 | EH36 | EH36 | A (SS400) | 6 | |

| B5 | EH36 | AH32 | A (SS400) | 6 | -FCAW -WIRE: DS II-81-K2 |

| Welded Joint | Welding Current (A) | Arc Voltage (V) | Travel Speed (cm/s) | Heat Input(kJ/cm) | |

|---|---|---|---|---|---|

| B1–4 | 1st (Face) | 850 | 32 | 32 | 51.0 |

| 2nd (Root) | 920 | 35 | 40 | 48.3 | |

| B5 | 1st Pass | 220 | 19 | 13 | 19.3 |

| 2nd–5th Pass | 260 | 20 | 20 | 15.6 | |

| 6th Pass | 340 | 29 | 25 | 23.7 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeongung, P.; An, G. Dissimilar Welding of Low Alloy Steels Welded Joints: Effect of Run-Off and Run-On Plates. Metals 2021, 11, 642. https://doi.org/10.3390/met11040642

Jeongung P, An G. Dissimilar Welding of Low Alloy Steels Welded Joints: Effect of Run-Off and Run-On Plates. Metals. 2021; 11(4):642. https://doi.org/10.3390/met11040642

Chicago/Turabian StyleJeongung, Park, and Gyubaek An. 2021. "Dissimilar Welding of Low Alloy Steels Welded Joints: Effect of Run-Off and Run-On Plates" Metals 11, no. 4: 642. https://doi.org/10.3390/met11040642

APA StyleJeongung, P., & An, G. (2021). Dissimilar Welding of Low Alloy Steels Welded Joints: Effect of Run-Off and Run-On Plates. Metals, 11(4), 642. https://doi.org/10.3390/met11040642